DigiSpeed-GX™

- Users Guide Page 1

Updated: 12. December 2006

DigiSpeed-GX™ DC-03

Isolated Control Voltage Generator

User’s Guide

DigiSpeed-GX™ PCB Ver:1.0

Firmware Ver: 1.0

Mach3 Ver: 1.84

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 2

Homann Designs

20 View St

HIGHETT VIC, 3190

AUSTRALIA

info@homanndesigns.com

http://www.homanndesigns.com

Copyright 2006 © Homann Designs. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form or by any means,

electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without the prior

written permission of Homann Designs.

Disclaimer

Homann Designs makes no representation or warranties with respect to the contents

hereof and specifically disclaim any implied warranties or merchantability or fitness for any

particular purpose. Information in this publication is subject to change without notice and

does not represent a commitment on the part of Homann Designs.

Feedback

We appreciate any feedback you may have for improvements on this document. Please send

your comments to info@homanndesigns.com

Trademarks

DigiSpeed™ and DigiSpeed-GX™ are trademarks of Homann Designs. All other brand and

product names mentioned herein are trademarks, services marks, registered trademarks, or

registered service marks of their respective owners and should be treated as such.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 3

Table of Contents

1 Introduction...................................................................................................................................... 5

1.1 Contents.....................................................................................................................................5

1.2 Overview................................................................................................................................... 6

2 Options............................................................................................................................................. 7

2.1 5Vdc – 15Vdc isolated DC-DC Converter................................................................................ 7

3 Features.............................................................................................................................................8

4 Board Description.............................................................................................................................9

4.1 Introduction............................................................................................................................... 9

4.2 Mode Indication LED..............................................................................................................10

4.2.1 Mode Indication.............................................................................................................. 10

4.2.2 Input Activity Indication................................................................................................. 10

4.3 Output Attenuation Trimpot.................................................................................................... 11

4.4 Output Voltage Selection JP1..................................................................................................11

4.5 Mode Selection Jumper Block JP2..........................................................................................12

5 Quick Start Guide – PWM Mode................................................................................................... 13

5.1 What you need.........................................................................................................................13

5.2 Mach3 Configuration Setup.................................................................................................... 13

5.2.1 Port Setup........................................................................................................................14

5.2.2 Spindle Setup Tab........................................................................................................... 14

5.3 Power to the DigiSpeed-GX....................................................................................................15

5.4 Connect the PWM Signal........................................................................................................ 15

5.5 Conclusion...............................................................................................................................16

6 Installation...................................................................................................................................... 16

6.1 DC Motor Speed Controller housing.......................................................................................16

6.2 Wiring installation................................................................................................................... 16

6.2.1 Motor Controller Connection..........................................................................................17

6.2.2 Initial Testing.................................................................................................................. 17

6.2.2.1 Attenuation Trimpot Speed Control........................................................................ 17

6.2.2.2 Computer Speed Control......................................................................................... 17

7 Operation........................................................................................................................................ 19

7.1 Operation Modes..................................................................................................................... 19

7.1.1 Analog Input Mode......................................................................................................... 19

7.1.2 PWM Input Mode........................................................................................................... 19

7.1.3 Attenuation Trimpot........................................................................................................20

8 Board Dimensions.......................................................................................................................... 21

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 4

Index of Tables

Table 1: Mode Select Jumper Block.................................................................................................. 12

Table 2: DigiSpeed-GX™ - Breakout board Connections................................................................. 14

Table 3: Mode Selection Jumpers...................................................................................................... 19

