Page 1

OPERATOR’S MANUAL

MANUAL DEL OPERADOR

UT43103 / 14 in. Electric Chain Saw

Scie à chaîne électrique de 35 cm (14 po)

Motosierra eléctrica de 35 cm (14 pulg.)

ALL VERSIONS

TOUTES LES VERSIONS

TODAS LAS VERSIONES

MANUEL D’UTILISATION

Your electric chain saw has been engineered and manufactured to Homelite’s high standard for dependability, ease of

operation, and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for buying a Homelite product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette scie à chaîne électrique a été conçue et fabriquée conformément

aux strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation de Homelite. Correctement entretenue, elle vous donnera

des années de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci d’avoir acheté un produit Homelite.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su motosierra eléctrica ha sido diseñada y fabricada de conformidad

con las estrictas normas de Homelite para brindar fiabilidad, facilidad

de uso y seguridad para el operador. Con el debido cuidado, le

brindará muchos años de sólido y eficiente funcionamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos la compra de un producto Homelite.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

Page 2

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction .......................................................................................................................................2

Introduction / Introducción

General Safety Rules ..................................................................................................................... 3-6

Règles de sécurité générales / Reglas de seguridad generales

Symbols ........................................................................................................................................ 7-8

Symboles / Símbolos

Electrical ............................................................................................................................................ 9

Caractéristiques électriques / Aspectos eléctricos

Glossary of Terms ............................................................................................................................10

Glossaire / Glosario de términos

Features ..................................................................................................................................... 11-12

Caractéristiques / Características

Assembly ................................................................................................................................... 12-13

Assemblage / Armado

Operation ................................................................................................................................... 13-21

Utilisation / Funcionamiento

Maintenance .............................................................................................................................. 22-29

Entretien / Mantenimiento

Bar and Chain Combinations .......................................................................................................... 30

Vue éclatée et liste des pièces / Vista desarrollada y lista de piezas

Troubleshooting ............................................................................................................................... 30

Dépannage / Corrección de problemas

Warranty ..........................................................................................................................................31

Garantie / Garantía

Parts Ordering and Service ............................................................................................... Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ......................................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIÓN

This product has many features for making its use more pleasant and enjoyable. Safety, performance,

and dependability have been given top priority in the design of this product making it easy to maintain

and operate.

* * *

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la conception de ce produit, l’accent a été mis sur la sécurité, les performances et la

fiabilité, afin d’en faire un outil facile à utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el

diseño de este producto se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo

cual se facilita su manejo y mantenimiento.

Page 2

Page 3

GENERAL SAFETY RULES

WARNING:

Do not attempt to operate this unit until you

have read thoroughly and understand completely all instructions, safety information, etc.

contained in this manual. Failure to comply can

result in accidents involving fire, electric shock,

or serious personal injury.

READ ALL INSTRUCTIONS

BASIC SAFETY PRECAUTIONS

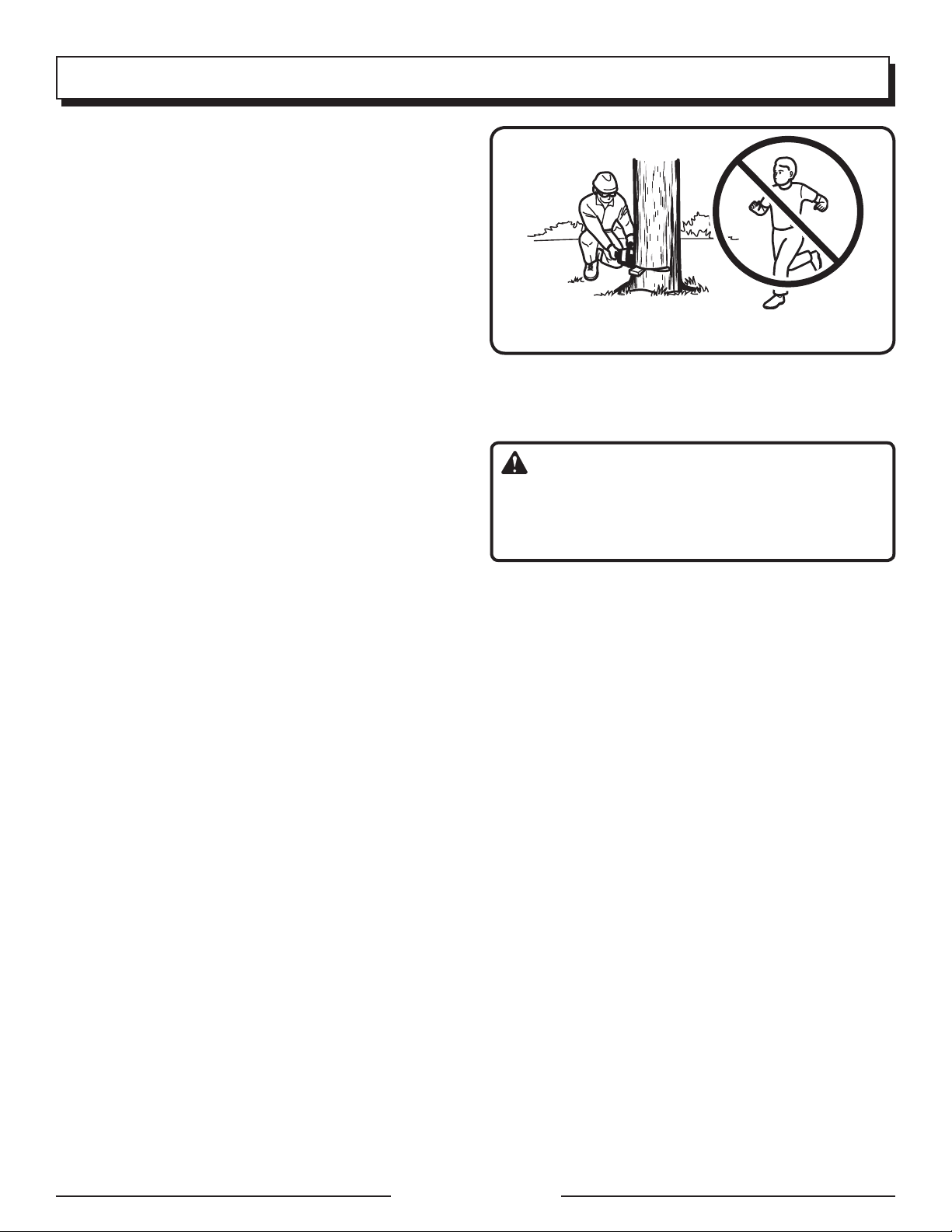

Do not start cutting until you have a clear work area,

secure footing, and a planned retreat path from

the falling tree. Cluttered areas invite accidents.

Keep ALL children, bystanders, visitors, and

animals out of the work area while starting or

cutting with the chain saw. Do not let visitors

contact chain saw or extension cord.

Do not operate chain saw in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Chain saws create

sparks which may ignite the dust or fumes.

WARNING: Use outdoor extension cords

marked SW-A, SOW-A, STW-A, STOW-A,

SJW-A, SJTW-A, or SJTOW-A. These cords

are rated for outdoor use and reduce the risk

of electric shock.

Polarized Plugs. To reduce the risk of electric

shock, this tool has a polarized plug (one blade

is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician

to install the proper outlet. Do not change the

plug in any way.

Make sure your extension cord is in good condi-

tion. When using an extension cord, be sure to

use one heavy enough to carry the current your

product will draw. A wire gauge size (A.W.G.)

of at least 14 is recommended for an extension

cord 50 feet or less in length. A cord exceeding

100 feet is not recommended. If in doubt, use

the next heavier gauge. The smaller the gauge

number, the heavier the cord. An undersized

cord will cause a drop in line voltage resulting

in loss of power and overheating.

Page 3 — English

Inspect extension cords periodically and, if

damaged, have repaired by a licensed electrician. Constantly stay aware of cord location.

Following this rule will reduce the risk of electric

shock or fire.

Dress Properly - Wear snug fitting clothing.

Always wear heavy, long pants, long sleeves,

overalls, jeans or chaps made of cut resistant

material or ones that contain cut resistant

inserts. Wear non-slip safety footwear. Wear

non-slip heavy duty gloves to improve your

grip and to protect your hands. Do not wear

jewelry, short pants, sandals, or go barefoot.

Do not wear loose fitting clothing, which could

be drawn into the motor or catch the chain or

underbrush. Secure hair so it is above shoulder

level. Wear hearing and head protection.

Heavy protective clothing may increase operator

fatigue, which could lead to heat stroke. During

weather that is hot and humid, heavy work should

be scheduled for early morning or late afternoon

hours when temperatures are cooler.

Always wear eye protection with side shields

marked to comply with ANSI Z87.1 as well as

head protection when operating this equipment.

Always be aware of what you are doing when

using the chain saw. Use common sense. Do

not operate the chain saw when you are tired,

ill, or under the influence of alcohol, drugs, or

medication.

Do not expose the chain saw to rain.

Do not use the chain saw in damp or wet locations.

Always be aware of extension cord while oper-

ating chain saw. Take precautions to avoid

tripping over cord. Keep cord away from chain

and operator at all times. Never carry saw by

the cord or pull it to disconnect from receptacle.

Keep cord from oil and sharp edges.

Stay alert and pay attention to what you are

doing. Use common sense when using this

unit.

Keep all parts of your body away from the saw

chain when the unit is running.

Always carry the chain saw by the front handle

with the unit unplugged and the guide bar

and saw chain positioned to the rear. When

Page 4

GENERAL SAFETY RULES

transporting your chain saw, use the appropriate

guide bar scabbard.

Never let anyone use your chain saw who has

not received adequate instructions in its proper

use. This applies to rentals as well as privately

owned saws.

Before you start the unit, make sure the saw

chain is not contacting any object.

Stop the chain saw before setting it down.

To avoid accidental starting, never carry the unit

with your finger on the switch trigger.

Maintain the unit with care. Keep the cutting

edge sharp and clean for best performance and

to reduce the risk of injury. Follow instructions

for lubricating and changing accessories.

Keep handles dry, clean, and free of oil and

grease.

Do not operate a chain saw with one hand! Use

a firm grip with thumbs and fingers encircling the

chain saw handles. Serious injury to the operator, helpers, bystanders, or any combination

of these persons may result from one-handed

operation. A chain saw is intended for twohanded use.

Guard against electric shock - Avoid body

contact with grounded surfaces such as metal

pipes and wire fences. There is an increased

risk of electric shock if your body is grounded.

Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Chain should slow to a

stop when the switch trigger is released. If the

chain continues to turn after the switch trigger

has been released, have the unit serviced by

your nearest Homelite service dealer.

Check for damaged parts. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other part that is damaged should be properly

repaired or replaced by an authorized service

dealer unless otherwise indicated elsewhere in

this manual.

All chain saw service, other than the items listed

in the operation and maintenance sections,

should be performed by your nearest Homelite

service dealer.

Always maintain a proper stance.

Do not use chain saw if switch does not turn it

on and off. Have defective switch replaced by

authorized service center.

Do not adapt your powerhead to a bow guide

or use it to power any attachments or devices

not listed for the saw.

Disconnect chain saw from power supply when

not in use, before servicing, and when making

adjustments and changing attachments, such

as saw chain and guard.

Do not cut vines and/or small underbrush.

Do not operate a chain saw in a tree, on a ladder,

rooftop or scaffold; this is extremely dangerous.

NOTE: The size of the work area depends on

the job being performed as well as the size tree

or work piece involved. For example, felling a

tree requires a larger work area than making

bucking cuts.

Use extreme caution when cutting small size

brush and saplings, because small material may

catch the saw chain and be whipped toward you

or pull you off balance.

When cutting a limb that is under tension, be

alert for spring back so that you will not be

struck when the tension in the wood fibers is

released.

Do not force the chain saw. The job can be

performed better and safer at the rate for which

it was intended.

Always use the right product for your applica-

tion. The chain saw should be used for cutting

wood only. Never use the chain saw to cut

plastic, masonry or non-wood building materials.

Do not use the chain saw for purposes not

intended.

Store chain saw when not in use. Chain saw

should be stored in a dry and high or locked area

out of the reach of children. When storing chain

saw place the scabbard on the bar and chain

and store the chain saw in carrying case.

Page 4 — English

Page 5

GENERAL SAFETY RULES

Save these instructions. Refer to them fre-

quently and use them to instruct others who

may use this product. If you loan someone this

product, loan them these instructions also.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

