Page 1

Publication

Please Contact

Technical Support At 203

-

736-8890 With Any Additional Questions

Page

Asse

mbly

Collet Impeller

You will need:

-A torque wrench with a 40 foot pound capacity

-Allen key socket and extension

-Liquid soap to lubricate o rings

Instructions

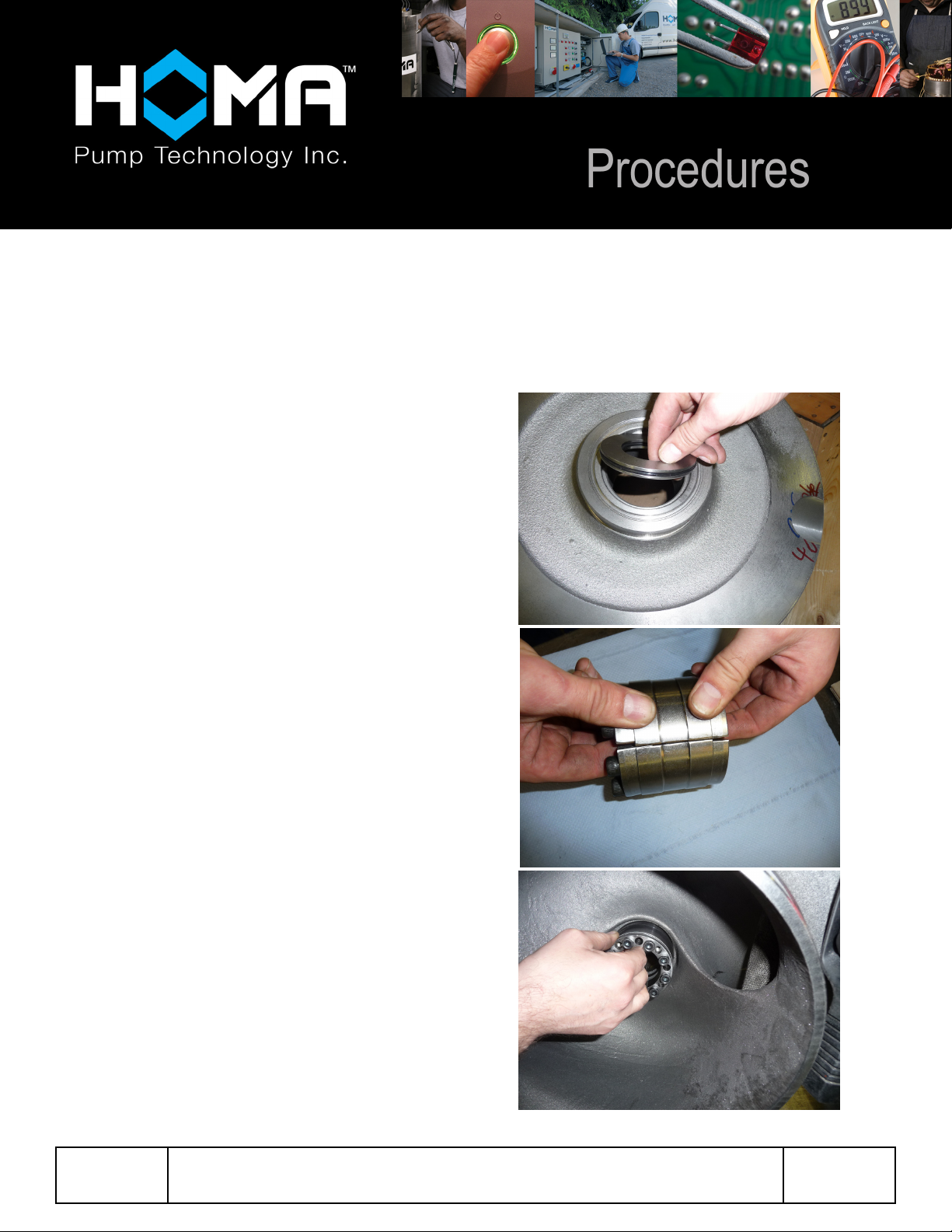

• Place o-ring around outside diameter and inside

diameter of distance ring, lubricate with liquid

soap, and place in impeller. (A) DO NOT USE

GREASE TO LUBRICATE.

• Lightly tap ring in with a plastic hammer.

• Loosen all screws in impeller locking

mechanism, and pull the opposite sides to

extend the mechanism. (B)

• Degrease inside and outside surface of locking

mechanism, shaft, and impeller borehole. Any

residual on these surfaces may cause collet to

slip.

A

B

• Place locking mechanism into impeller borehole.

(C)

• Lubricate inner o-ring in distance ring with liquid

soap.

• Slide impeller onto shaft until locking mechanism

reaches shoulder of the shaft.

• Be certain that the locking mechanism stays in

88FN2005

the proper position while installing on shaft.

C.

