Homeright FINISH MAX PRO Instruction Manual

ACABADO FINO

PULVERIZADOR

FINISH MAX PRO

®

ADVERTENCIA PARA DISMINUIR LOS RIESGOS DE LESIONES,

EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DE INSTRUCCIONES.

SÓLO PARA USO DOMÉSTICO.

MANTENGA A LOS NIÑOS LEJOS DEL ÁREA DE TRABAJO.

Para comunicarse con el departamento de servicio al cliente,

llame al: 1-800-264-5442 ó 763-780-5115, de 8:00 a. m. a 5:00 p. m.

(hora del Centro de EE.UU.).

Hecho en Taiwán

FINISH MAX PRO

®

FINE FINISH SPRAYER

WARNING TO REDUCE THE RISK OF INJURY,

USER MUST READ AND UNDERSTAND INSTRUCTION MANUAL.

FOR HOUSEHOLD USE ONLY.

KEEP CHILDREN AWAY FROM WORKING AREA.

For Customer Service Call:

1-800-264-5442 or 763-780-5115,

8 a.m. to 5 p.m. CST.

Made in Taiwan

PLEASE READ AND SAVE THIS INSTRUCTION MANUAL

FINITION FINE

PULVÉRISATEUR

FINISH MAX PRO

®

AVERTISSEMENT POUR RÉDUIRE LES RISQUES DE BLESSURE,

L’UTILISATEUR DOIT LIRE ET COMPRENDRE LE MANUEL

D’INSTRUCTION.

DESTINÉ À UN USAGE DOMESTIQUE SEULEMENT.

TENEZ LES ENFANTS ÉLOIGNÉS DE L’AIRE DE TRAVAIL.

Pour le service à la clientèle, appelez au : 1-800-264-5442 ou

(763) 780-5115, de 8h00 à 17h00, heure normale du Centre.

Fabriqué en Taïwan

Register Online Today

To Activate Your Two-Year Warranty

Go online at www.homeright.com or scan the QR Code to the left. See back page for warranty details.

2

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

IMPORTANT SAFEGUARDS ......................................................................................................................................................................................2

Warnings ......................................................................................................................................................................................................2

PROP 65 Warning ..............................................................................................................................................................................................3

Hazard: Explosion or Fire ...................................................................................................................................................................................3

Hazard: Hazardous Vapors .................................................................................................................................................................................3

Extension Cords .................................................................................................................................................................................................3

Storage ..............................................................................................................................................................................................................3

PARTS LIST ............................................................................................................................................................................................................4

FAST START QUICK REFERENCE GUIDE ...................................................................................................................................................................5

HOW TO USE ..........................................................................................................................................................................................................6

Practice First ..........................................................................................................................................................................................................6

Surface Prep ......................................................................................................................................................................................................6

Thinning Materials .............................................................................................................................................................................................7

Adjusting the Spray Pattern ...............................................................................................................................................................................8

Spraying Instructions .........................................................................................................................................................................................8

Air Blowing Nozzle .............................................................................................................................................................................................8

CLEAN UP & MAINTENANCE ....................................................................................................................................................................................9

TROUBLESHOOTING ..............................................................................................................................................................................................10

TWO-YEAR LIMITED WARRANTY ...........................................................................................................................................................................32

TABLE OF CONTENTS

IMPORTANT SAFEGUARDS

READ AND FOLLOW ALL SAFEGUARDS.

Like other power tools, the Fine Finish Sprayer is safe when properly used

but can be dangerous if misused. It is the responsibility of the user to read

and understand all instructions, IMPORTANT SAFEGUARDS, and safety

precautions before operating the unit and also to use the unit properly. Failure

to do so may result in personal injury or loss of life and product damage.

Do not try to repair (or disassemble) the unit yourself. Repairs should be

performed by a qualified shop familiar with this unit or returned to HomeRight.

See warranty. This unit is to be used with authorized parts only. When using

parts that do not comply with the specifications and safety devices of the

manufacturer, theuser assumes all risks and liabilities.

• DO NOT aim sprayer at yourself or anyone else; in the event of injury,

seek expert medical advice immediately.

• DO NOT cover the nozzle with any part of your body. High velocity jet can

cause accidental injuries.

• DO NOT leave your sprayer uncleaned or allow paint to dry in the pump.

An uncleaned sprayer will not work the next time it’s used and you could

void the warranty.

• DO NOT spray textured materials containing asbestos fibers.

• DO NOT spray any textured materials containing particles or fibers such

as metallic paints or fire retardant paints.

• DO NOT spray flammable liquid.

• DO NOT use the sprayer outside when it’s raining.

• DO NOT use sprayer below garage floor or grade level.

• DO NOT disassemble the sprayer without reading instructions.

• DO NOT allow any part of the body to come into contact with

the fluid stream.

• DO plug the cord or extension cord only into grounded power supply.

• DO keep the sprayer out of the reach of children.

• ALWAYS place the sprayer upright (do not place the sprayer upside down

or on its side) to prevent liquid from entering internal wiring and causing

electric shock.

• ALWAYS wear mask, goggles, and ear and eye protection while

operating the sprayer.

• When you stop spraying, ALWAYS unplug the cord to prevent unintended

operation.

• To prevent electrical shock, NEVER immerse the sprayer into water or

other liquids.

• NEVER leave sprayer unattended.

• NEVER leave sprayer plugged in while cleaning.

WARNINGS

3

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

IMPORTANT SAFEGUARDS (CONTINUED)

HAZARD: HAZARDOUS VAPORS

Paint, stain and solvents, insecticides, varnishes, and other materials may

be harmful if inhaled, causing severe nausea, fainting, or poisoning.

• Use a mask or respirator when spraying when there is a chance of

inhaling vapors.

• Use protective eyewear.

