Page 1

PT300 Weighing System

Users Manual

Intercomp Co.

3839 County Road 116

Medina, MN 55340 U.S.A.

763-476-2531

800-328-3336

Fax: 763-476-2613

www.intercompcompany.com

Manual #: 700028-G

Page 1 of 44

Page 2

Table of Contents

INTRODUCTION ............................................................................................................................................................................4

Weights and Measures............................................................................................................................................................... 4

SPECIFICATIONS ..........................................................................................................................................................................5

C

ONTROLS

E

LECTRICAL

P

ERFORMANCE

E

NVIRONMENTAL

P

HYSICAL

R

ADIO (OPTIONAL

O

PTIONAL EQUIPMENT

SCALE OPERATIONS .................................................................................................................................................................... 8

O

PERATIONAL OVERVIEW

D

ISPLAY DESCRIPTION

C

ONTROLS

ON / OFF .................................................................................................................................................................................. 9

PRINT / ACCUMULATE........................................................................................................................................................... 9

LOCAL / TOTAL .....................................................................................................................................................................10

ZERO.......................................................................................................................................................................................10

T

OTALIZING SETUP

S

ERIAL OUTPUT SETUP

On-Demand .............................................................................................................................................................................12

Continuous ..............................................................................................................................................................................12

Data Format ............................................................................................................................................................................13

Accumulating Print..................................................................................................................................................................13

U

SING ACCUMULATED TOTAL

Accumulating Print Axle .........................................................................................................................................................13

Accumulating Print Standard .................................................................................................................................................. 14

A

CCUMULATING PROCEDURE

W

EIGHING PROCEDURES

T

ABLE 1: WEIGHING COMBINATIONS

T

YPICAL SCALE LAYOUTS

......................................................................................................................................................................................5

.................................................................................................................................................................................... 5

................................................................................................................................................................................ 5

...........................................................................................................................................................................5

........................................................................................................................................................................................6

).......................................................................................................................................................................... 6

...................................................................................................................................................................7

.............................................................................................................................................................. 8

...................................................................................................................................................................8

......................................................................................................................................................................................9

.......................................................................................................................................................................11

.................................................................................................................................................................12

......................................................................................................................................................13

:...................................................................................................................................................... 15

............................................................................................................................................................... 17

........................................................................................................................................... 18

............................................................................................................................................................ 19

MODE MENU .................................................................................................................................................................................20

M

ODE MENU

S

ETTING THE MODE MENU PARAMETERS

CABLED SCALE USAGE ............................................................................................................................................................. 24