Illustration Index

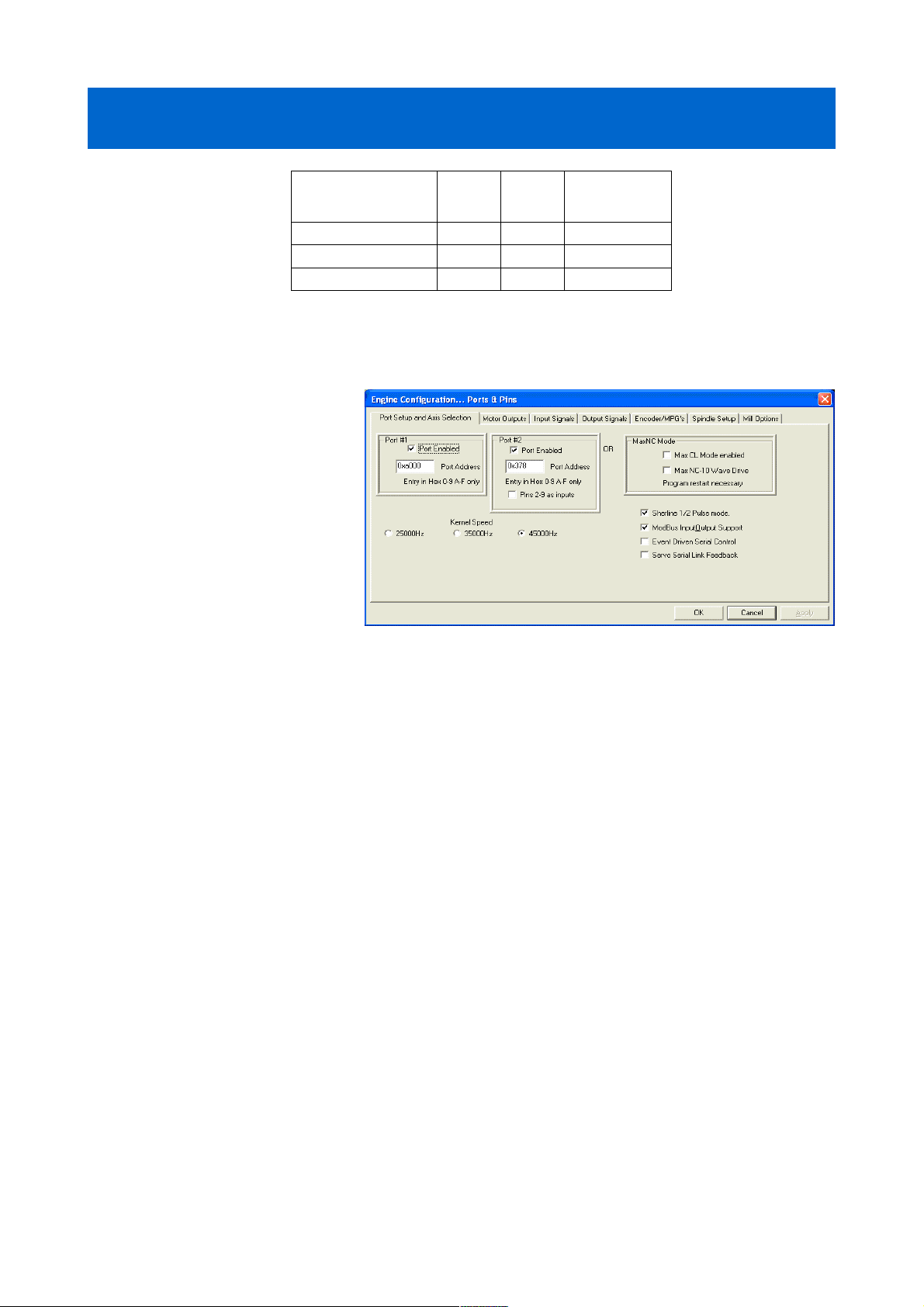

Illustration 1: Mach3 Port Setup.........................................................................................................14

Illustration 2: Mach3 Spindle Setup Tab............................................................................................15

Illustration 3: PCB Dimensions and Layout.......................................................................................21

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 5

1 Introduction

Thank you for purchasing Homann Designs' DigiSpeed-GX™ Isolated Voltage interface

unit. The DigiSpeed-GX™ provides a way for controlling DC motor speed controllers and

other devices that accept a 0-5Vdc, 0-10Vdc, 0-15Vdc voltage signal

This document is a User's Guide that describes the operation of the DigiSpeed-GX™. The

document contains information on how to use and integrate the board into your own

systems.