EXTENSION CORDS

Make sure your extension cord is UL/ETL/CSA listed and is in good

condition. When using an extension cord, be sure to use one heavy enough

for the current - for lengths less than 18 feet, usea No. 18 AWG. or

heavier; for lengths of 18 - 25 ft, useNo. 16 AWG. For lengths greater than

25 ft, use No. 14 AWG. If in doubt, use a heavier gauge. Anundersized cord

will cause a drop in line voltage resulting in loss of power andoverheating

and possible damage.

STORAGE

Make sure unit is clean and dry before storing. Store in a dry location. To

prevent damage, the electrical cord should not be crimped during storage.

1. HAZARD: Solvent and paint fumes can explode or ignite, causing

property damage and severe injury. Avoid all low ignition sources such

as static electricity, sparks, and open flames.

2. HAZARD: Paints, solvents, insecticides, and other materials may be

harmful if inhaled, causing severe nausea, fainting, orpoisoning.

3. HAZARD: Do not hold cord at plug connections to support cord. Failure

to observe may result in electrical shock.

PROP 65 WARNING

Handling the coated electrical wires of this product exposes you to lead, a

chemical known to the State of California to cause birth defects or other

reproductive harm. Wash hands after use.

HAZARD: EXPLOSION OR FIRE

Paint, stain and solvent fumes can explode or ignite, causing property

damage and/or severe injury.

Do not use materials with a flash point below 70°F (21°C). Flashpoint is the

temperature that a fluid can produce enough vapors to ignite.

Plastic can cause static sparks. Never use plastic to enclose the spray

area. Do not use plastic drop cloths when spraying flammable materials.

• Keep area well ventilated. Exhaust and introduce fresh air to keep fumes

from accumulating in work area.

• Do not spray in areas where there are ignition sources, static electricity,

sparks, pilot lights, heaters, hot objects, cigarettes, oropen flames.

• Have fire extinguishing equipment present and in good workingorder.

• Follow safety instructions and IMPORTANT SAFEGUARDS of material

manufacturers.

WARNINGS

CAUTION

SERVICING A DOUBLE-INSULATED PRODUCT

In a double-insulated product, two systems of insulation are provided

instead of grounding. No grounding means is provided on a double

insulated product, nor should a means of grounding be added to the

product. Servicing of a double-insulated product requires extreme care

and knowledge of the system and should only be done by qualified service

personnel. Replacement parts for a double-insulated product must be

identical to those parts in theproduct.

4

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

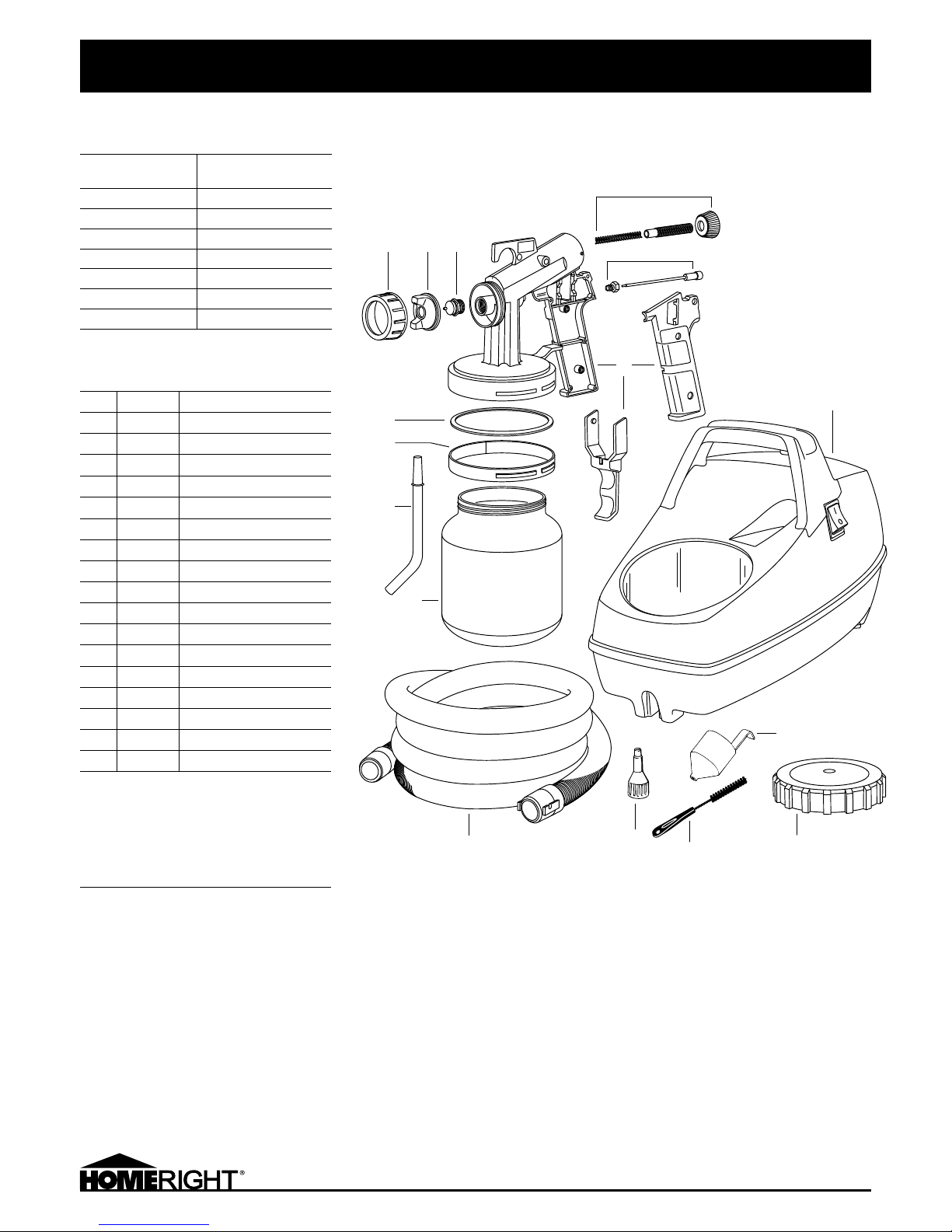

PARTS LIST

SPECIFICATIONS

Paint Compatibility Water or oil-based paints

and stains

Voltage 120V, 60 HZ

Watts 1000

Amps 10 amps

Air Supply 10.9 cfm

Container Capacity 0.8L ( 28 oz)

