HOLZMANN MASCHINEN ED 400FD Instruction Manual

HOLZMANN-MASCHINEN GmbH

Marktplatz 4 · 4170 Haslach · Austria Gewerbepark 8 · 4707 Schlüsslberg · Austria

Telefon +43.(0) 7289.71562 -0 Telefon +43.(0) 7248.61116 -0

Telefax +43.(0) 7289.71562 -4 Telefax +43.(0)7248. 61116-6

Email info@holzmann-maschinen.at www.holzmann-maschinen.at

www.holzmann-maschinen.at

Revision 3/ 06.05.2011

HOLZMANN ED 400FD

DEUTSCH ENGLISH

www.holzmann-maschinen.at

Dear Customer!

This manual contains Information and important instructions for the installation and

correct use of the metal lathe ED 400FD

This manual is part of the machine and

may not be stored separately from the

machine. Save it for later reference and

if you let other persons use the machine,

add this instruction to the ma-chine.

Please read and obey the security instructions!

Before rst use read this manual

carefully. It eases the correct use

of the machine and prevents misunderstanding and damages of machine and the

user’s health.

Due to constant advancements in product

design and construction pictures and content may di-verse slightly. However, if you

discover any errors, inform us please with

the product feedback form.

Technical specications are subject to

changes!

Copyright © 2011

This document is protected by international copyright law. Any unauthorized duplication, translation or use of pictures,

illustrations or text of this manual will be

pursued by law – court of jurisdiction is

A-4020 Linz, Austria!

Sehr geehrter Kunde!

Diese Bedienungsanleitung enthält Informationen und wichtige Hinweise zur Inbetriebnahme und Handhabung der Metalldrehbank ED 400FD

Die Bedienungsanleitung ist Bestandteil

der Maschine und darf nicht entfernt werden. Bewahren Sie sie für spätere Zwecke

auf und legen Sie diese Anleitung der Maschine bei, wenn sie an Dritte weitergegeben wird!

Bitte beachten Sie die Sicherheitshinweise!

Lesen Sie vor Inbetriebnahme diese Anleitung aufmerksam durch. Der sachgemäße

Umgang wird Ihnen dadurch erleichtert,

Missverständnissen und etwaigen Schäden wird vorgebeugt. Halten Sie sich an

die Warn- und Sicherheitshinweise. Missachtung kann zu ernsten Verletzungen

führen.

Durch die ständige Weiterentwicklung unserer Produkte können Abbildungen und

Inhalte gering-fügig abweichen. Sollten

Sie jedoch Fehler feststellen, informieren

Sie uns bitte über E-Mail oder Fax mit Produktinformationsformular am Ende dieser

Anleitung.

Technische Änderungen und Irrtümer vorbehalten!

Urheberrecht © 2011

Diese Dokumentation ist urheberrechtlich

geschützt. Die dadurch verfassungsmäßigen Rechte bleiben vorbehalten! Insbesondere der Nachdruck, die Übersetzung

und die Entnahme von Fotos und Abbildungen werden gerichtlich verfolgt – Gerichtsstand ist A-4020 Linz, Austria!

