Page 1

Hz

Installation, Operation, and

Maintenance Manual

GRP Series

Version 05/2019- No. 00507610.02

60

Page 2

Content

1.2. Preface .............................................................................................................................................................03

1.3. Proper use ........................................................................................................................................................03

1.4. Copyright ..........................................................................................................................................................03

1.5. Technical terms ................................................................................................................................................03

2. Safety .................................................................................................................................03

2.1. Instructions and safety information .................................................................................................................. 03

2.2. General safety ..................................................................................................................................................04

2.3. Operating personnel ......................................................................................................................................... 04

2.4. Electrical work ..................................................................................................................................................04

2.5. Operating procedure ......................................................................................................................................... 05

2.6. Safety and control devices ...............................................................................................................................05

2.7. Operation in an explosive atmosphere ............................................................................................................. 05

2.8. Sound Safety ....................................................................................................................................................05

2.9. Pumped fluids .................................................................................................................................................. 05

2.10. Danger due to spark generation .....................................................................................................................05

3. General description .......................................................................................................... 06

3.1. Application ........................................................................................................................................................ 06

3.2. Types of use .....................................................................................................................................................06

3.3. Construction .....................................................................................................................................................06

4. Package, Transport, Storage ...........................................................................................09

4.1. Delivery ............................................................................................................................................................. 09

4.2. Transport ........................................................................................................................................................... 09

4.3. Storage .............................................................................................................................................................09

4.4. Returning to the supplier ................................................................................................................................. 09

5. Installation and initial commissioning ...........................................................................10

5.1. General .............................................................................................................................................................10

5.2. Installation ........................................................................................................................................................11

5.3. Use of chains .................................................................................................................................................... 12

5.4. Initial operation .................................................................................................................................................12

5.5. Preparatory work ..............................................................................................................................................13

5.6. Electrical ..........................................................................................................................................................13

5.7. Direction of rotation .......................................................................................................................................... 14

5.8. Motor protection ............................................................................................................................................... 15

5.9. Variable Frequency Drives ................................................................................................................................15

5.10. Types of startups ............................................................................................................................................15

6. Maintenance .....................................................................................................................16

6.1. General .............................................................................................................................................................16

6.2 Maintenance intervals .......................................................................................................................................16

6.3. Maintenance tasks ...........................................................................................................................................17

6.4. Seal chamber .................................................................................................................................................... 18

7. Repairs ............................................................................................................................... 18

7.1. General .............................................................................................................................................................18

7.2. Changing the impeller ....................................................................................................................................... 18

7.3 Spare Parts ........................................................................................................................................................19

8. Shutdown ..........................................................................................................................19

8.1. Temporary shutdown ........................................................................................................................................ 19

8.2. Final shutdown / storage ..................................................................................................................................19

8.3. Restarting after an extended period of storage ................................................................................................ 19

9. Troubleshooting ...............................................................................................................19

10. Connection of pumps and mixers ................................................................................. 22

02 | English

Page 3

1.2. Preface

Dear Customer,

Thank you for choosing HOMA Pump Technology. You

have purchased a product which has been manufactured

to the latest technical standards. Read this operating and

maintenance manual carefully before first use, in order

to ensure the product is used safely. The documentation

contains all the necessary specifications for the product,

allowing you to use it properly. In addition, you will also

find information on how to recognize potential dangers,

reduce repair costs and downtime, and increase the reliability and working life of the product.

All safety requirements and specific manufacturer’s requirements must be fulfilled before the product is put

into operation. This operating and maintenance manual

supplements any existing national regulations on industrial safety and accident prevention. This manual must also

be accessible to personnel at all times and also be made

available where the product is used.

1.3. Proper use

In the event of improper use, there is a danger to life for

the user as well as for third parties. Additionally, the product and/or attachments may be damaged or destroyed.

It is important to ensure that the product is only operated in good condition and as intended. To do so, follow

the operating instructions. The pumps can be used in the

range specified by the manufacturer in accordance with

the current HOP.SEL version. Please note that the offered

pumps may only be used in the defined field of application. Operating the pump outside the application range

can lead to operational problems or significant damage to

the unit.

Please note that the surfaces of the product become very

hot!

“transportable” installation type

With this installation type the product is equipped with a

pedestal. It can be installed and operated at any location.

Please observe the values for the maximum submersion

depth and the minimum water coverage, and remember

that the surfaces of the product become very hot.

“S1” operating mode (continuous operation)

At the rated load, a constant temperature is reached that

does not increase even in prolonged operation. The operating equipment can operate uninterruptedly at the rated

load without exceeding the maximum permissible temperature.

Operating mode “S3“ (intermittent operation):

For this operating mode, after the abbreviation, the percent duty cycle is displayed, as well as the cycle duration

if it is greater than 10 minutes. For example: S3 40% 60

minutes means the pump can operate continuously for

40% (24 minutes) of one hour, and must then pause for

36 minutes.

Low Level Lockout

The low level lockout is designed to automatically shut

down the product if the water level falls below the minimum water coverage value of the product. This is made

possible by installing a float switch.

Level control

The level control is designed to switch the product on or

off depending on the water level. This is made possible by

installing a float switch.

1.4. Copyright

This operation and maintenance manual has been copyrighted by the manufacturer. This operation and maintenance handbook is intended for use by assembly, operating and maintenance personnel. It contains technical

specifications and diagrams which may not be reproduced

or distributed, either completely or in part, or used for any

other purpose without the expressed consent of the manufacturer.

1.5. Technical terms

Various technical terms are used in this operating and

maintenance manual.

Dry run

The product is running at full speed, however, there is no

liquid to be pumped. A dry run is to be strictly avoided. If

necessary, a safety device must be installed.

“wet” installation type

This installation type requires the product to be immersed

in the pumped fluid. It is completely surrounded by the

pumped fluid. Please observe the values for the maximum

submersion depth and the minimum water coverage.

“dry” installation type

In this installation type, the product is installed dry, i.e. the

pumped fluid is delivered to and discharged via a pipeline

system. The product is not immersed in the pumped fluid.

2. Safety

This chapter lists all the generally applicable safety instructions and technical information. Additionally, other

chapters contain specific safety instructions and technical information. All instructions and information must be

observed and followed during the various phases of the

product‘s lifecycle (installation, operation, maintenance,

transport etc.). The operator is responsible for ensuring

that personnel follow these instructions and guidelines.

2.1. Instructions and safety information

This manual uses instructions and safety information for

preventing injury and damage to property.

To make this clear for the personnel, the instructions and

safety information are distinguished as follows:

Each safety instruction begins with one of the following

signal words:

Danger: Serious or fatal injuries can occur!

Warning: Serious injuries can occur!

Caution: Injuries can occur!

Caution (Instruction without symbol): Serious damage

to property can occur, including irreparable damage!

English | 03

Page 4

Safety instructions begin with a signal word and description of the hazard, followed by the hazard source and

potential consequences, and end with information on

preventing it.

2.2. General safety

• Never work alone when installing or removing the

product.

• The machine must always be switched off before

any work is performed on it (assembly, dismantling,

maintenance, installation). The machine must be disconnected from the electrical system and secured

against being switched on again. All rotating parts

must be at a standstill.

• The operator should inform his/her superior immediately should any defects or irregularities occur.

• It is of vital importance that the system is shut down

immediately by the operator if any problems arise

which may endanger safety of personnel. Problems

of this kind include:

• Failure of the safety and/or control devices

• Damage to critical parts

• Damage to electric installations, cables and

insulation.

• Tools and other objects should be kept in a place

reserved for them so that they can be found quickly.

• Sufficient ventilation must be provided in enclosed

rooms.

• When welding or working with electronic devices,

ensure that there is no danger of explosion.

• Only use fastening devices which are legally defined

as such and officially approved.

• The fastening devices should be suitable for the

conditions of use (weather, hooking system, load,

etc). If these are separated from the machine after

use, they should be expressly marked as fastening

devices. Otherwise they should be carefully stored.

• Mobile working equipment for lifting loads should

be used in a manner that ensures the stability of the

working apparatus during operation.

• When using mobile working equipment for lifting

non guided loads, measures should be taken to avoid

tipping and sliding etc.

• Measures should be taken that no person is ever

directly beneath a suspended load. Furthermore,

it is also prohibited to move suspended loads over

workplaces where people are present.

• If mobile working equipment is used for lifting loads,

a second person should be present to coordinate the

procedure if needed (for example if the operator‘s

field of vision is blocked).

• The load to be lifted must be transported in such a

manner that nobody can be injured in the case of a

power cut. Additionally, when working outdoors,

such procedures must be interrupted immediately if

weather conditions worsen.

These instructions must be strictly observed.

