Page 1

Page 2

WARRANTY

SERVICE

Your satisfaction and

warranty

this

your

been

details

booklet. Normally, any problems concerning the product

dealer's

handled

service

to your satisfaction,

goodwill

are

explained

dpeartment

are

important to your dealer and to us.

in the Distributor's Limited Warranty at the back of

will

be

If

you have a warranty problem that has not

we

suggest you take the following action:

Discuss your problem with a member of dealership management. Often

complaints

reviewed with the

quickly resolved at that level.

Sewice

Manager, contact the owner of the dealership or the

If

the problem

has

already been

can

be

General Manager.

If

your problem still has not been resolved to your satisfaction, contact the

of

Customer Relations Department

-CAN

PYlKgR

4475

DlY"E,

EQlIIFNEhW

RN&R

GEORGlA

CtJmW

(404) 497-6400

We

will

need the following information

-

Your name, address. and telephone number

-Product model

-

Date

of purchase

-

Dealer name and address

-

Nature of the problem

and

serial

number

American Honda Motor

EORDA

SERVICE

MorOR

DIVISION

GRFEn

PARE(krAp

30136

DZPWET

in

CO,.

order to

INC..

..

assist

.

_._

you:

Co.,

Inc.:

All

Honda

handled by

After reviewing

taken.

Please

dealership, using the dealer's facilities, equipment, and personnel,

important

Your purchase of

all

the facts involved, you

bear

in mind that your problem

that

your initial contact

a

Honda product

will

be

advised

will

likely be resolved

be

with

the dealer.

is

greatly appreciated by both your dealer and

of

what

action can

at

the

so

it

is

very

be

American Honda Motor Company. We want to assist you in every way possible to

assure your complete satisfaction with your purchase.

..

Page 3

ASSElldBLY

1.

Assemble the link pins to the A-frame

halves using

%"jam

nuts, lock washers

and hex nuts.

2.

Join the frame halves together with the

spacing plate. Secure the plate at the front

.holes only with the hex bolts, lock washers

-

and hex nuts. Finger

3.

Assemble the frame angles to the A-frame

as

shown. Install the hex bolts, plain

tighten the bolts.

washers, lock washers and hex nuts:

-

finger

4.

Install the struts

A

angles. Finger

tighten.

first

at the rear

-

frame, and then at the

-

tighten the bolts.

rear

of

of

the frame

the

WASHER

LOCK WASHER

HEX. BOLT,

Yz

x

1

3h

HEX. BOLT,

'12

x

1

3h

HEX. NUT

NOTE The frame

most common cutting position

cutting angle

is

shown assembled for the

(goo).

is

determined by where the

struts are attached to the frame angles.

5.

Assemble a spring shank at positions

and 2-where frame angles attach to

-

frame-with existing hardware.

A

Assemble the remaining spring

shown.

Use

(thick) washers between

shanks

the springs and frame angles.*

6.

Align the springs and tighten

and

spring bolts securely.

