Page 1

FIRST EDITION

PRINTED IN U.S.A.

PART NO. 17287

-

Supplied with Product

Extra Copies $1

.OO

OWNERS

operating & Maintenance

MANUAL

HOMELITE

Automatic

Oiler

CHAIN

SAW

WARNING: CHAIN SAWS CAN BE DANGEROUS. TO REDUCE DANGER FOLLOW ALL SAFETY

PRECAUTIONS

IN

THIS OWNER'S MANUAL.

Courtesy of ParkinLube.com

Page 2

CONTENTS

rn

INTRODUCTION

Protection Against Vibration

.......................

.2

Hearing Protectors

................................. 2

SAFEmT*TIP:@

......................................

2

Safety Precautions (list)

............................

3

Your Physical Condition

...........................

.4

Protective Articles, Equipment and Supplies

........

.4

Section

1

-

PREPARING YOUR NEW SAW

Guide Bar and Chain Assembly

.....................

4

Chain Tension

....................................

.5

Chain Oil and the Oil System

.......................

5

Fueling the Saw

....................................

6

Section

2-

HOW TO START, STOP AND HOLD SAW

6

Section

3

-

KICKBACK, PUSH and PULL

What is Chain Saw Kickback?.

.....................

.8

How Should You Maintain Control of Your Saw?

.....

9

How Should You Reduce the Chance of Kickback?.

.

.9

Section

4

-

THE WORKING AREA

Work Area Precautions

...........................

.10

Handling and Securing the Saw

...................

.ll

.................

Unusually Hazardous Conditions.. 11

Section 5 - TECHNIQUES OF CUTTING

Bucking, Limbing and Pruning

.....................

12

Cutting Variations According to Stress Factors..

...

.12

Springpoles

......................................

.13

Boring with the Nose Section

......................

13

Tree Felling Techniques

..........................

.14

Notching..

.......................................

.14

Backcutting

.......................................

14

Felling Large Trees

................................

15

Felling "Leaners"

..................................

15

Changing Direction of Fall

........................

.15

Section

6

-

MAINTENANCE AND ADJUSTMENT

Hornelite@ Saw Chain..

............................

16

Filing Equipment

.................................

.16

How to File the Cutters

............................

16

Corrective Refiling..

...............................

17

How and When to Set Depth Gauge Clearance..

...

.17

Replacement of Worn Sprocket

...................

.18

Guide Bar Maintenance..

.........................

.18

Maintenance of Tanks, Caps and Pick-ups

.........

.18

Air Filter Maintenance

.............................

19

............................

Carburetor Adjustment 19

Rewind Starter Maintenance and Repairs

..........

.20

Ignition, Cooling and Exhaust System Maintenance .21

Storing Your Saw..

...............................

.22

INTRODUCTION

Facts About

XL@

Chain Saws

This Owner's Manual tells how to operate and

maintain^

your Model XL@ chain saw. You are urged to read the entire contents of this manual even before you begin to

assemble the unit. Proper preparation and maintenance

go hand-in-hand with the satisfactory operation of your

saw. So you should keep this manual handy.

PROTECTION AGAINST VIBRATION

The chain saw models discussed in this Owner's Manual

are not equipped with vibration reduction features and,

accordingly, are intended for occasional use only.

It has been determined that certain individuals, after long

periods of exposure to chain saw vibration possibly

coupled with exposure to cold weather, experience a

restriction of blood circulation through the fingers which

often has the appearance of Frostbite. This reduction of

the blood supply may result in an ailment sometimes

referred to as

Raynaud's Disease,

the exact causes of

which are presently unknown. Permanent damage may

result when early symptoms are ignored.

There are certain measures which can be taken to mini-

mize the risk of this ailment. These are as follows:

1. Wear gloves to keep the hands and wrists warm.

2. Keep the chain sharp so that you do not have

to bear down hard while cutting.

3. Limit your use of the saw to short and occasional periods.

4.

After each period of use, exercise to restore normal

blood circulation.

Your saw hasaspark arrestor screen built into the muffler

and a temperature screen integral with the exhaust cap.

In certain states where the law requires use of a spark

arrestor, it also requires the

owner/operator to keep a

spark arrestor in good condition (intact) in the exhaust

system at all times. The spark arrestor is a very fine

stainless steel mesh. Thus it is subject to warping,

cracking and burning out. Replacement spark arrestor

screens are available in blister packs as #D-93991,

or in kit form as #A-69586-6.

NOTICE

Model XL chain saws are designed for operation using

only conventional guide bars and saw chains. Do not

attempt to adapt this engine for use with a bow guide or

as a powerhead for any attachments or devices not listed

for the model XL in Homelite sales literature.

HEARING PROTECTORS

Long or continuous exposure to high noise levels, such

as involved in the operation of a chain saw, may cause

permanent hearing impairment or other possible effects.

Hearing protection devices are available from your

Homelite dealer or can be ordered through him. When

ordering, specify "Homelite Hearing Protectors

#92810."

HOMELITEB

SAFE@T@TIP@

(Pat. Pending)

This Homelite anti-kickback device is supplied with your

Model

XL@ at no extra charge. The instruction booklet

(#17067) packed with the SAFEmTmTIP tells you how to

install it properly on your guide bar, and

hoy to operate

with a

SAFEaTmTIP. When properly installed, the

SAFEmT-TIP prevents chain saw kickback, because it

covers the chain at the upper

90" quadrant of the guide

bar nose where kickback reaction could occur.

2

01979,

TEXTRON,

INC

Courtesy of ParkinLube.com

Page 3

r

SAFETY PRECAUTIONS FOR CHAIN SAW USERS

When you are going to cut wood-DO

IT RIGHT!

3

BASIC PRECAUTIONS

FOR PERSONAL SAFETY

Use safety footwear, snug-fitting cloth-

ing, and eye, hearing and head protection.

Wear non-slip gloves to improve your

grip. Do not wear scarfs, jewelry, or

neckties which could be drawn into the

engine or catch on the chain or under-

brush.

Always hold the chain saw with both

hands when the engine is running. Use a

firm grip with thumbs and fingers encircling the chain saw handles.

GUARD AGAINST KICKBACK:

a) Hold the chain saw firmly with both

hands. Don't overreach. You cannot

maintain good control of the saw

if

you cut above shoulder height.

b) Don't let the nose of the guide bar

contact a log, branch, the ground or

any other obstruction.

c) Cut at high engine speeds.

d) Keep the chain sharp. Don't operate

with a loose chain. Maintain the correct tension of the chain as prescribed

in this Owner's Manual.

Guard against the effects of a long or

continuous exposure to noise, such as

involved in the operation of a chain saw.

Hearing protection devices are available

from your local Homelite dealer'.

Never operate a chain saw when you are

fatigued.

Keep all parts of your body away from the

saw chain when the engine is running.

BASIC PRECAUTIONS WITH CHAIN SAWS

Always carry the chain saw with the

engine stopped, the guide bar and saw

chain to the rear, and the muffler away

from your body. When transporting your

chain saw, use the appropriate guide bar

scabbard.

Always use caution when handling fuel.

Move the chain saw at least

10

feet

(3

m)

from the fueling point before starting the

engine.

Keep the handles dry, clean and free of

oil or fuel mixture.

Before you start the engine, make sure

the saw chain is not contacting anything.

Shut off the engine before setting down

the saw. Do not leave the engine running

unattended.

Operate the chain saw only in well venti-

lated areas.

Be sure that the chain stops moving when

the throttle control is released.

BASIC PRECAUTIONS

IN

CUlTlNGMIORK AREA

Do not operate a chain saw in a tree un-

less you have been specifically trained to

do so.

Keep bystanders and animals out of the

work area.

Never start cutting until you have a clear

work area, secure footing, and a planned

retreat path from the falling tree.

Use extreme caution when cutting small

size brush and saplings, because slender

material may catch the saw chain and be

whipped toward you or pull you off

balance.

When cutting a limb that is under tension,

be alert for springback so that you will

not be struck when the tension in the

wood fibers is released.

BASIC PRECAUTIONS

ABOUT MAINTENANCE

Never operate a chain saw that is dam-

aged, improperly adjusted, or is not

completely and securely assembled. Be

sure that the saw chain stops moving

when the throttle control trigger is

released.

All chain saw service, other than items in

the Owner's Manual maintenance in-

structions, should be performed by competent chain saw service personnel. (If

improper tools are used to remove the

flywheel or clutch, or

if

an improper tool

is used to hold the flywheel in order to

remove the clutch, structural damage to

the flywheel could occur which could

subsequently cause the flywheel to

burst.)

Courtesy of ParkinLube.com

Page 4

YOUR PHYSICAL CONDITION

Work relaxed but stay alert. Take a break from work when-

serious ailments such as a heart condition, check with

ever you begin to tire. Never operate when tired or under

your doctor before doing any strenuous lifting, reaching,

the influence of alcohol or any drugs which may affect

pushing, chopping, shoveling, etc. Always do any lifting

your balance, coordination or judgement.

If

you have any

iob with vour leg muscles, not your back.