Non-observance can result in injury or serious

damage to property. This product may contain chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm.

www.p65warnings.ca.gov

2.3. Operating personnel

All personnel who work on or with the product must be

qualified for such work; electrical work, for example may

only be carried out by a qualified electrician. The entire

personnel must be of age. Operating and maintenance

personnel must also work according to local accident prevention regulations. It must be ensured that personnel

have read and understood the instructions in this operating and maintenance handbook; if necessary this manual

must be ordered from the manufacturer in the required

language.

2.4. Electrical work

Our electrical products are operated with alternating or industrial high-voltage current. The local regulations (e.g. 2017 NEC) must be adhered

to. The technical specifications must be strictly adhered to. If the machine has been switched off by a

protective device, it must not be switched on again until

the error has been corrected.

Beware of electrical current!

Incorrectly performed electrical work can result in

fatal injury! This work may only be carried out by a

qualified electrician.

Beware of Moisture!

Moisture penetrating into cables can damage them

and render them useless. Furthermore, water can

penetrate into the terminal compartment or motor

and cause damage to the terminals or the winding.

Never immerse cable ends in the pumped fluid or

other liquids.

2.4.1. Electrical connection

When the machine is connected to the electrical control

panel, especially when electronic devices such as soft

startup control or frequency drives are used, the relay

manufacturer‘s specifications must be followed in order

to conform to EMC. Special separate shielding measures

e.g. special cables may be necessary for the power supply

and control cables.

The connections may only be made if the equipment

meets NEC standards. Mobile radio equipment may

cause malfunctions.

Beware of electromagnetic radiation!

Electromagnetic radiation can pose a fatal risk for

people with pacemakers. Put up appropriate signs

and make sure anyone affected is aware of the

danger.

2.4.2. Ground connection

Our products (machine including protective devices and

operating position, auxiliary hoisting gear) must always be

grounded. If there is a possibility that people can come

into contact with the machine and the pumped liquid (e.g.

at construction sites), the grounded connection must be

additionally equipped with a fault current protection device. The electrical motors conform to motor protection

class IP 68 in accordance with the valid norms.

04 | English

Page 5

2.5. Operating procedure

When operating the product, always follow the locally

applicable laws and regulations for work safety, accident

prevention and handling electrical machinery. To help to

ensure safe working practice, the responsibilities of employees should be clearly set out by the owner. All personnel are responsible for ensuring that regulations are

observed. Certain parts such as the rotor and impeller rotate during operation in order to pump the fluid. Certain

materials can cause very sharp edges on these parts.

Beware of rotating parts!

The moving parts can crush and sever limbs. Never

reach into the pump unit or the moving parts during

operation. Switch off the machine and let the moving

parts come to a rest before maintenance or repair

work!

2.9. Pumped fluids

Each pumped fluid differs in regard to composition, corrosiveness, abrasiveness, TS content and many other

aspects. Generally, our products can be used for many

applications. For more precise details, see chapter 3, the

machine data sheet and the order confirmation. It should

be remembered that if the density, viscosity or the general

composition change, this can also alter many parameters

of the product. Different materials and impeller shapes

are required for different pumped fluids. The more exact

your specifications on your order, the more exactly we can

modify our product to meet your requirements.

If the area of application and/or the pumped fluid change,

we will be happy to offer supportive advice.

When switching the product into another pumped fluid,

observe the following points:

2.6. Safety and control devices

Our products are equipped with various safety and control

devices. These include, for example moisture sensors and

temperature sensors. These devices must never be dismantled or disabled. Equipment such as thermo sensors,

float switches, etc. must be checked by an electrician

for proper functioning before start-up. Please remember

equipment such as PT100 temperature monitors or float

switches require the use of a HOMA GO switch for connection. Please contact your HOMA distributor for information.Personnel must be informed of the installations

used and how they work.

Caution!

Never operate the machine if the safety and monitoring devices have been removed or damage, or if they

do not work.

2.7. Operation in an explosive atmosphere

Products marked as FM approved for suitable operation in

explosive atmosphere, are designed for Class I, Division

1, Groups C and D and Temperature class T4. The permitted ambient temperature is between -4°F and 104°F.

The enclosures protection class is IP68. The products

must meet certain guidelines for this type of use. Certain

rules of conduct and guidelines must be adhered to by

the operator as well. Products that have been approved

for operation in an explosive atmosphere are marked as

explosion-proof rated by FM. In addition, an “FM” symbol

must be included on the name plate!

2.8. Sound Safety

Depending on the size and capacity (kW), the products

produce a sound pressure of up to110 dB. The actual

sound pressure, however, depends on several factors.

These include, for example, the installation type (wet, dry,

transportable), fastening of accessories (e.g. suspension

unit) and pipeline, operating site, immersion depth, etc.

Once the product has been installed, we recommend that

the operator make additional measurements under all operating conditions.

• Products which have been operated in sewage or

waste water must be thoroughly cleaned with pure

water or drinking water before use.

• Products which have pumped fluids which are hazardous to health must always be decontaminated

before changing to a new fluid. Also clarify whether

the product may be used in a different pumped fluid.

• With products which have been operated with a

lubricant or cooling fluid (such as oil), this can escape

into the pumped fluid if the mechanical shaft seal is

defective.

Danger - explosive fluids!

It is absolutely prohibited to pump explosive liquids

(e.g. gasoline, kerosene, etc.). The products are not

designed for these liquids!

2.10. Danger due to spark generation

Mechanically generated sparks can ignite flammable gases and condensates. According to EN1127-1 Para.6.4.4,

sparks must also be excluded for category 2 in normal

operation. In normal operation no spark generation is possible due to fluid covering (medium covering of the pump

hydraulic).The ingress or suction of foreign bodies (stones,

pieces of metal, etc.) through the suction nozzles into the

pump hydraulic is not possible in an expected case of malfunction in which the enclosure fails as the pump cannot

suck up pumping medium nor its containing solids.

In the ventilated shaft, the explosion-protected submersible motor pumps are drained via a drain system with

two guide tubes of galvanized steel, between their guide

claws of grey cast iron that guide into the automatic coupling arrangement.

The guide velocity, with max 0.1 m/s (10cm/s) is so low

that no sparks can be generated even in the most disadvantaged conditions. In the first installation, the guide

claws of the drain arrangement should be lubricated with

ball bearing grease in order to supredd heat and spark

generation in the most disadvantaged case.

Caution: Wear ear protectors! In accordance with

the laws in effect, guidelines, standards and regulations, ear protection must be worn if the sound pressure is greater than 85 dB (A)! The operator is responsible for ensuring that this is observed!

English | 05

Page 6

3. General description

3.1. Application

Waste water disposal with small pipework cross-sections,

good delivery heads at relatively low flow rates and pressure drainage systems in areas with difficult topography.

GRP pumps shred solids in the pumped medium in next

to no time, so plastic pipework with a cross-section as

small as 2” can be used.

This significantly reduces the cost of materials and laying

the waste water systems. If the pumped medium contains corrosive substances, the corrosion resistance of

the materials used must be observed. For such applications, versions made partly or entirely of highly resistant