T

OTALIZING/PRINTING IN CURRENT LOOP MODE

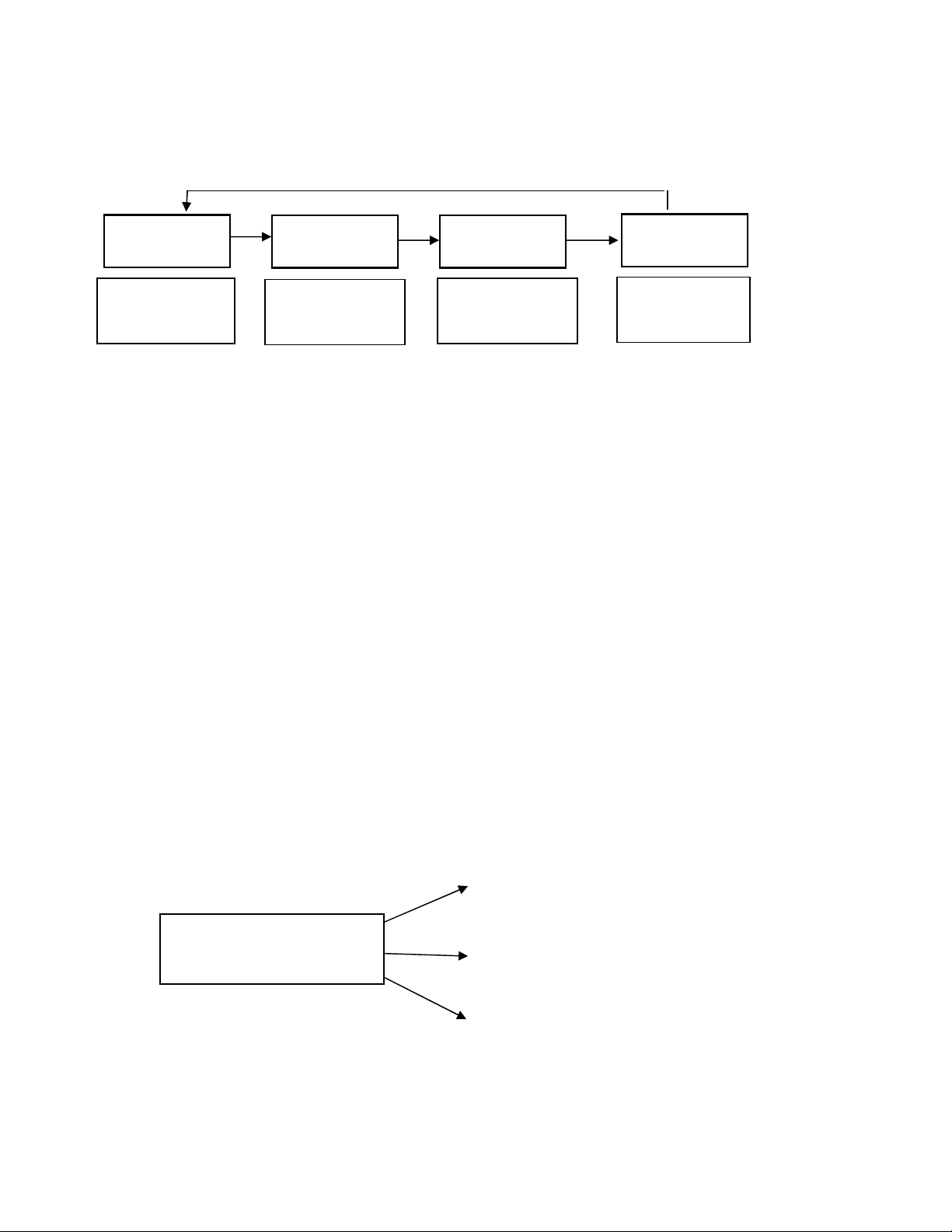

Example of Master/Slave designations....................................................................................................................................24

T

OTALIZING

P

RINTING

D

ATA INTERFACE

CALIBRATION ..............................................................................................................................................................................27

P

ROCEDURE: CALIBRATION (VERIFICATION

Check front/back load cell balance ......................................................................................................................................... 27

Scale Span Calibration............................................................................................................................................................28

P

ROCEDURE: CALIBRATION (ADJUSTMENT

Calibration Enable Jumper .....................................................................................................................................................30

C

ALIBRATION MENU

S

ETTING THE CALIBRATION PARAMETERS

Multiple Graduation Break Points .......................................................................................................................................... 32

W

EIGHT CALIBRATION

Corner Calibration (Both load cells) ...................................................................................................................................34

Corner Calibration (Single load cell) ..................................................................................................................................35

................................................................................................................................................................................. 20

.....................................................................................................................................21

.........................................................................................................................24

.................................................................................................................................................................................. 25

......................................................................................................................................................................................25

..........................................................................................................................................................................26

) ................................................................................................................................27

) .................................................................................................................................29

.....................................................................................................................................................................31

....................................................................................................................................32

.................................................................................................................................................................34

Page 2 of 44

Page 3

Span Calibration ..................................................................................................................................................................... 36

TROUBLESHOOTING ................................................................................................................................................................. 38

P

ROBLEM TABLE

E

RROR MESSAGES

D

IAGNOSTIC TESTS AND VOLTAGE MEASUREMENTS

Charger voltage.......................................................................................................................................................................40

Lamp........................................................................................................................................................................................ 40

Keys .........................................................................................................................................................................................40

Power down shutoff ................................................................................................................................................................. 40

Load Cells ...............................................................................................................................................................................40

Step Entries .............................................................................................................................................................................42

CONNECTOR ................................................................................................................................................................................43

HOW TO REACH INTERCOMP SERVICE .............................................................................................................................. 44

...........................................................................................................................................................................38

........................................................................................................................................................................39

..................................................................................................................... 40

"This document is the property of Intercomp Co. It contains material and

information that is confidential and protected under federal and/or state trade

secret, unfair competition, and copyright law. Any reproduction, use or

disclosure without written permission from Intercomp Co. is prohibited".

Page 3 of 44

Page 4

Introduction

Weights and Measures

The PT300 meets or exceeds class IIII standards for 400 division accuracy

from 0 lb to 20,000 lb. The certification was completed by the National Type

Evaluation Program (NTEP); in accordance with the National Institute of

Standards and Technology (NIST) Handbook 44. A NTEP Certificate of

Conformance Number 90-106P was issued under the National Conference of

Weights and Measures.

This operations manual describes the Intercomp Model PT300 platform specifications,

detailed operating procedures, and calibration.

This manual is separated into several sections, each containing information on a different

aspects of the scale. The specifications outline the design parameters for the scale. The

detailed operation section outlines the correct use of the scale for most applications. The

calibration section explains how to set the platform's adjustments.

Caution: Your PT300 scale is covered by a one year warranty and should be referred to the

factory for maintenance within the warranty period. Attempts to make any extensive repairs

within the warranty period may invalidate the warranty. If repairs are needed after the

warranty period, only qualified technicians should attempt such repairs.

