Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

2700 PSI PRESSURE WASHER

NETTOYEUR HAUTE PRESSION DE 2 700 PSI

LAVADORA A PRESIÓN DE 2 700 PSI

UT80709

UT80911

All Models

To register your Homelite

product, please visit:

http://register.homelite.com/

Pour enregistrer votre produit de

Homelite, s’il vous plaît la visite:

http://register.homelite.com/

Para registrar su producto de

Homelite, por favor visita:

http://register.homelite.com/

Your pressure washer has been engineer ed and manufactured to our high standard for dependability, ease of operation,

and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Ce nettoyeur haute pression a été conçu et fabriqué conformément

aux strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenu, il vous donnera des années

de fonctionnement robuste et sans problème.

Su lavadora de pr esión ha sido diseñada y fabricada

de conformidad con las estrictas normas para brindar

fiabilidad, facilidad de uso y seguridad para el operador . Con el

debido cuidado, le brindará muchos años de sólido y eficiente

funcionamiento.

AVERTISSEMENT :

blessures, l’utilisateur doit lire et veiller à bien comprendre

le manuel d’utilisation avant d’utiliser ce produit.

Merci de votre achat.

Pour réduire les risques de

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

ADVERTENCIA: Para reducir el riesgo de lesiones, el

usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

See this fold-out section for all of the figures referenced in the

operator’s manual.

Consulter l’encart à volets afin d’examiner toutes les figures

mentionnées dans le manuel d’utilisation.

Consulte esta sección desplegable para ver todas las figuras a las que se

hace referencia en el manual del operador.

i

Page 3

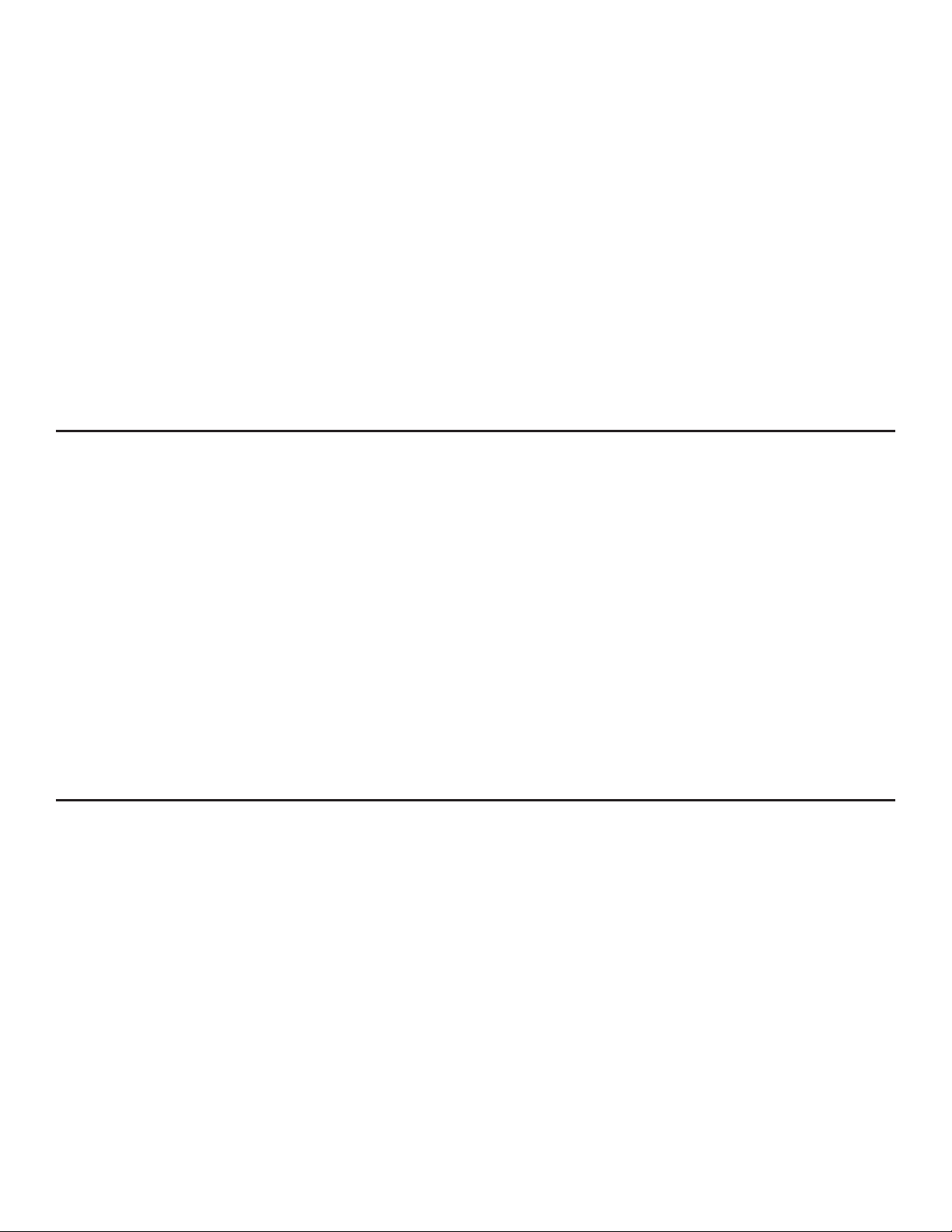

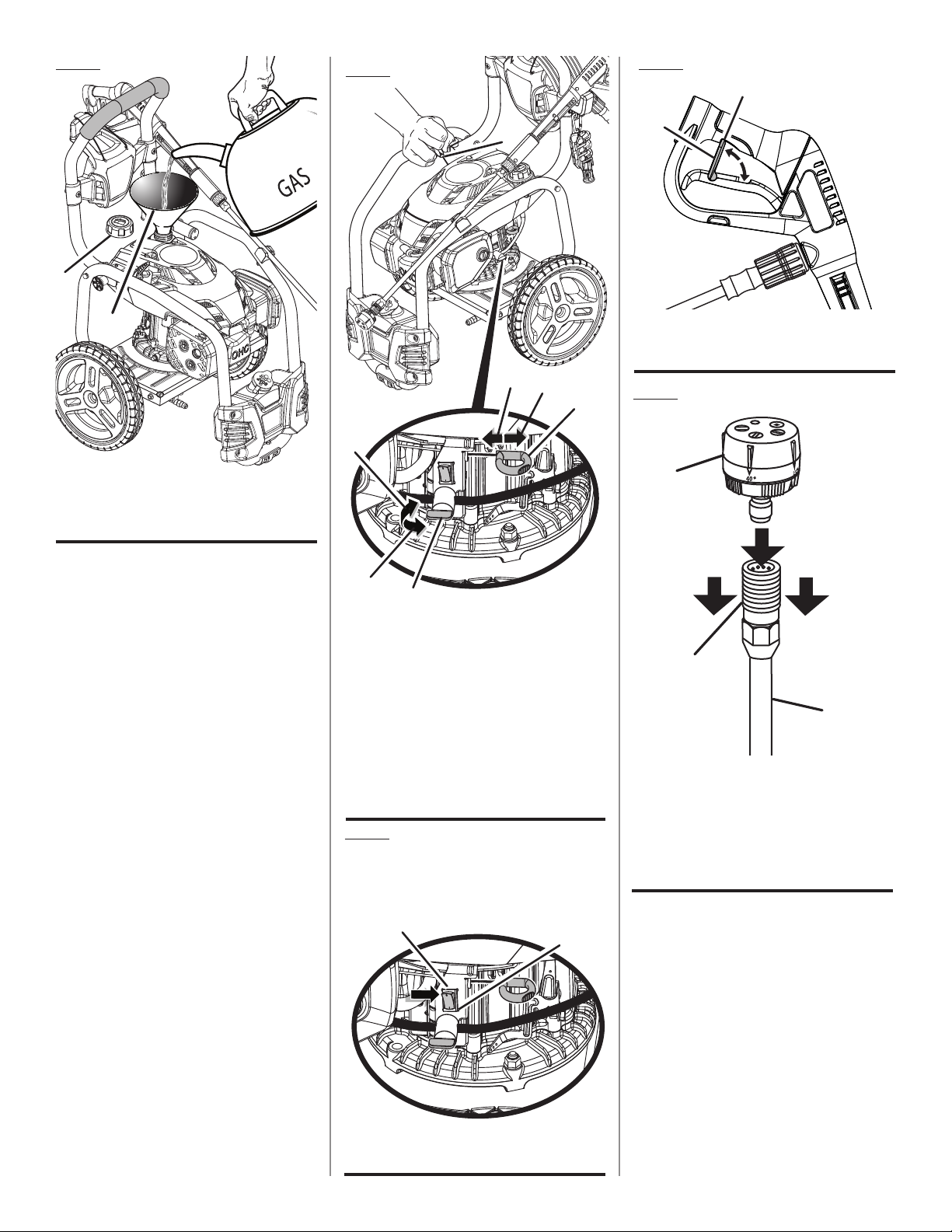

Fig. 1

H

G

F

E

O

I

P

N

M

J

A

K

D

B

C

A - 5-in-1 Change Over Nozzle (buse à permutation 5 en 1, boquilla

intercambiable 5 en 1)

B - Injection hose with filter (flexible d’injection avec filtre, manguera de

inyección avec filtre)

C - Detergent tank (réservoir de détergent, tanque de detergente)

D - Spray wand (lance de pulvérisation, tubo rociador)

E - High pressure hose storage (rangement de la tuyau haute pression,

almacenamiento del manguera de alta presión)

F - High pressure hose (tuyau haute pression, manguera de alta presión)

G - Handle (poignée, mango)

H - Trigger handle (poignée à gâchette, mango del gatillo)

Fig. 1a

Fig. 2

H

L

I - Trigger with lock out (gâchette avec verrou, gatillo con seguro)

J - On/off switch (commutateur marche / arrêt, interruptor de

encendido/apagado)

K - Fuel valve (robinet de carburant, válvula de combustible)

L - Fuel tank (éservoir de carburant, tanque de combustible)

M - Choke lever (levier d’étrangleur, palanca del anegador, palanca del

anegador)

N - Fuel cap(bouchon du réservoir, tapa del tanque de combustible)

O - Starter grip with rope (poignée du lanceur avec corde, mango del

arrancador con cuerda)

P - Muffler (silencieux, silenciador)

