This manual should be considered a permanent part of the vehicle

and should remain with the vehicle when it is resold.

This publication includes the latest production information available

before printing. Honda Motor Co., Ltd. reserves the right to make

changes at any time without notice and without incurring any obligation.

No part of this publication may be reproduced without written

permission.

The vehicle pictured in this owner’s manual may not match your actual

vehicle.

© 2019 Honda Motor Co., Ltd.

Welcome

Congratulations on your purchase of a new

Honda vehicle. Your selection of a Honda

makes you part of a worldwide family of

satisfied customers who appreciate Honda’s

reputation for building quality into every

product.

To ensure your safety and riding pleasure:

● Read this owner’s manual carefully.

● Follow all recommendations and

procedures contained in this manual.

● Pay close attention to safety messages

contained in this manual and on the vehicle.

● The following codes in this manual indicate

the country.

● The illustrations here in are based on the

AFS110MD MA type.

Country Codes

Code Country

AFS110MD

MA Malaysia

AFS110MCS

MA Malaysia

A Few Words About Safety

DANGER

WARNING

CAUTION

NOTICE

Your safety, and the safety of others, is very

important. Operating this vehicle safely is an

important responsibility.

To help you make informed decisions about

safety, we have provided operating

procedures and other information on safety

labels and in this manual. This information

alerts you to potential hazards that could hurt

you or others.

Of course, it is not practical or possible to

warn you about all hazards associated with

operating or maintaining a vehicle. You must

use your own good judgement.

You will find important safety information in a

variety of forms, including:

● Safety labels on the vehicle

● Safety Messages preceded by a safety alert

symbol and one of three signal words:

DANGER, WARNING, or CAUTION.

These signal words mean:

3

You WILL be KILLED or SERIOUSLY HURT

if you don’t follow instructions.

3

You CAN be KILLED or SERIOUSLY HURT

if you don’t follow instructions.

3

You CAN be HURT if you don’t follow

instructions.

Other important information is

provided under the following titles:

Information to help you avoid

damage to your vehicle, other

property, or the environment.

Contents

Vehicle Safety P. 2

Operation Guide P. 12

Maintenance P. 32

Troubleshooting P. 76

Information P. 94

Specifications P. 105

Index P. 108

Vehicle Safety

This section contains important information for safe riding of your vehicle.

Please read this section carefully.

Safety Guidelines .......................................... P. 3

Safety Precautions ........................................ P. 6

Riding Precautions........................................ P. 7

Accessories & Modifications...................... P. 10

Loading ........................................................ P. 11

Safety Guidelines

Vehicle Safety

Safety Guidelines

Follow these guidelines to enhance your safety:

● Perform all routine and regular inspections

specified in this manual.

● Stop the engine and keep sparks and flame

away before filling the fuel tank.

● Do not run the engine in enclosed or partly

enclosed areas. Carbon monoxide in exhaust

gases is toxic and can kill you.

Always Wear a Helmet

It’s a proven fact: helmets and protective apparel

significantly reduce the number and severity of

head and other injuries. So always wear an

approved helmet and protective apparel.

2 P. 6

Before Riding

Make sure that you are physically fit, mentally

focused and free of alcohol and drugs. Check

that you and your passenger are both wearing

an approved helmet and protective apparel.

Instruct your passenger on holding onto the

grab rail or your waist, leaning with you in turns,

and keeping their feet on the footpegs, even

when the vehicle is stopped.

Take Time to Learn & Practice

Even if you have ridden other vehicles, practice

riding in a safe area to become familiar with how

this vehicle works and handles, and to become

accustomed to the vehicle’s size and weight.

Ride Defensively

Always pay attention to other vehicles around

you, and do not assume that other drivers see

you. Be prepared to stop quickly or perform an

evasive maneuver.

continued

3

Safety Guidelines

Vehicle Safety

Make Yourself Easy to See

Make yourself more visible, especially at night, by

wearing bright reflective clothing, positioning

yourself so other drivers can see you, signaling

before turning or changing lanes, and using your

horn when necessary.

Ride within Your Limits

Never ride beyond your personal abilities or

faster than conditions warrant. Fatigue and

inattention can impair your ability to use good

judgement and ride safely.

Don’t Drink and Ride

Alcohol and riding don’t mix. Even one alcoholic

drink can reduce your ability to respond to

changing conditions, and your reaction time gets

worse with every additional drink. Don’t drink

and ride, and don’t let your friends drink and ride

either.

4

Keep Your Honda in Safe Condition

It’s important to keep your vehicle properly

maintained and in safe riding condition.

Inspect your vehicle before every ride and

perform all recommended maintenance. Never

exceed load limits (

your vehicle or install accessories that would

make your vehicle unsafe (

2 P. 11), and do not modify

2 P. 10).

If You are Involved in a Crash

Personal safety is your first priority. If you or

anyone else has been injured, take time to assess

the severity of the injuries and whether it is safe

to continue riding. Call for emergency assistance

if needed. Also follow applicable laws and

regulations if another person or vehicle is

involved in the crash.

If you decide to continue riding, first turn the

ignition switch to the (Off) position, and

evaluate the condition of your vehicle. Inspect for

Vehicle Safety

fluid leaks, check the tightness of critical nuts and

3

WARNING

bolts, and check the handlebar, control levers,

brakes, and wheels. Ride slowly and cautiously.

Your vehicle may have suffered damage that is

not immediately apparent. Have your vehicle

thoroughly checked at a qualified service facility

as soon as possible.

Safety Guidelines

Running the engine of your vehicle

while in an enclosed or even partially

enclosed area can cause a rapid build-up

of toxic carbon monoxide gas.

Carbon Monoxide Hazard

Exhaust contains poisonous carbon monoxide, a

colourless, odorless gas. Breathing carbon

monoxide can cause loss of consciousness and

may lead to death.

If you run the engine in confined or even partly

enclosed area, the air you breathe could contain

a dangerous amount of carbon monoxide. Never

run your vehicle inside a garage or other

enclosure.

Breathing this colourless, odorless gas

can quickly cause unconsciousness and

lead to death

Only run your vehicle’s engine

when it is located in a well ventilated

area outdoors.

5

Safety Precautions

Vehicle Safety

3

WARNING

Safety Precautions

● Ride cautiously and keep your hands on the

handlebar and feet on the footpegs.

● Keep passenger’s hands onto the grab rail or

your waist, passenger’s feet on the footpegs

while riding.

● Always consider the safety of your passenger,

as well as other drivers and riders.

Protective Apparel

Make sure that you and any passenger are

wearing an approved helmet, eye protection,

and high-visibility protective clothing. Ride

defensively in response to weather and road

conditions.

Helmet

#

Safety-standard certified, high-visibility, correct

size for your head

● Must fit comfortably but securely, with the chin

strap fastened.

6

● Face shield with unobstructed field of vision or

other approved eye protection

Not wearing a helmet increases the

chance of serious injury or death in a

crash.

Make sure that you and any passenger

always wear an approved helmet and

protective apparel.

Gloves

#

Full-finger leather gloves with high abrasion

resistance

Boots or Riding Shoes

#

Sturdy boots with non-slip soles and ankle

protection

Jacket and Trousers

#

Protective, highly visible, long-sleeved jacket and

durable trousers for riding (or a protective suit)

Riding Precautions

Vehicle Safety

Riding Precautions

Running-in Period

During the first 500 km (300 miles) of running,

follow these guidelines to ensure your vehicle’s

future reliability and performance.

● Avoid full-throttle starts and rapid

acceleration.

● Avoid hard braking and rapid down-shifts.

● Ride conservatively.

and braking distances are longer.

● Avoid continuous braking.

u Repeated braking, such as when

descending long, steep slopes can seriously

overheat the brakes, reducing their

effectiveness. Use engine braking with

intermittent use of the brakes to reduce

speed.

● For full braking effectiveness, operate both the

front and rear brakes together.

Brakes

Observe the following guidelines:

● Avoid excessively hard braking and

downshifting.

u Sudden braking can reduce the vehicle’s

stability.

u Where possible, reduce speed before

turning; otherwise you risk sliding out.

● Exercise caution on low traction surfaces.

u The tyres slip more easily on such surfaces

continued

7

Riding Precautions

Vehicle Safety

Engine Braking

#

Engine braking helps slow your vehicle down

when you release the throttle. For further slowing

action, downshift to a lower gear. Use engine

braking with intermittent use of the brakes to

reduce speed when descending long, steep

slopes.