materials (stainless steel) are also available

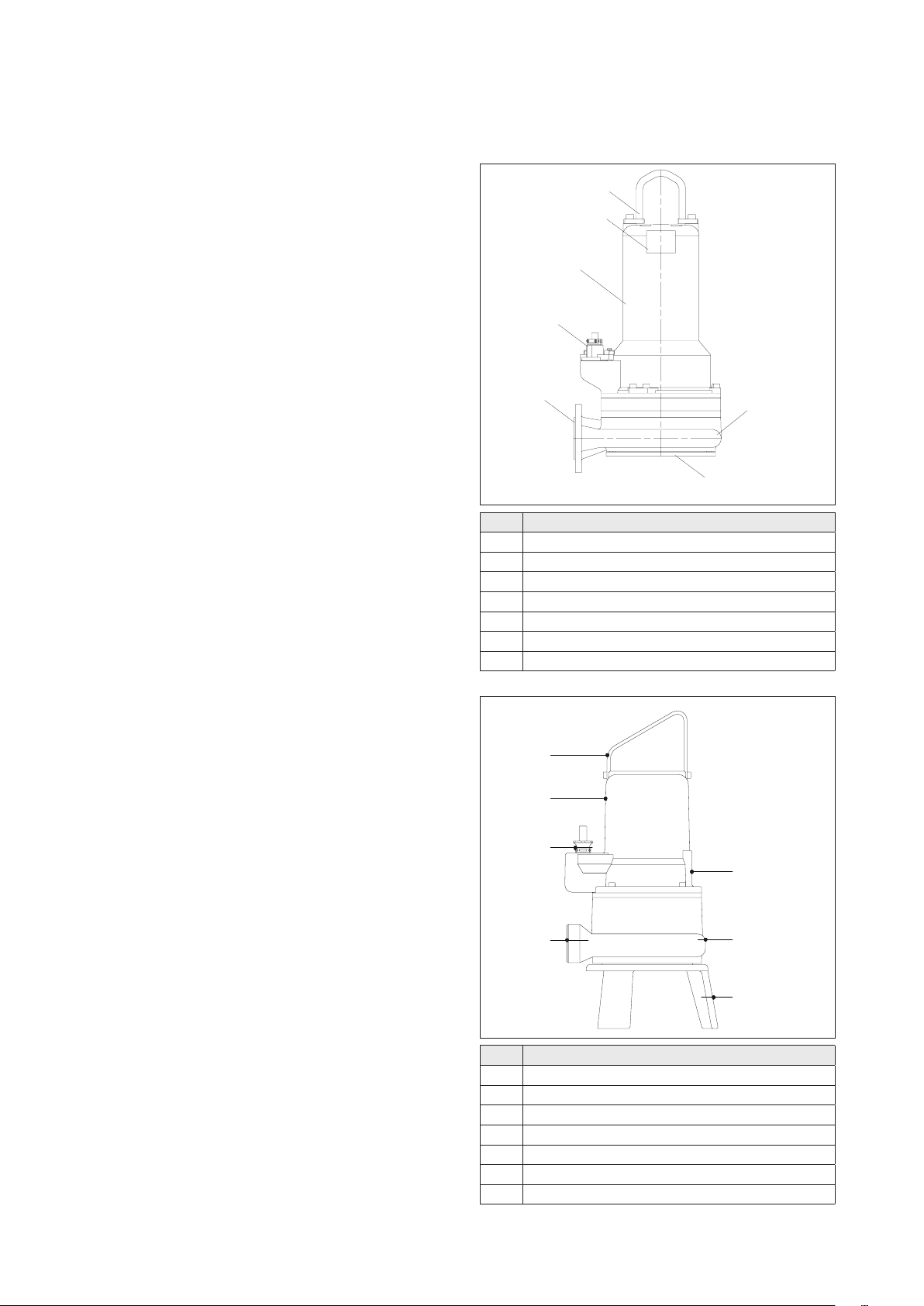

3.3. Construction

The major pump components consist of the motor housing, volute, and impeller.

According to the type of installation and motor cooling, the machine must be submerged in pumped liquid at least up to the top edge of the pump or motor

housing.

For continuous operation (S1) without a cooling jacket, the motor housing must be completely submerged.

The temperature of the pumped medium may be up to

104°F or up to 140°F for a short period. The maximum

density of the medium is 0.03757 lbs/in³ and the pH may

be from 6 – 11.

Stainless steel variants can be used at a pH of 4 - 14.

However, the pH alone only serves as a guideline. Consult

factory for assistance with chemically aggressive liquids.

Depending on the composition, it may be necessary to

use special sealing materials.

3.2. Types of use

The motors are designed for continuous operation (S1),

maximum 15 starts per hour.

The hydraulic is designed for permanent operation, e.g.

supply of industrial water.