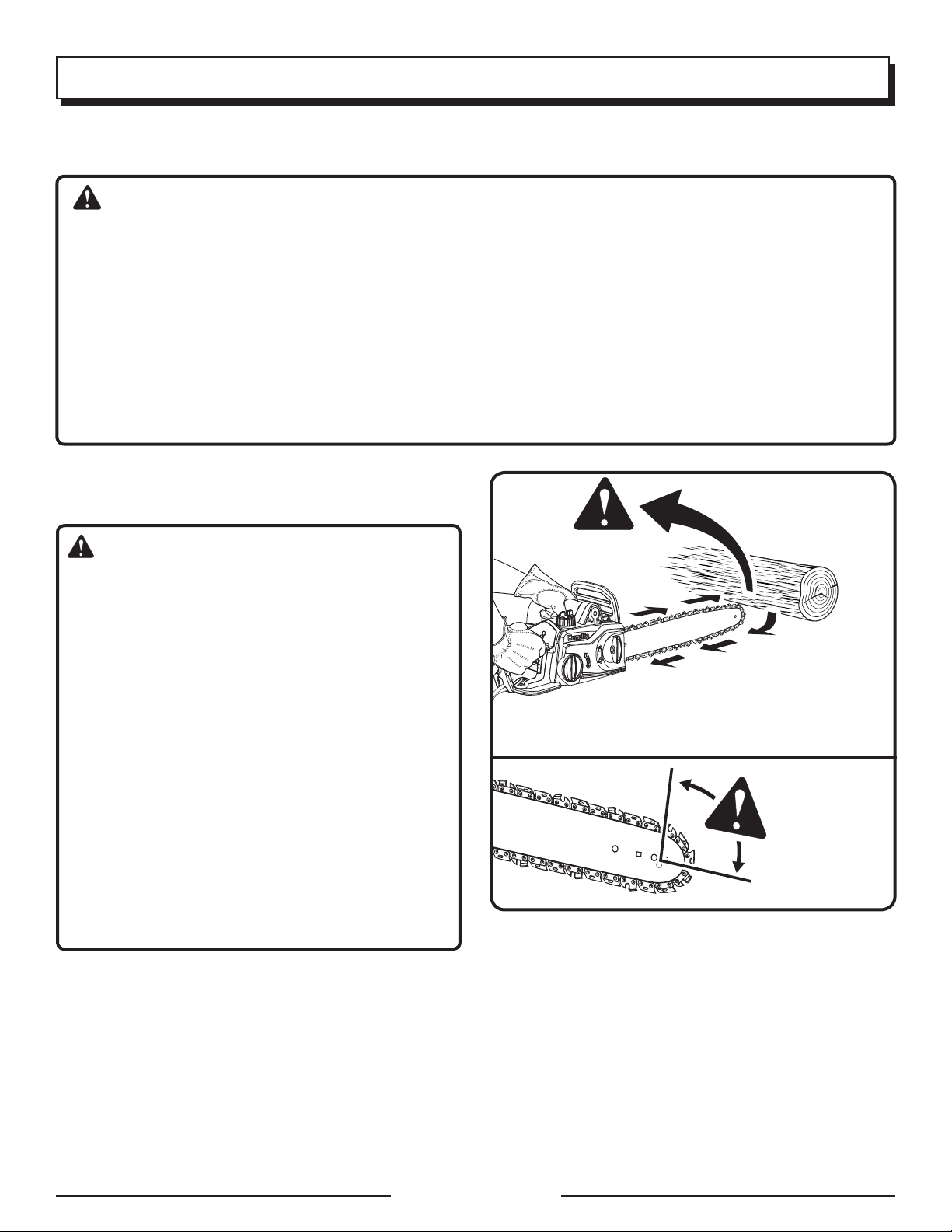

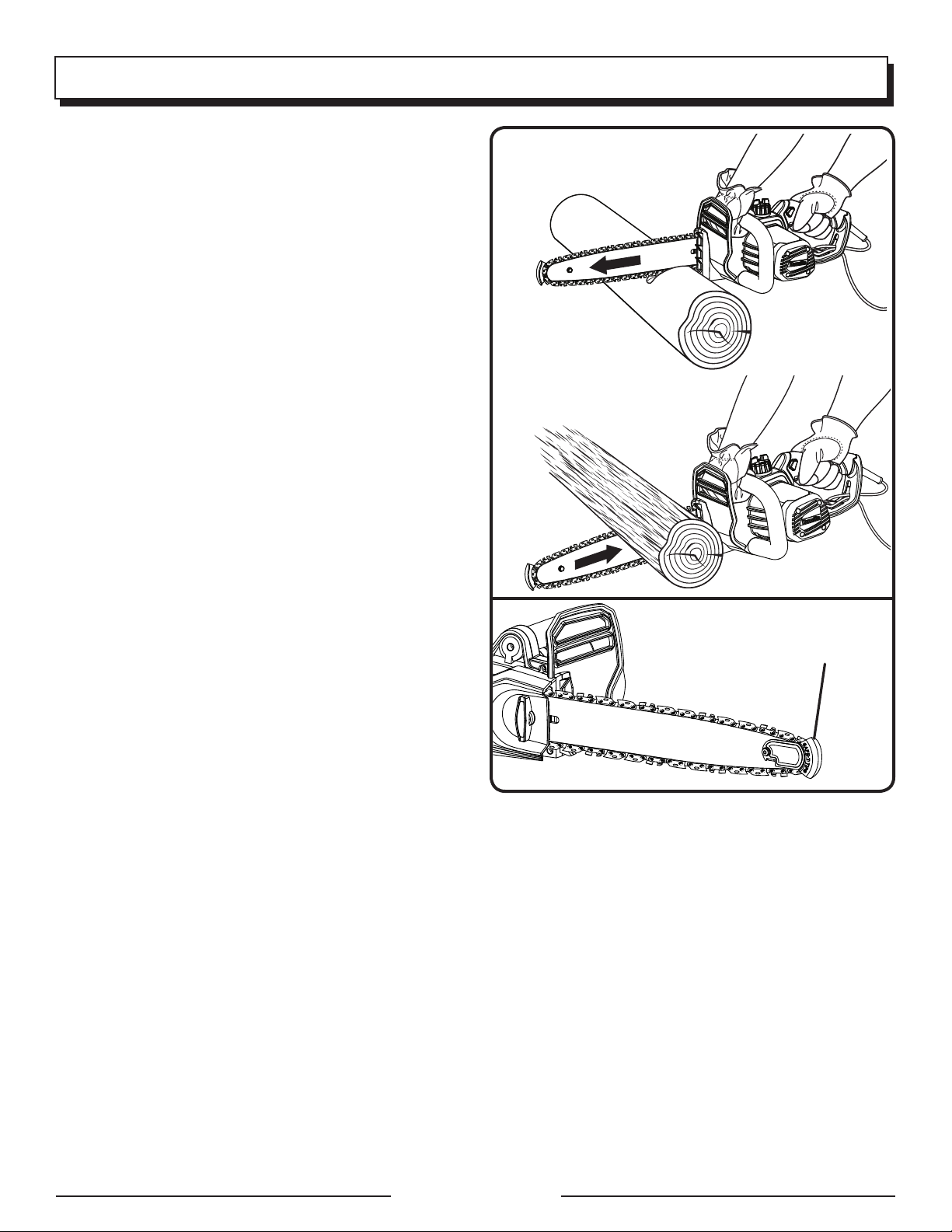

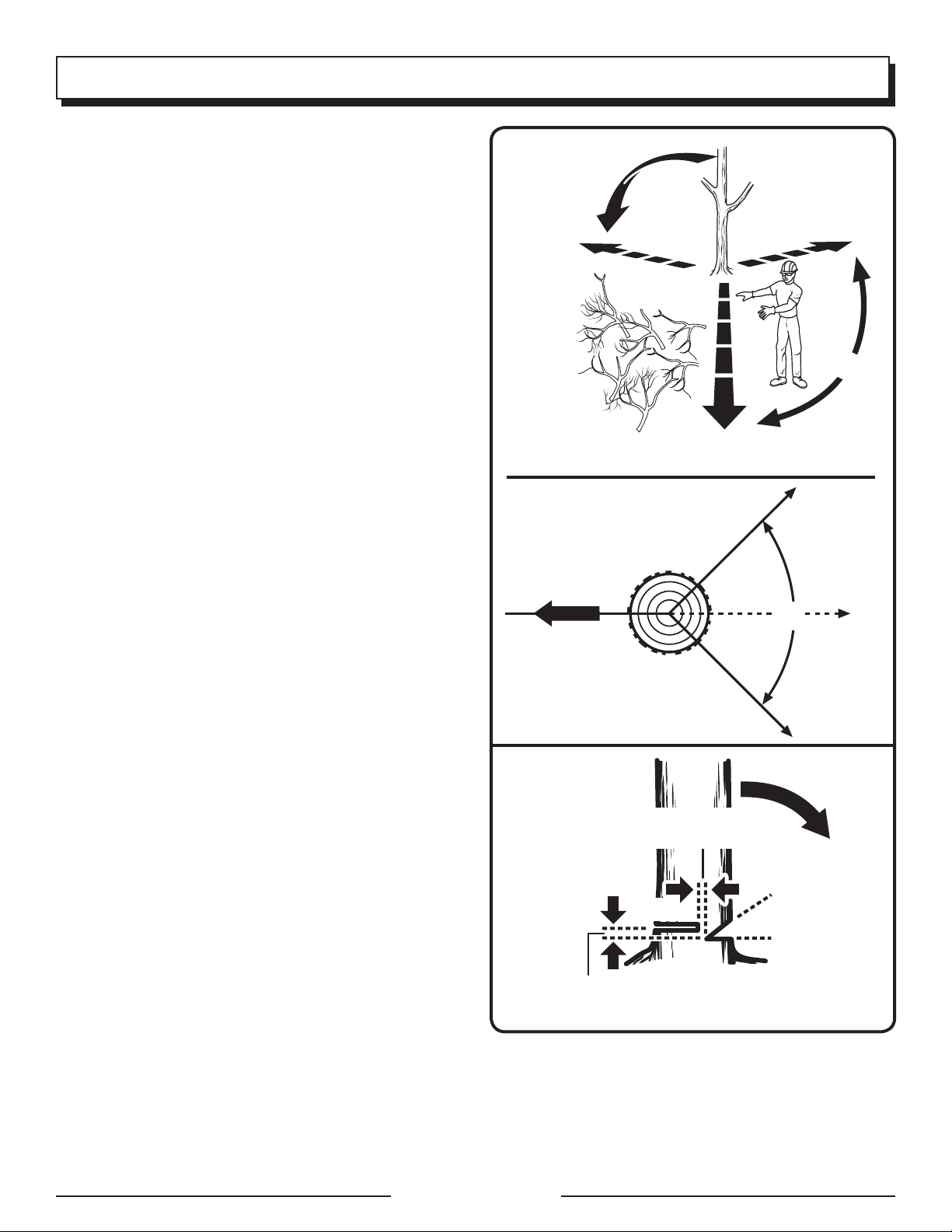

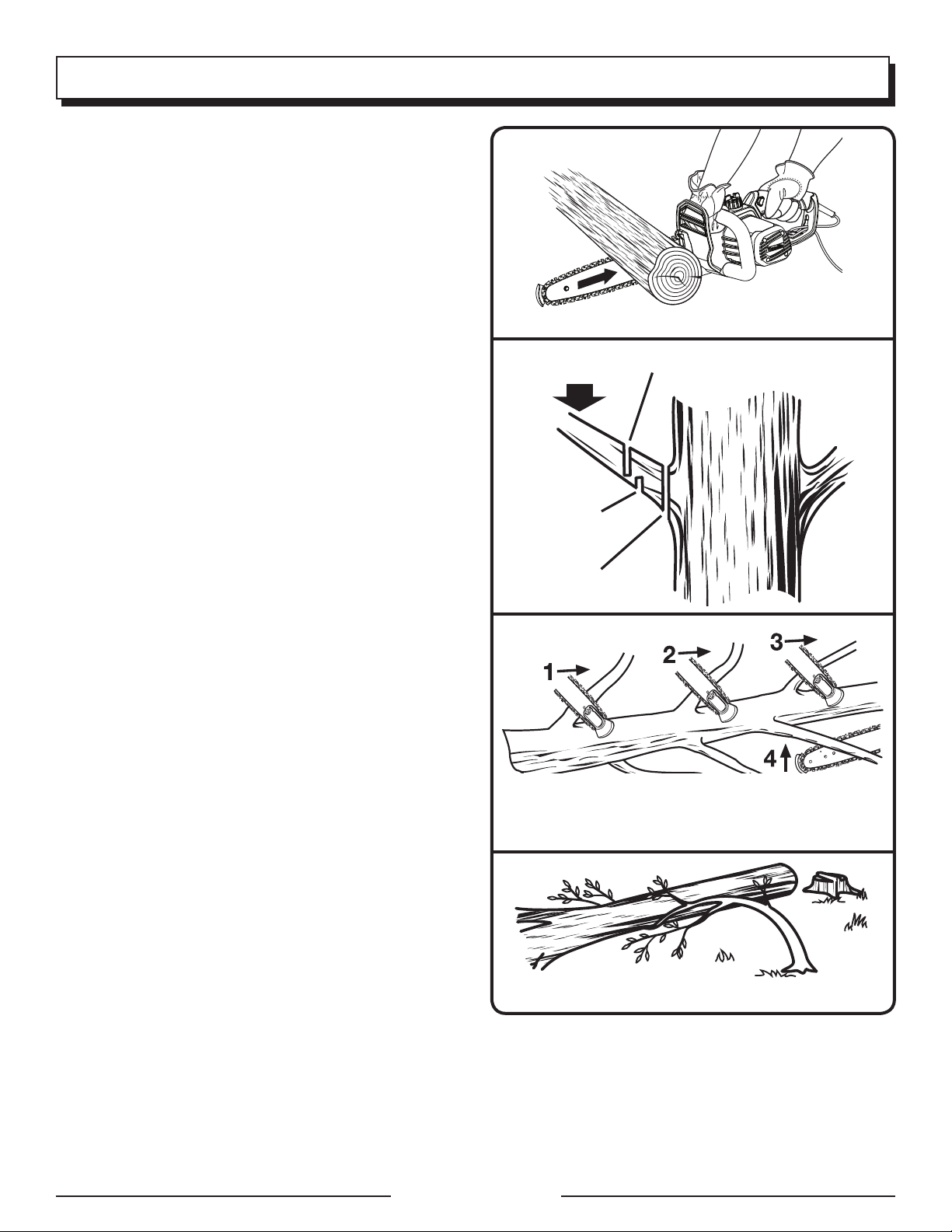

KICKBACK

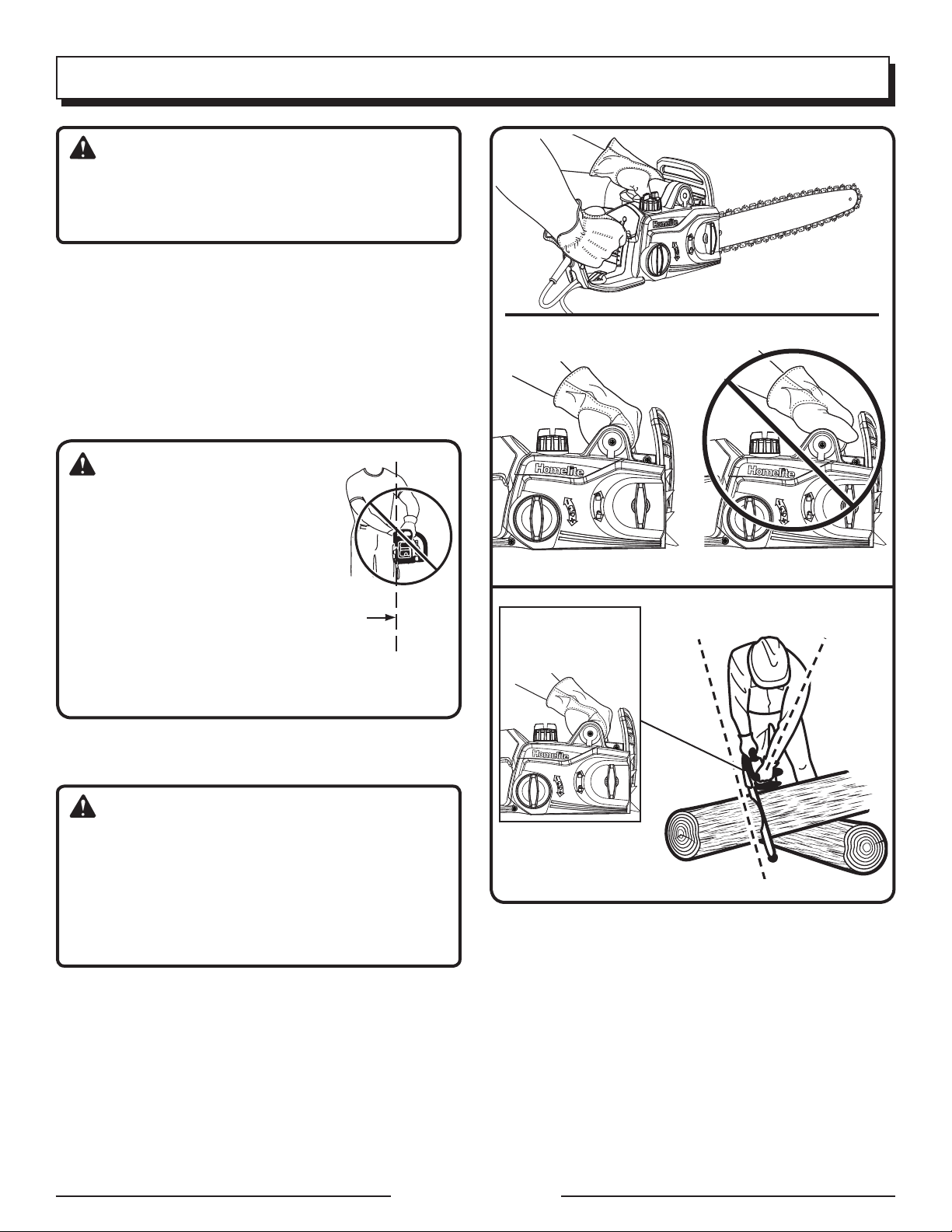

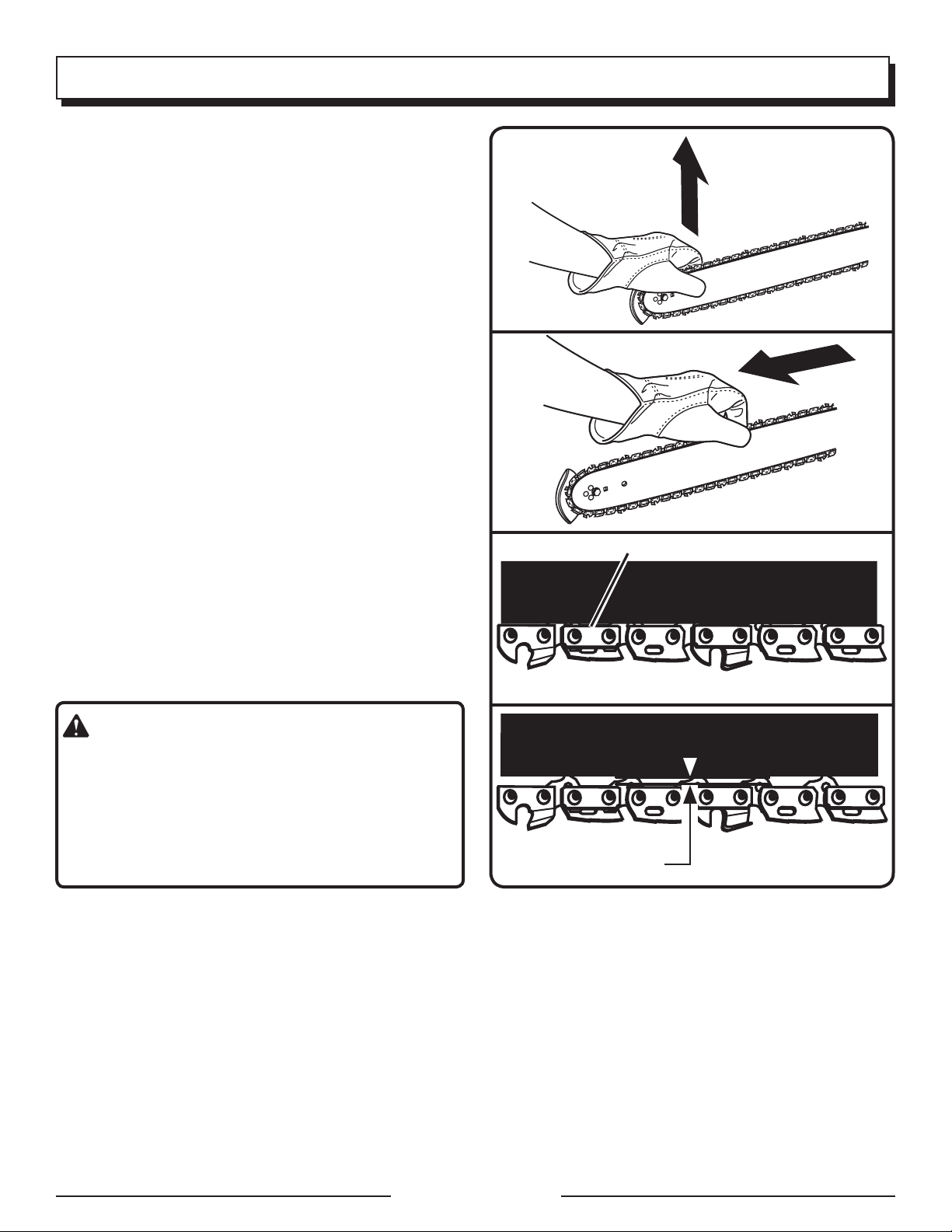

See Figures 1 - 2.

ROTATIONAL

KICKBACK

WARNING:

Kickback may occur when the moving chain

contacts an object at the upper portion of the

tip of the guide bar or when the wood closes in

and pinches the saw chain in the cut. Contact at

the upper portion of the tip of the guide bar can

cause the chain to dig into the object and stop

the chain for an instant. The result is a lightning

fast, reverse reaction which kicks the guide bar

up and back toward the operator. If the saw

chain is pinched along the top of the guide bar,

the guide bar can be driven rapidly back toward

the operator. Either of these reactions can cause

loss of saw control which can result in serious

injury. Do not rely exclusively upon the safety

devices built into the saw. As a chain saw user,

you should take several steps to keep your cutting jobs free from accident or injury.

The following precautions should be followed

to minimize kickback:

• Always grip the saw firmly with both hands.

Hold the saw firmly with both hands when

the unit is running. Place your right hand on

the rear handle and your left hand on the front

handle with your thumbs and fingers encircling

the chain saw handles. A firm grip together

with a stiff left arm will help you maintain

control of the saw if kickback occurs.

Page 5 — English

• Make sure that the area in which you are cutting is free from obstructions. Do not let the

nose of the guide bar contact a log, branch,

fence, or any other obstruction that could be

hit while you are operating the saw.

• Always cut with the unit running. Fully

squeeze the switch trigger and maintain cutting speed.

• Use replacement parts such as low kickback

chain, SAFE-T-TIP® anti-kickback nose

guards and special guide bars that reduce

BAR SHOWN WITHOUT

SAFE-T-TIP® NOSE GUARD

FOR ILLUSTRATION

PURPOSES ONLY

KICKBACK

DANGER ZONE

Fig. 1

Fig. 2

Page 6

GENERAL SAFETY RULES

the risks associated with rotational kickback.

Use only the replacement guide bars and low

kickback chains specified by the manufacturer for the saw.

With a basic understanding of kickback, you

can reduce or eliminate the element of surprise.

Sudden surprise contributes to accidents.

Do not overreach. Keep proper footing and

balance at all times.

Do not cut above shoulder height or overreach

when cutting. Don’t let nose of Guide Bar contact log, branch, ground or other obstruction.

Keep the SAFE-T-TIP® anti-kickback nose

guard properly mounted on the guide bar to

prevent rotational kickback.

Follow the sharpening and maintenance instruc-

tions for the saw chain.

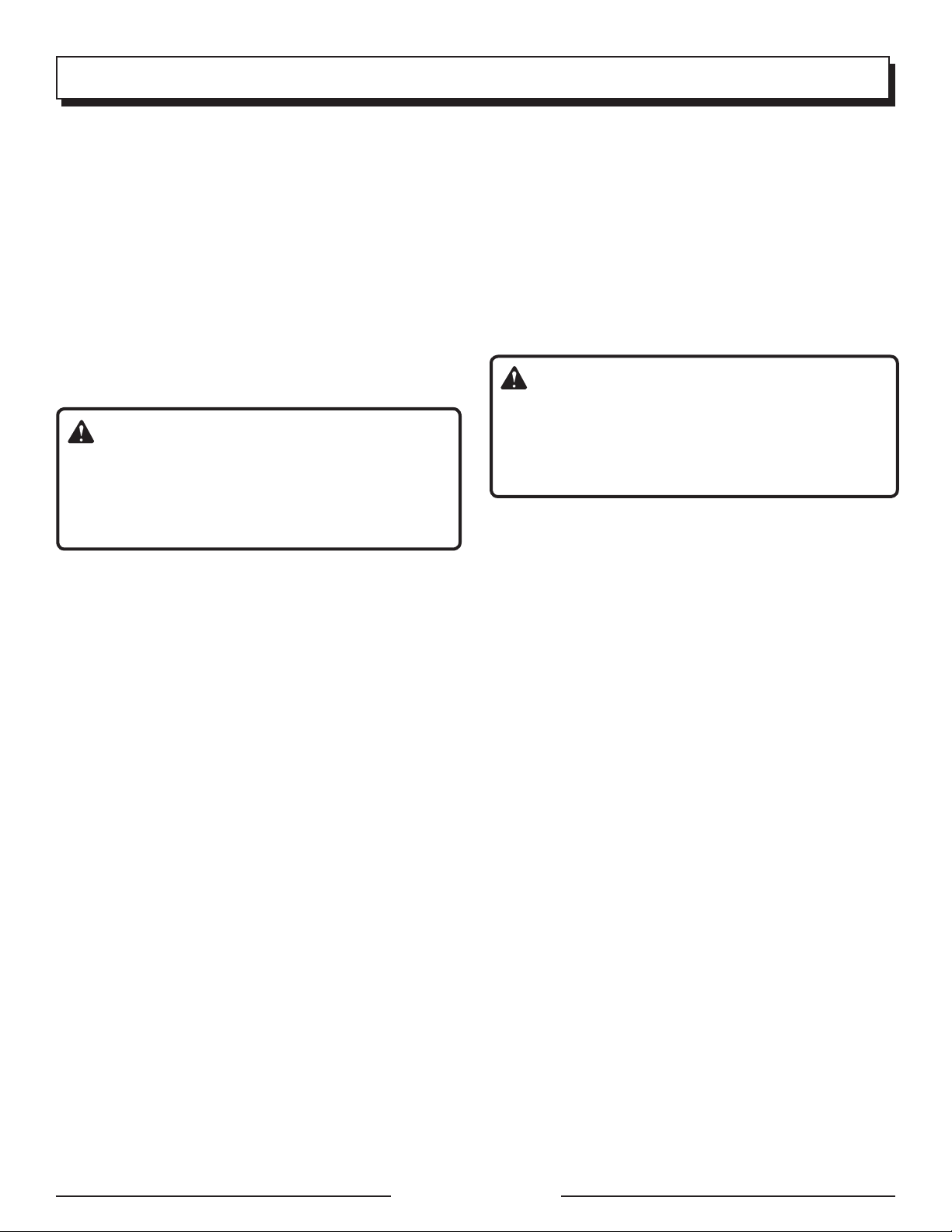

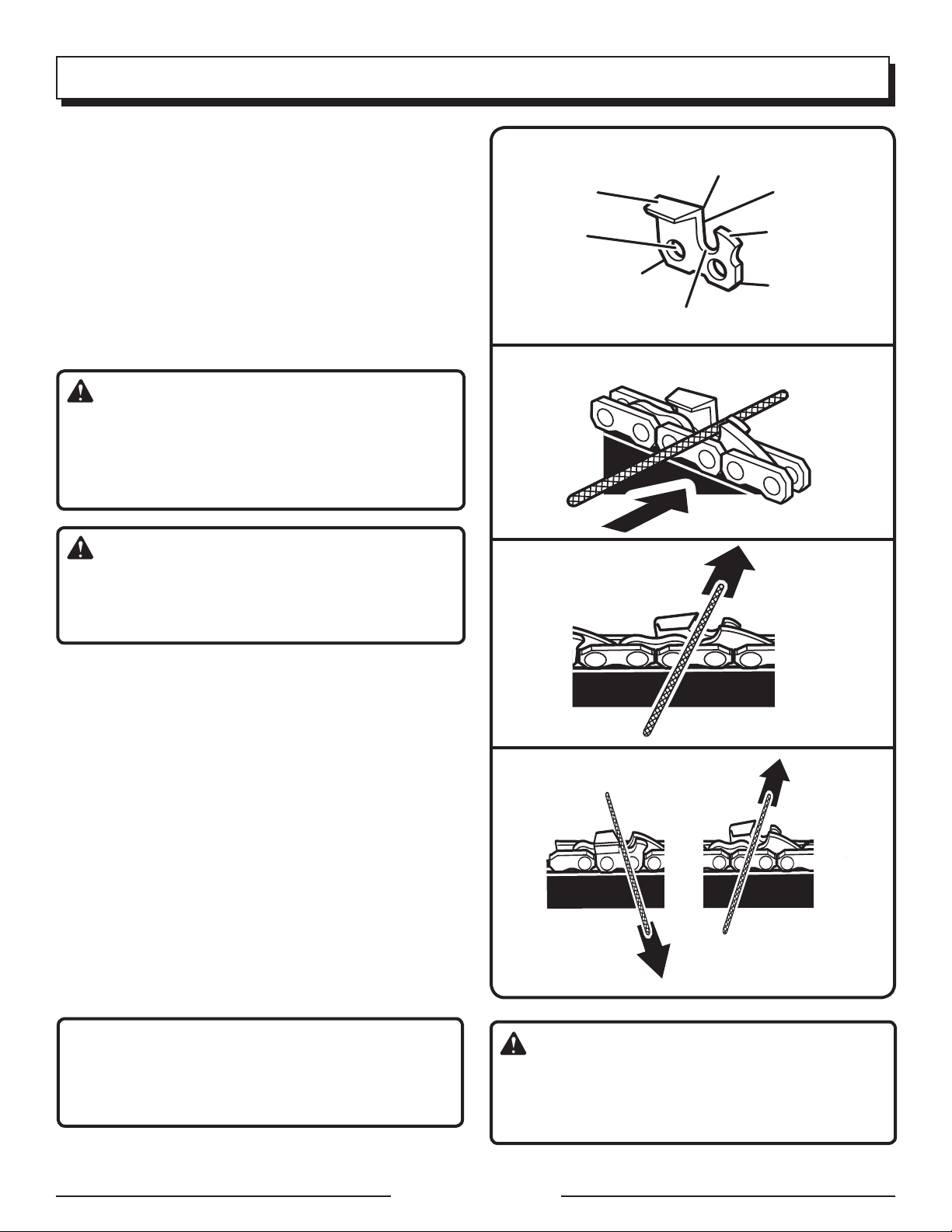

Push and Pull - This reaction force is always

opposite to the direction the chain is moving

where wood contact is made. Thus, the operator

must be ready to control the PULL when cutting

on the bottom edge of the bar, and PUSH when

cutting along the top edge. See Figure 3.

UNDERSTANDING YOUR CHAIN SAW

SAFETY DEVICES

See Figure 4.

SAFE-T-TIP® ANTI-KICKBACK NOSE

GUARD

The SAFE-T-TIP® prevents rotational kickback

from happening, because it covers the tip of the

bar where kickback is generated. Never attempt

any kind of cutting where the SAFE-T-TIP® would

have to be removed from the bar tip.

LOW KICKBACK SAW CHAIN

The rakers (depth gauges) ahead of each cutter