Weight 9.0 lbs ( 4.1 Kg)

Motor Speed 32,000 RPM

PARTS LIST

Item Part No. Description

1. C817821 Air Nut

2. C817824 Air Cap

3. C817866

Brass Fluid Nozzle, 2 mm Ø

4. C817867 Paint Control Adjusting Screw

5. C817737 Needle Assembly, 90 mm l

6. C817488 Gun Assembly

7. C817562 Turbine

8. C817561 Lid for Container

9. C817344 Viscosity Cup

10. C816545 Cleaning Brush

11. C817341 Air Blow Nozzle

12. C817513 Air Hose, 15 ft., Black

13. C817563 Container - Black

C817564 Container - Gray (not Shown)

14. C817823 Pick Up Tube

15. C817992 Blue Threaded Insert

16. C817822 Paint Cup Gasket

If you cannot obtain parts and accessories

at your local retail dealer, then call or

email: info@homeright.com

HomeRight, 1661 94th Lane N.E., Minneapolis,

Minnesota 55449-4324, Phone 763-780-5115

or 1-800-264-5442, 8:00 a.m. to 5:00 p.m. CST.

www.homeright.com

5

16

15

14

13

6

1 2 3

7

4

12

10

8

11

9

5

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

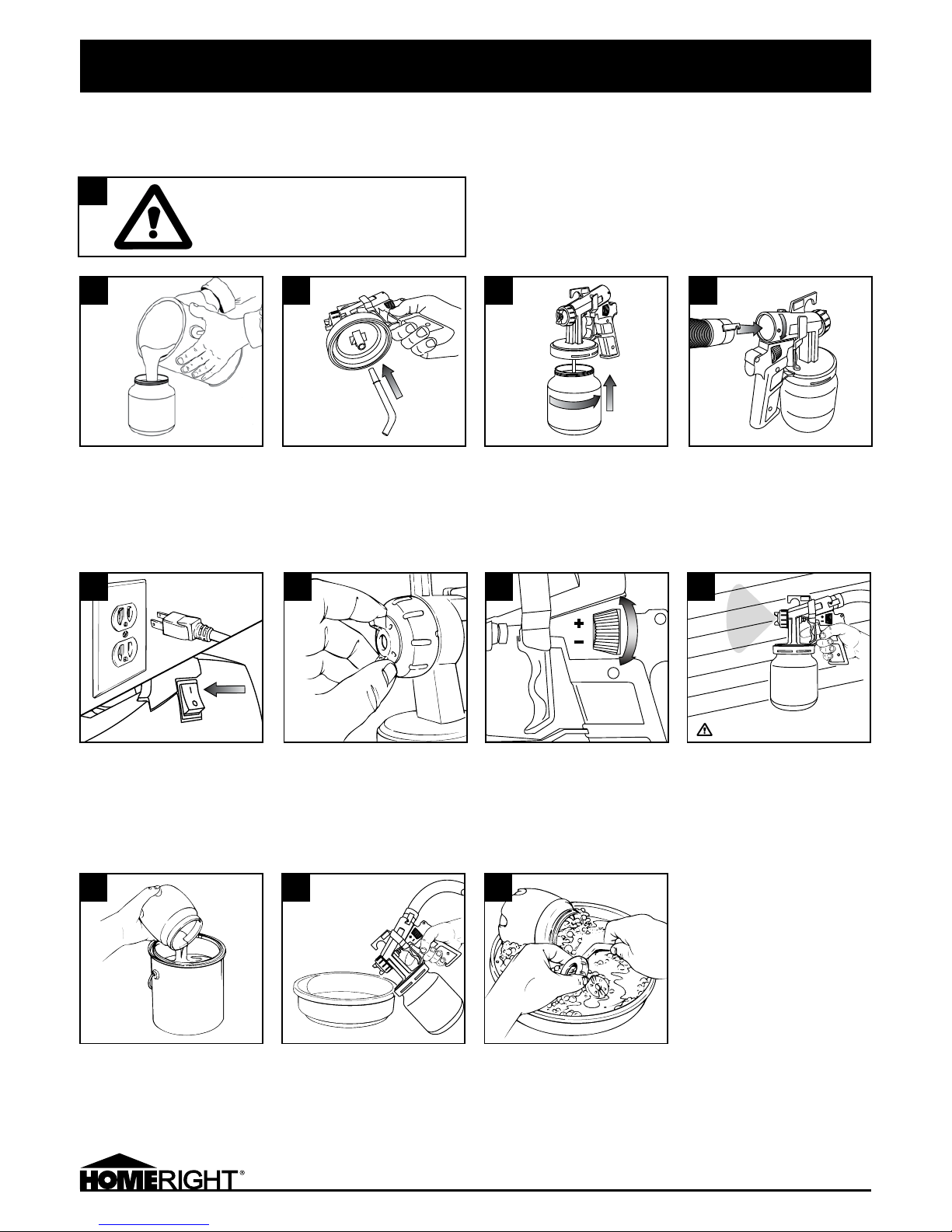

FAST START QUICK REFERENCE GUIDE

Cleaning Instructions

This is only a quick reference. Read the entire instruction manual prior to using the product.