Wet or Rainy Conditions

#

Road surfaces are slippery when wet, and wet

brakes further reduce braking efficiency.

Exercise extra caution when braking in wet

conditions.

If the brakes get wet, apply the brakes while

riding at low speed to help them dry.

8

Parking

● Park on a firm, level surface.

● If you must park on a slight incline or loose

surface, park so that the vehicle cannot move

or fall over.

● Make sure that high-temperature parts cannot

come into contact with flammable materials.

● Do not touch the engine, muffler, brakes and

other high-temperature parts until they cool

down.

● To reduce the likelihood of theft, always lock

the handlebar and remove the key when

leaving the vehicle unattended.

Use of an anti-theft device is also

recommended.

Parking with the Side Stand or Centre Stand

#

1.

Stop the engine.

2.

Using the side stand

Push the side stand down.

Slowly lean the vehicle to the left until its

weight rests on the side stand.

Riding Precautions

Vehicle Safety

Left handle grip

Using the centre stand

To lower the centre stand, stand on the left

side of the vehicle. Hold the left handle grip

and the grab rail. Press down on the tip of the

centre stand with your right foot and,

simultaneously, pull up and back.

Centre stand

Grab rail

3.

Turn the handlebar fully to the left.

u Turning the handlebar to the right reduces

stability and may cause the vehicle to fall.

4.

Turn the ignition switch to the (Lock)

position and remove the key.

2 P. 21

Refuelling and Fuel Guidelines

Follow these guidelines to protect the engine,

fuel system and catalytic converter:

● Use only unleaded petrol.

● Use recommended octane number. Using

lower octane petrol will result in decreased

engine performance.

● Do not use fuels containing a high

concentration of alcohol.

● Do not use stale or contaminated petrol or an

oil/petrol mixture.

● Avoid getting dirt or water in the fuel tank.

2 P. 103

9

Accessories & Modifications

Vehicle Safety

3

WARNING

Accessories &

Modifications

We strongly advise that you do not add any

accessories that were not specifically designed

for your vehicle by Honda or make modifications

to your vehicle from its original design. Doing so

can make it unsafe.

Modifying your vehicle may also void your

warranty and make your vehicle illegal to

operate on public roads and highways. Before

deciding to install accessories on your vehicle be

certain the modification is safe and legal.

10

Improper accessories or modifications

can cause a crash in which you can be

seriously hurt or killed.

Follow all instructions in this owner’s

manual regarding accessories and

modifications.

Do not pull a trailer with, or attach a sidecar to,

your vehicle. Your vehicle was not designed for

these attachments, and their use can seriously

impair your vehicle’s handling.

Vehicle Safety

Loading

3

WARNING

Loading

● Carrying extra weight affects your vehicle’s

handling, braking and stability.

Always ride at a safe speed for the load you

are carrying.

● Avoid carrying an excessive load and keep

within specified load limits.

Maximum weight capacity / Maximum

luggage weight

● Tie all luggage securely, evenly balanced and

close to the centre of the vehicle.

● Do not place objects near the lights or the

muffler.

2 P. 105

Overloading or improper loading can

cause a crash and you can be seriously

hurt or killed.

Follow all load limits and other loading

guidelines in this manual.

11

Operation Guide

Basic Operation Flow

#

Pre-ride Inspection

(P37)

Carefully inspect your vehicle to make

12

sure that it is safe to ride.

How to use basic features.

• Instruments (P18)

• Indicators (P19)

• Switches (P20)

• Steering Lock (P21)

Starting the Engine (P23)

#

Start and warm the engine.

Avoid revving the engine.

Acceleration

#

Apply throttle gradually.

Obey the speed limit.

Shift Change (P26)

#

Starting the

#

Vehicle

Before pulling away, indicate

your direction with the turn

signal switch, and check for

oncoming traffic.

Operation Guide

Braking

#

#

Close the throttle and apply the

front and rear brakes together.

u The brakelight will indicate that

you have applied the brakes.

Parking (P8)

Park on a firm level surface.

Use the stand, and lock the

steering.

Stopping

#

If pulling of the road, signal early

enough to show traffic that you are

pulling over, and pull over smoothly.

Turning Corners

#

Do your braking

before entering

corners.

Gradually reapply throttle

when exiting turn.

Refuelling (P28)

#

13

Operation Guide

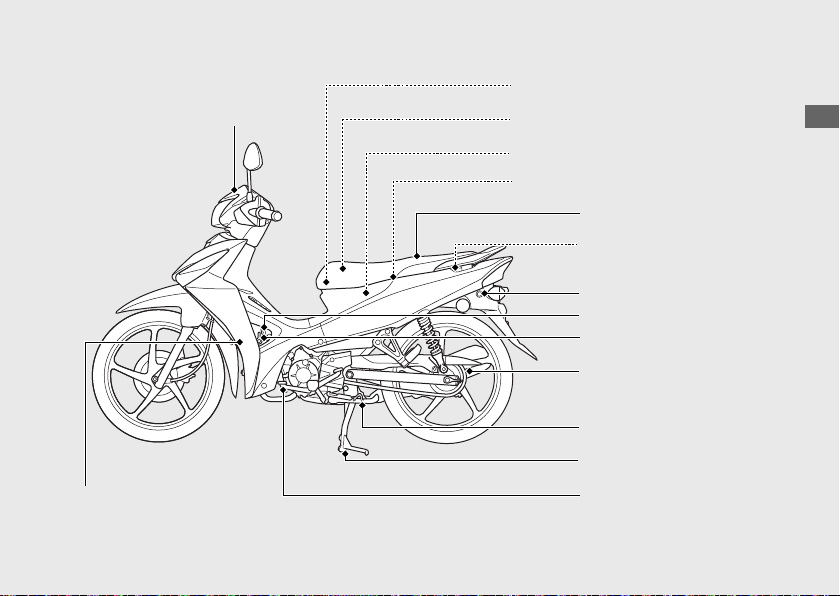

Parts Location

AFS110MD

Battery

(P56)

(P49)

Fuse box (P93)

Helmet holder (P30)

Throttle grip (P73)

Front brake lever (P61)

14

Kickstarter (P24)

Brakelight switch (P66)

Main pipe cover (P53)

Spark plug (P54)

Rear brake pedal (P63)

Engine oil drain bolt (P57)

Engine oil fill cap/dipstick

Operation Guide

Headlight case (P51)

Helmet holder (P30)

Luggage box (P31)

Tool (P31)

Seat (P30)

Document bag (P31)

Fuel fill cap (P28)

Seat lock (P30)

Choke lever (P24)

Fuel valve (P22)

Drive chain (P68)

Side stand (P67)

Crankcase breather

(P74)

Centre stand (P8)

Shift lever (P26)

continued

15

Parts Location

Operation Guide

AFS110MCS

Battery

Kickstarter (P24)

16

(Continued)

Brakelight switch (P66)

(P49)

Fuse box (P93)

Helmet holder (P30)

Throttle grip (P73)

Front brake fluid reservoir

(P59)

Main pipe cover (P53)

Spark plug (P54)

Rear brake pedal (P63)

Engine oil drain bolt (P57)

Engine oil fill cap/dipstick (P56)

Operation Guide

Headlight case (P51)

Helmet holder (P30)

Document bag (P31)

Luggage box (P31)

Tool (P31)

Seat (P30)

Fuel fill cap (P28)

Seat lock (P30)

Choke lever (P24)

Fuel valve (P22)

Drive chain (P68)

Side stand (P67)

Centre stand (P8)

Crankcase breather

(P74)

Shift lever (P26)

17

Operation Guide

Instruments

18

Speedometer

Gear range

Shows proper speed range for each gear.

Fuel gauge

Needle in the red mark, remaining fuel

approximately 0.93 litres (0.246 US gal,

0.205 Imp gal)

Odometer

Total distance ridden.

Operation Guide

Indicators

High beam indicator

If one of these indicators does not come on when it should, have your dealer check for

problems.

Left turn signal

indicator

Neutral indicator

Comes on when the

transmission is in Neutral.

Gear position indicators

Indicates 1st to 4th gear

position.

Right turn signal

indicator

19

Operation Guide

Switches

Headlight dimmer switch

• : High beam

• : Low beam

20

Start button

Horn button

Turn signal switch

u Pressing the switch turns the turn signal off.