PT300 Users manual

Rev G, Feb 2011

Features

lb or kg programmable readout.

Ability to display total weight.

Accumulating total function.

Auto zero tracking automatically corrects zero-weight display shifts.

5½ digit, 1 inch LCD readout, with automatic back lighting.

5-15 VDC and 120 VAC 60 Hz power sources standard.

RFI/EMI protection.

Low battery detection with automatic shutoff to protect batteries.

Built-in self-diagnostics to check: Load cells, Memory, Display, AD converter, and Power

supply.

Weigh pads manufactured from high strength aluminum alloys.

Page 4 of 44

Page 5

PT300 Users manual

Specifications

Controls

General On/Off, Print/Accumulate, Local/Total, Zero

Display 5 1/2 digit, 1 inch liquid crystal display (LCD), with automatic back

lighting.

Indicators: local weight, total weight, accumulated total weight

Electrical

Rev G, Feb 2011

Power source required

Charging Voltage 10 - 15 V DC.

Batteries

Charging Current 50 mA.

Charging Time 16 hours if the batteries are discharged.

Battery endurance Radio off: 400 hours with alkaline or NiMH

Filtering Adjustable averaging up to 30 seconds.

Auto-Zero Satisfies all HB-44 requirements.

5 - 15 VDC at battery input, 100-240 VAC when

using charger

4-AA size NiCd, NiMH, or alkaline cells.

150 hours of continuous use with Ni-Cads

Radio on: 300 hours with alkaline or NiMH

125 hours of continuous use with Ni-Cads

NOTE: For special setups that require a scale wireless

‘host’, that scale’s battery life is 40 hours (alkaline).

Performance

Speed 4 display updates per second

Accuracy

Calibration

interval

± 1% of reading or ± display graduation, whichever is greater.

Twelve months recommended

Environmental

Humidity 10 to 95% Non-Condensing.

Temperature Operating: -28 C to +65 C. / -20 F to +150 F.

Storage: -40 C to +75 C. / -40 F to +170 F.

EMI/RFI Meets Mil Spec 461

Page 5 of 44

Page 6

Physical

WARNING:

where the equipment should be used at distances greater than 20cm from

!

PT300 Users manual

Rev G, Feb 2011

Dimensions (PT300):

Weight (PT300): 37 lb / 16.8 kg

Dimensions (PT300DW): Overall: 3 x 26 x 20 in. / 76 x 660 x 508 mm

Weight (PT300DW): 49 lb / 22 kg

Overall: 3 x 16 x 20 in. / 76 x 406 x 508 mm

Pad: 12 x 12 in. / 305 x 305 mm

Pad: 22 x 14 in. / 559 x 356 mm

Radio (optional)

Radio frequency ISM 2.4GHz, 802.15.4

License requirements None. Pre-approved US/FCC, CAN/IC,

Range 200’ / 60m indoor, 300’ / 90m line of sight

the human body (with the exception of hands, wrists, feet, and ankles.

Operation at distances less than 20cm is strictly prohibited.

This equipment has been approved for mobile applications

EUR/CE

Page 6 of 44

Page 7

PT300 Users manual

Rev G, Feb 2011

Optional Equipment

PDA with Vehicle Weigh Software and Wireless Node (140661)

Laptop computer with Vehicle Weigh Software and Wireless Node (140667)

PT20 CPU (100540)

PT20 CPU Wireless Node (140659)

Charger and Cable (100480)

120/220V plug in transformer with internationals plugs, cable and PT connection.

2 scale carrying case (100047)

4 scale carrying case (100048)

6 scale carrying case (100049)

Interconnecting cable for 2 scales, 15 ft (101029)

Interconnecting cable for 4 scales (101032)

15, 25, 15 ft. spacing.

Interconnecting cable for 6 scales (101035)

15, 25, 15, 25, 15 ft. spacing.

Interconnecting/Charging Cable for 2 scales, 120/220V, international plugs (101030)

Interconnecting/Charging Cable for 4 scales, 120/220V, international plugs (101033)

Interconnecting/Charging Cable for 6 scales, 120/220V, international plugs (101036)

PT300 Dummy pad (100088)

Cast aluminum replica.

