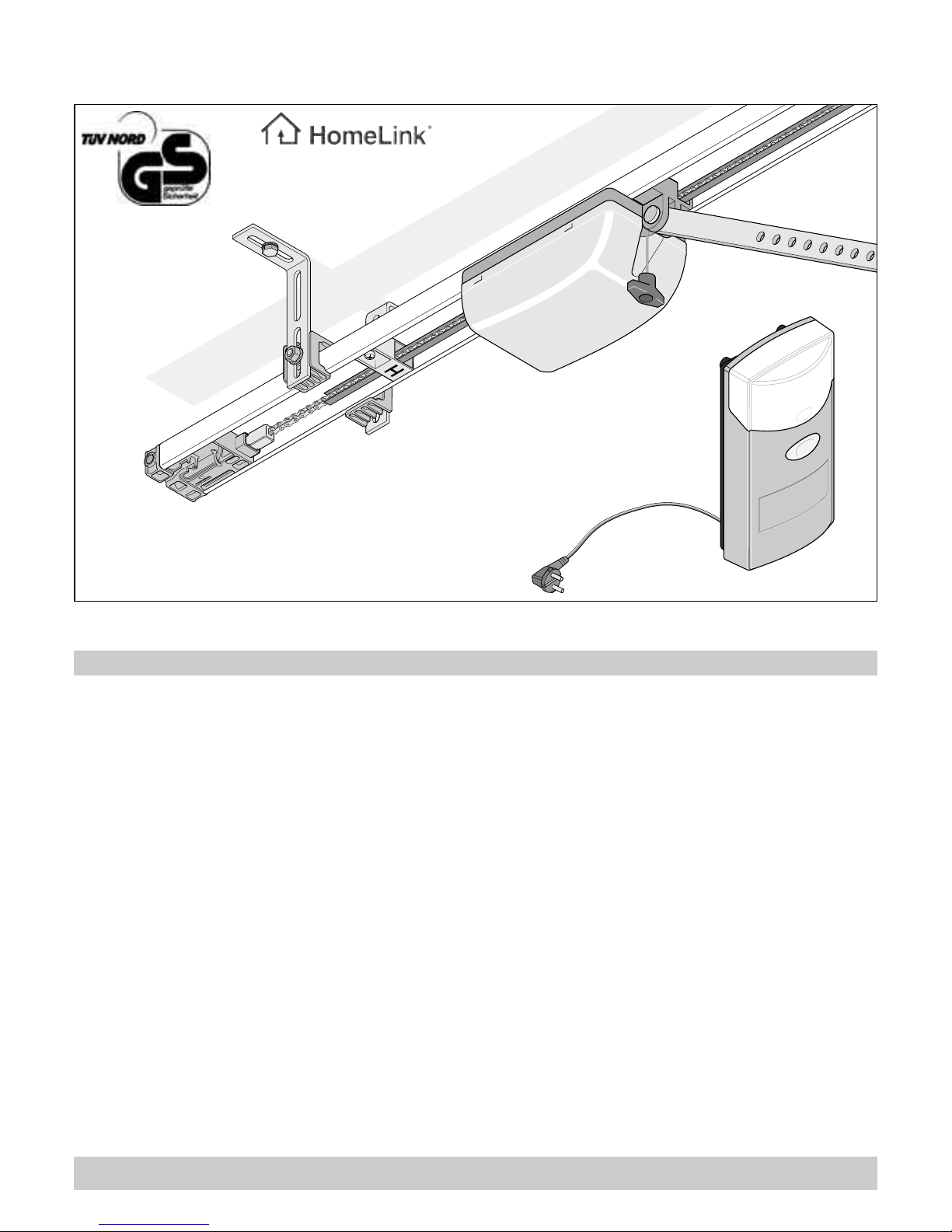

HomeLink duo vision 500, duo vision 800, duo vision 650 Installation And Operating Instructions Manual

Page 1

& Installation and operating instructions 1 - 22

&

46653V001-512007-0-OCE-Rev.B

duo vision 500, duo vision 650, duo vision 800

Page 2

Contents

1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols 2

Safety instructions 2

Normal use 2

Maximum door dimensions * 3

Technical data 3

EU manufacturer’s declaration 3

Preparations for installation . . . . . . . . . . . . . . . . . . . . . 4

Safety instructions 4

Supplied components 4

General installation information . . . . . . . . . . . . . . . . . . 5

Safety instructions 5

Door types and special accessories* 5

Installation tips 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Selection of installation option 6

Pre-assembly for installation options A/C 6

Pre-assembly for installation option B 7

Installation (example: option B) 8

Installing and connecting the control unit 9

Installing the socket outlet 10

Installing and connecting an additional push-button 11

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety instructions 12

Setting door OPEN + CLOSED final travel positions 12

Teaching in drive 12

Checking the limit positions for door CLOSED + OPEN 12

Checking emergency release 13

Checking force setting 13

Programming of remote control 13

Attaching instruction label 13

Attaching warning sign 13

Operation and handling . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety instructions 14

Opening door 14

Closing door 14

Pulse sequence of door movement 14

Emergency release 14

Control reset 14

Radio remote control receiver 15

Description of display and push-buttons 15

Teaching in manual remote control 15

Functions and connections . . . . . . . . . . . . . . . . . . . . . 17

Obstacle recognition (DIP 1, 2 + 3) 17

Connecting button 2 (DIP 2) 17

Direct socket unit 17

Connecting warning lamp (DIP 4) 17

Warning time (DIP 5) 17

Backjump (DIP 6) 17

Connecting light barrier 17

Defined opening and closing (DIP 7) 18

Trolley board 18

Partial opening (DIP 8) 18

Connecting external antenna 18

Maintenance and care. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Important information 19

Regular checks 20

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty and after-sales service 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EU Conformity Declaration

Messrs

SOMMER Antriebs- und Funktechnik GmbH

Hans-Böckler-Straße 21-27

D-73230 Kirchheim/Teck

declares herewith that the product designated below complies

with the relevant fundamental requirements as per Article 3 of

the R&TTE Directive 1999/5/EG, insofar as the product is used

correctly, and that the following standards apply:

Product: RF Remote Control for doors & gates

Type:

The relevant guidelines and standards are:

Kirchheim/Teck, 04.08.2004

Frank Sommer

Managing Director

- ETSI EN 300220-1:09-2000, -3:09-2000

-

ETSI EN 301489-1:07-2004, -3:08-2002

- DIN EN 60950-1:03-2003

RM04-868-2, RM03-868-4, RX01-868-2/4,

RFSDT-868-1, RFSW-868-1, RM02-868-2,

RM06-868-2, RM04-868-1, RM02-868-2-TIGA,

RM08-868-2, RM01-868,

RM02-434-2, RM03-434-4, RM04-434-2

Page 3

2

Symbols

Caution symbol:

Indicates a potential risk. Failure to follow instructions may

result in serious injuries.

Note symbol:

Information, useful advice.

Refers to the relevant illustration in the introduction or main

text.

Safety instructions

General

• Installation, connection and initial operation of the drive mechanism may

only be carried out by qualified specialists.

• Only install the drive mechanism to correctly aligned and weightbalanced doors. An incorrectly aligned door could cause serious injury or

damage to the drive mechanism.

• The manufacturer cannot be made liable for any damage or disruptions

to operation occurring due to non-compliance with the Installation and

Operating Instructions.

• Ensure that these Installation and Operating Instructions are located in

the garage in an easily accessible place.

• Observe and comply with the locally applicable accident prevention

regulations and EC standards.

• Observe and comply with the directive on 'Power-driven Windows, Doors

and Gates - BGR 232' issued by the Employers' Liability Insurance

Association (valid for the given user in Germany).

• Always disconnect the drive mechanism from the power supply before

carrying out any work.

• Only use the manufacturer's original spare parts, accessories and fixing

material.

Storage

• The drive mechanism may only be stored indoors, in a dry, sealed

environment at an ambient temperature of between -20°C and +50°C.

• The drive mechanism should be stored horizontally.

Operation

• The drive mechanism may only be operated after a risk-free force

tolerance has been set. Select the lowest possible force tolerance to

reduce the risk of injury.

• Keep your hands clear of any moving door or any moving parts.

• Keep children, disabled persons and animals away from the door.

• Only drive into and out of the garage when the door is fully opened.

• Risk of persons trapping or cutting themselves in/on the door system's

moving parts or edges where it closes.

• If the door is not equipped with a small door, or if there is no alternative

access to the garage, install an emergency release system (emergency

release lock or control cable) that can be activated from the outside.

+50°

20°

(1)

1

Radio remote control

• The radio remote control may only be used for equipment and systems

in which defective remote operation of the transmitter or radio receiver

does not constitute a risk to people, animals or property, or in cases

where this risk is eliminated by means of additional safety facilities.

• The user must be made aware of the fact that the remote control of

equipment with accident risk potential may only occur, if at all, when the

equipment concerned is clearly visible.

• Radio remote control may only be used if movement of the door can be

supervised and there are no persons or objects in the area of movement.

• Store the manual remote control such that there is no risk of it being

accidentally operated by, for instance, children or animals.

• The operator of this radio-controlled equipment is in no way protected

from interference from other telecommunications systems and facilities

(e.g. other radio-controlled equipment that is licensed to operate at the

same frequency range). Should serious interference be encountered,

please contact your nearest telecommunications office with interference

measuring facilities (radio signal localisation)!

• Do not use the manually-operated remote control near locations or

installations that are susceptible to radio interference (airports,

hospitals).

Rating plate

The rating plate is located on the cover of the control unit housing.

Exact type designation and date of manufacture (month/year) of the drive

are to be found on the rating plate.

Normal use

Caution! Risk of serious damage to drive!

Do not open or close the door with the drive system without first

adjusting the balance weight (springs tensions). Otherwise, the

motor (gear system) might be seriously damaged.

Caution! Risk to life and limb!

Remove all ropes and loops that are required for the manual

operation of the door.

• The drive is designed for the exclusive purpose of opening and closing

doors. Any other use does not constitute normal use. The manufacturer

accepts no liability for damage resulting from use other than normal use.

The user accepts sole responsibility for any risk thereby incurred.