ENGLISH

DEUTSCH

1

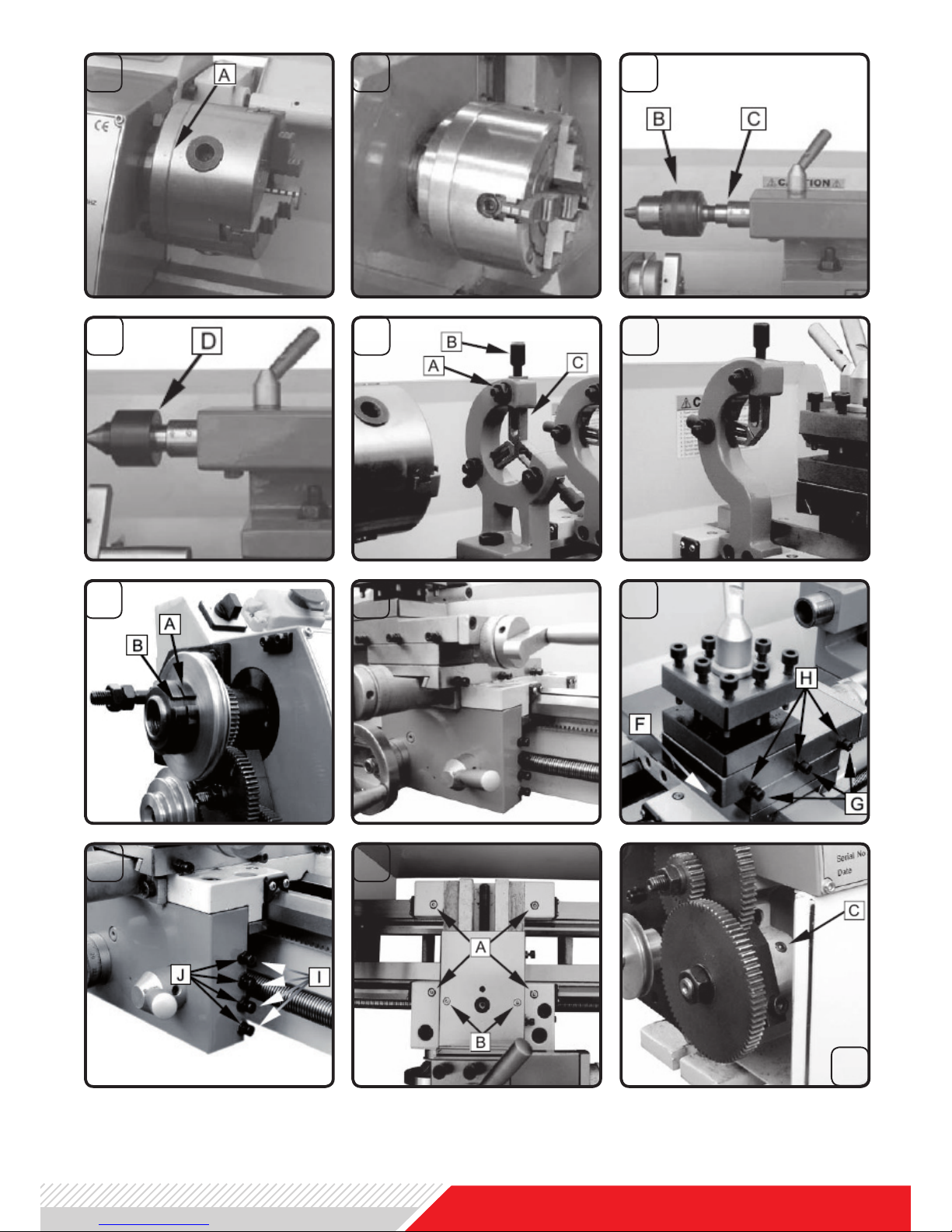

4

2

3

5 6

7 8 9

www.holzmann-maschinen.at

19

10 11 12

13 14 15

16 17 18

20

21 22

www.holzmann-maschinen.at

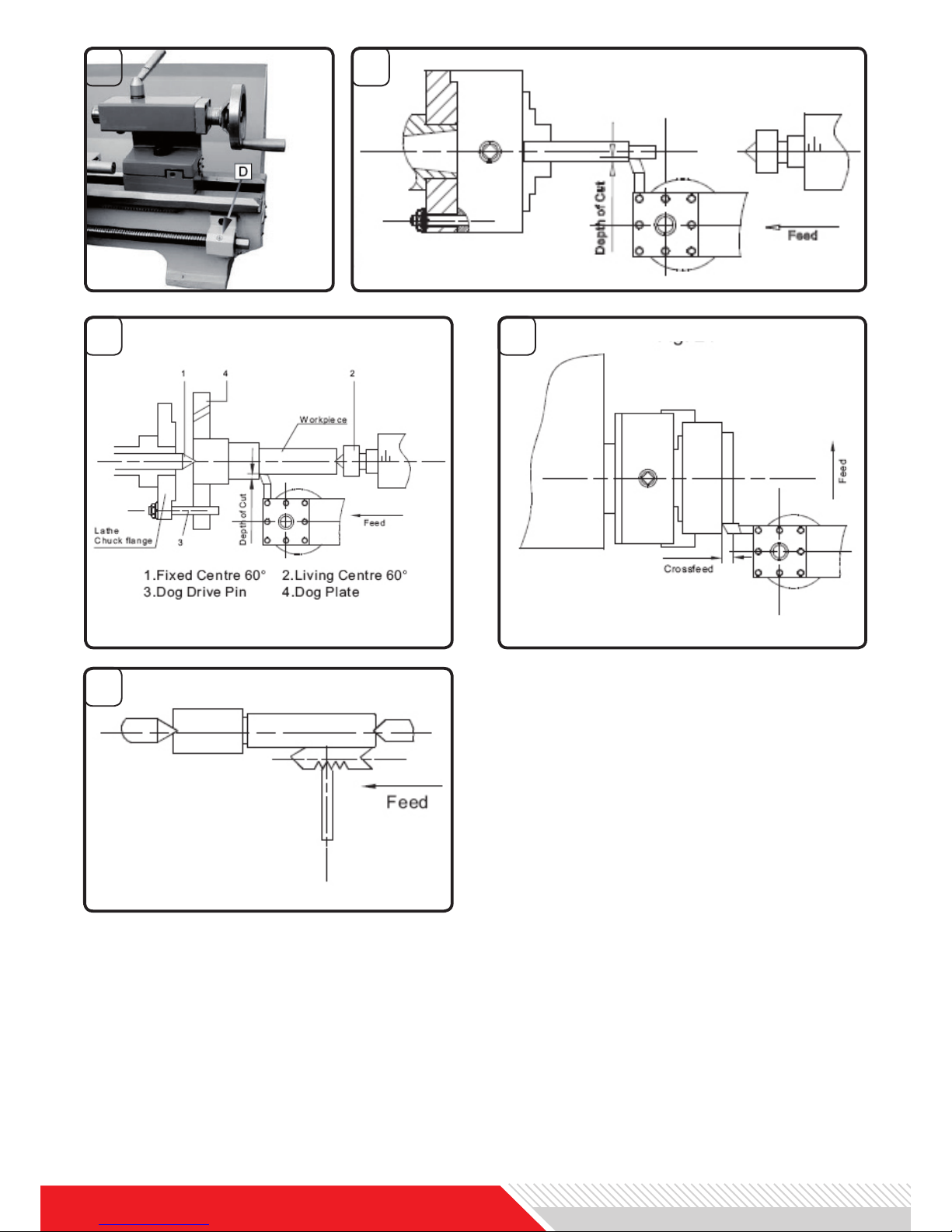

26 27 28

29 30 31

32 33 34

35 36

37

38 39

40

42

41

www.holzmann-maschinen.at

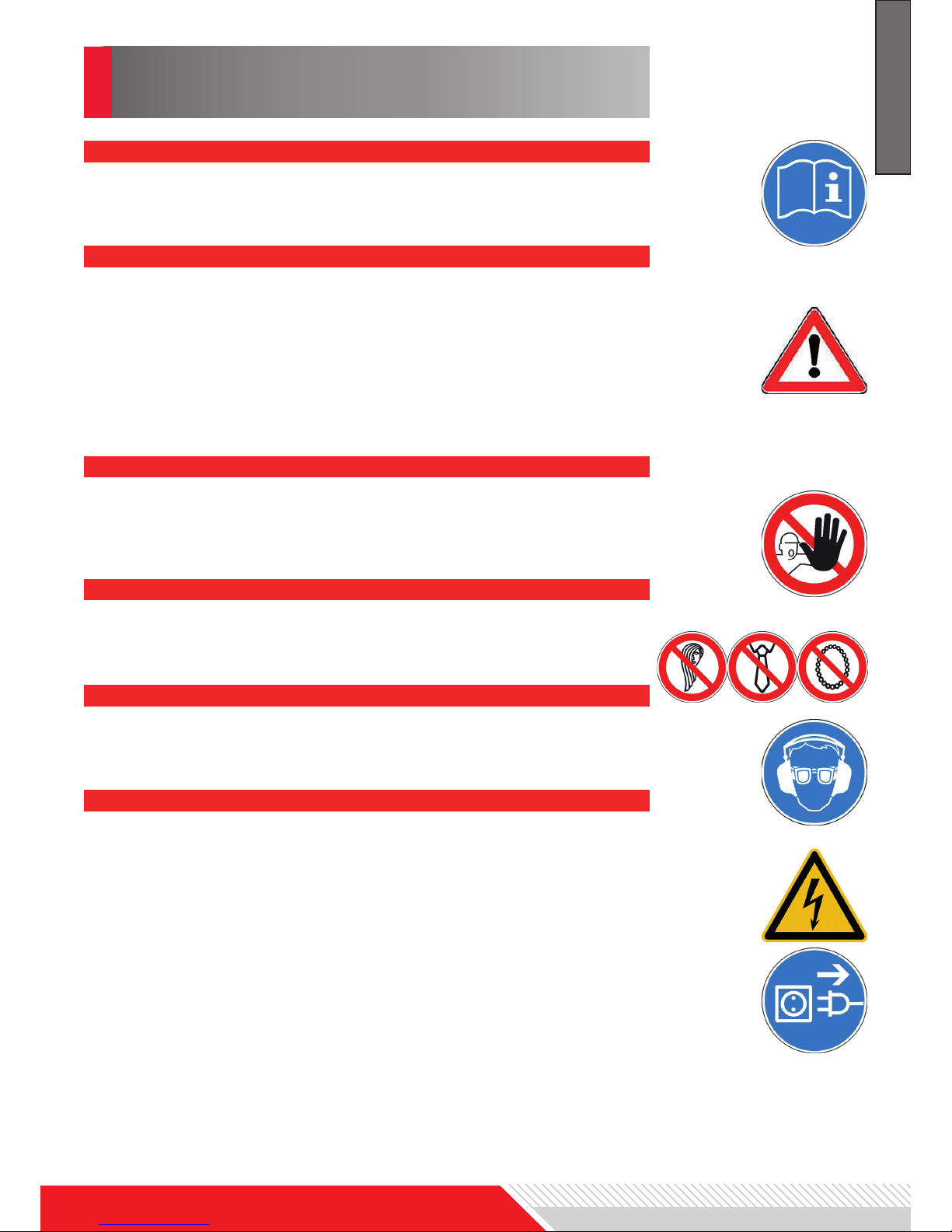

1. GENERAL SAFETY RULES

Read and understand the owner’s manual and labels afxed to

the machine. Learn its application and limitations as well as the

specic potential hazards peculiar to it.

Keep working area and the ground clean and free of oil and other

materials!

Assure that the working area is sufciently lighted!

Don’t use the machine outside!

The use of the machine is forbidden if you are tired, not concentrated as well if you are under the inuence of medicaments, alcohol and other drugs. Reduce distraction sources in the working

area.

BEWARE: Routine leads to insufcient attention.

The machine shall be used only by trained persons wiht an age

of at least 18 years.

Non authorized personnel, especially children, shall be kept away

from the machine! Make your workshop childproof.

