Page 1

Original Betriebsanleitung

Original Instruction Manual

HOMA Pumpenfabrik GmbH

Industriestr. 1

D-53819 Neunkirchen-Seelscheid

Version 03/2015 - No. 00510601.01

60 Hz

Baureihe / Serie

CHRS

HRS

Page 2

32

Contents

Contents

Page

1. General Information

33

1.1. Declaration of Conformity

33

1.2. Preface

34

1.3. Proper Use

34

1.4. Copyright

34

1.5. Warranty

34

2. Safety

36

2.1. Instructions and safety information

36

2.2. Guidelines used and CE-certification

36

2.3. General safety

36

2.4. Operating personal

37

2.5. Electrical work

37

2.6. Operating procedure

37

2.7. Safety and control devices

38

2.8. Operation in an explosive atmosphere

38

2.9. Pumped fluids

38

3. General description

38

3.1. Application

38

3.2. Types of use

38

3.3. Construction

38

4. Package, Transport and Storage

41

4.1. Delivery

41

4.2. Transport

41

4.3. Storage

41

4.4. Returning to the supplier

42

5. Installation and Start-Up

42

5.1. General

42

5.2. Installation

42

5.3. Start-Up

45

5.4. Electrical system

45

5.5. Motor protection

46

5.6. Operation with a static frequency converter

46

5.7. activation types

46

6. Maintenance

47

6.1. General

47

6.2. Maintenance

48

6.3. Change of oil

48

7. Additional for explosion-proofed submersible pumps

50

Attachement

8.1 Connection of pumps and mixers

62

8.2. Declaration of contamination

64

Page 3

33

1. General Information

EC Machinery Directive

2006/42/EEC

EC Directive, electromagnetic compatibility

04/108/EEC

EC Low Voltage Directive

06/95/EEC

EC Directive, explosion-prooved operating material

94/ 9/EEC

EC Directive, construction products

11/305/EEC

EN 60335-2-41

EN 60335-1

EN 60204 Part 1

EN 61000-6-1

EN 60034-1

EN 61000-6-3

EN 61000-6-2

EN 55014-2

EN 61000-3-3

EN 50014/18/19/20

EN 12050-1-4

EN 61000-6-4

EN 55014-1

EN 61000-3-2

EN ISO 12100-1 and -2

ISO 9906

DIN 24250

1.1. Declaration of Conformity

EC Declaration of conformity in line with the EC Machinery Directive 2006/42/EEC, Appendix IIA

We, HOMA Pumpenfabrik GmbH, Industries trasse 1, D-53819 Neunkirchen-Seelscheid, hereby declare that in

respect to their design and construction the following types, in the form in which they are marketed by us, conform

to the relevant fundamental safety and health requirements of the EC Machine Directives...:

CHRS

HRS

EC-Directives to which the types conform:

Relevant harmonized industrial standards:

Specially applied national standards and technical specifications (other applied standards for general

mechanical engineering are deposited at the construction office):

Vassilios Petridis

Technical Manager

Responsible for technical documents

HOMA Pumpenfabrik GmbH

Industriestr. 1

53819 Neunkirchen-Seelscheid (Germany)

This is an original instruction manual according to the EC Machinery Directive.

Page 4

34

1.2. Preface

Dear Customer,

Thank you for choosing one of our company’s products. You have purchased a product which has been

manufactured to the latest technical standards. Read this operating and maintenance manual carefully before you

first use it. This is the only way to ensure that the product is safely and economically used.

The documentation contains all the necessary specifications for the product, allowing you to use it properly. In

addition, you will also find information on how to recognize potential dangers, reduce repair costs and downtime,

and increase the reliability and working life of the product.

All safety requirements and specific manufacturer’s requirements must be fulfilled before the product

is put into operation. This operating and maintenance manual supplements any existing national regulations on

industrial safety and accident prevention. This manual must also be accessible to personnel at all times and also

be made available where the product is used.

1.3. Proper use

The HOMA products comply with the valid safety regulations and meet the demands of state-of-the-art

technology. In the event of improper use, there is a danger to life for the user as well as for third parties.

Moreover, the product and/or attachments may be damaged or destroyed.

It is important to ensure that the product is only operated in technically perfect condition and as intended.

To do so, follow the operating instructions.

1.4. Copyright

This operation and maintenance manual has been copyrighted by the manufacturer. This operation and

maintenance handbook is intended for the use by assembly, operating and maintenance personnel. It contains

technical specifications and diagrams which may not be reproduced or distributed, either completely or in part, or

used for any other purpose without the expressed consent of the manufacturer.

1.5. Warranty

Costs for removal and installation of the complained product at the installation place, costs for the ride of the

mechanicians to the location and from the installation place as well as costs for transport are not components of

our warranty. Hereby arose costs, especially costs for checking and transport are bearing by the sender or

operator of the pump. This is also valid for an asserted warranty claim if a check results that the unit works

faultless and is free of defects. All products have a high quality standard. Each product is defeated by a strict

technical end control before delivery. A warranty repair achieved by us does not extend the warranty period.

Replaced spare parts give no reasons for a new warranty period. Extensive claims are excluded, especially such

as diminution, change or compensation also for any kind of follow up damages.

To guarantee a quick transaction of a warranty claim, please return the product together with the warranty receipt,

purchase receipt and declaration of defect carriage paid to the manufacturer (address 1.4.6.).

Claims caused by damages of transport could be only accepted, if the damage is established or confirmed by

delivery in the presence of the forwarder, parcel service, train or post.

1.5.1. General information

This chapter contains the general information on the warranty. Contractual agreements have the highest priority

and are not superseded by the information in this chapter!

The manufacturer is obliged to correct any defects found in the products it sells, provided that the following

requirements have been fulfilled:

• The defects are caused by the materials used or the way the product was manufactured or designed.

• The defects were reported in writing to the manufacturer within the agreed warranty period.

• The product was used only as prescribed.

• All safety and control devices were connected and inspected by authorized personnel.

If no other provisions have been made, the warranty period applies to the first 12 months after initial start-up or to

a max. of 24 months after the delivery date. Other agreements must be made in writing in the order confirmation.

These agreements will remain valid at least until the agreed warranty period of the product has expired.

Page 5

35

1.5.2. Spare parts, add-ons and conversions

Only original spare parts as supplied by the manufacturer may be used for repairs, replacements, add-ons and

conversions. Only these parts guarantee a long working life and the highest level of safety. These parts have

been specially designed for our products. Self-made add-ons and conversions or the use of non-original spare

parts can seriously damage the product and/or injure personnel.

1.5.3. Maintenance

The prescribed maintenance and inspection work should be carried out regularly. This work may only be carried

out by qualified, trained and authorized personnel. The maintenance and inspection log supplied must be

properly updated. This enables you to monitor the status of inspections and maintenance work. Quick repairs

not listed in this operation and maintenance manual and all types of repair work may only be performed by the

manufacturer and its authorized servi ce centr es.

1.5.4. Damage to the product

Damage as well as malfunctions that endanger safety must be eliminated immediately by authorized personnel.

The product should only be operated if it is in proper working order. During the agreed warranty period, the

product may only be repaired by the manufacturer or an authorized service workshop! The manufacturer reserves

the right to recall the damaged product to the factory for inspection!

1.5.5. Exclusion from liability

No liability will be assumed for product damage if one or more of the following points apply:

• Incorrect design and on our part due to faulty and/or incorrect information provided by the operator or customer

• Non-compliance with the safety instructions, the regulations and the requirements set forth by German law and

this operating and maintenance manual

• Incorrect storage and transport

• Improper assembl y /dismantling

• Improper maintenance

• Unqualified repairs

• Faulty construction site and/or construction work

• Chemical, electrochemical and electrical influences

• Wear

This means the manufacturer’s liability excludes all liability for personal, material or financial injury.

1.5.6. Manufacturer’s addres s

HOMA Pumpenfabrik GmbH

Industriestrasse 1

D-53819 Neunkirchen-Seelscheid

Phone: +49 2247 / 7020

Fax: +49 2247 / 70244

Email: info@homa-pumpen.de

Homepage: www.homapumpen.de

Page 6

36

2. Safety

This chapter lists all the generally applicable safety instructions and technical information. Furthermore, every

other chapter contains specific safety instructions and technical information. All instructions and information must

be observed and followed during the various phases of the product's lifecycle (installation, operation,

maintenance, transport etc.). The operator is responsible for ensuring that personnel follow these instructions and

guidelines.