PT300DW Ramp (100072)

Page 7 of 44

Page 8

PT300 Users manual

Rev G, Feb 2011

Scale Operations

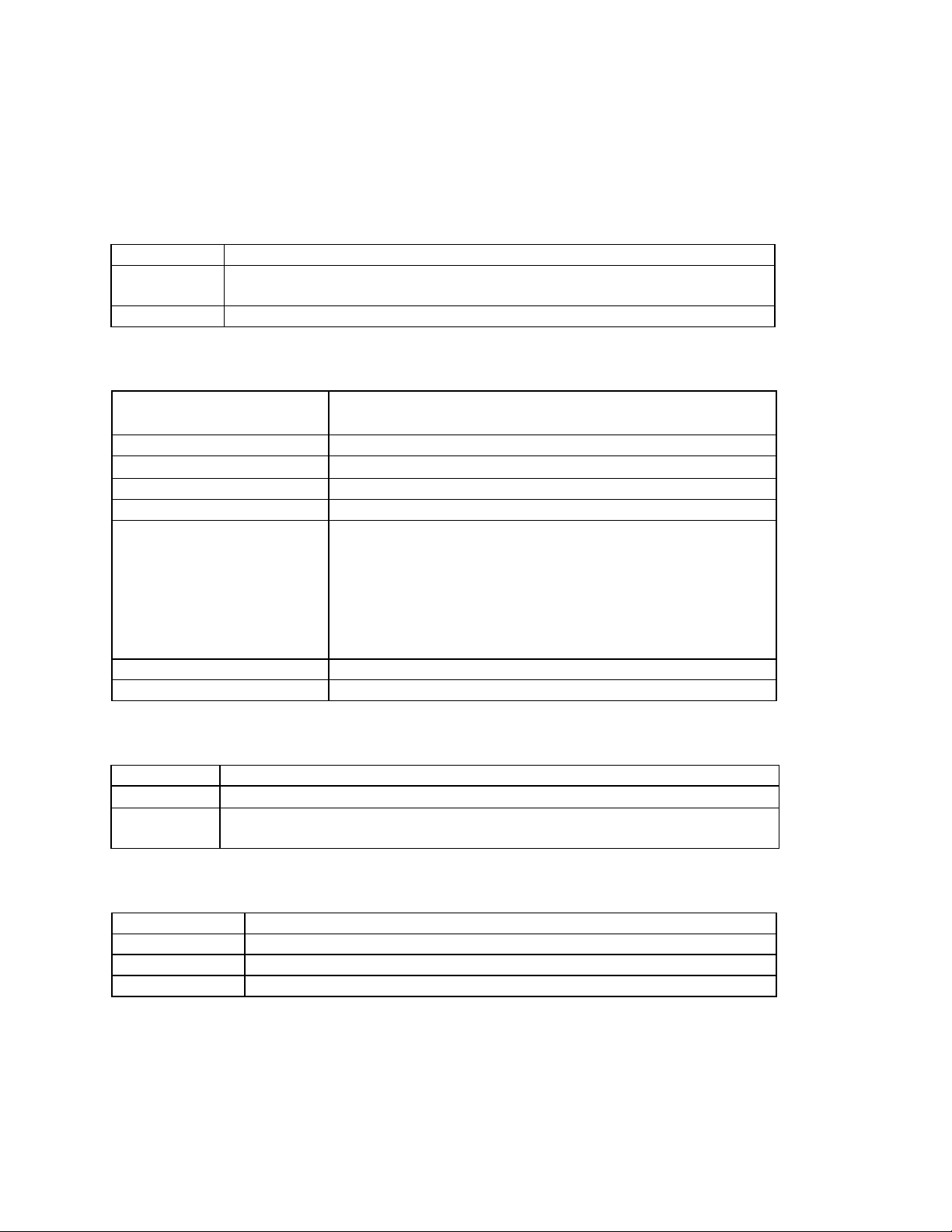

Operational Overview

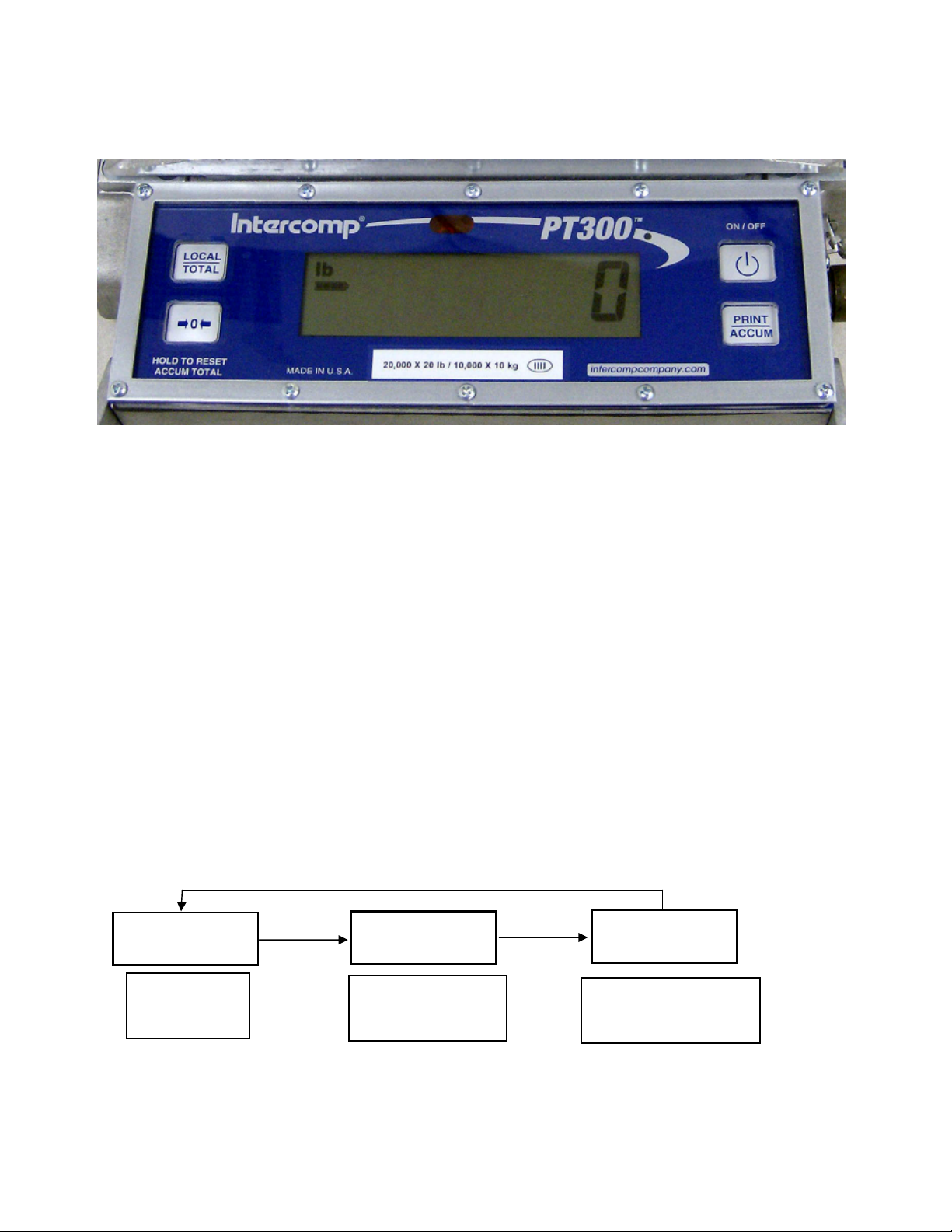

The control panel for the weighing platform is in the front section of the pad, along with the

electronics of the system. The control panel has a liquid crystal display (LCD) screen and several

control switches.