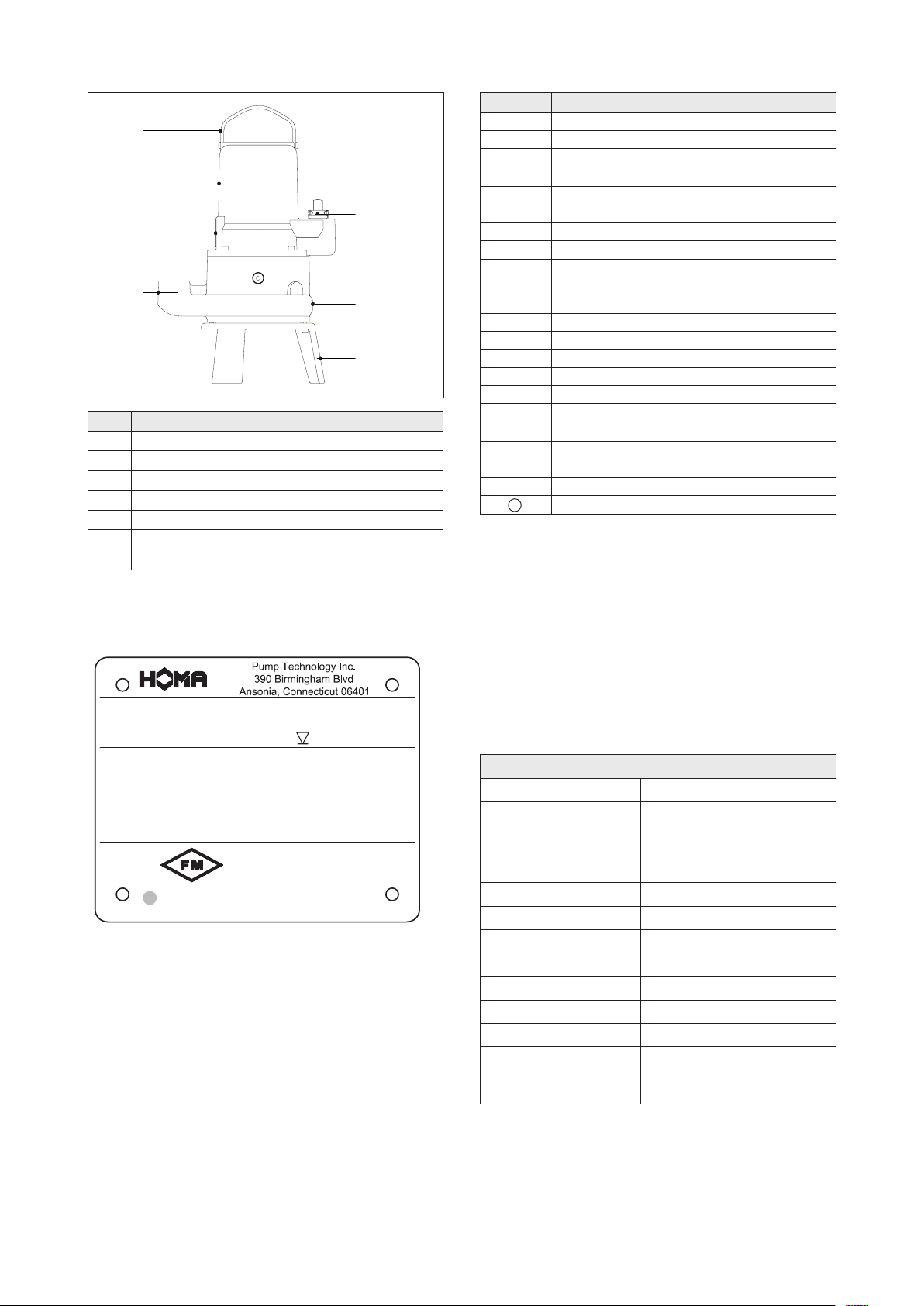

No. Description

1 Lifting handle

2 Name plate

3 Motor housing

4 Cable inlet

5 Discharge

6 Suction piece with cutting system

7 Volute

06 | English

No. Description

1 Lifting handle

2 Motor housing

3 Cable inlet

4 Discharge

5 Name plate

6 Volute

7 Suction cover with feet

Page 7

No. Description

1 Lifting handle

2 Motor housing

3 Name plate

4 Discharge

5 Cable inlet

6 Volute

7 Suction cover with feet

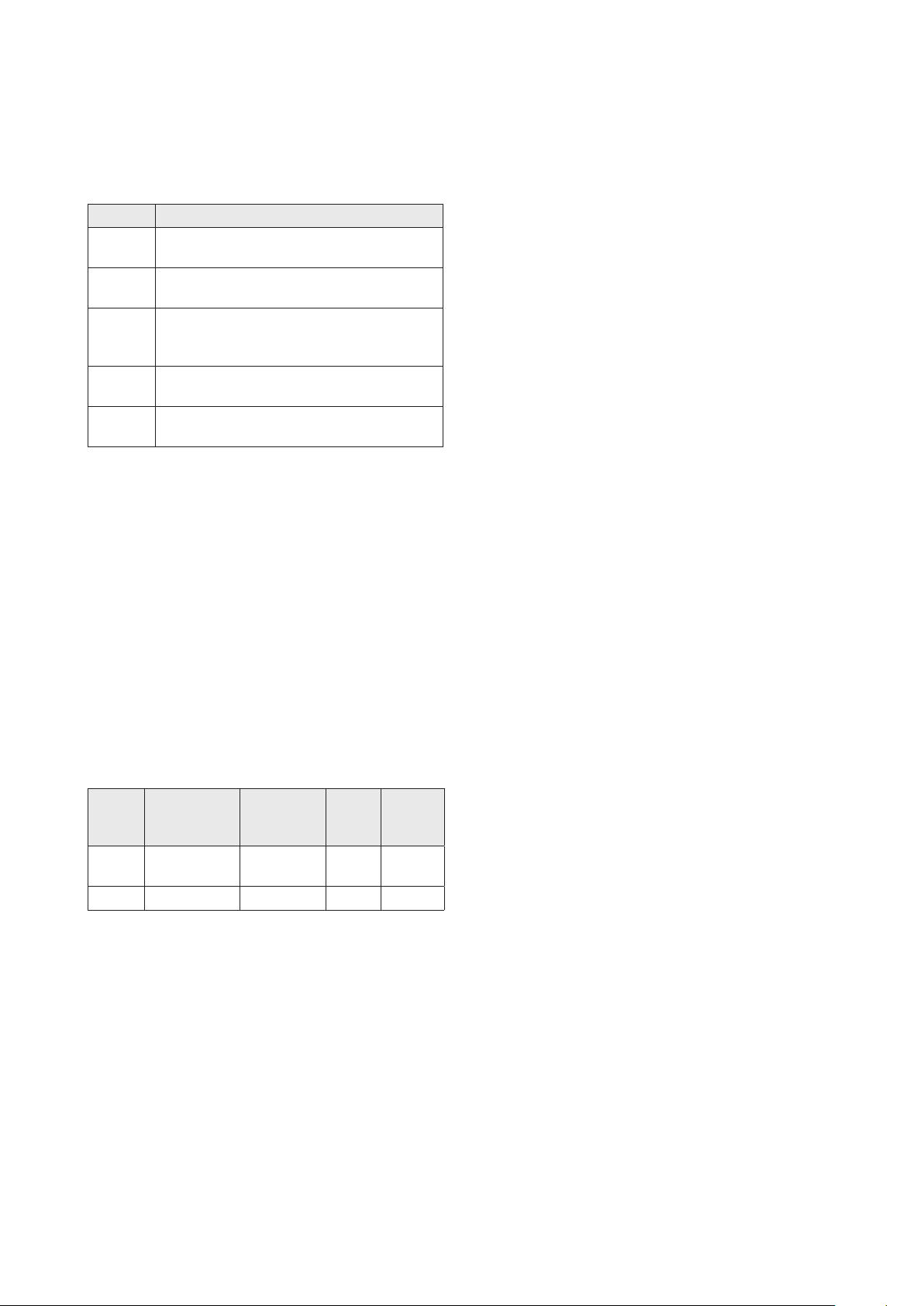

3.3.1. Type label

Pump:

Cont. Duty: 40° C amb.

Hmax:

Motor:

U: V

Hz

a

Cl.I,DIV.1,GR.CD

Hmin:

ft

P:

~

Flow max.:

I

:

HP

Nema code:

Wiring Diagram:

Operating Mode:

APPROVED

21

Thermally protected! See manual for cord replacement!

Do not remove covers while circuits are alive!

Sn:

Date:

cos

Ins. cl.:

φ:

IP 68

gpm

lbs

A

ft

rpm

No. Description

a

b

c

d

e

f

g

h

i

j

k

l

m

m a

n

o

p

q

r

s

t

21

3.3.2. Motor

The pump motor consists of the stator and shaft with

impeller assembly. The cable for the power supply is designed for maximum mechanical performance in accordance with the characteristic or pump name plate. Both

the cable entries and the cable are water-pressure tight to

the depth provided on the name plate. The shaft bearing

assembly is supported via robust, maintenance-free and

permanently lubricated roller bearings. All motors can also

be delivered in an explosion-proof version in accordance

with FM Class I, Division 1, Groups C & D.

General motor data

Service factor 1.15

Operating mode S1

Operating mode at 208V

only if a 208Vmotor was

ordered S3 42% 60min

Max. liquid temperature 35°C / 95°F

Insulation class H (180°C / 356°F)

Degree of protection IP68

Cable length 32 ft

Rotor shaft seal Silicon-carbide / Silicon-carbide

Rotor shaft seal GRP10-21 Silicon-carbide / Buna N

Mechanical shaft seal Silicon-carbide / Silicon-carbide

Bearing One grooved ball bearing (above),

Pump name

Serial number

Flow max

Hmax (Head max)

Hmin (Head min)

Submersion depth

Weight

Motor name

Date of manufacture

Voltage

Motor Power

Nominal current

Frequency

Phase

Motor speed

Cos phi

Temperature class

Nema Code Letter

Wiring diagram

Insulation class

Operating mode

Comments

double-row type angular ball bearing

(below)

English | 07

Page 8

3.3.3. Monitoring Equipment

The unit is equipped with various types of monitoring-safety equipment. The following table shows an overview of

the options available. The options may vary depending on

the size of the pressure outlet

Motortype Motorversion

…/C Temperature monitoring in the winding, Oil chamber

seal conditions sensor

...FM Temperature monitoring in the winding, Explosion

proof

.../C FM Temperature monitoring in the winding, Oil chamber

seal conditions sensor and motor connecting chamber,

Explosion proof

ET... Jacket cooled motor, thermal monitoring of winding,

monitoring of oil chamber seal

ET... FM Jacket cooled motor, thermal monitoring of winding,

monitoring of oil chamber seal, explosion-proof

Temperature Sensor

All pumps are equipped with a temperature sensor in

each motor winding. In standard pumps, the connections

for the temperature sensor are fed via the power cable to

the outside and are to be connected in the electric control box using the T1 and T3 power cable endings in such

a way that the motor automatically restarts after it has

cooled down.

Instead of the standard sensor, the explosion-proof versions are equipped with a temperature sensor assembly

that has a higher activation temperature. This is to be connected via the power cable endings T1 and T2 in such

a way that after activation, a manual reset is necessary

to restart the pump. The temperature sensor assembly

must be connected in the control panel so that it switches

off when it overheats.

Switch-off temperature of the sensors:

Motor

Frame

T 140°C / 284°F 140°C / 284°F 80°C /

Stator Winding

T1+T3

Regulator

Stator

Winding FM

T1+T2 Limiter

Lower

Bearing

Upper

Bearing

n/a

176°F

ET 125°C / 257°F 125°C / 257°F n/a n/a

Seal monitoring:

In case of a leak in the lower shaft seal, water enters

the oil chamber and changes the resistance of the oil.

The conductivity of the oil is monitored via one sensor to

ground. In the motor housing, another sensor monitors for

the resisitance to ground in case of water intrusion. The

sensors are to be connected via 2 cables (consult wiring

diagram) from the pump connection cables in the control

panel to a monitor galvanically separated from the probe

circuit. The response sensitivity should be adjustable from

0-100 kΩ, the standard setting being 50 kΩ. For external

seal probes an electrode relay with an intrinsically safe

circuit is to be chosen.

FM pumps: The sensors are connected via 2 cables

(labelled S1 and S2) of the pump connector cable in the

switching system to an evaluation device with an electrically isolated special circuit.

3.3.4. Sealing / Seal Housing

Sealing is accomplished in GRP24 and larger models by

two silicon carbide mechanical seals in a tandem arrangement, acting independently from each other. In smaller

models, sealing is accomplished by a silicon carbide lower

mechanical seal, and a nitrile rubber (Buna N) upper lip

seal. The seal housing is situated between the motor and

the pump housing. It consists of the bearing housing and

the pressure cover, which together form the sealing cavity with containing white mineral oil. Monitoring possibilities are available using the inspection plug on the bearing

housing and optional electronic monitoring.

3.3.5. Jacketed Pump Option

The cooling jacket has been supplied based upon the

specified operating conditions of this application. It is important this jacket is functioning properly, or the internal

motor components could become damaged. Several cooling configurations are available depending upon customer

preference and system requirements.

You must know what configuration of cooling system is

to be used with the pump prior to installation. In some

cases, field test results may indicate a change of cooling

method is required. Consult factory for necessary changes to the pump.

COOLING REQUIREMENTS

Standard Media Cooled –

This construction does not require any external piping and

it is completely self-contained. This design is suitable for

the routine collection system application. No pump modifications are required.

3.3.7. Volute

The volute depending on the model, will have one of several discharge connections. Please consult an available

drawing or your local HOMA distributor if you need help

identifying the discharge connection on your pump.

3.3.8. Impeller

The impeller is fastened directly to the motor shaft and

driven by it. GRP pumps are only available with an open

multi-channel impeller.

3.3.9. Cutter system

The cutter system includes a fixed cutting ring and a cutter head which is mounted on the motor shaft. Thereby

the cutter head turns with motor rotation speed and cut all

solids in the sewage. Both parts consist of stainless steel

hardened to HRC55.

08 | English

Page 9

4. Package, Transport, Storage

4.1. Delivery

On arrival, the delivered items must be inspected for damage and a check made that all parts are present. If any

parts are damaged or missing, the transport company or

the manufacturer must be informed on the day of delivery.

Any claim made at a later date will be deemed invalid.

Damage to parts must be noted on the delivery or freight

documentation.

4.2. Transport

Only the appropriate and approved fastening devices,

transportation means and lifting equipment may be used.

These must have sufficient load bearing capacity to ensure that the product can be transported safety. If chains

are used they must be secured against slipping.