Operation Guide

Ignition Switch

Switches the electrical system on/off, locks the

(On)

steering.

u Key can be removed when in the (Off) or

(Lock) position.

Steering Lock

Lock the steering when parking to help

prevent theft.

A U-shaped wheel lock or similar device is also

recommended.

!a

!b

Push

Turn

Ignition key

Turns electrical system on

for starting/riding.

(Off)

Turns engine off.

(Lock)

Locks steering.

Locking

#

!a Turn the handlebar all the way to the left or

right.

!b Push the key down, and turn the ignition

switch to the (Lock) position.

u Jiggle the handlebar if the lock is difficult

to engage.

!c Remove the key.

Unlocking

#

Insert the key, and turn the ignition switch to

the

(Off) position.

21

Operation Guide

Fuel Valve

The two-way fuel valve is used to control the

flow of fuel from the fuel tank to the

carburetor.

ON OFF

ON: normal position for riding.

OFF: for parking, storing, or transportation.

22

Operation Guide

Starting the Engine

!c

Start your engine using the following

procedure.

!b

!e

!g !i

!a

!d

!f

!h

To restart a warm engine, follow the

procedure for "High Air Temperature."

!e

continued

23

Starting the Engine

Operation Guide

NOTICE

•

If the engine does not start within 5 seconds, turn the

ignition switch to the

seconds before trying to start the engine again to

recover battery voltage.

•

Extended fast idling and revving the engine can

damage the engine, and the exhaust system.

•

Do not operate the kickstarter while the engine is

running as engine damage could result. Do not apply

excessive force on the kickstarter.

•

Fold up the kickstarter after the kickstarter is returned

to the pedal stop.

(Continued)

(Off) position and wait 10

Normal Air Temperature 10 - 35ºC

(50 - 95ºF):

!a Make sure the fuel valve is in the On position.

!b Turn the ignition switch to the (On) position.

!c Shift the transmission to Neutral (

indicator comes on).

!d Pull the choke lever up all the way to fully

ON.

24

!e Using the start button

With the throttle slightly open, press the start

button.

Using the kickstarter

Lightly depress the kickstarter until resistance

is felt.

Then let the kickstarter return to the top of its

stroke.

With the throttle slightly open, operate the

kickstarter. Kick from the top of the stroke

through to the bottom with a rapid,

continuous motion.

!af Immediately after the engine starts, push the

choke lever down to the halfway position.

!a!g Warm up the engine by opening and closing

the throttle slightly.

!h About a quarter minute after the engine

starts, push the choke lever down all the way

to fully OFF.

!i If idling is unstable, open the throttle slightly.

Operation Guide

High Air Temperature 35°C (95°F)

or above :

!?a Do not use the choke.

!b Using the start button

With the throttle slightly open, press the start

button.

Using the kickstarter

Lightly depress the kickstarter until resistance

is felt.

Then let the kickstarter return to the top of its

stroke.

With the throttle slightly open, operate the

kickstarter. Kick from the top of the stroke

through to the bottom with a rapid,

continuous motion.

Low Air Temperature 10°C (50°F) or

below :

!?a

Follow steps 1- 6 under “Normal Air Temperature.”

!a!b Warm up the engine by opening and closing

the throttle slightly.

!c Continue warming up the engine until it runs

smoothly and responds to the throttle, when

the choke lever is at fully OFF.

If the engine does not start:

!a Turn the ignition switch to the (Off)

position.

!b Push the choke lever down all the way to fully

OFF.

!c Open the throttle fully.

!d Crank the engine several times with the

kickstarter.

!e Follow steps 1-2 under “High Air

Temperature.”

If Engine Will Not Start (P77)

#

25

Operation Guide

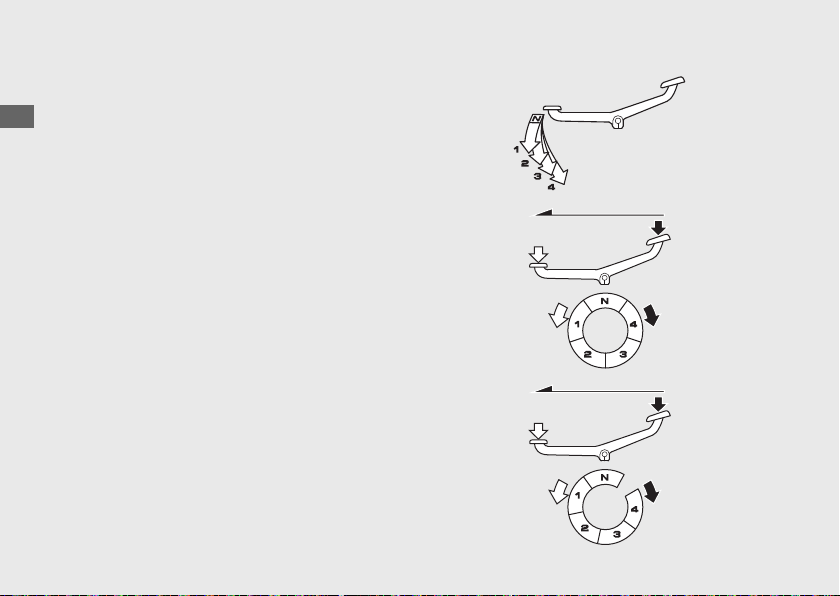

Shifting Gears

Your vehicle transmission has four forward

gears.

The gearshift operation differs when stopping

and when moving.

When stopping, change can be made from

4th to neutral directly with the 4-step rotary

system.

When moving, the forward 4-step return

system is used.

Change cannot be made from 4th to neutral

directly.

u Always return the throttle grip first before

changing gear.

u Operate lightly with the tips of your toes until

the shift lever is pushed down.

u Avoid changing gear needlessly and riding

with your foot on the shift lever since this may

damage the gear change mechanism and

clutch mechanism.

26

Stopping

Moving

Operation Guide

Proper shifting can prevent damaging the

engine and transmission.

Downshifting

Downshifting at speeds higher than those in

the table below may overrev the engine and

Upshifting

The upper limit speed of each gear is shown in

gear range.

(P18)

can cause damage to the engine and

transmission.

Follow the table below when downshifting the

gears.

Upshift to a higher gear before exceeding the

upper limit speed.

Upshifting at speeds higher than the upper

limit speed can cause damage to the engine.

Downshifting Acceptable Speed

From 4th to 3rd 75 km/h or less

From 3rd to 2nd 50 km/h or less

From 2nd to 1st 30 km/h or less

27

Operation Guide

Refuelling

Fuel type: Unleaded petrol only

Fuel octane number: Your vehicle is

designed to use Research Octane Number

(RON) 91 or higher.

Tank capacity: 3.7 litres (0.98 US gal,

0.81 Imp gal)

Refuelling and Fuel Guidelines (P9)

#

Opening the Fuel Fill Cap

!a Open the seat. 2 P. 30

!b Turn the fuel fill cap counterclockwise until it

stops and remove the fuel fill cap.

28

Lower edge of

filler neck

Do not fill with fuel above the lower edge of

the filler neck.

Fuel fill cap

Arrow marks

Operation Guide

Closing the Fuel Fill Cap

3

WARNING

!a Install and tighten the fuel fill cap firmly by

turning it clockwise.

u Make sure that the arrow marks on the

fuel fill cap and fuel tank is aligned.

!b Close the seat.

Petrol is highly flammable and explosive.

You can be burned or seriously injured

when handling fuel.

• Stop the engine, and keep heat,

sparks, and flame away.

• Handle fuel only outdoors.

• Wipe up spills immediately.

29

Operation Guide

Storage Equipment

Seat Open

Insert the ignition key into the seat lock and

turn it clockwise to unlock.

Seat Close

Close and push down on

until it locks. Make sure that the seat is locked

securely to pull it up lightly.

Take care not to lock your key in the

compartment under the seat.

Helmet Holders

3

WARNING

The helmet holders are located under the

seat.

u Use the helmet holders only when parked.

30

Ignition key

Seat lock

the rear of the seat

Riding with a helmet attached to the

holder can interfere with your ability to

safely operate the vehicle and could lead

to a crash in which you can be seriously

hurt or killed.

Use the helmet holder only while parked.

Do not ride with a helmet secured by the

holder.

Operation Guide

Luggage Box

Document compartment Document bag

Never exceed the maximum weight limit.