can minimize the force of a kickback reaction by

preventing the cutters from digging in too deeply at

the kickback zone. Only use replacement chain that

is equivalent to original chain or has been certified

as low kickback chain per ANSI B175.1.

Low kickback/skip tooth saw chain is a chain that

has met the kickback performance requirements

of ANSI B175.1 - 1991 (American National Standard for Power Tools - Gasoline-Powered Chain

PULL

PUSH

Fig. 3

SAFE-T-TIP

Saws-Safety Requirements) when tested on the

representative sample of chain saws below 3.8

c.i.d. specified in ANSI B175.1 - 1991.

As saw chains are sharpened during their useful

life, they lose some of the low kickback qualities

and extra caution should be used.

®

Fig. 4

GUIDE BARS

Generally, guide bars with small radius tips have

somewhat lower kickback potentials.

When making a replacement, be sure to order

one of the Homelite bars listed for the saw in this

operator’s manual. The proper size SAFE-T-TIP®

nose guard comes installed on the bar. Use only

guide bars that have a provision for mounting the

SAFE-T-TIP®.

Page 6 — English

Page 7

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with

this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may

result in property damage.

Some of the following symbols may be used on this product. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read The Operator’s

Manual

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Wear Eye and Head

Protection

Wet Conditions Alert Do not expose to rain or use in damp locations.

SAFE-T-TIP Nose Guard

Operate With Two Hands Hold and operate the saw properly with both hands.

One Handed Do not operate the saw using only one hand.

Kickback DANGER! Beware of kickback.

Bar Nose Contact Avoid bar nose contact.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1, along with head protection.

The SAFE-T-TIP nose guard on the guide bar helps prevent

kickback.

Page 7 — English

Page 8

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

Wear Gloves

Wear Safety Footwear Wear non-slip safety footwear when using this equipment.

Keep Bystanders Away Keep all bystanders and animals at least 50 ft. away.

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type of current

Direct Current Type or a characteristic of current

n

o

.../min

No Load Speed Rotational speed, at no load

Class II Construction Double-insulated construction

Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

Wear non-slip, heavy-duty protective gloves when handling

the chain saw.

Page 8 — English

Page 9

FEATURES

ELECTRICAL

DOUBLE INSULATION

Double insulation is a concept in safety in electric

power tools, which eliminates the need for the usual

three-wire grounded power cord. All exposed metal

parts are isolated from the internal metal motor

components with protecting insulation. Double

insulated tools do not need to be grounded.

WARNING:

The double insulated system is intended to

protect the user from shock resulting from a

break in the tool’s internal insulation. Observe

all normal safety precautions to avoid electrical

shock.

NOTE: Servicing of a product with double insulation

requires extreme care and knowledge of the system

and should be performed only by a qualified service

technician. For service, we suggest you return the

product to your nearest authorized service center

for repair. Always use original factory replacement

parts when servicing.

Before using any extension cord, inspect it for loose

or exposed wires and cut or worn insulation.

A proper extension cord is available at an authorized

service center.