• Doors operating automatically with a drive must comply with the

standards and directives valid at the given time: e.g. EN 12604,

EN 12605.

• The drive system may only be operated if it is in proper working order.

Always follow standard safety procedures and adhere to the instructions

in this installation and operating manual.

• Any defects that may impair the safe operation of the equipment should

be eliminated without delay.

• The door leaves must be stable and twist-proof, i.e. they should not bend

or twist during opening or closing operations.

• The drive mechanism is unable to compensate for any defects in the

door or for its incorrect installation.

• Only use the drive mechanism in a dry, indoor environment where there

is no risk of explosion.

• Do not use drive in rooms where a hostile environment prevails

(e.g. salty air).

General information

Page 4

General information

3

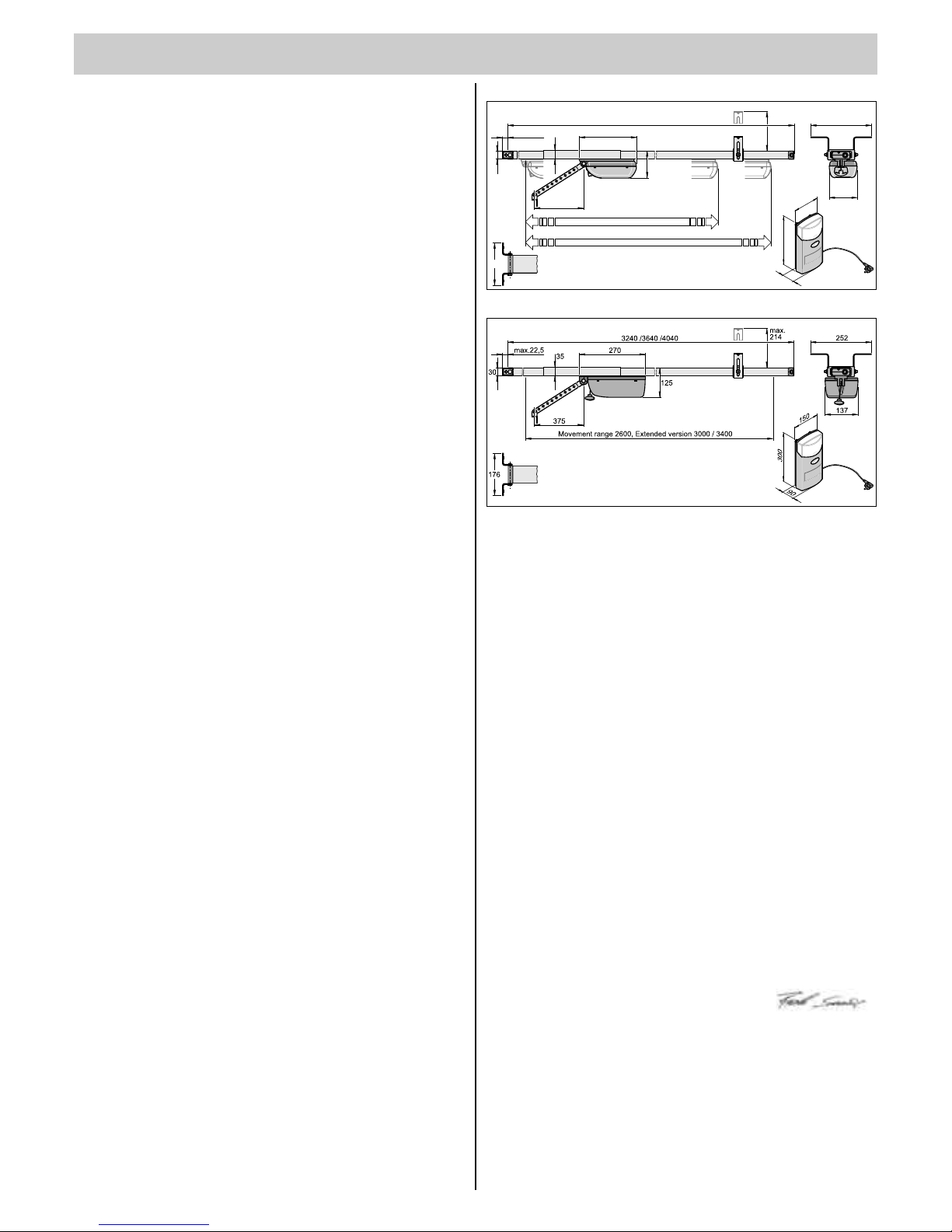

Maximum door dimensions *

duo vision: 500 650 800

Max. width:

- Up-and-over door: 3500 5000 5500 mm

- Sectional door: 3500 5000 5500 mm

- Swing door **: - 2800 2800 mm

- Side-opening sectional door or lateral shutter door:

Rail 2600 2350 2350 2350 mm

Rail 3000 2750 2750 2750 mm

Rail 3400 3150 3150 3150 mm

- Canopy and non-protruding door: - 4000 4500 mm

Height (approx.):

- Up-and-over door:

Rail 2600 2600 2600 2600 mm

Rail 3000 3000 3000 3000 mm

Rail 3400 3400 3400 3400 mm

- Sectional door:

Rail 2600 2350 2350 2350 mm

Rail 3000 2750 2750 2750 mm

Rail 3400 3150 3150 3150 mm

- Swing door **:

Rail 2600 - 2800 3000 mm

- Side-opening sectional door or lateral shutter door:

Rail 2600 2300 3000 3000 mm

- Canopy and non-protruding door:

Rail 2600 - 1900 1900 mm

Rail 3000 - 2300 2300 mm

Rail 3400 - 2700 2700 mm

Duty cycle: 15 15 15 %

* door according to EN 12604, EN 12605.

** with standard swing-out door hinges prod. no. 1501.

If a higher door is required, rails of the respective length must be ordered.

Alternatively, the necessary height can be achieved by installing rail

extensions. Please contact your stockist for more information.

Technical data

General

Rated voltage: 220 … 240 V AC

Rated frequency: 50/60 Hz

Light: max. 32.5 V, max. 34 W, BA 15s

alternatively 24 V, 21 W, BA 15s

Operating temp. range: -20 - +50 °C

Protection class IP 20

Workplace-specific emission value < 75 dBA - operator only

duo vision: 500 650 800

Maximum traction and

pressure force: 500 650 800 N

Rated traction: 150 195 240 N

Rated current consumption: 0.5 0.7 0.8 A

Rated power consumption: 110 150 160 W

Maximum speed: 150 180 130 mm/s

Power consumption, stand-by: ~ 7 ~ 2 ~ 2 W

Weight with rail 2600: 16.0 16.0 16.0 kg

rail 3000: 17.4 17.4 17.4 kg

rail 3400: 18.4 18.4 18.4 kg

duo vision 500, duo vision 650

duo vision 800

Packaging (L x W x H):

- Drive 790 x 160 x 160 mm

- Rail 2600 1665 x 160 x 50 mm

- Rail 3000 1860 x 160 x 50 mm

- Rail 3400 2060 x 160 x 50 mm

EU manufacturer’s declaration

Messrs.

SOMMER Antriebs- und Funktechnik GmbH

Hans-Böckler-Strasse 21-27

D-73230 Kirchheim/Teck, Germany

herewith declares that its drives:

- duo vision 500, duo vision 650, duo vision 800

comply with the following directives:

- Machine Directive 98/37EC

- Low Voltage Directive 73/23/EEC

- EU Electromagnetic Compatibility Directive 89/336/EEC

Above all, the following standards/draft standards were applied:

- EN 12453:2000, EN 60335-1:2002 (+A11:2004, +A1:2004)

- EN 13849-1:2006, DIN EN 55014-1:1999-10, DIN EN 55014-2:1997-10

- DIN EN 61000-6-2:2000-03, DIN EN 61000-3-2:1998-10

- DIN EN 61000-3-36:1998-11

Please note:

The door system may not be commissioned until such time as it has been

established that the system in which the given drive is to be installed

satisfies the specifications of all relevant EU directives.

Kirchheim/Teck, 01.12.2007 Frank Sommer

Managing Director

252

120

2600

3000 / 3400

375

30

max.22,5

max.