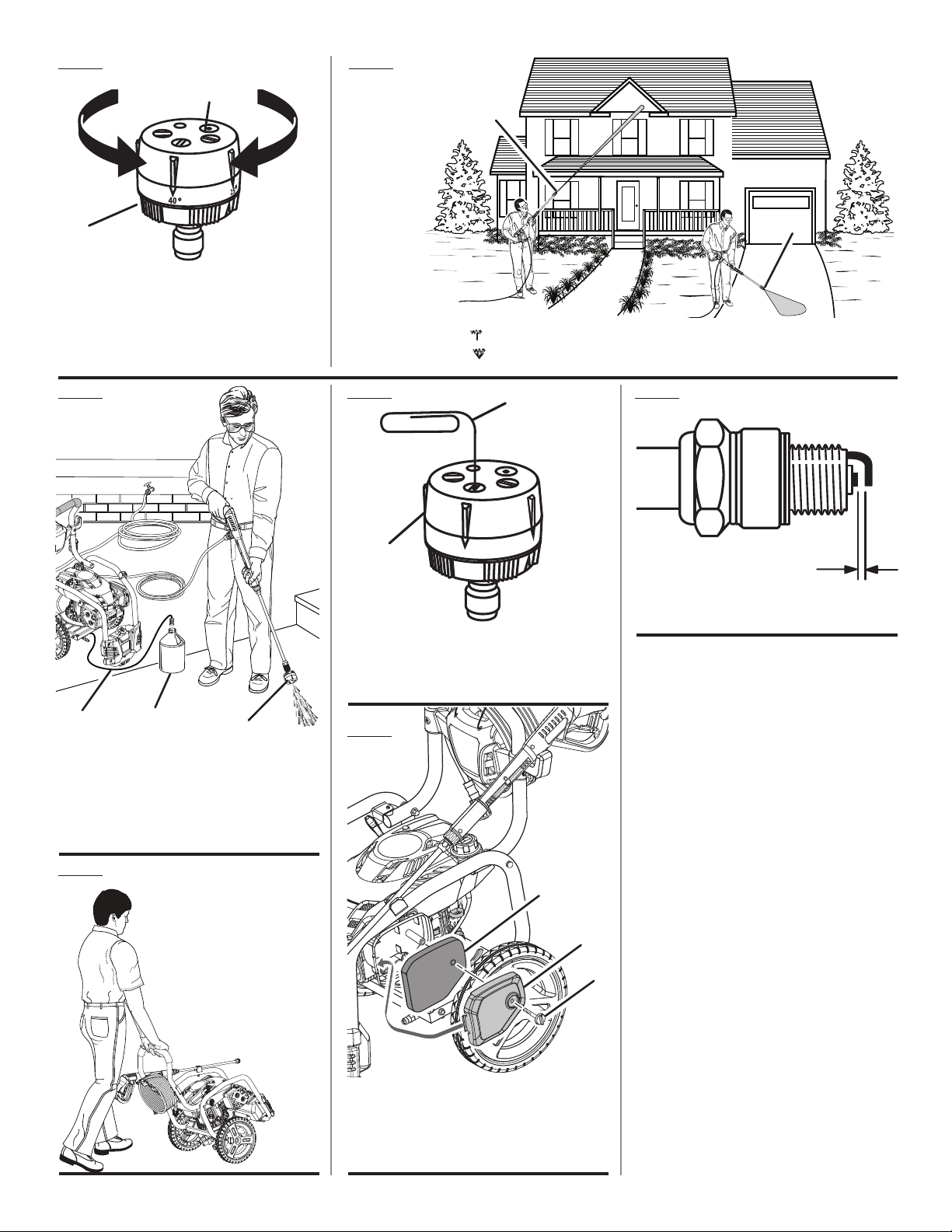

Fig. 3

A

B

A - Phillips screwdriver (tournevis phillips,

destornillador phillips)

B - Combination wrench (clé mixte, llave de

combinación)

A

A - Handle release knob (bouton de dégagement

de la poignée, perilla de liberación del

mango)

ii

C

B

D

F

D

A

A - Bolt (boulon, perno)

B - Hose storage (entreposage de la tuyau,

almacenamiento del manguera)

C - Handle (guidon, mango)

D - Hex nut (écrou hexagonal, tuerca hexagonal)

E - Trigger handle holder (support de la poignée

à gâchette, almacenamiento de mango del

gatillo)

F - Washer (rondelle, arandela)

E

Page 4

Fig. 4 Fig. 7 Fig. 10

A

C

B

A

A

B

A - High pressure hose (tuyau haute pression,

A - Hex nut (écrou hexagonal, tuerca hexagonal)

B - Spray wand holder (support de la lance

d’arrosage, soporte del tubo rociador)

C - Screw (vis, tornillo)

manguera de alta presión)

B - Collar (collier, collarín)

Fig. 8

Fig. 5

A

B

C

A - Trigger handle (poignée à gâchette, mango

del gatillo)

B - Connector (connecteur, conector)

C - Spray wand (lance de pulvérisation, tubo

rociador)

Fig. 6

C

B

A

A - Water intake (rise d’eau, entrada de agua)

B - Screen (tamis, cedazo)

C - Garden hose (tuyau d’arrosage, manguera de

jardín)

Fig. 9

A

B

A - Detergent tank cap (bouchon du réservoir de

détergent, tapa del depósito de detergente)

B - Filter (filtre, filtro)

C - Injection hose(flexible d’injection, manguera

de inyección)

C

Fig. 11

A

B

L

I

O

B

C

A

A - Collar (collier, collar)

B - Inlet coupler (raccord d’entrée, acoplador de

entrada)

C - High pressure hose (tuyau haute pression,

manguera de alta presión)

A - Oil cap/dipstick (bouchon / jauge d’huile,

tapa del aceite con varilla de nivel)

B - Upper fill level (supérieur remplir le niveau

nivel de carga superior)

B

A - Injection hose fitting (raccord du flexible

d’injection, adaptador de la manguera de

inyección)

B - Injection hose (flexible d’injection, manguera

de inyección)

iii

Page 5

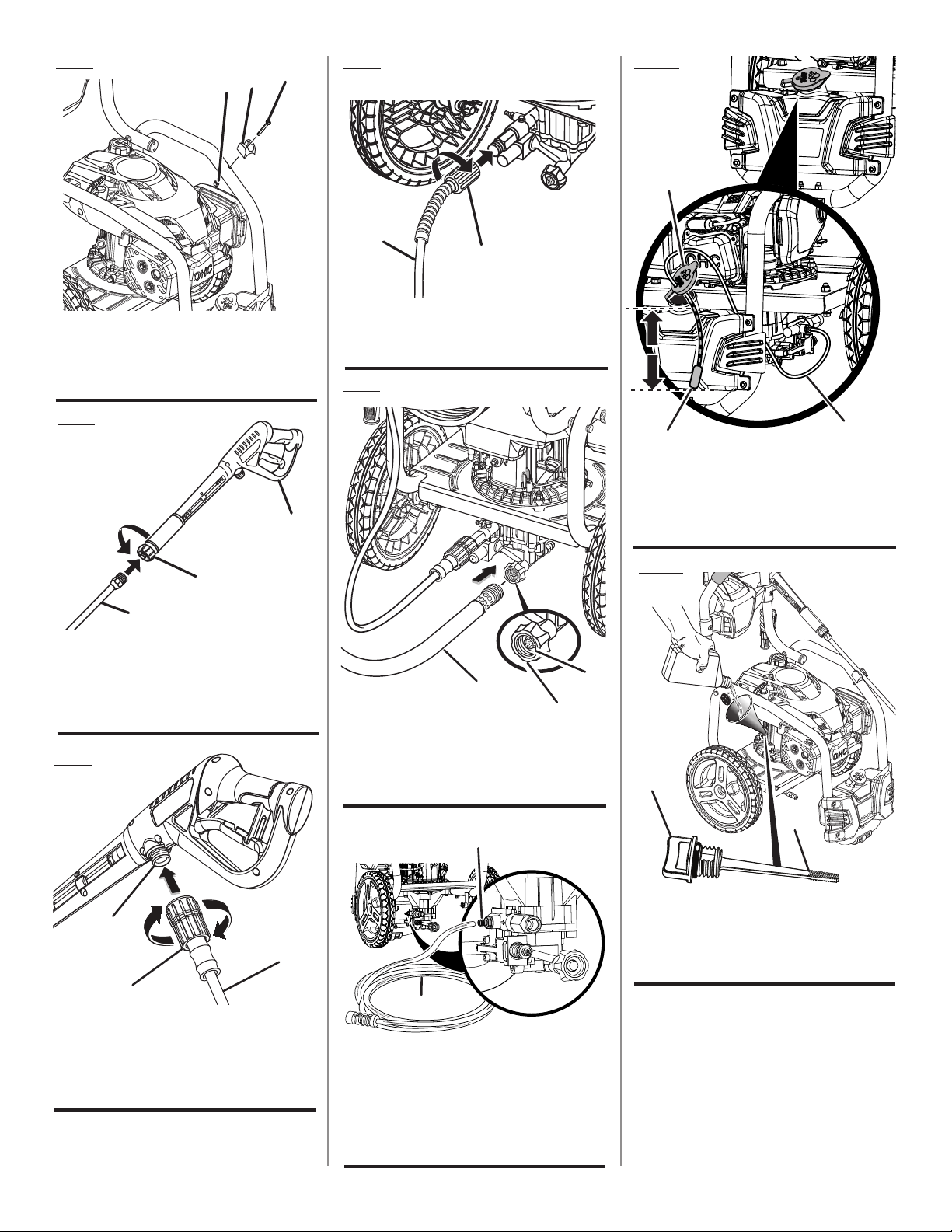

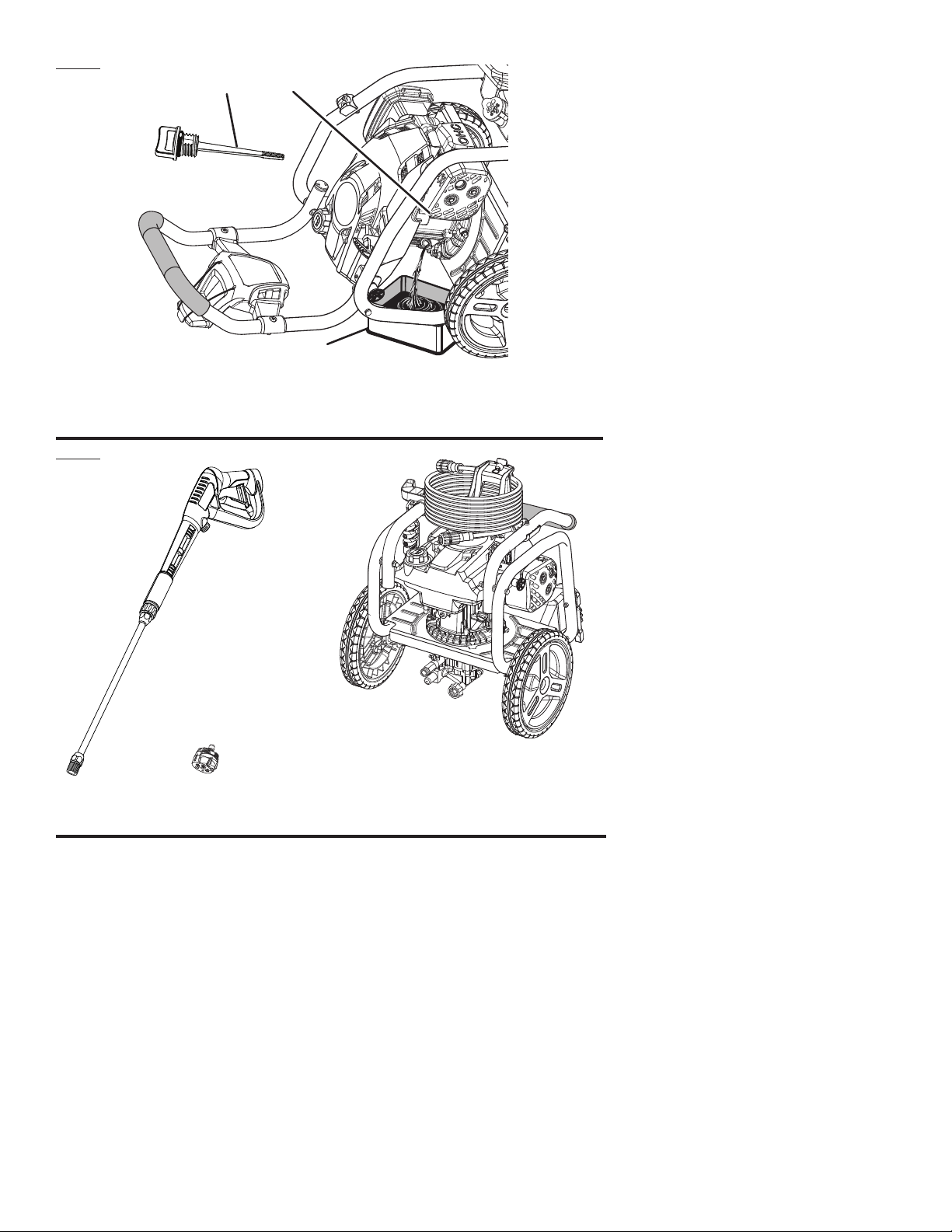

Fig. 12

B

Fig. 13

Fig. 15

A

B

A

A

A - Funnel (entonnoir, embudo)