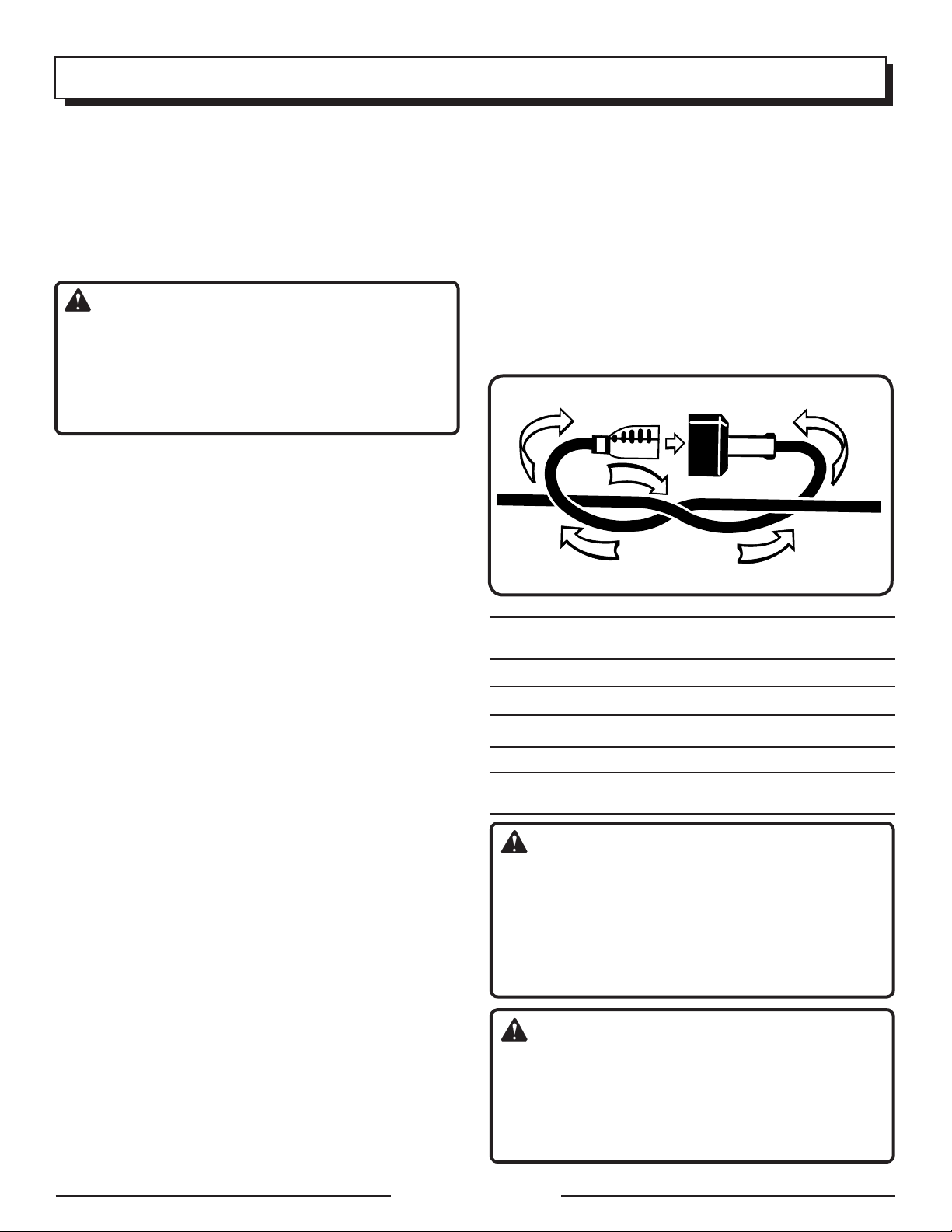

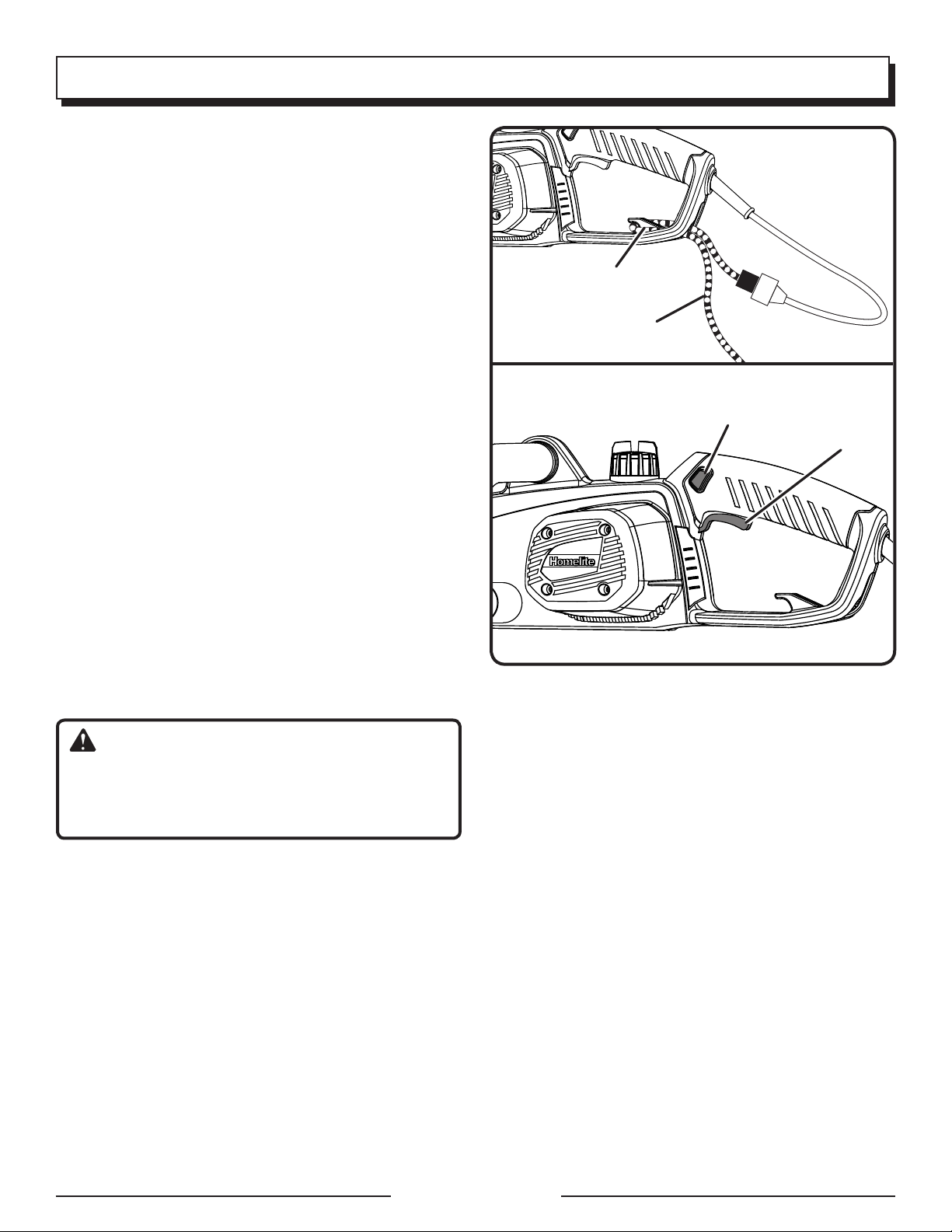

It is possible to tie the extension cord and power

cord in a knot to prevent them from becoming

disconnected during use. Make the knot as shown

in figure 5, then connect the plug end of the power

cord into the receptacle end of the extension cord.

This method can also be used to tie two extension

cords together.

Fig. 5

ELECTRICAL CONNECTION

This product has a precision-built electric motor.

It should be connected to a power supply that is

120V, AC only (normal household current), 60

Hz. Do not operate this product on direct current

(DC). A substantial voltage drop will cause a loss of

power and the motor will overheat. If the product

does not operate when plugged into an outlet,

double-check the power supply.

EXTENSION CORDS

See Figure 5.

When using a power tool at a considerable

distance from a power source, be sure to use

an extension cord that has the capacity to

handle the current the product will draw. An

undersized cord will cause a drop in line voltage,

resulting in overheating and loss of power. Use the

chart to determine the minimum wire size required

in an extension cord. Only round jacketed cords

listed by Underwriter’s Laboratories (UL) should

be used.

When working outdoors with a product, use an

extension cord that is designed for outside use.

This type of cord is designated with “W-A” or “W”

on the cord’s jacket.

**Ampere rating (on product data plate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

WARNING:

Keep the extension cord clear of the working

area. Position the cord so that it will not get

caught on lumber, tools, or other obstructions while you are working with a power

tool. Failure to do so can result in serious

personal injury.

WARNING:

Check extension cords before each use. If

damaged replace immediately. Never use the

product with a damaged cord since touching

the damaged area could cause electrical shock

resulting in serious injury.

Page 9 — English

Page 10

GLOSSARY OF TERMS

Bar Tip Guard

An attachment that may be provided on the end of the

guide bar to prevent the chain at the end of the guide

bar from contacting the wood.

Bucking

The process of cross cutting a felled tree or log into

lengths.

Chain Saw Powerhead

A chain saw without the saw chain and guide bar.

Clutch

A mechanism for connecting and disconnecting a driven

member to and from a rotating source of power.

Drive Sprocket or Sprocket

The toothed part that drives the saw chain.

Felling

The process of cutting down a tree.

Felling Back Cut

The final cut in a tree felling operation made on the

opposite side of the tree from the notching undercut.

Front Hand Guard

A structural barrier between the front handle of a chain

saw and the guide bar, typically located close to the hand

position on the front handle, and sometimes employed

as an activating lever for a chain brake.

Front Handle

The support handle located at or toward the front of

the chain saw. This handle is for the left hand.

Guide Bar

A solid railed structure that supports and guides the

saw chain.

Kickback

The backward or upward motion, or both, of the guide

bar occurring when the saw chain near the nose of the

top area of the guide bar contacts any object such as a

log or branch, or when the wood closes in and pinches

the saw chain in the cut.

Low-Kickback Chain

A chain that complies with the kickback performance

requirements of ANSI B175.1 when tested on a representative sample of chain saws.

Normal Cutting Position

Those positions assumed in performing the bucking

and felling cuts.

Notching Undercut

A notch cut in a tree that directs the tree’s fall.

Oiler Control

A system for oiling the guide bar and saw chain.

Rear Handle

The support handle located at or toward the rear of the

saw. It normally contains the switch trigger. This handle

is for the right hand.

Reduced Kickback Guide Bar

A guide bar which has been demonstrated to reduce

kickback significantly.

Replacement Saw Chain

A chain that complies with the kickback performance

requirements of ANSI B175.1 when tested with specific

chain saws. It may not meet the ANSI performance

requirements when used with other saws.

Saw Chain

A loop of chain having cutting teeth that cut the wood,

and that is driven by the motor and is supported by

the guide bar.

Spiked Bumper (Spike)

The pointed tooth or teeth for use when felling or bucking

to pivot the saw and maintain position while sawing.

Switch Trigger

A device that when operated will complete or interrupt an

electrical power circuit to the motor of the chain saw.

Switch Linkage

The mechanism that transmits motion from a trigger

to the switch.

Kickback (Pinch)

The rapid pushback of the saw which can occur when

the wood closes in and pinches the moving saw chain

in the cut along the top of the guide bar.

Kickback (Rotational)

The rapid upward and backward motion of the saw

which can occur when the moving saw chain near the

upper portion of the tip of the guide bar contacts an

object, such as a log or branch.

Page 10 — English

Switch Lock-out

A movable stop that prevents the unintentional operation

of the switch until manually actuated.

Page 11

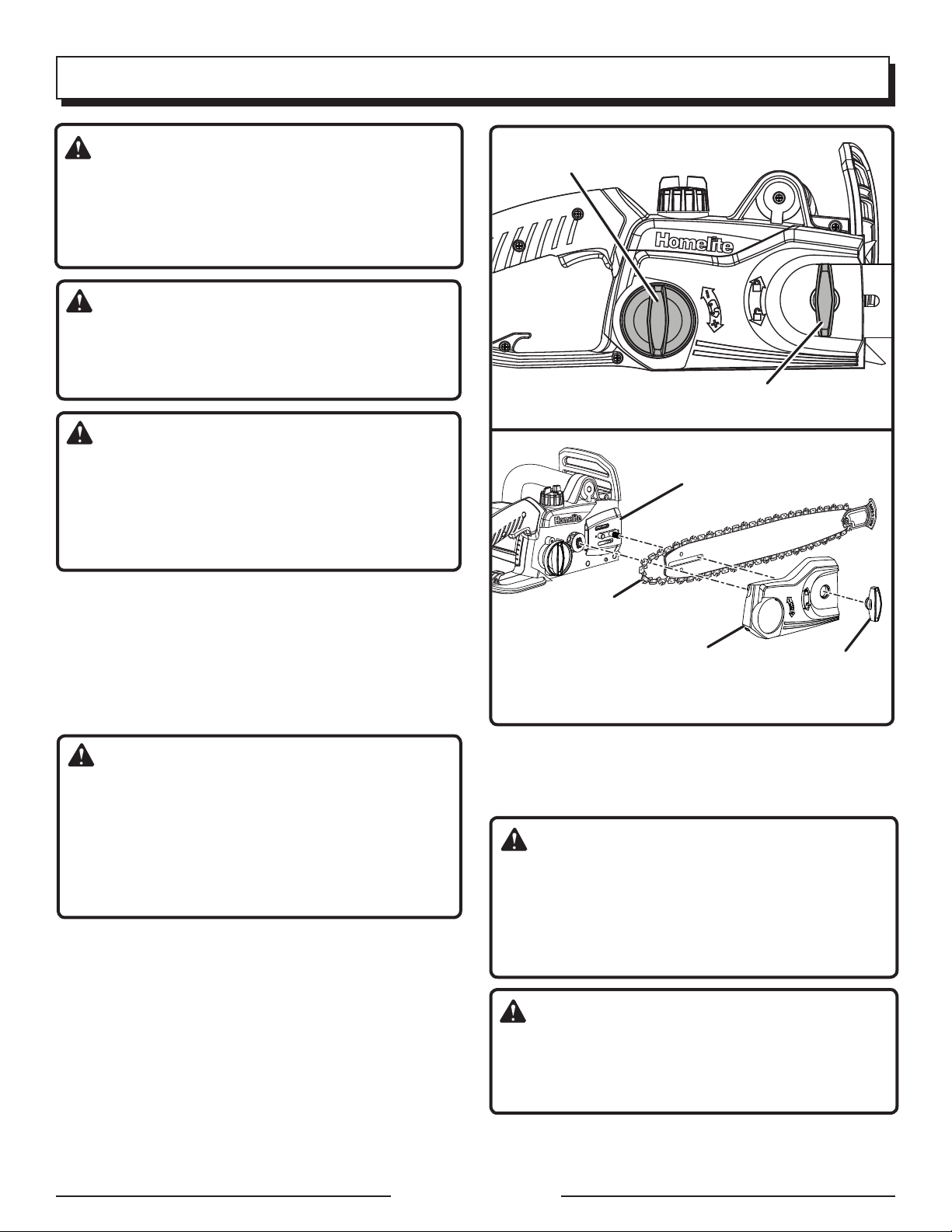

FEATURES

PRODUCT SPECIFICATIONS

UT43103

Bar length ........................................................................................................................................14 in.

Chain pitch .................................................................................................................................. .375 in.

Chain gauge ................................................................................................................................ .050 in.

Chain type ............................................................................................................Low Profile Skip Tooth

Drive sprocket ..............................................................................................................................7-tooth

Input .......................................................................................................120 V, AC only, 60 Hz, 9 Amps

Chain oil tank capacity .....................................................................................................................6 oz.

Weight - No bar, chain, or lubricant ..............................................................................................7.8 lbs.