When working with the machine, don’t wear loose clothing, long

hair openly or loose jewellery like necklaces etc. Loose objects

might be catched by rotating parts and cause serious injuries.

Use proper safety clothing and devices when operating the machine (safety glasses, ear protectors)!

Assure yourself that your feeding current complies with the requirements of the motor - check the typeplate.

Electric checks and the electric installation of the machine may

only be performed by a qualied electrician.

DO NOT touch leading machine parts.

Prior to any Cleaning, Check, maintenance or tool change shut

the machine off and disconnect it from the power supply in order

to prevent unintended start up of the machine.

READ THE MANUAL

AVOID DANGEROUS CONDITIONS

OPERATOR

CLOTHING

SAFETY EQUIPMENT

ELECTRIC CONNECTION

ENGLISH

www.holzmann-maschinen.at

MAINTAIN SAFETY GUARDS, COMPONENTS AND SIGNS

NEVER FORCE YOUR MACHINE

DO NOT OVERREACH

SECURE SMALL WORKPIECES

MAINTAIN TOOLS WITH CARE

It will do a better job if used at its designed output rate.

Forcing your machine shortens it`s lifespan, may cause machine

defects and poses a security risk.

Keep proper footing and balance at all times.

When processing small workpieces, x them with a suitable device like a vice, downholder, to avoid accidents.

Do not x or feed small workpieces by hand.

Keep your hands away from dangerous area, allways guide the

workpiece or tool securely.

Assure yourself to keep your working tools always sharp and in

best working condition.

Defect or blunt tools pose a security risk.

Assure yourself, that all safety guards and safety devices of your

machine are working in best condition. Damaged Safety guards

have to be repaired before using the machine again.

Check the function of the machines Safety components like

Emergency OFF Buttons and Disconnectors in regular intervals.

Defect Safety components have to be replaced immediately.

Check the condition of the Safety signs and operation rule plates

on your machine. Replace missing or non-readable ones.

Before leaving the machine, shut it off and wait until the motor

and all rotating parts stop.

Form a habit to check that there are no tools, keys, wrenches ...

on the machine/tool before you start the machine.

Remove all accessories and tools from the machine before you

switch it on.