Maximum Weight: 5 kg (11 lb)

u Do not store any items that are flammable or

susceptible to heat damage.

u Do not store valuables or fragile articles.

Tool

The tools are in the luggage box.

Tools

The document bag is in the document

compartment in the reverse side of the seat.

Luggage box

Document Bag

31

Maintenance

Please read “Importance of Maintenance” and “Maintenance Fundamentals”

carefully before attempting any maintenance. Refer to “Specifications” for service

data.

Importance of Maintenance ...................... P. 33

Maintenance Schedule ............................... P. 34

Maintenance Fundamentals....................... P. 37

Tool............................................................... P. 48

Removing & Installing Body Components

Battery.....................................................................P. 49

Headlight Case......................................................P. 51

Main Pipe Cover...................................................P. 53

Spark Plug.................................................... P. 54

Engine Oil..................................................... P. 56

Brakes ........................................................... P. 59

Side Stand .................................................... P. 67

... P. 49

Drive Chain...................................................P. 68

Throttle.........................................................P. 73

Crankcase Breather .....................................P. 74

Other Adjustments...................................... P. 75

Adjusting the Headlight Aim ............................ P. 75

Maintenance

Importance of Maintenance

3

WARNING

Importance of Maintenance

Keeping your vehicle well-maintained is

absolutely essential to your safety and to protect

your investment, obtain maximum performance,

avoid breakdowns, and reduce air pollution.

Maintenance is the owner’s responsibility. Be

sure to inspect your vehicle before each ride, and

perform the periodic checks specified in the

Maintenance Schedule.

2 P. 34

Improperly maintaining your vehicle or

failing to correct a problem before you

ride can cause a crash in which you can

be seriously hurt or killed.

Always follow the inspection and

maintenance recommendations and

schedules in this owner’s manual.

Maintenance Safety

Always read the maintenance instructions before

you begin each task, and make sure that you

have the tools, parts, and skills required. We

cannot warn you of every conceivable hazard

that can arise in performing maintenance. Only

you can decide whether or not you should

perform a given task.

Follow these guidelines when performing

maintenance.

● Stop the engine and remove the key.

● Place your vehicle on a firm, level surface

using the side stand, centre stand or a

maintenance stand to provide support.

● Allow the engine, muffler, brakes, and other

high-temperature parts to cool before

servicing as you can get burned.

● Run the engine only when instructed, and do

so in a well-ventilated area.

33

Maintenance

Maintenance Schedule

The maintenance schedule specifies the

maintenance requirements necessary to

ensure safe, dependable performance, and

proper emission control.

Maintenance work should be performed in

accordance with Honda’s standards and

specifications by properly trained and

equipped technicians. Your dealer meets all of

these requirements. Keep an accurate record

of maintenance to help ensure that your

vehicle is properly maintained.

Make sure that whomever performs the

maintenance completes this record.

34

All scheduled maintenance is considered a

normal owner operating cost and will be

charged to you by your dealer. Retain all

receipts. If you sell the vehicle, these receipts

should be transferred with the vehicle to the

new owner.

Honda recommends that your dealer should

road test your vehicle after each periodic

maintenance is carried out.

Maintenance Schedule

Maintenance

R

R

I

IIIIIII

I

Pre-ride

Items × 1,000 km 1 6 12 18 24 30 36

Check

2 P. 37

× 1,000 mi 0.6 4 8 12 16 20 24

Frequency *

Fuel Line –

Fuel Level 28

I

1

Annual

Check

I I I I I I I

Regular

Replace

Refer to

page

Fuel Strainer Screen –

Throttle Operation 73

Air Cleaner *

Crankcase Breather *

2

3

Spark Plug 54

Valve Clearance –

Engine Oil 56

I I I I I I I I

I

I

R

I

R

R

I I I I I I

R R R R R R R R

47

74

Engine Oil Strainer Screen –

Engine Oil Centrifugal filter –

Engine Idle Speed –

Secondary Air Supply System –

Maintenance Level

Maintenance Legend

: Intermediate. We recommend service by your dealer, unless

you have the necessary tools and are mechanically skilled.

R

Procedures are provided in an official Honda Shop Manual.

: Technical. In the interest of safety, have your vehicle serviced by

I I

: Inspect (clean, adjust, lubricate, or replace, if necessary)

I

: Replace

: Clean

: Lubricate

your dealer.

continued

35

Maintenance Schedule

Maintenance

I

I

IIIIIII

I

IIIIIII

IIIIIII

IIIIIII

I

1

Annual

Check

R

Items × 1,000 km 1 6 12 18 24 30 36

Secondary Air Supply Pair Filter *

Pre-ride

Frequency *

Check

2 P. 37

4

× 1,000 mi 0.6 4 8 12 16 20 24

Drive Chain Every 500 km (300 mi) 68

Brake Fluid *4 (AFS110MCS) 2 years 59

Brake Shoes Wear (AFS110MD) 65

I I I I I I I I

I I I I I I I I

Brake Shoes/Pads Wear (AFS110MCS) 60, 65

Brake System 59

Brakelight Switch 66

I I I I I I I I I

I I I I I I I

Headlight Aim 75

Lights/Horn –

Clutch System –

I

I I I I I I I I

Side Stand 67

Suspension –

Nuts, Bolts, Fasteners –

I I I I I I I

I I I I I

Wheels/Tyres 44

Steering Head Bearings –

I I I I

Notes:

*1 :

At higher odometer reading, repeat at the frequency interval established here.

*2 :

Service more frequently when riding in unusually wet or dusty areas.

*3 :

Service more frequently when riding in rain or at full throttle.

*4 :

Replacement requires mechanical skill.

36

Regular

Refer to

Replace

3 years –

page

Maintenance

Maintenance Fundamentals

AFS110MD

AFS110MCS

Pre-ride Inspection

To ensure safety, it is your responsibility to

perform a pre-ride inspection and make sure

that any problem you find is corrected. A preride inspection is a must, not only for safety,

but because having a breakdown, or even a

flat tyre, can be a major inconvenience.

Check the following items before you get on

your vehicle:

● Fuel level - Fill fuel tank when necessary.

2 P. 28

● Throttle - Check for smooth opening and

full closing in all steering positions.

● Engine oil level - Add engine oil if

necessary. Check for leaks. 2 P. 56

● Drive chain - Check condition and slack,

adjust and lubricate if necessary. 2 P. 68

2 P. 73

● Brakes - Check operation;

Front and Rear: check shoes wear (

2 P. 65)

and freeplay, adjust if necessary. 2 P. 62, 64

Front: check brake fluid level and pad wear.

2 P. 59, 60

Rear: check shoes wear and freeplay, adjust

if necessary.

● Lights and horn - Check that lights,

2 P. 65

indicators and horn function properly.

● Wheels and tyres - Check condition, air

pressure and adjust if necessary. 2 P. 44

37

Maintenance Fundamentals

Maintenance

3

WARNING

NOTICE

NOTICE

Replacing Parts

Always use Honda Genuine Parts or their

equivalents to ensure reliability and safety.

Installing non-Honda parts may make

your vehicle unsafe and cause a crash in

which you can be seriously hurt or killed.

Always use Honda Genuine Parts or

equivalents that have been designed

and approved for your vehicle.

38

Battery

Your vehicle has a maintenance-free type

battery. You do not have to check the battery

electrolyte level or add distilled water. Clean the

battery terminals if they become dirty or

corroded.

Do not remove the battery cap seals. There is no

need to remove the cap when charging.

Your battery is a maintenance-free type and can be

permanently damaged if the cap strip is removed.

An improperly disposed of battery can be harmful to the

environment and human health.

Always confirm local regulations for proper battery

disposal instruction.

Maintenance Fundamentals

Maintenance

3

WARNING

What to do in an emergency

#

If any of the following occur, immediately see

your doctor.

● Electrolyte splashes into your eyes:

u Wash your eyes repeatedly with cool

water for at least 15 minutes. Using

water under pressure can damage your

eyes.

● Electrolyte splashes onto your skin:

u Remove affected clothing and wash

your skin thoroughly using water.

● Electrolyte splashes into your mouth:

u Rinse mouth thoroughly with water, and

do not swallow.

The battery gives off explosive hydrogen

gas during normal operation.

A spark or flame can cause the battery

to explode with enough force to kill or

seriously hurt you.

Wear protective clothing and a face

shield, or have a skilled mechanic do the

battery servicing.