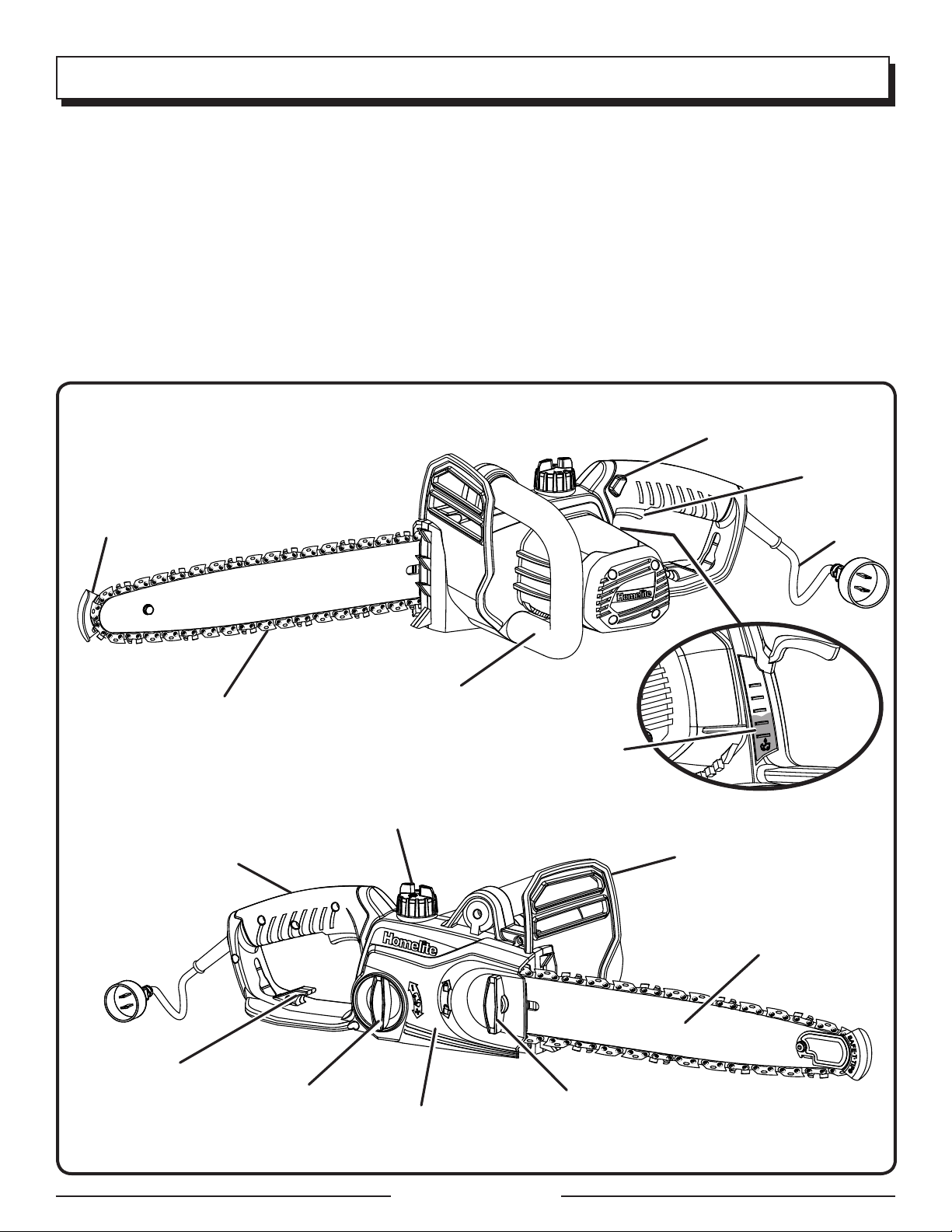

SWITCH

LOCK-OUT

SWITCH

TRIGGER

POWER

SAFE-T-TIP®

CORD

LOW KICKBACK

CORD

RETAINER

SAW CHAIN

REAR

HANDLE

TENSIONING

CHAIN

KNOB

FRONT

HANDLE

OIL RESERVOIR

CAP

CHAIN COVER

QUICK VIEW

OIL INDICATOR

FRONT HAND

GUARD

GUIDE

BAR

CHAIN COVER

LOCK KNOB

Fig. 6

Page 11 — English

Page 12

FEATURES

KNOW YOUR CHAIN SAW

See Figure 6.

The safe use of this product requires an understanding of the information on the tool and in

this operator’s manual as well as a knowledge

of the project you are attempting. Before use of

this product, familiarize yourself with all operating

features and safety rules.

CHAIN TENSIONING KNOB

This feature allows user to adjust the tension of

the chain.

GUIDE BAR

The factory-equipped guide bar has a small

radius tip that offers a somewhat lower kickback

potential.

LOW KICKBACK SAW CHAIN

The low kickback saw chain helps minimize the

force of a kickback reaction by preventing the

cutters from digging in too deeply at the kickback

zone.

QUICK VIEW OIL INDICATOR

Semi-transparent oil reservoir that allows user to

see when to add oil.

SAFE-T-TIP® ANTI-KICKBACK NOSE

GUARD

The Safe-T-Tip® Anti-Kickback Nose Guard is an

attach-ment provided on the end of the guide bar

to prevent the chain on the end of the guide bar

from contacting the wood.

SWITCH LOCK-OUT

A control feature designed to prevent the motor

from being accidently started.

SWITCH TRIGGER

Squeeze the switch trigger to operate the unit after

switch lock-out has been pushed in. Release the

switch trigger to stop the unit.

ASSEMBLY

UNPACKING

This product has been shipped completely

assembled.

Carefully remove the product and any acces-

sories from the box. Make sure that all items

listed in the packing list are included.

WARNING:

Do not use this product if any parts on the Packing List are already assembled to your product

when you unpack it. Parts on this list are not

assembled to the product by the manufacturer

and require customer installation. Use of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the product carefully to make sure no

breakage or damage occurred during shipping.

Do not discard the packing material until you

have carefully inspected and satisfactorily operated the product.

If any parts are damaged or missing, please call

1-800-242-4672 for assistance.

PACKING LIST

Chain Saw

Sleeve

Operator’s Manual

WARNING:

If any parts are damaged or missing do not

operate this product until the parts are replaced.

Use of this product with damaged or missing

parts could result in serious personal injury.

Page 12 — English

Page 13

ASSEMBLY

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

OPERATION

DANGER:

Never use near power lines or other electric

sources. Contact with power lines or electric

sources will result in death by electrocution or

serious injury.

WARNING:

WARNING:

Do not connect to power supply until assembly

is complete. Failure to comply could result in

accidental starting and possible serious personal injury.

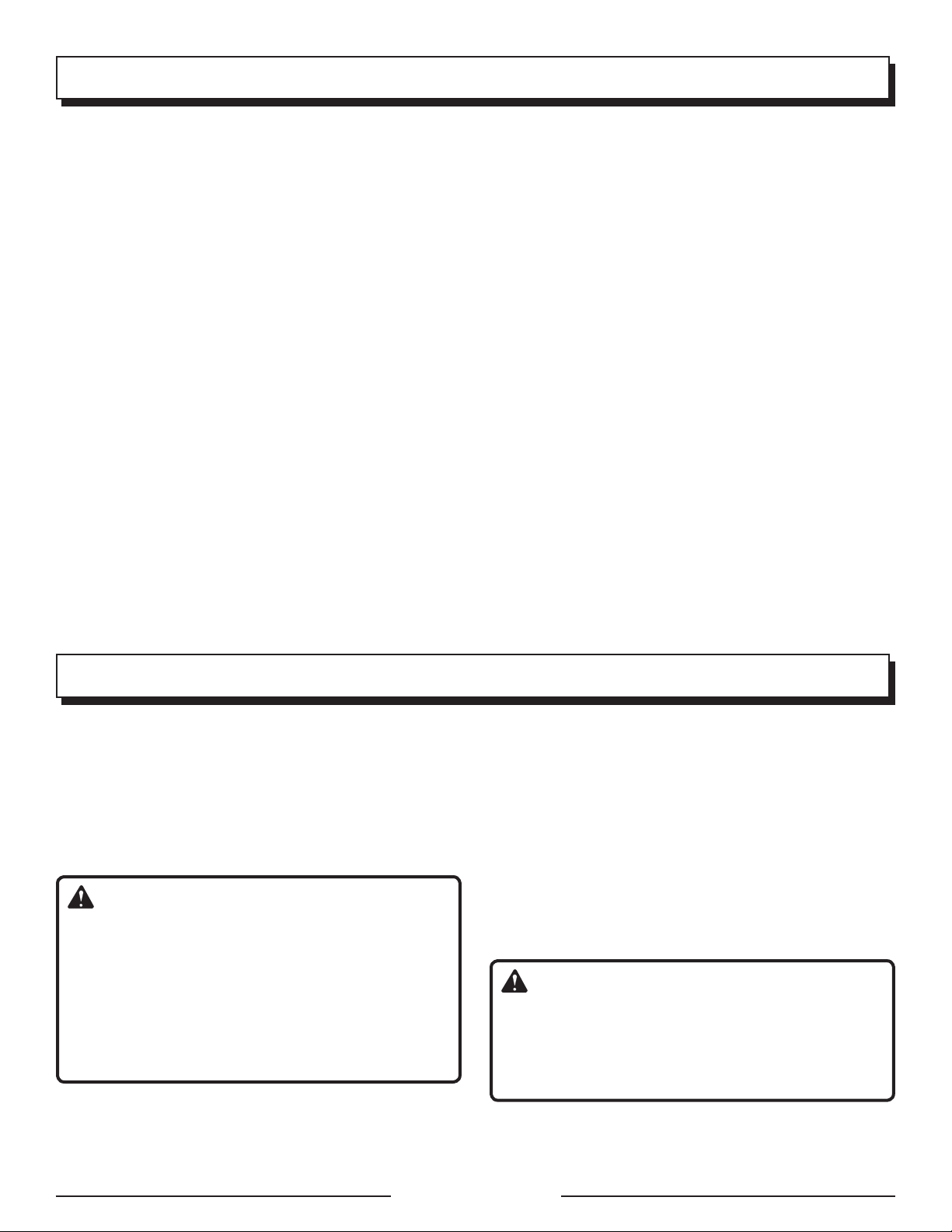

CHAIN

LUBRICANT

OIL RESERVOIR

CAP

Do not allow familiarity with this product to

make you careless. Remember that a careless

fraction of a second is sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1, along with

head protection. Failure to do so could result in

objects being thrown into your eyes and other

possible serious injuries.

WARNING:

Do not use any attachments or accessories

not recommended by the manufacturer of this

product. The use of attachments or accessories

not recommended can result in serious personal

injury.

APPLICATIONS

You may use this product for the purposes listed

below:

Basic limbing, felling, and woodcutting

Removing buttress roots

QUICK VIEW

OIL INDICATOR

Fig. 7

ADDING BAR AND CHAIN LUBRICANT

See Figure 7

Use HOMELITE Bar and Chain Lubricant. It is

designed for chains and chain oilers, and is formulated to perform over a wide temperature range

with no dilution required.

NOTE: Chain saw comes from the factory with

no bar and chain oil added. Level should also be

checked after every 20 minutes of use and refilled

as needed.

Remove oil cap.

Carefully pour the bar and chain oil into the tank.

Wipe off excess oil.

Check and fill the oil tank when quick view oil indi-

cator is below the second to last indicator line.

Repeat as needed.

NOTE: Do not use dirty, used or otherwise

contaminated oils. Damage may occur to the

bar or chain.

Page 13 — English

Page 14

OPERATION

NOTE: It is normal for oil to seep from the saw

when not in use. To prevent seepage, empty the

oil tank after each use then run for one minute.

When storing the unit for a long period of time

(three months or longer) be sure the chain is lightly

lubricated; this will prevent rust on the chain and

bar sprocket.

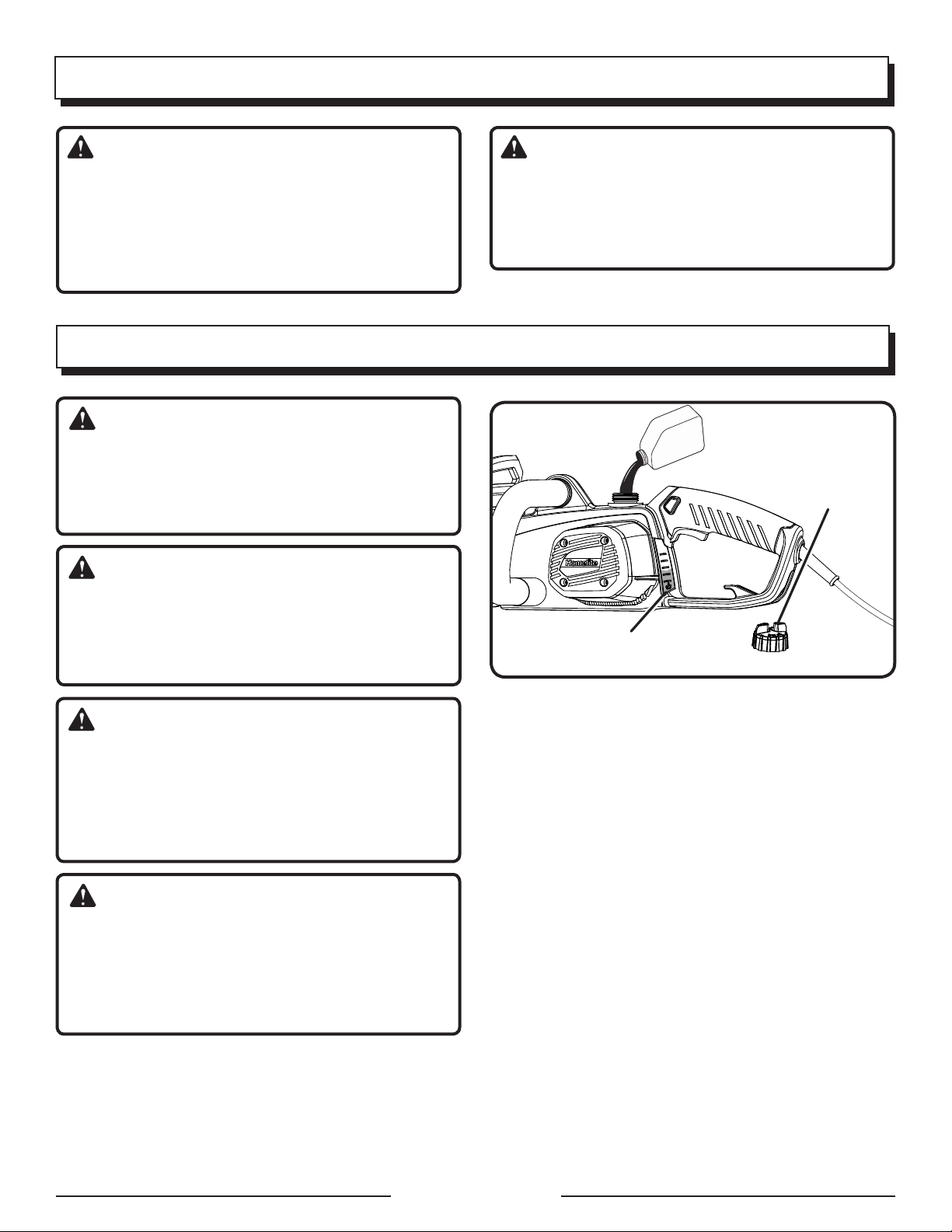

CONNECTING TO POWER SUPPLY

See Figure 8

This chain saw is designed with a cord retainer

that prevents the extension cord from being pulled

loose while using.

Form a loop with the end of the extension cord.

Insert loop portion of extension cord through

the opening in the side of the rear handle and

place over cord hitch.

Slowly pull loop against cord retainer until the

slack is removed.

Plug chain saw into extension cord.

NOTE: Failure to remove all excess cord slack

from extension cord retainer could result in plug

loosening from receptacle.