1.1 Contents

The box received when ordering the DigiSpeed-GX™ contains the following:

• DigiSpeed-GX™ isolated voltage interface unit.

• 2 x 0.1” jumpers.

• 4 x 4mm plastic PCB stand-offs.

Copyright 2006 © Homann Designs Revision 0.1

*** WARNING ***

The KB Electronics DC speed controller circuit, and other similar

speed controllers as found in Asian imported mini lathes and mini

mills are at mains voltage potential. This voltage is lethal. Do not

attempt to do this conversion if you are not qualified to do so.

Confidence is no replacement for qualification!

If you feel that this project is beyond your abilities to SAFELY

complete, we can install the unit for you. Please contact us for details

Please ensure you read the complete manual before attempting to

install or use this device.

DigiSpeed-GX™

- Users Guide Page 6

1.2 Overview

The DigiSpeed-GX Isolated Voltage Interface Unit is designed to allow devices such as

the Gecko G-100 motion controller and computer CNC programs such as Mach2,

TurboCNC and other CNC programs to control devices that require an isolated DC control

voltage.

DigiSpeed-GX is designed primarily for use with KB Electronics style DC motor

controllers, such as the KBIC-120. This is the type of controller found in the Sherline

Mills and Lathes. DigiSpeed-GX will work with other types of DC motor controllers

such as those found in the Asian imported mini lathes and Mills.

The DigiSpeed-GX™ is also well suited for use with VFDs such as the Automation Direct

GS2 series and other motor speed controllers which accept a 0-5Vdc, 0-10Vdc speed

control voltage.

The form factor of the DigiSpeed-GX PCB has been designed for easy installation. Due

to its compact size, it can also be installed unobtrusively into many of the existing speed

controller or CNC controller enclosures.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 7

2 Options

The DigiSpeed-GX™ is a versatile unit. It has an on-board LED indicator, mode select

jumpers, and an attenuation multi-turn trim-pot The board is designed to be installed into

existing motor speed controller housings, external CNC housings or other enclosures.

2.1 5Vdc – 15Vdc isolated DC-DC Converter.

Depending on the installation, the device being controlled by the DigiSpeed-GX™ may

not be able to provide the 10Vdc supply required by the isolated analog circuitry. In such

situations, the optional On-board 5Vdc - 15Vdc isolated DC-DC converter may be used to

provide the required supply.

Note: The DigiSpeed-GX™ Attenuation trimpot may be used to scale the output voltage to 0-10Vdc,

or to a voltage that is required by the device being controlled by the DigiSpeed-GX™ .

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 8

3 Features

The main features of the DigiSpeed-GX controller are;

• Controlled by a RISC Microchip micro-controller.

• PCB

o FR4 Material

o Double Sided, Plated through holes

o Silk-Screened on Component Side

o Solder Mask on Both Sides

• Small PCB footprint 2”(L) x 1”(W)

• Four 4mm mounting holes (supplied with matching stand-offs)

• 5V dc XXXmA power requirements.

• Opto-isolation between the computer logic Voltages and the analolg output control voltages.

• Maximum DC Speed controller voltage for the control supply of 15Vdc

• 10 bit resolution providing more than 1000 steps from 0 to Max Output voltage.

• Four methods to control motor speed.

o 0-5V analog Voltage

o PWM - A low frequency PWM signal. (2Hz – 100Hz )

o On-Board multi-turn trimpot

• Output Control Voltage Attenuator.

• SMT LED indicating the mode and state of the DigiSpeed-GX controller.

• Pluggable 3.5mm terminal block connectors for easy installation and maintenance.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 9

4 Board Description

4.1 Introduction

The DigiSpeed-GX controller provides the capability to

control a device such as the the spindle speed of a DC or AC

motor via computer control

May of the devices that the DigiSpeed-GX is designed to

work with such as the KBIC-120 controller supplied by KB

Electronics, use a “Hot Ground” circuitry. That is, the

reference voltages for setting the speed are at MAINS

POTENTIAL voltage. This voltage is dangerous and can be

lethal.