all

frame

The

1

as

'h x 1

PLAIN WASHER

LOCK WASHER

HEX. BOLT,

PLAIN WASHER

LOCK WASHER

3h

HEX. NUT

POSITION

Yz

x

1

3h

HEX. NUT

>A

FRAME

ANGLES

1

h

Page 4

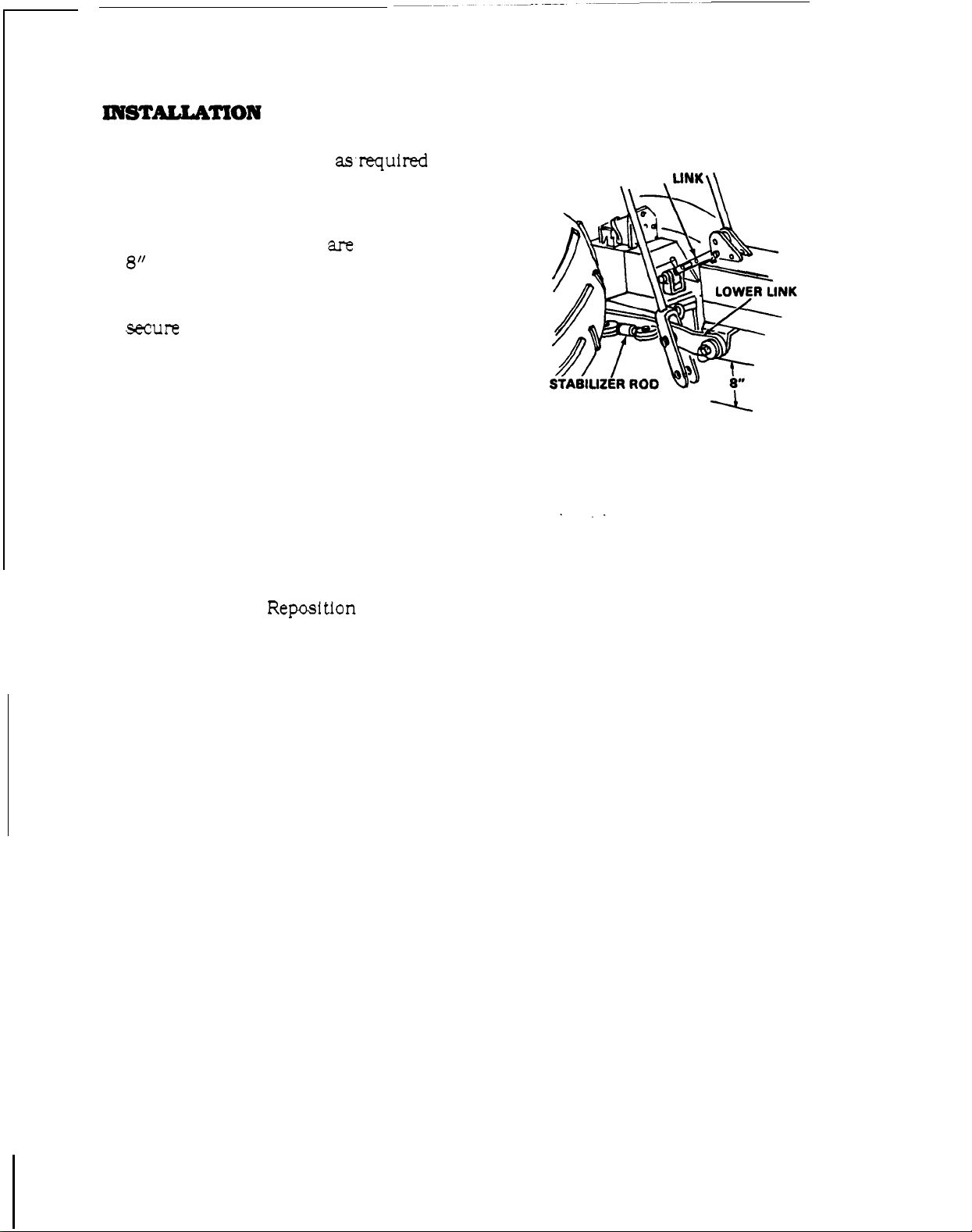

1.

Adjust the tractor wheels asmquired to

provide maximum plant foliage

clearance.

UPPER

LINK

\\

With the hitch lowered, adjust the lower

links

until

the link

8"

from

the ground.

2.

Attach the cultivator to the lower

secure

3.

Connect the upper link

and the

with

with

lower

hitch

spring pins.

and

balls

are

approximately

links

and

rod

to the hitch

hole in the A-Frame: secure

spring pins.

OPERATXON

Adjust the cultivator angle and shank placement according to the type and row

spacing of the crop:

Reposition the

struts

to change the angle: remove the left

right front shanks for wider crops.

and

When necessary. adjust the upper link to make the front or

shallower

or

deeper.

rear

shanks dig

Page 5

11

15

AMERICAN HONDA

SPRING SHANK CULTIVATOR

Page 6

HOXVA

CODE

#

3755782

Loading...

Loading...