NEVER LEAVE MACHINE RUNNING UNATTENDED

REMOVE UNUSED TOOLS, KEYS, WRENCES

ENGLISH

ENGLISH

This metal turning lathe shall be used expicitly for turning and

drilling of metal and plastic materials suitable for chip removal.

The processing of other materials is not allowed!

never process magnesium - Burn Hazard!

Besides the information of this manual and the specic work safety rules valid in your country you should be familiar (through

proper education & experience) with the specic operation, safety and processing rules that have to be obeyed when working

with a metal lathe.

Do not wear gloves when working with the machine.

It might be catched in rotating parts and cause severe injuries.

Comply to the rules of max. workpiece diameter, length etc ...

Always check the fastening tool to be mounted properly so that

it cannot become loose.

Check the workpiece for being fastened correctly.

Use the lathe chucks within the frame they are designed.

Do not attempt to fasten workpieces with diameters that do not

match with the chuck. Do not overfasten the chuck.

Process only short workpieces without tailstock.

Additionally, if the workpiece length is more than 3 times the

workpiece diameter, the workpiece has to be secured with the

tailstock as well by all means.

Avoid the combination of short fastening diameters with big

machining diamterers.

Avoid short fastening lengths

Always be informed about the technical limitations of your tools.

Especially - never use a tool at turning speeds that lie above the

max. alowed turning speed of the tool.

Perform tapping, threading in general and the machining of non

centrally fastenend workpieces only at slow turning speeds.

2. SPECIFIC RULES

CORRECT USE

OBEY THE SPECIFIC WORK RULES FOR METAL LATHES

www.holzmann-maschinen.at

The workplace must have:

sufcient lighting conditions to prevent

shadows or eye strain.

a clean, level underground that is vibration resistent! We strongly recommend to

install the the metal lathe onto a solid,

vibration-resistent workbench.

enough place around the machine for safe

handling and feeding of the material.

A proper, compatible electric supply circuit.

Humidity: max. 90% for max. 25°C

max. 70% for max. 40°C

height above sea level: max. 1000m

Do not use the machine outdoors.

Do not use the machine in workplaces

with explosion and re hazard.

The work with a metal lathe always contains a certain risk that can never be eliminated entirely. This is a non complete shortlist indicating some of the most

dangerous remaining residual risks:

Risk of personal injury due to coming into

contact with the rotating workpiece or

rotating chuck.

Risk of personal injury through chips -

wear safety goggles.

Risk of electrocution when touching leading machine components.

Risk of personal injury by touching sharp

workpiece edges.

You can minimize these residual risks by

following all security, maintenance and

operation rules.

WORKPLACE REQUIREMENTS INAPPROPRIATE MACHINE USAGE

RESIDUAL RISKS

Any use that does not comply with the

security rules, maintenance guidelines or

operation rules described in this manual.

Any use that does not comply to max.

workpiece dimensions, max. turning

speed or other technical limitations.

The use of the machine by not sufciently trained persons in general.

HOLZMANN Maschinen cannot be made

liable for any damages to machine and

person being a direct or indirect consequence of inproper use of the machine.

ENGLISH

3. MACHINE SETUP

Remove the wooden crate around the lathe.

Check the contents of the shipping container:

ED 400FD metal lathe

Test Flow Chart

Toolbox

Contents of the Toolbox:

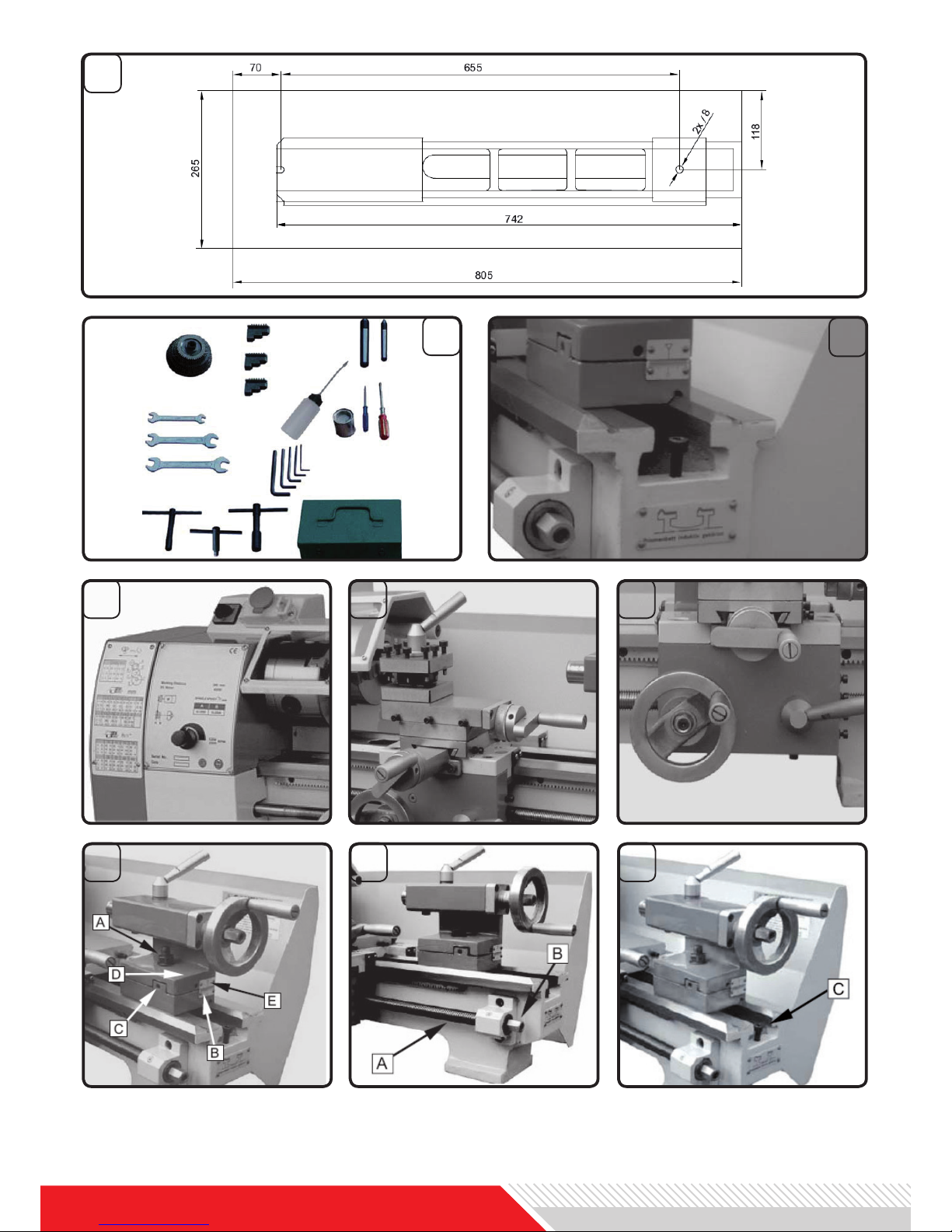

See Figure 2

1 Dead center MT3

1 Dead center MT2

3 External Jaws

1 Oil gun

1 Cross screwdriver

1 Flat screwdriver

1 Key for 3-Jaw chuck

5 Hex Socket wrenches

3 Double End Head Wrenches

1 Change Gears

Unbolt the lathe from the shipping crate

bottom.

Choose a location for the lathe that:

fulls all requirements from the security

section.

With adequate lifting equipment, slowly

raise the lathe off the shipping crate bottom.

DO NOT LIFT the machine by a spindle.

Make sure that the lathe is balanced before lifting it.

Lifting has to be performed by respectivel

trained persons.

ATTENTION

!

Read and understand the security and

Machine setup sections of this manual

before attempting to set-up the machine.

Failure to do so might result in machine

damage or even serious injuries!

CHECK DELIVERY CONTENT

SETTING TO WORKPLACE

To avoid twisting the bed, the lathe`s lo-

cation must be absolutely at and level.

Bolt the lathe to the stand (if used). If

using a bench, through bolt for best performance. Check Figure 1 for the boring

hole distances.

Clean all rust protected surfaces using

a mild commercial solvent, kerosene or

diesel fuel. Do not use paint thinner gasolone or lacquer thinner. These will damage painted surfaces. Cover all cleaned

surfaces with a light lm of 20W machine

oil.

Remove the end gear cover. Clean all

components of the end gear assembly

and coat all gears with a heavy, non-slinging grease.

Lubricate the machine at all lubrication

points and ll the oil reservoirs to operating level before placing the lathe into

service!

Instructions for lubrication can be found

in the maintenance section of this manual.

LUBRICATE ALL SLIDEWAYS LIGHTLY

BEFORE EVERY USE. LUBRICATE THE

CHANGE GEARS AND THE LEADSCREW

SLIGHTLY WITH A LITHIUM-BASED GREASE.