1. Unplug sprayer, remove container,

and empty contents.

2. Fill sprayer container with cleaning

solution, plug in, turn on and

operate trigger until solution

comes through nozzle.

3. Remove parts. Clean and dry

thoroughly according to Step Two

of the Clean Up instructions. See

page 9.

1 2 3

Spraying Instructions

7 8

2

1

3 4

1. Read all warnings and safety

instructions in the user’s manual

before use.

2. Thin material as necessary.

(Seepage 7.) Remove and fill

container with material. Use a filter

to strain material if it is old.

3. Insert the pick-up tube into the

cylinder housing. See Page 6,

Figure B to determine orientation

of pick-up tube.

7. Adjust spray pattern to horizontal or

vertical. (See page 8.)

4. Attach container to sprayer.

8. Set the flow to maximum by

turning the volume control knob

fully clockwise.

6

6. Plug sprayer into outlet.

Turn sprayer On.

9

9. Spray surface, keeping sprayer

level. Use a sweeping and

overlapping motion.

HAZARDOUS VAPORS

5

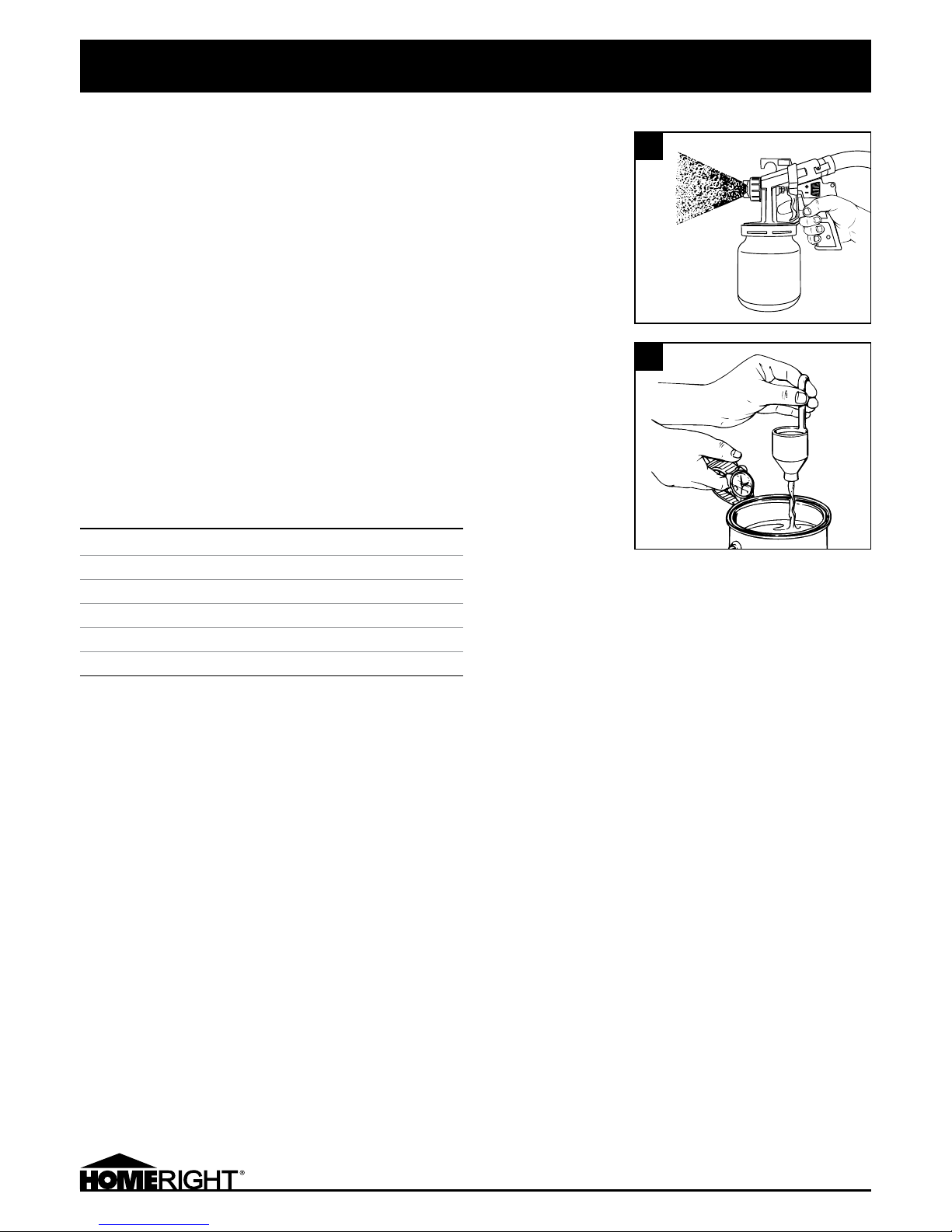

5. Insert air hose with locking tabs

into rear of spray gun, turn until

tabs lock into place. Insert other

end of air hose into turbine.

RISK OF EXPLOSION OR FIRE

HAZARDOUS VAPORS

6

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

PRACTICE FIRST

Practice spraying water on newspaper or cardboard. This will give you the feel of the sprayer and

familiarize you with its features. Follow the instructions for adjusting to the proper spraypattern.