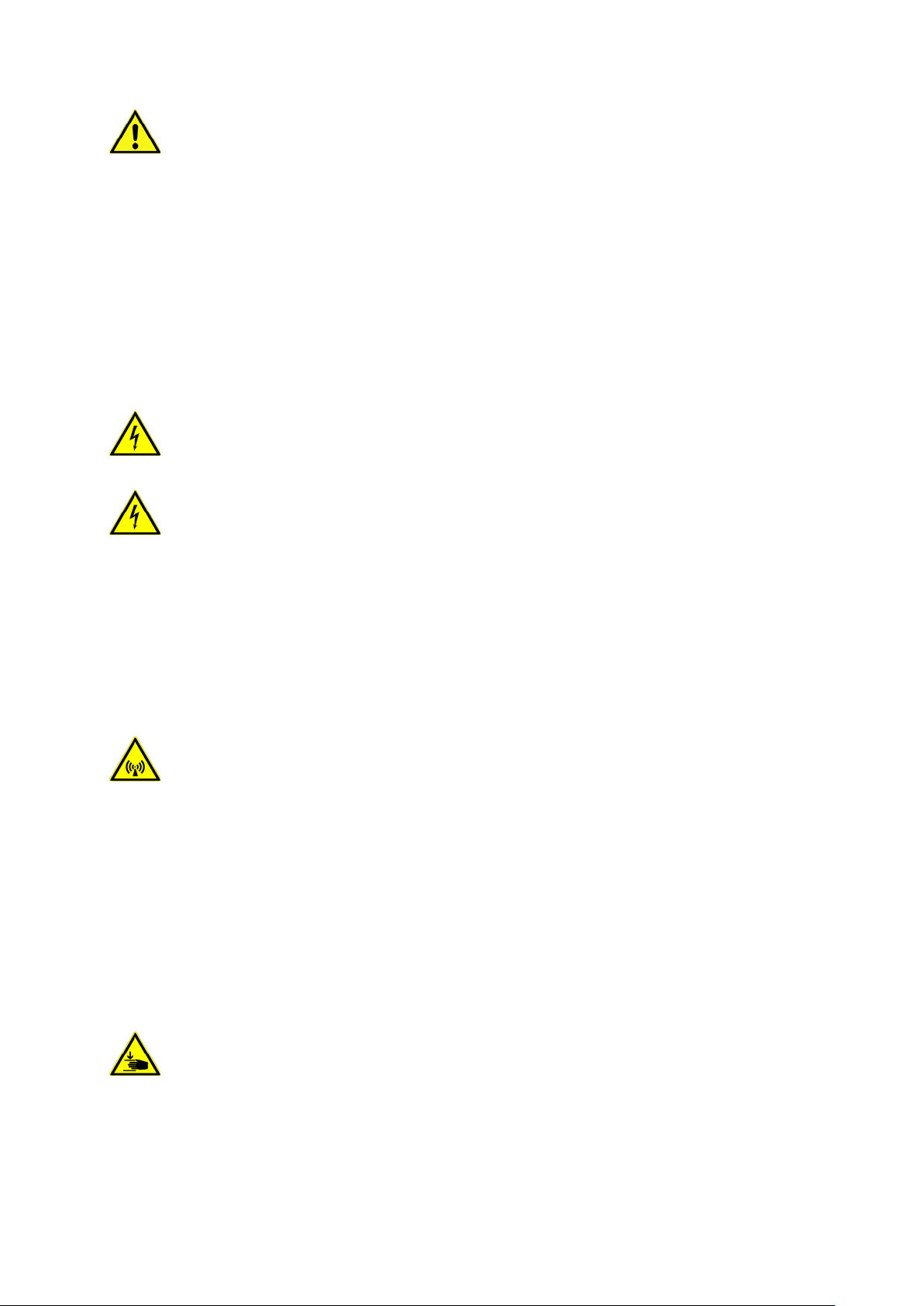

2.1. Instructions and safety information

This manual uses instructions and safety information for preventing injury and damage to property.

To make this clear for the personnel, the instructions and safety information are distinguished as follows:

Each safety instruction begins with one of the following signal words:

Danger: Serious or fatal injuries can occur!

Warning: Serious injuries can occur!

Caution: Injuries can occur!

Caution (Instruction without symbol): Serious damage to property can occur, inc lud ing irreparable damage!

Safety instructions begin with a signal word and description of the hazard, followed by the hazard source and

potential consequences, and end with information on preventing it.

2.2 Guidelines used and CE certification

Our products are subject to

- various EC directives

- various harmonized standards

- various national standards.

Please consult the EU Declaration of Conformity for the precise information and the guidelines and norms in

effect. The EU Declaration of Conformity is issued in accordance with EU Directive 2006/42/EEC, Appendix II A.

Also, various national standards are also used as a basis for using, assembling and dismantling the product.

These include the German accident prevention regulations, VDE regulations, German Equipment Safety Law etc.

The CE symbol is found either on the type plate or next to the type plate. The type plate is attached to the motor

casing.

2.3 General safety

• Never work alone when installing or removing the product.

• The machine must always be switched off before any work is performed on it (assembly,

dismantling, maintenance, installation). The machine must be disconnected from th e electrica l

system and secured against being switched on again. All rotating parts must be at a standstill.

• The operator should inform his/her superior immediately should any defects or irregularities occur.

• It is of vital importance that the system is shut down immediately by the operator if any problems

arise which may endanger safety of personnel. Problems of this kind include:

• Tools and other objects should be kept in a place reserved for them so that they can be found

quickly.

• Sufficient ventilation must be provided in enclosed rooms.

• When welding or working with electronic devices, ensure that there is no danger of explosion.

• Only use fastening devices which are legally defined as such and officially approved.

• The fastening devices should be suitable for the conditions of use (weather, hooking system, load,

etc). If these are separated from the machine after use, they should be expressly marked as

fastening devices. Otherwise they should be carefully stored.

• Mobile working equipment for lifting loads should be used in a manner that ensures the stability of

the working apparatus during operation.

• When using mobile working equipment for lifting non guided loads, measures should be taken to

avoid tipping and sliding etc.

• Measures should be taken that no person is ever directly beneath a suspended load. Furthermore, it

is also prohibited to move suspended loads over workplaces where people are present.

• If mobile working equipment is used for lifting loads, a second person should be present to

coordinate the procedure if needed (for example if the operator's field of vision is blocked).

• The load to be lifted must be transported in such a manner that nobody can be injured in the case of

a power cut. Additionally, when working outdoors, such procedures must be interrupted immediately

if weather conditions worsen.

Failure of the safety and/or control devices

Damage to critical parts

Damage to electric installations, cables and insulation.

Page 7

37

These instructions must be strictly observed. Non-observance can result in injury or serious

damage to property.

2.4. Operating personal

All personnel who work on or with the product must be qualified for such work; electrical work, for example may

only be carried out by a qualified electrician. The entire personnel must be of age.

Operating and maintenance personnel must also work according to local accident prevention regulations.

It must be ensured that personnel have read and understood the instructions in this operating and

maintenance handbook; if necessary this manual must be ordered from the manufacturer in the required

language.

2.5. Electrical work

Our electrical products are operated with alternating or industrial high-voltage current. The local regulations (e.g.

VDE 0100) must be adhered to. The “Electrical connection” data sheet must be observed when connecting the

product. The technical specifications must be strictly adhered to. If the machine has been switched off by a

protective device, it must not be switched on again until the error has been corrected.

Beware of electrical current!

Incorrectly performed electrical work can result in fatal injury!

This work may only be carried out by a qualified electrician.

Beware of damp!

Moisture penetrating cables can damage them and render them useless. Furthermore, water can

penetrate into the motor and cause damage to the terminals or the winding.

Never immerse cable ends in the pumped fluid or other liquids.

2.5.1. Electrical connection

When the machine is connected to the electrical control panel, especially when electronic devices such as soft

startup control or frequency drives are used, the relay manufacturer's specifications must be followed in order to

conform to EMC. Special separate shielding measures e.g. special cables may be necessary for the power supply

and control cables.

The connections may only be made if the relays meet the harmonized EU standards. Mobile radio equipment may

cause malfunctions.

Beware of electromagnetic radiation!

Electromagnetic radiation can pose a fatal risk for people with pacemakers. Put up appropriate signs and

make sure anyone affected is aware of the danger.

2.5.2. Ground connection

Our products (machine including protective devices and operating position, auxiliary hoisting gear) must always

be grounded. If there is a possibility that people can come into contact with the machine and the pumped liquid

(e.g. at construction sites), the grounded connection must be additionally equipped with a fault current protection

device. The electrical motors conform to motor protection class IP 68 in accordance with the valid norms.

2.6. Operating procedure

When operating the product, always follow the locally applicable laws and regulations for work safety, accident

prevention and handling electrical machinery. To help to ensure safe working practice, the responsibilities of

employees should be clearly set out by the owner. All personnel are responsible for ensuring that regulations are

observed. Certain parts such as the rotor and propeller rotate during operation in order to pump the fluid. Certain

materials can cause very sharp edges on these parts.

Beware of rotating parts!

The moving parts can crush and sever limbs. Never reach into the pump unit or the moving parts during

operation. Switch off the machine and let the moving parts come to a rest before maintenance or repair

work!

Page 8

38

2.7. Safety and control devices

Our products are equipped with various safety and control devices. These include, for example suction strainers,

thermo sensors, sealed room monitor etc. These devices must never be dismantled or disabled.

Equipment such as thermo sensors, float switches, etc. must be checked by an electrician for proper functioni ng

before start-up (see the “Electrical Connection” data sheet). Please remember that certain equipment requires a

decoder device or relay to function properly, e.g. posistor and PT100 sensor. This decoder can be obtained from

the manufacturer or a speciali st electr oni cs dea ler.