The personnel must be qualified for the tasks and must

follow all applicable national safety regulations during

the work. The product is delivered by the manufacturer/

shipping agency in suitable packaging. This normally precludes the possibility of damage occurring during transport and storage.

Beware of electrical current!

Damaged power supply cables can cause fatal injury! Defective cables must be replaced by a qualified

electrician immediately.

Beware of moisture!

Moisture penetrating cables can damage them and

render them useless. Therefore, never immerse cable ends in the pumped fluid or other liquids.

• The machine must be protected from direct sunlight,

heat, dust, and frost. Heat and frost can cause considerable damage to impellers, rotors and coatings.

• The impeller must be turned at monthly intervals.

This prevents the bearing from locking and the film

of lubricant on the mechanical shaft seal is renewed.

This also prevents the gear pinions (if present on the

product) from becoming fixed as they turn and also

renews the lubricating film on the gear pinions (preventing rust film deposits).

Beware of sharp edges!

Sharp edges can form on rotors and impellers.

There is a risk of injuries. Wear protective gloves.

Never lift the pump by its power cable! Jacketed

pump should not be lifted or supported by the jacket.

Damage to sealing O Rings may result.

4.3. Storage

Newly supplied products are prepared that they can be

stored for 1 year. The product should be cleaned thoroughly before interim storage.

The following should be taken into consideration for

storage:

• Place the product on a firm surface and secure it

against falling over. Submersible mixers and auxiliary lifting devices should be stored horizontally,

submersible sewage pumps and submersible motor

pumps should be stored horizontally or vertically. It

should be ensured that they cannot bend if stored

horizontally.

Falling Hazard!

Never leave the pump unsecured!

• The product has to be stored in a place free from

vibrations and agitation to avoid damage to the ball

bearings.

• The device should be stored in a dry place without

temperature fluctuation.

• The product may not be stored in rooms where welding work is conducted as the resulting gases and radiation can damage the elastomer parts and coatings.

• Be careful to not remove or damage the corrosion

resistant coatings.

• Any suction or pressure connections on products

should be closed tightly before storage to prevent

impurities.

• The power supply cables should be protected against

kinking, damage and moisture.

• The cable will wick water into the pump if it is not protected properly. Power cable lead should be covered

with shrink tubing or suitable sealing material during

storage.

• If the product has been stored for longer than six

months it should be cleaned of impurities such as

dust and oil deposits before start-up. Rotors and impellers should be checked for smooth running, housing coating and damage.

• After remaining in storage for longer than one year,

it is necessary to change the oil in the seal chamber.

This is necessary even if the pump has never been

run, due to natural deterioration of mineral oil.

Before start-up, the filling levels (oil, cooling fluid

etc.) of the individual products should be checked and

topped up if required. Please refer to the machine data

sheet for specifications on filling. Damaged coatings

should be repaired immediately. Only a coating that

is completely intact fulfills the criteria for intended

usage!

If these rules are observed, your product can be stored

for a longer period. Please remember that elastomer parts

and coatings become brittle naturally. If the product is

to be stored for longer than 6 months, we recommend

checking these parts and replacing them as necessary.

Please consult the manufacturer.

4.4. Returning to the supplier

Products which are delivered to the factory must be clean

and correctly packaged. In this context, clean means

that impurities have been removed and decontaminated if it has been used with materials which are hazardous to health. The packaging must protect the product

against damage. Please contact the manufacturer before

returning!

English | 09

Page 10

5. Installation and initial commissioning

5.1. General

To avoid damage to the lifting unit during installation and

operation, the following points must be observed:

• The installation work must be performed by qualified

personnel, in compliance with safety regulations.

• The pump must be inspected for damage prior to installation.

• For level controls, pay attention to the minimum water coverage.

• Air bubbles in the volute and pipework must be avoided (by suitable ventilation devices or a slight incline

of the pump).

• Protect the pump from frost.

• The lifting device must have a maximum load capaci-

ty which is greater than the weight of the pump with

attachments and cable.

• The power lines of the pump must be laid in such a

way, that a safe operation and easy assembly/disassembly is ensured.

• The power lines must be fixed properly in the operating room to prevent the cable from hanging loosely.

Depending on the cable length and weight, a cable

holder must be attached every 2-3 m.

• The foundation/structure must have sufficient

strength for secure and functionally correct fastening

of the pump. The operator is responsible for this.

• Verify low level lockout is functioning.

• Use baffles for the inlet. This prevents air entry into

the pumping medium, which can lead to unfavorable

operating conditions and result in increased wear.

• Do not install more than one check valve into any piping system or problems will occur.

No. Description

1 Pipe

2 Coupling system

3 Wet well

4 Inlet

5 Baffle plate

6 min. liquid level

7 Pump

External Seal Probe Installation Procedure

Mechanical Seal Leak Detection probe has been

shipped loose to protect from shipping damage.

Please follow this procedure to install the probe.

1. Lay pump on its side with the plug on the seal chamber facing upwards as indicated.

2. Unscrew the plug with the proper wrench, taking

care not to damage the sealing surface.

3. Verify that seal chamber oil level is within ¼” of the

indicated value. Measurement is from oil level to the

top of hole. See IOM Manual for seal chamber oil volume, if required.

4. Remove the new sealing gasket from package and

install it onto the seal probe plug.

5. Install the seal probe with gasket into the opening,

taking care not to damage the cable. Then tighten the

seal probe with the proper wrench until snug. Do not

overtighten. Once tight, verify the seal gasket is properly seated and the cable is not pinched or twisted.

NOTE: At installation of the seal probe be careful not

to bind the seal probe cord as it is being installed into

the pump.

6. Lift pump into a vertical position and inspect for any

leaks.

7. Secure seal probe cable to pump body and power cable with tyraps before installing pump.

10 | English

Page 11

5.2. Installation

Risk of falling!

When installing the pump and accessories, work is

carried out directly on the water‘s edge! Carelessness or wearing the wrong shoes can lead to falling.

This is life threatening! Take all safety precautions to

prevent this.

Torque Values

PUMP

Installation

Bolts

Anchors

SIZE TORQUE

Autocoupling 8 M16X60mm 146 Nm / 108 ft lb

4 M16 100 Nm / 74 ft lb

Ring stand 4 M16x25mm 146 Nm / 108 ft lb

Notes:

1. Flange bolts must be tightened in cross pattern to

avoid damage to the raised face flanges.

2. Standard flange bolts are 316SS

3. Standard anchors are plated steel.

4. Autocoupling systems include qty. 4 M12 anchors for

the upper bracket. Torque to 51 Nm / 38 ft lb.

5. Anchor bolt holes should be drilled to the actual diameter of the anchor (M12 anchor requires 12mm

diameter hole).

Submerged installation on ring stand

Attach the ring stand (available as an accessory) with

screws to the pump suction nozzle. 90° connection-elbow or connection loop to the pressure port of the pump,

mount pressure line. Gate valves and check valves may

need to be installed in accordance with local regulations.

The pressure line must be fitted free of tension, when

using a hose, ensure it is laid kink-free.

Secure the pump by the handle with a cable or chain,

and lower it into the pumping medium. Properly position

power cable and chain so they stay above the pump and

cannot enter the pump suction.

guide tubes, using a plumb bob where necessary.

• Check the correct installation dimensions of the

pump(s) (see dimensional drawings in the appendix).

• Drill mounting holes for the guide rail bracket on the

inside edge of the shaft opening. If this is not possible due to the space available, the guide rail bracket

can also be mounted in an offset position with a 90°

folded plate on the underside of the shaft cover. Provisionally fasten the guide rail bracket with 2 screws.

• Align the base elbow to the shaft floor, use a plumb

bob from the pipe bracket - the guide tubes must be

exactly perpendicular! Fasten the base elbow to the

wet well floor using anchor bolts. Ensure that the

base elbow is exactly horizontal! If the wet well floor

is uneven, support the bearing surface accordingly.

• Mount the pressure pipes with fittings free of tension

according to the usual mounting principles.

• Insert both guide rails into the eyelets on the base

elbow and cut to size according to the position of the

guise rail bracket. Partially unscrew the guide rails

bracket, insert them into the guide rails and fasten

the bracket. The guide rails must be positioned with

no play at all, otherwise vibration will occur during operation of the pump.

• Clean the wet well of any solid material (debris,

stones, etc.) before commissioning.

• Mount the guide claw on the pump discharge. For

threaded discharge connections, apply pipe sealant

to the threads for installation and DO NOT OVER

TIGHTEN. DISCHARGE THREADS ARE NOT NPT.

Ensure that the rubber profile seal is correctly seated

in position in the guide claw (as a seal against the

coupling base), so that it will not fall out when lowering the pump. See graphic below

• Attach the chain to the pump handle or lifting lugs.