This style of controller uses a control voltage, usually in the

0 –10Vdc range to control the motor speed from 0 – max

speed. In reality, this voltage can be anywhere in the range

of 5Vdc to 15vdc. The maximum output voltage of the

DigiSpeed-GX and thus the speed of the motor can be

limited by an attenuation trim-pot that reduces this control

voltage supply.

AC motor controllers are usually Variable Frequency Drives (VFD) and have terminals for

the connection of an external manual control potentiometer, or a 0-5Vdc, 0-10Vdc control

voltage.

The DigiSpeed-GX circuitry is essentially in two parts. One part contains low voltage

logic level circuitry that includes a micro controller and interfaces to the PC or controlling

device. It is supplied by 5Vdc that is referenced to the controlling devices ground. The

other part of the DigiSpeed-GX circuitry is connected to the DC Speed controller

control circuitry. This part is at MAINS POTENTIAL.

The two parts of the circuitry are separated by opto-isolation. This ensures that the

dangerous MAINS POTENTIAL voltages are kept away from the low level logic

circuitry. The two parts of circuitry must never be connected together. If it happens, a

catastrophic failure of the DigiSpeed-GX circuit and your PC will occur.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 10

The DigiSpeed-GX controller provides a control voltage in place of the control voltage

provided by the manual speed control potentiometer. This voltage can be varied from 0V

to 100% of the maximum control voltage by computer software.

There are 1023 steps from 0 to the maximum control voltage. If your maximum spindle

speed is 6000 rpm, this effectively provides for a 6-rpm resolution in controlling spindle

speed.

4.2 Mode Indication LED

The DigiSpeed-GX controller contains a SMT LED that is used to indicate the input

mode that has been selected and when activity on the input is present.

4.2.1 Mode Indication

The DigiSpeed-GX controller used the indicator LED to show which input mode is

selected. It does this by flashing the LED on power up as described below;

• LED Off – This indicates that there is no 5Vdc power supplied to the DigiSpeed-

GX .

• Single Flash – Indicates that the DigiSpeed-GX is powered in Analog input

Mode.

• Double Flash – Indicates that the DigiSpeed-GX is powered in PWM input

Mode.

• Triple Flash – Indicates that the DigiSpeed-GX is powered in Multi-turn

Trimpot input Mode.

4.2.2 Input Activity Indication

The DigiSpeed-GX controller uses the LED to indicate when there is activity on the

input. This activity is as described below;

Copyright 2006 © Homann Designs Revision 0.1

DO NOT GROUND THE MAINS POTENTIAL SIDE OF THE

***YOU HAVE BEEN WARNED***

CIRCUITRY

DigiSpeed-GX™

- Users Guide Page 11

• LED Off – This indicates that there is no 5Vdc power supplied to the DigiSpeed-

GX .

• Lazy RED Double Flash – Indicates that the DigiSpeed-GX is powered on, and

there is no activity on the input source.

• Fast RED Flash – Indicates that the DigiSpeed-GX is powered, and there is

activity on the input source.

4.3 Output Attenuation Trimpot

The DigiSpeed-GX controller contains an Output Attenuation Trimpot. The purpose of

this is to attenuate or reduce the full scale output voltage of the controller. This may be

used to reduce the maximum speed of a spindle.

By turning the screw in the 11 turn trimpot VR1, in a Counter-Clockwise direction, the

output voltage will be reduced, or attenuated.

Some VFDs and motor controllers require a 0 – 5Vdc voltage to control spindle speed, yet

provide a 10Vdc voltage supply. In this instance, the attenuator may be used to reduce the

10V control voltage to 5V as required by the controller.

4.4 Output Voltage Selection JP1

Note: This jumper is only fitted when the optional DC-DC isolated voltage generator is fitted.

The DigiSpeed-GX controller contains an Output voltage selection jumper, JP1. The

purpose of this is to select the source of the isolated voltage that is generated.