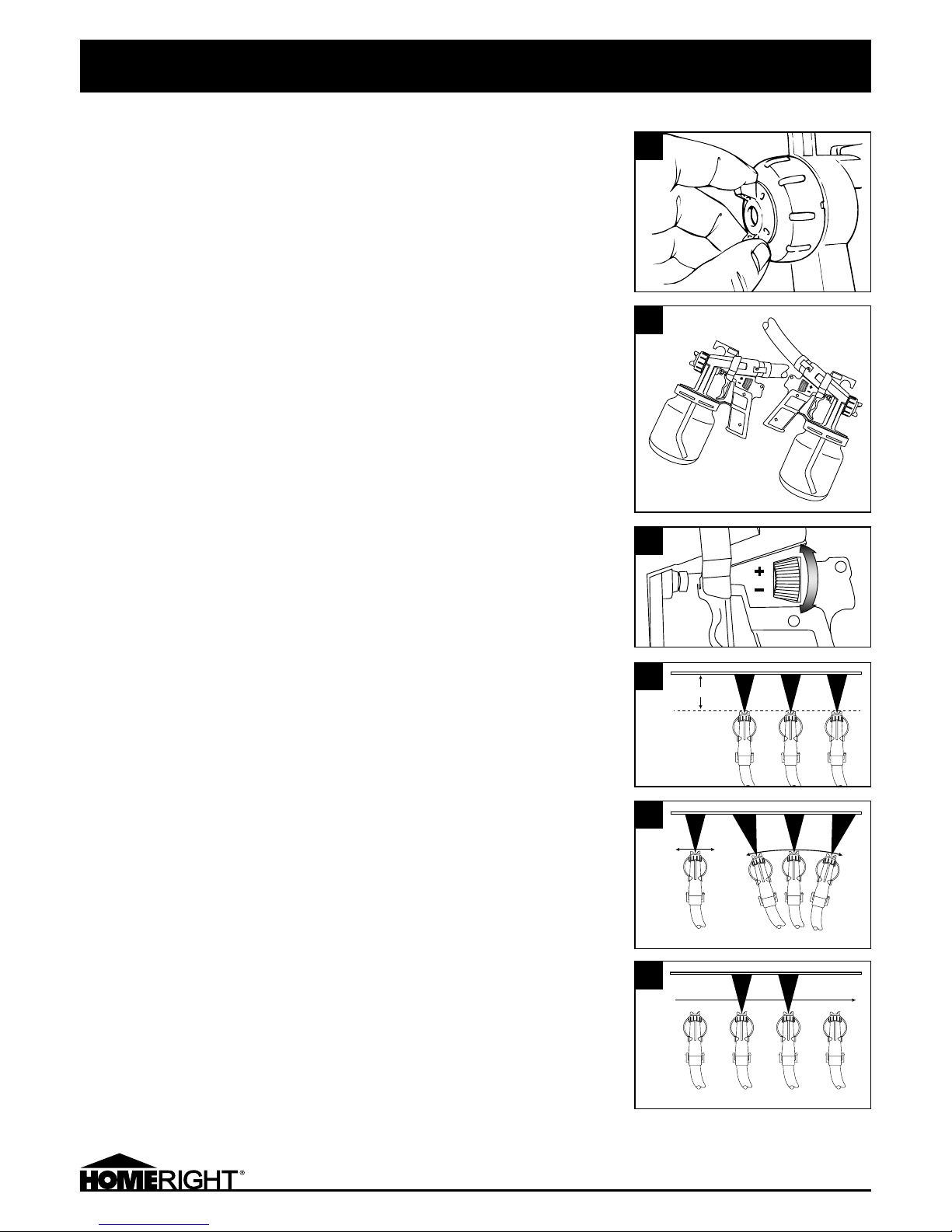

1. Make sure the spray tip is screwed on tightly. Familiarize yourself with the spray cap: Turn its wings

to adjust to a horizontal or vertical spray pattern. (See Figure A.)

2. Remove the container from the spray gun by turning it counterclockwise.

3. Firmly insert the pick-up tube. (See Figure B.) Place the pick-up tube with its angle pointing forward

if you’ll be spraying mostly in the downward direction, and place it facing backward if you’ll be

spraying mostly in an upward direction. This tube placement can be adjusted/changed at any time

during your project.