SECTION 1 -PREPARING YOUR NEW SAW

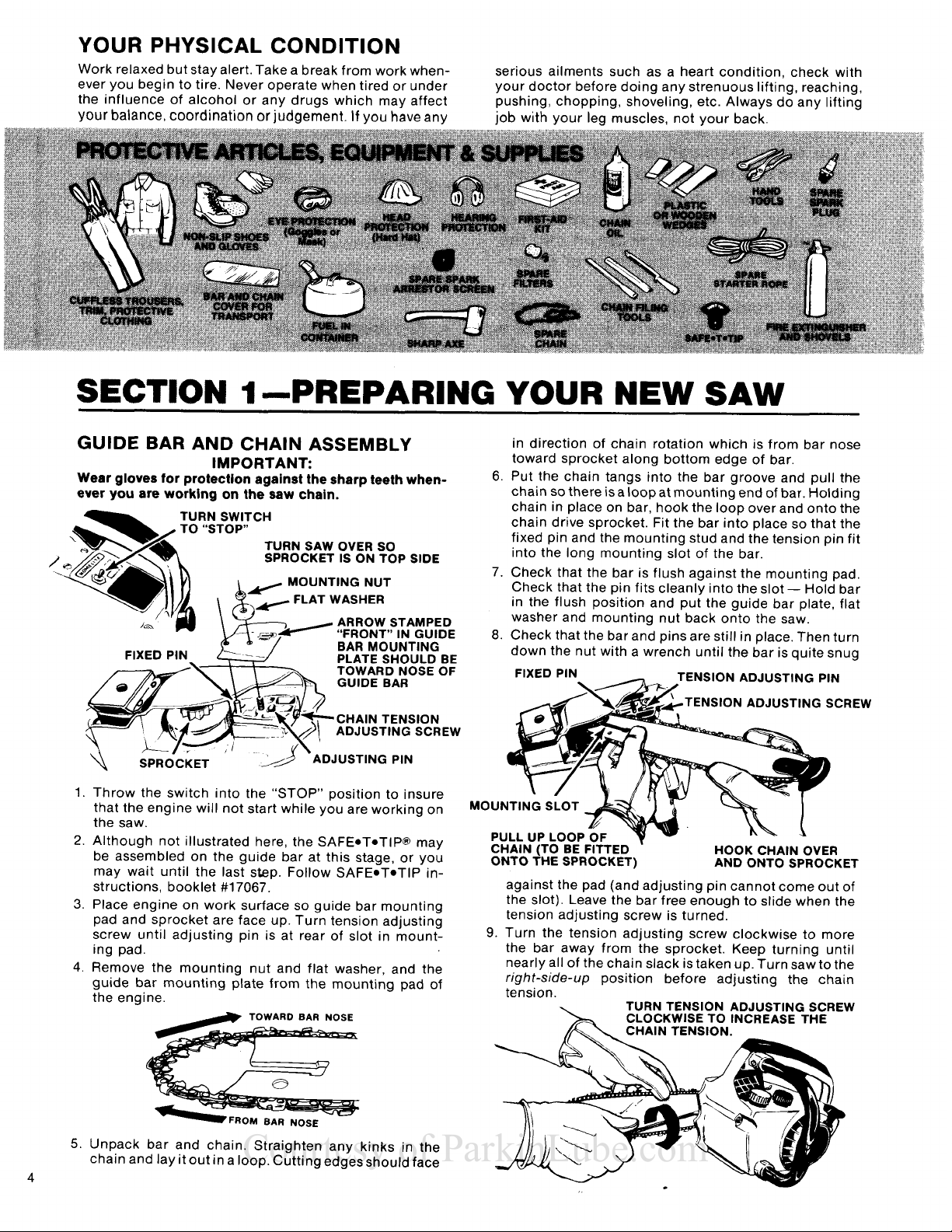

GUIDE BAR AND CHAIN ASSEMBLY

IMPORTANT:

Wear gloves for protection against the sharp teeth whenever you are working on

the

saw chain.

TURN SAW OVER SO

SPROCKET IS ON TOP SIDE

FLAT WASHER

ARROW STAMPED

"FRONT" IN GUIDE

BAR MOUNTING

PLATE SHOULD

BE

TOWARD NOSE OF

GUIDE BAR

CHAIN TENSION

ADJUSTING SCREW

ADJUSTING PIN

1. Throw the switch into the "STOP" position to insure

that the engine will not start while you are working on

the saw.

2.

Although not illustrated here, the SAFE*T.TlP@ may

be assembled on the guide bar at this stage, or you

may wait until the last step. Follow

SAFE.T*TIP in-

structions, booklet

#17067.

3.

Place engine on work surface so guide bar mounting

pad and sprocket are face up. Turn tension adjusting

screw until adjusting pin is at rear of slot in mount-

ing pad.

4.

Remove the mounting nut and flat washer, and the

guide bar mounting plate from the mounting pad of

the engine.

5.

Unpack bar and chain. Straighten any kinks in the

chain and lay it out in a loop. Cutting edgesshould face

in direction of chain rotation which is from bar nose

toward sprocket along bottom edge of bar.

6. Put the chain tangs into the bar groove and pull the

chain so there isa loop at mounting end of bar. Holding

chain in place on bar, hook the loop over and onto the

chain drive sprocket. Fit the bar into place so that the

fixed pin and the mounting stud and the tension pin fit

into the long mounting slot of the bar.

7. Check that the bar is flush against the mounting pad.

Check that the pin fits cleanly into the slot

-

Hold bar

in the flush position and put the guide bar plate, flat

washer and mounting nut back onto the saw.

8.

Check that the bar and pins are still in place. Then turn

down the nut with a wrench until the bar is quite snug

ENSION ADJUSTING PIN

TENSION ADJUSTING SCR

PULL UP LOOP

HOOK CHAIN OVER

ONTO THE SPROCKET)

AND ONTO SPROCKE

IEW

against the pad (and adjusting pin cannot come out of

the slot). Leave the bar free enough to slide when the

tension adjusting screw is turned.

9.

Turn the tension adjusting screw clockwise to more

the bar away from the sprocket. Keep turning until

nearly all of the chain slack is taken up. Turn saw to the

right-side-up

position before adjusting the chain

tension.

TURN TENSION ADJUSTING SCREW

CLOCKWISE TO INCREASE THE

h

CHAIN TENSION.

Courtesy of ParkinLube.com

Page 5

CHAIN

TENSION

1.

Proper tension is extremely important. The mounting

nut should be loose enough to permit movement of the

guide bar tension adjustment. Hold up the nose of the

bar during theadjustment

stepsand until the mounting

nut has been tightened completely. This will take up

any clearance between the bar mounting slot and the

mounting pins in the direction in which pressure is

most often applied during cutting.

2. "Snap" the chain to remove any kinks (pull chain away

from bar and let go several times).

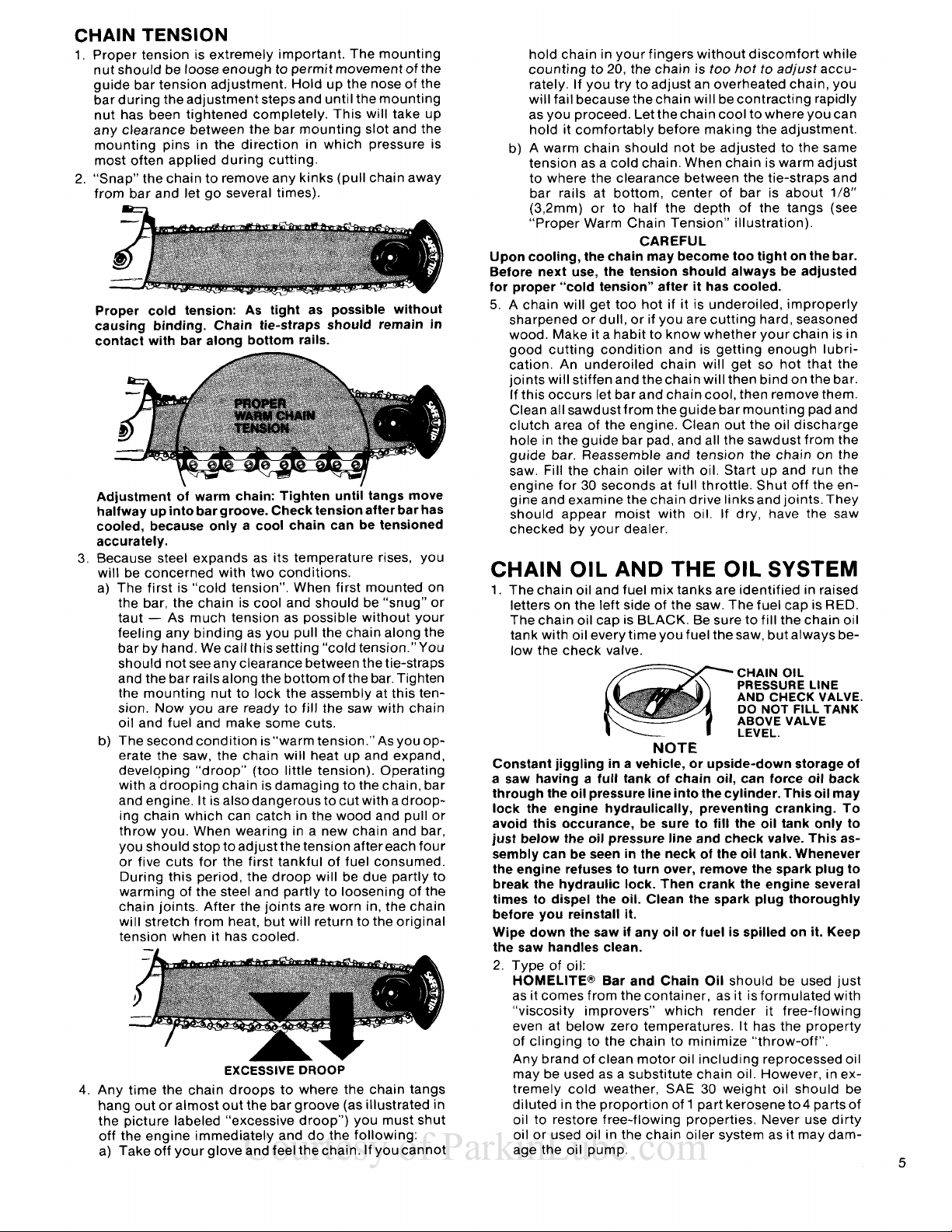

Proper cold tension: As tight as possible without

causing binding. Chain tie-straps should remain in

contact with bar along bottom rails.

Adjustment of warm chain: Tighten until tangs move

halfway up into bar groove. Check tension after bar has

cooled, because only a cool chain can be tensioned

accurately.

3. Because steel expands as its temperature rises, you

will be concerned with two conditions.

a) The first is "cold tension". When first mounted on

the bar, the chain is cool and should be "snug" or

taut

-

As much tension as possible without your

feeling any binding as you pull the chain along the

bar by hand. We call thissetting "cold

tension."You

should not seeany clearance between the tie-straps

and the bar rails along the bottom of the bar. Tighten

the mounting nut to lock the assembly at this tension. Now you are ready to fill the saw with chain

oil and fuel and make some cuts.

b) The second condition

isUwarm tension." As you operate the saw, the chain will heat up and expand,

developing "droop" (too little tension). Operating

with a drooping chain is damaging to the chain, bar

and engine. It is also dangerous to cut with a droop-

ing chain which can catch in the wood and pull or

throw you. When wearing in a new chain and bar,

you should stop to adjust the tension after each four

or five cuts for the first tankful of fuel consumed.

During this period, the droop will be due partly to

warming of the steel and partly to loosening of the

chain joints. After the joints are worn in, the chain

will stretch from heat, but will return to the original

tension when it has cooled.