Personnel must be informed of the installations used and how they work.

Caution

Never operate the machine if the safety and monitoring devices have been removed or damage, or if they

do not work.

2.8. Operation in an explosive atmosphere

Products marked as explosion-proof are suitable for operation in an explosive atmosphere. The products must

meet certain guidelines for this type of use. Certain rules of conduct and guidelines must be adhered to by the

operator as well.

Products that have been approved for operation in an explosive atmosphere are marked as explosion-protected

“Ex”. In addition, an “Ex” symbol must be included on the type plate! When used in an explosive atmosphere, the

additional chapter entitled “Explosion protection according to the …standard” must be observed!

2.9. Pumped fluids

Each pumped fluid differs in regard to composition, corrosiveness, abrasiveness, TS content and many other

aspects. Generally, our products can be used for many applications. For more precise details, see chapter 3, the

machine data sheet and the order confirmation. It should be remembered that if the density, viscosity or the

general composition change, this can also alter many parameters of the product.

When switching the product into another pumped fluid, observe the following points:

• Products which have been operated in sewage or waste water must be thoroughly cleaned with

pure water or drinking water before use.

• Products which have pumped fluids which are hazardous to health must always be decontaminated

before changing to a new fluid. Also clarify whether the product may be used in a different pumped

fluid.

• With products which have been operated with a lubricant or cooling fluid (such as oil), this can

escape into the pumped fluid if the mechanical shaft seal is defective.

Danger - explosive fluids!

It is absolutely prohibited to pump explosive liquids (e.g. gasoline, kerosene, etc.). The products are not

designed for these liquids!

3. General description

3.1. Application

Submersible mixers are used for various applications such as mixing, homogenization and suspension of liquids

with low to medium viscosity. Max. 6% liquids in the medium!

3.2. Types of Use

The motors are designed for continuous operation (S1), maximum 15 starts per hour.

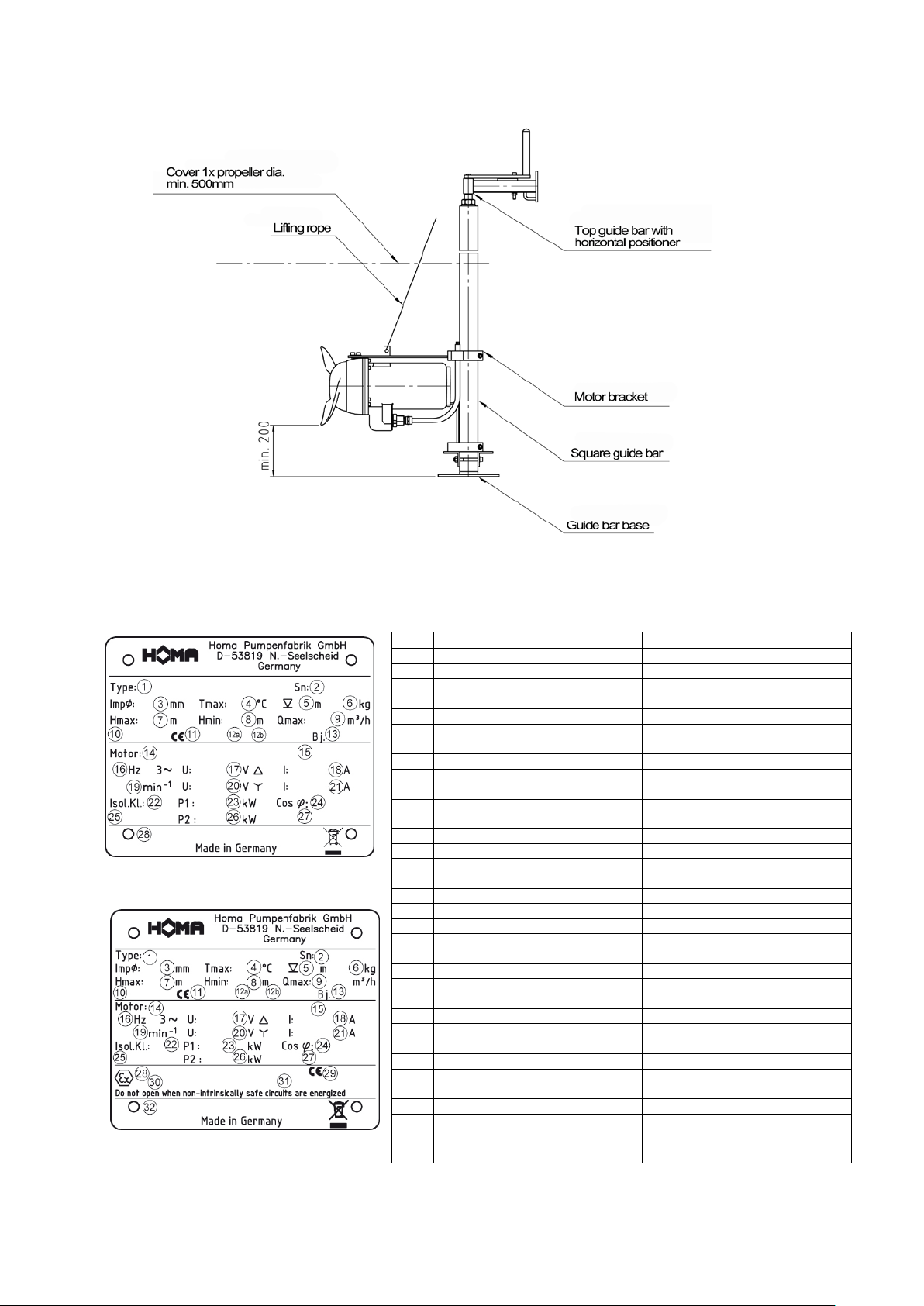

3.3. Construction

The pump consists of the motor and the pump housing as well as the propeller which belongs to it.

All important parts of the pump are characterized by generous dimensioning.

Page 9

39

No.

3 Ph

3 Ph FM

1

Type description

Type description

2

Serial number

Serial number

3

Impeller diameter

Impeller diameter

5

Immersion depth

Immersion depth

6

Weight

Weight

7

Hmax (delivery head max)

Hmax (delivery head max)

8

Hmin (delivery head min)

Hmin (delivery head min)

9

Qmax (delivery volume max)

Qmax (delivery volume max)

10

Standard

Standard

test lab

test lab

12a

Year type test

Year type test

12b

Declaration of performance

Declaration of performance

13

Build year

Build year

14

Motor type

Motor type

15

IE-Marking

IE-Marking

16

Frequency

Frequency

18

Nominal current 3-phase

Nominal current 3-phase

19

Motor RPM

Motor RPM

20

Voltage – Star connection

Voltage - Star connection

21

Nominal current Star connection

Nominal current Star connection

22

Insulation class

Insulation class

23

Power P1

Power P1

25

Protection class

Protection class

26

Power P2

Power P2

28

Text field sales

Ex-certification number

29 Ex-test lab

31 Ex-i- power circuit details

32 Text field sales

3.3.1. Type label

3 Ph

3 Ph Ex

4 Temperature of medium Temperature of medium

11 Construction product regulations-

Construction product regulations-

17 Voltage – 3-phase Voltage – 3-phase

24 Cos phi Cos phi

27 Operating class Operating class

30 Ex-Designation

Page 10

40

3.3.2. Motor

General motor data

Operating mode

S1

Insulation class

H (180°C)

Degree of protection

IP68

Cable length

10 m / 15m

Shaft sealing HRS

CHRS

NBR

Viton

Bearing

one grooved ball bearing (suspension side)

one double-row type angular ball bearing (propeller side)

The three-phase asynchronous motor is made from sheet metal with a double-varnished winding wire as well as

the motor shaft with rotor package. The power supply cable is designed for the maximum mechanical load and is

sealed against water pressure from the pumped liquid. The motor cable lead connections are sealed from the

pumped liquid as well. The bearings used are permanently lubricated maintenance-free antifriction bearings.

All models are available with explosion proof motors according to ATEX Ex II 2 G EExd.

3.3.3. Control devices

The pump is equipped with various safety and control devices:

Temperature Sensors

The mixers have a set of temperature sensors built in the stator windings.

Standard models have the sensors connected to the motor power supply cable, the wire ends marked T1 and T3.

They must be connected to the safety circuit of the control box in order to provide an automatic re-st art of the

motor, when the motor cools.

Explosion proof models with motors up to 15 kW have a set of temperature sensors built-in, with a higher switchoff temperature, connected to the motor cable, the wire ends marked T1 and T2. They must be connected t o a

special relay in the starter box in order to provide manual pump re-start.

All explosion proof models have both sets of sensors built-in, as described above, with wire ends marked T1, T2,

T3. They have to be connected accordingly as described above. The temperature sensor set must be connected

to the switchgear unit so that it switches off if it overheats.

Check of Direction of Rotation

After the electrical connection has been made, check that the agitator propeller is rotating in the correct direction.

As seen from the motor, the propeller must rotate clockwise.

