Homewood LODG0806DSL-1AA Instruction manual

Brigstock Road, Wisbech PE13 3JJ

TOOLS REQUIRED

● Hammer

● Step ladder

● Sand paper

● Battery-powered drill/screwdriver

● 8mm drill

● Pencil

● Tape measure

● Gloves

● Sharp knife and saw

Assembly of Lodge Playhouse

Adult Assembly Only - do not attempt to modify this building

Thank you and congratulations on the purchase of y

We believe that this product will give you many years of excellent service. This is a

natural product manufactured to a high standard therefore if you have any queries or

experience any difficulties then please contact our customer service hotline on

01945 465 295.

Normal office hours: 8.30 am to 5.00 pm Monday to Friday.

Preparation of base

We recommend that the base onto which your building will stand should be at least

75mm larger in each direction than the total floor size of the building.

Floor area of the building: 2390x2690 (8’x9’) including verandah.

Total height clearance: 2606mm

The chosen position in your garden for the siting of the building should be excavated to

a depth of 75mm to allow a base of sand, on to which paving slabs can be evenly laid -

THEY MUST BE LEVEL AND FIRM.

Treatment/care of your Garden Building

Treat with a suitable decorative wood finish immediately. We recommend that all timber

pieces be treated again prior to assembly and again within 3 months of assembly. We

further recommend that all pieces are treated again at least annually or as frequently as

the instructions on the product used recommends.

We would suggest that all wall panels be treated in an upside-down position to allow

the finish/treatment to ingress into the tongue and groove jointing.

We would also remind you that you would rarely (if ever) be able to re-treat the

underside of the floor following assembly. We strongly recommend that the underside

of the floor is treated an absolute minimum of twice (not including pre-treatment).

Garden buildings are not waterproof, therefore on assembling building we

recommend using a silicon based sealant between wall panels and between wall

panels and floor.

Parts List

our Shire garden building.

