Homer MG-15 Instruction Manual

ALFA IN a.s. © 2013 www.alfain.eu HOMER MG-150 MANUAL EN 1.doc

MIG/MAG WELDING MACHINES

HOMER MG-15

INSTRUCTION MANUAL

Content:

1.

INTRODUCTION..................................................................................................2

2. SAFETYINSTRUCTIONSANDWARNINGS............................................................2

3. CONDITIONSOFUSE...........................................................................................6

4. TECHNICALDATA................................................................................................6

5. ACCESSORIES......................................................................................................7

6. DESCRIPTIONOFTHEAPPLIANCE.......................................................................9

7. GETTINGSTARTED............................................................................................10

8. WELDING..........................................................................................................13

9. ROUTINEMAINTENANCE&INSPECTION..........................................................14

10. STATEMENTOFWARRANTY.............................................................................15

11. DISPOSAL..........................................................................................................15

12. DECLARATIONOFCONFORMITY...................................................................... 16

page 2 of 16

ALFA IN a.s. © www.alfain.eu

1. INTRODUCTION

Congratulations on your new ALFA IN product. We are proud to have you as

our customer and will strive to provide you with the best service and reliability

in the industry.

This Operating Manual has been designed to instruct you on the correct use

and operation of your ALFA IN product. Your satisfaction with this product

and its safe operation is our ultimate concern. Therefore please take the time

to read the entire manual, especially the Safety Precautions. They will help

you to avoid potential hazards that may exist when working with this product.

Read and understand this entire Manual and your employer’s safety

practices before installing, operating, or servicing the equipment. While the

information contained in this Manual represents the Manufacturer's best

judgement, the Manufacturer assumes no liability for its use.

Welding machine HOMER MG-150 of our private brand HOMER tools is

aimed for MIG/MAG welding.

The machine can weld various types of joints (butt, single-sided, doublesided, fillet, lap, etc.) using wire diameter from 0.6 to 0.8 mm, respectively.

1.0 mm (flux cored wire) of different metals and alloys (carbon and alloy

steels, aluminium alloys, etc.). HOMER MG-150 is especially designed for

bodywork operations or maintenance work. Very good welding can be

achieved under a protective atmosphere of CO2. The machine welds very

well by means of using high-quality self-shielding wire (no gas cylinder and

pressure reducer needed).

2. SAFETY INSTRUCTIONS AND WARNINGS

OPERATION AND MAINTENANCE OF WELDING EQUIPMENT CAN

BE DANGEROUS AND HAZARDOUS TO YOURHEALTH.

Arc welding produces intense electric and magnetic emissions that may

interfere with the proper function of cardiac pacemakers, hearing aids, or

other electronic health equipment. Persons who work near arc welding

applications should consult their medical health professional and the

manufacturer of the health equipment to determine whether a hazard

exists.

Once the packing has been opened, make sure that the machine is not

damaged. If in any doubt, call the service centre.

This equipment must only be used by qualified personnel.

During installation, any electric work must only be carried out by trained

personnel.

The machine must be used in a dry place with good ventilation.

page 3 of 16

ALFA IN a.s. © www.alfain.eu

Make sure that no metal dust can be drawn in by the fan inside the

machine, as this could cause damage to the electronic circuits.

It is prohibited to connect more than one generator in series or in parallel.

When installing the machine, follow the local regulations on safety.

The position of the machine must allow easy access by the operator to

the controls and connectors.

When the welding machine is operating, all its covers and doors must be

closed and well fixed.

Do not expose the welding machine to direct sunlight or to heavy rain.

This equipment conforms to protection rating IP23S.

The operator must wear gloves, clothes, shoes, and a helmet or a

welder’s helmet, which protect and are fire-resistant in order to protect

him against electric shock, flashes and sparks from cutting.

The operator must protect his eyes with safety visor or mask designed for

welding, fitted with standard safety filters. He should also be aware that

during arc welding ULTRAVIOLET RADIATION is emitted. Therefore it is

vital that his face is also protected from radiation. Ultraviolet rays produce

the same harmful effect as sun burning on unprotected skin.