Cleaning the Battery Terminals

#

1.

Remove the battery. 2 P. 49

2.

If the terminals are starting to corrode and are

coated with a white substance, wash with

warm water and wipe clean.

continued

39

Maintenance Fundamentals

Maintenance

NOTICE

NOTICE

3.

If the terminals are heavily corroded, clean

and polish the terminals with a wire brush or

sandpaper. Wear safety glasses.

4.

After cleaning, reinstall the battery.

The battery has a limited life span. Consult your

dealer about when you should replace the

battery. Always replace the battery with another

maintenance-free battery of the same type.

Fuses

Fuses protect the electrical circuits on your

vehicle. If something electrical on your vehicle

stops working, check for and replace any blown

fuses.

2 P. 93

Inspecting and Replacing Fuses

#

Turn the ignition switch to the (Off) position to

remove and inspect fuses. If a fuse is blown,

replace with a fuse of the same rating. For fuse

ratings, see “Specifications.”

Blown fuse

2 P. 107

Installing non-Honda electrical accessories can overload

the electrical system, discharging the battery and possibly

damaging the system.

40

Replacing a fuse with one that has a higher rating greatly

increases the chance of damage to the electrical system.

Maintenance Fundamentals

Maintenance

*1.

If a fuse fails repeatedly, you likely have an

electrical fault. Have your vehicle inspected by

your dealer.

Engine Oil

Engine oil consumption varies and oil quality

The JASO T 903 standard is an index for engine

oils for 4-stroke motorcycle engines. There are

two classes: MA and MB. For example, the

following label shows the MA classification.

Oil code

deteriorates according to riding conditions and

time elapsed.

Check the engine oil level regularly, and add the

recommended engine oil if necessary. Dirty oil or

old oil should be changed as soon as possible.

Selecting the Engine Oil

#

For recommended engine oil, see

“Specifications.”

2 P. 106

*2.

The SAE standard grades oils by their viscosity.

*3.

The API classification specifies the quality and

performance rating of engine oils. Use SG or

higher oils, excluding oils marked as “Energy

Conserving” or “Resource Conserving” on the

circular API service symbol.

Oil classification

If you use non-Honda engine oil, check the label

to make sure that the oil satisfies all of the

following standards:

● JASO T 903 standard

● SAE standard

● API classification

*2

: 10W-30

*3

: SG or higher

*1

: MA

Not recommended Recommended

41

Maintenance Fundamentals

Maintenance

NOTICE

AFS110MCS

NOTICE

Brake Fluid

Do not add or replace brake fluid, except in an

emergency. Use only fresh brake fluid from a

sealed container. If you do add fluid, have the

brake system serviced by your dealer as soon as

possible.

Brake fluid can damage plastic and painted surfaces.

Wipe up spills immediately and wash thoroughly.

Recommended brake fluid:

Honda DOT3 or DOT4 Brake Fluid or

equivalent

Drive Chain

The drive chain must be inspected and

lubricated regularly. Inspect the chain more

frequently if you often ride on bad roads, ride at

high speed, or ride with repeated fast

acceleration.

42

2 P. 68

If the chain does not move smoothly, makes

strange noises, has damaged rollers, has loose

pins, or kinks, have the chain inspected by your

dealer.

Also inspect the drive sprocket and driven

sprocket. If either has worn or damaged teeth,

have the sprocket replaced by your dealer.

Normal

(GOOD)

Use of a new chain with worn sprockets will cause rapid

chain wear.

Worn

(REPLACE)

Damaged

(REPLACE)

Maintenance Fundamentals

Maintenance

Cleaning and Lubricating

#

After inspecting the slack, clean the chain and

sprockets while rotating the rear wheel.

Use a dry cloth with high flash-point solvent.

Use a soft brush if the chain is dirty.

After cleaning, wipe dry and lubricate with the

recommended lubricant.

Recommended lubricant:

Drive chain lubricant

If not available, use SAE 80 or 90 gear oil.

Never use petrol or low flash point solvents for

cleaning the drive chain.

A fire or explosion could result.

Avoid getting lubricant on the brakes or tyres.

Avoid applying excess chain lubricant to prevent

spray onto your clothes and the vehicle.

43

Maintenance Fundamentals

Maintenance

Crankcase Breather

Service more frequently when riding in rain, at

full throttle, or after the vehicle is washed or

overturned. Service if the deposit level can be

seen in the transparent section of the drain

tube.

If the drain tube overflows, the air filter may

become contaminated with engine oil causing

poor engine performance.

2 P. 74

Inspecting for Damage

#

Inspect the tyres for

cuts, slits, or cracks

that exposes fabric or

cords, or nails or other

foreign objects

embedded in the side

of the tyre or the

tread. Also inspect for

any unusual bumps or bulges in the side walls of

the tyres.

Tyres (Inspecting/Replacing)

Checking the Air Pressure

#

Visually inspect your tyres and use an air

pressure gauge to measure the air pressure at

least once a month or any time you think the

tyres look low. Always check air pressure when

your tyres are cold.

44

Inspecting for Abnormal Wear

#

Inspect the tyres for

signs of abnormal

wear on the contact

surface.

Maintenance

Inspecting Tread Depth

3

WARNING

#

Inspect the tread wear indicators. If they become

visible, replace the tyres immediately.

or TWI

Maintenance Fundamentals

Riding on tyres that are excessively worn

or improperly inflated can cause a crash

in which you can be seriously hurt or

killed.

Wear indicator

location mark

Follow all instructions in this owner’s

manual regarding tyre inflation and

maintenance.

continued

45

Maintenance Fundamentals

Maintenance

AFS110MD

AFS110MCS

3

WARNING

Have your tyres replaced by your dealer.

For recommended tyres and air pressure, see

“Specifications.”

Follow these guidelines whenever you replace

tyres.

● Use the recommended tyres or equivalents of

the same size, construction, speed rating, and

load range.

● Remember to replace the inner tube

whenever you replace a tyre. The old tube will

probably be stretched, and it could fail if

installed in a new tyre.

● Do not install a tube inside a tubeless tyre on

this vehicle. Excessive heat build-up can cause

the tube to burst.

● Use only tubeless tyres on this vehicle. The

rims are designed for tubeless tyres, and

during hard acceleration or braking, a tubetype tyre could slip on the rim and cause the

tyre to rapidly deflate.

46

2 P. 106

Installing improper tyres on your vehicle

can adversely affect handling and

stability, and can cause a crash in which

you can be seriously hurt or killed.

Always use the size and type of tyres

recommended in this owner’s manual.

Maintenance Fundamentals

Maintenance

Air Cleaner

This vehicle is equipped with a viscous type air

cleaner element.

Air blow cleaning or any other cleaning can

degrade the viscous element performance and

cause the intake of dust.

Do not perform the maintenance.

Should be serviced by your dealer.

47

Maintenance

Tool

The tools are stored in the luggage box.

2 P. 31

You can perform some roadside repairs,

minor adjustments and parts replacement

with the tools contained in the kit.

● Spark plug wrench

● Standard/Phillips screwdriver

● Screwdriver handle

48

Maintenance

Removing & Installing Body Components

Screws

3.

Battery

Removal

#

Make sure the ignition switch is in the

position.

1.

Open the seat. 2 P. 30

2.

Remove the battery cover by removing the

screws.

Battery cover

(Off)

Disconnect the negative - terminal from

the battery.

4.

Disconnect the positive + terminal from

the battery.

5.

Remove the battery taking care not to drop

the terminal nuts.

Negative

terminal

Positive

terminal

Battery

continued

49

Removing & Installing Body Components u Battery

Maintenance

Installation

#

Install the parts in the reverse order of

removal. Always connect the positive +

terminal first. Make sure that bolts and nuts

are tight.

For proper handling of the battery, see

“Maintenance Fundamentals.”

“Battery Goes Dead.” 2 P. 86

50

2 P. 38

Removing & Installing Body Components u Headlight Case

Maintenance

Removal

Headlight Case

Rearview mirrors

Rubber dust covers

Lock nut

Lock

nut

#

1.

Pull up the rubber dust covers.

2.

Loosen the lock nuts by turning clockwise.

3.

Loosen the rearview mirrors and remove

them by turning them clockwise.

4.

Loosen the mirror adapters by turning

counterclockwise and remove them.