RETENUE

DE CORDON

EXTENSION

CORD

SWITCH

LOCK-OUT

Fig. 8

SWITCH

TRIGGER

STARTING AND STOPPING THE CHAIN

SAW

See Figure 9.

WARNING:

Keep body to the left of the chain line. Never

straddle the saw or chain, or lean over past the

chain line.

Starting the chain saw:

Make sure chain tension is at desired setting.

Refer to Adjusting the Chain Tension in the

Maintenance section of this manual.

Make sure the chain cover lock knob is tight to

the chain cover.

Make sure no objects or obstructions are in

immediate vicinity which could come in contact

with the bar and chain.

Press and hold the switch lock-out. This makes

the switch trigger operational.

Press and hold the switch trigger, release the

switch lock-out and continue to squeeze the

switch trigger for continued operation.

Fig. 9

Stopping the chain saw:

NOTE: It is normal for the chain to coast to a stop

once the trigger switch is released.

Release the switch trigger to stop the chain

saw.

Upon release of the switch trigger, the switch

lock-out will be automatically reset to the lock

position.

PREPARING FOR CUTTING

PROPER GRIP ON HANDLES

See Figure 10.

See General Safety Rules for appropriate safety

equipment.

Wear non-slip gloves for maximum grip and

protection.

Hold the saw firmly with both hands. Always

keep your left hand on the front handle and your

right hand on the rear handle so that your body

is to the left of the chain line.

Page 14 — English

Page 15

OPERATION

WARNING:

Never use a left-handed (cross-handed) grip or

any stance that would place your body or arm

across the chain line.

Maintain a proper grip on the saw whenever the

motor is running. The fingers should encircle

the handle and the thumb is wrapped under the

handlebar. This grip is least likely to be broken by

a kickback or other sudden reaction of the saw.

Any grip in which the thumb and fingers are on the

same side of the handle is dangerous because a

slight kick of the saw can cause loss of control.

WARNING:

DO NOT operate the switch

trigger with your left hand

and hold the front handle

with your right hand. Never

allow any part of your body

to be in the chain line while

operating a saw. Improper

operation of the chain saw

could result in serious personal injury.

CHAIN

LINE

PROPER GRIP

THUMB ON

UNDERSIDE OF

HANDLE BAR

CHAIN LINE

PROPER HAND

GRIP POSITION

IMPROPER GRIP

Fig. 10

STRAIGHT

ARM

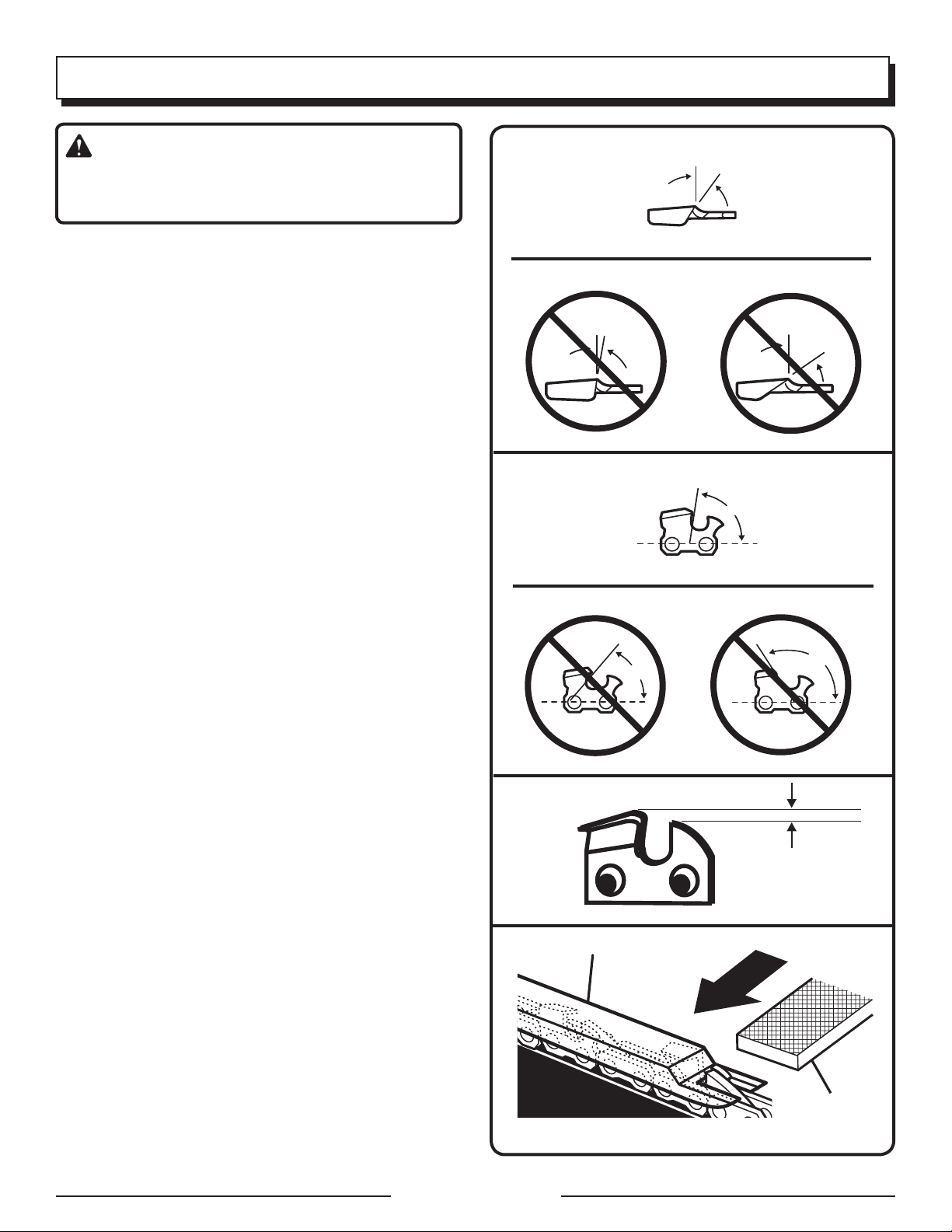

PROPER CUTTING STANCE

See Figure 11.

WARNING:

Always use the proper cutting stance described

in this section. Never kneel when using the

chain saw, except when felling a tree as illustrated in Figure 12. Kneeling could result in

loss of stability and control of the chain saw,

resulting in serious personal injury.

Balance your weight with both feet on solid ground.

Keep left arm with elbow locked in a “straight

arm” position to withstand any kickback force.

Keep your body to the left of the chain line.

Keep your thumb on underside of handlebar.

Page 15 — English

Fig. 11

BASIC OPERATING/CUTTING

PROCEDURES

Practice cutting a few small logs using the following

technique to get the “feel” of using the saw before

you begin a major sawing operation.

Take the proper stance in front of the wood with

the saw idling.

Page 16

OPERATION

Press the switch lock-out and squeeze the

switch trigger then release switch lock-out and

let the chain accelerate to full speed before

entering the cut.

Begin cutting with the saw against the log.

Keep the unit running the entire time you are

cutting, maintain a steady speed.

Allow the chain to cut for you; exert only light

downward pressure. Forcing the cut could result

in damage to the bar, chain, or motor.

Release the switch trigger as soon as the cut

is completed, allowing the chain to stop. If you

run the saw without a cutting load, unnecessary

wear can occur to the chain, bar, and unit.

Do not put pressure on the saw at the end of

the cut.

WORK AREA PRECAUTIONS

See Figure 12.

Cut only wood or materials made from wood;

no sheet metal, no plastics, no masonry, no

non-wood building materials.

Never allow children to operate the saw. Allow

no person to use this chain saw who has

not read this operator’s manual or received

adequate instructions for the safe and proper

use of this chain saw.

Keep everyone – helpers, bystanders, children,

and animals – a SAFE DISTANCE from the

cutting area. During felling operations, the safe

distance should be a least twice the height of the

largest trees in the felling area. During bucking

operations, keep a minimum distance of 15 feet

between workers.

Always cut with both feet on solid ground to

prevent being pulled off balance.

Do not cut above shoulder height as a saw held

higher is difficult to control against kickback

forces.

Do not fell trees near electrical wires or build-

ings. Leave this operation for professionals.

Cut only when visibility and light are adequate

for you to see clearly.

Fig. 12

FELLING TREES

HAZARDOUS CONDITIONS

WARNING:

Do not fell trees during periods of high wind or

heavy precipitation. Wait until the hazardous

weather has ended.

When felling a tree, it is important that you heed

the following warnings to prevent possible serious

injury.

Do not cut down trees having an extreme lean or

large trees with rotten limbs, loose bark, or hollow trunks. Have these trees pushed or dragged

down with heavy equipment, then cut them up.

Do not cut trees near electrical wires or buildings.

Check the tree for damaged or dead branches

that could fall and hit you during felling.

Periodically glance at the top of the tree during

the backcut to assure the tree is going to fall in

the desired direction.

If the tree starts to fall in the wrong direction,

or if the saw gets caught or hung up during the

fall, leave the saw and save yourself!

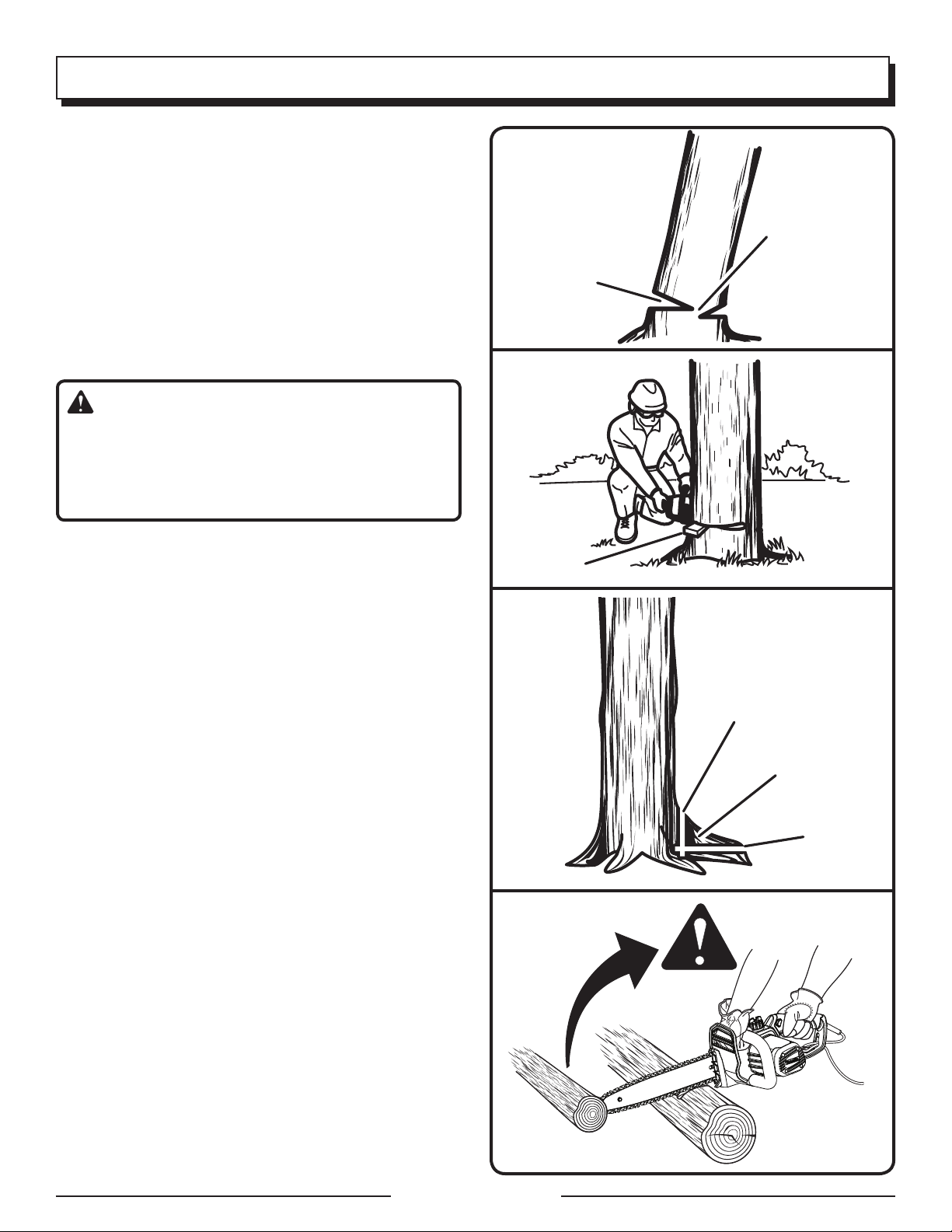

PROPER PROCEDURE FOR TREE

FELLING

See Figures 13 - 16.

Felling a tree — When bucking and felling

operations are being performed by two or more

persons, at the same time, the felling operation

should be separated from the bucking operation

Page 16 — English

Page 17

OPERATION

by a distance of at least twice the height of the

tree being felled. Trees should not be felled in a

manner that would endanger any person, strike

any utility line or cause any property damage. If

the tree does make contact with any utility line,

the utility company should be notified immediately.

Operator should keep on the uphill side of terrain

as the tree is likely to roll or slide after it is felled.

Pick your escape route (or routes in case the

intended route is blocked). Clear the immediate

area around the tree and make sure there are

no obstructions in your planned path of retreat.

Clear the path of safe retreat approximately 135°

from the planned line of fall.

Consider the force and direction of the wind, the

lean and balance of the tree, and the location of

large limbs. These things influence the direction

in which the tree will fall. Do not try to fell a tree

along a line different from its natural line of fall.

Remove dirt, stones, loose bark, nails, staples,

and wire from the tree where felling cuts are to

be made.

Notched Undercut. Cut a notch about 1/3 the

diameter of the trunk in the side of the tree.

Make the notch cuts so they intersect at a right

angle to the line of fall. This notch should be

cleaned out to leave a straight line. To keep the

weight of the wood off the saw, always make

the lower cut of the notch before the upper cut.

PLANNED LINE

OF FALL

135° FROM

PLANNED

LINE OF FALL

PLANNED

LINE OF

FALL

135°

135°

SAFE RETREAT

45°

90°

45°

90°

PATH OF

PATH

OF SAFE

RETREAT

Fig. 13

Felling Backcut. As the felling cut gets close

to the hinge the tree should begin to fall. If

there is any chance the tree may not fall in the

desired direction or it may rock back and bind

the saw chain, stop cutting before the felling cut

is complete and use wedges of wood, plastic

or aluminum to open the cut and drop the tree

along its desired line of fall. Make the backcut

level and horizontal, and at a minimum of 2 in.

above the horizontal cut of the notch.

NOTE: Never cut through to the notch. Always

leave a band of wood between the notch

and back cut (approximately 2 in. or 1/10 the

diameter of the tree). This is called “hinge” or

“hingewood.” It controls the fall of the tree and

prevents slipping or twisting or shootback of

the tree off the stump.

Page 17 — English

HINGE

2 in. OR 1/10 DIA

NOTCH -

APPROX. 1/3

DIAMETER

OF TRUNK

BACK CUT

2 in.

On large diameter trees, stop the back cut

before it is deep enough for the tree to either

fall or settle back on the stump. Then insert soft

wooden or plastic wedges into the cut so they

do not touch the chain. Drive wedges in, little

by little, to help jack the tree over.

Fig. 14

Page 18

OPERATION

When bucking or felling with a wedge, it may

be necessary to remove the SAFE-T-TIP antikickback device to allow the bar to be drawn

through the cut. After you complete the cut,

reinstall the tip immediately.

As tree starts to fall, stop the chain saw and put

it down immediately. Retreat along the cleared

path, but watch the action in case something

falls your way.

Be alert for overhead limbs falling and watch

your footing.

WARNING:

Never cut through to the notch when making a

back cut. The hinge controls the fall of the tree,

this is the section of wood between the notch

and backcut.