B - Fuel cap (bouchon de carburant, tapa del

tanque de combustible)

C

D

B

E

F

A - Recoil starter (lanceur à rappel, arrancador

B - Choke (volet de départ, anegador)

C - Start (démarrage, arranque)

D - Run (marche, marcha)

E - On (marche, encendido)

F - Off (d’arrêt, apagado)

G - Fuel valve (robinet de carburant, válvula de

G

retráctil)

combustible)

A - Slot (fente, ranura)

B - Lock out (bouton de verrouillage, seguro)

Fig. 16

A

B

C

D

Fig. 14

ON/OFF SWITCH

COMMUTATEUR MARCHE / ARRÊT

INTERRUPTOR DE ENCENDIDO Y APAGADO

B

A

A - ON position (marche, encendido)

B - OFF position (arrêt, apagado)

iv

A - 5-in-1 Change Over Nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

B - “Click” (déclic, hasta que trabe)

C - Quick-connect collar (casquillo de conexión

rápida)

D - Spray wand (tubo rociador)

Page 6

Fig. 17

Fig. 18

B

A

A

A - 5-in-1 Change Over Nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

B - Spray selector (spray selector, spray

selector)

A - Soap Long Range [ ] (détergent à longue portée, largo plazo)

B - Soap Short Range [ ](détergent à courte portée, corto plazo)

Fig. 21Fig. 19

A

Fig. 23

B

A - 0.030 in. [0,762 mm (0,030 pulg)]

A - Paper clip (pièces de papier, clips de papel)

B - 5-in-1 Change Over Nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

B

A

B

A

C

A - Detergent container (réservoir de détergent,

recipiente del detergente)

B - Injection hose (flexible d’injection, manguera

de inyección)

C - 5-in-1 Change Over Nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

Fig. 20

MOVING THE PRESSURE WASHER

DÉPLACEMENT DE LA MACHINE

PARA MOVER LA MÁQUINA

Fig. 22

C

B

A

A - Air filter knob (bouton de filtre à air, perilla

del filtro de aire)

B - Air filter cover (couvercle du filtre à air, tapa

del filtro de aire)

C - Air filter (filtre à air, filtro de aire)

v

Page 7

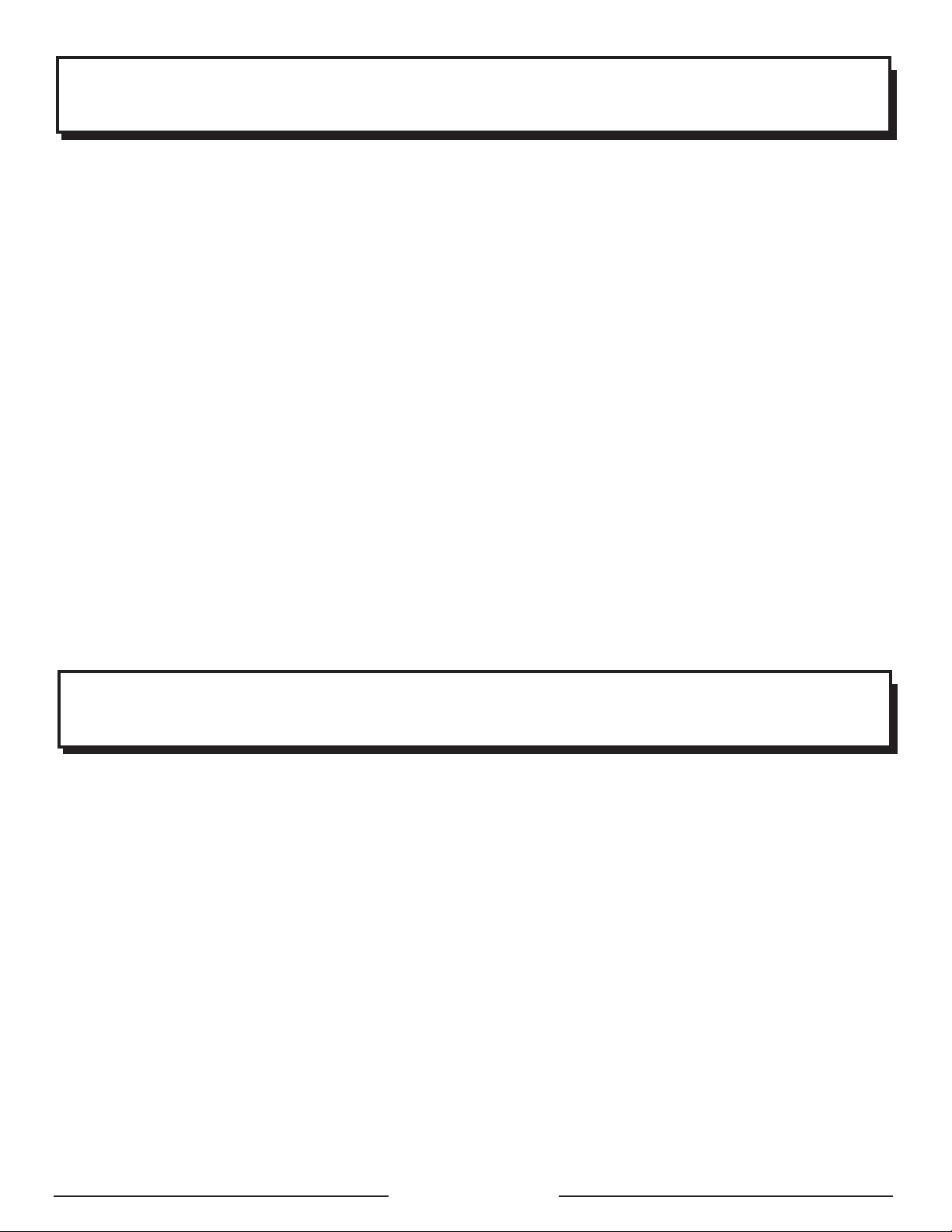

Fig. 24

BA

L

I

O

C

A - Oil cap/dipstick (bouchon/jauge d’huile, tapa del aceite con varilla de nivel)

B - Oil fill hole (orifice de remplissage d’huile, agujero de llenado de aceite)

C - Container (récipient, recipiente)

Fig. 25

TO STORE THE MACHINE

REMISAGE DE LA MACHINE

PARA GUARDAR LA MÁQUINA

vi

Page 8

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction ......................................................................................................................................................................2

Introduction / Introducción

Important Safety Instructions ........................................................................................................................................... 3

Règles de sécurité générales / Reglas de seguridad generales

Specific Safety Rules ........................................................................................................................................................ 4

Règles de sécurité particulières / Reglas de seguridad específicas

Symbols .........................................................................................................................................................................5-6

Symboles / Símbolos

Features ............................................................................................................................................................................7

Caractéristiques / Características

Assembly .......................................................................................................................................................................7-9

Assemblage / Armado ...............................................................................................................................................................7-9 / 8-9

Operation ...................................................................................................................................................................10-13

Utilisation / Funcionamiento .................................................................................................................................................9-13 / 9-12

Maintenance ..............................................................................................................................................................13-15

Entretien / Mantenimiento

Troubleshooting .............................................................................................................................................................. 16

Dépannage / Solución de problemas

Warranty ....................................................................................................................................................................17-21

Garantie / Garantía

Parts Ordering and Service ...............................................................................................................................Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ......................................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIÓN

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

* * *

Ce produit offre de nombr euses fonctions destinées à r endre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el diseño de este producto

se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo cual se facilita su manejo y mantenimiento.

Page 2 — English

Page 9

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock,

fire and/or carbon monoxide poisoning which will cause

death or serious personal injury.

READ ALL INSTRUCTIONS

Know your tool. Read the operator’s manual carefully.

Learn the machine’s applications and limitations as well

as the specific potential hazards related to this tool.

Keep guards in place and in working order. Never oper-

ate the tool with any guard or cover removed. Make sure

all guards are operating properly before each use.

Remove adjusting keys and wrenches. Form habit of

checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

To reduce the risk of injury, keep children and visitors

away. All visitors should wear safety glasses and be kept

a safe distance from work area.

Keep the area of operation clear of all persons,

particularly small children, and pets.

Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

Carbon monoxide, a colorless, odorless, and extremely

dangerous gas, can cause unconsciousness or death.

Use right tool. Don’t force tool or attachment to do a

job it was not designed for. Don’t use it for a purpose not

intended.

Dress properly. Do not wear loose clothing, gloves,

neckties, or jewelry. They can get caught and draw you

into moving parts. Rubber gloves and nonskid footwear

are recommended when working outdoors. Also wear

protective hair covering to contain long hair.

Do not operate the equipment while barefoot or when

wearing sandals or similar lightweight footwear. Wear

protective footwear that will protect your feet and improve

your footing on slippery surfaces.

Exercise caution to avoid slipping or falling.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1. Following this rule will reduce the risk of serious personal injury.

Don’t overreach or stand on unstable support. Keep

proper footing and balance at all times.

Use only recommended accessories. The use of

improper accessories may cause risk of injury.

Follow the maintenance instructions specified in this

manual.

Check damaged parts. Before further use of the

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

Never leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

Keep the engine free of grass, leaves, or grease to

reduce the chance of a fire hazard.

Keep the exhaust pipe free of foreign objects.

Follow manufacturer’s recommendations for safe

loading, unloading, transport, and storage of

machine.

Be thoroughly familiar with controls. Know how to stop

the product and bleed pressure quickly.

Keep tool dry, clean, and free from lubricant and

grease. Always use a clean cloth when cleaning. Never use

brake fluids, gasoline, petroleum-based products, or any

solvents to clean tool.

Stay alert and exercise control. Watch what you are

doing and use common sense. Do not operate tool when

you are tired. Do not rush.

Do not operate the product while under the influence

of drugs, alcohol, or any medication.

Check the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire, or string

which can be thrown or become entangled in the

machine.

Do not use tool if switch does not turn it off. Have

defective switches replaced by an authorized service

center.

Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting.

Avoid dangerous environment. Don’t use in damp or

wet locations or expose to rain. Keep work area well

lit.

Never use in an explosive atmosphere. Normal

sparking of the motor could ignite fumes.

Do not operature while smoking or near an open

flame.

Do not operate around dry brush, twigs, cloth rags, or

other flammable materials.