EXCESSIVE DROOP

4. Any time the chain droops to where the chain tangs

hang out or almost out the bar groove (as illustrated in

the picture labeled "excessive droop") you must shut

off the engine immediately and do the following:

a) Take off your glove and feel the chain. If you cannot

hold chain in your fingers without discomfort while

counting to 20, the chain is too hot to adjust accurately. If you try to adjust an overheated chain, you

will fail because

thechain will becontracting rapidly

as you proceed. Let

thechain cool to where you can

hold it comfortably before making the adjustment.

b) A warm chain should not be adjusted to the same

tension as a cold chain. When chain is warm adjust

to where the clearance between the tie-straps and

bar rails at bottom, center of bar is about

1/8"

(3,2mm) or to half the depth of the tangs (see

"Proper Warm Chain Tension" illustration).

CAREFUL

Upon cooling, the chain may become too tight on the bar.

Before next use, the tension should always be adjusted

for proper "cold tension" after it has cooled.

5.

A chain will get too hot if it is underoiled, improperly

sharpened or dull, or if you are cutting hard, seasoned

wood. Make it a habit to know whether your chain is in

good cutting condition and is getting enough lubrication. An underoiled chain will get so hot that the

joints will stiffen and

thechain will then bind on the bar.

If this occurs let bar and chain cool, then remove them.

Clean all sawdust from

theguide bar mounting pad and

clutch area of the engine. Clean out the oil discharge

hole in the guide bar pad, and all the sawdust from the

guide bar. Reassemble and tension the chain on the

saw. Fill the chain oiler with oil. Start up and run the

engine for

30

seconds at full throttle. Shut off the en-

gine and examine the chain drive

linksand joints.They

should appear moist with oil. If dry, have the saw

checked by your dealer.

CHAIN OIL AND

THE

OIL

SYSTEM

1.

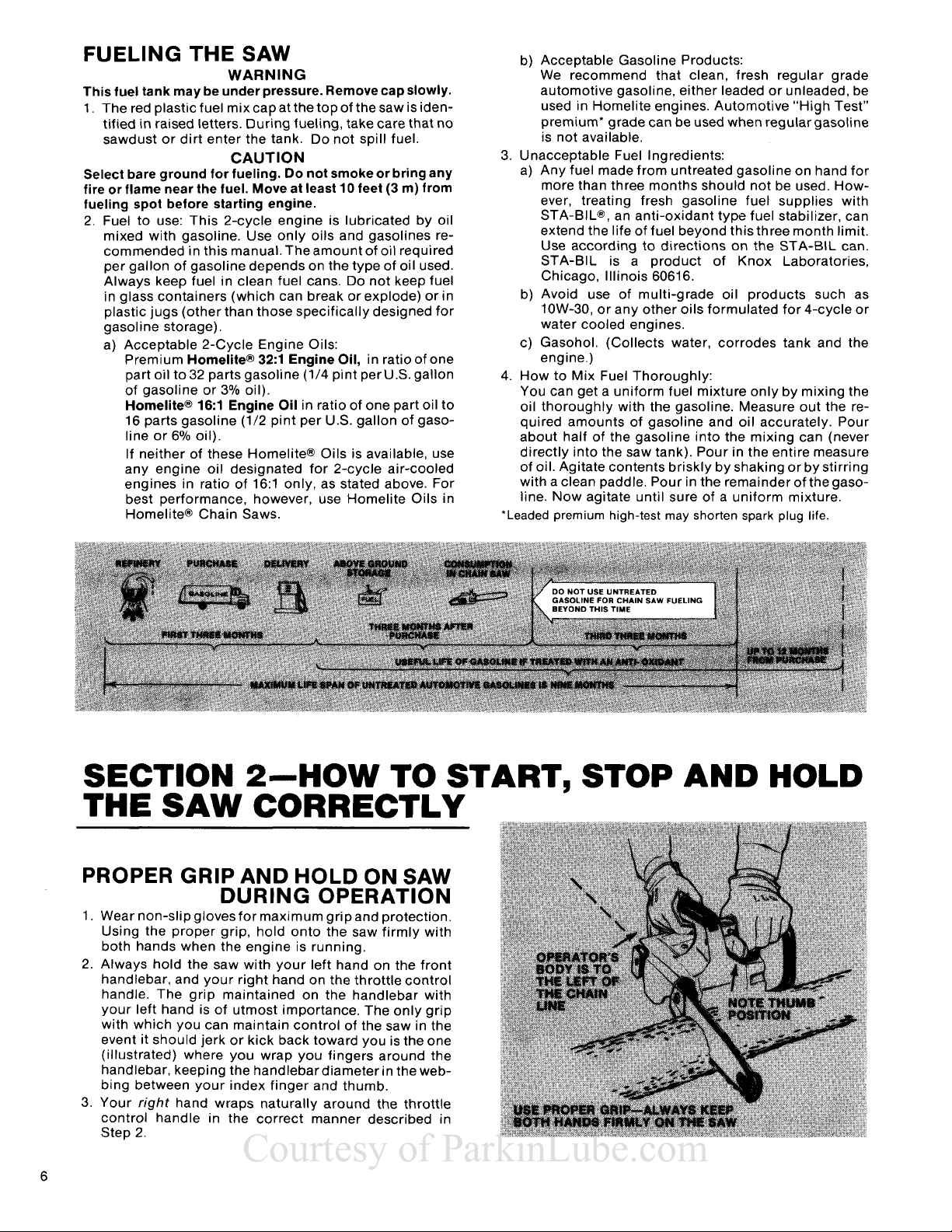

The chain oil and fuel mix tanks are identified in raised

letters on the left side of the saw. The fuel cap is RED.

The chain oil cap is BLACK. Be sure to fill the chain oil

tank with oil every time you fuel the saw, but always be-

low the check valve.

CHAIN OIL

PRESSURE

LINE

AND CHECK VALVE.

DO NOT

FILL TANK

ABOVE VALVE

LEVEL.

NOTE

Constant jiggling in a vehicle, or upside-down storage of

a saw having a full tank of chain oil, can force oil back

through the oil pressure line into the cylinder. This oil may

lock the engine hydraulically, preventing cranking. To

avoid this occurance, be sure to fill the oil tank only to

just below the oil pressure line and check valve. This assembly can be seen in the neck of the oil tank. Whenever

the engine refuses to turn over, remove the spark plug to

break the hydraulic lock. Then crank the engine several

times to dispel the oil. Clean the spark plug thoroughly

before you reinstall it.

Wipe down the saw if any oil or fuel is spilled on it. Keep

the saw handles clean.

2.

Type of oil:

HOMELITEB Bar and Chain Oil

should be used just

as it comes from the container, as it is formulated with

"viscosity improvers" which render it free-flowing

even at below zero temperatures. It has the property

of clinging to the chain to minimize "throw-off".

Any brand of clean motor oil including reprocessed oil

may be used as a substitute chain oil. However, in extremely cold weather, SAE

30

weight oil should be

diluted in the proportion of

1

part keroseneto4 partsof

oil to restore free-flowing properties. Never use dirty

oil or used oil in the chain oiler system as it may damage the oil pump.

Courtesy of ParkinLube.com

Page 6

FUELING THE SAW

WARNING

This fuel tank may be under pressure. Remove cap slowly.

1.

The red plastic fuel mixcap at the top of the saw is identified in raised letters. During fueling, take care that no

sawdust or dirt enter the tank. Do not spill fuel.

CAUTION

Select bare ground for fueling. Do not smoke or bring any

fire or flame near the fuel. Move at least

10

feet

(3

m) from

fueling spot before starting engine.

2. Fuel to use: This 2-cycle engine is lubricated by oil

mixed with gasoline. Use only oils and gasolines recommended in this manual. The amount of oil required

per gallon of gasoline depends on the type of oil used.

Always keep fuel in clean fuel cans. Do not keep fuel

in glass containers (which can break or explode) or in

plastic jugs (other than those specifically designed for

gasoline storage).

a) Acceptable 2-Cycle Engine Oils:

Premium

Hornelite@

32:l

Engine Oil,

in ratio of one

part oil to 32 parts gasoline

(1/4 pint per U.S. gallon

of gasoline or

3% oil).

Hornelite@

16:l

Engine Oil

in ratio of one part oil to

16 parts gasoline

(1/2 pint per U.S. gallon of gaso-

line or

6% oil).

If neither of these

Hornelite@ Oils is available, use

any engine oil designated for 2-cycle air-cooled

engines in ratio of

16:l only, as stated above. For

best performance, however, use Homelite Oils in

Homelitee Chain Saws.

b) Acceptable Gasoline Products:

We recommend that clean, fresh regular grade

automotive gasoline, either leaded or unleaded, be

used in

Homelite engines. Automotive "High Test"

premium* grade can be used when regular gasoline

is not available.

3. Unacceptable Fuel Ingredients:

a) Any fuel made from untreated gasoline on hand for

more than three months should not be used. However, treating fresh gasoline fuel supplies with

STA-BILe, an anti-oxidant type fuel stabilizer, can

extend the life of fuel beyond this three month limit.

Use according to directions on the STA-BIL can.

STA-BIL is a product of Knox Laboratories,

Chicago, Illinois 60616.

b) Avoid use of multi-grade oil products such as

10W-30, or any other oils formulated for 4-cycle or

water cooled engines.

c) Gasohol. (Collects water, corrodes tank and the

engine.)

4.

How to Mix Fuel Thoroughly:

You can get a uniform fuel mixture only by mixing the

oil thoroughly with the gasoline. Measure out the required amounts of gasoline and oil accurately. Pour

about half of the gasoline into the mixing can (never

directly into the saw tank). Pour in the entire measure

of oil. Agitate contents briskly by shaking or by stirring

with a clean paddle. Pour in the remainder of the gaso-

line. Now agitate until sure of a uniform mixture.

*Leaded

premium high-test may shorten spark plug

life.