If the direction of rotation of the agitator propeller is incorrect, transpose two of the three conductor phases (L1,

L2, L3) coming directly from the mains.

Beware of rotating propeller!

The moving propeller can crush and sever limbs. Switch off the machine and let the moving parts come to

a rest before maintenance or repair work!

Seal condition sensors oil chamber

Agitator motors in the HRS…/C and CHRS…/C series are fitted as standard with monitoring of the sealing of the

oil barrier chamber.

Two sensors monitor the conductibility of the oil filling. The sensors are to be connected via the connecting cables

with the cable-end designations S1 and S2 in the switchgear to an evaluation instrument with a galvanically

isolated sensor circuit (electrode relay). If the shaft seal leaks, water enters the oil chamber and changes the

resistance of the oil. Response sensitivity should be adjustable from 0-100 kÙ. The standard setting is 50 kÙ. If

this is an antiexplosion design, select electrode relays with intrinsically safe circuits for sensors.

Motor cooling

They are cooled by the surrounding liquid.

3.3.4. Propeller

A self cleaning propeller from stainless steel is used.

Page 11

41

4. Package, Transport, Storage

4.1. Delivery

On arrival, the delivered items must be inspected for damage and a check made that all parts are present. If any

parts are damaged or missing, the transport company or the manufacturer must be informed on the day of

delivery. Any claim made at a later date will be deemed invalid. Damage to parts must be noted on the delivery or

freight documentation.

4.2. Transport

Only the appropriate and approved fastening devices, transportation means and lifting equipment may be used.

These must have sufficient load bearing capacity to ensure that the product can be transported safety. If chains

are used they must be secured against slipping.

The personnel must be qualified for the tasks and must follow all applicable national safety regulations during the

work.

The product is delivered by the manufacturer/shipping agency in suitable packaging. This normally precludes the

possibility of damage occurring during transport and storage. The packaging should be stored in a safe place if

the location used is changed frequen tly .

4.3. Storage

Newly supplied products are prepared that they can be stored for 1 year. The product should be cleaned

thoroughly before interim stora ge.

The following should be taken into considerat ion for storage:

• Place the product on a firm surface and secure it against falling over. Submersible mixers and

auxiliary lifting devices should be stored horizontally, submersible sewage pumps and submersible

motor pumps should be stored horizontally or vertically. It should be ensured that they cannot bend

if stored horizontally.

Danger from falling over!

Never put down the product unsecured. If the product falls over, injury can occur!

• The product has to be stored at a place free from vibrations and agitation to avoid damage from the

ball bearings. We recommend a dry, frost-protected room with a temperature of between 5 °C and

25 °C for storage.

• The product may not be stored in rooms where welding work is conducted as the resulting gases

and radiation can damage the elastomer parts and coat ing s.

• It is responsible to take care that the corrosion coating will not be spoiled

• Any suction or pressure connections on products should be closed tightly before storage to prevent

impurities.

• The power supply cables should be protected against kinking, damage and moisture.

Beware of electrical current!

Damaged power supply cables can cause fatal injury! Defective cables must be replaced by a qualified

electrician immediately.

Beware of damp!

Moisture penetrating cables can damage them and render them useless. Therefore, never immerse cable

ends in the pumped fluid or other liquids.

• The machine must be protected from direct sunlight, heat, dust, and frost. Heat and frost can cause

considerable damage to propellers, rotors and coatings.

• The rotors or propellers must be turned at regular intervals. This prevents the bearing from locking

and the film of lubricant on the mechanical shaft seal is renewed. This also prevents the gear

pinions (if present on the product) from becoming fixed as they turn and also renews the lubricating

film on the gear pinions (preventing rust film deposits).

Beware of sharp edges!

Sharp edges can form on rotors and propellers. There is a risk of injuries. Wear protective gloves.

• If the product has been stored for a long period of time it should be cleaned of impurities such as

dust and oil deposits before start-up. Rotors and propellers should be checked for smooth running,

housing coating and damage.

Page 12

42

• After storage longer than one year the oil of motor and, if necessary the gear have to be changed.

This is also necessary if the product never had run (natural deterioration of mineral oil).

Before start-up, the filling levels (oil, cooling fluid etc.) of the individual products should be checked and

topped up if required. Please refer to the machine data sheet for specifications on filling. Damaged

coatings should be repaired immediately. Only a coating that is completely intact fulfills the criteria for

intended usage!

If these rules are observed, your product can be stored for a longer period. Please remember that elastomer parts

and coatings become brittle naturally. If the product is to be stored for longer than 6 months, we recommend

checking these parts and replacing them as necessary. Please consult the manufacturer.

4.4. Returning to the supplier

Products which are delivered to the plant must be clean and correctly packaged. In this context, clean means that

impurities have been removed and decontaminated if it has been used with materials which are hazardous to

health. The packaging must protect the product against damage. Please contact the manufacturer before

returning!

5. Installation and Start-Up

5.1 General

In order to prevent damage to the mixer or serious injury during installation the following points must be observed:

• Installation work may only be carried out by qualified persons. The safety instructions must be

followed at all times.

• The mixer must be inspected for damages before any installation work is carried out.

• Protect the mixer from frost.

• The operating area must be laid out for each machine. You must ensure that lifting gear can be

fitted without any trouble, since this is required for assembly and removal of the machine.

• The maximum bearing capacity must be greater than the weight of the machine, add-on units and

cable.

• Electric power cables must be laid out in such a way that safe operation and non-problematic

assembly/dismantling are possible at all times.

• The electric power cables should be fastened properly to the pipes with cable holders or other

suitable equipment. This should prevent loose hanging and damage to the electric power cables.

Depending on the cable length and weight, a cable holder should be fitted every two or three

meters.

• The structural components and foundations must be of sufficient stability to ensure safe and

functional operation. The operator or supplier is responsible for the provision.

• Never let the unit run dry.

• Use defector plates for the pumped fluid intake that air cannot introduce into the pumped liquid. this

will lead to that the pump will run smoothly and is subjected to higher wear and tear.

5.2 Installation

Danger of falling!

Installation work for the mixer and its accessories is performed directly on the edge of the basin.

Carelessness or wearing inappropriate clothing could result in a fall. There is a risk of fatal injury! Take

all necessary safety precautions to prevent this.

Mixer

The mixer is delivered ready assembled. During installation of the mixer please check the following:

• Propeller

The propeller must not touch the tank floor or walls in any possible installation position (min. 40 cm

distance).

• Motor Cable

The cable must not be stretched even when the mixer is completely lowered. The cable should be

positioned with always providing large bending radius in order to prevent breaking.

The connecting cable should be guided as tight as possible towards the top, so it is not caught in the

flow.

Page 13

43

• Operating Voltage / Direction Control

The operating voltage of the system is to check for conformity according to type plate data.

The protective cap located on the cable must be removed just before the electrical connection.

After electrical connection, the correct direction of the stirring propeller mixer must be inspected. The

propeller must rotate clockwise when viewed from the motor.

If the rotational direction of the stirring propeller is incorrect, two of the three conductor phases (L1, L2,

L3) that are directly supplied from the mains must the interchanged.