HINGE

BACK CUT

Fig. 15

REMOVING BUTTRESS ROOTS

See Figure 17.

A buttress root is a large root extending from the

trunk of the tree above the ground. Remove large

buttress roots prior to felling. Make the horizontal

cut into the buttress first, followed by the vertical

cut. Remove the resulting loose section from the

work area. Follow the correct tree felling procedure

as stated in Proper Procedure For Tree Felling

after you have removed the large buttress roots.

BUCKING

See Figure 18.

Bucking is the term used for cutting a fallen tree

to the desired log length.

Always make sure your footing is secure and

your weight is distributed evenly on both feet.

Cut only one log at a time.

Support small logs on a saw horse or another

log while bucking.

WEDGE

KICKBACK

Fig. 16

VERTICAL

CUT

LOOSE

SECTION

HORIZONTAL

CUT

Fig. 17

Keep a clear cutting area. Make sure that no

objects can contact the guide bar nose and

chain during cutting, this can cause kickback.

To avoid the danger, keep the SAFE-T-TIP antikickback device attached while cutting. Refer

to Kickback earlier in this manual.

Page 18 — English

Fig. 18

Page 19

OPERATION

When bucking on a slope, always stand on the

uphill side of the log. To maintain complete

control of the chain saw when cutting through

the log, release the cutting pressure near the

end of the cut without relaxing your grip on the

chain saw handles. Do not let the chain contact

the ground. After completing the cut, wait for the

saw chain to stop before you move the chain

saw. Always stop the motor before moving from

tree to tree.

BUCKING WITH A WEDGE

See Figure 19.

If the wood diameter is large enough for you to

insert a soft bucking wedge without touching the

chain, you should use the wedge to hold the cut

open to prevent pinching.

NOTE: When bucking or felling with a wedge, you

may need to remove the SAFE-T-TIP anti-kickback

device to allow the bar to be drawn through the

cut. After you complete the cut, reinstall the tip.

WEDGE

LOG SUPPORTED AT ONE END

FINISHING CUT

LOAD

Fig. 19

BUCKING LOGS UNDER STRESS

See Figure 20.

Make the first bucking cut 1/3 of the way through

the log and finish with a 2/3 cut on the opposite

side. As you cut the log, it will tend to bend. The

saw can become pinched or hung in the log if you

make the first cut deeper than 1/3 of the diameter

of the log.

Give special attention to logs under stress to

prevent the bar and chain from pinching.

OVERBUCKING

See Figure 21.

Begin on the top side of the log with the bottom

of the saw against the log; exert light pressure

downward. Note that the saw will tend to pull

away from you.

1ST CUT 1/3 DIA

LOG SUPPORTED AT BOTH ENDS

1ST CUT 1/3 DIA

LOAD

FINISHING CUT

Fig. 20

Page 19 — English

OVERBUCKING

Fig. 21

Page 20

OPERATION

UNDERBUCKING

See Figure 22.

Begin on the under side of the log with the top

of the saw against the log; exert light pressure

upward. During underbucking, the saw will tend

to push back at you. Be prepared for this reaction

and hold the saw firmly to maintain control.

LIMBING

See Figure 23.

Limbing is removing branches from a fallen tree.

Work slowly, keeping both hands on the chain

saw with a firm grip. Always make sure your

footing is secure and your weight is distributed

evenly on both feet.

Leave the larger support limbs under the tree

to keep the tree off the ground while cutting.

Limbs should be cut one at a time. Remove the

cut limbs from the work area often to help keep

the work area clean and safe.

Branches under tension should be cut from the

bottom up to avoid binding the chain saw.

Keep the tree between you and the chain saw

while limbing. Cut from the side of the tree

opposite the branch you are cutting.

PRUNING

See Figure 24.

Pruning is trimming limbs from a live tree.

Work slowly, keeping both hands on the chain

saw with a firm grip. Always make sure your

footing is secure and your weight is distributed

evenly on both feet.

UNDERBUCKING

SECOND CUT

LOAD

FIRST CUT

1/3 DIAMETER

FINISHING CUT

CUT LIMBS ONE AT A TIME AND LEAVE SUPPORT

LIMBS UNDER TREE UNTIL LOG IS CUT

Fig. 22

Fig. 23

Fig. 24

Do not cut from a ladder, this is extremely dan-

gerous. Leave this operation for professionals.

Do not cut above shoulder height as a saw held

higher is difficult to control against kickback.

Page 20 — English

SPRINGPOLE

Fig. 25

Page 21

OPERATION

When pruning trees it is important not to make

the finishing cut next to the main limb or trunk

until you have cut off the limb further out to

reduce the weight. This prevents stripping the

bark from the main member.

Underbuck the branch 1/3 through for your first

cut.

Your second cut should overbuck to drop the

branch off.

Now make your finishing cut smoothly and

neatly against the main member so the bark will

grow back to seal the wound.

WARNING:

If the limbs to be pruned are above shoulder

height, hire a professional to perform the pruning. Cutting above shoulder height could result

in an accident, causing serious personal injury.

CUTTING SPRINGPOLES

See Figure 25.

A springpole is any log, branch, rooted stump, or

sapling which is bent under tension by other wood

so that it springs back if the wood holding it is cut

or removed. On a fallen tree, a rooted stump has

a high potential of springing back to the upright

position during the bucking cut to separate the log

from the stump. Watch out for springpoles — they

are dangerous.

WARNING:

Springpoles are dangerous and could strike the

operator, causing the operator to lose control

of the chain saw. This could result in severe or

fatal injury to the operator.

Page 21 — English

Page 22

MAINTENANCE

WARNING:

Before performing any maintenance, make sure

the tool is unplugged from the power supply.

Failure to comply could result in accidental

starting and possible serious personal injury.

WARNING:

When servicing, use only identical Homelite

replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1, along with

head protection. Failure to do so could result in

objects being thrown into your eyes and other

possible serious injuries.

CHAIN TENSIONING

KNOB

CHAIN COVER

LOCK KNOB

MOUNTING

SURFACE

Fig. 26

BAR

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from

various types of commercial solvents and may be

damaged by their use. Use clean cloths to remove

dirt, dust, lubricant, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating

lubricants, etc., come in contact with plastic

parts. Chemicals can damage, weaken or

destroy plastic which may result in serious

personal injury.

LUBRICATION

All of the bearings in this product are lubricated with

a sufficient amount of high grade lubricant for the

life of the unit under normal operating conditions.

Therefore, no further lubrication is required.

CHAIN

CHAIN COVER

CHAIN COVER

LOCK KNOB

Fig. 27

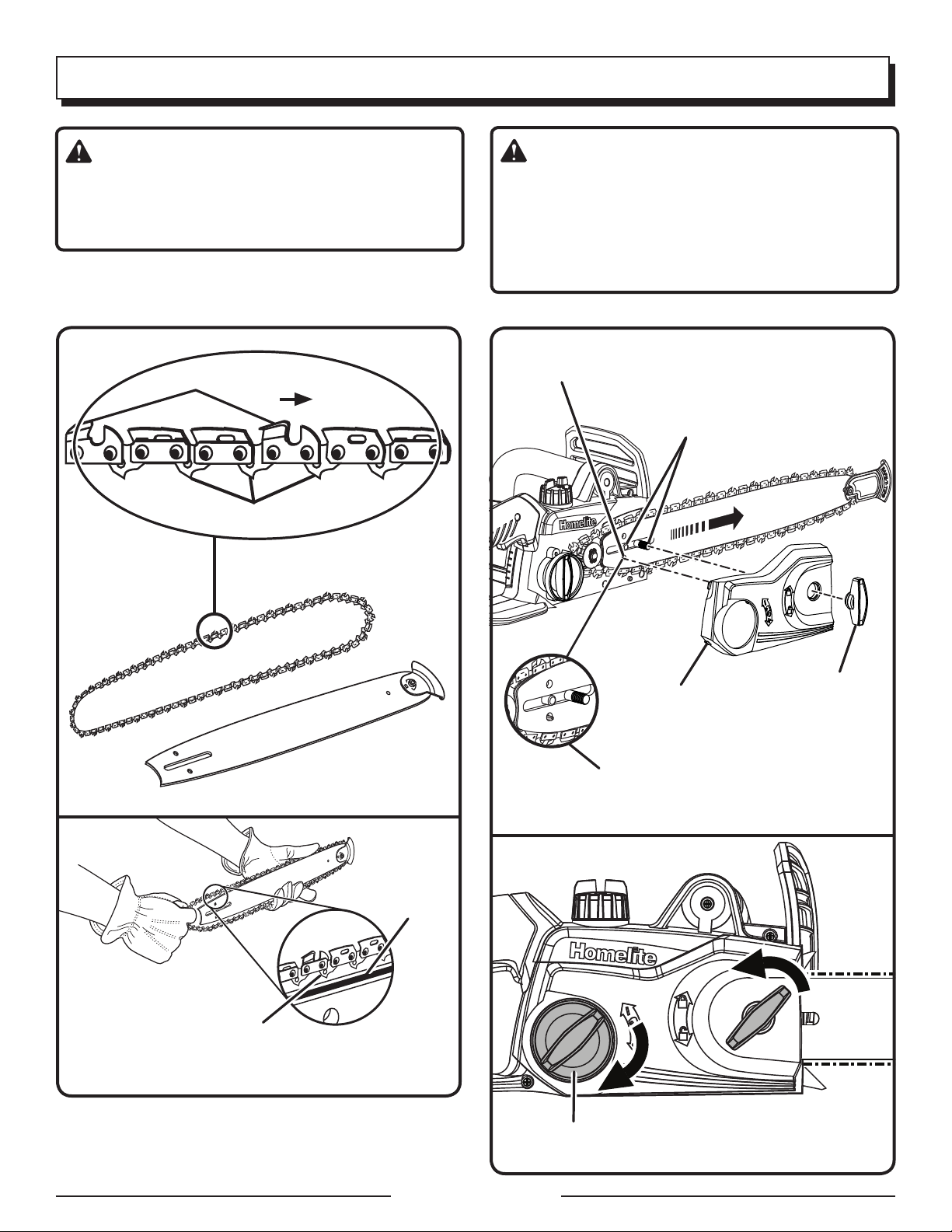

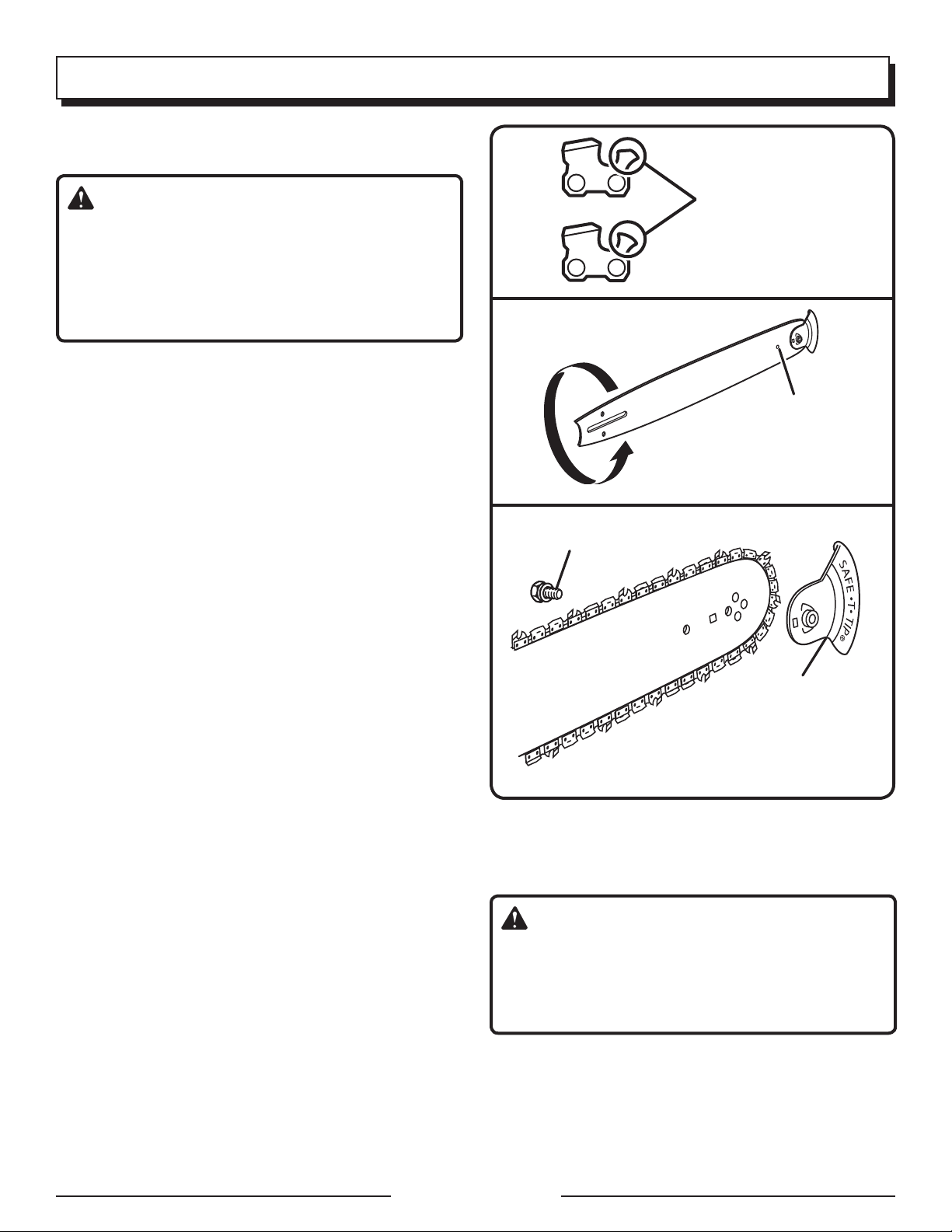

REPLACING THE GUIDE BAR AND

CHAIN

See Figures 26 - 33.

WARNING:

Never start the motor before installing the guide

bar, chain, chain cover, and chain cover lock

knob. Starting the motor without all parts and

the chain at proper tension may result in serious

personal injury.

WARNING:

To avoid serious personal injury, read and

understand all the safety instructions in this

section.

Page 22 — English

Page 23

MAINTENANCE

CAUTION:

Always wear gloves when handling the bar and

chain; these components are sharp and may

contain burrs.

CUTTERS

CHAIN DRIVE LINKS

CHAIN ROTATION

WARNING:

Never touch or adjust the chain while the motor

is running. The saw chain is very sharp; always

wear protective gloves when performing maintenance to the chain to avoid possible serious

lacerations.

CHAIN TENSIONING

PIN HOLE

BAR STUDS

CHAIN DRIVE LINKS

Fig. 28

BAR GROOVE

Fig. 29

CHAIN

COVER

CHAIN TENSIONING

PIN

CHAIN COVER

LOCK KNOB

Fig. 30

CHAIN TENSIONING

Page 23 — English

KNOB

Fig. 31

Page 24

MAINTENANCE

NOTE: When replacing the guide bar and chain,

always use the specified bar and chain listed in

the Bar and Chain Combinations section later

in this manual.

Disconnect chain saw from power supply.

Rotate the chain cover lock knob counterclock-

wise and remove knob.

Remove the chain cover.

Remove the bar and chain from the mounting

surface.

Remove the old chain from the bar.

Lay out the new saw chain in a loop and

straighten any kinks. The cutters should face

in the direction of chain rotation. If they face

backwards, turn the loop over.

Place the chain drive links into the bar groove as

shown.

NOTE: Make certain of direction of chain.

Position the chain so there is a loop at the back

of the bar.

Fig. 32

Fig. 33

FLATS ON DRIVE LINKS

Hold the chain in position on the bar and place

the loop around the sprocket.

Fit the bar flush against the mounting surface so

that the bar studs are in the long slot of the bar.

WARNING:

When placing the bar on the bar studs, ensure

that the chain tensioning pin is in the chain tension pin hole. Failure to properly place the chain

tensioning pin in the chain tensioning pin hole

could cause the chain to come loose, resulting

in serious personal injury.