For model GRP 10-50 series pumps, attach tether

through the large opening of the lifting handle. DO

NOT attach to the small, rear tab. Insert the pump

with the guide rails in the guide claw ears. Lower

the pump into the wet well. If the pump is seated on

the base elbow, it automatically seals itself off to the

pressure line and is ready for operation.

• Hang the end of the retrieval chain from a hook at the

wet well opening.

• Hang the motor connection cable of the pump in the

shaft at an appropriate length, with strain relief. Make

sure that the cables can not be bent or damaged.

Correct

Rubber Ring

Incorrect

Rubber Ring

Wet well installation with automatic coupling system

The following instructions apply to the installation of the

original HOMA Autocoupling system:

• Determine the approximate position of the position

of the base elbow and the upper pipe bracket for the

English | 11

Page 12

Dry Installation

Foundation and Piping Requirements:

General

The following recommendations are basic guidelines

which are intended to outline basic requirements in the

design of the dry pit station. It is essential that a licensed

professional engineer be retained by the owner to design

the station and all support structures.

Foundations

Foundations may consist of any structure heavy enough

to provide permanent rigid support for the pump and inlet

elbow stand. Concrete foundations built up from the solid

ground are the most commonly used. The concrete floor

shall be level. The space required by the inlet stand and

the location of the foundation anchor bolts are shown on

the outline dimension drawing. Foundation bolts are to be

embedded in the concrete.

Suction Piping

Suction piping should be at least as large as the pump

inlet elbow suction. If reducers are utilized they should

be of the conical type. If the liquid source level is below

the volute horizontal centerline, the reducer must be

eccentric and installed with the level side up. If the liquid

level is above the pump volute horizontal centerline, either

eccentric or concentric reducers may be used. Suction

piping should be run as straight as possible. All pipe flange

joints should be gasketed to prevent air from entering the

pipe. High points that may collect vapor are to be avoided.

Isolation valves such as gate valves can be installed in order to facilitate the removal of the pump for maintenance.

Any valve installed in the suction line should be installed

with the stems horizontal.

• Attach the other end to the lifting device.

• Ensure tension on the chain, and then lift the pump in

a slow and controlled manner.

• Gently lower the pump into operating space.

• Lower the pump to the operating point and make

sure that the pump has a secure footing or the coupling system is engaged correctly.

• Remove the chain from the lifting device and secure

it to the safety chain, which is located at the top of

the operating room. This ensures that the chain can

not fall into the operating area and constitute a danger to anyone.

Please note the following diagrams during installation.

Discharge Piping

A check valve and isolation valve shall be installed in the

discharge line. The check valve should be installed between the pump discharge flange and the isolation valve.

If pipe increasers are used on the discharge line, they

should be placed between the check valve and the pump.

The inlet elbow stand allows the pump to be installed in

a stationary position in a dry pit. Place the inlet stand in

position and tighten the anchor nuts.

Lower the pump on to the top flange of the inlet stand.

DO NOT ALLOW SLACK ON THE LIFTING CABLE UNTIL

THE PUMP IS BOLTED DOWN. Make sure the flange bolt

holes align with the mounting holes on the underside of

the volute. Secure the pump to the mounting flange with

the fasteners that are specified in the accessory fastener

selection table below.

5.3. Use of chains

Chains are used to lower a pump in the operating space

or to pull it out. They are not intended to secure a floating

pump. Intended use is as follows:

• Fasten one end of the chain on the handle of the

pump provided for this purpose. If your pump has

two ring bolts as an attachment point, you must use

a double-strand chain. When doing so, the angle of

inclination of the chain strands must be between 0°

and 45°.

No. Description

1 Chain guard

2 Chain

3 Handle

4 Pump

5.4. Initial operation

This chapter contains all the important instructions for operating personnel for the safe commissioning and operation of the machine. The following information must be

strictly adhered to and checked:

• Type of installation

• Operating mode

• Minimum submergence

12 | English

Page 13

After a long downtime, these specifications are also

to be checked and any defects are to be rectified! The

operation and maintenance manual must always be

kept with the machine, or be kept in a designated place

where it is always accessible for all of the operating

personnel.

To avoid injury to persons or damage during operation of

the machine, the following points must be observed:

• The initial operation may only be carried out by qualified and trained personnel accompanied by an authorized HOMA representative following the safety

instructions.

• All staff working on the machine must receive, read,

and understand the instructions.

• Activate all safety devices and emergency stop

switches before initial operation.

• Electrical and mechanical adjustments may only be

performed by professionals.

• This machine is only suitable for use at the specified

operating conditions.

Make sure that all temperature sensors and monitoring

devices, seal chamber probe, are connected and tested

for function.

Risk of electrocution!

Improper use of electricity can be fatal! All pumps

with exposed cable ends must be connected by a

qualified electrician.

All electrical work shall be carried out under the supervision of an authorized, licensed electrician. The present

state adopted edition of the National Electrical Code as

well as all local codes and regulations shall be complied

with.

5.6.1 Verification of power supply

Prior to making any electrical connections or applying

power to the pump, compare the power supply available

at the pump station to the data on the unit‘s nameplate.

Confirm that both voltage and phase match between

pump and control panel.

5.5. Preparatory work

This pump has been designed so that it will operate reliably and for long periods under normal operating conditions. This requires, however, that you comply with all

advice and instructions.

Please check the following points:

• Cable routing - no loops, slightly taut

• Liquid temperature and immersion depth check - see

machine data sheet

• If a hose is used on the discharge side, it should be

flushed before use with fresh water so that no deposits cause blockages

• For wet installation, the wet well must be cleaned

• The pressure and suction side pipe systems are to be

clean and all valves are to be opened.

• If the pump is jacketed with media cooling, the jacket

must be completely bled of air, i.e. it must be completely filled with the medium and there may be no

more air in it. The venting can be done by suitable

ventilation devices in the system, or, if available, by

venting screws at the outlet nozzle.

• Check the accessories, pipe system and suspension

unit for firm and correct fit

• Review the present level control.

• An isolation test and a level control must be carried

out before commissioning.

5.6.2 Power lead wiring

HOMA pumps may be provided with 1 or more cables,

depending on motor horsepower and operating voltage.

Power leads L1, L2, & L3 may be provided as single conductor, or as multiple conductors. Multiple conductor

configurations may use leads from separate cables, or

may use two conductors within one cable. Please refer

to wiring diagram in the appendix for specific connection

details. The pump must be connected electrically through

a motor starter with proper circuit breaker protection in

order to validate warranty. Do not splice cables.

5.6.3 Thermal switch wiring

Pumps are equipped with thermal switches embedded in

the stator windings which are normally closed, automatically resetting switches. Switches will open when the

internal temperature rises above the design temperature,

and will close when the temperature returns to normal.

Thermal switches must be wired to a current regulated

control circuit in accordance with the NEC.

Identify thermal switch leads marked T1 and T2 in the

power or control cable.

The resistance across the leads will be 0.5 Ohms. Thermal leads must be connected to the thermal overload

relay located in the control panel. Thermal switch leads

must be connected to validate warranty.

5.6. Electrical

When installing and selecting electrical lines and when

connecting the motor, the relevant local and NEC regulations must be observed. The motor must be protected by

a motor protection circuit breaker. Connect the motor per

the wiring diagram. Pay attention to the direction of rotation! If rotation is in the wrong direction, the machine will

not perform to specifications. And can be damaged under

adverse circumstances.

Check the operating voltage, and ensure there is uniform

power consumption by all phases in accordance with the

machine data sheet.

Note: All sizes of Class 1, Div. 1 pumps for hazardous

service must have thermal switch leads connected to

a current regulated control circuit in accordance with

NEC.

5.6.4 Seal probe wiring

The mechanical seal leak detector probe utilized in the

pump is a conductive probe which is normally open. The

intrusion of water into the seal chamber completes the

electrical circuit. Control panel provisions will sense this

circuit closure, and will provide indication or alarm functions depending on the panel design.

English | 13

Page 14

Either single or dual wire systems may be provided. Sin-

START

REACTION

ROTOR

REACTION

ATTENTION

The direction of rotation

is correct if the

impeller/propeller rotates

in a clockwise manner

when viewing down from

top of the placed unit

ATTENTION

The start reaction is

counter clockwise

gle wire systems utilize one energizing conductor, and

the pump casing and neutral lead as the ground or return

portion of the circuit. The dual wire systems utilize two

separate conductors for each leg of the circuit.

( ) The standard capacitor kit provided includes:

____________ µf start capacitor

____________ µf run capacitor.

With either system, the seal probe leads must be wired

into a control circuit provided in the control panel. This

control circuit must energize the probe with a regulated

power source, and sense the closed circuit in event of

water intrusion Indication and alarm functions must also

be provided in the control circuit. Please see control panel

wiring diagram for seal probe connection points.

For Hazardous Area Classification Pumps, leak detector circuit must be in conformance with applicable NEC codes and regulations.