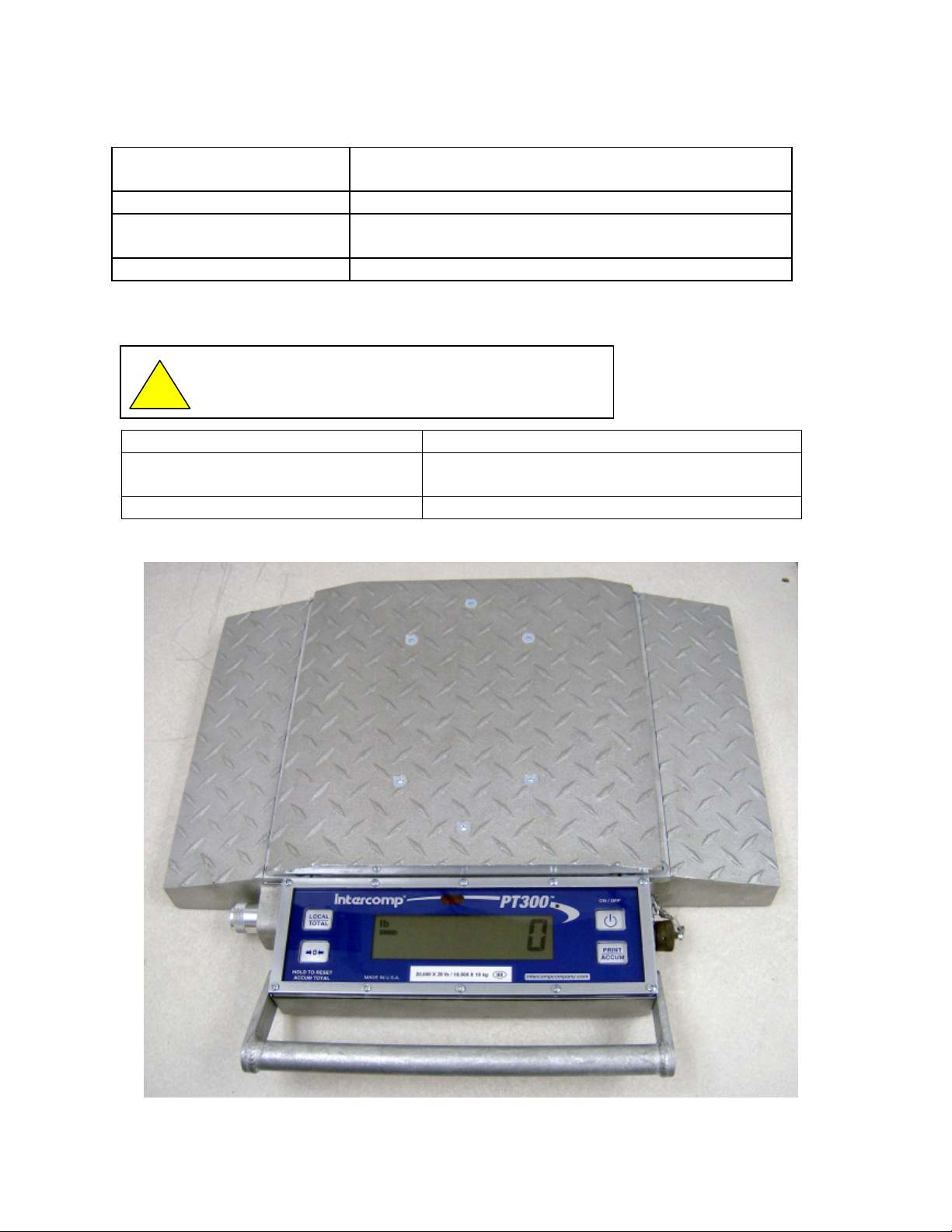

Display Description

The display is a Liquid Crystal Display unit, providing one line of 5 1/2 digits. The screen shows

the weights read from the pad. The TOTAL icon indicates measurement mode as in the table

below the PT300 display. Information displayed includes indicators for both “lb” and “kg”, a

segment bar to show battery charge level, error conditions and set-point indicators when set-point

thresholds are reached. The display contains an automatic backlight for use in low-light

conditions.

Mode status Setting

TOTAL not lit Local

TOTAL lit Total

TOTAL flashing Accumulated Total

Page 8 of 44

Page 9

Controls

2000

20002000

2000

5500

55005500

5500

P-03

P-03P-03

P-03

5 seconds

for 2 seconds

displayed for 1

ON / OFF

Press and hold this key to apply power to the weighing system electronics. Make sure to

hold this key until the display responds (up to 1 second). When power is first applied, the

weighing system rapidly performs self-tests of the pad and the internal electronics. When

the tests have completed successfully, the system begins weighing. If a problem is

detected, the screen displays an error message.

If the PT300 is powered up, press this button to turn the scale off. The PT300 retains the

setup information, and calibration in a special memory device (non-volatile memory) that is

not affected by power loss or battery condition.

PT300 Users manual

Rev G, Feb 2011

PRINT / ACCUMULATE

Press this button to print. When using the accumulated total function: press the PRINT /

ACCUMULATE button to add the total to the accumulated total. See section titled “Using

Accumulated Total”.

New accumulated total = total weight (all scales in system) + old accumulated total

Once a successful accumulation has a occurred, the scale will automatically toggle it’s display

to show the current weight, accumulated total, and number of accumulations.

current weight

displayed for

Note: The scale will not accumulate and will display the error message “Ac

current weight is negative, zero, or if the weight is in motion. These Protections are added

to ensure that only valid readings are accumulated into the total. Also, after a successful

accumulation, ALL scales in the system must return to zero before you accumulate the next

total accumulated

weight displayed

total number of

accumulations

Ac.Err

Err” if the

AcAc

ErrErr

Page 9 of 44

Page 10

PT300 Users manual

Rev G, Feb 2011

weight. If you attempt to accumulate the next weight before allowing the scale(s) to return

to zero, the error message “Ac

The accumulated total weight can be viewed only on the scale you are accumulating from.

After the PRINT/ACCUMULATE button is first pushed; the display will show “Ac. X” as the

system will accumulate the next reading and send it to print. (X will show the number of

accumulations this session) Once a successful accumulation has occurred, pressing the

LOCAL/TOTAL button will cycle the display to show number of accumulations, current local

weight, current total weight on all scales, and the accumulated total. When the local

weight, current total weight, or accumulated total is displayed, the total icon will be lit up,

flashing, or off. (as shown in the display description).

Ac.Err

Err” will be displayed.

AcAc

ErrErr

LOCAL / TOTAL

The local weight is the weight on that scale only. The total weight is the weight on all of the

scales in your system. Pressing the LOCAL / TOTAL button toggles between local weight

and total weight. The indicator bars (as shown in the display description) will show whether

the scale is displaying the local or total weight.

Note: If the system is not setup correctly, the “error” icon and message “t0t

displayed when trying to view the total weight. See section titled “Totalizing Setup”.

t0t” will be

t0tt0t

ZERO

Sets the weighing system to read zero pounds or kilograms. If pressed while a pad holds

weight, that weight becomes the zero condition for the pad. This can be useful to cancel

the weight of any weighing fixtures, such as tail cones or wheel chocks. When the weight

is removed, a negative weight displays until the system is re-zeroed. This switch is used

any time the scale shows a non-zero value with no weight on the pads.