4. Fill the container with water and re-fasten it.

5. Plug in the sprayer and turn on.

6. Engage the trigger and wait a few seconds for the unit to start spraying the water.

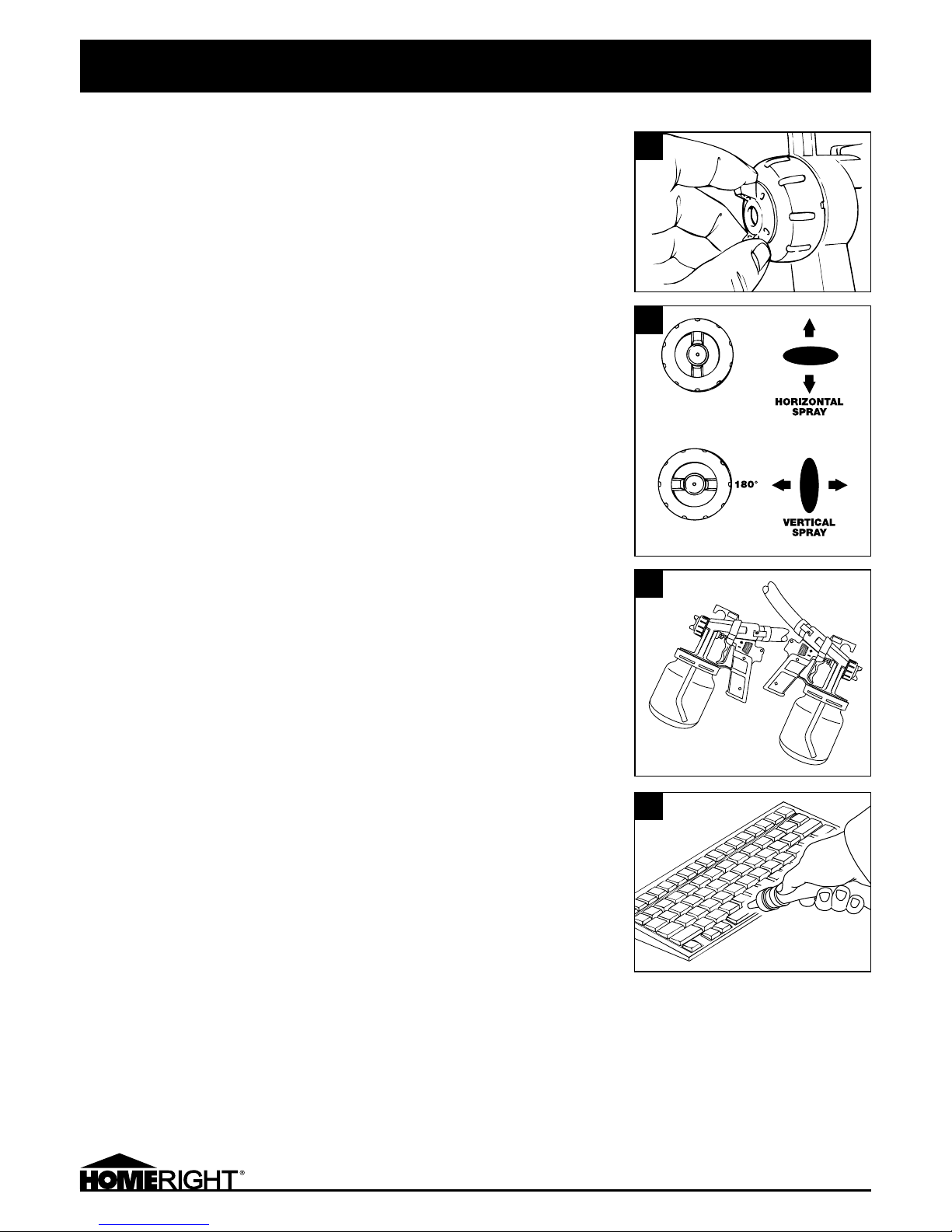

7. Turn the volume control knob fully clockwise to get maximum flow. Then, turn it counterclockwise

and notice how the spray pattern changes in width and intensity. Adjust this knob until you get a

good spray pattern. (See Figure C.)

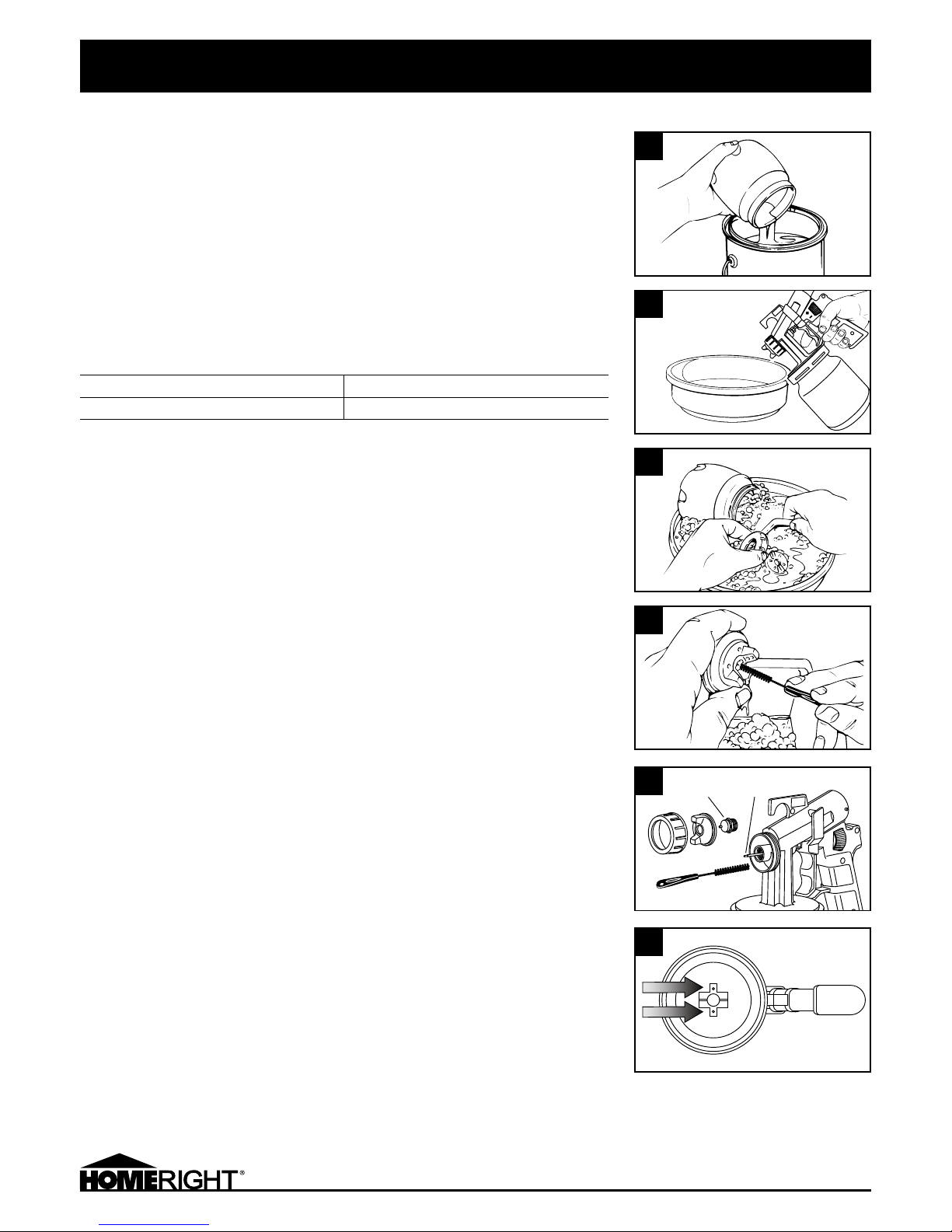

NOTE: The best distance for spraying is 4 to 10 inches from the surface you’re spraying. Too far

away may result in overspray (and wasted liquid), and too close may cause liquid build-up (runs)

(see Figure D).