Replace the chain cover.

Replace the chain cover lock knob; rotate knob

clockwise to tighten. The bar should still be free

to move for tension adjustment.

Remove all slack from the chain by turning the

chain tensioning knob clockwise until the chain

seats snugly against the bar with the drive links

in the bar groove.

Lift the tip of the guide bar up to check for sag.

Release the tip of the guide bar and turn the

chain tensioning knob 1/2 turn clockwise.

Repeat this process until sag does not exist.

Page 24 — English

Fig. 34

≈ .050 in.

Hold the tip of the guide bar up and tighten the

chain cover lock knob.

The chain is correctly tensioned when there is no

sag on the underside of the guide bar, the chain

is snug, but it can be turned by hand without

binding.

NOTE: If chain is too tight, it will not rotate. Loosen

the chain cover lock knob slightly and turn the

chain tensioning knob 1/4 turn counterclockwise.

Lift the tip of the guide bar up and retighten the

chain cover lock knob. Ensure that the chain will

rotate without binding.

Fig. 35

Page 25

MAINTENANCE

ADJUSTING THE CHAIN TENSION

See Figures 34 - 35.

WARNING:

Never touch or adjust the chain while the motor

is running. The saw chain is very sharp. Always

wear protective gloves when performing maintenance on the chain.

Stop the motor and disconnect from power

supply before setting the chain tension.

Slightly loosen the chain cover lock knob.

Turn the chain tensioning knob clockwise to

tension the chain.

NOTE: A cold chain is correctly tensioned when

there is no slack on the underside of the guide

bar, the chain is snug, and it can be turned by

hand without binding.

Rotate the chain cover lock knob clockwise to

secure.

Retension the chain whenever the flats on the drive

links hang out of the bar groove.

NOTE: During normal saw operation, the tem-

perature of the chain increases. The drive links

of a correctly tensioned warm chain will hang

approximately .050 in. out of the bar groove.

NOTE: New chains tend to stretch; check

the chain tension frequently and tension as

required.

CAUTION:

A chain tensioned while warm may be too tight

upon cooling. Check the “cold tension” before

next use.

RAKER (DEPTH GAUGE) CLEARANCE

.025 in.

Fig. 36

INSPECT DRIVE SPROCKET

Fig. 37

Use only a low-kickback chain on this saw. This

fast- cutting chain provides kickback reduction

when properly maintained.

For smooth and fast cutting, maintain the chain

properly.

The chain requires sharpening when the wood

chips are small and powdery, the chain must be

forced through the wood during cutting, or the

chain cuts to one side. During maintenance of the

chain, consider the following:

Improper filing angle of the side plate can

increase the risk of severe kickback.

Raker (depth gauge) clearance.

• Too low increases the potential for kickback.

CHAIN MAINTENANCE

See Figures 36 - 37.

WARNING:

Before performing any maintenance, make sure

the tool is unplugged from the power supply.

Failure to comply could result in accidental

starting and possible serious personal injury.

Page 25 — English

• Not low enough decreases cutting ability.

If the cutter teeth hit hard objects such as nails

and stones, or are abraded by mud or sand on

the wood, have an authorized service center

sharpen the chain.

NOTE: Inspect the drive sprocket for wear or

damage when replacing the chain. If signs of

wear or damage are present in the areas indicated, have the drive sprocket replaced by an

authorized service center.

Page 26

MAINTENANCE

NOTE: If you do not fully understand the correct

procedure for sharpening the chain after reading the

instructions that follow, have the saw chain sharpened by an authorized service center or replace

with a recommended low-kickback chain.

SHARPENING THE CUTTERS

See Figures 38 - 41.

Be careful to file all cutters to the specified angles

and to the same length, as fast cutting can only be

obtained when all cutters are uniform.

WARNING:

Before performing any maintenance, make sure

the tool is unplugged from the power supply.

Failure to comply could result in accidental

starting and possible serious personal injury.

WARNING:

The saw chain is very sharp. Always wear protective gloves when performing maintenance to

the chain to prevent serious personal injury.

TOP PLATE

RIVET

HOLE

HEEL

CUTTING

CORNER

GULLET

SIDE PLATE

DEPTH GAUGE

TOE

Fig. 38

Fig. 39

Tension the chain prior to sharpening. Refer to

Adjusting The Chain Tension.

Use a 5/32 in. diameter round file and holder.

Do all of your filing at the midpoint of the bar.

Keep the file level with the top plate of the tooth.

Do not let the file dip or rock.

Using light but firm pressure. Stroke towards

the front corner of the tooth.

Lift the file away from the steel on each return

stroke.

Put a few firm strokes on every tooth. File all left

hand cutters in one direction. Then move to the

other side and file the right hand cutters in the

opposite direction.

Remove filings from the file with a wire brush.

CAUTION:

A dull or improperly sharpened chain can cause

excessive motor speed during cutting, which

may result in severe motor damage.

Fig. 40

LEFT HAND

CUTTERS

RIGHT HAND

CUTTERS

Fig. 41

WARNING:

Improper chain sharpening increases the potential of kickback , which could result in serious

personal injury.

Page 26 — English

Page 27

MAINTENANCE

WARNING:

Failure to replace or repair a damaged chain

could cause serious injury.

TOP PLATE FILING ANGLE

See Figure 42

CORRECT 30° – file holders are marked with

guide marks to align file properly to produce

correct top plate angle.

LESS THAN 30° – for cross cutting.

MORE THAN 30° – feathered edge dulls

quickly.

SIDE PLATE ANGLE

See Figure 43.

CORRECT 80° – Produced automatically if you

use the correct diameter file in the file holder.

HOOK – “Grabs” and dulls quickly; increases

the potential of KICKBACK. Results from using

a file with a diameter too small or a file held too

low.

TOP PLATE FILING ANGLE

LESS THAN 30°

SIDE PLATE FILING ANGLE

HOOK

30°

CORRECT

INCORRECT

CORRECT

BACKWARD SLOPE

MORE THAN 30°

Fig. 42

80°

BACKWARD SLOPE – Needs too much feed

pressure; causes excessive wear to the bar and

chain. Results from using a file with a diameter

too large or file held too high.

MAINTAINING DEPTH GAUGE

CLEARANCE

See Figure 44 - 46.

Maintain the depth gauge at a clearance of .025

in. Use a depth gauge tool for checking the

depth gauge clearances.

Every time the chain is filed, check the depth

gauge clearance.

Use a flat file and a depth gauge jointer to lower

all gauges uniformly. Use a .025 in. depth gauge

jointer. After lowering each depth gauge, restore

original shape by rounding the front. Be careful

not to damage adjoining drive links with the

edge of the file.

Depth gauges must be adjusted with the flat file

in the same direction the adjoining cutter was

filed with the round file. Use care not to contact

cutter face with flat file when adjusting depth

gauges.

INCORRECT

RAKER (DEPTH GAUGE) CLEARANCE

.025 IN.

DEPTH GAUGE JOINTER

Fig. 43

Fig. 44

FLAT FILE

Fig. 45

Page 27 — English

Page 28

MAINTENANCE

MAINTAINING THE GUIDE BAR

See Figure 47.

WARNING:

Before performing any maintenance, make sure

the chain has stopped moving and the tool is

unplugged from the power supply. Failure to

comply could result in accidental starting and

possible serious personal injury.

Every week of use, reverse the guide bar on the

saw to distribute the wear for maximum bar life.

The bar should be cleaned every day of use and

checked for wear and damage.

Feathering or burring of the bar rails is a normal process of bar wear. Such faults should be smoothed

with a file as soon as they occur.

A bar with any of the following faults should be

replaced:

Wear inside the bar rails that permits the chain

to lay over sideways

Bent guide bar

Cracked or broken rails

Spread rails

Lubricate guide bars weekly with a sprocket at

their tip. Using a grease syringe, lubricate weekly

in the lubricating hole. Turn the guide bar and

check that the lubrication holes and chain groove

are free from impurities.

RESTORE ORIGINAL

SHAPE BY ROUNDING

THE FRONT

Fig. 46

LUBRICATING

HOLE

Fig. 47

MOUNTING

SCREW

SAFE-T-TIP

Fig. 48

MOUNTING THE SAFE-T-TIP® NOSE

GUARD

See Figures 48 - 49.

Disconnect chain saw from power supply.

Mount the SAFE-T-TIP on the bar nose.

Fit the locking rivet or tab in the recessed hole

in the guide bar.

Tighten the screw with wrench until snug.

From the snug position, tighten the screw an

additional 3/4 of a turn using a wrench.

Page 28 — English

MAINTAINING THE SAFE-T-TIP

®

NOSE

GUARD

See Figures 47 - 48.

WARNING:

Although the guide bar comes with a SAFE-TTIP antikickback device already installed, check

the tightness of the mounting screw before each

use to avoid possible serious personal injury.

Page 29

MAINTENANCE

Use the following instructions to tighten the mounting screw of the nose guard. These are specially

hardened screws. If you cannot install the screw

tightly, replace both the screw and the SAFE-T-TIP

before further operation.

NOTE: Do not replace the screw with an ordinary

screw. Use only identical replacement parts from

the manufacturer when replacing parts.

In addition to preventing chain contact with solid

objects at the nose of the bar, the SAFE-T-TIP also

helps keep the chain away from abrasive surfaces,

such as the ground. Keep it on the right hand side

of the bar where it will be between the chain and

the ground during flush with ground cutting.

The mounting screw requires a 5/16 in. wrench (or

adjustable wrench) to achieve the recommended

torque of 35 to 45 in.lb. A torque within this range

can be achieved by using the following method.

Tighten the screw with wrench until snug.

From the snug position, tighten the screw an

additional 3/4 of a turn using a wrench.

STORING THE PRODUCT

Clean all foreign material from the product. Store

it in a well-ventilated place that is inaccessible

to children. Keep away from corrosive agents

such as garden chemicals and de-icing salts.

TIGHTEN

3/4 OF A

TURN

Fig. 49

Page 29 — English

Page 30

BAR AND CHAIN COMBINATIONS

Chain specifications: .375 in. pitch, low profile skip tooth, .050 in. chain gauge

Length of Bar Guide Bar Part Number Chain Part Number Drive Links

14 in. 310625001 901212001 52

TROUBLESHOOTING

Problem Possible Cause Solution

Bar and chain

running hot and

smoking.

Motor runs,

but chain is not

rotating.

Motor runs, chain

rotates but does

not cut.

Chain tensioning

dial is difficult to

turn.

Check chain tension for over tight

condition

Chain oil tank empty.

Chain tension too

tight.

Check guide bar and

chain assembly.

Check guide bar and

chain for damage.

Dull chain.

Chain on backwards.

Tip of guide bar is not

raised.

Chain cover lock knob

is too tight.

Tension chain. Refer to Adjusting Chain Tension ear-

lier in this manual.

Check oil tank.

Retension chain, Refer to Adjusting Chain Tension

earlier in this manual.

Refer to Replacing Bar and Chain earlier in this man-

ual.

Inspect guide bar and chain for damage.

Sharpen chain.

Reverse direction of chain.

Raise tip of guide bar while rotating tension adjustment

dial.

Press in the clutch cover lock knob and rotate counterclockwise to slightly loosen the clutch cover before

attempting to adjust chain tension.

CALL

www.homelite.com

CALL US FIRST

For any questions about operating or maintaining your product,

call the Homelite® Help Line!

Your product has been fully tested prior to shipment to ensure

your complete satisfaction.

Page 30 — English

Page 31

WARRANTY

LIMITED WARRANTY STATEMENT

Homelite Consumer Products, Inc., (“Homelite”) warrants

to the original retail purchaser that this HOMELITE brand

outdoor product is free from defect in material and

workmanship and agrees to repair or replace, at Homelite’s,

discretion, any defective product free of charge within these

time periods from the date of purchase.

Two years for all models if used for personal, family, or

household use;

90 days for any unit used for other purposes, such as

rental or commercial.

This warranty extends to the original retail purchaser

only and commences on the date of the original retail

purchase.

Any part of the this product manufactured or supplied

by Homelite and found in the reasonable judgment of

Homelite to be defective in material or workmanship will

be repaired or replaced without charge for parts and labor

by a Homelite authorized service center.

The product, including any defective part, must be returned

to an authorized service dealer within the warranty period.

The expense of delivering the product to the dealer for

warranty work and the expense of returning it back to the

owner after repair or replacement will be paid by the owner.

Homelite’s responsibility in respect to claims is limited to

making the required repairs or replacements and no claim

of breach of warranty shall be cause for cancellation or

rescission of the contract of sale of any HOMELITE brand

product. Proof of purchase will be required by the dealer

to substantiate any warranty claim. All warranty work must

be performed by a Homelite authorized service center.

This warranty is limited to ninety (90) days from the date of

original retail purchase for any HOMELITE brand product

that is used for rental or commercial purposes, or any other

income-producing purpose.

This warranty does not cover any HOMELITE brand product

that has been subject to misuse, neglect, negligence, or

accident, or that has been operated in any way contrary

to the operating instructions as specified in this operator’s

manual. This warranty does not apply to any damage to

the product that is the result of improper maintenance or

to any product that has been altered or modified. The

warranty does not extend to repairs made necessary

by normal wear or by the use of parts or accessories

which are either incompatible with the HOMELITE

brand product or adversely affect its operation,

performance, or durability. In addition, this warranty does

not cover:

A. Tune-ups – Spark Plugs, Carburetor, Carburetor

Adjustments, Ignition, Filters

B. Wear items – Bump Knobs, Outer Spools, Cutting

Lines, Inner Reels, Starter Pulleys, Starter Ropes, Drive

Belts, Tines, Felt Washers, Hitch Pins, Mulching Blades,

Blower Fans, Blower and Vacuum Tubes, Vacuum Bags

and Straps, Guide Bars, Saw Chains

Homelite reserves the right to change or improve

the design of any HOMELITE brand product without

assuming any obligation to modify any product previously

manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION

TO THE STATED WARRANTY PERIOD. ACCORDINGLY,

ANY SUCH IMPLIED WARRANTIES INCLUDING

MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN

THEIR ENTIRETY AFTER THE EXPIRATION OF THE

APPROPRIATE TWO-YEAR, ONE-YEAR, OR NINETY-DAY

WARRANTY PERIOD. HOMELITE’S OBLIGATION UNDER

THIS WARRANTY IS STRICTLY AND EXCLUSIVELY

LIMITED TO THE REPAIR OR REPLACEMENT OF

DEFECTIVE PARTS AND HOMELITE DOES NOT ASSUME

OR AUTHORIZE ANYONE TO ASSUME FOR THEM ANY

OTHER OBLIGATION. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY

TO YOU. HOMELITE ASSUMES NO RESPONSIBILITY

FOR INCIDENTAL, CONSEQUENTIAL, OR OTHER

DAMAGES INCLUDING, BUT NOT LIMITED TO, EXPENSE

OF RETURNING THE PRODUCT TO AN AUTHORIZED

HOMELITE SERVICE CENTER AND EXPENSE OF

DELIVERING IT BACK TO THE OWNER, MECHANIC’S

TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES,

RENTAL OF A LIKE PRODUCT DURING THE TIME

WARRANTY SERVICE IS BEING PERFORMED, TRAVEL,

LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS

OF REVENUE, LOSS OF USE OF THE PRODUCT,

LOSS OF TIME, OR INCONVENIENCE. SOME STATES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

This warranty applies to all HOMELITE brand products

manufactured by or for Homelite and sold in the United

States and Canada.

To locate your nearest Homelite authorized service

center, dial 1-800-242-4672 or log on to our website at

www.homelite.com.

Page 31 — English

Page 32

NOTES / NOTAS

Page 32

Page 33

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT :

Ne pas essayer d’utiliser cet outil avant d’avoir lu

entièrement et bien compris toutes les instructions,

règles de sécurité, etc., contenues dans ce