SECTION 2-HOW TO START, STOP AND HOLD

THE SAW CORRECTLY

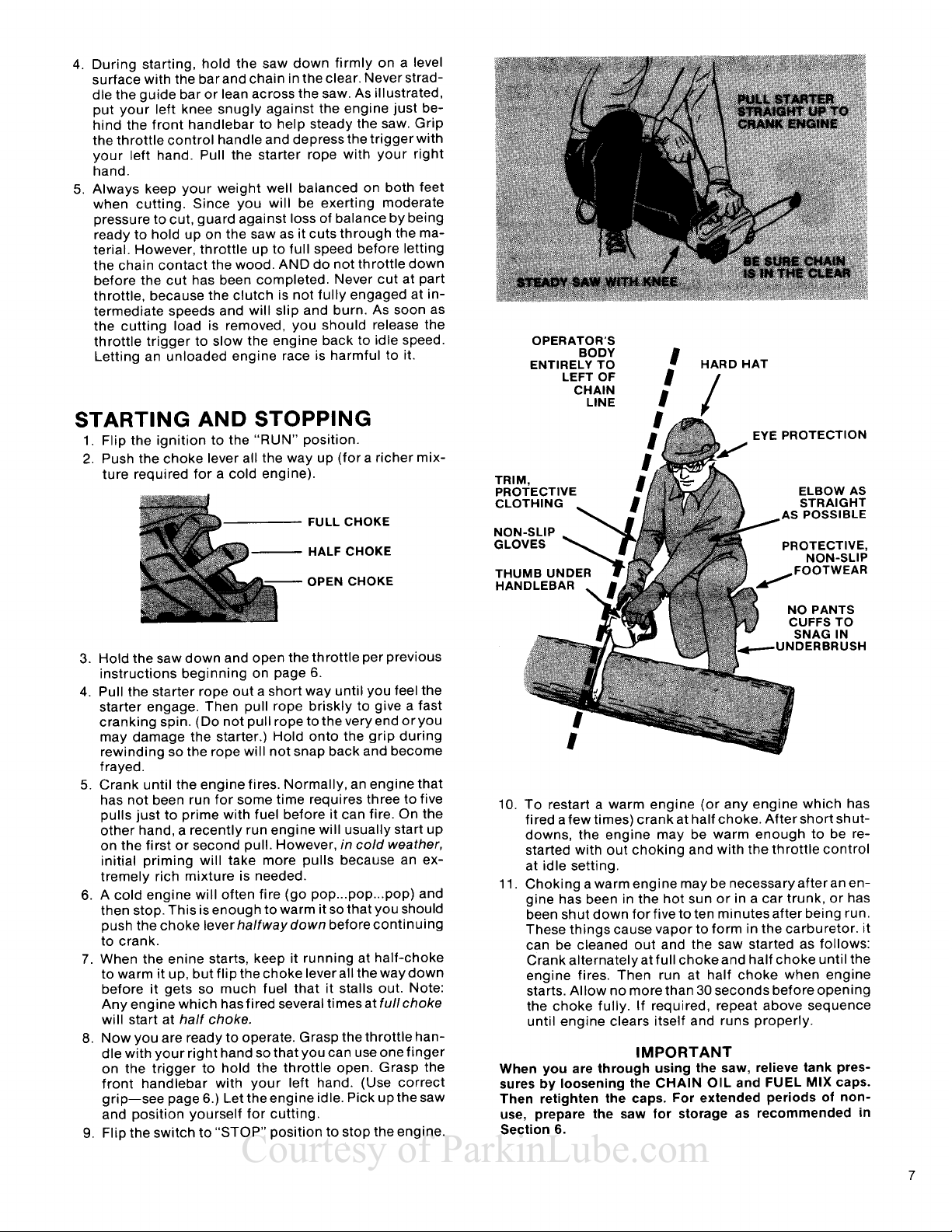

PROPER GRIP AND HOLD ON SAW

DURING OPERATION

1. Wear non-slip glovesfor maximum gripand protection.

Using the proper grip, hold onto the saw firmly with

both hands when the engine is running.

2. Always hold the saw with your left hand on the front

handlebar, and your right hand on the throttle control

handle. The grip maintained on the handlebar with

your left hand is of utmost importance. The only grip

with which you can maintain control of the saw in the

event it should jerk or kick back toward you is the one

(illustrated) where you wrap you fingers around the

handlebar, keeping the handlebar diameter in the webbing between your index finger and thumb.

3. Your

right

hand wraps naturally around the throttle

control handle in the correct manner described in

Step

2.

Courtesy of ParkinLube.com

Page 7

4.

During starting, hold the saw down firmly on a level

surface with the bar and chain in the clear. Never straddle the guide bar or lean across the saw. As illustrated,

put your left knee snugly against the engine just behind the front handlebar to help steady the saw. Grip

the throttle control handle and depress the trigger with

your left hand. Pull the starter rope with your right

hand.

5.

Always keep your weight well balanced on both feet

when cutting. Since you will be exerting moderate

pressure to cut, guard against loss of balance by being

ready to hold up on the saw as it cuts through the material. However, throttle up to full speed before letting

the chain contact the wood. AND do not throttle down

before the cut has been completed. Never cut at part

throttle, because the clutch is not fully engaged at intermediate speeds and will slip and burn. As soon as

the cutting load is removed, you should release the

throttle trigger to slow the engine back to idle speed.

Letting an unloaded engine race is harmful to it.

STARTING AND STOPPING

1.

Flip the ignition to the "RUN" position.

2.

Push the choke lever all the way up (for a richer mixture required for a cold engine).

FULL CHOKE

HALF CHOKE

OPEN CHOKE

3. Hold the saw down and open the throttle per previous

instructions beginning on page 6.

4.

Pull the starter rope out a short way until you feel the

starter engage. Then pull rope briskly to give a fast

cranking spin. (Do not pull rope to the very end or you

may damage the starter.) Hold onto the grip during

rewinding so the rope will not snap back and become

frayed.

5.

Crank until the engine fires. Normally, an engine that

has not been run for some time requires three to five

pulls just to prime with fuel before it can fire. On the

other hand, a recently run engine will usually start up

on the first or second pull. However,

in

cold weather,

initial priming will take more pulls because an ex-

tremely rich mixture is needed.

6. A cold engine will often fire (go pop

...p op ...p op) and

then stop. This is enough to warm it so that you should

push the choke lever halfway down before continuing

to crank.

7.

When the enine starts, keep it running at half-choke

to warm it up, but flip the choke lever all the way down

before it gets so much fuel that it stalls out. Note:

Any engine which

hasfired several timesat fullchoke

will start at half choke.

8.

Now you are ready to operate. Grasp the throttle handle with your right hand so that you can use one finger

on the trigger to hold the throttle open. Grasp the

front handlebar with your left hand. (Use correct

grip-see page 6.) Let the engine idle. Pick up the saw

and position yourself for cutting.

9.

Flip the switch to "STOP" position to stop the engine.

OPERATOR'S

BODY

ENTIRELY TO

LEFT OF

CHAIN

LINE

HARD HAT

EYE PROTECTION

TRIM,

PROTECTIVE ELBOW AS

STRAIGHT

AS POSSIBLE

PROTECTIVE,

NON-SLIP

HANDLEBAR

NO PANTS

CUFFS TO

UNDERBRUSH

10. To restart a warm engine (or any engine which has

fired afewtimes)

crankat half choke.Aftershort shutdowns, the engine may be warm enough to be restarted with out choking and with the throttle control

at idle setting.

11. Choking a warm engine may be necessary after an engine has been in the hot sun or in a car trunk, or has

been shut down for five to ten minutesafter being run.

These things cause vapor to form in the carburetor. it

can be cleaned out and the saw started as follows:

Crank alternately at full

chokeand half choke until the

engine fires. Then run at half choke when engine

starts. Allow no more than 30 seconds before opening

the choke fully. If required, repeat above sequence

until engine clears itself and runs properly.

IMPORTANT

When you are through using the saw, relieve tank pressures by loosening the

CHAIN OIL

and

FUEL

MIX

caps.

Then retighten the caps. For extended periods of

nonuse, prepare the saw for storage as recommended in

Section

6.

Courtesy of ParkinLube.com

Page 8

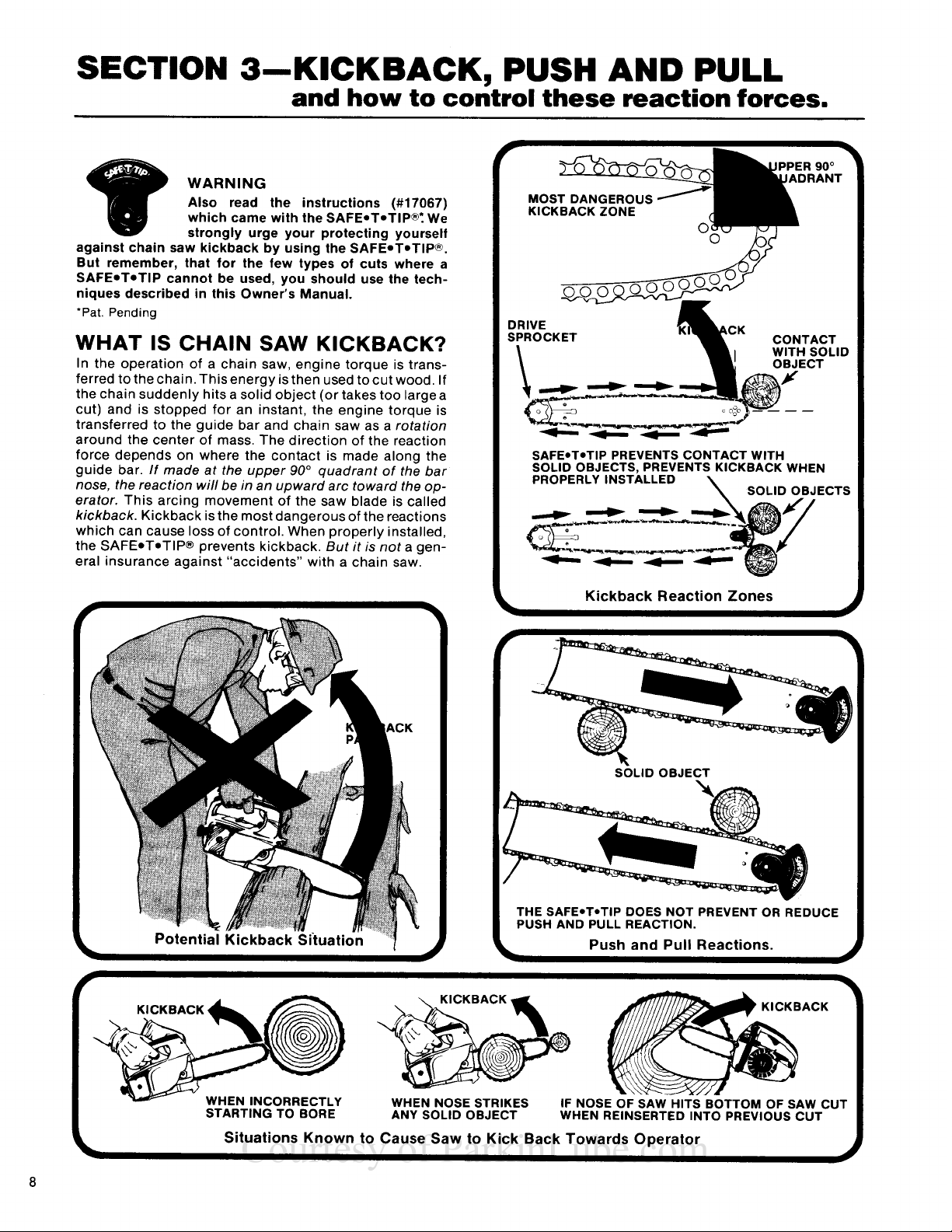

SECTION 3-KICKBACK, PUSH AND PULL

and how to control these reaction forces.