8. Keep a stiff wrist. Do not arch your wrist at the beginning or end of the stroke. (See Figure E.)

Do not stop the motion of the unit while spraying. The path of the sprayer must pass beyond the

area being sprayed, and the switch must be triggered on and off as the sprayer passes into and out

of the spraying area. (See Figure F.)

NOTE: Stopping the motion of the sprayer or swinging into a new stroke pattern while spray is

being delivered will result in heavy spray build-up at the edges of the stroke.

SURFACE PREP

Thoroughly clean all objects and surfaces to be sprayed before spraying material on them. You may

want to mask or cover areas not intended to be sprayed.

SMALL PROJECTS

This sprayer uses airflow to transfer liquid to the work piece. It is recommended that for small projects,

the user first tests the sprayer without adding liquid to the cup. The airflow may cause small pieces to

move or fall during operation. Use caution and good judgement before spraying liquid.

HOW TO USE

A

B

C

4-10 inches

Correct Incorrect

Start Trigger Release End

F

E

D

7

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

THINNING MATERIALS

In order for your sprayer to operate properly it is important to make sure the stain or paint is

thin enough to be sprayed. Materials can differ from brand to brand, this guide can offer only

general information. Follow paint or stain manufacturer’s guideline for thinning. The final guide

to correctly thinned stain or paint is achieving the proper spray pattern as shown in Figure A.

Always follow the coverage rate recommended by the manufacturer regardless of the thinning

required. Because there is a variance in viscosity between paint and stain brands, it might be

necessary to thin 5 to 15 percent to achieve optimum spray pattern.

Use the viscosity cup (included) and the chart below to determine whether you’ll need to thin the

material you’re using:

1. Dip the viscosity cup fully into the liquid you intend to spray.

2. Lift the viscosity cup out of the liquid, and, holding the cup over the paint or stain can, time

how long it takes for the liquid to drain out of the cup. This is known as the liquid’s run-out

time. If it takes longer than the time shown on the chart for the liquid to leave the viscosity

cup, thin the liquid until the run-out time falls within the time bracket shown for the liquid

you’re using.

3. When you’ve completed this process, clean the viscosity cup with warm, soapy water if

you’re using a water-based product or per the manufacturer’s instructions if you’re using an

oil-based product.

RUN-OUT TABLE AND THINNING CHART

Material (Oil- or Water-based) Run-Out Time (seconds)

Clear Sealer No thinning required

Enamel 25 to 40

Polyurethane No thinning required

Primer 30 to 45

Stain No thinning required

Varnish 20 to 50

NOTES:

• Be sure pick-up tube is inserted tightly into the intake port.

• Thin material according to the procedure outlined above.

• Before each use, check the Brass Fluid Nozzle and Brass Fluid Needle for dried paint.

Keep Brass Fluid Needle clean.

• Always thoroughly clean the sprayer after each use.

(See CLEAN UP AND MAINTENANCE, page 9.)

• Turn control knob counterclockwise for less flow — see Page 6 Step 7 for more detail.

• Strain old paint or stain before using.

• Slowly stir paint or stain. To prevent air bubbles, do not shake stain or paint.

HOW TO USE (CONTINUED)

A

B

8

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

ADJUSTING THE SPRAY PATTERN

By turning the wings of the tip, the Finish Max Pro Fine Finish Sprayer sprays in one of two

patterns: horizontal or vertical. (See Figure D.) DO NOT engage the trigger while turning the tip,

and be sure not to spray toward you, as this could cause injury. (See Figure C & D)

SPRAYING INSTRUCTIONS

Caution: Do not twist electrical cord. Make sure heavy objects are not placed on it.

Keep electrical cord away from heat and sharp objects. To avoid a tripping hazard,

make sure cord is not in a heavy traffic area. Do not use the cord if it is damaged.

Use appropriate breathing protection, eye protection, gloves and clothing.

1. Make sure the container is empty and dry.

2. Pour paint or stain into the container.

3. Be sure the pick-up tube is inserted tightly in the intake port and the tube’s angle

is as you want it. (Figure E.)

4. Affix the container to the sprayer by turning the container counterclockwise.

5. Refer back to “Practice First” on pg 6. Follow Steps 5 thru 8, keeping in mind you are now

spraying paint or stain. If, after making adjustments, you still are not satisfied with the spray

pattern, refer to TROUBLESHOOTING on page 10.

6. Hold the sprayer 4 to 10 inches from the surface to be painted. While the angled pick-up

tube permits you to spray in an upward or downward direction, try to tilt the sprayer as little

as possible. Do not tip more than 45 degrees when motor is switched off.

7. Overlap each stroke by about 1/3 of the spray pattern.

NOTE: If you stop spraying for 30 minutes or longer: Before continuing, retest the spray pattern

by spraying on newspaper or cardboard. If you are unable to adjust the spray pattern properly,

it is possible the stain or paint material has started to dry. If this happens, clean the sprayer.

See CLEAN UP INSTRUCTIONS.

NOTE: If the spray pattern still is not correct, you may need to thoroughly clean the nozzle and

needle. To keep the unit spraying properly, you should expect to clean it after dispensing each

five to nine gallons of paint or stain. After cleaning, reassemble the parts.

AIR BLOWING NOZZLE

The air blowing nozzle is a breeze-dusting device, suitable for dusting computer heat sinks,

keyboards, air conditioner filter meshes and all kinds of precision instruments. (See Figure F.)