Please Be Prepared To Provide Pump Serial Number During Call

1 of 2

Page 2

Publication

Please Contact

Technical Support At 203

-

736-8890 With Any Additional Questions

Page

80

2

90

•

E.

Part

number

4492007

4492010

4492016

4492020

4492025

4492027

4492033

Inside

Diameter (inch)

1.575

1.75

2.2

2.36

2.56

2.75

Outside

Diameter (inch)

2.5

2.875

2.875

3.35

3.35

3.75

4.33

Torque (inch

pounds)

100

120

140

160

400

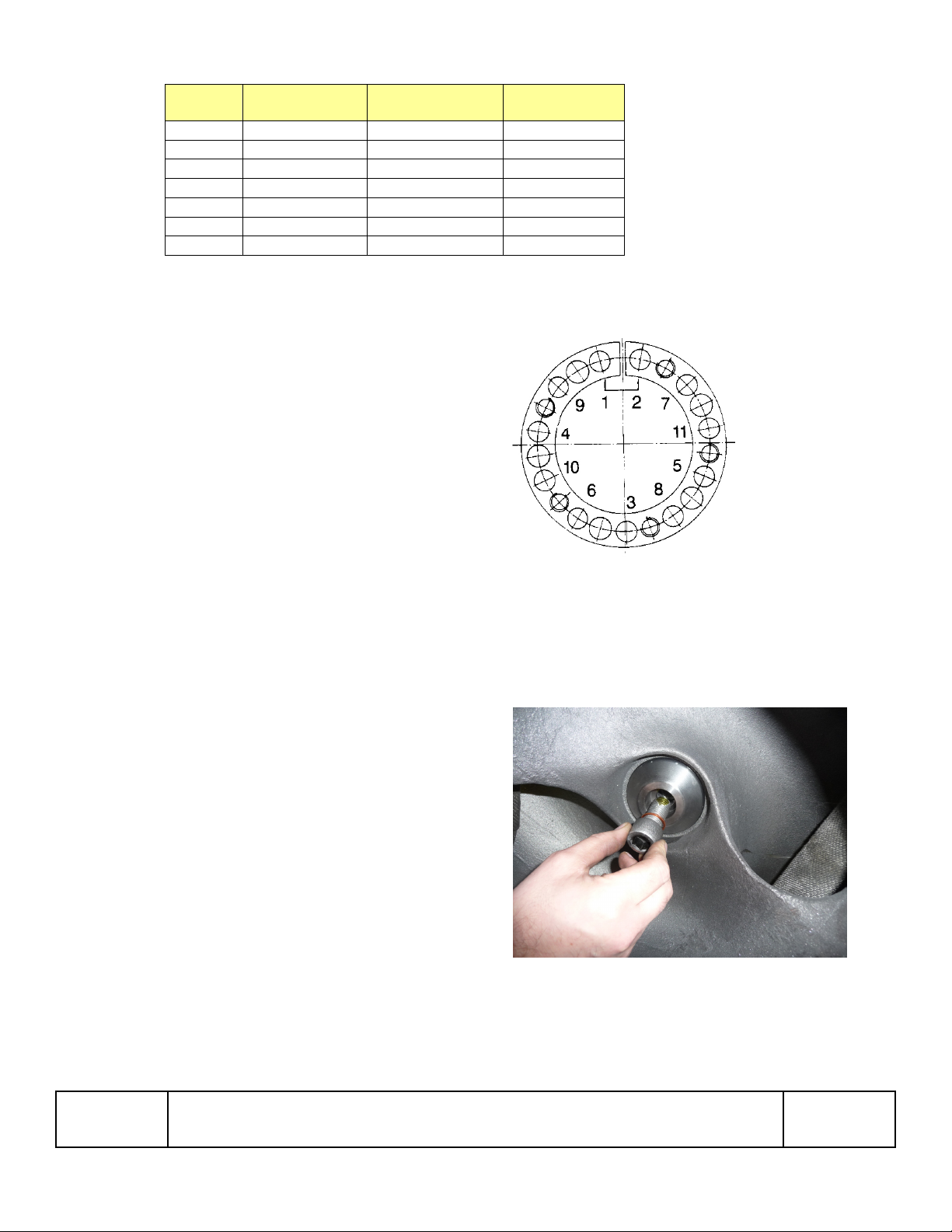

Snug all screws in locking mechanism.

• Tighten screws in the order shown in (D)

• Tighten the screws to the required torque,

given in table (E).

• Retighten screws in the same pattern to

the same torque to ensure the collet will

not slip. This will take 5-8 repetitions. THE

COLLET WILL NOT HOLD IF SCREWS

ARE ONLY TIGHTENED ONCE.

• Put o-ring on cover disc and lubricate it.

• Install cover disc over locking mechanism

D

on impeller borehole.

• Make certain to place copper washer and

loctite on bolt before installation. (F)

• Tighten bolt.

F.

88FN2005

Please Be Prepared To Provide Pump Serial Number During Call

2 of 2

Loading...

Loading...