214

3240 /3640 /4040

35

150

300

90

176

245

115

Page 5

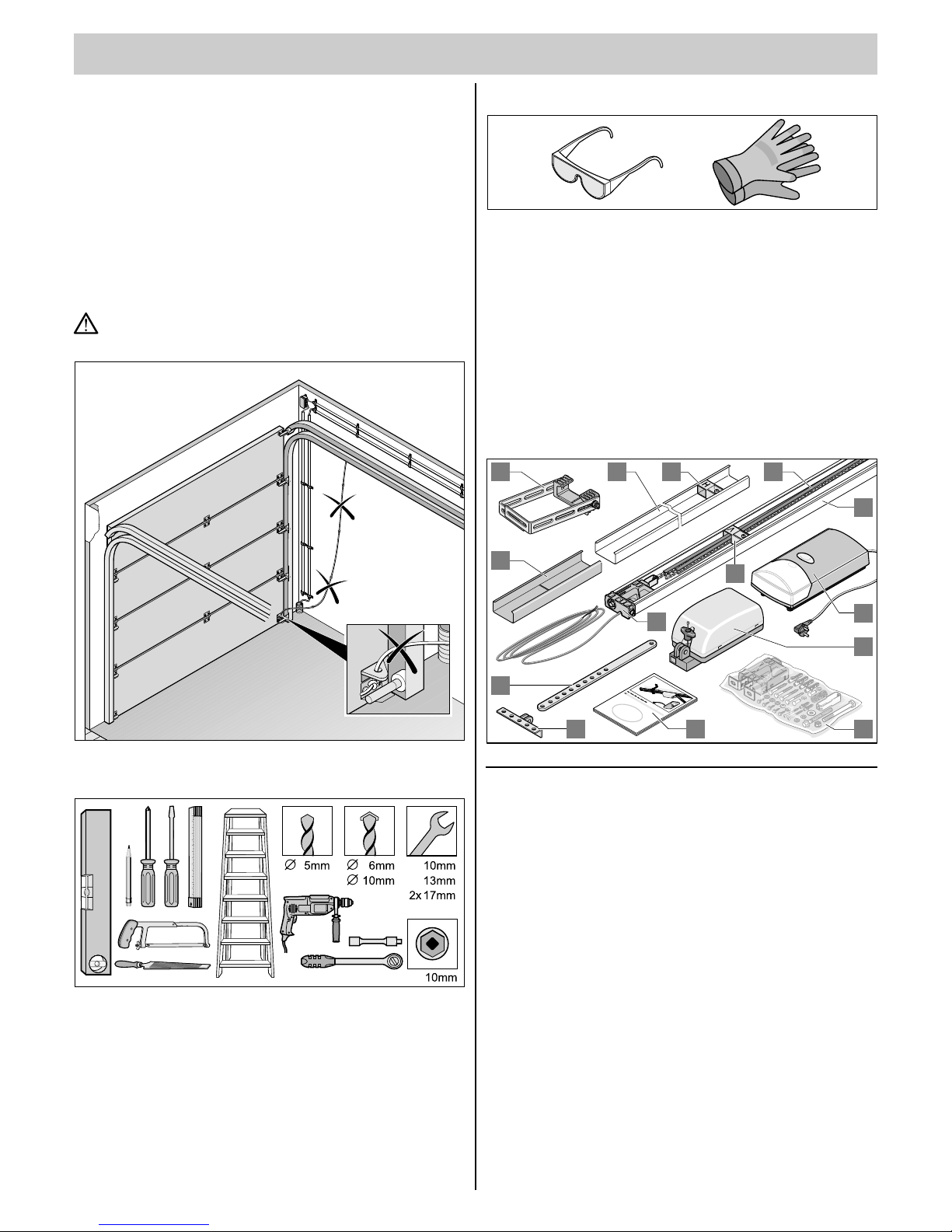

Personal protective equipment

• Protective goggles (for drilling)

• Protective gloves (for handling of cut perforated steel strips, etc.)

Installing wicket-door facility or

release lock

• If your garage door is fitted with a wicket door but no wicket-door safety

facility, you need to have one installed (see 'Accessories' instructions).

• If your door has no wicket door and your garage has no separate

entrance, install a release lock or Bowden wire to facilitate drive mechanism release from the outside (see 'Accessories' instructions).

Supplied components

• The scope of delivery may vary according to the type of drive supplied.

Item Component duo

1. Control housing 1

(push buttons, mains cable, illumination)

2. Trolley (chain case) 1

3. C-rails (uncoated) 2

4. Slide-on module (uncoated) 2

5. Switch trigger “H” 1

6. Switch trigger “V” 1

7. Chain in chain case (duo) 1

(plastic chain case is not packaging do not remove)

8. Connecting rod 1

9. Door hinge 1

10. Suspension bracket 1

11. Installation and operating manual 1

12. Assembly kit (duo) 1

13. Slide-in module with control line 1

(length 5,000 mm)

D

M

on

t

ag

e

u

nd

B

e

trie

b

ss

a

nle

itu

n

g

1

34

D

119

8

10 5

1

2

3

3

12

13

4

6

7

Safety instructions

• The power cable supplied as standard may be neither shortened nor

lengthened.

• The voltage of the power source must correspond to that indicated on the

drive's rating plate.

• All devices requiring external connection must be equipped with safe

contact separation as per IEC 364-4-41 to isolate them from the mains

voltage supply.

• Live parts of the drive (voltage-carrying parts e.g. C-rails) may not be

connected to earth or to the live parts or protective conductors of other

circuits.

• IEC 364-4-41 must be observed when laying the external device conductors.

Caution! Risk to life and limb!

Remove all ropes and loops that are required for the manual

operation of the door.

Tools required

Mit SOMMER sind Sie immer gut ausgerichtet!

Preparations for installation

4

Page 6

5

Safety instructions

• Installation, connection and initial operation of the drive mechanism may

only be carried out by qualified specialists.

• Do not operate the door when people, animals or objects are in its area

of movement.

• Keep children, disabled persons and animals away from the door.

• Safety goggles should be worn when drilling the mounting holes.

• Cover the drive mechanism up when drilling to ensure it does not get

soiled.

The walls and ceiling must be firm and stable. Only fit the drive

mechanism to a correctly aligned door. A door that has not been

aligned correctly can cause serious injuries.

• Doors must be stable because they are subjected to high traction and

pressure forces. Light doors made of plastic or aluminium must be

strengthened before installation if necessary. Ask your specialist retailer

for advice.

• Remove door locking system or disable same.

• Only use approved fixing materials (e.g. screws, plugs) that are

appropriate for the given material the ceilings and walls are made of.

• Check that the door runs easily.

• The door must be balanced.

Test : Manually open the door half-way. It must stay still in this position.

If the door moves downwards or upwards, mechanically readjust it.

Ask your specialist retailer for advice.

• Check the distance between the highest door position (HDP, see fig. 11

for sprint/marathon and fig. 11 for duo) and the ceiling. The distance

between HDP and the lower edge of the C-rail must be between minimum 5 mm and maximum 65 mm, whereby the push rod must be at an

angle of max. 30° (see fig. 21)! If the clearance is less than is permissible, the drive mechanism has to be moved back and an extended drive

rail fitted. Ask your local stockist for advice.

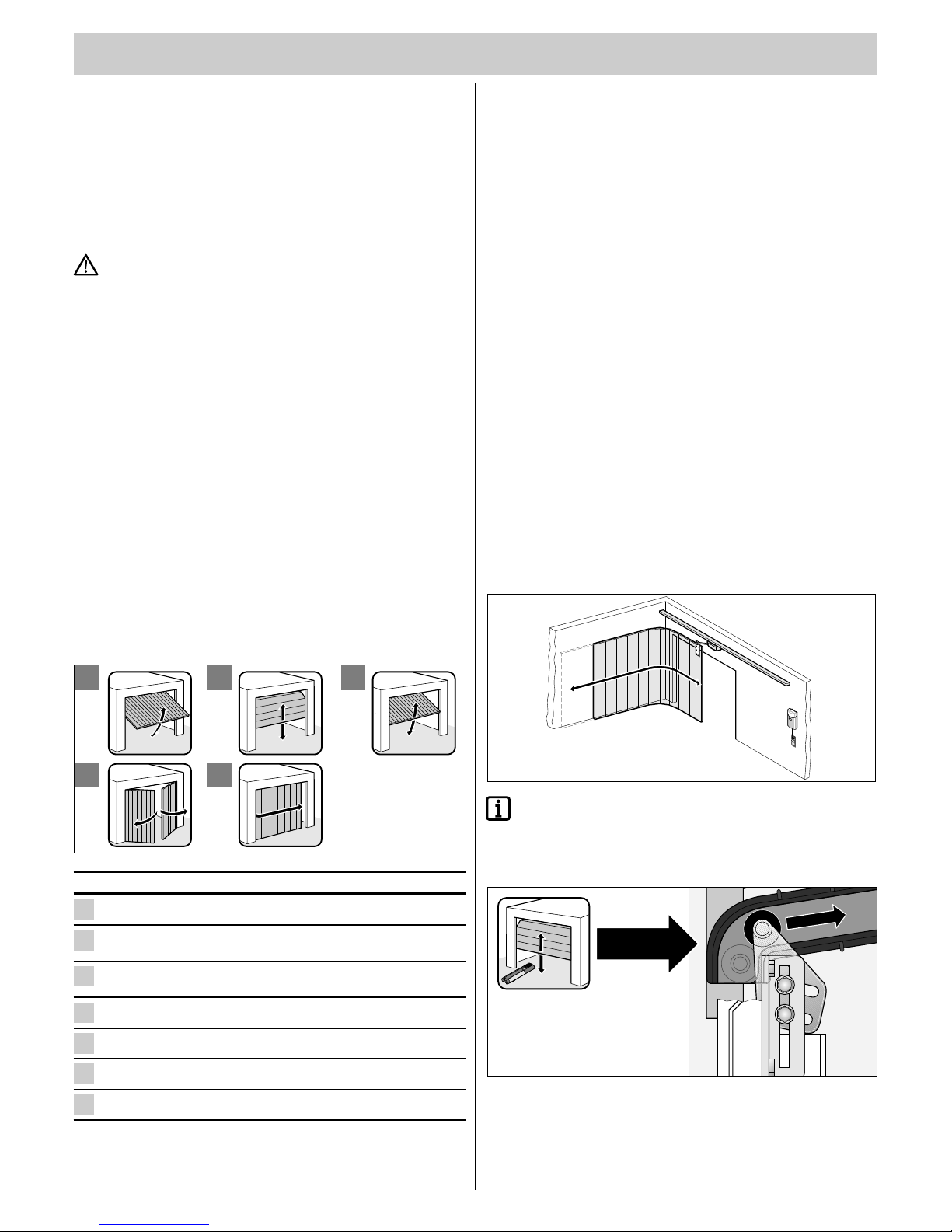

Door types and special accessories*

* Accessories are not included in the delivery.

Door type Accessories

Up-and-over door No special accessories required

Sectional door with Sectional door

single runner rail fitting with boomerang*

Sectional door with Sectional door

double runner rail fitting without boomerang*

Shutter-type door No accessories required

Canopy and non-protruding door Tilting arm*

Swing door Swing-door fitting*

Side-opening sectional door Please consult specialist retailer

5

4

3

2

2

2

1

12 3

45

Installation tips

• • Check that all the parts have been supplied before you start

installation work in order to save time and unnecessary work if a part is

missing.

• Installation work can be carried out quickly and reliably by two persons.

• The drive mechanism can be installed to one side of the door if it cannot

be installed at the centre. It is important to note that the door does not

bend as a result and jam in the guide rails.

Check : Open and close the door several times by hand

holding it at the point where you intend fitting the drive

mechanism. If the door can be moved in this way

without difficulty (in compliance with the above forces),

then the drive mechanism can be fitted at this point.

• Emergency Release

If the garage has no separate entrance (e.g. wicket-door), the user must

be able to operate the emergency release mechanism from the outside.

This is why the emergency release should be run to the outside where it

can be activated via a Bowden wire or a release lock. See 'Accessories'

section.