Note: This system contains a feature called Auto Zero Tracking (AZT), which corrects for

slight zero changes during normal operation. An example of a zero change could be a

buildup of dirt on the pads.

Another function of the zero key is to clear the accumulated total. Press and hold the

ZERO key until the display reads “CLr

accumulated total and the accumulation number. All other scales you have connected will

also be zeroed through the interconnect cables. This allows you to zero your entire system

with one key press.

CLr.tttt“ and release the ZERO key. This will reset the

CLrCLr

Page 10 of 44

Page 11

PT300 Users manual

---04

---04---04

---04

01---

01---01---

01---

scale ID#

Rev G, Feb 2011

Totalizing Setup

This section covers configuring a scale set for either self-totalizing or connection to a PC/PDA

for advanced display features. For accumulating multiple weights on a scale or scale set, see

the “Using Accumulated Total” section. In ‘self-totalizing’ mode, the LOCAL/TOTAL button

works to switch between weight on that particular scale (LOCAL) and the total weight of

connected scales (TOTAL). If the system is not setup correctly, the “error icon” and message

“t0t

t0t “will be displayed when trying to view the total weight.

t0tt0t

1. To enter into totalizing setup: Simultaneously press the LOCAL/TOTAL and ZERO buttons.

2. Message “SCid

displayed with 3 dashes following it. This is the scale number (ID). Use the LOCAL/TOTAL

button to increment and the ZERO button decrement the number. When the desired

number is displayed, press the PRINT/ACCUMULATE.

3. Message “SCLS

will show three dashes and then a number. This number is the total number of scales in

the system. Use the LOCAL/TOTAL button to increment and the ZERO button decrement

the number. When the desired number is displayed, press the PRINT/ACCUMULATE

button. The maximum number of scales is 32.

4. If the scale# is ‘1’, the display will ask if the scale is the “HOSt

PRINT/ACCUMULATE button. Use the LOCAL/TOTAL or the ZERO button to toggle the

display “Yes

“yes” if the scale network consists of scales only. If your system uses an external device

such as a PDA or PC to view the weights, this setting should be set to “no” since the

external host controls the network. Press the PRINT/ACCUMULATE button to save the

setting.

Example 1 of correct scale settings: 4 pad system with PDA or PC:

Scale ID Number of Scales *Host setting

SCid” will be displayed. Press PRINT/ACCUMULATE button. A number will be

SCidSCid

SCLS” will be displayed. Press the PRINT/ACCUMULATE button. The display

SCLSSCLS

total # of scales

(only displayed on scale #1)

HOSt”. Press the

HOStHOSt

Yes” or “no

YesYes

no”. A ‘Host’ controls the scale network, and this setting should be set to

nono

Scale #1:

Scale #2:

Scale #3:

Scale #4:

[01---

01---] [---

01---01---

[00002222---

---] [---

------

[00003333---

---] [---

------

[00004444---

---] [---

------

---04

04] [ no

------

0404

---04

04]

------

0404

---04

04]

------

0404

---04

04]

------

0404

Page 11 of 44

no ]

nono

Page 12

PT300 Users manual

Example 2 of correct settings: 4 pad totalizing system using scales only:

Scale ID Number of Scales *Host setting

Rev G, Feb 2011

Scale #1:

Scale #2:

Scale #3:

Scale #4:

* Host setting is only available when scale ID is set to ‘01’

[01---

01---] [---

01---01---

[00002222---

---] [---

------

[00003333---

---] [---

------

[00004444---

---] [---

------

---04

04] [ yes

------

0404

---04

04]

------

0404

---04

04]

------

0404

---04

04]

0404

------

yes ]

yesyes

Serial Output Setup

There are three different serial output modes for the PT300, “on-demand”, “continuous”, and

“accumulating print”. The rest of this section provides more information on these modes.

To setup the serial output mode: Press the PRINT/ACCUMULATE and ZERO buttons

simultaneously until the display shows “bbbb.LitE

through the menu (12 times) until the display shows “Prt t

button once to display setting number. Set print mode to the number of the print mode wanted by

using the LOCAL/TOTAL button to increment and the ZERO button decrement the number. .

Communication Mode Setting

On-Demand 0

Continuous 1

Accumulating Print Axle 2

Accumulating Print Standard 3

Note: For best results, only set one scale to ‘1, ‘2 or ‘3. This should also be the scale you

are printing from. ‘0’ is the default setting.