5.6.5 Start / Run Capacitors and Relays

All single phase motors require start and run capacitors

along with a start relay to operate. Capacitors and relays

must be sized for the specific motor.

Capacitors are sized based on ideal conditions.

The run capacitor may need to be resized to match the

available field voltage. Each cap kit shipped is supplied

with a wiring diagram and start up procedure.

5.6.6 Single Phase Pump Start-Up Procedure

Run Capacitor sizing can vary depending on the incoming

supply voltage provided. HOMA Single Phase pumps are

provided with Start and Run Capacitor(s) sized for 220230V under load. Frequently, the available line voltage is

considerable different than indicated, and the Run capacitor(s) may need to be resized to match the available field

voltage. The following procedure will allow you to verify

proper operation of your single phase pump, and/or make

necessary changes to you capacitors to correct for your

power supply.

After verifying wiring is in accordance with your pump requirements, start pump and record the following readings

from each of the (3) pump cable leads.

( ) Additional run capacitors have been included for use

in tuning the pump to match available line voltages for

optimum performance.

____________ µf run capacitor

____________ µf run capacitor

____________ µf run capacitor

This form is provided for your use in optimizing the performance and service life of your single phase pumps, and is

applicable to most Capacitor Start/Capacitor Run motors.

Please contact our customer service with any questions

or if you require any additional information or assistance.

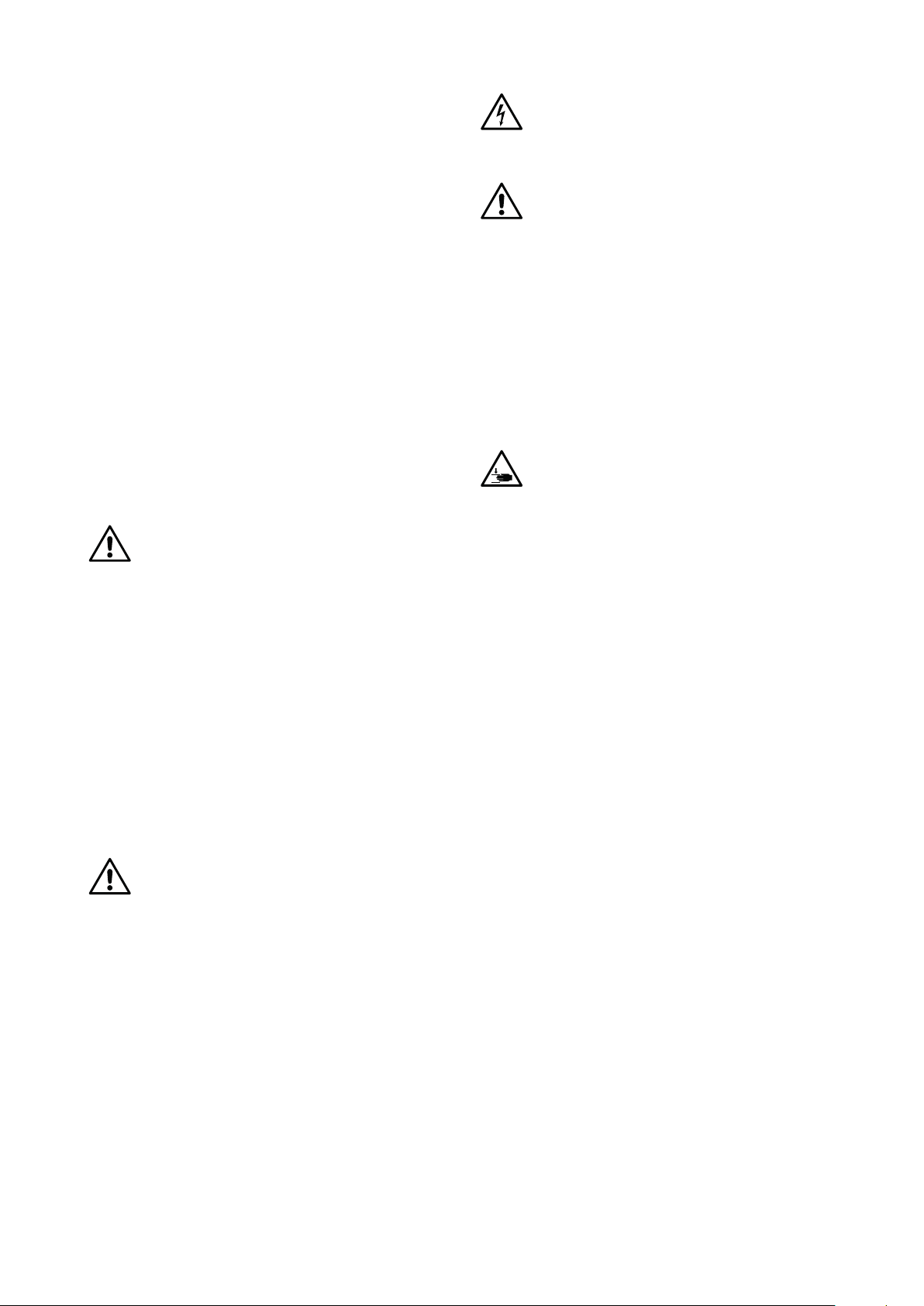

5.7. Direction of rotation

Rotation Direction Check

All pumps have the proper rotation direction when connected to a clockwise field of rotation (U, V, W -> L1, L2,

L3). If the pump rotation is backwards, swap two lead and

reconnect. For smaller pumps, the check can be done by

observing the pump’s movement while starting.

To do this, set the pump lightly on the ground in a perpendicular fashion and switch it on briefly. When observing

from above, the pump itself moves slightly in a counter-clockwise direction when rotating in the right direction.

The correct direction of rotation of the pump is achieved

once the pump moves counter-clockwise, since when

viewed from above, the motor starts in a clockwise direction.

Current under load:

U1________Amps,>U2________Amps,>Z2________Amps

U1: (Should be) highest reading

U2: middle reading

Z2: lowest reading

Lead U1 (common) should have the highest current reading. Lead Z2 (start) should have the lowest reading.

If Z2 current draw is greater than the current draw of either U1 or U2, a smaller size Run capacitor (lower microfarad rating) is required to correct the condition. Example:

If a 60 µf Run capacitor was supplied, change to a 50 µf

Run capacitor and check current readings. Typically, only

one step down in capacitor size is required, but in certain

instances 2 steps may be required.

14 | English

For large pumps, the direction can also be determined by

looking through the pump discharge into the volute. Briefly run the motor in order to verify it is running clockwise.

Caution – Rotating Impeller!

Do not touch the rotating impeller or reach into the

volute through the pressure outlets!

Never reach into the volute or touch any rotating

parts during operation. Switch the machine off and

wait until all rotating parts have come to a stop prior

to carrying out maintenance and repair work!

Page 15

It is also possible to check the direction of rotation with a

“motor and phase rotation indicator”. This measurement

device is held from the outside up to the motor housing

of the switched-on pump and displays the direction of rotation via an LED.

The switch breaks specified in the technical data must be

adhered to before turning on again. If there is a new fault,

the machine must again be shut down immediately. The

machine may only be started up again after troubleshooting.

5.8. Motor protection

The minimum requirement is a thermal relay/motor protection circuit breaker with temperature compensation,

differential triggering, and reclosing lock in accordance

with VDE 0660 or similar national regulations. If the equipment is connected to power grids where problems often

occur, we recommend the additional use of protective

devices (e.g. overvoltage protection or under voltage protection or phase failure relays, lightning protection, etc.).

When connecting the machine, the local and legal requirements must be adhered to.

5.9. Variable Frequency Drives

Special considerations must be taken when operating

pumps with variable frequency drives (inverters).The inverter circuit design, horsepower required by pump, motor cooling system, power cable length, operating voltage,

and anticipated turndown ratio must be fully evaluated

during the design stage of the installation.

As a minimum, properly sized load reactors and filters

must be installed between the inverter and the pump

to protect the pump motor from damaging voltage

spikes.

Warranty coverage will not be provided on any pump motor that is operated with a variable frequency drive, unless

the load side of the inverter is properly isolated from the

pump.

The following items should be checked:

• Current consumption (permissible deviation between

phases max. 5%)

• Voltage difference between the individual phases

(max. 1%)

• Switching frequency and pauses (see Technical Data)

• Air entry at the inlet - if necessary, a baffle plate must

be attached

• Minimum water coverage, level control, dry run protection

• Smooth running

• Check for leaks: if necessary, take the necessary

steps according to the chapter “Maintenance”

5.10. Types of startups

Types of startup using with cables with exposed ends

Direct start up

At full load, the motor protection circuit breaker should

be set to the rated current. In partial load operation it is

recommended to set the motor protection circuit breaker

5% above the measured current at the operating point.

Soft start

At full load, the motor protection should be set to the rated current. In partial load operation, it is recommended to

set the motor protection 5% above the measured current

at the operating point. The starting time must be max.