• Canopy and non-protruding doors

As the mechanical lock of a door with a drive mechanism has to be

dismantled or deactivated, it is possible to open the door manually up to

approx. 50mm depending on the door construction.

In order that, when opening the doors, the spring latches are unlocked

first before the drive opens the door. These spring latches are

connected to the drive via a locking set in order to first unlock the spring

latches before a drive opens the door when opening the door.

• Swing door / Side-opening sectional door

In the case of drives that push open a door of the above-mentioned type

(see fig.), the connections made in the direct socket unit have to be

swapped around as follows:

- wires 3 + 4 (sprint and duo).

Other pulse generators include: Funkcodys, radio-operated

interior switches and key-operated switches. In the case of the

Funkcody and radio-operated interior switch, no cable need be

run to the drive. Contact your local dealer for advice.

Adjustment of the top roller in a sectional door

General installation information

Page 7

6

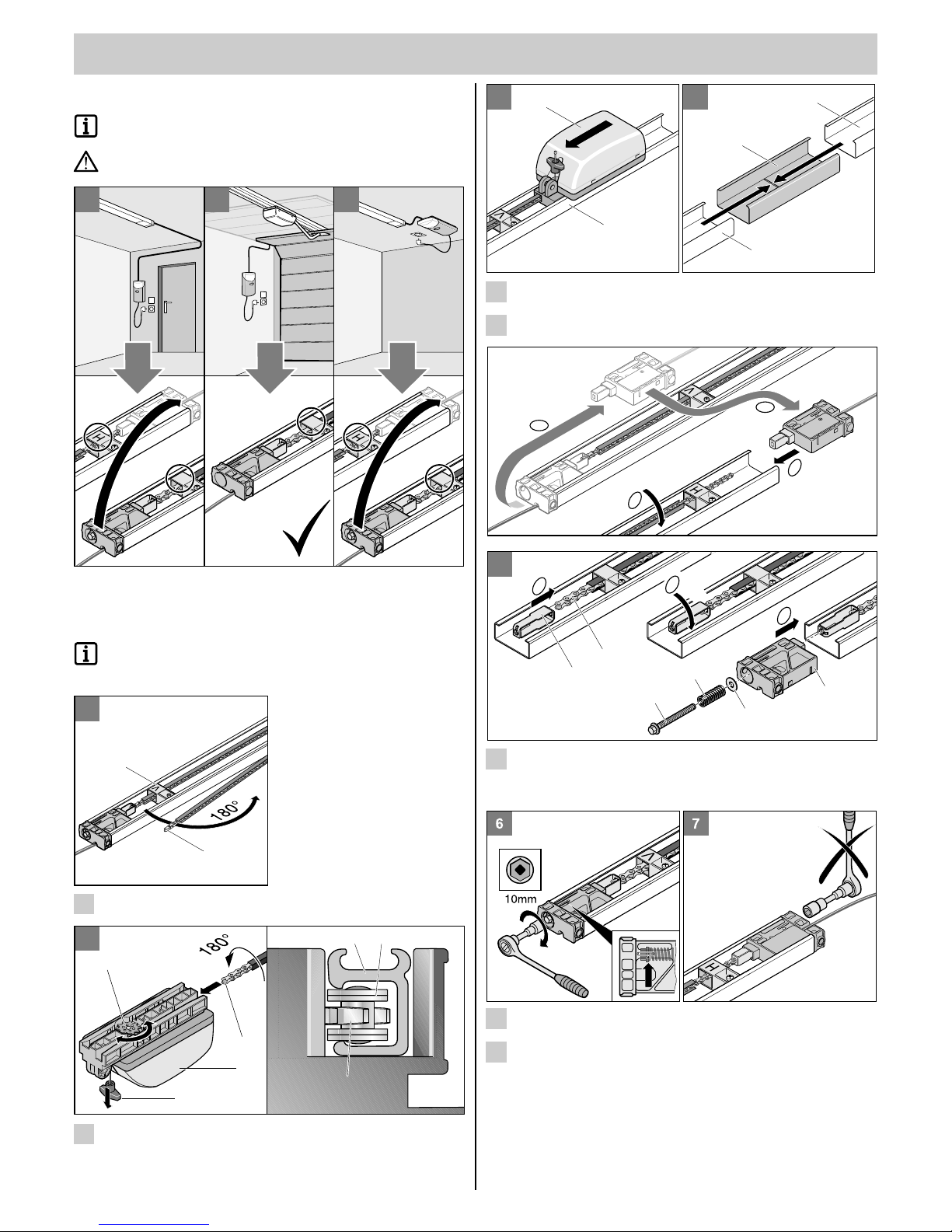

• Push bogie truck (1) onto C-rail (2).

• Slot two C-rails (1) into connecting element (2) and push together as

far as they will go.

• Attach the tensioner (1) to the chain (2) and turn it by 90°.

Slide in the slide-in module (6) and push the tensioner (1) through it.

Place the washer (5) and the spring (4) onto the tensioning bolt (3)

and screw it into the tensioner (1).

• Tighten chain until the mark (arrow) is reached.

• Do not tighten on this side, as the unit is supplied pre-tensioned.

7

6

5

5

a

c

90°

b

1

2

3

4

5

6

V

V

C

A

B

90°

D

4

3

3

2

1

4

1

1

2

Selection of installation option

Select the desired installation option. For options (A/C), change

the position of power supply unit.

Caution!

The plastic chain case is not packaging - do not remove!

Pre-assembly for installation

options A/C

Dispose of packaging material according to the applicable

statutory regulations.

• Remove the operator from its packaging.

• Release the switch trigger (1) and move it in the direction of the

arrow. Open the chain case (2).

• Slide the trolley (1) onto the chain (2) with the chain case (4). The

chain (2) engages in the chain wheel (3). If the chain wheel (3) does

not turn, pull the emergency release (N) once. The chain wheel (3) is

released.

2

2

N

2

1

3

2

4

3

3

1

1

1

2

V

V

CBA

V

ok

7 7

Installation

Page 8

Installation

7

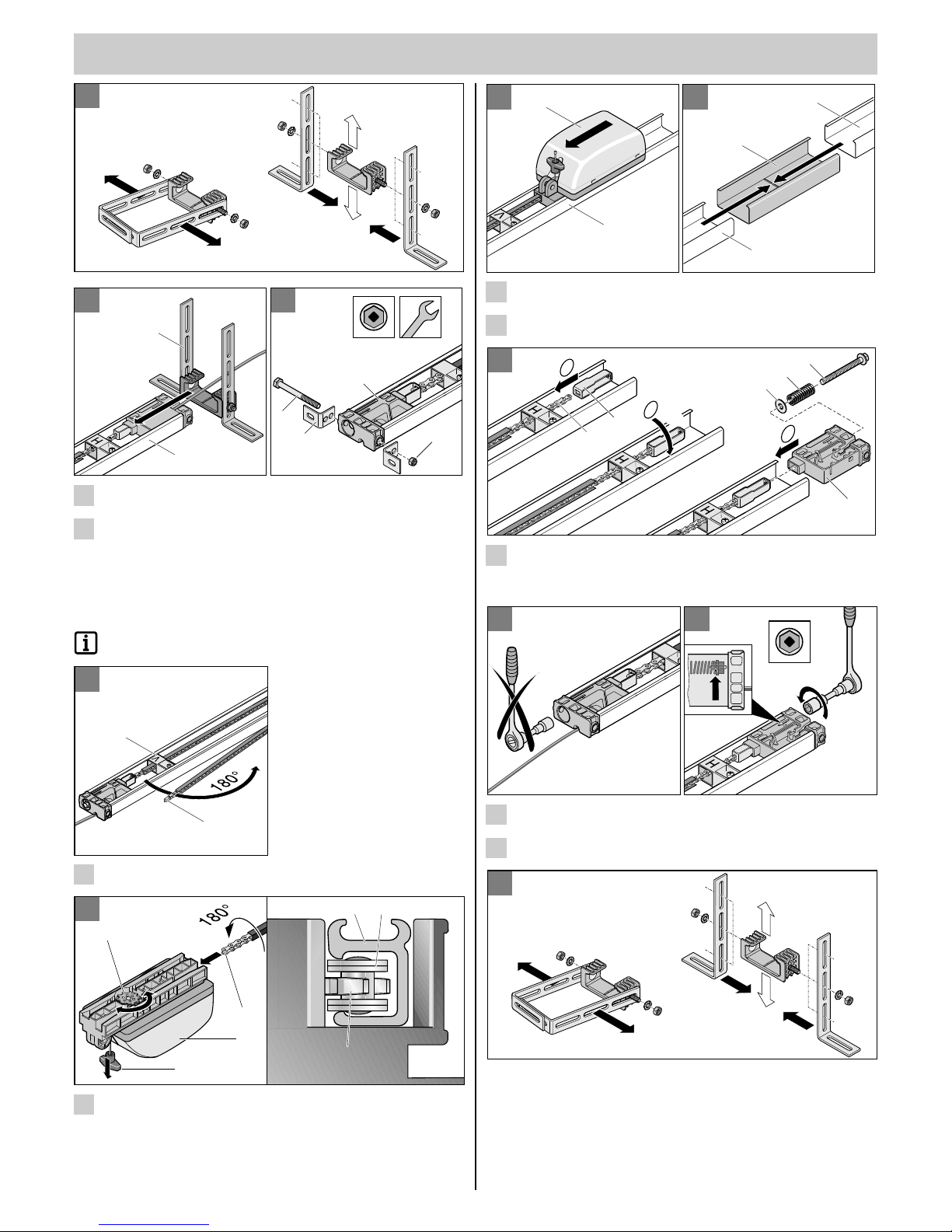

• Push ceiling suspension fitting (1) onto C-rail (2).

• Mount bracket (2) with screw (1) and nut (3) onto the connecting

element (4).

Pre-assembly for installation

option B

• Remove drive system from packaging.

Dispose of the packaging correctly in accordance with local

requirements.

• Release the switch trigger (1) and move it in the direction of the

arrow. Open the chain case (2).