WARNING: Risk of injection or injury – Do not direct

discharge stream at persons.

tool, a

Page 3 — English

Page 10

SPECIFIC SAFETY RULES

Never direct a water stream toward people or pets,

or any electrical device.

Before starting any cleaning operation, close doors

and windows. Clear the area to be cleaned of debris,

toys, outdoor furniture, or other objects that could create

a hazard.

Never pick up or carry a machine while the engine is

running.

Never start the machine if ice has formed in any part

of the equipment.

Do not use acids, alkalines, solvents, flammable

material, bleaches, or industrial grade solutions

in this product. These products can cause physical

injuries to the operator and irreversible damage to the

machine.

Always operate the machine on a level surface. If the

engine is on an incline, it could seize due to improper

lubrication (even at the maximum lubricant level).

WARNING: High pressure jets can be dangerous

if subject to misuse. The jet must not be directed at

persons, animals, electrical devices, or the machine

itself.

Hold the handle and wand securely with both hands.

Expect the trigger handle to move when the trigger is

pulled due to reaction forces. Failure to do so could cause

loss of control and injury to yourself and others.

Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by the manufacturer).

Protective covers must always cover rotating parts

when the engine is running.

Keep cooling air intake (recoil starter area) and muffler

side of the engine at least 3 feet away from buildings,

obstructions, and other combustible objects.

Keep the engine away from flammables and other

hazardous materials.

Keep away from hot parts. The muffler and other engine

parts become very hot; use caution.

Do not touch the spark plug and ignition cable when

starting and operating the engine.

Check fuel hoses and joints for looseness and fuel

leakage before each use.

Check bolts and nuts for looseness before each use.

A loose bolt or nut may cause serious engine problems.

Always refuel outdoors. Never refuel indoors or in a

poorly ventilated area.

Never store the machine with fuel in the fuel tank

inside a building w here ignition sources are p resent,

such as hot water and space heaters, clothes dryers,

and the like.

If the fuel tank has to be drained, do this outdoors.

To reduce the risk of fire and burn injury, handle fuel

with care. It is highly flammable.

Do not smoke while handling fuel.

Add fuel before starting the engine. Never remove the

cap of the fuel tank or add fuel while the engine is running

or when the engine is hot.

Loosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

Replace all fuel tank and container caps securely.

Wipe spilled fuel from the unit. Move 30 feet away from

refueling site before starting engine.

If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

Never attempt to burn off spilled fuel under any

circumstances.

Before storing, allow the engine to cool.

Store fuel in a cool, well-ventilated area, safely away

from spark and/or flame-producing equipment.

Store fuel in containers specifically designed for this

purpose.

Empty fuel tank and restrain the unit from moving

before transporting in a vehicle.

When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

ONLY use cold water.

Make sure minimum clearance of 3 feet is maintained

from combustible materials.

Never spray close to the surface to be cleaned as you

can damage the surface.

After stopping the engine, always pull the trigger on

the trigger handle to relieve stored pressure in the

high pressure hose. Failure to do so could result in seri-

ous personal injury.

For outdoor use only.

Ensure the high pressure hose is properly connected

before using the product.

Save these instructions. Refer to them frequently and

use them to instruct other users. If you loan someone this

tool, loan them these instructions also.

Page 4 — English

Page 11

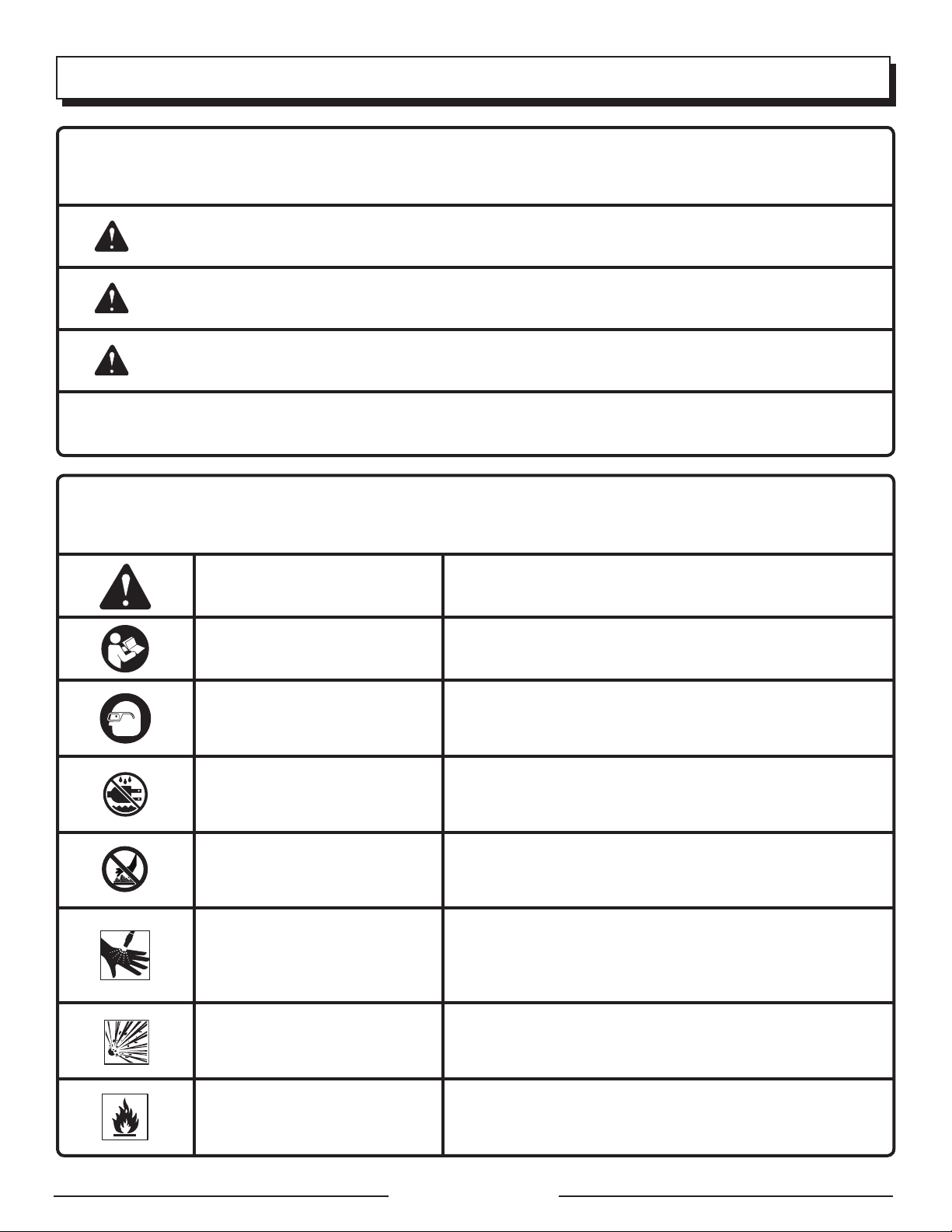

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

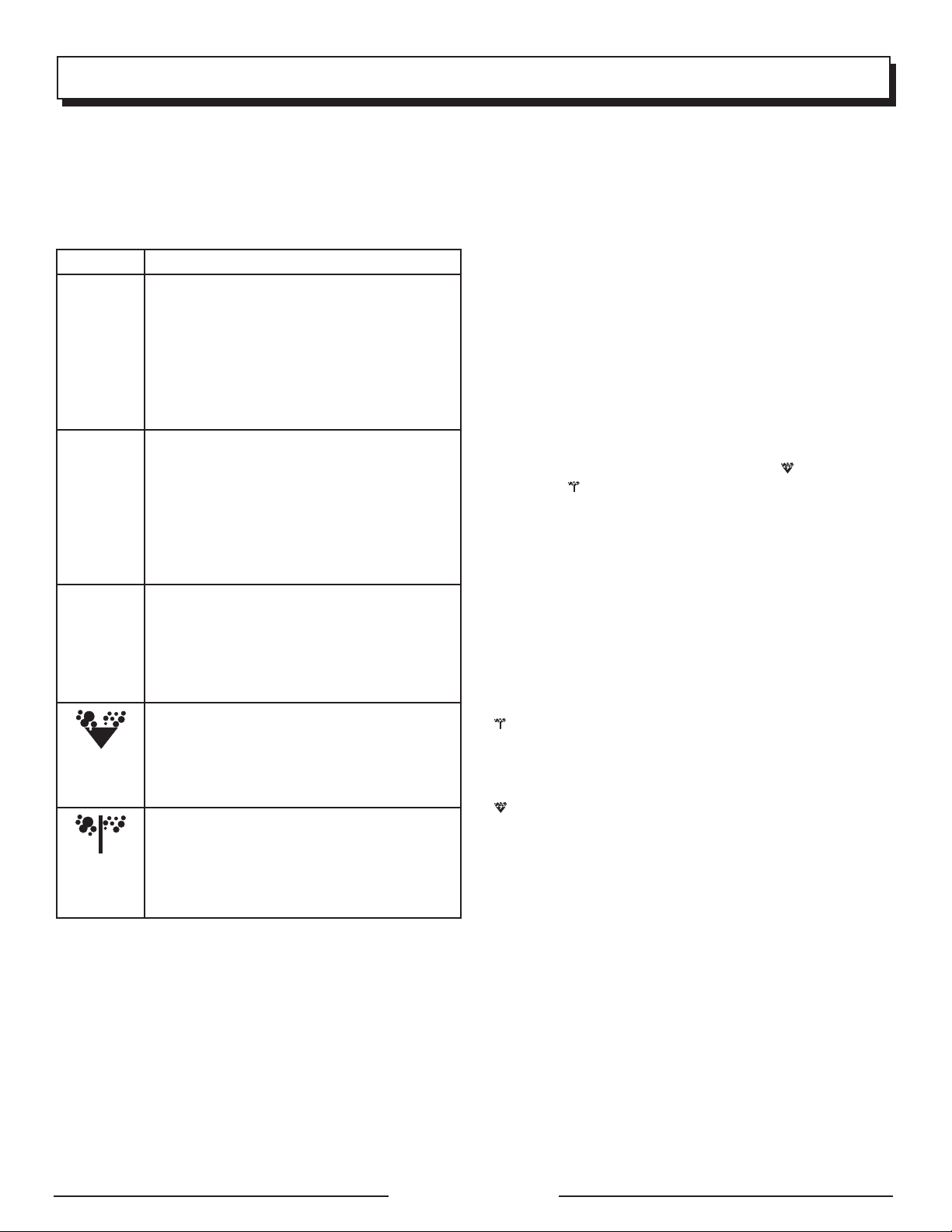

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Some of the following symbols may be used on this pr oduct. Please study them and lear n their meaning for safe

operation of this product.

SYMBOL NAME EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Indicates an imminently hazar dous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

To reduce the risk of injury, user must r ead and understand

operator’s manual before using this product.

Eye Protection

Wet Conditions Alert Do not expose to rain or use in damp locations.

Hot Surface

Risk of Injections

Risk of Explosion

Risk of Fire

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

To reduce the risk of injury or damage, avoid contact with any

hot surface.

To reduce the risk of injection or injury, never dir ect a water

stream towards people or pets or place any body part in the

stream. Leaking hoses and fittings are also capable of causing

injection injury. Do not hold hoses or fittings.