Mirror

adapter

Mirror

adapter

continued

51

Removing & Installing Body Components u Headlight Case

Maintenance

Headlight Case

Screw B

Boss

Screws A

5.

Remove the screws A and screw B.

6.

Release the bosses by pressing the rear

Socket

Boss

Rear handle

cover

Screws A

handle cover.

7.

Remove the headlight case and disconnect

the socket.

52

Installation

#

Install the parts in the reverse order of

removal.

u To install the rearview mirrors.

1.

Install the mirror adapters.

2.

Install the rearview mirrors by turning

counterclockwise until they will no longer

turn.

3.

Loosen the rearview mirrors approximately

2 turns.

4.

Adjust the rearview mirrors.

5.

Tighten the lock nuts and install the rubber

dust covers.

Removing & Installing Body Components u Main Pipe Cover

Maintenance

Screws A

Slots

Removal

Main Pipe Cover

Screw B

Main pipe cover

Screws A

Screw B

Screw C

#

1.

Remove the screws A, screws B and screw C.

2.

Slightly release the tabs from the slots.

3.

Remove the main pipe cover.

Installation

#

Install the parts in the reverse order of

removal.

Tabs

Screw B

53

Maintenance

Spark Plug

NOTICE

Checking Spark Plug

For the recommended spark plug, see

“Specifications.” 2 P. 106

Use only the recommended type of spark plug

in the recommended heat range.

Using a spark plug with an improper heat range can cause

engine damage.

1.

Disconnect the spark plug cap from the

spark plug.

2.

Clean any dirt from around the spark plug

base.

3.

Remove the spark plug using provided

spark plug wrench. 2 P. 48

54

Spark plug cap

Spark plug wrench

4.

Inspect the electrodes and centre porcelain

for deposits, erosion or carbon fouling.

u If the erosion or deposit is heavy,

replace the plug.

u Clean a carbon or wet-fouled plug with

a plug cleaner, otherwise use a wire

brush.

Maintenance

NOTICE

5.

Check the spark plug gap using a wire-type

feeler gauge.

u If adjustment is necessary, bend the side

electrode carefully.

The gap should be:

0.8 to 0.9 mm (0.03 to 0.04 in)

Side electrode

Spark plug gap

6.

Make sure the plug washer is in good

condition.

7.

Install the spark plug. With the plug washer

attached, thread the spark plug in by hand

to prevent cross-threading.

Spark Plug u Checking Spark Plug

8.

Tighten the spark plug:

● If the old plug is good:

NGK: 1/6 turn after it seats.

DENSO: 1/8 turn after it seats.

● If installing a new plug, tighten it twice to

prevent loosening:

a) First, tighten the plug:

NGK: 1/4 turn after it seats.

DENSO: 3/4 turn after it seats.

b) Then loosen the plug.

c) Next, tighten the plug again:

NGK: 1/6 turn after it seats.

DENSO: 1/8 turn after it seats.

An improperly tightened spark plug can damage the

engine. If a plug is too loose, a piston may be damaged. If

a plug is too tight, the threads may be damaged.

9.

Install the parts in the reverse order of

removal.

u

When reinstalling the spark plug cap, take

care to avoid pinching any cable or wires.

55

Maintenance

Engine Oil

Checking the Engine Oil

1.

If the engine is cold, idle the engine for 3 to

5 minutes.

2.

Turn the ignition switch to the (Off)

position and wait for 2 to 3 minutes.

3.

Place your vehicle on its centre stand on a

firm, level surface.

4.

Remove the oil fill cap/dipstick and wipe it

clean.

5.

Insert the oil fill cap/dipstick until it seats,

but don’t screw it in.

6.

Check that the oil level is between the

upper level and lower level marks in the oil

fill cap/dipstick.

7.

Securely install the oil fill cap/dipstick.

56

Upper level

Lower level

Oil fill cap/dipstick

Engine Oil u Adding Engine Oil

Maintenance

NOTICE

Adding Engine Oil

If the engine oil is below or near the lower

level mark, add the recommended engine oil.

2 P. 41, 106

1.

Remove the oil fill cap/dipstick. Add the

recommended oil until it reaches the upper

level mark.

u Place your vehicle on its centre stand on

a firm, level surface when checking the

oil level.

u Do not overfill above the upper level

mark.

u Make sure no foreign objects enter the

oil filler opening.

u Wipe up any spills immediately.

2.

Securely reinstall the oil fill cap/dipstick.

Overfilling with oil or operating with insufficient oil can

cause damage to your engine. Do not mix different brands

and grades of oil. They may affect lubrication and clutch

operation.

For the recommended oil and oil selection

guidelines, see “Maintenance Fundamentals.”

2 P. 41

Changing Engine Oil

Changing the oil requires special tools. We

recommend that you have your vehicle

serviced by your dealer.

1.

If the engine is cold, idle the engine for 3

to 5 minutes.

2.

Turn the ignition switch to the (Off)

position and wait for 2 to 3 minutes.

continued

57

Engine Oil u Changing Engine Oil

Maintenance

3.

Place your vehicle on its centre stand on a

firm, level surface.

4.

Place a drain pan under the drain bolt.

5.

Remove the oil fill cap/dipstick, drain bolt

and sealing washer to drain the oil.

u Discard the oil at an approved

recycling centre.

6.

Install a new sealing washer onto the drain

bolt. Tighten the drain bolt.

Torque: 24 N·m (2.4 kgf·m, 18 lbf·ft)

7.

Fill the crankcase with the recommended

oil (2 P. 41, 106) and install the oil fill cap/

dipstick.

Required oil

When changing oil:

0.8 litres (0.8 US qt, 0.7 Imp qt)

8.

Check the oil level. 2 P. 56

9.

Check that there are no oil leaks.

58

Drain bolt

Sealing washer

Maintenance

Brakes

AFS110MCS

Checking the Front Brake Fluid

1.

Place your vehicle in an upright position on

a firm, level surface.

2.

Check that the brake fluid reservoir is

horizontal and that the fluid level is above

the L (lower) level mark.

If the brake fluid level in the reservoir is below

the L (lower) level mark or the brake lever

freeplay becomes excessive, inspect the brake

pads for wear. If the brake pads are not worn,

you most likely have a leak. Have your vehicle

inspected by your dealer.

Front brake fluid reservoir

L (lower) level

mark

59

Brakes u Inspecting the Front Brake Pads

Maintenance

AFS110MCS

Inspecting the Front Brake Pads

Check the condition of the brake pad wear

indicators.

The pads need to be replaced if a brake pad is

worn to the indicator.

Inspect the brake pads from below the brake

caliper.

If necessary have the pads replaced by your

dealer.

Always replace both left and right brake pads

at the same time.

60

Disc

Brake pads

Wear

indicators

Brakes u Inspecting the Front Brake Lever Freeplay

Maintenance

AFS110MD

Inspecting the Front Brake

Lever Freeplay

1.

Place your vehicle on its centre stand on a

firm, level surface.

2.

Measure the distance of the front brake

lever before the starts to take hold.

Freeplay at the tip of the brake lever:

10 to 20 mm (0.4 to 0.8 in)

Freeplay

Check the brake cable for kinks or signs of

wear. If necessary have it replaced by your

dealer.

Lubricate the brake cable with a commercially

available cable lubricant to prevent premature

wear and corrosion.

Make sure the brake arm, spring and fastener

are in good condition.

61

Brakes u Adjusting the Front Brake Lever Freeplay

Maintenance

AFS110MD

Adjusting nut

Adjusting the Front Brake Lever

Freeplay

Adjust the freeplay of the brake lever with the

front wheel pointed straight ahead.

Make sure the cut-out on the adjusting nut is

seated on the brake arm pin when adjusting

the freeplay.

Brake arm pin

If proper adjustment cannot be obtained by

this method, see your dealer.

62

Decrease

freeplay

Brake arm pin

Adjusting

nut

1.

Adjust by turning the front brake adjusting

Increase

freeplay

nut a half-turn at a time.

2.

Apply the brake several times and check

for free wheel rotation after the brake lever

is released.

3.

Push the brake arm to confirm that there is

a gap between the front brake adjusting

nut and brake arm pin.

Brakes u Inspecting the Rear Brake Pedal Freeplay

Maintenance

NOTICE

Rear brake pedal

Brake arm

Push

Brake arm pin

Adjusting nut

Gap

After adjustment, confirm the freeplay of the

brake lever.