The operator is obliged to warn anyone near the welding area of the risks

that welding involves and to arrange to provide adequate protection

equipment.

Keep all fumes and gases from the breathing area.

Keep your head out of the fume plume.

Use an air-supplied respirator if ventilation is not adequate to remove all

fumes and gases.

The kinds of fumes and gases from the plasma arc depend on the kind of

metal being used, coatings on the metal, and the different processes.

You must be very careful when welding any metals which may contain

one or more of the following:

Antimony Chromium Mercury

Nickel Cobalt Arsenic

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

Always read the Material Safety Data Sheets (MSDS) that should be

supplied with the material you are using. These MSDSs will give you the

information regarding the kind and amount of fumes and gases that may

be dangerous to your health.

It is very important to arrange for sufficient ventilation, especially when

welding in enclosed spaces. We suggest using suitable fume extractors

to prevent the risk of intoxication by fumes or gas generated by the

welding process.

Noise can cause permanent hearing loss. Welding arc processes can

page 4 of 16

ALFA IN a.s. © www.alfain.eu

cause noise levels to exceed safe limits. You must protect your ears from

loud noise to prevent permanent loss of hearing.

To protect your hearing from loud noise, wear protective ear plugs and/or

ear muffs. Protect others in the workplace.

Noise levels should be measured to be sure the decibels (sound) do not

exceed safe levels.

The operator must ensure all flammable materials are removed from the

work area to avoid any risk of fire.

The operator must NEVER weld containers that have previously

contained petrol, lubricants, gas or similar flammable materials, even if

the container has been empty for a considerable time. THERE IS A

VERY HIGH RISK OF EXPLOSION.

The operator must be aware of all the special regulations which he needs

to conform to when cutting in enclosed spaces with a high risk of

explosion.

To prevent electric shock, we strongly suggest the following rules:

Do not work in a damp or humid environment.

Do not use the machine if its cables are damaged in any way.

Make sure that the earthing system of the electric equipment is

correctly connected and operational.

The operator must be insulated from the metal components

connected to the return wire.

The earthing of the piece being worked could increase the risk of

injury to the operator.

EN 60974-1 Standard: Open-circuit voltage. During the operation of the

machine, the highest voltage, with which it is possible to come into

contact, is the open-circuit voltage between the clamps.

The maximum open-circuit voltage of the plasma machines is established

by national and international standards (EN 60974-1) depending on the

type of current to be used, on its waveform and on the hazards arising

from the work place. These values are not applicable to the strike

currents and those for stabilisation of the arc that could be above it.