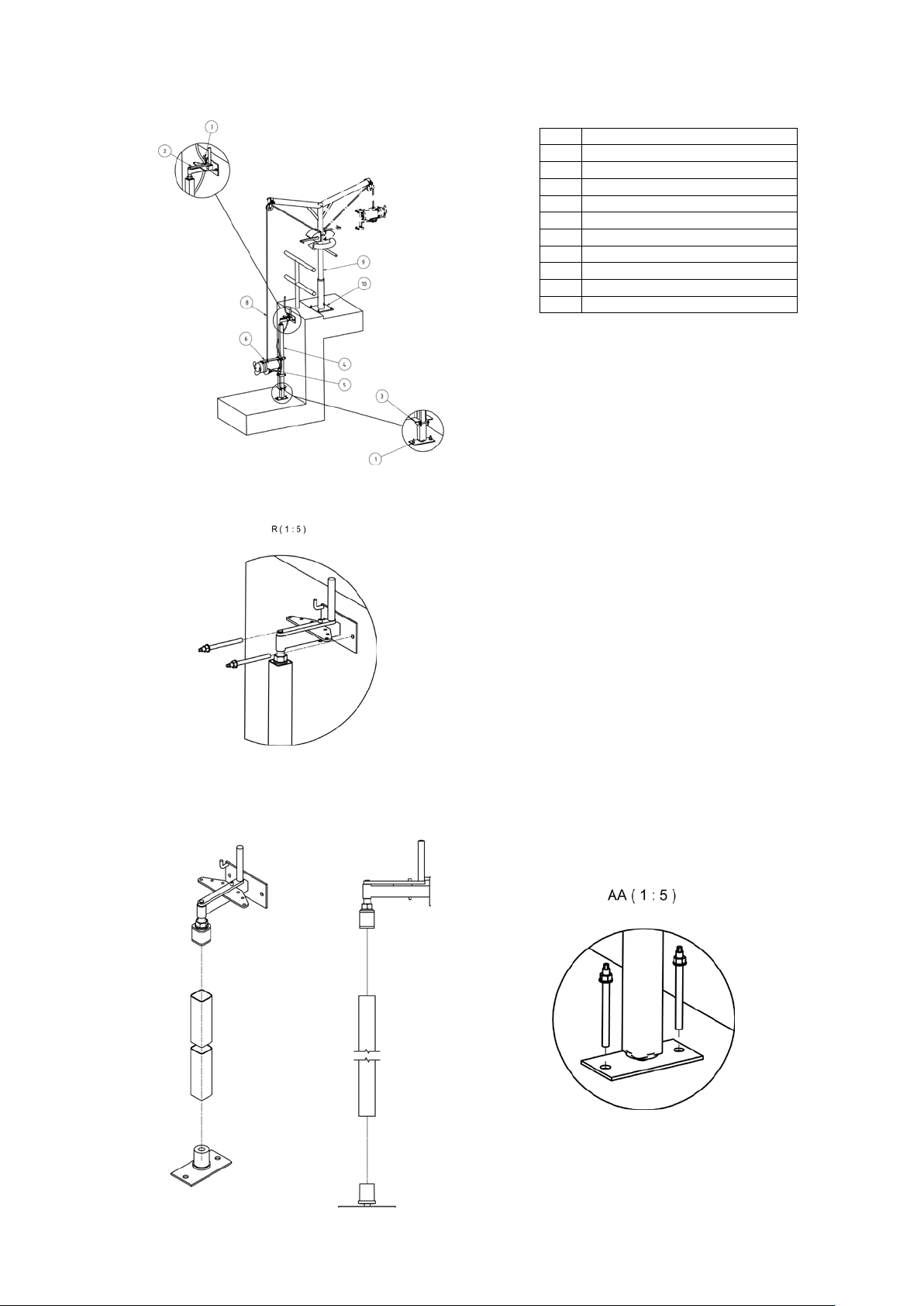

Assembling the motor bracket to the mixer

Fasten the mixer to the motor bracket (Item 12) as illustrated, using two cylinder head screws (Item 1), one

cylinder head screw (Item 2) and the associated U-washers (Items 3 & 4).

Lay the connecting cable between the pipe clamps (Item 6) and screw it to the motor bracket using two cylinder

head screws and U-washers (Items 5 & 4). Great care should also be taken to ensure that the cable is always laid

or assembled on a large radius, so that any sharp bend in the cable is prevented.

Lowering and guiding mechanisms

Before assembling the lowering and guiding mechanism, the local conditions governing installation (basin shape,

circulation conditions etc.) must be ascertained. It must be ensured that the mixer is freely mobile in the built-in

condition and that additional fittings have no effect on flow.

Page 14

44

No.

Description

1

lower fastening

2

upper fastening

3

angle clamp bracket

4

square tube

5

mixer

6

motor bracket

7

cable anchor clamp

8

stainless steel w ir e

9

lifting gear

10

floor-mounted box column

The upper fastening (Item 2) must be attached in the basin first of all. Use the supplied anchor rods and bonding

anchor cartridges for this purpose.

In the next step, attach the square tube (Item 4, to be provided on site) to the upper and lower fastenings (Item 1).

Next, hold the upper fastening on the anchor rods intended for that purpose and fasten the anchor rods with the

nuts. The position of the lower fastening has now been determined. Use the supplied anchor rods and bonding

anchor cartridges for fastening it.

Page 15

45

Now install the angle clamp brackets (Item 3). These represent the bearing point of the motor bracket.

Now lower the mixer on to the bracket in the basin. When the motor bracket lies on the angle clamp bracket, the

connecting cable must be clamped in the cable anchor clamp. At the same time it must be ensured that the cable

is led upwards as tautly as possible so that it is not caught by the delivery flow.

5.3. Start-Up

The mixer must only be started when fully submerged, in order to prevent overheating of the

motor.

Any change of mixer position must only be done with mixer having been switched off and

propeller not rotating.

Before start up, check again that all steps of installation procedure have been properly carried

out. Make sure that the mixer is sufficiently submerged (see chapter 8+9), and that there are no solid

parts in the tank which might damage the propeller. Furthermore, it must be ensured that the mixer is

immersed at least half the diameter of the propeller.

Make sure that all necessary safety precautions have been carried out, e.g. to prevent persons from falling into

the tank. After longer standstill of the mixer, clean the propeller and motor surface from dried remains of mixing

liquid in order to prevent cooling problems.

5.4. Electrical system

Observe the relevant local and national regulations when laying out and selecting the electric lines as well as

when connecting the motor. The motor must be protected by a motor protection switch.

Have the motor connected in accordance with the "Wiring connection" data sheet. Pay attention to the direction of

rotation. If the direction of rotation is incorrect, the machine will not perform as specified, and under certain

circumstances, can become damaged. In accordance with the machine data sheet, check the operating voltage

and make certain that the current consumption remains uniform during all phases.

Make sure that all temperature sensors and monitoring devices, are connected and that their function is tested.

For details on this, see the wiring diagram.

Page 16

46

Beware of electrical current!

Incorrectly performed electrical work can result in fatal injury.

This work may only be carried out by a qualified electrician.

5.5. Motor protection

The minimum requirement is a thermal relay / motor protection switch with temperature compensation,

differential triggering and an anti-reactivation device in accordance with VDE 0660 or the appropriate national

regulations. If the machines are connected to electrical systems in which faults frequently occur, we recommend

installing additional protective devices (overvoltage, undervoltage or phase failure relays, lightning protection).

Local and national regulations must be adhered to when connecting the mac hin e.

5.6. Operation with a static frequency converter

The following points must be observed when operating the converter:

• T he pump is suitable for operation with the frequency converter according to DIN EN 60034-17.

• Voltage peaks at the motor winding must be avoided and, where appropriate, suitable filters must be

provided in the motor lead.

• T he proper groun din g of the e ntire sy ste m must be ensur ed.

• The specifications of the frequency converter manufacturer must be observed.

• Under certain circumstances, a shielded cable is necessary to comply with EMC directives.

• The information sheet "Using HOMA pumps with the frequency converter" must be observed.

5.7. Activation types

Activation types for cables with free ends (without plugs)

Star-delta activation

If the motor protection is installed in the line:

Set the motor protection to 0.58 x the rated current. The maximum start-up time in star-delta mode is 3 seconds. If

the motor protection is not installed in the line, set the motor protection to the rated current when fully loaded.

Starting transformer/soft start

Motor protection should be set to the rated current when fully loaded. At partial load, we recommend that motor

protection is set 5% above the measured current at the operating point. The maximum start-up time at reduced

voltage (approx. 70%) is 3 seconds.

Operation with frequency transformers

The machine can be operated on frequency transformers. Observe chapter 5.6 of this manual.

If the submersible mixers are operated with a frequency converter type HRG185, the evaluation of the PTC

thermistor must be done via a RL94/9/EC function-tested triggering device.

5.7.1. After Start-Up

The rated current is briefly exceeded during the start-up procedure. Once this process has ended, the operating

current should no longer exceed the rated current.

If the motor does not start immediately after the machine is switched on, it must be switched off immediately. The

start pauses specified in the technical data must be adhered to before starting up again. If the fault recurs, the

machine must be switched off again immediately. The machine may only be started again once the fault has been

rectified.

The following items should be monitored:

• Operating voltage (permissible deviation +/- 5% of the rated voltage)

• Frequency (permissible deviation -2% of the rated frequency)

• Current consumption (permissible deviation between phases is a maximum of 5%)

• Voltage difference between the individual phases (max. 1%)

• Starts and stops per hour (see technical data)

• Minimum water immersion level, level control unit, dry-run protection

• Smooth running

• Check for leaks, if need be, follow the necessary steps as set out in “Maintenance”

Page 17

47

6. Maintenance

6.1 General

The machine and the entire system must be inspected and maintained at regular intervals. The time limit for

maintenance is set by the manufacturer and applies to the general conditions of use. The manufacturer should be

consulted if the system is to be used with corrosive and/or abrasive pumped liquids, as the time limit between

inspections may need to be reduced.

Note the following information:

• The operating and maintenance manual must be available to the maintenance personnel and its

instructions followed. Only the repair and ma inte nance measures listed here may be performed.

• All maintenance, inspection and cleaning work on the machine and the system may only be carried

out by trained specialists exercising extreme care in a safe workplace. Proper protective clothing is

to be worn. The machine must be disconnected from the electricity supply before any work is carried

out. There must be no way that it can be inadvertently switched on. Additionally, the appropriate

protective measures as defined by the BGV/GNV should be enforced when working in basins and/or

containers.

• Above a weight of 50kg, only hoisting gear which has been officially approved and which is in a

technically perfect condition should be used for lowering and raising the machin e.

Make sure that all fastening devices, ropes and safety devices of the hand winch are in a technically

perfect condition. Work may only commence if the auxiliary hoisting gear has been checked and found to

be in perfect working order. If it is not inspected, danger to personnel may result!

• Wiring work on the machine and system must be carried out by an electrician. For machines

approved for work in areas subject to explosion danger, please refer to the “Explosion protection in

accordance with the regulation” chapter.