WARNING

Also read the instructions

(#17067)

which came with the SAFE*T.TIP@: We

strongly urge your protecting yourself

against chain saw kickback by using the

SAFE*T.TIP@.

But remember, that for the few types of cuts where a

SAFE*T*TIP cannot be used, you should use the techniques described in this Owner's Manual.

'Pat.

Pending

WHAT IS CHAIN SAW KICKBACK?

In the operation of a chain saw, engine torque is trans-

ferred

tothechain.Thisenergy is then used tocut wood. If

the chain suddenly hits a solid object (or takes too largea

cut) and is stopped for an instant, the engine torque is

transferred to the guide bar and chain saw as a rotation

around the center of mass. The direction of the reaction

force depends on where the contact is made along the

guide bar. If made at the upper

90"

quadrant of the bar

nose, the reaction will be in an upward arc toward the operator. This arcing movement of the saw blade is called

kickback. Kickback is the most dangerous of the reactions

which can cause loss of control. When properly installed,

the

SAFE.TmTIP@ prevents kickback. But it is not a gen-

eral insurance against "accidents" with a chain saw.

MOST DANGEROUS

KICKBACK ZONE

WITH SOLID

SAFE.T*TIP PREVENTS CO

SOLID OBJECTS, PREVENT BACK WHEN

PROPERLY INSTALLED

SOLID OBJECTS

Kickback Reaction Zones

SOLID

OBJECT

I

THE SAFE*T*TIP DOES NOT PREVENT OR REDUCE

PUSH AND PULL REACTION.

I

Push and Pull Reactions.

I

HEN INCORRECTLY WHEN NOSE STRIKES IF NOSE TTOM OF SAW CUT

STARTING TO BORE

ANY SOLID OBJECT

WHEN REINSERTED INTO PREVIOUS CUT

1

Situations Known to Cause Saw to Kick Back Towards Operator

Courtesy of ParkinLube.com

Page 9

Besides kickback, the directional reaction forces which

you must control are

push

and

pull.

Kickback,

push

and

pull

reactions are all illustrated on these pages.

HOW SHOULD YOU MAINTAIN

CONTROL OF THE SAW?

1.

First of all, you must keep the front handlebar diameter

in the webbing between the thumb and index finger of

your left hand. This grip helps maintain control of the

saw and limits the possibility that your hand will come

in contact with the chain. See the illustrations of the

correct and incorrect grips.

Do not place thumb over top of handlebar because

your hand can slip.

Don't forget to wear your gloves.

2.

Hold the front handlebar close to the balance point of

the saw (or where you can best oppose and absorb the

push, pull and kickback forces of the saw without

having it twist out of your grip).

Do not reverse right and left hand positions on the

saw handles.

3.

Get a good grip on the rear handle.

4.

Maintain your balance on both feet, and do not reach

above chest height with the saw engine, or reach so

far forward that you could be drawn off balance by

the saw's reactions.

5.

Stand a bit to one side so that no point of your body is

behind the chain line (in the line the saw will take if

it kicks back).

HOW SHOULD YOU REDUCE THE

CHANCE OF KICKBACK?

1.

Avoid letting the nose section of the saw contact any

object. Note: A

SAFE.T.TlP@ (pat. pending), when

properly installed on the bar nose, will prevent kickback.

2.

Avoid use of the nose section of the saw for cutting. Cut

well back on the straight section of the bar.

3.

Be sure to keep your chain sharpand properly tensioned on the saw, because a loose or dull chain is apt to

increase the chance of kickback.

4.

Use extreme caution when cutting brush, hedges and

other "whippy" material. Unless the saw hasa properly

installed

SAFE.T.TIP, cut only one pieceat a timeand

make sure that the nose of the saw stays in the clear.

5.

Never bore with the nose section of the saw unless you

absolutely have to. If you really

must

make a boring

cut with the nose, follow our instructions on page

13

for minimum risk of kickback.

Courtesy of ParkinLube.com

Page 10

SECTION

4-THE

WORKING

AREA

WORK AREA PRECAUTIONS

reason. In fact, we advise limiting your cutting to chest

heiaht, because a saw held hiaher than this is difficult to

Cut only wood or materials made from wood; no sheet

conltrol against kickback forces. Limbing from off-the-

metal, no plastics, no masonry, no non-wood building

ground positions, such as in trees or from ladders, is

ex-

materials.

tremely dangerous. Ladders can slip-you can fall. Unless

Do not allow children to operate your saw, EVER. Allow

you have had specific training in cutting aloft, leave

cut-

no person to use this chain saw who has not read this

ting aloft to experienced tree men.

Owner's Manual or received adequate instructions for the

safe and proper use of this chain saw.

WHEN LIMBING, STANDING WITH THE

KEEP BYSTANDERS

LOG BETWEEN YOU AND THE WORK

DISTANCE FROM TH

OFFERS MAXIMUM SAFETY.

Everyone-helpers, bystanders, children and animals,

and other operators-must be kept a safe distance from

the cutting area. During felling operations, the safe

dis-

CUTTING ALOFT OR FROM

tance should be at least twice the height of the largest

LADDERS IS EXTREMELY

DANGEROUS.

trees in the felling area. During bucking operations, space

buckers and limbers adequately so

they cannot interfere

with each other. Only one

person should be working on

LEAVE SOME SUPPORTING BRANCHES UNCUT.

a tree.

AFTER YOU HAVE BUCKED UP THE LOG SECTIONS

YOU CAN CUT OFF THESE LAST FEW LIMBS

In areas near roadways or power lines, do not operate un-

SAFE DISTANCE FOR

ti1 you have permission from the authorities. When work-

SPACING WORKERS IS

TWICE THE HEIGHT

ing near roads, you must post flagmen to control traffic. If

OF THE TALLEST TREES.

you accidentally knock down a power line or discover one

that is down, DO NOT GO NEAR IT, but notify the power

company as soon as you are able. A downed power line is

a good illustration of why woodsmen should pair up and

always keep within calling distance of one another. In the

event of trouble such as this, one man can stand guard

while the other summons help.

OPERATOR HAS POOR

CONTROL OF SAW IF HE

OVERREACHES OR CUTS

ABOVE CHEST HEIGHT.

STAND ON UPHILL

SIDE

WHEN CUTTING

BECAUSE LOG MAY ROLL.

During bucking operations alwayscutfrom the uphill side

so that the cut-off section of the log will not roll over you.

You can be pulled off balance if you have your weight all

on one leg, so be sure to stand with both feet on solid

ground. Make sure that cut-off wood will not fall on your

toes or on your head. Do not cut straight overhead

forthis

DON'T GO NEAR DOWNED POWER LINES.

SEND SOMEONE TO NOTIFY THE POWER

COMPANY. STAND BY TO WARN OTHERS

TO KEEP CLEAR.

KEEP WITHIN CALLING

DISTANCE OF OTHERS IN

CASE HELP IS NEEDED.

Courtesy of ParkinLube.com

Page 11

When the diameter of the wood is large enough for a

wedge to be inserted in

thecut behind the saw chain, usea

wedge to hold the cut open when there is a danger of pinching the saw blade. When felling large trees, wedges

should also be used to control the fall. Never use hard

metal wedges which could damage the saw chain. Note:

Remove

SAFEoToTIP before using wedge.

Clear your working area of all materials likely to trip you,

snag the saw, catch fire from the hot exhaust, or block

your safe retreat from a falling tree.

Before cutting limbs or felling trees, inspect

thearea to be

sure the wood will not strike buried pipelines or damage

property.

Always use a muffler on your saw and keep it in good repair. A faulty muffler (or open exhaust) can cause hearing

damage and is also a fire hazard. Be sure to use a spark

arrestor on your muffler under dry woods conditions, and

always when required by the law or local authorities. In

some states, a spark arrestor is required by law and it is

the operator's legal responsibility to see that it is in good

condition at all times. Check the muffler and spark ar-

restor at regular intervals. Careful! Never touch a hot

muffler.

HOT ENGINE

EXHAUST PARTICLES

SPARK ARRESTOR

\

A

SCREEN

.

..'.

.

-

.-_a

ONLY SMALL, QUICK-COOLING

PARTICLES CAN GET PAST

THE SCREEN.

HANDLING AND

SECURING THE SAW

ALL EQUIPMENT MUST BE SECURED

IN VEHICLES

WITH STRAPPING OR

TIE-DOWNS. PERSONNEL SHOULD NOT

BE

TRANSPORTED IN THE SAME

COMPARTMENT

AS

EQUIPMENT

AND

FUEL SUPPLIES.

A SPARK ARRESTOR IS ONLY ABOUT

90%

EFFICIENT IN PREVENTING FIRES.

LOCAL AUTHORITIES MAY CLOSE THE

FOREST DURING EXTREMELY DRY PERIODS.

Inspect your saw every day before use. Keep the fuel cap,

oil cap and air filter cover on tightly. Check condition of

the fuel line, spark plug and spark plug wire. DO NOT OPERATE IF THE ENGINE BACKFIRES OR THE SAW

LEAKS FUEL. Have your saw serviced by an authorized

serviceman. Be sure to keep your saw chain in proper condition on the saw. Remember that a dull or loose chain

snags more easily than a sharp, snug chain. Touch

upthe

chain after two hours of steady cutting and sharpen it

thoroughly after

8-10

hours of use. (See Chain and Bar

Maintenance in Section

6.)

If chain is damaged by abrasives or hits a stone or nail, put on a spare chain immediately and have the damaged chain repaired and sharpened.

If there is anything wrong with

thesaw have itfixed before

further operation. The idle speed adjustment should be

maintained so that the chain stops moving after the engine is brought back to idle. Adjust the idle speed whenever necessary (see Section

6).

NOTE

Do not disassemble the rotor (flywheel). Special techniques are required (on a dealer level) for safe removal

and installation of the rotor. Never start up your engine

unless the guide bar and chain are installed. Without the

guide bar in place, the clutch can fly off or explode.

UNUSUALLY HAZARDOUS

CONDITIONS

Do not fell trees or go underneath them during periods of

high wind or heavy precipitation. Take nochancesduring

periods of extreme hazard. You can wait to do your cutting

after the hazard has ended.