If the jumper is fitted between pins 1-2 (towards the DC-DC generator) then the

Generators 15Vdc voltage will be used. In this instance there is no need to connect the

motor controller to pin AV+ on connector J2

If the jumper is fitted between pins 2-3 (away from the DC-DC generator) then the voltage

supplied by the DC motor controller via connector J2, pin AV+ will be used.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 12

4.5 Mode Selection Jumper Block JP2

The DigiSpeed-GX can operate in a number of modes, depending on the type of control

signal that is provided by your CNC software and or controller. The mode is selected via

the mode selection jumpers as shown in the picture below;

Jumper JP2 consists of a two jumpers . MSI is the jumper closest to the Input Terminal

block J1. MS2 is immediately below MS2.

Jumper Function Position

MS1 Mode

Select

Top

MS2 Mode

Select

Bottom

Table 1: Mode Select Jumper Block

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 13

5 Quick Start Guide – PWM Mode

This section is intended to allow you to quickly setup and verify the operation of your

DigiSpeed-GX™ controller with Mach3 for use in PWM mode. Initially, this will be done

with the DigiSpeed-GX™ unit being connected to computer but not your Motor Drive.

Once you are familiar with the operation of the DigiSpeed-GX's operation, it can then be

connected to the motor drive.

The DigiSpeed-GX circuitry is essentially in two parts. One part contains low voltage

logic level circuitry that includes a micro controller and interfaces to the PC via the parallel

port. It is supplied by 5Vdc that is referenced to the PC parallel port ground. The other part

of the DigiSpeed-GX circuitry is connected to the DC Speed controller control circuitry.

This part is at MAINS POTENTIAL.

The quick start setup will verify the connection to the Microprocessor and logic side of the

DigiSpeed-GX™ controller.

5.1 What you need

To get started, you need:

• DigiSpeed-GX™ controller.

• Breakout board or other mechanism for connecting the DigiSpeed-GX™ control

lines to the Computer Printer port.

• A PC with a printer port and Mach3 installed and running.

This quick start setup is done with the DigiSpeed-GX™ unit sitting on the bench and NOT

connected to your Motor controller.

Mach3 controls the DigiSpeed-GX™ in PWM mode only. Therefore you need to place

jumper JP1 into the mode selection jumper block.

5.2 Mach3 Configuration Setup

The example setup describes how Mach3 is configured for the DigiSpeed-GX™. Your

configuration may differ depending on what Printer Port number you are using, and what

pins in the port are connected to which DigiSpeed-GX™ pins.

For this example, printer port 2 is being used with the port pins connected as shown in

Table 2 below.

Notes:

1. It is advisable to use a breakout board between the Printer port and the DigiSpeed-GX™.

2. The 5V supply for the DigiSpeed-GX™ must be obtained from the breakout board, as it cannot be

supplied from the printer port.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 14

Signal Printer

Port Pin

Number

PC

Input/Out

put

DigiSpeed-GX

J1 Pins

PC Parallel Port GND (0V) 18-25 - GND

PWM 1 Out VIn

5Vdc with respect to Pin 1 - - +5V

Table 2: DigiSpeed-GX™ - Breakout board Connections

5.2.1 Port Setup

From the Options menu

in Mach3, select the

Ports & Pins Setup

item. As shown in

Illustration 1 below,

Port 2 is enabled and is

set to the default printer

port address 0X378.

The other items on this

page are not concerned

with the DigiSpeedGX™ Setup.

5.2.2 Spindle Setup Tab

The Spindle setup tab is used to configure various option regarding the Spindle operation.

As shown in Illustration 2 below, the following items are configured:

• Motor Control – As shown below, the following items are setup:

• The Use 'Spindle Motor Output' check box is ticked.

• The 'PWM Control' check box is ticked.

• The PWM base frequency is set to 50.

• The minimum PWM % is set to 0

• Pulley ratios – The maximum spindle speeds for the pulley ratios you have are set up

to allow Mach3 to calculate the required PWM percentage.