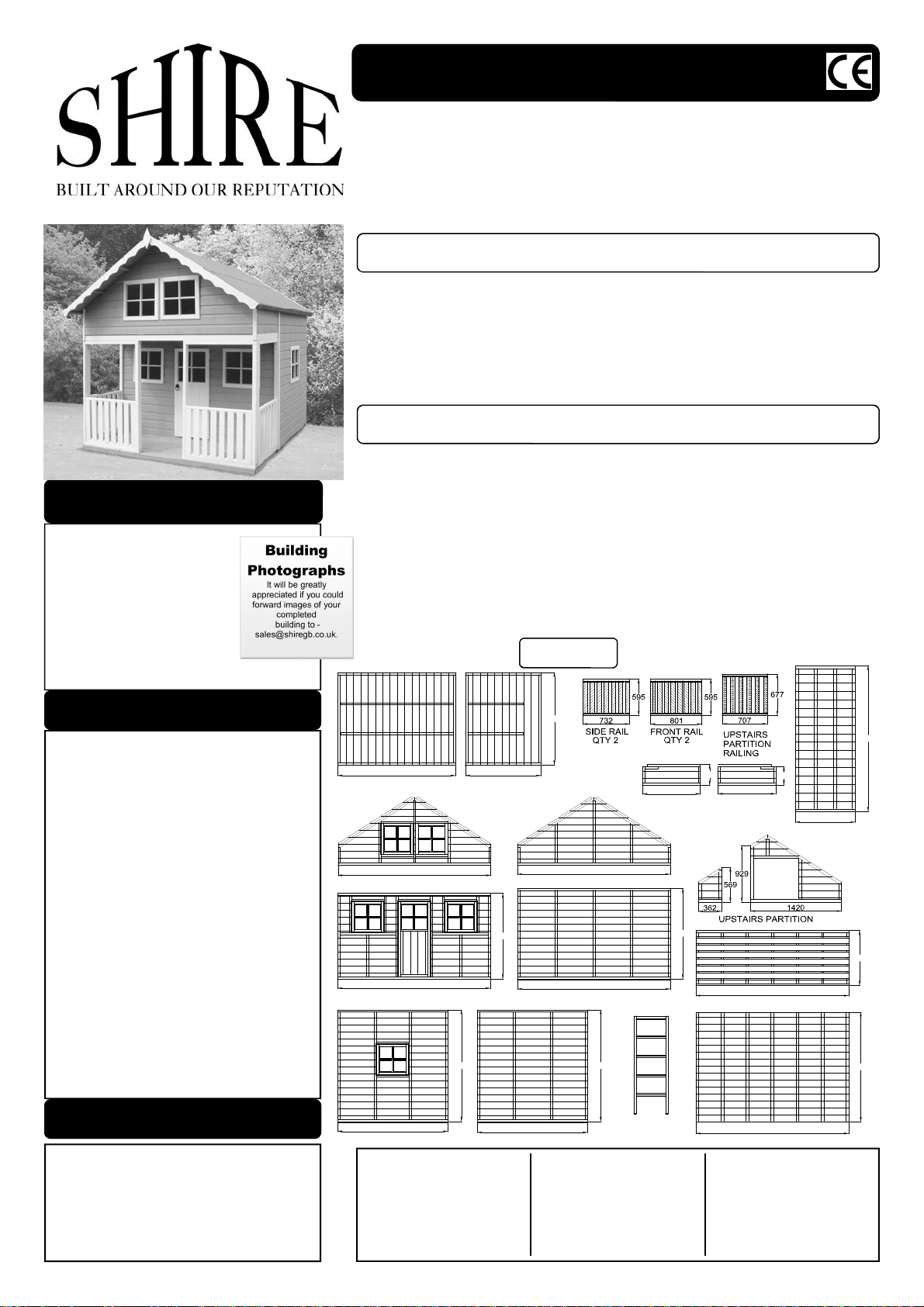

EXTERNAL VIEW OF PANELS

IMPORTANT!

PLEASE READ PRIOR TO ASSEMBLY OF

THE BUILDING

EVERY PRECAUTION IS TAKEN TO

ENSURE THAT YOUR BUILDING HAS NO

ELEMENT INCORRECTLY PLACED OR

POSSIBLY HAZARDOUS, HOWEVER

PRIOR TO USE PLEASE CHECK ALL

SURFACES FOR THE FOLLOWING:

1 RAISED GRAIN, SPLINTERS: sand

down timber to smooth fin ish

2 NAIL/SCREW/PIN HEADS PROUD: tap

home to be flush with surface of timber

3 DAMAGED SCREW HEADS

RESULTING IN SHARP SPLINTERS OF

METAL: replace

4 SHARP ENDS OF NAILS/ SCREWS/

PINS PROTRUDING THROUGH THE

PANEL: remove and reposition.

5 ENSURE ALL PARTS ARE SECURED

AGAINST REASONABLE FORCE:

remove and refit

6 ENSURE THERE ARE NO LOOSE

PARTS: remove and refit/discard

We recommend that protective

gloves be worn throughout

PLEASE NOTE

Wood is a natural product and is therefore

prone to changes in appearance, including

some warping, movement and splitting,

particularly during unusual climatic conditions

(long hot or wet spells of weather). As a natural

occurrence this is not covered by a guarantee.