• Slide the trolley (1) onto the chain (2) with the chain case (4). The

chain (2) engages in the chain wheel (3). If the chain wheel (3) does

not turn, pull the emergency release (N) once. The chain wheel (3) is

released.

2

2

N

2

1

3

2

4

3

3

1

1

1

2

10

9

910

17mm 17mm

1

2

2

4

1

3

V

8

• Push trolley (1) onto C-rail (2).

• Slot two C-rails (1) into connecting element (2) and push together as

far as they will go.

• Hook tensioner (1) in chain (2) and turn it 90°. Insert connecting

element (6) and push tensioner (1) through it. Place plain washer (5)

and spring (4) onto the tensioning bolt (3) and screw it into the

tensioner (1).

• Do not tighten on this side, as the unit is supplied pre-tensioned.

• Tighten chain until the mark (arrow) is reached.

8

7

6

6 7

10mm

V

5

5

a

c

1

6

2

3

4

5

90°

b

4

3

3

2

1

4

1

1

2

Page 9

Installation

8

• Push ceiling suspension fitting (1) onto C-rail (2).

• Mount bracket (2) with screw (1) and nut (3) onto the connecting

element (4).

Installation (example: option B)

Use a non-slip, stable stepladder!

If the distance between the ceiling and the lower edge of the

C-rail is greater than 245 mm, then extend the suspension

bracket (with perforated steel strip).

• Determine door's highest up-position (THP):

Open door and measure smallest clearance (min. 35 mm) between

top edge of door and ceiling. The distance between HDP and the

lower edge of the C-rail must be between minimum 5 mm and maximum 65 mm, whereby the push rod must be at an angle of max. 30°

(see fig. 21)!

Please note that this distance might be smaller, if the door

handle is located at the centre of the door. Ensure that the door

can move freely.

11

THPTHP

11

5 - 56mm

min. 35mm

THP

THP

11

5 - 56mm

min. 35mm

10

9

For installation on the ceiling (D), drill holes at distances of

15 mm, if possible. Smaller angle of inclination of the fixing

brackets.

• The drive mechanism can be mounted on lintel (S) or ceiling (D).

• Determine the front centre point (VM) of the door and mark it on the

door and on the lintel or ceiling.

• Mark points 74 mm to right and left of the centre of door (VM), and at

same height on lintel or ceiling (see Fig. 11).

• Drill two holes (Ø 10 x 65 mm).

Wear safety goggles when drilling!

Check thickness of ceiling, particularly with prefabricated

garages!

• Transfer door centre mark (HM) to ceiling. Close door.

• Insert plug (1). Lift up operator (2) at front. Secure lintel fitting (3) at

the front with two screws (4) and plain washers (5).

• Lift up drive (2).

17 18

B

600

0

1

B

1

HM

3

2

5

4

S10

16

16

2

S10

4

5

31

S10

4

5

31

B

A/C

15

14

15

½½½

½

HMHM

15

VM

74mm 74mm

10mm

65mm

14

THP

13

12

12

S

30

30

15

15

D

½

½

½

½

VM

VM

13

Page 10

Installation

9

Caution!

Mount the drive in parallel to the runner rails of the door.

• Align ceiling bracket (1). The position should be within the range

(B = 0 … 600 mm).

• Align drive mechanism horizontally to rear centre of door (HM). Mark

position of holes. Drill two holes (Ø 10 x 65 mm deep).

Wear safety goggles when drilling!

Check thickness of ceiling, particularly with prefabricated

garages!

• Insert plug (1). Fit two screws (2) with plain washers (3). Tighten

screws securely.

• Align C-rail (4) at correct height. If necessary, move screws (5).

Tighten screws (5).

• Mount drive shaft (1):

Insert the long bolt (2) and slide on the securing clip (3).

• Attach the door hinge (4) to the connecting rod (1) using the short

bolt (5). Slide on the securing clip (3).

• Pull once on emergency release wire (N), thus disengaging bogie

unit (1). Tighten screw (8) on lintel fitting.

• Use drive shaft (2) to push bogie unit (1) as far forward as possible

(3). If necessary, release cut-off buffer (4).

• Align angle of door fitting (5) with centre of door (VM) and mark 5 drill

holes. Drill 5 holes (Ø 5 mm).

Use screws that are appropriate to the door material.

Wear safety goggles when drilling!

• Insert 5 hexagon-head screws (6) and tighten securely.

• Release cut-off buffer (4) and push right up to bogie unit (7).

• Tighten cut-off buffer screw (4) securely.

• Release rear cut-off buffer (1) and push right back to stop (2).

Open door (3) by hand.

21

21

4

N

1

2

6

max. 30°

4

5

3

20

19

19

2

3

5

4

3

N

1

2

48

7

3

6

5

1

N

20

18

17

HM

Trim (e.g. saw off and debur) projecting part of ceiling bracket (4).

• Push cut-off buffer (1) right up to end stop (6) against bogie unit (5),

until it clicks. Securely tighten screw on switch-trigger (1).

Installing and connecting

the control unit

Selection of the installation option

Position the push button in such a way that the operator can see

the door, while he/she is not inside the operating area of the

door.

The cable must be permanently installed. Install cable in such a

way that it is possible to expand the power supply in option A (if

the cable is at right angles to the C-rail, install it with a loop).

Touch the control unit (4) only at its edge!

Do not touch the electronic components!

• Remove the lamp cover (1). Loosen the screws (2) and remove the

cover (3), and then remove the control unit (4).

Installation options A/B

• Choose a suitable location for the installation of the control housing

(1), preferably near a power socket (2).

Minimum height from the floor - 1.6 m.

Please note when selecting location of control unit housing (1)

that the maximum length of the control cable (3) is 6900 mm and

no longer!

• Install the control line (24 V) (3) to the control housing (1) in the

garage. Do not yet plug in the power plug (4)!

23

B23

1,6m

3

1

2

4

2

4

1,6m

3

1

A23

2

4

2

4

22

22

1

2

4

3

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

CA B

Page 11

• Drill 4 holes (Ø 6 x 40 mm deep). Place plugs (2) in holes. Supplied

components 2 plugs, 2 screws and 2 washer.

• Position, align and then secure the control housing using 4 screws

(1) and 4 washer (6).

• Insert the end of the control cable (5) into the rear of the control unit

(4).

• Connect the control cable (5): connect the core marked 3 (green) to

terminal 3 and the core marked 4 (red) to terminal 4 of direct socket

unit (2). Shorten the control cable (5) if necessary.

In the case of swing doors, connect wire marked 3 (green) to

terminal 4 of the direct socket unit (2) and the one marked 4 (red)

to terminal 3.

• Plug the control board (1) into the basic rack (2) and into the terminal

bar (3). Replace the cover (3) and tighten the screws (4). Mount the

lamp hood (5).

Installing the socket outlet

Socket outlet may only be installed by a qualified electrician.

Protect socket with a fuse (16 A slow-blow).

Observe applicable VDE regulations!

• Install socket (1) on ceiling at a distance of approx. 0.5 m to the

control unit housing (2).

• Install socket (1) on ceiling at a distance of approx. 0.5 m to the

control unit housing (2).

• Install and connect the connection cable from the socket outlet (1) to

the mains power supply. Do not plug the connector (3) into the

socket outlet yet!

27

27

A/B 27

H

1

3

2

4

C27

26

26

5

1

2

3

4

Time

Reset

Radio

LED2

LED1

Time

Reset

Radio

LED2

LED1

Time

Reset

Radio

LED2

LED1

Time

Reset

Radio

LED2

LED1

6

25

24

25

2

1

2

3

4

5

6

1

2

3

4

5

6

5

3

4

4x

24

250

ca 150

2

4x

95

1

6

Installation

10

Be careful not to drill into the socket outlet feeder and do not

plug the mains plug in yet!

• Drill 2 holes (Ø 6 x 40 mm deep). Place plugs (2) in the holes.

• Position, align and then secure the control housing using 2 screws

(1) and 2 washer (6).

• Insert the end of the control cable (5) into the rear of the control unit

(4).

• Connect the control cable (5): connect the core marked 3 (green) to

terminal 3 and the core marked 4 (red) to terminal 4 of direct socket

unit (1). Shorten the control cable (5) if necessary.

In the case of swing doors, connect wire marked 3 (green) to

terminal 4 of the direct socket unit (2) and the one marked 4 (red)

to terminal 3.

• Plug the control board (1) into the basic rack (2) and into the terminal

bar (3). Replace the cover (4) and tighten the screws (5). Mount the

lamp hood (6).

Installation option C

• Choose a suitable location for the installation of the control housing

(1), preferably near a power socket (2).

Please note when selecting location of control unit housing (1)

that the maximum length of the control cable (3) is 6900 mm and

no longer!

• Install the control line (24 V) (3) to the control housing (1) in the

garage. Do not yet plug in the power plug (4)!

Be careful not to drill into the socket outlet feeder and do not

plug the mains plug in yet!

23

1

3

2

4

23

26

26

5

1

3

2

4

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

6

25

24

24

25

2

1

2

3

4

5

6

1

2

3

4

5

6

5

34

4

95

S6

1

2

5

6

ca

150

Page 12

Installation

11

Installing and connecting an

additional push-button

Only necessary if a further push-button is required in addition to

the one already installed.

Use the contact only for potential-free normally closed contacts.

External voltage may damage or even destroy the control unit.

Position the push-button in such a way that the operator can see

the door, while he/she is not inside the operating area of the

door.

• Never lead the button cable along the power line, as this could lead to

interference in the control system. The power line must be permanently

installed.

• Install push-button (1) in an appropriate, easily accessible location in

the garage. Minimum height from the floor: 1,6 m

• Install button cable (2) in garage. Connect end of cable to push button (1).

Only hold outside edge of control board (7)! Do touch the

electronic components.

• Remove the lamp cover (3). Loosen the screw (4) and remove the

hood (5). Pull the control board (1) upwards from the basic rack (6).

28

7

6

3

4

5

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

1,6m

2

1

C28

7

6

3

4

5

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

B28

1,6m

2

1

7

6

3

4

5

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

1,6m

A28

2

1

Connect the key switches (potential-free NO contact), if any, to

the terminals 5 + 6.

• Connect the push-button cable (3) to terminals 5 + 6 of the terminal

bar (4).