Make sure the brake arm, spring and fastener

are in good condition.

Do not turn the adjuster beyond its natural limits.

Inspecting the Rear Brake Pedal

Freeplay

1.

Place your vehicle on its centre stand on a

firm, level surface.

2.

Measure the distance of the rear brake

pedal before the starts to take hold.

Freeplay at the tip of the rear brake

pedal: 20 to 30 mm (0.8 to 1.2 in)

Freeplay

Make sure the brake rod, brake arm, spring

and fastener are in good condition.

63

Brakes u Adjusting the Rear Brake Pedal Freeplay

Maintenance

Adjusting nut

Adjusting the Rear Brake Pedal

Freeplay

Make sure the cut-out on the adjusting nut is

seated on the brake arm pin when adjusting

the freeplay.

1.

Adjust by turning the rear brake adjusting

nut a half-turn at a time.

Brake arm pin

If proper adjustment cannot be obtained by

this method, see your dealer.

64

Decrease

freeplay

Brake arm pin

Adjusting nut

2.

Apply the brake several times and check

Increase

freeplay

for free wheel rotation after the brake

pedal is released.

Maintenance

3.

NOTICE

AFS110MCS

AFS110MD

Brake panel

Front

Push the brake arm to confirm that there is

a gap between the rear brake adjusting nut

and brake arm pin.

Brake arm

Brakes u Inspecting the Brake Shoe Wear

Inspecting the Brake Shoe Wear

The rear brake is equipped with a brake wear

indicator.

Push

Brake arm pin

Adjusting nut

After adjustment, confirm the freeplay of the

Gap

rear brake pedal.

Make sure the brake rod, brake arm, spring

and fastener are in good condition.

Do not turn the adjuster beyond its natural limits.

The front and rear brake are equipped with a

brake wear indicator.

Arrow

Reference

mark

Brake arm

continued

65

Brakes u Adjusting the Brakelight Switch

Maintenance

Brake panel

Rear

Arrow

Reference

mark

Adjusting the Brakelight Switch

Check the operation of the brakelight switch.

Hold the brakelight switch and turn the

adjusting nut in the direction A if the switch

operates too late, or turn the nut in the

direction B if the switch operates too soon.

Brakelight switch

Brake arm

When the brake is applied, an arrow attached

to the brake arm moves toward a reference

mark on the brake panel. If the arrow aligns

with the reference mark on full application of

the brake, the brake shoes must be replaced.

See your dealer for this service.

When the brake service is necessary, see your

dealer. Use only Honda Genuine Parts or its

equivalent.

66

Adjusting nut

B

A

Maintenance

Side Stand

1.

Checking the Side Stand

Side stand spring

Check that the side stand operates

smoothly. If the side stand is stiff or

squeaky, clean the pivot area and lubricate

the pivot bolt with clean grease.

2.

Check the spring for damage or loss of

tension.

67

Maintenance

Drive Chain

Inspecting the Drive Chain

Slack

Check the drive chain slack at several points

along the chain. If the slack is not constant at

all points, some links may be kinked and

binding.

Have the chain inspected by your dealer.

1.

Shift the transmission to Neutral. Stop the

engine.

2.

Place your vehicle on its centre stand on a

firm, level surface.

68

3.

Check the slack in the lower half of the

drive chain midway between the sprockets.

Drive chain slack:

20 to 30 mm (0.8 to 1.2 in)

u Do not ride your vehicle if the slack

exceeds 50 mm (2.0 in).

Drive Chain u Inspecting the Drive Chain Slack

Maintenance

4.

Rotate the rear wheel and check that the

chain moves smoothly.

5.

Inspect the sprockets. 2 P. 42

6.

Clean and lubricate the drive chain. 2 P. 43

69

Drive Chain u Adjusting the Drive Chain Slack

Maintenance

Rear axle nut

Scale graduations

End of drive chain

Scale graduations

Adjusting the Drive Chain Slack

Adjusting the chain requires special tools.

Have the drive chain slack adjusted by your

dealer.

1.

Shift the transmission to Neutral. Stop the

engine.

2.

70

Place your vehicle on its centre stand on a

firm, level surface.

3.

Loosen the rear axle nut.

4.

Loosen the lock nuts on both sides of the

drive chain adjusters.

Adjusting nut

Lock nut

adjuster

Drive chain adjuster

Adjusting nut

End of drive

chain adjuster

Drive chain adjuster

5.

Turn both adjusting nuts an equal number

Lock nut

of turns until the correct drive chain slack

is obtained. Turn the adjusting nuts

clockwise to tighten the chain. Turn the

adjusting nuts counterclockwise and push

the rear wheel toward the front to provide

more slack.

Drive Chain u Adjusting the Drive Chain Slack

Maintenance

Adjust the slack at a point midway

between the drive sprocket and the driven

sprocket.

Check the drive chain slack.

6.

Check rear axle alignment by making sure

2 P. 68

the end of the drive chain adjuster aligns

with the scale graduations on both sides

of the swingarm.

Both marks should correspond. If the axle

is misaligned, turn the right or left

adjusting nut until the marks are aligned

7.

Tighten the rear axle nut.

Torque: 59 N·m (6.0 kgf·m, 44 lbf·ft)

8.

Hold the adjusting nuts and tighten the

lock nuts.

9.

Recheck drive chain slack.

10 .

Rear brake pedal freeplay is affected

when repositioning the rear wheel to

adjust drive chain slack. Check rear brake

pedal freeplay and adjust as necessary.

2 P. 63

and recheck chain slack.

If a torque wrench was not used for

installation, see your dealer as soon as

possible to verify proper assembly.

Improper assembly may lead to loss of

braking capacity.

continued

71

Drive Chain u Adjusting the Drive Chain Slack

Maintenance

Checking the Drive Chain Wear

#

If the drive chain slack is excessive when the

rear axle is moved to the furthest limit of

adjustment, the drive chain is worn and must

be replaced.

Chain:

DID420AD2

72

RK420EL

KMC420JB

If necessary have the drive chain replaced by

your dealer.

Maintenance

Freeplay

Throttle

Checking the Throttle

With the engine off, check that the throttle

rotates smoothly from fully closed to fully

open in all steering positions and throttle

freeplay is correct. If the throttle does not

move smoothly, close automatically, or if the

cable is damaged, have the vehicle inspected

by your dealer.

Freeplay at the throttle grip flange:

2 to 6 mm (0.1 to 0.2 in).

Flange

73

Maintenance

Crankcase Breather

Cleaning the Crankcase

Breather

1.

Place a suitable container to receive

deposits.

2.

Remove the crankcase breather tube and

drain deposits.

3.

Reinstall the crankcase breather tube.

74

Crankcase breather tube

Maintenance

Other Adjustments

Headlight

Adjusting the Headlight Aim

You can adjust vertical aim of the headlight for

proper alignment. To move the headlight,

loosen the adjusting bolt.

Tighten the adjusting bolt after adjustment.

Obey local laws and regulations.

Up

Down

Adjusting bolt

75

Troubleshooting

Engine Will Not Start.................................. P. 77

Tyre Puncture .............................................. P. 78

Electrical Trouble ........................................ P. 86

Battery Goes Dead...............................................P. 86

Burned-out Light Bulb ........................................P. 86

Blown Fuse.............................................................P. 93

Troubleshooting

Engine Will Not Start

Starter Motor Operates But

Engine Does Not Start

Check the following items:

● Check the correct engine starting sequence

2 P. 23

● Check that there is petrol in the fuel tank

Starter Motor Does Not

Operate

Check the following items:

● Check the correct engine starting sequence.

2 P. 23

● Check for a blown fuse 2 P. 93

● Check for a loose battery connection or

battery terminal corrosion 2 P. 39, 49

● Check the condition of the battery 2 P. 86

If the problem continues, have your vehicle

inspected by your dealer.

77

Troubleshooting

Tyre Puncture

AFS110MD

3

WARNING

Repairing a puncture or removing a wheel

requires special tools and technical expertise.

We recommend you have this type of service

performed by your dealer.

After an emergency repair, always have the

tyre inspected/replaced by your dealer.

Tube Repair and Replacement

If a tube is punctured or damaged, you should

replace it as soon as possible. A tube that is

repaired may not have the same reliability as a

new one, and it may fail while you are riding.

If you need to make a temporary repair by

patching a tube or using an aerosol sealant,

ride cautiously at reduced speed and have the

tube replaced before you ride again.