Fuel and its vapors are explosive and can cause severe burns

or death.

Fuel and its vapors are extremely flammable and explosive. Fire

can cause severe burns or death.

Page 5 — English

Page 12

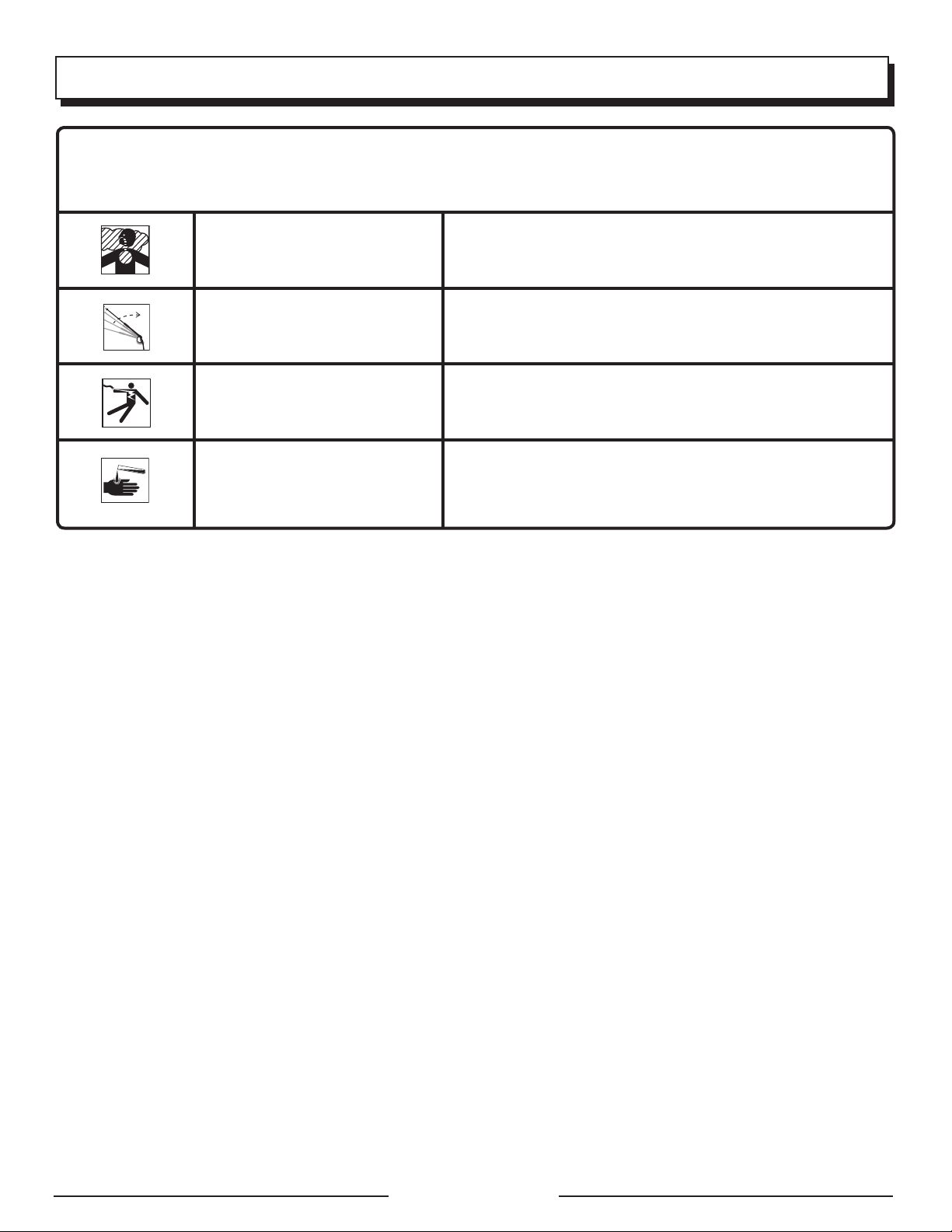

SYMBOLS

Some of the following symbols may be used on this pr oduct. Please study them and lear n their meaning for safe

operation of this product.

SYMBOL NAME EXPLANATION

Gas products emit carbon monoxide, an odorless, colorless,

Toxic Fumes

poison gas. Breathing carbon monoxide can cause nausea,

fainting, or death.

Kickback

Electric Shock

Chemical Burns

To reduce the risk of injury from kickback, hold the spray wand

securely with both hands when the machine is on.

Failure to use in dry conditions and to observe safe practices

can result in electric shock.

To reduce the risk of injury or damage, DO NOT USE ACIDS,

ALKALINES, BLEACHES, SOLVENTS, FLAMMABLE MATERIAL,

OR INDUSTRIAL GRADE SOLUTIONS in this product.

Page 6 — English

Page 13

FEATURES

PRODUCT SPECIFICATIONS

Fuel Tank Capacity .................................................................................................................................................... 0.22 gal.

Oil capacity ....................................................................................................................................................................20 oz.

Maximum Pounds Per Square Inch Pressure* .........................................................................................................2,700 psi

Maximum Gallons Per Minute* ...................................................................................................................................2.4 gpm

Maximum Inlet Water Temperature ................................................................................................................................104˚F

*Max. rating determined by PWMA Standard 101

KNOW YOUR PRESSURE WASHER

See Figure 1.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

5-IN-1 CHANGE OVER NOZZLE

The 5-in1 Change Over Nozzle makes it easy to change

spray patterns.

FUEL TANK

This fuel tank has a maximum capacity of 0.22 gal. Use

unleaded automotive gasoline in the engine.

FUEL VALVE

The fuel valve must be open to start the engine and should

always be closed before storing the machine.

HOSE STORAGE

Once the high pressure hose is rolled, hang it on the back of

the machine using the hook-and-loop strap to secure in place.

ON/OFF SWITCH

The on/off switch is used in combination with the starter

grip and rope to start the engine. It is also used to turn the

engine off.

STARTER GRIP WITH ROPE

The starter grip with rope is pulled to start the machine.

SPARK ARRESTOR

This engine is not factory equipped with a spark arr estor.

In some areas it is illegal to operate an engine without a spark

arrestor. A spark arr estor is available by calling customer

service for assistance.

THERMAL RELIEF VALVE

This pump feature will pr event water temperatur es fr om

reaching harmful levels by r eleasing a small amount of

water. Once the water has drained, the thermal relief valve

will reset itself.

TRIGGER HANDLE

The trigger handle has a gripping surface that provides added

control of the spray wand and helps reduce fatigue.

TRIGGER WITH LOCK OUT

Pulling the trigger r eleases a str eam of water for high

pressure cleaning. The lock out provides protection against

unauthorized use.

TOOLS NEEDED

The following tools (not included or drawn to scale) are needed for assembly:

See Figure 1a.

7/16 in. wrench

Phillips head screwdriver

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

Page 7 — English

WARNING:

Do not use this product if any parts on the Packing List

are already assembled to your product when you unpack

it. Parts on this list are not assembled to the product by

the manufacturer and require customer installation. Use

of a product that may have been improperly assembled

could result in serious personal injury.

Page 14

ASSEMBLY

NOTE: This tool is heavy. To avoid back injury, lift with

your legs, not your back, and get help when needed.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, p lease c all

1-800-242-4672 for assistance.

PACKING LIST

Pressure Washer

25 ft. High Pressure Hose

Trigger Handle Holder

Trigger Handle

Screw (1/4-20 x 1.65 in., Pan Hd.)

Screw (1/4-20 x 1.85 in. Pan Hd.)

Screw (1/4-20 x 2.27 in. Pan Hd.)

Spray Wand

5-in-1 Change Over Nozzle

Injection Hose plus Filter

Flat Washer

4-Cycle Engine Lubricant (SAE 30 or SAE 10W30)

Hose Storage

Operator’s Manual

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could r esult in serious

personal injury.

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

RAISING AND LOWERING THE HANDLE

See Figure 2.

To raise the handle (for moving the pressure washer): pull

the handle up until the handle release knob snaps into

locking position. Ensure the lock is secured in the frame

hole before moving.

To lower the handle (for storing or transporting the pres-

sure washer): pull the handle release knob out and lower

the handle to the down position.

NOTE: The handle can not be locked in the down posi-

tion.

Never use the handle to lift the pressure washer. The handle

should only be used for moving the unit by r olling it on its

wheels.

INSTALLING HOSE STORAGE, TRIGGER

HANDLE HOLDER, AND SPRAY WAND HOLDER

See Figures 3 - 4.

Raise handle as described in the Raising and Lowering

Handle section.

Place hose storage onto the handle as shown.

Align the holes in the hose storage with the holes in the

handle.

Insert bolt (1/4-20 x 1.65 in.) through the holes in the left

side of the handle and hose storage.

Place nut onto bolt and tighten.

Place the trigger handle holder onto the handle as shown.

Align the holes in the trigger handle holder with the holes

in the hose storage and the handle.

Insert bolt (1/4-20 x 2.27 in.) through the holes in handle,

hose storage, and trigger handle holder.

Turn bolt while holding the nut in place to tighten and

secure.

Place spray wand holder onto pressure washer frame.

Align the holes in the spray wand holder with the holes

in the pressure washer frame.

Insert screw (1/4-20 x 1.85 in.) through the holes in the

spray wand holder and the pressure washer frame.

Place nut onto screw and tighten.

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug when assembling parts.

Page 8 — English

ASSEMBLING THE SPRAY WAND TO THE

TRIGGER HANDLE

See Figure 5.

Place the threaded end of the spray wand in the connector

on the end of the trigger handle.

Turn the connector clockwise until it stops. This secures

the spray wand in place.

Page 15

ASSEMBLY

CONNECTING HIGH PRESSURE HOSE TO

TRIGGER HANDLE

See Figure 6.

Screw the collar o n t he high pressure hose into the

trigger handle inlet coupler by turning the hose collar

clockwise.

Pull on the hose to be certain it is properly secured.

CONNECTING THE HIGH PRESSURE HOSE TO

THE PUMP

See Figure 7.

After the high pressure hose has been uncoiled and attached

to the spray wand:

Align the collar on the threaded nipple on the pump.

Insert the nozzle on the end of the high pressure hose

collar into the threaded nipple.

Turn the collar clockwise to tighten the hose securely to

the pump.

Pull on the hose to be certain it is properly secured.

CAUTION:

Do not run the pressure washer pump without water supply connected and tur ned on, as this may damage the

high pressure seals and decrease pump life. Completely

unwind the hose from its reel or coil and make sure the

hose is not being restricted by tires, rocks, or any other

objects that may lessen or prevent water flow to the

pressure washer.

To connect the garden hose to the machine:

Uncoil the garden hose.

NOTE: There must be a min imum of 10 feet of

unrestricted hose between the pressure washer intake and

the hose faucet or shut off valve (such as a “Y” shut off

connector).

With the hose faucet turned completely off, attach the

end of the garden hose to the water intake. Tighten by

hand.

ATTACHING INJECTION HOSE

See Figures 9 - 10.

Before detergent can be used with this machine, the injection

hose must be attached.

Push the open end of the clear injection hose securely

over the fitting on the back of the unit.

NOTE: Keep injection hose away from hot surfaces.

Open the cap on the detergent tank.

Remove the filter from the injection hose.

From the top of the cap, slide the injection hose through

the hole in the cap.