ENGLISH

www.holzmann-maschinen.at

4. MACHINE DESCRIPTION

The ED 400FD is a High Quality metal

turning lathe, especially designed for the

sophisticated private user but as well

for professional workshops requiring the

machine for processing small to middle

workpieces.

The lathe bed is made of high-grade iron

with low vibration and rigidity. It integrates the headstock and drive unit, for attaching the carriage and leadscrew. The

two precision-ground V-sideways, reenforced by heat hardening and grinding,

are the accurate guide for the carriage

and tailstock. The main motor is mounted

to the rear of the left side of the bed.

The headstock is cast from high grade,

low vibration cast iron. It is bolted to the

machine bed with four screws. The headstock houses the main spindle with two

precision taper roller bearings and the

drive unit.

The main spindle transmits the torque

during the turning process. It also holds

the workpieces and clamping devices

(e.g. 3-jaw chucks)

The carriage is made from high quality

cast iron. The slide parts are smoothly

ground. They t the V on the bed without

play. The lower slide parts can be easily

and simply adjusted. The cross slide is

mounted on the carriage and moves on

a dove tailed slide. Play in the cross slide

may be adjusted with the gibs.

Move the cross slide with the handwheel.

A four way tool post is tted on the top

slide and allows four tools to be clamped.

Loosen the center clamp handle to rotate

any of the four tools into position.

The apron is mounted on the bed. It

houses the half nut with an engaging lever for activating the automatic feed.

LATHE BED - FIG. 3

The half nut gibs can be adjusted from

the outside.

A rack, mounted on the bed, and a pinion

operated by handwheel on the carriage

allow for quick travel of the apron.

The leadscrew A is mounted on the front

of the machine bed. It is connected to

the gearbox at the left for automatic feed

and is supported by bearing on both ends.

The hex nut B on the right end is designed to take up play on the leadscrew.

The tailstock slides on a V way and can

be clamped at any location. The tailstock

has a heavy-duty spindle with a morse

taper MT2 socket and a graduated scale.

The spindle can be clamped at any location with a clamping lever. The spindle is

moved with a handwheel at the end of

the tailstock.

Fit the securing screw C at the end of the

lathe on order to prevent the tailstock

from falling off the lathe bed.