5s. The starting voltage is to be set at 40% of the rated

voltage according to the rating plate.

Start up with HOMA GO switch

Plug the connector into the socket provided and press the

on/off switch on the GO switch.

5.10.1. After start up

The nominal current is briefly exceeded on start-up. After completion of this operation, the operating current

should not exceed the nominal current. If the motor does

not start immediately after switching on, it must be shut

down immediately.

English | 15

Page 16

6. Maintenance

6.1. General

The machine and the entire system must be inspected

and maintained at regular intervals. The time limit for

maintenance is set by the manufacturer and applies to

the general conditions of use. The manufacturer should

be consulted if the system is to be used with corrosive

and/or abrasive pumped liquids, as the time limit between

inspections may need to be reduced.

Note the following information:

• The operating and maintenance manual must be

available to the maintenance personnel and its instructions followed. Only the repair and maintenance

measures listed here may be performed.

• All maintenance, inspection and cleaning work on the

machine and the system may only be carried out by

trained specialists exercising extreme care in a safe

workplace. Proper protective clothing is to be worn.

The machine must be disconnected from the electricity supply before any work is carried out. There must

be no way that it can be inadvertently switched on.

• Above a weight of 50kg / 110 pounds, only hoisting

gear which has been officially approved and which is

in a technically perfect condition should be used for

lowering and raising the machine.

Make sure that all fastening devices, ropes and safety devices are in a technically perfect condition. Work

may only commence if the auxiliary hoisting gear has

been checked and found to be in perfect working order.

If it is not inspected, danger to personnel may result!

Oil type: white mineral oil. Used oil is to be disposed ac-

cordingly.

When using white mineral oil, note the following:

• Machines which have previously been operated using other lubricants must first be thoroughly cleaned

before they can be operated using white mineral oil.

Screw

(fill with oil)

Screw

(drain oil)

• Wiring work on the machine and system must be

carried out by an electrician. For machines approved

for work in areas subject to explosion danger, please

refer to the “Explosion protection in accordance with

the regulation” chapter.

• When working with inflammable solvents and cleaning agents, fires, unshielded lighting and smoking are

prohibited.

• Machines which circulate fluids hazardous to health,

or which come into contact with them, must be decontaminated. It must be ensured that no dangerous

gases can form or are present.

• Ensure that all necessary tools and materials are

available. Tidiness and cleanliness guarantee safe and

problem-free operation of the machine. After working on the machine all cleaning materials and tools

should be removed from it. All materials and tools

should be stored in an appropriate place.

• Operating supplies such as oil and lubricants must

be collected in appropriate vessels and properly disposed. Appropriate protective clothing is to be worn

for cleaning and maintenance jobs. Only lubricants

expressly recommended by the manufacturer may

be used. Oils and lubricants should not be mixed.

Only use genuine parts made by the manufacturer.

A trial run or functional test of the machine must be

performed as instructed in the general operating conditions.

6.2 Maintenance intervals

Before initial start-up or after a longer period of storage:

• Check insulation resistance

• Check oil level in seal chamber

• Check that impeller rotates freely by hand

Monthly:

• Monitor the amperage and voltage

• Check the used relays for proper operation

Every six months:

• Visual inspection of the power supply cable

• Visual inspection of the cable holder and the cable

bracing

• Visual inspection of accessories, e.g. the suspension

device and hoisting gears

8,000 operating hours or after two years, whichever

is earlier:

• Check the insulation resistance

• Check the lubricant in the seal chamber

• Functional inspection of all safety and control devices

16 | English

Page 17

15,000 operating hours or after five years, whichever

is earlier:

• General overhaul

If it is used in highly abrasive or corrosive material, the

maintenance intervals should be reduced!

6.3. Maintenance tasks

Monitoring the current consumption and voltage

The current consumption and voltage is to be monitored

periodically for all winding phases. This remains constant

during normal operation. Slight fluctuations are a result

of the composition of the pumped fluid. The current consumption can assist in early detection and correction of

damage and/ or faulty operation in the impeller/propeller,

bearings and/or the motor. More extensive resulting damage can thus be largely prevented and the risk of a total

failure can be reduced.

Checking the used relays for posistors, oil chamber

monitors, etc.

Check the relays used are functioning fault-free. Defective

devices must be immediately replaced, because these

cannot ensure safe operation of the machine. The test

procedure details should be followed closely (in the operating instructions for each relay).

Checking the insulation resistance

To check the insulation resistance, the power supply cable must be disconnected. The resistance can then be

measured with an insulation tester (measuring voltage =

1000V DC).

The following values may not be exceeded:

• The insulation resistance may not be below 20 MΩ

during initial operation. For all further measurements

the value must be greater than 2 MΩ.

• Insulation resistance too low: Moisture may have

penetrated the cable and/or the motor.

Do not connect the machine, consult manufacturer!

Visual inspection of power supply cables

The power supply line must be examined for bubbles,

cracks, scratches, chafed areas and/or crushed sections.

If damage is found, the power cable must be exchanged

immediately.

The cables may only be changed by the manufacturer

or an authorized/certified service workshop. The machine may not be used again until the damage has

been adequately rectified.

Visual examination of the cable holders (carabiners)

and the cable bracing

When the machine is used in basins or pits, the lifting

cables/cable holders (carabiners) and the cable bracing

are subject to constant wear. Regular inspections are necessary in order to prevent the lifting cables/cable holders

(carabiners) and/or cable bracing from wearing out and to

prevent the electricity cable from being damaged.

The lifting cables/cable holders (carabiners) and the cable bracing are to be immediately replaced if any signs of

wear appear.

Visual inspection of accessories

Inspect accessories such as suspension units and hoisting gear to check whether they are secured in a stable

manner. Loose and/or defective accessories should be

repaired immediately or replaced.

Oil Level check in Seal Chamber

Visual Inspection of Oil Chamber:

Oil Level

Please take the precise filling quantity from the spare

parts list or contact the manufacturer with the pump serial

number.

Oil Condition

The condition of the mechanical seals can be visually inspected as follows: Put the pump in horizontal position, so

that the oil chamber drain plug is on top (for larger pumps:

one of both oil chamber screws). Remove the drain plug

and take out a small quantity of oil. The oil becomes greyish white like milk if it contains water. This may be the

result of defective shaft seals. In this case the condition

of the shaft seals should be checked by a HOMA Service

shop.

Oil type: Mineral Oil

Used oil has to be disposed according to the existing environmental rules and regulations.

Functional inspection of safety and control devices

Monitoring devices are temperature sensors in the motor,

oil chamber monitors, motor protection relays, overvoltage relays, etc.

Motor protection and overvoltage relays and other trip

elements can generally be triggered manually for test

purposes. To inspect the oil chamber monitor or the temperature sensor, the machine must be cooled to ambient

temperature and the electrical supply cable of the monitoring device in the switch cabinet must be disconnected.

The monitoring device is then tested with an ohmmeter.

The following values should be measured:

Bi-metal sensor: Value = “0” - throughput

PTC sensor: A PTC sensor has a cold resistance of be-

tween 20 and 100 Ω. For 3 sensors in series this would

result in a value of between 60 and 300 Ω.

PT 100 sensor: PT 100 sensors have a value of 100ohms

at 0°C. Between 0°C and 100°C this value increases by

0.385 Ω per 1°C. PT 20 sensors have a value of 107.7 Ω

at 20°C.

Moisture sensor: This value must approach infinity. If

there is a low value, there may be water in the oil.

Also observe the instructions of the optionally available

evaluation relay.

In the case of larger deviations, please consult the

manufacturer.

Please consult the appropriate operating manual for details on inspecting the safety and monitoring devices on

the auxiliary lifting gear.

English | 17

Page 18

General overhaul

During this the bearings, shaft seals, O rings and power

supply cables are inspected and replaced as required in

addition to normal maintenance work. This work may only

be conducted by the manufacturer or an authorized service workshop.

7. Repairs

7.1. General

When carrying out repair work, the following information

should always be noted:

Changing the oil

The drained oil must be checked for dirt and water content. If the oil is very dirty and shows water intrusion, it

must be changed again after four weeks. If there is again

water in the oil then, it seems likely that a seal is defective. In this case, please consult the manufacturer. If a oil

chamber or leakage monitoring system is being used, the

display will light up again within four weeks of changing

the oil if a seal is defective.

The general procedure for changing oil is as follows:

Switch off the machine, let it cool down, disconnect it

from the power supply (have this done by an electrician), lock out tag out the control panel, clean it and

place it vertically on a solid base. Warm or hot oil may

be pressurized. The leaking oil may cause burns. For

that reason, let the machine cool down to ambient

temperature before you touch it.

6.4. Seal chamber

As there are several versions and designs of these motors, the exact location of the drain plugs varies depending

on the model used.

• Slowly and carefully remove the drain plug.