1842

ROOF PANEL - QTY 2

2390

FRONT GABLE

2390

FRONT PANEL

1828 1828

1722

WINDOW SIDE PANEL

QTY DESCRIPTION

4 Frame 44x44x1319mm

4 Frame 44x70x1319mm

4 Frame 44x44x820mm

4 Frame 44x70x889mm

24 Glazing

96 Beading

1182

ROOF PANEL - QTY 2

1404

1722

PLAIN SIDE PANEL

1 Ring handle

1 Wooden knob

2 Vents

2 Fascia profiled

2 Fascia plain

2 Diamonds

52 80mm screws

1514

BACK GABLE

BACK PANEL

2390

2390

900

LH UPSTAIRS

SIDE PANEL

LADDER

342

900

RH UPSTAIRS

SIDE PANEL

1488

2390

VERANDAH FLOOR

2390

FLOOR PANEL

104 60mm screws

1 45mm flat head screw

4 25mm black screws

50 40mm nails

250 Felt nails

192 15mm panel pins

2 Felt roll 6.4mtr x 1mtr

2390

304

934

UPSTAIRS FLOOR

900

1790

22/07/08

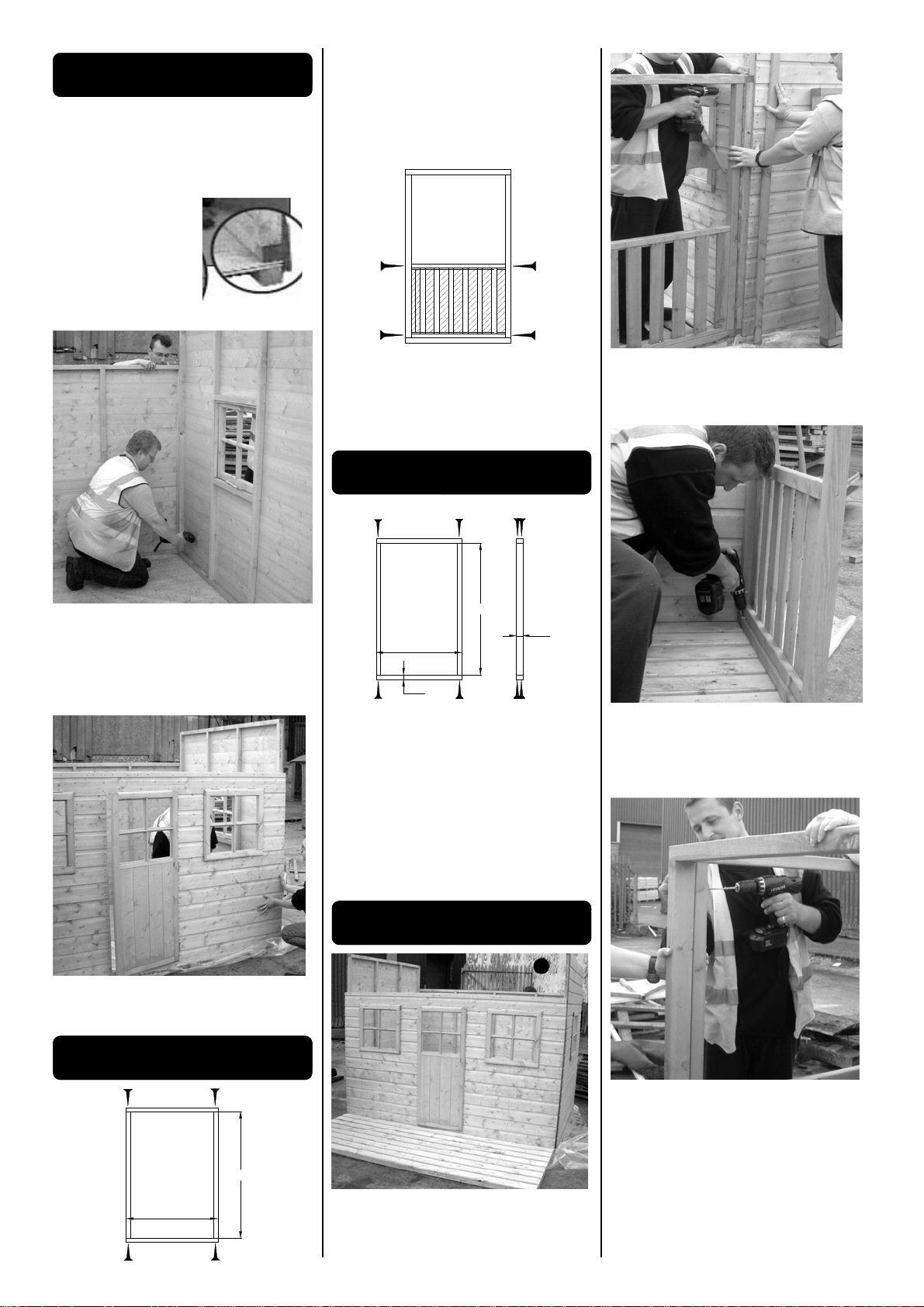

A Floor & Walls

Remove all travel protection blocks from

bottom edge of panels.

1. Ensure that your base is firm and

absolutely level.

2. Lay floor of building on base.

3. Pre drill panels in 2

places, top and bottom.

4. Place back panel onto

floor ensuring the cladding has overhung the

floor. The front and back

panels extend from floor

edge to floor edge.

5. Place side panel next to back panel and

join together from the inside using 2 x 60 mm

screws

6. Place other side in position and join to back

panel from the inside using 2 x 60 mm

screws.

1. Place two 44 x 44 x 820 mm pieces of

framework on a flat level surface. Position two

44 x 44 x 1319 mm pieces of framework

between the 820 mm pieces. Secure together

using 4 x 80 mm screws, one at each end.

2. Position side rail within framework. Secure

together through the frame into railing framework at the top and bottom using 2 x 80 mm

screws per side.

3. Repeat for other side rail.

C Verandah Front Railing

1. Place two 44 x 70 x 889 mm pieces of

framework on a flat level surface. The 44 mm

side will be facing upwards. Position two 44 x

70 x 1319 mm of framework inside the 889

mm pieces. Secure together using 8 x 80 mm

screws, two per end.

2. Secure front rail within the frame as per

side rail.

3. Repeat for other front rail.

889

44

1319

SIDE

VIEW

70

2. Place side railing against front of building

inline with edge of verandah floor. Secure to

front panel of using 2 x 60 mm screws, one at

the top and one at the bottom.

3. Secure side railing to verandah floor

through floor bearers using 2 x 60 mm

screws. You will need to position the screws

at an angle.

4. Repeat for other side rail.

7. Place front panel in position and join to

side panels from the inside using 2 x 60 mm

screws per side.

B Verandah Side Railing

820

1319

D Verandah Assembly

1. Position verandah floor against front of

building.

5. Place front railing against side railing,

ensuring rail is flush and square. Secure rails

together through side railing using 2 x 60 mm

screws, one at the top and one at the bottom.

6. Secure front railing to verandah floor

through floor bearers using 2 x 60 mm

screws. Again you will need to position the

screws at an angle.

7. Repeat for other front rail.

Loading...

Loading...