78

Anytime a tube is replaced, the tyre should be

carefully inspected as described.

Riding your vehicle with a temporary

tyre or tube repair can be risky. If the

temporary repair fails, you can crash and

be seriously injured or killed.

If you must ride with a temporary tyre or

tube repair, ride slowly and carefully and

do not exceed 50 km/h (30 mph) until

the tyre or tube is replaced.

Tyre Puncture u Emergency Repair Using a Tyre Repair Kit

Troubleshooting

AFS110MCS

3

WARNING

Emergency Repair Using a Tyre

Repair Kit

Riding your vehicle with a temporary

tyre repair can be risky. If the temporary

If your tyre has a minor puncture, you can

make an emergency repair using a tubeless

tyre repair kit.

Follow the instructions provided with the

emergency tyre repair kit.

Riding your vehicle with a temporary tyre

repair is very risky. Do not exceed 50 km/h (30

km/h). Have the tyre replaced by your dealer

as soon as possible.

repair fails, you can crash and be

seriously injured or killed.

If you must ride with a temporary tyre or

tube repair, ride slowly and carefully and

do not exceed 50 km/h (30 mph) until

the tyre is replaced.

79

Tyre Puncture u Removing Wheels

Troubleshooting

AFS110MD

Speedometer

Front axle nut

Removing Wheels

Follow these procedures if you need to

remove a wheel in order to repair a puncture.

Front Wheel

#

Removal

1.

Place your vehicle on its centre stand on a

firm, level surface.

2.

Support your vehicle securely and raise the

front wheel off the ground using a

maintenance stand or a hoist.

3.

Remove the speedometer cable by

4.

5.

6.

80

pushing the tab.

Remove the front brake adjusting nut and

disconnect the front brake cable from the

brake arm.

Remove the front axle nut.

Remove the front axle shaft, front wheel,

and side collar.

Brake arm

Front brake

adjusting nut

Tab

Front axle shaft

cable

Front brake cable

Troubleshooting

Brake panel

Installation

1.

Install the side collar into the right side

wheel hub.

2.

Position the wheel between the fork legs

and insert the front axle shaft from the right

side, through the right fork leg and wheel

hub.

3.

Make sure that the lug on the left fork leg is

located in the slot of the brake panel.

4.

Tighten the front axle nut.

Torque: 59 N·m (6.0 kgf·m, 44 lbf·ft)

5.

Install the speedometer cable securely.

6.

Install the front brake cable and front brake

adjusting nut.

7.

Adjust the front brake lever freeplay. 2 P. 62

8.

After installing the wheel, apply the brake

lever several times and then check if the

wheel rotates freely. Recheck the wheel if

the brake drags or if the wheel does not

rotate freely.

Tyre Puncture u Removing Wheels

If a torque wrench was not used for

installation, see your dealer as soon as

possible to verify proper assembly.

Improper assembly may lead to loss of

braking capacity.

continued

Lug

Slot

81

Tyre Puncture u Removing Wheels

Troubleshooting

AFS110MCS

Speedometer

Front Wheel

#

Removal

1.

Place your vehicle on its centre stand on a

firm, level surface.

2.

Support your vehicle securely and raise the

front wheel off the ground using a

maintenance stand or a hoist.

3.

Remove the speedometer cable by

pushing the tab.

4.

Remove the front axle nut.

5.

Remove the front axle shaft, front wheel,

speedometer gearbox and side collar.

u Avoid getting grease, oil, or dirt on the

disc or pad surfaces.

u Do not pull the brake lever while the

front wheel is removed.

82

Front axle nut

gearbox

Tab

Front axle shaft

Tyre Puncture u Removing Wheels

Troubleshooting

NOTICE

Installation

1.

Attach the side collar and speedometer

gearbox to the wheel.

2.

Position the wheel between the fork legs

and insert the front axle shaft from the right

side, through the right fork leg and wheel

hub.

When installing a wheel or caliper into original position,

carefully fit the brake disc between the pads to avoid

scratching them.

3.

Make sure that the lug on the left fork leg is

located in the slot of the speedometer

gearbox.

4.

Tighten the front axle nut.

Torque: 59 N·m (6.0 kgf·m, 44 lbf·ft)

5.

After installing the wheel, apply the brake

lever several times and then check if the

wheel rotates freely. Recheck the wheel if

the brake drags or if the wheel does not

rotate freely.

6.

Install the speedometer cable securely.

Speedometer

Lug

gearbox

If a torque wrench was not used for

installation, see your dealer as soon as

possible to verify proper assembly.

Improper assembly may lead to loss of

braking capacity.

continued

Slot

83

Tyre Puncture u Removing Wheels

Troubleshooting

Drive chain

Rear Wheel

#

Removal

1.

Support your vehicle securely and raise the

rear wheel off the ground using the centre

stand or a hoist.

2.

Remove the rear brake adjusting nut.

3.

Disconnect the brake rod from the brake

arm.

4.

Disconnect the brake stopper arm from the

brake panel by removing the cotter pin,

brake stopper arm nut, washer and rubber

grommet.

5.

Loosen the drive chain lock nuts and drive

chain adjusting nuts on both sides of the

drive chain adjusters.

84

adjusting nut

Drive chain

lock nut

Brake

arm

Rear brake

adjusting nut

6.

Remove the rear axle nut while holding the

Brake stopper arm nut

Drive chain

adjuster

Rear axle nut

Brake rod

Brake

stopper

arm

Cotter pin

rear axle shaft at the other end with a

wrench.

7.

Remove the drive chain from the driven

sprocket by pushing the rear wheel

forward.

Tyre Puncture u Removing Wheels

Troubleshooting

Drive chain adjuster

8.

Remove the rear axle shaft, drive chain

adjusters, side collars and rear wheel from

the swingarm.

Drive chain

adjusting nut

Rear axle

shaft

3.

Tighten the brake stopper arm nut.

Torque: 22 N·m (2.2 kgf·m, 16 lbf·ft)

4.

Adjust the rear brake pedal freeplay. 2 P. 64

5.

Adjust the drive chain slack. 2 P. 70

6.

After installing the wheel, apply the brake

pedal several times and then check if the

wheel rotates freely. Recheck the wheel if

the brake drags or if the wheel does not

rotate freely.

Drive chain lock nut

Installation

1.

To install the rear wheel, reverse the

removal procedure.

2.

Tighten the rear axle nut.

Torque: 59 N·m (6.0 kgf·m, 44 lbf·ft)

Drive chain

If a torque wrench was not used for

installation, see your dealer as soon as

possible to verify proper assembly.

Improper assembly may lead to loss of

braking capacity.

A used cotter pin may not effectively secure a

fastener. Always replace a used cotter pin with

a new one.

85

Troubleshooting

Electrical Trouble

NOTICE

Battery Goes Dead

Charge the battery using a motorcycle battery

charger.

Remove the battery from the vehicle before

charging.

Do not use an automobile-type battery

charger, as these can overheat a motorcycle

battery and cause permanent damage.

If the battery does not recover after

recharging, contact your dealer.

Jump starting using an automobile battery is not

recommended, as this can damage your vehicle’s

electrical system.

86

Burned-out Light Bulb

Follow the procedure below to replace a

burned-out light bulb.

Turn the ignition switch to the (Off) or

position.

(Lock)

Allow the bulb to cool before replacing it.

Do not use bulbs other than those specified.

Check the replacement bulb for correct

operation before riding.

For the light bulb wattage, see

“Specifications.”

2 P. 107

Electrical Trouble u Burned-out Light Bulb

Troubleshooting

Pin

1.

Headlight Bulb

#

“3“ mark

Remove the headlight case. 2 P. 51

2.

Remove the rubber cover.

3.

Slightly press down on the pin and turn it

clockwise until it releases from the

headlight bulb housing.

4.

Remove the bulb.

5.

Install a new bulb and parts in the reverse

order of removal.

u Install the rubber cover with its “

3” mark

facing up.

Do not touch the glass surface with your

fingers. If you touch the bulb with your bare

hands, clean it with a cloth moistened with

Rubber cover

Bulb

alcohol.

continued

87

Electrical Trouble u Burned-out Light Bulb

Troubleshooting

Position Light Bulb

#

1.

Remove the main pipe cover. 2 P. 53

2.

Pull the socket without turning it.

3.

Pull out the bulb without turning it.

4.