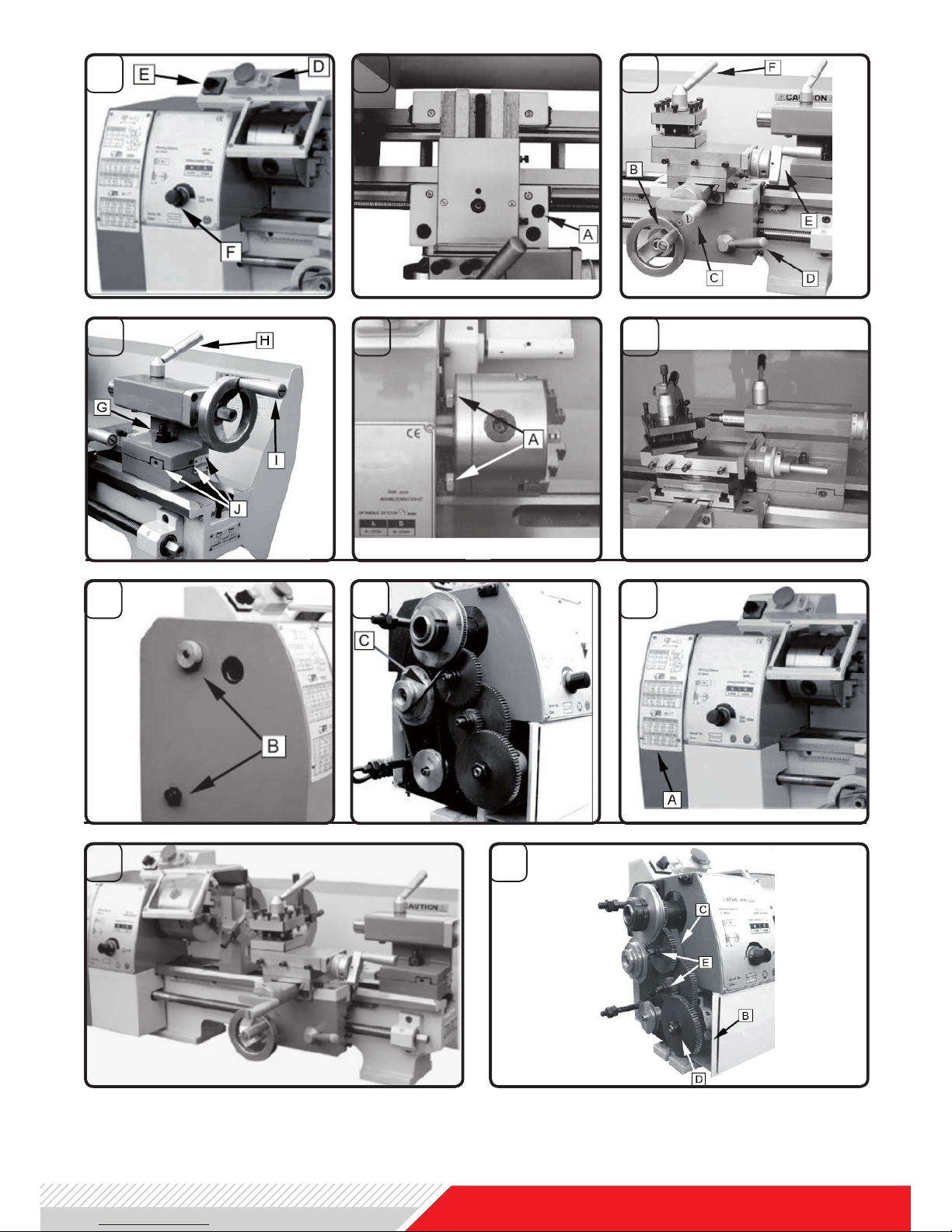

See gure 10, number D. The machine

can be switched on and off with the ON/

OFF button. Depress to stop all machine

functions. To restart, lift the cover and

press the green ON button.

See gure 10, number E. After the machine is switched on, turn the spindle direction switch E to the position „F“ for

counter clockwise rotation or to position

„R“ for clockwise spindle rotation. „0“ is

the OFF position and the spindle remains

idle.

See gure 10, number F. Turn the control knob clockwiese to increase and anti

clockwise to reduce the spindle speed.

The speed range depends from the drive

belt position.

CARRIAGE - FIG. 5

HEADSTOCK - FIG. 4

APRON - FIG. 6

LEADSCREW - FIG. 8

TAILSTOCK - FIG. 9

EMERGENCY BUTTON ON/OFF

SPINDLE DIRECTION SWITCH

VARIABLE SPEED CONTROL KNOB

ENGLISH

CARRIAGE LOCK - Fig. 11

Turn the hex socket cap screw A clockwise and tighten it to lock. Turn it counterclockwise to loosen and unlock.

CAUTION: The carriage lock screw must

be unlocked before engaging into automatic feeds! Otherwise machine damage

might occur.

See Figure 12, number B.

Rotate the handwheel clockwise to move

the apron assembly towards the tailstock

(right).

Rotate the handwheel counter-clockwise

to move the apron assembly towards the

headstock (left).

See Figure 12, number C.

Clockwise rotation moves the cross slide

towards the rear of the machine.

See Figure 12, number D.

Move the lever down to engage. Move

the lever up to disengage.

See Figure 12, number E.

Rotate the lever to move the compound

rest.

See Figure 12, number F.

Rotate counter-clockwise to loosen and

clockwise to tighten. Rotate the tool post

when the lever is unlocked.

See Figure 13, number G.

Turn hex nut clockwise to lock and counter-clockwise to unlock.

See Figure 13, number H.

Rotate the lever clockwise to lock the

spindle and counter-clockwise to unlock.

LONGITUDINAL TRAVERSE HANDWHEEL

CROSS TRAVERSE LEVER

HALF NUT ENGAGE LEVER

COMPOUND REST TRAVERSE LEVER

TOOL POST CLAMPING LEVER

TAILSTOCK CLAMPING SCREW

TAILSTOCK QUILL CLAMPING LEVER

See Figure 13, number I

Rotate clockwise to advance the quill.

Rotate counter-clockwise to retract the

quill.

See Figure 13, number J

Three set screws loacted on the tailstock

base are used to off-set the tailstock for

cutting tapers. Loosen lock screw on tailstock end. Loosen one side set screw while tightening the other until the amount

of off-set is indicated on scale. Tighten

lock screw.

TAILSTOCK QUILL TRAVERSE HANDWHEEL

TAILSTOCK OFF-SET ADJUSTMENT

ENGLISH

Loading...

Loading...