Push the injection hose filter onto the end of the injec-

tion hose and pull enough hose through the cap so the

injection hose filter will rest at the bottom of the detergent

tank.

Close the cap on the detergent tank.

CONNECTING THE GARDEN HOSE TO THE

PRESSURE WASHER

See Figure 8.

CAUTION:

Always observe all local regulations when connnecting

hoses to the water main. Some areas have restrictions

against connecting directly to public drinking water supply to prevent the feedback of chemicals into the drinking

water supply. Direct connection through a receiver tank

or backflow preventer is usually permitted.

The water supply must come from a water main. NEVER

use hot water or water fr om pools, lakes, etc. Befor e

connecting the garden hose to the pressure washer:

Run water through the hose for 30 seconds to clean any

debris from the hose.

Inspect the screen in the water intake.

If the screen is damaged, do not use the machine until

the screen has been replaced.

If the screen is dirty, clean it before connecting the garden

hose to the machine.

Page 9 — English

Page 16

OPERATION

WARNING:

Do not allow familiarity with this pr oduct to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

WARNING:

Do not use any attachments or accessories not recommended by the manufacturer of this product. The use of

attachments or accessories not recommended can result

in serious personal injury.

WARNING:

Never direct a water stream toward people or pets, or

any electrical device. Failure to heed this warning could

result in serious injury.

APPLICATIONS

You may use this tool for the purposes listed below:

Removing dirt and mold from decks, cement patios, and

house siding

Cleaning boats, outdoor furniture, and grills

ADDING LUBRICANT TO THE ENGINE

See Figure 11.

NOTE: This machine has been shipped with approximately

2 oz. of lubricant in the engine from testing. You must add

lubricant to the engine before starting it the first time.

CAUTION:

Any attempt to start the engine without adding lubricant

will result in engine failure.

Place pressure washer on a flat, level surface.

Unscrew the lubricant cap / dipstick by turning counter-

clockwise.

Using 4-stroke engine lubricant (SAE 30 or SAE 10W30),

add engine lubricant until the fluid level rises to the upper portion of the hatched area on the dipstick (18 oz.,

4-cycle engine lubricant provided). Do not overfill.

Replace the lubricant cap / dipstick and securely tighten.

NOTE: This engine has a total lubricant capacity of 20 oz.

OXYGENATED FUELS

DO NOT USE E85 FUEL. IT WILL VOID YOUR WARRANTY.

NOTE: Fuel system damage or performance problems re-

sulting from the use of an oxygenated fuel containing more

than the percentages of oxygenates stated below are not

covered under warranty.

Ethanol. Gasoline containing up to 10% ethanol by volume

(commonly referred to as E10) is acceptable. E85 is not.

ADDING GASOLINE TO THE FUEL TANK

See Figure 12.

WARNING:

Gasoline and its vapors are highly flammable and

explosive. To prevent serious personal injury and pr operty damage, handle gasoline with care. Keep away from

ignition sour ces, handle outdoors only, do not smoke

while adding fuel, and wipe up spills immediately.

When adding gas to the pressure washer, make sure the unit

is sitting on a flat, level surface. If the engine is hot, let the

pressure washer cool before adding gas. ALWAYS fill the

fuel tank outdoors with the machine turned off.

NOTE: Use unleaded gas only. DO NOT mix lubricant with gas.

Before removing the fuel cap, clean the area around it.

Remove the fuel cap.

Insert a clean funnel into the fuel tank then slowly

pour gasoline into the tank. Fill tank to approximately

1-1/2 in. below the top of the tank neck (this allows for

fuel expansion).

Replace fuel cap and tighten until the cap “clicks”.

Clean up any spills before starting the engine.

WARNING:

Always shut off engine before fueling. Never add fuel to

a machine with a running or hot engine. Move at least

30 ft. from refueling site before starting engine. Do not

smoke and stay away fr om open flames and sparks!

Failure to follow these instructions could result in serious

personal injury.

Page 10 — English

Page 17

OPERATION

STARTING AND STOPPING THE PRESSURE

WASHER

See Figures 13 - 14.

CAUTION:

Do not run the pressure washer pump without water supply connected and tur ned on, as this may damage the

high pressure seals and decrease pump life. Completely

unwind the hose from its reel or coil and make sure the

hose is not being restricted by tires, rocks, or any other

objects that may lessen or prevent water flow to the

pressure washer.

Before starting the engine:

Connect all hoses.

Check all fluids (lubricant and gas).

Turn on the garden hose then squeeze the trigger to

relieve air pressure; hold the trigger until a steady stream

of water appears.

To start the engine:

Turn the fuel valve to the ON position.

Put the on/off switch in the ON position.

Push choke into the START position.

Grasp the starter grip with rope and pull slowly until

resistance is felt. Give the starter grip with rope a short,

brisk pull to start the engine.

NOTE: Do not allow the starter grip with rope to snap

back after starting; return it gently to its original place.

CAUTION:

If the engine does not start after each pull of the starter

grip with rope, squeeze the trigger to relieve water pressure before attempting to start the engine again.

Let engine run for several seconds, then gradually slide

the choke lever fully toward the RUN position.

To stop the engine:

Put the on/off switch in the OFF position.

Turn the fuel valve to the OFF position.

Shut off the water supply and pull trigger to release

water pressure.

USING THE SPRAY WAND TRIGGER

See Figure 15.

Pull back and hold the trigger to operate the pressure

washer.

Release the trigger to stop the flow of water through the

nozzle.

To engage the lock out:

Push up on the lock out until it clicks into the slot.

To disengage the lock out:

Push the lock out down and into its original position.

For the most effective cleaning, the spray nozzle should be

between 8 in. and 24 in. fr om the surface to be cleaned. If

the spray is too close it can damage the cleaning surface.

INSTALLING/REMOVING NOZZLES

See Figure 16.

WARNING:

NEVER change nozzles or spray patterns without locking the lock out on the trigger handle and NEVER point

the wand at your face or at others. The quick-connect

feature contains small springs that could eject the nozzle

with some force. Failure to heed this may cause personal

injury.

Using the quick-connect collar, changing the nozzle is easy.

To connect the nozzle to the trigger handle:

Turn off the pressure washer and shut off the water

supply. Pull trigger to release water pressure.

Engage the lock out on the trigger handle by pushing up

on the lock out until it clicks into the slot.

Push the nozzle into the quick-connect collar until it clicks

in place and is secured properly.

To disconnect a nozzle from the trigger handle once the

cleaning job is complete:

Turn off the pressure washer and shut off the water

supply. Pull trigger to release water pressure.

Engage the lock out on the trigger handle by pushing up

on the lock out until it clicks into the slot.

Remove the nozzle by placing hand over nozzle then

pulling back the quick-connect collar.

WARNING:

Hold the handle and wand securely with both hands. Expect the trigger handle to move when the trigger is pulled

due to reaction forces. Failure to do so could cause loss

of control and injury to yourself and others.

Page 11 — English

Page 18

OPERATION

USING THE 5-IN-1 CHANGE OVER NOZZLE

See Figure 17.

There are five spray pattern settings located on the 5-in-1

Change Over Nozzle. To select a spray pattern, rotate the

spray selector to the desired setting.

Nozzle Application

Spot cleaning of high, hard-to-reach areas

• Removingcaked-onmudfromheavycon-

0º

25º

40º

Soap

Short

Range

Soap

Long

Range

struction, farm, or lawn equipment

• Cleaningtar,glue,orstubbornstainsfrom

concrete

• Cleaningoverheadareas

• Removing rust from steel and oxidation

from aluminum

For general purpose or large surfaces

• Generalcleaningofdirt,mud,andgrime

• Cleaningroofs,gutters,anddownspouts

• Removinglightmildewstains

• Removingalgaeandbacteriabuild-upfrom

pools

• Rinsingsurfacesinpreparationforpainting

For wide-angle rinsing

• Lightcleaningandwashing

• Washing andrinsing ofpainted surfaces

and boats

• Cleaning roofs, windows, patios, and

driveways

For short range detergent applications

• Driveways, walkways, decks andpatios,

vehicles, fences, paint prep, patio furniture,

and lawn equipment

For long range detergent applications

• Secondstorywashing

USING THE HIGH PRESSURE HOSE

The high pressure hose features an outer covering that provides strength to the hose. If the outer covering becomes

damaged, the hose must be replaced immediately. Do not

use a high pressure hose if the outer covering is damaged.

To prevent damage to the outer covering:

Inspect the hose before every use.

Fully unwrap and straighten hose before use.

Do not allow the high pressure hose to be kinked.

Keep hose away from hot surfaces and sharp edges.

Do not pull unit by high pressure hose.

Do no t allo w ho se to be crushed o r w rapped ar ound

objects.

WASHING WITH DETERGENT

See Figures 18 - 19.

Use only detergents designed for pressure washers; household detergents, acids, alkalines, bleaches, solvents, flammable material, or industrial grade solutions can damage

the pump. Many detergents may require mixing prior to use.

Prepare cleaning solution as instructed on the solution bottle.

Remove the cap from the detergent container and pour

detergent in the container. Replace cap on container.

Rotate the spray selector on the 5-in-1 Change Over

Nozzle to either the Soap Short Range [ ] or Soap Long

Range [ ] setting.

Spray the detergent on a dry surface using long, even,

overlapping strokes. To prevent streaking, do not allow

detergent to dry on the surface.

NOTE: To use a detergent bottle, open the detergent container

cap. Next, remove the filter from the end of the injection hose

then slide the hose out of the cap. Place the injection hose

filter back on the hose and place the hose in the bottom of

the bottle.

For long range detergent application:

With the nozzle installed on the spray wand and the engine

shut off, rotate the spray selector to the Soap Long Range

[

] setting.

For short range detergent application:

With the nozzle installed on the spray wand and the engine

shut off, rotate the spray selector to the Soap Short Range

[

] setting.

Before shutting off the engine:

Place the injection hose in a bucket of clean water.

Flush for 1 - 2 minutes (spray clear water through the

spray wand).

Shut off the engine.

NOTE: Shutting OFF ( O ) the engine WILL NOT relieve pres-

sure in the system. Pull trigger to release water pressure.

RINSING WITH THE PRESSURE WASHER

Turn off the pressure washer and shut off the water

supply. Pull trigger to release water pressure.

Engage the lock out on the trigger handle by pushing up

on the lock out until it clicks into the slot.

Rotate the spray selector on the 5-in-1 Change Over

Nozzle to either the [40º], [25º], or [0º] setting depending

on the job. Refer to the chart in Using the 5-in-1 Change

Over Nozzle to determine which setting is correct for

your application.

Page 12 — English

Page 19

OPERATION

When using these settings, test a small area first to avoid

surface damage.

Start at the top of the area to be rinsed and work down,

overlapping the strokes.

MOVING THE PRESSURE WASHER

See Figure 20.

NOTE: Never lift or carry this product using the handle and

never place the unit in any position other than upright on

its wheels.

Turn the pressure washer off and ensure the fuel valve is

closed.

Pull the handle up until the handle release knob snaps into

the locking position (if not already up and locked). Ensure

the lock is secured in the frame hole before moving.

Tilt the machine toward you until it balances on the wheels

then roll the machine to the desired position.

For long term storage, see Storing the Pressure Washer

in the Maintenance section of this manual.

MAINTENANCE

WARNING:

When servicin g, use only identical replacement parts.