• Plug the control board (1) into the basic rack (2) and into the terminal

bar (3). Replace the cover (4) and tighten the screws (5). Mount the

lamp hood (6).

30

29

30

29

4

1

2

3

4

5

6

1

2

3

4

5

6

3

56

1

3

2

6

5

4

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

Page 13

12

Safety instructions

Once the drive has been installed, the person responsible for

installation has to issue an EU Conformity Declaration for the

door system in accordance with Machine Directive 98/37/EG as

well as fitting the CE seal and the rating plate.

This also applies to doors installed for private purposes and in

cases where the drive has been retrofitted to a manual door.

These Instructions as well as the drive's Installation and

Operating Instructions should be kept by the user for reference

purposes.

The force setting is relevant to the system's safety and must

therefore be carried out with due care and attention. An excessively high force setting can injure people and/or animals and

damage property.

Select as low a force setting as possible to ensure that obstacles

are identified in a fast, safe manner.

Risk of sudden closing or opening!

When the emergency release is actuated, the door might sud den ly be opened or closed, due to a damaged spring or incorrect

balance weight. This might damage or even destroy the drive

unit.

Setting door OPEN + CLOSED final

travel positions

While adjusting the settings, open and close the gate manually.

Do not operate it with the engaged drive system.

The distance over which the drive mechanism moves the door can be

increased/reduced by using the cut-out buffer (V + H).

Check that the door opens and closes completely. If it does not, its travel

must be adjusted.

Limit position door CLOSED

• Release the trolley, if it is not yet released. Pull the emergency

release rope (N) once. It must be possible to slide the trolley back

and forth by hand.

• Close the door by hand.

• Release the switch trigger (V) and slide it towards the trolley until it

triggers the limit switch. Secure the switch trigger (V) with screws in

this position.

Door OPEN final travel position

• Open the door by hand.

• Release the switch trigger (H) and slide it towards the trolley until it

triggers the limit switch. Secure the switch trigger (H) with screws in

this position.

• Close the door by hand.

• Lock the trolley (1):

Pull the emergency release rope (N) once. Move the trolley by hand

a little bit forward until the chain wheel engages with a loud clicking

sound.

V

N

1

H

1

N

Teaching in drive

Whenever the door “opens” or “closes”, the control unit automatically reads

in the force required and memorises it when the end position is reached.

• Plug in power plug.

The first movement of the drive after the power is connection

must be “door OPEN”. If this is not the case, exchange the wires

to terminals 3 + 4.

• Press the push button (1). The door is opened to limit position

“door OPEN”.

• Close gate, press button (1).

Reset the control unit

DIP switch 4 ON, light bulb (2) is on after a control reset.

DIP switch 4 OFF, light bulb (2) flashes after a control reset.

• Press button (3) until such time as lamp (2) goes out.

• When lamp goes out, force settings have been deleted and button (3)

can be released.

• Light bulb (2) flashes - control reset successful.

Carry out following procedure twice:

• Press push-button (1) oncex

Door opens as far as cut-off buffer (H, end position for door OPEN)

• Lamp (2) starts to flash

• Press push-button (1) once

Door closes as far as cut-off buffer (V, end position for door CLOSED)

• Lamp (2) starts to flash.

When all force values are read and saved, the lamp (2) ceases flashing.

The operator has been 'taught' successfully!

Checking the limit positions for door

CLOSED + OPEN

The trolley of the drive system can be extended or shortened by means of

the switch triggers.

Check whether the door is opening and closing properly. If this is not the

case, adjust the trolley.

• Actuate the control device (e.g. push-button, remote control device,

etc.) once.

The door is opened.

If it fails to reach the desired limit positions for door OPEN + CLOSED,

readjust the limit positions. For detailed instructions, see chapter “Adjusting

door OPEN + CLOSED settings”.

1

2

2

1

Time

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

2

1

T

ime

Reset

Radio

LED2

LED1

Time

Reset

Radio

LED2

LED1

Reset

Reset

3

3

2

1

ON

DIP

3

4

5

6

8

7

Commissioning

Page 14

Commissioning

13

Checking emergency release

With sectional doors, or doors with ceiling guides, you have the

option of activating the backjump with DIP switch 6 in order to

offload the operator and door mechanisms.

• Close the door with the drive.

• Pull the emergency release (N) 1x.

If the emergency release cannot be operated, loosen the end switch

(V) and move it in direction (1).

• Open the door with the drive and close it again. Test the emergency

release again.

Checking force setting

Whenever the door is opened or closed, the control unit compares the

memorised force setting with the force actually needed and automatically

adjusts the memorised setting accordingly when the given final travel

position is reached.

For checking details see 'Maintenance and Care' section.

Programming of remote control

Prior to the initial programming of the hand-held transmitters,

clear the memory of the radio receiver.

Clearing radio receiver memory

• Press and hold the programming key (1).

- After 5 seconds, the LED (3.1 or 3.2) flashes. After another

10 seconds, the LED is constantly on (3.1 or 3.2).

- After 25 seconds, all LEDs are on (3.1 + 3.2).

• Release the programming key (1). All channel data has been

deleted.

Programming remote control device

• Press the programming button (1)

- 1x for channel 1; LED (3.1) is on

- 2x for channel 2, LED (3.2) is on

- If no other code signal is transmitted within 10 seconds, the radio

receiver switches to standard operation.

- Aborting programming: repeatedly press the programming key (1)

until all LEDs are off.

• Press and hold desired hand-held transmitter button (5) until the LED

(3.1 / 3.2) is off (depending on the selected channel).

• The LED is off. - The programming process is completed.

The hand-held transmitter has transmitted the radio codes to the

radio receiver.

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

5

Time

Reset

Radio

LED2

LED1

Time

Reset

Radio

LED2

LED1

adio

LED2

LED1

adio

LED2

LED1

3.2

1

3.1

V

N

1

Continue with programming all other hand-held transmitters. To do this,

repeat the above steps. The maximum number of memory blocks is 112

per radio receiver.

Attaching instruction label

• Attach the instruction label for the operation of the emergency

release to the emergency release rope.

Attaching warning sign

• Attach the warning signs (text + triangle sign) at a position where

they are clearly visible, e.g. beside the push button (warning triangle)

and on the door leaf (text + warning triangle).

1.

1.

2.

2.

1.

1.

2.

2.

N

N

465

02V0

00-17

2006

-0-O

C

E_Re

v.A

1x1x

1x1x

4650

2V

00

0-172

00

6

-0

-O

C

E_R

e

v.A

A

B

Page 15

14

Emergency release

Caution!

The emergency release may only be used in the event of an

emergency (power failure, failure of drive, etc.) to open or close

the door. Do not use it to open and close the door in other

situations, as this could damage the door or the drive mechanism.

Risk of damage!

When operating the emergency release, it is possible that the

door may open or close automatically due to the spring breaking

or the weight balance being set incorrectly. Drive can suffer damage or be destroyed.

Engaging or disengaging the drive can occur in any door position.

• Pull once on emergency release wire (N): the drive mechanism

disengages and the door can be opened manually.

• Pull on emergency release cord (N) once again: drive locks into

position; door can only be moved with the drive.

• Door is fitted with a wicket door but no safety mechanism for the

wicket door - retro-fit wicket-door safety mechanism (see

'Accessories' instructions).

• Door has no wicket door and garage no second entrance - install

release lock or Bowden wire providing outside release access

(see 'Accessories' instructions).

Control reset

DIP switch 4 ON, light bulb (2) is on after a control reset.

DIP switch 4 OFF, light bulb (2) flashes after a control reset.

After a control reset, the drive unit must be programmed again.

• Press button (3) until such time as lamp (2) goes out.

• When lamp goes out, force settings have been deleted and button (3)

can be released.

• Light bulb (2) flashes - control reset successful.

2

1

Time

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

2

1

T

ime

Reset

Radio

LED2

LED1

Time

Reset

Radio

LED2

LED1

Reset

Reset

3

3

2

1

ON

DIP

3

4

5

6

8

7

N

N

Safety instructions

• Keep children, disabled persons and animals away from the door.

• Keep your hands clear of a door in operation and any moving parts.

• Only drive into and out of the garage when the door is fully opened.

• Risk of persons trapping or cutting themselves in/on the door system's

moving parts or edges where it closes.

Opening door

• Press button (1) or manually-operated remote control once.

• The door stops moving if this button is pressed again while the door

is opening. Dependent on DIP switch 7 setting.

• If the button is pressed again the door closes.

Closing door

• Press button (1) or manually-operated remote control once.

• The door stops moving if this button is pressed again while the door

is closing. Dependent on DIP switch 7 setting.

• If this button is pressed again the door opens.

Pulse sequence of door movement

Adjust the pulse sequence with DIP switch 7.

• DIP 7 OFF, default settings for all drive:

open - stop - close - stop - open - …

• DIP 7 ON:

Button 1: open - stop - open - stop - …

Button 2: close - stop - close - stop - …

2

1

ON

DIP

3

4

5

6

8

7

1x

1x

1x

1x

STOP STOP

1

1

Operation and handling

Page 16

Operation and handling

15

Interim stop

If an interim stop occurs due to the operation of a push-button or the

manual remote control, the drive unit stops immediately. The next command

given sends the drive in the opposite direction. See 'Pulse Sequence of

Door Movement' section.

Safety stop 1

(automatic force cut-off)

When the automatic force cut-off is activated, the drive stops or reverses.

When the next command is given, the drive moves in the opposite direction.

See 'Pulse Sequence of Door Movement' section.

- Safety stop when door closes - door reverses

- Safety stop when door opens - door stops.

Safety stop 2

(automatic force cut-off)

When the safety input is tripped (e.g. someone crosses light barrier), the

drive stops, reverses or opens, depending on the given DIP switch settings

of DIP switch 1 + 3.

See 'Obstacle Recognition' section for given drive type.

When the next command is given, the drive moves in the opposite direction.

See 'Pulse Sequence of Door Movement' section.