• When working with inflammable solvents and cleaning agents, fires, unshielded lighting and

smoking are prohibited.

• Machines which circulate fluids hazardous to health, or which come into contact with them, must be

decontaminated. It must be ensured that no dangerous gases can form or are present.

• Ensure that all necessary tools and materials are available. Tidiness and cleanliness guarantee safe

and problem-free operation of the machine. After working on the machine all cleaning materials and

tools should be removed from it. All materials and tools should be stored in an appropriate place.

• Operating supplies such as oil and lubricants must be collected in appropriate vessels and properly

disposed of (in accordance with the 75/439/EEC directive and with §§5a, 5b AbfG). Appropriate

protective clothing is to be worn for cleaning and maintenance jobs. This is to be disposed of in

accordance with waste code TA 524 02 and EC Directive 91/689/EEC. Only lubricants expressly

recommended by the manufacturer may be used. Oils and lubricants should not be mixed. Only use

genuine parts made by the manufacturer.

A trial run or functional test of the machine must be performed as instructed in the general operating

conditions.

Before maintenance or repair disconnect the mixer from the power supply to prevent accidental starting

of the mixer!

In accordance with the product liability law we point out that we shall not be liable for damages caused by

our product due to unauthorized repair by persons other than the manufacturer or an authorized workshop or due

to the use of spare parts other than original HOMA parts. The same product liability limitations are valid for

accessories.

Before maintenance or repair make sure that all rotating parts stand still!

Before carrying out maintenance and service, the mixer must be thoroughly flushed with clean water.

When loosening of the oil chamber control screw , overpr essur e can escape. Relea se the s crew only

when pressure balance is secured.

If not otherwise stated, the torque values of the be-low tables should be used.

Values stated are for clean, lubricated screws.

Page 18

48

Fixing torque [Nm] for screws A2/A4

A2/A4,

Hardeness class 70

A2/A4,

Hardeness class 80

DIN912/DIN933

DIN912/DIN933

M6

7 Nm

11,8 Nm

M8

17 Nm

28,7 Nm

M10

33 Nm

58 Nm

M12

57 Nm

100 Nm

M16

140 Nm

245 Nm

M20

273 Nm

494 Nm

(Coefficient of friction = 0,2)

6.2. Maintenance

It is imperative to keep a maintenance list to be always informed about the submersible mixer. This list must be

presented to the trade association, the technical inspection agencies and the manufacturer of the system or of the

mixer when requested.

The full warranty requires the annual inspection of the mixer by the manufacturer of the system or of the mixer.

6.2.1. General (Monthly or every 500 operating hours)

Clean the mixer from all attached solids. Check the motor cable for damages. In case of any damages of cable

surface replace cable through mixer manufacturer or authorized repairshop.

Check mixer painting and surface for scratches or damages. Repaint surface or replace damaged parts.

6.2.2. Electric Motor

The current consumption must be checked for all 3 phases monthly. Damages of the motor, transmission and

bearing can be detected via the power consumption.

Lubrication: The bearings are lubricated for life (when noises arise, bearings must be replaced at the manufacturer's works).

The oil in the oil chamber should be changed after every 6000 hours of operation.

Oil condition: Place mixer horizontally so that one of the oil chamber screws is at the top. Remove the screw and

extract a small amount of oil. If the oil is milky or cloudy, it indicates a defective shaft seal. In this case, have the

condition of the shaft seals checked by HOMA-workshop or factory service.

Replace shortages

Isolation test: If the insulation resistance is less than 2 megohms, do not turn the submersible mixer on. (Measuring DC voltage 1500 Volts).

6.2.3. Stirring Propeller

Inspection: Inspect the stirring propeller periodically. Remove random wound foreign bodies such as twines,

cords, etc. They can cause uneven running and thus create strong vibrations in the system and can lead to

damage on the mixer components. With uneven running, the stirring propeller must be cleaned.

6.3. Change of oil

position when changing oil.

When releasing the oil level screws, excess pressure may escape from the oil chamber or the gearbox. Only

remove the screws completely after the pressure was equalized.

The thread and the magnets (on the gearbox) of the screws must be clean before screwing them back on.

The sealing rings must be always replaced with new parts.

Change oil only with motor at operation temperature. Note that the mixer must be in a horizontal

Page 19

49

6.3.1 Oil chamber

Oil specification: bio degradable Shell Ondina 917. Remove used oil according to local regulations! Oil capacity is

1,0 liter.

Steps:

1. Remove screw

2. Release oil

3. 4. Fill in correct quantity of oil (see below table)

5. Re-fasten screw

Page 20

50

7. Additional for FM submersible pumps

7.1. GENERAL INSTRUCTIONS

This manual is intended to provide basic installation and start-up guidance. It is to be read and thoroughly studied

prior to attempting to install or operate any of the equipment supplied. Equipment damage, which occurs by not

following these instructions will void the warranty.

7.2. SAFETY PRECAUTIONS

Only trained qualified personnel shall be utilized for installation and start-up.

The following is a general list of safety precautions that should be followed when installation starting-up or

servicing the pump.

The pump station owner or operator is ultimately responsible for ensuring that all equipment is installed,

started up and operated in a safe manner.

• Do not work alone.

• Double check to make sure that all lifting equipment is in good working order and that it has adequate lifting

capacity for the weight that it will handle.

• Wear safety helmet, goggles and protective shoes, or appropriate safety materials required.

• Before working on the pump make sure that the power is disconnected and cannot be energized by others.

Lockout and tag the control panel circuit breaker.

• Do not stand under suspended loads!

• Never enter or work within a wet well without first checking to make sure sufficient oxygen is present and that

there are no explosive or poisonous gases present.

• All personnel, who work with sewage pumping equipment and systems shall be vaccinated against diseases

that can occur. If there are any questions or doubts in this area it is strongly suggested that the local health

agency be contacted.

• For Hazardous Area Classifications, only use pumps with suitable Explosion Proof Rating.

7.3. EQUIPMENT INVENTORY AND INSPECTION

Upon arrival of pump shipment carefully unpack all components and compare with shipping and purchase order

documents to ensure that the order is complete. Also inspect equipment for any damage that might have occurred

in shipment. If any problems are detected contact an authorized HOMA customer service immediately.

7.4. TRANSPORTATION AND STORAGE PROCEDURE

Always lift the pump by its lifting bail or eye bolt.

Never lift the pump by its power cable! Jacketed pump should never stored or shipped with the

pump by the jacket. Damage to Sealing O ring may result.

Pumps should be stored in an upright position, taking extreme care to protect the power cable and control cables

from crushing, nicks or tears which would permit water intrusion.

Power cable ends must be protected from immersion in water as well as moisture intrusion. The cable will wick

water into the pump if it is not protected properly. Power cable leads should be covered with shrink tubing or

suitable sealing material durin g storage.

Short Term Storage: Short term storage is defined as any time less than six months. We recommend that pump

and accessories be stored in its original shipping container in a dry, temperature controlled area. If climate

controlled storage is not possible, all exposed parts should be inspected before storage and all surfaces that have

the paint scratched, damaged or worn should be re-coated with air dry enamel paint. The pump should be stored

in an upright position.

Long Term Storage: Any storage time exceeding six months is considered long term. In addition to the

safeguards specified above, the impeller should be rotated once a month to prevent the mechanical seals from

being damaged, and the pump should be inspected. The seal chamber oil should be drained and replaced prior to

commissioning. The pump should be stored in an upright position.

Page 21

51

7.5. ELECTRICAL INSTALLATION

7.5.1. GENERAL GUIDELINES

All electrical work shall be carried out under the supervision of an authorized, licensed electrician. The present

state adopted edition of the National Electrical Code as well as all local codes and regulations shall be

complied with.

7.5.2. VERIFICATION OF POWER SUPPLY

Prior to making any electrical connections or applying power to the pump, compare the power supply available at

the pump station to the data on the unit's nameplate. Confirm that both voltage and phase match between pump

and control panel. The voltage supplied at the pump shall be +5 / -10% of the nameplate value, frequency shall be

+ / - 1% of the nameplate value, the voltage phase balance shall be within 1% and the maximum corrected power

factor shall be 1.0.

7.5.3. POWER LEAD WIRING

HOMA pumps may be provided with 1 or more cables, depending on motor horsepower and operating voltage.

Power leads L1, L2, & L3 may be provided as single conductor, or as multiple conductors. Multiple conductor

configurations may use leads from separate cables, or may use two conductors within one cable. Please refer to

wiring diagram in the appendix for specific connection details. The pump must be connected electrically through a

motor starter with proper circuit breaker protection in order to validate warranty. Do not splice cables.

7.5.4. THERMAL SWITCH WIRING

Pumps are equipped with thermal switches embedded in the stator windings which are normally closed,

automatically resetting switches. Switches will open when the internal temperature rises above the design

temperature, and will close when the temperature returns to normal. Thermal switches must be wired to a current

regulated control circuit in accordance with the NEC.

Identify thermal switch leads marked T1 and T3 in the power or control cable.

The resistance across the leads will be 0.5 Ohms. Thermal leads must be connected to the thermal overload relay

located in the control panel. Thermal switch leads must be connected to validate warranty.