Do not use saws to cut down trees having an extreme lean

or large trees that have rotten limbs, loose bark, or hollow

trunks. Have these trees pushed or dragged down with

power equipment. Then you can cut them up.

Work only when visibility and

light areadequate for you to

see perfectly what you are doing.

Courtesy of ParkinLube.com

Page 12

SECTION 5-TECHNIQUES OF CUTTING

When you

are

going

to

cut

wood--DO

IT

RIGHT!

BUCKING, LlMBlNG AND PRUNING

For your first cutting experience, set upa small log so that

one end is off the ground. Practice your overbucking tech-

nique by cuttina firewood lenath sections off the raised

CUTTING VARIATIONS ACCORDING

TO THE STRESS FACTORS

-A

SAW BLADE PINCHED

end. (see illustration.)

-

When the piece to be cut issupported on theends, but not

along the point where you want to cut, it will bend as you

make your cut. If you are overbucking a log that will bend

downward at the cut, your saw will be pinched if you cut

more than 1/3 the log diameter. So

overbuck 1/3, then re-

move the saw and finish with an underbucking cut from

the bottom of the log. This

1/3-2/3 cutting technique helps

to avoid pinching of the saw and splitting of wood that is

1. Position yourself and the saw for cutting. Hold the saw

under stress.

with small diameterwood, you can make the

whole cut by underbucking as long as you don't care if the

near the log and throttle

UP

to full speed just before let-

wood

splits,

The

reverse

of

the

above

is

true

when

the

lie

is

ting

the

touch

the

wood'

Then

exert

moderate

such that the log will bend upward at the cut. In this case,

feed pressure to help

thechain cut the wood.Thechain

underbuck 1/3 through, and then overbuck so that thecut

must always be running at full throttle speed when it is

will

open

up

instead

of

closing

on

the

saw

blade,

contacting the wood, or you will burn out the clutch.

2.

If desired you can pivot the saw blade back and forth

FINISHING CUT

STRESS

during cutting. This often helpstospeed up thecutting

a bit.

PIVOT ACTION MAY BE USED

IN CUTTING

1

1st

CUT

1/3

dia.

3.

You will notice a slight amount of

pull

reaction during

cutting. So be ready for the moment the saw breaks

through the wood and

pull

ceases. You must be ready

to stop pushing down on the saw and hold the saw nose

up. The moment the chain breaks clear, release the

throttle trigger so the engine will not overspeed.

OVERBUCK UNDERBUCK

4.

When you have mastered the overbucking technique,

try underbucking to see what it feels like.

Place the saw blade under the log. Throttle up and ex-

ert upward pressure to cut clear through. Now you are

ready to learn when to

overbuck and when to under-

buck in order to avoid pinching the chain in the wood.

FINISHING CUT

WEDGE INSERTED TO

HOLD CUT OPEN

Sometimes it is impossible to avoid pinching (with just

standard cutting techniques) or difficult to predict which

way a log will bend when cut. You can do this to prevent

pinching: If the wood diameter is large enough for you to

insert a soft bucking wedge without touching the chain,

you should use the wedge to hold the cut open. Sometimes a pocket in the ground will allow the cut section of

log to settle, resulting in a pinch. The wedge

isalso useful

here, but in

thiscase you can cut on a slight angle (as illustrated) so that any settling of the log will result in increasing the gap between the cut log sections.

Courtesy of ParkinLube.com

Page 13

IF CUT-OFF SECTION IS

LIKELY TO SETTLE AND

BIND

AGAINST CHAIN, BUCK ON

NGLE SO CUT OPENS UP

NOTE

A

wedge cannot be used with a SAFE*T*TIP@

(Pat.

Pending)

on the bar, unless you are sure that you can either remove

the wedge or roll the log so the saw can be retrieved from

the cut.

When pruning shade trees it is important not to make the

flush cut next to the main limb or trunk until you have lopped off the limb further out to reduce the weight. This prevents stripping the bark from the main member. Unless

the branch to be pruned is supported by another branch,

the stress will be downward (see illustration). Underbuck

the branch

1/3

through, then overbuck todrop the branch

off. Now make your finishing cut smoothly and neatly

against the main member so the bark will grow back to

seal the wound. Don't forget to paint the wound with a tree

preservative to prevent insect attacks and rot.

WHEN BRANCHES ARE TRIMMED NEATLY

FLUSH WlTH THE TRUNK AND THE WOUND PAINTED

WlTH A PRESERVATIVE. THE BARK CAN GROW

BACK TO SEAL THE

WOUND

SPRINGPOLES

A springpole is any log or branch or sapling which is bent

under tension by other wood so that it will spring back if

the wood holding it is cut or removed. Watch out for

springpoles. They are potentially dangerous.

THIS IS A SPRINGPOLE BENT

DOWN UNDER

HIGH STRESS

BORING WlTH THE NOSE SECTION

KICKBACK DANGER

There is a great possibility that the saw will kick back

during the start of the boring cut.

Boring should be attempted only by experienced oper-

ators because it requires extreme care and attention to

proper technique. Do not bore unless there is no other

way to make a cut. Boring is usually resorted to in order to

avoid an obstacle or when it is necessary to make blind

holes such as cut-outs for log cabin windows. The

SAFE*T*TlP@ (Pat. Pending) must be removed for a boring cut. Boring increases the chance of kickback

andalso

wears the chain and bar at an accelerated rate.

Study the panel illustrating a boring operation. As shown,

the danger will be minimized if you can make first contact

on the underside

of

the bar as far back from the bar nose

as you can get. Then cut downwardinto the wood until the

tip is buried in the cut. Gradually bring the saw level, then

bore through the wood to the full length of the blade. Now

you can cut either upward or downward through the wood

as shown in the panel.

BORING

-

-

.

-

. .

-

-

TECHNIQUE

1

MAKE FIRST

CONTACT ON

LOWER

QUADRANT

2

CUT DOWNWARD

TOBURYNOSE

OF SAW IN THE

WOOD AND ALIGN

SAW FOR THE BORE

4

CUT UPWARD OR

DOWNWARD AS

REQUIRED

Courtesy of ParkinLube.com

Page 14

TREE FELLING TECHNIQUES

CAUTION

If the saw gets caught or hung up in a tree during felling,

leave the saw and save yourself. The saw can be replaced

and you cannot!

1.

Pick your escape route (or routes in case the intended

route is blocked). Clean the immediateareaaround the

tree, and make sure there are no obstructions in your

planned path of retreat.

CLEAR PATH OF

SAFERETREAT

2.

Consider the factors of wind direction and speed, the

natural lean and the balance of the tree, and the location of large limbs. These things influence thedirection

in which the tree will fall. Do not try to fell

a

tree along a

line different from its natural line of fall until you have

had considerable experience in felling trees which present no problem as to where they will fall.

3.

Take into consideration whether the trunk is sound or

so rotted inside as to snap and crash while being cut.

Also look for broken or dead branches (widow makers)

AND don't go below any widow makers.

4.

In tight situations where a mistake in the direction of

fall could ruin other trees or destroy property, attach a

tether line to the tree as illustrated.

IN DIRECTION PLANNED

ROPES USED

TO CONTROL

DIRECTION OF FALL

5. If the tree is not badly out of balance, cuta notch about

1/3

the diameter of the trunk. This notch whetherstandard or "Humboldt" is made in the side the tree is to fall.

And the cuts of the notch are made so they intersect at

a right angle to the line of fall. This notch should be

cleaned out to leave a straight line. To keep the weight

of the wood off the saw always make the lower cut of

the notch before the uppercut. We illustrate acommon

notch made with a horizontal cut and an angular cut

above it.

AUHumboldt" notch, with the horizontal notch

on top, is made when trees are to be cut for saw log

processing.

UNCUT

B A DIRECTION OF FALL

COMMON NOTCH HUMBOLDT NOTCH

6.

The backcut is always made level and horizontal and at

a minimum of

2

inches (51mm) above the horizontal

cut of the notch. As a guide to placing the back cut

above the notch, figure

10°/o

of the face diameteras the

proper height. Be very careful to make a level back cut,

as a slanted back cut can cause the tree to split or

"barber chair" (see illustration).

7.

You must never

cut

through to the notch. Always leave

a band of wood uncut between the notch and back cut.

This is called "hinge" or "hingewood." It controls the

fall of the tree and prevents slipping or twisting or

shoot-back of the tree off the stump. If the tree starts

over in the wrong direction, or if the saw getscaught or

hung up during the fall, leave the saw and save yourself!

MAKE BACKCUT

2"

OR MORE

ABOVE HORIZONTAL CUT OF

NOTCH

Courtesy of ParkinLube.com

Page 15

8.

On large diameter trees, it is proper to stop the back cut

before it is deep enough for the tree

toeither fall or settle back on the stump. Then soft wooden or plastic

wedges (not hard metal) are inserted behind the saw so

they do not touch the chain. The wedges can

bedriven

in, little by little, to help jack the tree over.

WHEN WEDGE IS

-

NEEDED TO HOLD

CUT OPEN, REMOVE

SAFE*T.TlP@

9.

Trees larger than the saw can cut in one cut, can be

both notched and back-cut in a series of cuts, as illustrated. Start the notching cuts from one side and draw

the saw through to the other

sideof the notch. Start the

back cut on one side of the tree, pivoting the saw

through to form the desired hinge on that side.

Then remove and reverse the saw for the second cut.

Insert the saw in the first cut, very carefully soasnotto

cause kickback, and cut back toward and around the

back of the trunk. Complete the back cut by cutting towards the notch to complete the hinge section.

NOTE

Insert your felling wedges in the back cut. Remove the

saw before tree is ready to fall and drive the wedges in to

fell the tree.

NORMAL SEQUENCE USED

TO

FELL VERY

LARGE TREES

(UP

TO TWICE BAR LENGTH

IN DIAMETER)

1st CUT-USE

PIVOT ACTION

2nd

CUT-REINSERT

SAW AND

DRAW IT

AROUND THE BACK

FELLING

CUT-INSERT

#FELLING

WEDGE

BEHIND

BLADE.

CONTINUE TO

CUT FORWARD

TOWARD

NOTCH

DRIVE WEDGE

INTO BACK

CUT TO HELP

FORCE TREE

OVER. REMOVE

SAW

FELLING LEANERS

This variation is designed to prevent splitting and "barber

chair" of leaners.

All standard felling techniques apply to leaning trees except as follows:

1.

Make the directional control face notch shallower than

usual.

2.

Make shallow notches on both sides of the tree to cut

through the outer layer (sapwood).

3.

Now make your back cut to leave a parallel hinge.