Copyright 2006 © Homann Designs Revision 0.1

Illustration 1: Mach3 Port Setup

DigiSpeed-GX™

- Users Guide Page 15

This now concludes the configuration of the Mach3 software for the DigiSpeed-GX™. The

next step is to hook up the unit to your breakout board for testing.

5.3 Power to the DigiSpeed-GX

The first step in the installation is to provide 5V power to the DigiSpeed-GX™ controller.

Wire DigiSpeed-GX™ J1- GND pin to a logic ground terminal on your CNC controller

breakout board. This logic ground is the same as the PC printer port 0V potential, found on

pins 18 to 25 of your printer port.

Wire DigiSpeed-GX™ J1-+5V to a 5Vdc supply on your CNC controller's breakout

board. This needs to be 5Vdc with respect to the PC printer port ground.

Turn on your CNC controller. This should provide the 5Vdc supply to the DigiSpeedGX™. Verify this is the case, by checking that the Mode Indicator LED is flash a slow

double flash. If not, turn off the CNC controller and check the wiring.

5.4 Connect the PWM Signal

Wire DigiSpeed-GX™ J1-Vin to pin 1 of the printer port via your CNC controller's

breakout board.

You can now test that the PWM speed value is being received by the DigiSpeed-GX™. Set

the spindle speed to zero typing it into the speed DRO, or entering the command 'S 0' into

the MDI window .

Copyright 2006 © Homann Designs Revision 0.1

Illustration 2: Mach3 Spindle Setup Tab

DigiSpeed-GX™

- Users Guide Page 16

Now enter a spindle speed of 1000 into the DRO and enable the spindle. You should now

observe the DigiSpeed-GX™ Mode Indicator LED perform a continuous Red fast flash.

This indicates that the DigiSpeed-GX™ is enabled and is generating an analog control

voltage on the output.

5.5 Conclusion

You should now have your DigiSpeed-GX™ operating correctly with Mach3. You are now

ready to install the unit into your Motor Speed controller's enclosure, your CNC controller

or a separate enclosure.

6 Installation

Before attempting the installation please read the entire manual. If you are unsure of

anything, do not do the installation. Get help from someone who is qualified for this type

of work. I am not responsible for damage or injury resulting from the installation or use of

this device.

It is advisable to integrate the The DigiSpeed-GX with your control software before

installing and connecting it to your Motor Controller. The unit is powered from a breakout

board. Therefore it is possible to test and become familiar with it's operation prior to

connecting it to a motor controller.

The board has indicator LEDs that provide status of what is occurring. These can be used

to assist in the integration.

The DigiSpeed-GX may be mounted into an existing motor controller enclosure or

external enclosures. The hardware installation is dependent on what you are installing the

DigiSpeed-GX into. The physical installation is first covered in the section below,

followed by the electrical installation.

6.1 DC Motor Speed Controller housing

If the DigiSpeed-GX™ is to be installed into an existing Motor speed controller housing,

ensure that there is sufficient space to safely install the DigiSpeed-GX™.

Refer to the PCB layout and dimensions diagram in determining the positions of holes for

mounting. The unit may be mounted using the 4 stand-offs provided.

6.2 Wiring installation

Once the DigiSpeed-GX controller is installed into a housing the following wiring is

required.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 17

6.2.1 Motor Controller Connection

The DigiSpeed-GX is connected to the motor controller via the three terminal pluggable

connector J2.

• The terminal labeled AV+ connects to the potentiometer positive voltage

connector on the speed controller.

• The terminal labeled Vout connects to the potentiometer connector on the speed

controller.

• The terminal labeled AGnd connects to the potentiometer control voltage on the

speed controller.

These three connections plug into your speed controller in place of your existing manual

speed potentiometer. Unless you are using a voltage isolation board these leads are at

***MAINS VOLTAGE POTENTIAL ***. They can cause serious injury or death. Do

not connect any earthed test equipment to this terminal block as it is at mains potential.

6.2.2 Initial Testing

6.2.2.1 Attenuation Trimpot Speed Control.

To test the DigiSpeed-GX control manually via the attenuation trimpot VR1:

1. Turn off the Motor Speed controller and the CNC controller .

2. Set the DigiSpeed-GX mode to Attenuation Trimpot by inserting jumpers MS1

and MS2.