The open-circuit voltage, for as many adjustments as possible, must

never exceed the values relating to the various cases shown in the

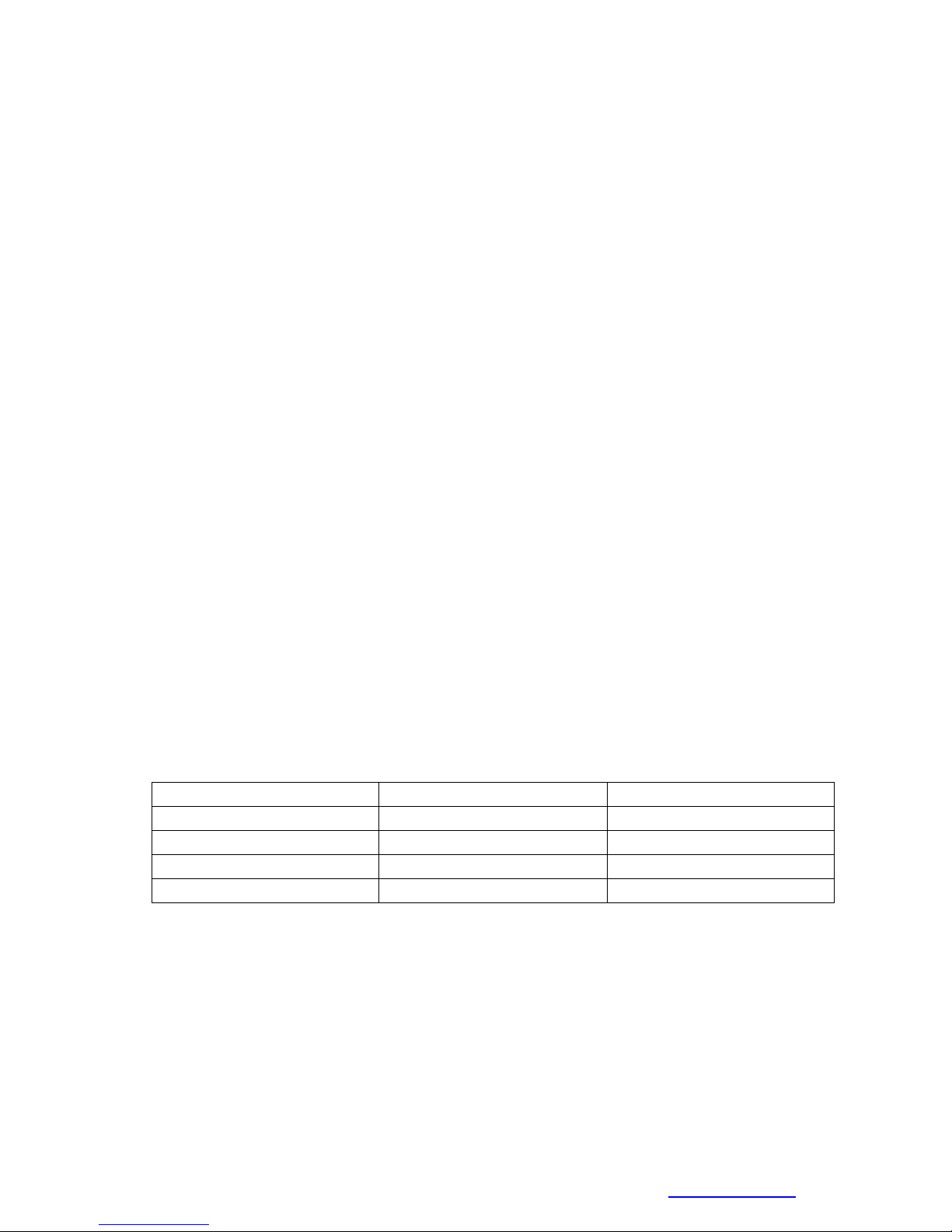

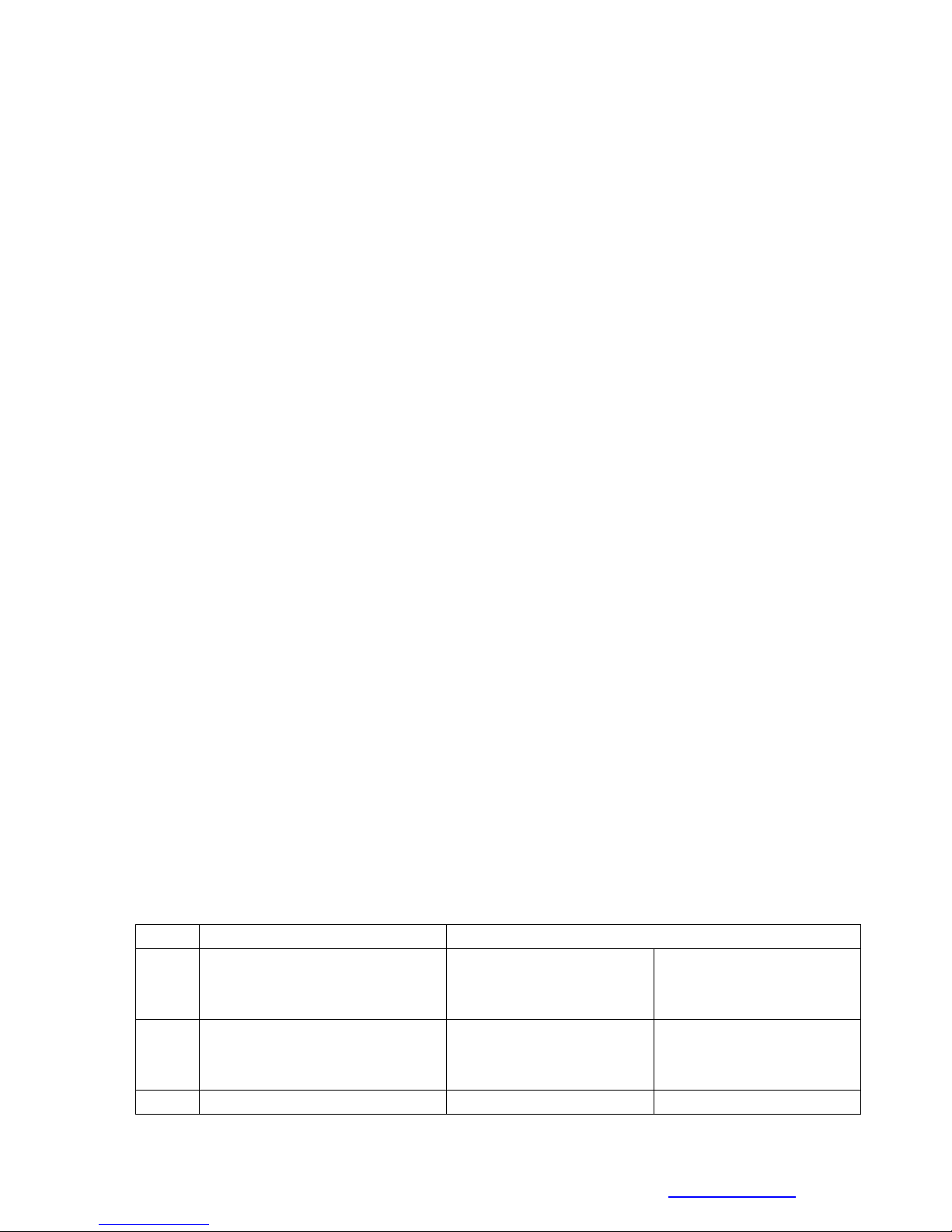

following table:

Case Working conditions Open-circuit voltage

1 Places with increased

risk of electric shock

DC current: 113V

peak value

AC current: 68V

peak value and 48V

effective

2 Places without increased

risk of electric shock

DC current: 113V

peak value

AC current: 113V

peak value and 80V

effective

3 Torches held DC current: 141V AC current: 141V

page 5 of 16

ALFA IN a.s. © www.alfain.eu

mechanically with

increased protection for

the operator

peak value peak value and

100V effective

4 Plasma cutting DC current: 500V

peak value

In case 1, the dc machines with rectifier must be built in such a way that,

in case of a fault developing in the rectifier (for example open circuit,

short circuit or lack of power), the permitted values cannot be exceeded.

The welding machines of this type can be marked with the symbol:

S

Before opening the machine switch off the machine and disconnect it

from the power socket.

Only personnel authorised by this company can carry out maintenance

on the machine.

2.1 ELECTROMAGNETIC COMPATIBILITY (EMC)

This machine conforms to EN 60974-10 standard. However, the

electromagnetic emissions generated could prove not be compatible with the

maximum permitted levels for some classes of electrical equipment, such as

the following:

Domestic electronic appliances (radios, TVs, videos, telephones,

burglar alarms, etc.).

Computers, robots, electro-medical instruments and life-support

systems.

Radio-television transmitters and receivers.

Pacemakers and hearing aids.

All very sensitive electrical equipment.

The operator is responsible for the installation and use of the cutting

machine. If there should be any fault in operations of other systems located

in the immediate vicinity of the generator, we recommend suspending

operations and consulting the manufacturers.

2.2 PROTECTIVE UTTILITIES

Welding helmet with filter shade at least 10

Welding gloves

Welding apron and cloth

Welding boots

2.3 RISK OVERVIEW

Risk of electric shock.

Ultraviolet light and light radiation

Risk of inhaling gas fumes and dust particles

Loading...

Loading...