WHEN CUTTING LEANERS, AVOID

SPLITTING AND BARBER CHAIR BY

MAKING THE FACE NOTCH (1) AS

DEEP AS IS SAFE. THEN MAKE

SlDE

NOTCHES

(2

AND

3)

TO CUT

THROUGH THE SAPWOOD BEFORE

STARTING THE

BACKCUT

(4).

CHANGING THE

DIRECTION OF FALL

(from

the

natural line of fall)

1.

Where you would leave a parallel hinge (hingewood of

equal thickness on both sides) the hinge is left thicker

on the side toward which you want the tree to swing

(away from the natural line of fall).

2.

Place your wedges in the back cut between the backcenter and the narrow side of the hinge. Drive in the

wedges to force the tree over in the direction desired.

SlDE NOTCH

FELLING

WEDGES

BACKCU

THIN END OF

HINGE

NATURAL

LINE OF

FALL INDICATED

+

---A

BY LEAN AND

BALANCE

THICK

END/.

FACE

NOTCH

\J1

OF HINGE

Courtesy of ParkinLube.com

Page 16

SECTION 6-MAINTENANCE

8

ADJUSTMENT

HOMELITEB SAW CHAIN

LEFT HAND

DEPTH GAUGE

/

RIGHT HAND CUTTER

CUTTER

-

/

\.

/

RIVETS

/

TIE-STRAP

Saw chain is identified by a number stamped on either its

tie-straps or its drive links. You may select any chain

stamped "375" or

"37." Do not usechainsof other number

series such as "25" or "38" as they will be of either the

wrong pitch for your sprocket, or the wrong configuration

for your saw. The original chain supplied with your saw

was either Type 37 Saw Chain or 375 Saw Chain. Which-

ever of these chains you choose in replacement, be sure

to use our sprocket and drum assembly #A-70221-A

which fits both types.

FILING EQUIPMENT

Purchase our assembly #DA-92617 which consists of a

file holder and a 5/32"

(4mm) diameter "fast-cut" round

file

(#92604). When about half to 5/8 of the tooth steel has

been filed away, you should switch to a

1/8" (3.2 mm) di-

ameter file

(#92605). The 1/8" diameter file fits into the

same file holder. The reason for switching to a smaller diameter file on "short-filed" teeth is that they are reduced

in height due to their tapered top plate configuration.

You will also need a depth gauge tool

(.020" or 0.5 mm,

#D-92630) and a flat file

(#92609).

HOW TO FILE THE CUTTERS

If you do not have a chain filing vise you can do a satisfactory job "on the bar" if you tighten the chain tension

enough that the chain doesn't wobble. And, do all of your

filing at the mid-point of the bar. Wear gloves for protection. Be sure to file all cutters to the same length. This

must be done because of the taper of the teeth; if some

cutters are shorter than others only the longer cutters will

get a chance to cut. Also be careful to file all cutters to the

specified angles, as fast cutting can be obtained only

when all cutters are uniform. Each cutter then gets a

chance to cut.

1. Hold file against cutter face at

a35O angle. (It is marked

on the holder.)

2. Keep the file level with the tooth top plate. Do not let file

dip or rock.

3. File in one direction only

-

towards front cornerof the

tooth. Move file away on the return stroke.

35" GUIDE MARK

ON HOLDER

CHAIN TRAVEL

4.

Use light but firm pressure, mostly towards back of

tooth. Avoid heavy downward pressure. The holder will

keep

10O/0 to 20% of the file diameter above the cutting

edge IF YOU LET IT. This will produce the desired beveled hollow-ground under-edge automatically.

5.

Put a few firm strokes in every tooth, filing all cutterson

one side, then those on the other side of the chain. Rotate file in holder occasionally.

6. Examine your filing job in strong light. A sharp edge

will not reflect light and a dull edge will. However,

sharpening does not alone make a good cutting tooth.

An abraded tooth, for instance, may still not cut until

you have removed the worn or rounded off portion of

the steel so that the sharp cutting edge is the highest

part of the chain. In other words; the edge and not the

flat

plate

of the cutter has to contact the wood first (see

"Filing Out Skid-Nose Wear Pattern", page 17).

NOW EXAMINE YOUR FILING JOBHERE'S WHAT YOU SHOULD GET:

2.

Beveled under edge.

I

1.

35" top plate angle.

LINE OF CHAIN TRAVEL-

--

3. Side plate 85" to line of chain travel.

EDGE MUST BE HERE ON KERF LlNE

1(

KERF LlNE

EDGE MUST NOT BE HERE

Courtesy of ParkinLube.com

Page 17

FILING OUT "SKID-NOSE"

WEAR PATTERN

EDGED CUTTER BITES

OOD.

"SKID-NOSE" describes the edge area of teeth which

have hit hard objects such asstones, nails, etc., or cut dirt,

SKID-NOSE OF ABRADED CUTTER

sand, etc. The "skid-nose" rides the wood surface keeping

PREVENTS EDGE FROM CUTTING.

the sharp edges out of the wood. The friction at the "skid-

nose" area overheats the cutter steel, and the chain gets

"soft". The only way to restore the chain to good condition

is to file away all of the "skid-nose" steel. And, then

toad-

FILE AWAY ENTIRE SKID-NOSE

just all cutters to the same length. As this may be tedious

F TOOTH TO RESTORE.

to do by hand-filing, consider having it done by your servicing dealer on an electric grinder.

REFILE ANY TEETH HAVING ONE OR MORE OF THESE FAULTS

1

Forward Hook

Chain will grab and jerk.

Producing rough-cutting.

Caused by excessive

downward filing pressure,

or tip of file held too

low on tooth.

Back Slope

Chain resists entering wood.

Scrapes instead of cutting.

Causes excessive heat and

wear to bar and chain. Caused

by lowering handle end of

file or holding file too

high on tooth.

Improper Top Plate

Angles

Blunt angle requires too

much feed pressure to cut.

Too sharp an angle causes

binding. Produces a rough

cut, robs power from saw,

and increases bar wear.

Caused by holding file at

wrong angle or letting it

drift or rock during the stroke.

Cutters Filed

at Non-Matching

Angles or Lengths

Chain will not cut at its

best. May cut off line or

"run" to one side. Drag will

slow down engine. Caused

by letting filing angle or pressure

vary from tooth to tooth, or

filing one side of chain

differently from the other.

Thin Feathered Edges

When they almost immediately

break off, you have a dull chain.

Usually found on chain filed

with a hook (see "Forward

Hook"). Caused by pressing

down too hard on file.

Blunt Cutting Edges

Although edge is durable, it

won't cut properly. Scrapes

wood, robs power, and produces dust instead of chips.

Caused by holding file too high

on face of tooth.

HOW AND WHEN TO SET DEPTH GAUGE CLEARANCE

AFTER FILING WlTH

JOINTER, GAUGE WILL

HAVE FLAT TOP

SO

...

Every second or third time the teeth are sharpened, or if a

large amount of steel is removed from the cutters, the

depth gauge should be checked for correct depth. Use a

USE A FLAT FILE

depth gauge tool and a flat file. Fit the tool over the chain

TO RECURVE THE FRONT

so that the slotted end points towards the bar nose and the

SMOOTHLY

depth gauge pr0jec.t~ up through the slot. File the depth

gauge flush with the top of the tool. File all gauges to this

height. If the gauges are too high, the chain teeth will not

get a good bite. If too low, the teeth will take too large a

bite, causing the chain to grab and jerk. If some gauges

DO NOT NICK DRIVE LINK

are higher than others, the chain will cut off line, favoring

WlTH THE FlLE

the side having the lowest gauges.

Courtesy of ParkinLube.com

Page 18

REPLACING WORN CHAIN

AND SPROCKET

As the chain and sprocket wear together, they both will

change in pitch. Therefore, it is a good idea to always

change the sprocket and drum assembly whenever you

are installing a new chain. Otherwise the old sprocket will

wear down the new chain and you will have lost some of

the life of your new chain. You can tell by the wear pattern whether the sprocket needs replacement. Always

change the sprocket when the wear approaches 1/32"

(0.8mm) deepness, or if you see deep wear marks on

both sides of the sprocket teeth. The clutch drum,

sprocket and clutch should be removed only by an

authorized Homelite serviceman or dealer, as servicing

must be done properly with great care. When a sprocket

and drum are replaced, all clutch parts should be

checked by your dealer. The replacement sprocket and

drum assembly includes a new grease-packed needle

bearing and inner race, and a new retaining ring.

GUIDE BAR

After each day of use, reverse the guide bar on the saw so

that the rails which were on the bottom will be on the top.

This distributes the wear for

miximum bar life. The bar

should also be cleaned everyday of use and checked for

wear and damage.

Feathering or burring of the bar rails is a normal process

of bar wear. But these burrs should be smoothed with a file

or stone as soon as they occur, because they slow down

your cutting. Also check that the bar rails are parallel (of

equal height). If not, file or grind them parallel. Pinched

rails can be opened by carefully prying them apart with a

screwdriver.

The following faults are either uneconomical or impossible

to repair (on any XL size and type bar) and will require bar

replacement:

a) Wear inside the bar rails, called "hourglass" because

of its cross section shape. It comes from too little chain

tension and permits the chain to flop over sideways.

b) Bent guide bar

-

if only slightly bowed, the bar might

be

rebent straight. But compound twistsorsharp bends

call for replacement.

c) Cracked or broken rails.

d) Spread rails-peening will not satisfactorily close the

rails of the laminated bar such as any XL bar.

Sprocket nose

PowerTipm Guide Barsareoptional equipment available as XL guide bar replacements. The lubricant in the sprocket nose of a Power Tip bar (in the XL

length class) is expected to last for the life of the nose

sprocket under normal conditions of use. However, the

grease can be changed by pumping through the small

lube hole in the bar nose with a needle nose grease gun.

But as long as the nose sprocket turns smoothly, we advise retaining the original lubricant. Because, once you

change thegrease you must re-lube on a daily basis thereafter.

BAR NOSE SHOULD STILL BE WARM

WHEN NOSE IS LUBRICATED

NEEDLE NOSE GREASE GUN

LUBE HOLE

We sell a grease-packed needle nose lube gun (as part

#D92680) for sprocket nose bars. You can also use needle

nose lube gun

(#24258-1) with Homelit8All-Temp MultiPurpose Grease (W7193) or a good quality lithium base

grease. The replacement sprocket (#A-70239-8) for

Power Tip bars comes assembled and lubricated on a

shaped mount which you can use to slide the assembly

into the bar nose. When the sprocket is positioned in the

bar nose, use the rivets in the kit to peen the sprocket

assembly into place.