3. Turn the attenuation trimpot Anti-Clockwise eleven complete turns.

4. Power up the DigiSpeed-GX .

5. Turn on the Motor Speed controller. Ensure that there is 5Vdc power applied to the

DigiSpeed-GX. You can verify this by the Lazy Double Flash of the LED

illuminated on the DigiSpeed-GX.

6. Slowly turn the trimpot Clockwise unit the required maximum spindle speed is

reached.

6.2.2.2 Computer Speed Control.

To test the DigiSpeed-GX control from Mach3:

1. Turn off the Motor Speed controller and the CNC controller .

2. Set the DigiSpeed-GX mode to :PWM by inserting jumpers MS1 only.

3. Power up the DigiSpeed-GX .

4. Turn on the Motor Speed controller. Ensure that there is 5Vdc power applied to the

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 18

DigiSpeed-GX. You can verify this by the Lazy Double Flash of the LED

illuminated on the DigiSpeed-GX.

Run through the tests detailed in the Quick Start Guide section with the understanding that

the spindle is not powered and operational.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 19

7 Operation

7.1 Operation Modes

The DigiSpeed-GX™ has four operational modes, selected by jumpers MS1, MS2 in

jumper block JP2. The selection of the modes is described below.

Mode MS1 MS2

ANALOG

Removed Don't Care

PWM

Installed Removed

Attenuation Trimpot

Installed Installed

Table 3: Mode Selection Jumpers

The selection of the mode is done at power up initialization.

Note: If the mode selection jumpers are modified after the unit is powered up, the new mode will

not take effect until the power is cycled.

Each of the modes is discussed in detail below.

7.1.1 Analog Input Mode

In this mode the DigiSpeed-GX controller accepts an analog 0-5Vdc signal. 0Vdc

represents 0%, varying to 5Vdc which represents 100% of maximum spindle speed.

This will provide 1023 speed increments from 0 to 100% of maximum spindle speed.

With the DigiSpeed-GX module supplied with power, and no analog signal is present,

the LED will be a Red slow double flash. This indicates that the spindle is active but the

speed is set to 0 %. Then, when an analog voltage signal is present, the LED will be a fast

continuous flash, indicating that the spindle is active and the speed is set to a value greater

than 0 %.

7.1.2 PWM Input Mode

In this mode the DigiSpeed-GX controller accepts an “Active Low” Pulse Width

Modulation signal. The duty cycle of this signal represents 0 to 100% of maximum spindle

speed.

The PWM signal period can be in the range of 2Hz to 50Hz. The optimum period is 50Hz.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 20

This will provide 1023 speed increments from 0 to 100% of maximum spindle speed.

With +5V is supplied to the DigiSpeed-GX module, and no PWM signal is present, the

LED will be a Red slow double flash. This indicates that the spindle is active but the speed

is set to 0 %. Then, when a PWM signal is present, the LED will be a fast continuous

flash, indicating that the spindle is active and the speed is set to a value greater than 0 %.

7.1.3 Attenuation Trimpot

In this mode the DigiSpeed-GX controller uses the attenuation trimpot to generate the

oiutput voltage. It assumes there is a fullscale analog voltage input and then attenuates it

to produce 0% to 100% of the output voltage.

With +5V is supplied to the DigiSpeed-GX module, the LED will be a slow double flash

when the trimpot is set to maximum attenuation by turning the screw fully counterclockwise..

When the attenuation is not set at maximum, the LED will flash at a fast rate, with the

output voltage generated as a percentage of the full scale voltage.

Copyright 2006 © Homann Designs Revision 0.1

DigiSpeed-GX™

- Users Guide Page 21

8 Board Dimensions

Copyright 2006 © Homann Designs Revision 0.1

Illustration 3: PCB Dimensions and Layout

DigiSpeed-GX™

- Users Guide Page 22

Copyright 2006 © Homann Designs Revision 0.1

Loading...

Loading...