Use of any other parts may cr eate a hazar d or cause

product damage.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

WARNING:

Before inspecting, cleaning or servicing the machine, shut

off engine, wait for all moving parts to stop, and disconnect spark plug wire and move it away from spark plug.

Failure to follow these instructions can result in serious

personal injury or property damage.

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating lubricants, etc., come in contact with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal injury.

Only the parts shown on the parts list are intended to be

repaired or replaced by the customer. All other parts should

be replaced at an authorized service center.

Before running the engine, perform the followi ng pr eoperation steps:

Check that all bolts, nuts, etc., are securely tightened.

Make sure the air filter is clean.

Check both the engine lubricant level and the fuel tank

level; refill as needed.

Inspect the work area for hazards.

If there is excessive noise o r vibration, stop the unit

immediately.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, lubricant, grease, etc.

Page 13 — English

Page 20

MAINTENANCE

NOZZLE MAINTENANCE

See Figure 21.

Excessive pump pr essure (a pulsing sensation felt while

squeezing the trigger) may be the r esult of a clogged or

dirty nozzle.

Turn off thepressure washer andshut off the water

supply. Pull trigger to release water pressure.

Removethenozzlefromthespraywand.

NOTE: Never point the spray wand at your face.

Usingastraightenedpaperclipornozzlecleaningtool

(not provided), free any foreign materials clogging or

restricting the nozzle.

Usingagardenhose,flushdebrisoutofnozzlebyback

flushing (running the water through the nozzle backwards

or from the outside to the inside).

Reconnectthenozzletothespraywand.

Turnonthewatersupplyandstarttheengine.

CLEANING THE AIR FILTER

See Figure 22.

A dirty air filter will cause starting dif ficulty, loss o f

performance, and shorten the life span of the engine. Check

the air filter monthly. For best performance, replace the air

filter at least once a year.

Unscrew air filter knob, then remove the air filter cover.

Lift the edge of the air filter carefully and pull it out.

Wash the air filter with warm, soapy water.

Rinse and squeeze to dry.

Reinstall the air filter.

NOTE: Make sure the filter is seated properly inside the

cover. Installing the filter incorrectly will allow dirt to enter

the engine, causing rapid engine wear.

Reinstall the air filter cover.

CHECKING SPARK PLUG

See Figure 23.

Clean the area around the base of the spark plug before

removing to keep dirt and debris out of the engine. Remove spark plug.

Clean off carbon deposits on the spark plug electrode

using a plug cleaner or wire brush. Replace the plug if

worn. (Recommended spark pl ug: BPR6HS (NGK) or

equivalent.)

Check electrode gap. The gap should be .03 in. (0.7- 0.8 mm).

Adjust the gap, if necessary, by carefully bending the

ground electrode.

Reinstall spark plug. Tighten securely.

CHANGING ENGINE LUBRICANT

See Figure 24.

Shut off the engine.

Clean the area around the lubricant fill cap/dipstick, then

remove the lubricant fill cap/dipstick.

Tilt the pressure washer on its side as shown. Drain lu-

bricant into approved container.

NOTE: Drain the lubricant while the engine is still warm

but not hot. Warm lubricant will drain quickly and more

completely.

After the crankcase is completely drained, return the

pressure washer to an upright position.

Fill with lubricant following the instructions in Adding

Lubricant To The Engine earlier in this manual.

NOTE: Consult hazardous waste management guidelines in

your area for the proper way to dispose of used lubricant.

PUMP LUBRICATION

The pump on this product was lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication is required.

STORING THE PRESSURE WASHER

See Figure 25.

Store the pressure washer with the gas tank empty by either

draining the tank or running the pr essure washer until the

gas runs out. Allow 30 minutes of “cool down” time before

storing the machine. Never place the unit in any position

other than upright on its wheels.

Store in a dry, covered area where the weather can’t damage it.

It is important to store this product in a frost-free area. Always

empty water fr om all hoses, the pump, and the deter gent

bucket before storing.

NOTE: Use of a fuel stabilizer and pump saver will give you

better performance and increase the life of the machine.

Discharge Fuel:

Drain the fuel tank completely . Stored gas can go stale in

30 days.

Page 14 — English

Page 21

MAINTENANCE

Engine Lubricant:

Drain the lubricant and replace with fresh, clean lubricant.

Spark Plug:

Disconnect spark plug wire and remove the spark plug.

Pour about a teaspoon of clean, air-cooled, four-cycle

lubricant through the spark plug hole into the combustion

chamber.

Leaving the spark plug out, pull the starter cord two or

three times to coat the inside of the cylinder wall.

Inspect the spark plug and clean or replace, as necessary.

Reinstall the spark plug, but leave the spark plug wire

disconnected.

Air Filter:

Clean the air filter.

Hoses and Pump:

Flush the injection hose with clean water for 1-2 minutes.

Remove all hoses. Empty the pump by pulling on the recoil

starter about 6 times. This should remove most of the liquid

from the pump.

Handle:

Pull the handle release knob out and lower the handle to

the down position.

PREPARING FOR USE AFTER STORAGE

Pull the starter grip with rope three or four times to clean

lubricant from the combustion chamber.

Remove spark plug from the cylinder. Wipe lubricant from

the spark plug and return it to the cylinder.

Reconnect the spark plug wire.

Refuel the machine as described earlier in the operator’s

manual.

PERIODIC MAINTENANCE SCHEDULE

Maintenance Items Each Use 20 hours 50 hours

Check for leakage and loose parts •

Check and refill engine lubricant •

Change engine lubricant * •

Clean spark plug •

Clean air cleaner •

Replace air cleaner element •

Clean fuel cap •

Clean and adjust spark plug and electrodes •

Replace spark plug •

Remove carbon from cylinder head ** •

Check and adjust valve clearance ** •

Clean and adjust carburetor ** •

Check fuel lines •

*Initial lubricant change should be performed after first twenty hours of operation. Thereafter change lubricant every fifty hours. Dispose

of waste lubricant safely and responsibly. Do not pour into sewage drains, onto garden soil or into open streams. Your local zoning or

environmental regulations will give you more detailed instructions on proper disposal.

**As to the procedures for these items, consult your nearest Subaru service dealer.

Page 15 — English

Page 22

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Engine fails to start No fuel in tank Fill tank

Spark plug shorted or fouled Replace spark plug

Spark plug is broken (cracked

porcelain or electrodes broken)

Ignition lead wire shorted, broken, or

disconnected from spark plug

Ignition inoperative

Engine hard to start Water in gasoline Drain entire system and refill with fresh fuel

Weak spark at spark plug Contact authorized service center

Engine lacks power Dirty air filter Clean or replace air filter

Detergent fails to mix with spray Detergent injection hose is not properly

submerged

Spray selector on the 5-in-1 Change

Over Nozzle is set to either the [40º],

[25º], or [0º] setting

Pump doesn’t produce pressure Spray selector o n t he 5-in-1 Chang e

Over Nozzle is set to either the Soap

Short Range [

[ ] setting.

Inadequate water supply Provide adequate water flow

] or Soap Long Range

Replace spark plug

Replace lead wire or attach to spark plug

Contact authorized service center

Insert injection hose into detergent

container or detergent bottle

Rotate the spray sel ector on th e 5 -in-1

Change Over Nozzle to either the Soap

Short Range [

setting

Rotate the spray sel ector on th e 5 -in-1

Change over Nozzle to either the [40º], [25º],

or [0º] setting

] or Soap Long Range [ ]

Machine doesn’t reach high

pressure

Trigger handle or spray wand leaks Check connections and / or replace trigger

handle or spray wand

Nozzle is clogged Clean nozzle

Pump is faulty

Air in line

Diameter of garden hose is too small

Water supply is restricted

Not enough inlet water

Spray s elector on the 5-in-1 Chang e

Over Nozzle is set to either the Soap

Short Range [

[ ] setting.

] or Soap Long Range

Contact authorized service center

Squeeze trigger on trigger handle to

remove air from line

Replace with 3/4 in. garden hose

Check garden hose for kinks, leaks, and

blockages

Open water source full force

Rotate the spray sel ector on th e 5 -in-1

Change Over Nozzle to either the [40º], [25º],

or [0º] setting

Page 16 — English

Page 23

WARRANTY

FEDERAL EMISSIONS COMPONENT DEFECT WARRANTY

EMISSIONS COMPONENT DEFECT WARRANTY COVERAGE - This emission warranty is applicable in all States, except

the State of California.

Fuji Heavy Industries Ltd. and Robin America Inc., Lake Zurich, Illinois, (herein “ROBIN AMERICA”) warrant(s) to the initial retail purchaser

and each subsequent owner, that this Nonroad engine (herein “engine”) has been designed, built, and equipped to conform at the time

of initial sale to all applicable regulations of the U.S. Environmental Protection Agency (EPA), and that the engine is fr ee of defects in

materials and workmanship which would cause this engine to fail to conform with EPA regulations during its warranty period.

For the components listed under PARTS COVERED, the service dealer authorized by ROBIN AMERICA will, at no cost to you, make the

necessary diagnosis, repair, or replacement necessary to ensure that the engine complies with applicable U.S. EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to

the initial purchaser and continues for a period of 3 years.

PARTS COVERED

Listed below are the parts covered by the Emission Components

Defect W arranty. Some of the parts listed below may require

scheduled maintenance and are warranted up to the first scheduled

replacement point for that part.

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or pressure regulator

or fuel injection system).

(ii) Air/fuel ratio feedback and control system, if applicable.

(iii) Cold start enrichment system, if applicable.

(iv) Regulator assembly (gaseous fuel, if applicable)

(2) Air Induction System

(i) Intake manifold, if applicable

(ii) Air filter.

(3) Ignition System

(i) Spark plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system, if applicable.

(4) Exhaust manifold, if applicable

(5) Miscellaneous Items Used in Above Systems.

(i) Electronic controls, if applicable

(ii) Hoses, belts, connectors, and assemblies.

(iii) Filter lock assembly (gaseous fuel, if applicable)

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest authorized Robin America service dealer. Bring your sales receipts

indicating date of pur chase for this engine. The service dealer

authorized by ROBIN AMERICA will perform the necessary repairs

or adjustments within a reasonable amount of time and furnish you

with a copy of the repair order. All parts and accessories replaced

under this warranty become the pr operty of ROBIN AMERICA.

WHAT IS NOT COVERED*

* Conditions resulting from tampering, misuse, improper adjustment

(unless they were made by the service dealer authorized by ROBIN

AMERICA during a warranty repair), alteration, accident, failure

to use the recommended fuel and lubricant, or not performing required

maintenance services.

* The replacement parts used for required maintenance services.

* Consequential damages such as loss of time, inconvenience, loss

of use of the engine or equipment, etc.

* Diagnosis and inspection charges that do not result in warranty-

eligible service being performed.

* Any non-authorized replacement part, or malfunction of authorized

parts due to use of non-authorized parts.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner , you are responsible for the performance

of the required maintenance listed in your owner’s manual.

ROBIN A MERICA r ecommends t hat y ou r etain all r eceipts

covering maintenance on your engine, but ROBIN AMERICA

cannot deny warranty solely for the lack of r eceipts or for your

failure to ensur e the performance of all scheduled maintenance.

As the engine owner, you should however be aware that ROBIN

AMERICA may deny warranty coverage if your engine or a part

has failed due to abuse, neglect, impr oper maintenance, or

unapproved modifications.