Default settings:

- safety input tripped when door closes:

- door reverses

- safety input tripped when door opens:

- no response (door opens)

Overload protection

If the drive mechanism is subjected to excessive strain when opening or

closing the door, this is recognised by the control unit which then stops the

drive mechanism. After approx. 20 seconds or a control unit reset, the

control unit deactivates the overload protection.

The drive mechanism can now recommence normal operation.

Operation following a power failure

The force values remain saved even during a power failure. The first

movement of the unit following a power cut is always door OPEN.

Radio remote control receiver

Homelink compatible!

If your vehicle is equipped with a Homelink system (version 7),

you can reach our drive/radio receiver at 868.6 MHz. With holder

Homelink systems, you must use a different frequency (40.685 or

434.42 MHz). For more information, please visit:

"http://www.eurohomelink.com"

• To ensure safe operation, local safety regulations relevant to the

equipment concerned must be observed! Information regarding this can

be obtained from electricity suppliers, the VDE and employers' liability

insurance associations.

• The operator of this radio-controlled equipment is in no way protected

from interference from other telecommunications systems and facilities

(e.g. other radio-controlled equipment that is licensed to operate at the

same frequency range).

• Try replacing the batteries should reception problems be encountered.

Description of display and

push-buttons

1 Setting button

Puts radio receiver in a given operating mode:

self-learn, delete and normal

2 Internal antenna

3 LED

Display which channel has been selected.

3.1 LED channel 1

3.2 LED channel 2

4 Connection for external antenna (6)

If the radio range of the internal antenna is not sufficient, you have

the option to connect an external antenna.

5 Manual remote control button

6 External antenna

Teaching in manual remote control

• Press setting button (1)

- Press 1x for channel 1; LED (3.1) lights up

- Press 2x for channel 2; LED (3.2) lights up

- If no radio code is transmitted within 10 seconds, the receiver

switches back to normal operating mode.

- Interrupting setting mode: press setting button (1) as often as

required to put out all LEDs

• Press and hold desired hand-held transmitter key until the LED (3.1 /

3.2) is off - depending on the selected channel.

• The LED is off - the programming process is completed.

The hand-held transmitter has transmitted the radio code to the radio

receiver.

Teaching in further manual remote controls. Repeat above steps.

Max. 112 memory slots are available per radio receiver.

Disabling manual remote control

button at the receiver

If a user of a multi-user garage facility moves house and wants to take his

manual remote control with him, then all the codes of the given user’s

manual remote control have to be deleted from the radio receiver.

For security reasons, each manual remote control button and/or

combination of buttons should be deleted!

• Press setting button (1) and keep depressed for 5 seconds until an

LED starts to flash (any LED).

• Release setting button (1) - radio receiver is in delete mode.

• Press push-button on the manual remote control, the one whose

code is required to be deleted on the radio receiver - LED goes out deletion process complete.

Repeat procedure for all push-buttons and combination of buttons.

5

2

6

4

3.1

3.2

1

2

1

ON

DIP

3

4

5

6

8

7

8

9

10 11

12

7

Page 17

Operation

16

Deleting a channel from the radio

receiver

• Press setting button (1) and keep pressed

- press 1x for channel 1; LED (3. 1) lights up

- press 2x for channel 2; LED (3.2) lights up

- The LED that lights up depends on which channel has been

selected. After 5 seconds, the LED starts to flash and then remains

lit after a further 10 seconds.

• Release setting button (1) - deletion process complete.

Deleting the radio receiver’s memory

If a manual remote control is lost, then for security reasons all channels on

the receiver have to be deleted! After this has been done, all the manual

remote controls have to be re-set into the receiver.

• Press and hold the programming key (1).

- After 5 seconds, the LED (3.1 or 3.2) flashes. After another

10 seconds, the LED is constantly on (3.1 or 3.2).

- After 25 seconds, all LEDs are on (3.1 + 3.2).

• Release the programming key (1) - all channel data has been deleted.

Connecting an external antenna

• An external antenna can be fitted if the possible range with the radio

receiver's internal antenna is insufficient.

• The antenna cable must not exert any mechanical load on the radio

receiver. Fit strain relief.

• Connect external antenna (6) to terminal (4).

Page 18

General tips

• At delivery, all DIP switches are in OFF position. All additional functions

are disabled.

Obstacle recognition (DIP 1, 2 + 3)

DIP switch 1

OFF No response in the event of a safety input interruption.

In the event of a force cut-off, the door is halted.

ON Drive stops door

DIP switch 2: Safety contact strip

OFF NC contact for light barrier

ON Button connection for button 2

(partial opening, preset opening and closing)

DIP switch 3: Behaviour of drive unit during closing of door

OFF Drive stops and opens door a little (reversal)

ON Drive stops and opens door completely

Connecting button 2 (DIP 2)

Use the contact only for potential-free normally closed contacts.

External voltage may damage or even destroy the control unit.

No further safety connections are available.

Button 2 can be used in conjunction with the following functions:

- Preset opening and closing

- Partial opening

• Permitted cable cross-section: max. 0,75 mm².

Terminal 7 + 8 Push-button 2 connection, only if DIP switch 2 is ON

Direct socket unit

• Permissible cable cross-section: max. 1,5 mm².

Terminal 1 + 2 Transformer

Terminal 3 C-rail

Terminal 4 Chain

Swap connections (terminals 3 + 4) around if drive is to be used in conjunc-

tion with swing doors.

Use the contact only for potential-free normally closed contacts.

External voltage may damage or even destroy the control unit.

Terminal 5 + 6 Push-button connection (push-button 1),

potential-free NC contact

8

9

10

11

12

7

2

1

ON

DIP

3

4

5

6

8

7

Drive behaviour upon closing the door

If the door meets an obstacle (force cut-off) or if the safety input is interrupted (person triggering the light barrier), this is detected by the drive system,

depending on the position of the DIP switches 2 + 3.

Drive behaviour upon opening the door

If the door meets an obstacle (force cut-off) or if the safety input is interrupted (person triggering the light barrier), this is detected by the drive system,

depending on the position of the DIP switch 1.

2

3

4

5

6

1

Connecting warning lamp (DIP 4)

• Permissible cable cross-section: max. 0,75 mm².

Terminal 11 + 12 Non-regulated DC 24 V (max. 34 V), max. 1 A

DIP switch 4

OFF Connected warning lamp flashes (control unit generates flashing)

ON Door status indicator

- is lit when door is not closed

- is out when door is closed

Warning time (DIP 5)

The warning lamp starts to flash after push-button is pressed or manual

remote control operated during the three seconds before the drive starts up.

If the push-button is pressed again or the manual remote control is operated during the 3 seconds, the early warning period is ended prematurely.

The early warning period functions in conjunction with both internal lighting

and with a connected warning lamp.

DIP switch 5

OFF Deactivated

ON Activated; internal lighting and warning lamp flash for 3 seconds.

Backjump (DIP 6)

In sectional doors, you have the option to set DIP switch 6 to

position ON in order to release the load from the drive system

and the door. It also facilitates the activation of the emergency

release.

This feature serves the purpose of supporting door and drive mechanism

operation. The drive mechanism moves briefly back in a door OPEN direction once it has reached the door CLOSED final travel position, thus taking

some of the strain off the other equipment.

DIP switch 6

OFF Deactivated

ON Activated

Connecting light barrier

• Permissible cable cross-section: max. 0,75 mm².

Terminal 7 + 8 Safety connection, only if DIP switch 2 is OFF

Terminal 9 + 10 regulated DC 24 V, max. 0.1 A

Terminal 9: DC 24 V

Terminal 10: Earth

Settings: see Obstacle detection (DIP 1, 2 + 3)

8

9

10

11

12

7

2

1

ON

DIP

3

4

5

6

8

7

8

9

10 11

12

7

2

1

ON

DIP

3

4

5

6

8

7

Functions and connections

17

Page 19

Functions and connections

18

Defined opening and closing (DIP 7)

With this function, the door can only be opened with button 1/

radio channel 1, and can only be closed with button 2/radio

channel 2.

Button 1/radio channel 1: opening door; button 2/radio channel 2: closing

door. The function may also be used for operation with 2 buttons or one

hand-held transmitter.

Requirement:

DIP switch 8 OFF, 2 buttons connected (DIP switch 2 ON) or 2 hand-held

transmitter buttons programmed.

DIP switch 7

OFF Deactivated

ON Activated

Trolley board

Terminal 1 Power supply to chain

2 Power supply to rail

3 + 4 End switch gate OPEN

5 Motor cable

6 Motor cable

7 + 8 End switch gate CLOSED

5

2

1

4

6

7

8

3

2

1

ON

DIP

3

4

5

6

8

7

1

2

Partial opening (DIP 8)

This function opens the door either completely or partially, depending on

the given setting.

Ideas for use: garage ventilation, opening of side-opening door for personal

access, to name but a few. Partial opening can also occur using just two

push-buttons or just the manual remote control.

DIP switch 8

OFF Deactivated

ON Activated, DIP switch 7 not functioning

Partial opening using 2 push-buttons

Fit additional push-button and connect as push-button 2 to terminals 1 + 2.

Button 1 always opens the door fully.

If the door has been partially opened by pressing push-button 2, it can be

fully opened by pressing push-button 1.

Push-button 2 only carries out partial opening when the door is closed.

Should the door have been fully opened using push-button 1 or partially

opened with push-button 2, it can be closed by again pressing push-button 2.

Procedure:

1. Close door.

2. Set DIP switch 8 to ON, thus activating partial opening functionality

- always leave DIP switch 8 in ON position; the OFF position

automatically deletes the partial opening function that has been set.

3. Press push-button 2 (opens door from CLOSED final travel position)

- door opens until such time as push-button 2 is pressed again or OPEN

final travel position has been reached.

4. Press push-button 2 when the desired position has been reached.

5. Close door by pressing push-button 2.

Partial opening has been memorised and door is opened to set position by

pressing push-button 2.

Set DIP switch 8 to OFF position to delete partial opening setting

Partial opening via manual remote control

(2-channel operation)

Teaching in 2 manual remote control push-buttons:

e.g. push-button 1 on to radio channel 1 and push-button 2 on to channel 2

Radio channel 1 always has the same function as push-button 1

Radio channel 2 always has the same function as push-button 2

Connecting external antenna

Supplied vacant as standard

TorMinal interface

See TorMinal Operating Instructions

2

1

ON

DIP

3

4

5

6

8

7

2

1

ON

3

4

5

6

7

8

9

10 11

12

2

1

ON

DIP

3

4

5

6

8

7

Page 20

Changing fuses (duo)

• Disconnect plug from socket.