SLIDE REPLACEMENT SPROCKET INTO PLACE

RIGHT OUT OF KIT PACKAGE

SPROCKET NOSE BAR

RIVETS AND OLD

NOSE REMOVED

TANKS, CAPS

and

PICK-UP FILTERS

ORIFICE OF PRESSURE-

FEED SYSTEM IS NOT

USED

IN

POSITIVE

DISPLACEMENT PUMP

$6

TYPE SYSTEM.

1.

Regular maintenance should be performed every 50

operating hours or once a year. It consistsof changing

the fuel pick-up filter in the fuel tank, and cleaning the

orifice and the screen type

pick-up filter

in thechain oil

tank.

2. These instructions include troubleshooting because

the pick-ups can become clogged any time sawdust

enters the tank.

a) When asked to cut wood, the saw will falter if the

fuel filter is clogged or the line is kinked. Flush out

the tank with clean fuel. Install a new felt filter if

the old one feels "crusty" or hard when rolled in

the fingers.

b) The saw chain must always be moist with oil in the

area of the connecting links and rivets. The flow of

oil may be blocked either at the pick-up or at the

discharge. Flush out the oil tank. Clean the oil discharge hole in the guide bar mounting pad. Pick or

blow clean the screen of the pick-up filter. And if

the saw has an orifice in the pick-up line, be sure

this is open, but do not put anything through the

orifice that would enlarge its metering capacity.

c) If the above maintenance is of no avail, have the saw

checked by your Homelite Dealer or Factory

Service Center.

Courtesy of ParkinLube.com

Page 19

T TO

AIR FILTER MAINTENANCE

CASTING, THEN SNAP INTO PLACE

To Inspect and Clean or Change

the Air Filter

1. Refer to the illustrations. Use the slot at the top of the

The spongy element removes dirt from the air. When it

back plastic filter cover to pry off the cover.

clogs up, the saw will smoke excessively and lose power.

2.

Clean the area around the filter before removing filter.

The filter should be changed when dirty, but in an emer-

gency, can be cleaned in detergent and water or a

clean-

3.

Fit clean filter in place carefully.

ing solvent and allowed to dry. The normal life

expec-

4.

Before operating, reinstall plastic cover as follows:

tancy of the element is

lot015 hours of operation. How-

Start cover on by putting choke lever through the slot

ever, extremely dirty operating conditions may cause the

and placing tabbed bottom and rear edges into

posi-

filter to clog in four or five hours. You should keep some

tion. Press cover into place. WARNING: Never run the

spares on hand for quick-changing.

engine without the filter.

CARBURETOR ADJUSTMENT

The carburetor isan all-position, diaphragm type having a

factory-calibrated, high-speed mixture system for proper

high speed performance. It has two adjustments which

may require adjustment from time to time to achieve the

desired idling characteristics.

The first adjustment is the idle speed screw. This screw is

used to adjust the idle speed. It does this by holding the

throttle shutter partly open to let fuel and air be drawn

through the carburetor for idling.

The second adjustment is the idle mixture adjustment

needle. This needle adjusts the amount of fuel to get the

correct mixture required for idling.

Always clean or change the air filter before attempting

any carburetor adjustment.

Adjustment for Starting

-

1. No adjustments are required for starting a cold engine

at full throttle (trigger depressed) or for operating.

2.

Adjustment for proper idle speed and mixture may be

required if a hot or warm engine cannot be started at

idle throttle or if the engine idles roughly or refuses

to accelerate.

a) Turn the idle mixture adjustment needle slowly

clockwise until it gently closes against its seat (do

not force). Then open it 1 1/4 turns.

b) Turn the idle speed screw clockwise 1/2 turn at a

time and keep trying to start the engine each time,

until it does start and will keep idling.

Adjustments After Engine Is at

Operating Temperature

The saw should be started up and a few cuts made to warm

it up. Then idle the saw and make the following adjustment:

1. Turn idle mixture needle slowly in one direction, then

the other. Leave set where the engine idles the fastest.

2. If this idle speed is too slow, the engine will falter. Turn

the idle speed screw slowly clockwise to increase the

speed until the engine no longer falters at idle.

3.

If the speed (in Step 1) is so fast that the chain rotates

rapidly, or takes too long to stop rotating after the engine is throttled back to idle, turn the idle speed screw

counterclockwise until the chain stops turning (but no

slower than this setting).

4.

What you have done in the above steps is to adjust the

throttle for the proper idle setting, and then adjust the

mixture for that setting. Any time you adjust the idle

speed, always readjust the idle mixture needle for the

best mixture as in Step 1.

Carburetors of saws which bear this circular sticker

have had the standard circuit plate replaced with a

high altitude plate for optimum performance at high

altitudes.

WARNING

At low altitudes this modification will cause lean

operation and overheating. DO NOT OPERATE SAW

BELOW

5000

FEET UNLESS CARBURETOR CONTAINS

THE STANDARD PLATE. If changing back to standard

plate, remove the high altitude sticker from the saw.

Courtesy of ParkinLube.com

Page 20

STARTER REPAIRS

HOLD ONTO

LIFT PULLEY

112

INCH.

MAKE SURE SPRING IS DETACHED

FROM PULLEY. PUSH SPRING COILS

DOWN INTO HOUSING.

LIFT OFF

THE PULLEY.

FLAT WASHER

WASHER FACED

SL. HEX HD. SCREW

The starter has few parts and can be disassembled and repaired under field emergency

conditions,as when the

rope breaks.

1. Remove the guide bar and chain.

2. Remove the screw through the top of the handlebar

and the four screws through the

starter/fan housing

to the engine housing. Lift

thestarter/fan housing and

the handlebar off the engine. Remove the plastic air

filter cover.

3.

TO

ADD

MORE SPRING TENSION:

If the grip does

not rewind all the way to the housing and stay in place,

it may need another turn of tension. Note the rounded

notch in the edge of the pulley. Pull out

thegrip about

one foot and hold the pulley from rewinding. Turn the

pulley to locate the notch at the rope entry hole in the

housing. Hook up a loop of rope between the housing

and the pulley. Grasp the loop and wind one turn tension (or more if necessary) in a clockwise direction.

Hold pulley from turning. Pull the rope back out

through the hole.

4.

To replace starter rope or repair starter spring: Un-

screw the starter screw and remove the flat washer.

WARNING

Put on safety glasses and gloves before removing the

pulley.

5.

Grasp the toothed pulley hub and pull the pulley out

of position about a half-inch or the width of your

finger. Using a thin bladed screwdriver, insert it between the pulley and the housing to free the pulley

from the spring. Push the spring coils

intothe housing.

CAUTION

If you lift the pulley too far out before detaching the spring,

the coils may fly apart. They are relatively difficult to

rewind.

6.

Replace the recoil spring if broken or bent. If the inner

spring loop has been straightened so that it does not

engage the pulley, bend in the whole loop carefully

until it is curved enough that the end can engage the

pulley.

7.

Integrally-banded replacement springs are installed

by hooking outer end in housing notch (as illustrated)

and pushing coils into housing. Original equipment

springs are unbanded. These must be installed by

hooking outer end, then winding coils into housing.

Be very careful not to let coils fly apart. Tape or tie

coils together before disposal.

8.

Clean the pulley post and the pulley.

9.

To replace the rope, cut old rope and remove it. Push

new rope through rope hole and draw the end out

through the pulley slot. Tie asimple knottightly in the

other end. Coat it with acetone type cement to set the

knot and trim the rope neatly up to the knot. When dry,

pull the rope to draw the knot through the hole. Run

the rope through the hole in the housing, thread the

starter grip onto the rope and knot this end. Draw the

knot into the grip.

10. Grease the pulley post lightly (not too much grease)

and drop the pulley into place over the post. Pull rope

out to the end to straighten it, then wind pulley counterclockwise to wind rope onto it.

11.

Test for spring engagement by pulling rope out and

letting it rewind. If it does not rewind all the way, pull

rope out and hold pulley from turning. Pull up a loop

of rope between housing and pulley (use the notch)

and wind 1 turn extra tension onto the pulley by holding rope and using it to turn the pulley clockwise.

Hold pulley from turning, and pull rope out until it

runs straight through the housing hole onto the

pulley. Let pulley rewind. If grip does not rewind up

to the housing, repeat this procedure to add one more

turn at a time until grip comes up to the housing. Now

add one additional turn of tension in the same manner.

12. Secure pulley with the flat washer and screw. Press

the housing lightly against the rotor while pulling the

starter rope a short distance and letting it rewind until the housing clicks flush against the engine cover.

You may then safely secure it with the four screws

previously removed. Fasten the handlebar to the engine cover with one screw at the top.

Courtesy of ParkinLube.com

Page 21

IGNITION, COOLING AND EXHAUST SYSTEM

HOURS OF OPERATION:

AND MUFFLER SHOULD BE REMOVED.

ING PASSAGES AND CYLINDER

FINS SHOULD BE CLEANED.

SPARK PLUG

T PORT DOES NOT

Y REQUIRE CLEANING

in the starter housing or around the muffler.

2.

Occasionally, (perhaps every 50 operating hours) the

MUFFLER BOD

muffler and starter assemblies should be removed fora

LONG SPACE

thorough cleaning of the cooling air passage, including the slots formed by the cylinder fins.

3.

The engine has a miniature, self-sealing tapered seat

SPARK ARRESTOR

type Champion #DJ-7J spark plug. Whenever there is

trouble starting the engine, always immediately

re-

SHORT SPACER

place it with a new DJ-7J plug (or its equivalent of the

same type and heat range). Leave the new plug in the

saw at least until you have found the troubleand gotten

the saw started.

4. When installing the tapered seat type spark plug in this

engine, you must get a gas-tight seal without overtightening the plug. To do this, first make the plug

MUFFLER CAP

finger tight and then use the spark plug wrench to

tighten 1/16 turn more.

MUFFLER SCRE

5. The most frequent cause of ignition trouble is spark

plug fouling. This can be due to a build-up of hard

engine deposits, but is often due to soft deposits or

merely wetness caused by a) flooding, b) improper

fuel of some nature, c) wrong adjustment of the

carburetor idle mixture or prolonged idling of the

engine, and d) wrong spark plug gap setting.

GAP

.025"

6.

Fouled plugs often can be restored, first by cleaning

sandblasting are not recommended, as these methods

and then by resetting the firing gap.

drive into the plug harmful particles which cannot be

re-

moved with solvent.

NOTE

The metal electrodes should be filed or scraped down

Cleaning by hand-brushing or hydro-honing followed by

to the bare metal, then gapped to

,025"