However it is NOT suitable for liquid spraying.

HOW TO USE (CONTINUED)

C

D

F

E

D

9

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

DO NOT ALLOW SPRAYED MATERIAL TO DRY IN SPRAY GUN,

ALWAYS CLEAN WITHIN 30 MINUTES OF USE

Proper clean up is essential to keep your sprayer in optimum working condition. Dried by-products will

act like glue and cause moving parts to stick or holes to plug. Failure to properly clean your sprayer will

damage the unit. Take the time to clean your sprayer immediately after each use.

Run cleaning solution through unit

1. Unplug the sprayer from electrical outlet. Pull trigger on spray gun, hold trigger down for a few

seconds, this allows material inside unit to flow back into container.

2. Empty any remaining material from container (see figure A).

3. Fill container with a small amount of cleaning solution.

MATERIAL CLEANING SOLUTION

Latex Warm soapy water

Oil-Based Use manufacturer’s recommendation

4. Plug Sprayer into an electrical outlet. Turn Turbine on.

5. Spray cleaning solution and run solution through unit until clean (see figure B).

6. Unplug the sprayer from electrical outlet.

7. Remove container and properly discard any remaining cleaning solution.

Clean all removable Spray Gun Components in warm soapy water (see figures C & D).

8. Container

9. Pick-up tube

10. Air Cap and Nut

11. Paint Cup Gasket found in the spray gun cap

12. Spray tip. Unscrew and remove the air cap and nut. Use an 17 mm wrench or socket to unscrew

the Brass Fluid Nozzle. (use a counterclockwise motion)

Clean the Spray gun housing, brass fluid nozzle and fluid needle housing in warm soapy water

before reassembly

13. Use the brush provided to clean housing around needle (see figure E).

14. Thoroughly clean needle

15. There are two air holes deeply seated in the pick-up tube housing. (see figure F). Inspect holes

after the housing has been cleaned. If holes are clogged, it may be necessary to use a long piece

of straightened wire (a paperclip is ideal) to remove debris, be careful not to enlarge holes.

Reassemble

16. Make sure all components are thoroughly dried.

17. Place a drop of oil on the shank of the needle between the trigger and the front of the gun.

18. Insert brass fluid nozzle. Place air cup and screw on air nut.

19. Install pick up tube.

20. Inspect Paint Cup Gasket to ensure it is undamaged and then insert into cup.

21. Screw on container.

CLEAN UP & MAINTENANCE

A

1

B

C

D

E

F

Brass

Fluid

Nozzle

Needle

Assembly

10

FINISH MAX PRO FINE FINISH SPRAYER (C800850) ENGLISH

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Sags or runs A. Too much paint.

B. Gun moving too slowly.

C. Paint too thin.

D. Gun held at incorrect angle or too close to

painting surface.

E. Spray overlaps too much.

A. Turn paint control knob counterclockwise.

B. Move gun faster.

C. Add unthinned paint to achieve correct time

through viscosity test cup.

D. Hold gun at right angle to the painting surface at a

distance of 4-10 inches.

E. Overlap spray by approximately 1/3 width of spray

pattern.

Dry spray A. Insufficient paint coming from the spray gun.

B. Gun held too far from surface.

C. Overspray from a preceding section when gun

is not held at right angle to painting surface.

D. Spray patterns not well overlapped.

A. Turn paint control knob clockwise.

B. Hold gun at a distance of 4-10 inches or closer for

small objects.

C. Hold gun at right angle to the painting surface.

D. Overlap spray by approximately 1/3 width of spray

pattern.

Striped or uneven coverage A. Gun tilted or not held at right angle to painting

surface.

B. Dirt or burrs on air-cap or paint tip cause heavy

top and bottom pattern.

C. Spray patterns not well overlapped.

A. Hold the gun at right angle to painting surface.

B. Clean or replace air-cap or paint tip.

C. Overlap spray by approximately 1/3 width of

spray pattern.

Spitting or spraying lumps A. Solid particles in paint.

B. Loose pick up tube.

A. Strain paint.

B. Ensure pick up tube is firmly pushed into place.

Weak or no spray A. Low volume of paint from container due to

blocked air passageway in spray gun body.

B. Paint not thin enough.

C. Lid gasket missing/dirty.

A. Clean passageway (3 mm vent holes in the

container lid).

B. Add the appropriate amount of solvent to the

paint. Add only a small amount of solvent to the

paint at one time.

C. Replace/clean lid washer.

Top-or bottom-heavy pattern or

heavy right or left side pattern

A. Horn holes partially blocked.

B. Obstruction on paint tip or dirt on air cap seat

or paint tip seat.

A. Determine if obstruction is on air cap or paint

tip by making a test pattern, rotating air cap half

turn, and spraying another test pattern. If defect is

inverted, obstruction is on air cap.

B. Clean air cap with non-metallic instrument. If

obstruction is on paint tip, check for fine burring

which can be removed with 600 wet or dry

sandpaper. For dried paint inside, open and wash.

Fluttering spray A. Lack of paint.

B. Blocked paint passages.

C. Damaged paint nozzle or needle.

C. Lid gasket missing/dirty.

A. Refill container.

B. Clean.

C. Clean needle set or replace if necessary.

D. Clean/replace lid washer.

Paint leaking from guide nut A. Loose guide nut.

B. Worn guide washer.

A. Tighten guide nut.

B. Replace guide washer.

Paint leaking from front

of gun.

Needle not seated properly due to:

A. Worn or damaged paint nozzle.

B. Dirt or dried paint in nozzle.

C. Guide washer too tight preventing needle

from seating.

D. Broken spring.

E. Scored or damaged needle.

A. Replace nozzle.

B. Clean nozzle.

C. Loosen guide washer.

D. Replace spring.

E. Replace needle.

Loading...

Loading...