You are responsible for presenting your engine to the nearest service

dealer authorized by ROBIN AMERICA when a problem exists.

If you have any questions r egarding your warranty rights and

responsibilities, you should contact the Robin America customer

service department at 1-630-350-8200 for the information.

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY MAINTENANCE AND REPAIRS

You are responsible for the proper maintenance of the engine. You

should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise.

These receipts and maintenance records should be transferred to

each subsequent owner of the engine. ROBIN AMERICA reserves

the right to deny warranty coverage if the engine has not been

properly maintained. Warranty claims will not be denied, however,

solely because of the lack of required maintenance or failure to

keep maintenance records.

MAINTENANCE, R EPLACEMENT, O R RE PAIR O F E MISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED

BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER,

WARRANTY REPAIRS MUST BE PERFORMED BY A SER VICE

DEALER AUTHORIZED BY ROBIN AMERICA. THE USE OF

PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MA Y

HAVE A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by ROBIN AMERICA are used for

maintenance replacements or for the repair of components affecting emission control, you should assur e yourself that such parts

are warranted by their manufacturer to be equivalent to the parts

authorized by ROBIN AMERICA in their performance and durability.

HOW TO MAKE A CLAIM

All repair qualifying under this limited warranty must be performed

by a service dealer authorized by ROBIN AMERICA. In the event

that any emission-related part is found to be defective during the

warranty period, you shall notify Robin America customer service

department at 1-630-350-8200 and you will be advised of the appropriate warranty service dealer or service providers where the

warranty repair can be performed.

Page 17 — English

Page 24

WARRANTY

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Robin America Inc. (herein “ROBIN AMERICA”) are pleased to explain the emission control

system warranty on your small off-road engine (SORE). In California, new SOREs must be designed, built, and equipped to meet

the State’s stringent anti-smog standards. ROBIN AMERICA must warrant the emission contr ol system on your SOREs for the

periods of time described below, provided there has been no abuse, neglect or improper maintenance of your SOREs.

Your emissions control system may include parts such as the carburetor or fuel-injection system, fuel lines, and the ignition system.

Also included may be hoses, clamps, connectors and other associated components.

Where a warrantable condition exists, ROBIN AMERICA will repair your small off-road engine at no cost to you including

diagnosis, parts, and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for three (3) years. If any emission related part on your engine is defective, the part

will be repaired or replaced by ROBIN AMERICA.

OWNER’S WARRANTY RESPONSIBILITIES:

- As the SORE owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual. ROBIN

AMERICA recommends that you retain all receipts covering maintenance on your SORE, but ROBIN AMERICA cannot deny warranty solely for the lack of receipts.

- As the SORE owner, you should, however, be aware that ROBIN AMERICA may deny you warranty coverage if your SORE or a

part has failed due to abuse, neglect, or improper maintenance, or unapproved modifications.

- You are responsible for presenting your SORE to a distribution center or service center authorized by ROBIN AMERICA Inc.,

940 Lively Blvd., Lake Zurich, IL 60047 as soon as a problem exists. The warranty repairs should be completed in

a reasonable amount of time, not to exceed 30 days.

If you have a question regarding your warranty coverage, you should contact the Robin America Inc. Customer Service Department at 1-630-350-8200.

GENERAL EMISSIONS WARRANTY COVERAGE

- California Only -

ROBIN AMERICA warrants to the ultimate purchaser and each subsequent purchaser that the SORE (1) has been designed, built,

and equipped so as to conform with all applicable regulations; and (2) is free from defects in materials and workmanship that cause

the failure of a warranted part to conform with those regulations as may be applicable in the terms and conditions stated below.

a) The warranty period begins on the date the engine is

delivered to an ultimate purchaser or first placed into service.

The warranty period is three years.

b) Subject to certain conditions and exclusions as stated below,

the warranty on emissions related parts is as follows:

(1) Any warranted part that is not scheduled for replacement

as required maintenance in your owner’s manual is warranted for the warranty period stated above. If the part

fails during the period of warranty coverage, the part will

be repaired or replaced by ROBIN AMERICA according to

subsection (4) below. Any such part repaired or replaced

under warranty will be warranted for the remainder of the

period.

(2) Any warranted part that is scheduled only for regular

inspection in your owner’ s manual is warranted for the

warranty period stated above. Any such part repaired or

replaced under warranty will be warranted for the remaining warranty period.

(3) Any warranted part that is scheduled for r eplacement

as r equired maintenance in your owner’ s manu al is

warranted for the period of time before the first scheduled

replacement date for that part. If the part fails before the

first scheduled replacement, the part will be repaired or

replaced by ROBIN AMERICA according to subsection (4)

below. Any such part repaired or replaced under warranty

will be warranted for the remainder of the period prior to

the first scheduled replacement point for the part.

(4) Repair or r eplacement of any warranted part under

the warranty pr ovisions herein must be performed at a

warranty station at no charge to the owner.

(5) Notwithstanding the provisions herein, warranty services

or repair will be provided at all of our distribution centers

that are franchised to service the subject engines.

(6) The owner must not be charged for diagnostic labor that

leads to the determination that a warranted part is in fact

defective, provided that such diagnostic work is performed

at a warranty station.

(7) ROBIN AMERICA is liable for damages to other engine

components proximately caused by a failure under warranty of any warranted part.

(8) Throughout the engine warranty period stated above,

ROBIN AMERICA will maintain a supply of warranted parts

sufficient to meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of

any warranty maintenance or repairs and must be provided

without charge to the owner. Such use will not reduce the

warranty obligations of ROBIN AMERICA.

(10) Add-on or modified parts that are not exempted by the

Air Resources Board may not be used. The use of any

non-exempted add-on or modified parts by the ultimate

purchaser will be grounds for disallowing a warranty claims.

ROBIN AMERICA will not be liable to warrant failur es of

warranted parts caused by the use of a non-exempted

add-on or modified part.

Page 18 — English

Page 25

WARRANTY

When warranty repair is needed, the engine must be brought to an

authorized service dealer or warranty station’s place of business

during normal business hours. In all cases, a r easonable time,

not to exceed 30 days, must be allowed for the warranty repair

to be completed after the engine is r eceived by the authorized

service dealer or warranty station.

MAINTENANCE, REPLACEMENT AND REPAIR OF

EMISSION-RELATED PARTS

Only warranted engine replacement parts approved by

AMERICA

maintenance or repairs on emission-related parts. If other than

authorized parts are used for maintenance, replacement, or repair

of components affecting emission control, you should assure

yourself that such parts are warranted by their manufacturer to

be equivalent to authorized parts in performance and durabil ity. ROBIN AMERICA, however, assumes no liability under this

warranty with respect to parts other than authorized parts. The

use of non-authorized replacement parts does not invalidate the

warranty on other components unless the non-authorized parts

cause damage to warranted parts.

PARTS COVERED UNDER THE CALIFORNIA EMISSIONS

WARRANTY

The r epair or r eplacement of any warranted part otherwise

eligible for warranty coverage may be excluded from such warranty

coverage if

been abused, neglected, or improperly maintained, and that such

abuse , neglect , or improper maintenance was the direct cause of

should be used in the performance of any warranty

ROBIN AMERICA demonstrates that the engine has

ROBIN

the need for repair or replacement of the part. That notwithstanding, any adjustment of a component that has a factory installed,

and properly operating, adjustment limiting device is still eligible

for warranty coverage. The following emissions warranty parts

list are covered.

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or pressure regulator or

fuel injection system)

(ii) Air/fuel ratio feedback and control system, if applicable

(iii) Cold start enrichment system, if applicable.

(iv) Regulator assembly (gaseous fuel, if applicable)

(2) Air Induction System

(i) Intake manifold, if applicable

(ii) Air filter

(3) Ignition System

(i) Spark plugs

(ii) Magneto or electronic ignition system

(iii) Spark advance/retard system, if applicable

(4) Exhaust manifold, if applicable

(5) Evaporation Systems

(i) Fuel lines

(ii) Fuel line fittings

(iii) Carbon canister

(iv) Canister mounting brackets

(v) Carburetor purge port connector

(vi) Fuel tank

(vii) Fuel cap

(viii) Clamps

HIGH ALTITUDE ENGINE OPERATION■

Please have an authorized Robin America service dealer modify this engine if it is to be run continuously above 5000 feet (1500

meters).Failuretodoso,mayresultinpoorengineperformance,sparkplugfouling,hardstarting,andincreasedemissions.

Carburetor modification by an authorized Robin America service dealer will improve performance and allow that this engine meets

EPA(EnvironmentalProtectionAgency)andCaliforniaARB(AirResourcesBoard)emissionstandardsthroughoutitsusefullife.

An engine converted for high altitudes can not be run at 5000 feet or lower. In doing so, the engine will overheat and cause

serious engine damage. Please have an authorized Robin America service dealer restore high altitude modified engines to the original

factory specification before operating below 5000 feet.

AIR INDEX

To show compliance with California emission regulations, a hangtag has been provided displaying the Air Index level and durability

period of this engine.

The Air Index level defines how clean an engine’s exhaust is over a period of time. A bar graph scaled from “0” (most clean) to “10”

(least clean) is used to show an engine’s Air Index level. A lower Air Index level represents cleaner exhaust from an engine. The

period of time (in hours) that the Air Index level is measured is known as the durability period. Depending on the size of the engine,

a selection of time periods can be used to measure the Air Index level (see below).

Descriptive Term Applicable to Emissions Durability Period

Moderate 50 hours (engine from 0 to 80 cc)

125 hours (engine greater than 80 cc)

Intermediate 125 hours (engine from 0 to 80 cc)

250 hours (engine greater than 80 cc)

Extended 300 hours (engine from 0 to 80 cc)

500 hours (engine greater than 80 cc)

NOTICE: This hangtag must remain on this engine or piece of equipment, and only be r emoved by the ultimate purchaser before

operation.

Valve Clearance 0.12 mm (0.0047 in.)

(Intake and Exhaust) NOTE: Adjust the valve clearance while the engine is cold.

Emissions Durability Period 500 hours

(California only)

Page 19 — English

Page 26

WARRANTY

LIMITED NON-ENGINE WARRANTY

STATEMENT

Homelite Consumer Products, Inc., (“Homelite”) warrants

to the original retail purchaser that this HOMELITE brand

pressure w asher is f ree f rom d efect in mat erial and

workmanship and agrees to repair or replace, at Homelite’s

discretion, any defective product free of charge within these

time periods from the date of purchase.

Twoyearsiftheproductisusedforpersonal,familyor

household use;

90days,ifanyoftheaboveproductsareusedforany

other purpose, such as commercial or rental.

This warranty extends to the original retail purchaser only

and commences on the date of the original retail purchase.

Any part of the this product manufactured or supplied by

Homelite and found in the reasonable judgment of Homelite

to be defective in material or workmanship will be repaired

or replaced without charge for parts and labor by a Homelite

Authorized Service Center.

The product, including any defective part, must be returned

to a Homelite Authorized Service Center within the warranty

period. The expense of delivering the product to the service

center for warranty work and the expense of returning it

back to the owner after repair or replacement will be paid

by the owner. Homelite’s responsibility in respect to claims

is limited to making the required repairs or replacements

and no claim of br each of warranty shall be cause for

cancellation or rescission of the contract of sale of any

HOMELITE brand product. Proof of purchase will be required