Note: All sizes of Class 1, Div. 1 pumps for hazardous service must have thermal switch leads connected

to a current regulated control circuit in accordance with NEC.

7.5.5. SEAL PROBE WIRING

The mechanical seal leak detector probe utilized in the pump is a conductive probe which is normally open. The

intrusion of water into the seal chamber completes the electrical circuit. Control panel provisions will sense this

circuit closure, and will provide indication or alarm functions depending on the panel design.

Either single or dual wire systems may be provided. Single wire systems utilize one energizing conductor, and the

pump casing and neutral lead as the ground or return portion of the circuit. The dual wire systems utilize two

separate conductors for each leg of the circuit.

With either system, the seal probe leads must be wired into a control circuit provided in the control panel. This

control circuit must energize the probe with a regulated power source, and sense the closed circuit in event of

water intrusion Indication and alarm functions must also be provided in the control circuit. Please see c ontrol

panel wiring diagram for seal probe connection points.

For Hazardous Area Classification Pumps, leak detector circuit must be in conformance with applicable NEC

codes and regulations.

7.5.6. START / RUN CAPACITORS AND RELAYS:

All single phase motors require start and run capacitors along with a start relay to operate. Capacitors and relays

must be sized for the specific motor.

Capacitors are sized based on ideal conditio ns.

The run capacitor may need to be resized to match the available field voltage. Each cap kit shipped is supplied

with a wiring diagram and start up procedure.

7.5.7. Variable Frequency Drives

Special considerations must be taken when operating pumps with variable frequency drives (inverters).

The inverter circuit design, horsepower required by pump, motor cooling system, power cable length, operating

voltage, and anticipated turndown ratio must be fully evaluated during the design stage of the installation.

As a minimum, properly sized load reactors and filters must be installed between the inverter and the

pump to protect the pump motor from damaging voltage spikes. Warranty coverage will not be provided on

any pump motor that is operated with a variable frequency drive, unless the load side of the inverter is properly

isolated from the pump.

Page 22

52

7.6. ADDITIONAL PUMP PROTECTIVE DEVICES

Several optional pump protection devices are available to protect submersible motors from damage, and may

have provided in your pump.

Temperature Sensing RTD*: PT100 sensors are available in two critical locations on larger machines, the lower

bearings and motor windings. N.C. Circuit - 108 ohm

Moisture Sensors: Two styles of moisture sensors are available on HOMA pumps.

Moisture Detectors*: These are micro float switches designed to detect small amounts of liquid. These are

available in the stator housing of 50hp and larger size pumps. N.C. Circuit - 268 ohm

Leakage Detectors*: These normally open, single or 2 wire probes are used to detect the presence of water in the

pump. Single wire probes use the pump ground to complete circuit. Optional leak detectors can be installed as

follows:

• Stator Chamber installation: Probe placed in bottom of stator housing to detect presence of w at er in the

chamber.

• Stator or Motor cap installation: Probe used to detect the presence of water only into the stator housing

or motor cap terminal board.

• Closed loop cooling Installation: Probe placed in stator housing to detect the presence of liquid in the dry

chamber.

* relay is required for sensor operation.

7.7. MECHANICAL INSTALLATION

7.7.1. PUMPS WITH AUTOCOUPLING SYSTEMS

The HOMA Auto-Coupling is a quick removal system used in keeping personnel from having to enter the wet well.

The pump mounts on a stationary base and operates completely or partially submerged (minimum 10” over

volute) in the pumping media.

The HOMA Auto-Coupling kit consists of a base, guide claw flange, upper guide rail bracket, profile seal and base

anchor bolts. Refer to dimensional drawing for details.

For all pumps, attach the guide claw flange to the pump discharge flange with the fasteners and gaskets included

with the auto-coupling kit. Use tightening torque’s indicated i n the table below. Do not over tighten! Install the

profile gasket (if not already installed at the factory) into the guide claw with the large diameter fitted into the

groove inside the claw. Refer to the diagram included with the auto-coupling kit for proper profile gasket

installation.

Install suitable lifting chain of an adequate size and length to permit proper lowering and raising of the pump.

Properly locate the base and with the anchor bolts fasten to the floor of the pump station. Make sure when

locating and securing the anchor bolts that the base will align properly with the access cover at the top elevation

of the station. Place the base in position, and level the base.

If the base is not level, proper sealing of the pump to base may not occur!

Place the guide rails (supplied by others), cut to length in to the rings of the base. The rails will be secured at the

top of the pump station with the upper guide bar bracket and to extend down to the sump floor.

For stations exceeding 10 feet in depth intermediate guide bar brackets are recommended. One bracket is

recommended for each additional 10 feet of station depth.

Check that the guide system is properly installed in the vertical orientation by using levels and a plumb line. Fully

tighten all anchors and mounting bolts.

Connect the station riser piping to the outlet flange of the base.

Before lowering the pump, verify the direction of impeller rotation (refer to start-up section for procedure).

Make sure to use lifting equipment that has adequate capacity for the pump that will be handled. Before

installing pump, check to be certain the profile seal (rubber ring) is properly positioned in the guide claw flange.

Then position pump so the guides on the discharge flange engage the rails. Slowly lower the pump along the

guide rail. Once the pump reaches its bottom location it will automatically connect to the base.

It is recommended that the stationary base elbow be visible before lowering the unit. If this is not possible, ensure

all debris is removed from wet well.

Do not install more than one check valve into any piping system or problems will occur.

Page 23

53

7.7.2. INSTALLATION OF PUMPS WITH RING STANDS

The ring stand design allows for a free standing, simple economical installation or to be transportable from one

installation to another.

It is intended to operate completely or partially submerged in the pumping liquid.

Install the ring stand to the underside of the volute with the supplied fasteners provided. Apply thread locking

compound and tighten the bolts using the torque table indicated in the table. Do not over tighten! Install suitable

lifting devise of an adequate length to ensure proper lowering and raising capabilities. Lower the pump into the

area where it is required. Properly position power cable and chain so they stay above pump and cannot enter the

pump suction.

7.7.3. INSTALLATION OF PUMPS FOR DRY PIT APPLICATIONS

Foundation and Piping Requirements:

General

The following recommendations are basic guidelines which are intended to outline basic requirements in the

design of the dry pit station. It is essential that a licensed professional engineer be retained by the owner to

design the station and all support structures .

Foundations

Foundations may consist of any structure heavy enough to provide permanent rigid support for the pump and inlet

elbow stand. Concrete foundations built up from the solid ground are the most commonly used. The concrete floor

shall be level. The space required by the inlet stand and the location of the foundation anchor bolts are shown on

the outline dimension drawing. Foundation bolts are to be embedded in the concrete.

Suction Piping

Suction piping should be at least as large as the pump inlet elbow suction. If reducers are utilized they should be

of the conical type. If the liquid source level is below the volute horizontal centerline, the reducer must be

eccentric and installed with the level side up. If the liquid level is above the pump volute horizontal centerline,

either eccentric or concentric reducers may be used. Suction piping should be run as straight as possible. All pipe

flange joints should be gasketed to prevent air from entering the pipe. High points that may collect vapor are to be

avoided. Isolation valves such as gate valves can be installed in order to facilitate the removal of the pump for

maintenance. Any valve installed in the suction line should be installed with the stems horizontal.

Discharge Piping

A check valve and isolation valve shall be installed in the discharge line. The check valve should be installed

between the pump discharge flange and the isolation valve. If pipe increasers are used on the discharge line, they

should be placed between the check valve and the pump.

The inlet elbow stand allows the pump to be installed in a stationary position in a dry pit. Place the inlet stand in

position and tighten the anchor nuts.

Lower the pump on to the top flange of the inlet stand. DO NOT ALLOW SLACK ON THE LIFTING CABLE

UNTIL THE PUMP IS BOLTED DOWN. Make sure the flange bolt holes align with the mounting holes on the

underside of the volute. Secure the pump to the mounting flange with the fasteners that are specified in the

accessory fastener selection table below.

Page 24

54

Bolts

PUMP MODEL

Anchors

SIZE

TORQUE

3”

8

M16X60mm

146 Nm / 108 ft lb

AUTOCOUPLING

4

M16

100 Nm / 74 ft lb

AUTOCOUPLING

4

M16

100 Nm / 74 ft lb

3” & 4”

4

M16x25mm

146 Nm / 108 ft lb

RING STAND

3” & 4”

8

M16x40mm

146 Nm / 108 ft lb

AUTOCOUPLING

4

M16

100 Nm / 74 ft lb

6"

4

M20x40mm

200 Nm / 150 ft lb

DRY SUMP (1 Piece)

4

M16

100 Nm / 74 ft lb

6"

8

M20x65mm

200 Nm / 150 ft lb

DRY SUMP (N/PMotor)

4

M16

100 Nm / 74 ft lb

6"

8

M20x70mm

200 Nm / 150 ft lb

DRY SUMP (F Motor)

4

M16

100 Nm / 74 ft lb

8”

8

M20x70mm

200 Nm / 150 ft lb

AUTOCOUPLING

4

M20

200 Nm / 150 ft lb

8"

4

M20x30mm

200 Nm / 150 ft lb

8"

8

M20x75mm

200 Nm / 150 ft lb

4” 8 M16X60mm 146 Nm / 108 ft lb

DRY SUMP 4 M16 100 Nm / 74 ft lb

6” 8 M20x70mm 200 Nm / 150 ft lb

RING STAND

6" 8 M20x45mm 200 Nm / 150 ft lb

RING STAND

DRY SUMP (2 Piece) 4 M20 200 Nm / 150 ft lb

Notes:

7. For pumps larger than 8” please consult factory.

8. Flange bolts must be tightened in cross pattern to avoid damage to the raise face flanges.

9. Standard flange bolts are 316SS

10. Standard anchors are plated steel.

11. Autocoupling systems include qty. 4 M12 anchors for the upper bracket. Torque to 51 Nm / 38 ft lb.

12. Anchor bolt holes should be drilled to the actual diameter of the anchor (M12 anchor requires 12mm

diameter hole).