• Remove the lamp hood (1). Loosen the screws (2) and remove the

hood (3).

• Pull the control unit (2) upwards from the basic rack (4).

• Replace defective fuse.

1. Fuse for warning light connection, terminals 11 + 12

Fuse 1 A, fast acting

• Plug the control board (1) into the basic rack (2) and into the terminal

bar (3).

• Replace the cover (4) and tighten the screws (5).

Mount and engage the lamp cover (6).

5

1

3

2

4

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

6

8

9

10

11

12

7

1

1

2

4

3

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

Reset

Radio

LED2

LED1

19

Important information

Never use a hose or a high-pressure cleaner to spray down the

drive or the control unit housing.

• Always disconnect the mains plug prior to working on the drive mechanism.

• Never use lyes or acids for cleaning purposes.

• Wipe drive clean with a dry cloth as required.

• Keep your hands clear of a moving door and any moving parts.

• There is a risk of persons trapping or cutting themselves in/on the door

system's moving parts or edges where it closes.

• All fixing screws on the drive should be properly checked and tightened if

necessary.

• Check the door at least annually, in accordance with the manufacturer’s

instructions.

Cleaning chain and drive unit rail

• The chain (7) or the drive rail (8) is dirty - clean it with a cloth.

• If required, lubricate the chain (7) and the drive rail (8) with

conductive oil.

Do not use grease!

Recommended oil types: Ballistol, WD40 contact spray

Changing bulb (duo)

• Disconnect plug from socket.

• Remove lamp hood (1).

• Turn bulb (2) anticlockwise and remove.

• Fit new bulb (32,5 Volt, 34 Watt, BA 15s or 24 Volt, 21 Watt,

BA 15s) and turn clockwise until it locks into position.

• Mount the lamp hood (1).

2

1

T

ime

Reset

Radio

LED2

LED1

T

ime

Reset

Radio

LED2

LED1

7

8

Maintenance and care

Page 21

Maintenance and care

20

Test

Behaviour yes/no

Remedy

Use 50 mm object to stop

door wing from closing

Drive reverses when

contact with object is made

yes

no

• Leave all settings as they are

• Have door correctly adjusted by a person qualified to

do so

Automatic force cut-off

Adopt procedure described

in 'Emergency Release'

section

Emergency release can be

activated easily (pull 1x,

operator is unlocked)

yes

no • Adjust end switch for door CLOSED, or activate

backjump (DIP switch 6 ON)

• Repair emergency release or have it repaired

• Check door. See door maintenance instructions

Emergency release mechanism

Open/Close door whilst, at

same time, operating safety

switch unit

Door behaves in accordance with setting of DIP

switch 1,2 or 3

yes

no • Check wiring, tighten terminal connection

• Correctly adjust DIP switch

•

Take door drive mechanism out of operation and ensure

it cannot restart by accident. Contact after-sales service!

Safety switch unit, if provided

Open/Close door whilst, at

same time, interrupting the

light barrier

Door behaves in accordance with setting of DIP

switch 1,2 or 3

yes

no • Check wiring, tighten terminal connection

• Correctly adjust DIP switch

• Clean light barrier

• Correctly adjust light barrier

•

Take door drive mechanism out of operation and ensure

it cannot restart by accident. Contact after-sales service!

Light barrier, if applicable

Regular checks

Check safety devices regularly, every year at the very least, to ensure they function correctly (e.g. BGR 232).

Safety devices that are sensitive to pressure (e.g. safety switch unit) should be checked every four weeks to ensure they function correctly;

see pr EN 60335-2-95.

Possible cause

• Automatic cut-off of supply is

working as it should

• Door incorrectly adjusted

• Everything in order!

• The mechanical door and

drive components are

strained

• Emergency release is

defective

• Door jam

• Everything in order!

• Broken cable, loose terminal

• DIP switch maladjusted

• Switch unit defective

• Everything in order!

• Broken cable, loose terminal

• DIP switch maladjusted

• Light barrier soiled

• Light barrier maladjusted

(bent bracket)

• Light barrier defective

Page 22

21

Disassembly

Observe safety instructions!

The sequence of operations is identical to that described in the Section

entitled "Installation" but in reverse order. The setting procedures described

are not applicable.

Correct disposal

Observe appropriate local regulations!

Warranty and after-sales service

The warranty granted complies with statutory requirements. Contact your

local stockist for any warranty claims. Warranty entitlements only apply to

the country in which the given drive was purchased.

Batteries, fuses and bulbs are not covered by the warranty.

If you require after-sales service, spare parts or accessories, please

contact your specialist retailer.

We have made every effort to ensure that these instructions are as clear

and concise as possible. However, if you have any queries or wish to comment on this document, please contact us with your suggestions:

Fax.: 0049 / 7021 / 8001 - 403

e-mail: doku@sommer.eu

Troubleshooting

Fault Possible cause Remedial action

Drive mechanism inoperative, lamp not lit

Lamp flashes

Lamp is not lit when door closes and opens

Drive does not function

Drive does not function when operated using

manual remote control

Drive does not function when operated using

push-button

Door stops when opening, moves approx.

10 cm in reverse direction then stops

No mains power

No control unit installed

Fuse in garage circuit has blown

Operator is not programmed,

no force values are saved

Bulb defective

Fuse of light bulb defective

Control unit installed incorrectly

Light barrier interrupted

Battery in manual remote control is flat

Manual remote control has not been

taught in to radio receiver.

Wrong radio frequency

Command is permanently present as

push-button is jammed

Push-button not connected or defective

Obstacle has tripped automatic force

switch-off

Incorrect force values "taught" or force

tolerance is too low

Switch-trigger set incorrectly

Door defective or door settings

incorrect (e.g. spring shaft)

Connect mains supply plug

Install control unit

Replace the fuse.

Use a different appliance, e.g. electric drill, to check the supply

'Teaching' the drive. See section on “Commissioning”

Replace bulb, see “Maintenance and Care' section”

Replace fuse

Slot control unit correctly into socket unit

Eliminate interruption

Change battery

Teach in manual remote control

Check frequency (40 MHz with wire aerial; 868/434 MHz without

external aerial)

Release push-button or replace manual remote control

Connect push-button or replace

Remove obstacle; open door completely

Delete force values and repeat teach-in procedure

Reset cut-off buffer; see 'Setting Limit Switches' section

Have door adjusted correctly or repaired by a person qualified to do

so

Further troubleshooting tips

Many problems can be solved by a control reset (deletion of

force values) and subsequent reprogramming of the operator!

Homelink compatible!

If your vehicle is equipped with the latest Homelink system

(version 7), you can reach our drive/radio receiver at 868.6 MHz.

With older Homelink versions, use other radio frequencies

(40.685 or 434.42 MHz). For more details, visit

www.eurohomelink.com or contact your local stockist.

Should you be unable to find and eliminate the fault with the help of this

table, then take the following steps:

• Complete control system reset (deletion of programmed force values).

• Disconnect attached accessories (e.g. light barrier) and connect the

bridge at the safety terminal.

• Set all DIP switches to default settings.

• Set all potentiometers to default settings.

• If settings have been changed using the TorMinal, carry out a control unit

reset using the TorMinal.

• Check all connections at the direct plug-type adapters and the terminal

bar (sprint/duo), and retighten them, if necessary.

To eliminate drive faults, follow the instructions in the table below. If you are

encountering any difficulties, contact your stockist or visit the

“http://www.sommer.eu” for support.

TroubleshootingMiscellaneous

Page 23

22

Fault Possible cause Remedial action

Door stops when opening, moves approx.

10 cm in reverse direction then stops

Door stops when opening

Operator does not close door

Drive opens gate but then no further reaction

to a command given via push-button or

remote controller

The drive closes the door; subsequently no

response to pressing of button or radio

transmitter

Connected warning light does not light up

Opening or closing speed varies

Operator does not terminate “Learn”

sequence

Only in units with radio receiver!

All LEDs are flashing

LED 3.1 or 3.2 is continuously on

LED 3.1 or 3.2 is on

Obstacle has tripped automatic force

switch-off

Incorrect force values "taught" or force

tolerance is too low

Switch-trigger set incorrectly

Connected light barrier interrupted and

DIP switch 1 on ON

Power supply to photoelectric cell

interrupted

Drive unit was disconnected from the

power supply

Safety input tripped

(e.g. photocell defective)

Door CLOSED limit switch in the trolley

defective

“Door OPEN” limit switch in the trolley

defective

Fuse defective

Bulb defective

Operator starts slowly and then picks

up speed

Chain rail dirty

Chain rail lubricated with unsuitable

oil

Incorrect chain tension

End positions set incorrectly

All memory positions are occupied

(max. 112 positions)

Radio signal is being received;

remote control transmitter button might

be defective or an external signal is

received.

Radio receiver is in “teaching” mode

and expects a code signal from a

remote control device.

Remove obstacle. Use push-button to close the door completely

Delete force values and repeat teach-in procedure

Adjust switch-trigger; see chapter “Adjusting end switches”

Eliminate interruption or set DIP switch 2 to OFF

Check connection

Replace fuse

The first command issued after restoration of the mains supply

results in the drive opening the gate fully

Remove obstacle from light barrier

Repair photoelectric cell

Socket unit not plugged in correctly

Replace limit switch

Replace limit switch

Replace fuse, see 'Maintenance and Care' section

Replace bulb

“Soft run” mode - completely normal

Clean rail and re-lubricate,

see chapter “Maintenance and care”

Clean rail and re-lubricate,

see chapter “Maintenance and care”

Tighten chain; see “Installation duo”

Adjust end positions (see general instructions in “Commissioning”)

Delete all radio control devices no longer in use

Install additional radio receiver

Remove battery from the remote control transmitter

Wait until the external signal decays

Press desired button on remote control transmitter

Troubleshooting

Page 24

Loading...

Loading...