7.7.4. JACKETED PUMP OPTION

The cooling jacket has been supplied based upon the specified operating conditions of this application. It is

important this jacket is function properly, or the internal motor components could become damaged.

Several cooling configurations are available depending upon customer preference and system requirements. You

must know what configuration of cooling system is to be used with the pump prior to installation. In some cases,

field test results may indicate a change of cooling method is required. Consult factory for necessary changes to

the pump.

Cooling Requirements

1 - Standard Media Cooled – This construction does not require any external piping and it is completely self-

contained. This design is suitable for the routine collection system application. No pump modifications are

required.

Required Hardware – Automatic air bleed valve mounted in upper vent port or a ¼” or 3/8” elbow and small

block valve for venting. A length of hose routed to the sump should be attached to either air bleed or the

block valve outlet.

Start Up Requirements – This jacket must be vented at start up. Additional venting may be required after

situations where the suction or discharge piping has been removed for maintenance and reinstalled. Some

adverse operating conditions can allow air to become trapped in this jacket. This must be periodically vented

off. If this occurs, it is recommended the small air bleed valve is utilized.

Page 25

55

2 - Media Cooled with External Flush - This construction requires an external flow of water, typically re-use

water. Applications which require this option are typically heavy slurry or sludge service often found in the

treatment plant. This option routes the externally supplied water into the pumped media. No pump modifications

are required.

Required Hardware – Mounting a regulating valve, pressure gauge and automated block valve between the

water supply and the upper jacket port is required. The supply valve should be adjusted to allow the supply of

water to exceed pump discharge pressure. This assures a positive flow of water into the pump chamber. The

block valve should be automated to open whenever the pump is operated.

Start Up Requirements – This jacket must be vented at start up. Additional venting may be required if cooling

water supply is interrupted.

3 - External Fluid Cooled - This option requires an external flow of water like in option 2 above, but is used

where dilution of the pumped product is not desirable. The supply of water is internally isolated from the pumped

media. The water inlet is routed into the jacket’s lowest port and returned out of the highest port. This option does

NOT allow water to enter the pumped media and pump must be ordered from factory this way.

Required Hardware – Mounting a regulating valve, pressure gauge and automated block valve between the

water supply and the upper jacket port is required. The supply valve should be adjusted to allow for a good

supply of water to flow through the jacket. The block valve should be automated to open whenever the pump

is operated.

Start Up Requirements – This jacket must be vented at start up. Additional venting should not be required.

Vent Valve Installation

HOMA dry pit pumps are supplied with a valve and fitting that must be installed and maintained to ensure the

proper performance of these pumps.

The opening for this valve is located on the base of the motor cap near the mounting screws. The pump is

shipped with a plug installed which must be removed prior to start up.

This opening is a metric straight thread and requires an adapter included with the valve and fitting hardware. It is

also recommended that a length of hose be attached to the valve and routed back to the sump.

Note: Leave vent valve open in wet pit pump application to

prevent air entrapment in jacket.

Page 26

56

7.8. INSTALLATION / START UP TROUBLESHOOTING:

Only authorized service personnel who are trained professionals shall troubleshoot and repair pumps that are

experiencing operational or performance difficulties.

All HOM A pumps are factory tested, yet startup difficulties can occur with any mechanical equipment.

Please note that our technical support staff stands ready to assist you with any problem or difficulty you

might encounter with our equipment.

The following is a tabulation of common start-up problems and possible causes.

Symptom: Possible Causes

Pump will not start: 1, 2, 3, 4, 27, 28, 29, 31, 32

Little or zero discharge: 5, 6, 7, 8, 16, 30, 32

Insufficient discharge flow/pressure: 5, 6, 9, 10, 11, 12, 26, 30

Excessive power consumption: 6 , 9 , 13, 28, 30

Excessive current draw: 6, 13, 14, 15, 19, 26, 30

Excessive pump vibration/noise: 12, 15, 16, 25, 26, 28, 31

Pumps runs & motor protection trips: 17, 18, 19, 20, 21, 28

Pumps run manually, but not automatically: 22, 23, 24

Pump runs hot: 7, 19, 25, 26, 28

Listing of Possible Causes:

28. Incorrect or no power supplied to motor.

29. Power cable cut.

30. Short to ground in cable or motor winding.

31. Control panel circuit breaker open.

32. Actual system head is higher than calculated or specified.

33. Incorrect impeller rotation direction.

34. Sump liquid level is below pump's minimum submerg enc e require me nt .

35. Closed discharge valve or jammed check valve.

36. Wear ring(s) worn. (If Applicable).

37. Vortex at pump's suction.

38. Discharge valve partially closed.

39. Insufficient NPSHA (Dry Pit Application).

40. Actual system head is lower than specified resulting in over pumping condition.

41. Voltage supply to motor is lower than required by motor.

42. Damaged bearings.

43. High system head causing pump to operate at extremely reduced capacity.

44. Object stuck inside impeller.

45. Motor not receiving proper voltage on all three phases.

46. Phase/currents unbalanced or too high.

47. Insulation between phases and earth ground, <1M-ohm.

48. Density of the pumping media too high.

49. Defective level sensor.

50. Hand/Off/Auto switch not in Auto Position.

51. Defective H/O/A switch, relay or contactor coil.

52. Air Captured in Cooling Jacket.

53. Pump not properly seated on Auto Coupling.

54. Water intrusion through junction box.

28. VFD or Soft Start not functioning properly.

29. Run capacitor size to large (1ph).

30. Start capacitor size to small (1ph).

31. Profile seal not sealing or missing.

32. Start relay or capacitor damaged (1ph).

Please note that some possible causes may not relate to your particular model.

Page 27

57

7.9. MAINTENANCE

Regular maintenance will help ensure longer pump life and more reliable operation. It is recommended that

pumps in intermittent operation be inspected twice a year and pumps in continuous operation be inspected every

1,000 hours. The following is a listing of required inspection and maintenance items.

If any of the problems described in the following list exists, stop operating the pump to avoid damage or

personal injury.

1. CABLE ENTRY

Make sure that the cable entry flange and strain relief clamp are tight. If the cable entry is showing signs of

leakage remove cable from entry, remove grommet, cut a piece of cable off so that the grommet seats on a new

portion of the cable, replace grommet, and re in stal l cabl e ass embly , into the top of the moto r.

Note: Explosion Proof cables are sealed with a Factory Mutual Approved potting compound. Please consult

factory for instruction.

2. CABLES

Inspect the cable for cuts, scrapes or sharp bends. If the outer jacket is damaged, replace the cable. Splices of

the power or control cable within the wet well area are not acceptable.

3. MOTOR INSULATION RESISTANCE

Megger the insulation between the phases; and between any phase and ground. Resistance values should be

greater than 1 M ohm. If abnormal readings are obtained, contact authorized service center immediately.

4. EXTERNAL PARTS ON PUMP

Make sure that all screws, bolts and nuts are tight. Check the condition of pump lifting eyes and replace if

damaged or worn, Replace any external part that appears worn or damaged.

5. SEAL CHAMBER OIL

Note: Use extreme care when removing the seal chamber plug, as the chamber may become pressurized if seal

failure has occurred.

Seal chamber oil should be checked for signs of water intrusion, or other impurities any time the pump is removed

from wet well. To check the condition of the oil, remove the oil fill plug. Drain the chamber volume into a

transparent container. Visually check sample for impurities or emulsification (oil may appear cream-like if a sma ll

amount of water is present). If significant water intrusion has occurred, remove and replace lower mechanical

seal. Unless obvious mechanical damage has occurred to the lower seal, it is good practice to replace the upper

and lower mechanical seals as a set. Refill seal chamber with fresh oil to the bottom of fill plug port (when pump is

in vertical position) and replace oil fill plug.

6. IMPELLER

Periodically inspect impeller by turning pump on its side, remove suction strainer nuts and strainer to expose

impeller and relocate position of adjusting plate (suction cover) as needed. Replace the impeller if it is damaged

or worn.

7.10. SPARE PARTS

In order to obtain spare parts identify the required parts, and contact authorized HOMA customer service with