Press the PRINT/ACCUMULATE button. Now the display will display “PbAUd

PRINT/ACCUMULATE button to change the baud rate set, press the LOCAL/ TOTAL or the

ZERO button to cycle through the baud rates available. The baud rates available are: 1200, 2400,

4800, 9600, 19200, 38400, 57600, and115200. When the desired baud rate is displayed, press

the PRINT/ACCUMULATE button. The baud rate only needs to be set on the scale doing the

printing. The settings are saved once PRINT/ACCUMLATE is pressed to advance the menu, and

the scale can then be turned off to exit the Mode Menu.

LitE”, Press the PRINT/ ACCUMULATE button to scroll

LitELitE

Prt t”. Press the PRINT/ACCUMULATE

Prt tPrt t

PbAUd”. Press the

PbAUdPbAUd

On-Demand

The weight is transmitted every time the PRINT/ACCUMULATE key is pressed. Press

PRINT/ACCUMULATE to print either the local or total weight (depending on the local/total

setting of the scale). This is the default print mode.

Continuous

The PT300 automatically and continuously outputs the weight at a rate of about once per

second.

Page 12 of 44

Page 13

PT300 Users manual

Rev G, Feb 2011

Data Format

When the serial output is set to either on-demand or continuous mode, the

transmitted data is in the format shown below:

AAAAAAA BB<cr><lf>

Item Meaning ASCII Hex ASCII Decimal

AAAAAAA weight

BB units “lb” or “kg”

<cr> carriage return 0D 13

<lf> linefeed 0A 10

The AAAAAAA field will vary in length depending on the length of the number and

could contain a decimal point and/or a minus sign. The weight will either be local

weight or total weight, depending on which mode you’re in.

Accumulating Print

See section titled “Using Accumulated Total” for both the Axle and the standard formats.

Using Accumulated Total

The PT300 platforms can be used separately, in pairs, or in groups to measure a support load or

the total weight in one measuring procedure.

To use the Accumulated Total feature, the scales need to be numbered correctly and the scale

you intend to print from or display the accumulated total must have it’s print mode set to one of

two ‘Accumulating Print’ modes. See the “Totalizing Setup” and “Serial Output Setup” sections for

details.

Accumulating Print Axle

Press the PRINT/ACCUMULATE button to add the current total weight to the accumulated

total weight. At the same time, a print ticket will be generated (assuming you have a printer

in the system). The print ticket format is in respect to a vehicle’s individual wheels and

axles or a standard weight accumulation mode.

For example wheel and axle, think of “WHL 1” as scale 1

and “AXL 1” as the total weight of scale 1 and scale 2.

The following print ticket example is a 4 scale system:

PRINT / ACCUMULATE

button has been pressed

PRINT / ACCUMULATE

button has been pressed

WHL 1: 7460 WHL 2:

7400

AXL 1: 14860

WHL 3: 10110 WHL 4:

10070

AXL 2: 20180

SUBTOTAL GRP 1: 35040

ACCUM TOTAL: 35040

WHL 1: 10110 WHL 2:

10070

AXL 1: 20180

WHL 3: 9800 WHL 4:

9500

AXL 2: 19300

SUBTOTAL GRP 2: 39480

ACCUM TOTAL: 74520

Page 13 of 44

Page 14

PT300 Users manual

scale

scales

this session

10110

1011010110

10110

this session

AC

ACAC

AC

.

2

2 2

2

39480

3948039480

39480

74520

7452074520

74520

Rev G, Feb 2011

Once a successful accumulation has occurred, press the LOCAL/TOTAL button to toggle

the display through the current local weight, current total weight, accumulated total, and the

number of accumulations that make up the total.

Current local

weight on this

Note: The scale will not accumulate and will display the error message “Ac

current weight is negative, zero, or if the weight is in motion. These Protections are added

to ensure that only valid readings are accumulated into the total. Also, after a successful

accumulation, ALL scales in the system must return to zero before you accumulate the next

weight. If you attempt to accumulate the next weight before allowing the scale(s) to return

to zero, the error message “Ac

The accumulated total weight can be viewed only on the scale you are accumulating from.

After the PRINT/ACCUMULATE button is first pushed; the display will show “Ac. X” as the

system will accumulate the next reading and send it to print. (X will show the number of

accumulations this session) Once a successful accumulation has occurred, pressing the

LOCAL/TOTAL button will cycle the display to show number of accumulations, current local

weight, current total weight on all scales, and the accumulated total. When the local

weight, current total weight, or accumulated total is displayed, the total icon will be lit up,

flashing, or off. (as shown on page)

Current total

weight on all

Ac.Err

AcAc

Err” will be displayed.

ErrErr

Total weight of

accumulations

Total number of

accumulations

Ac.Err

AcAc

Err” if the

ErrErr

Accumulating Print Standard

A standard accumulation shows total weight of multiple items weighed on 1 or more scales.

The following print ticket example is a 1 scale system after 3 items are weighed: (950lb,

1000lb, and 1500lb)

950 lb

ACCUM TOTAL: 950 lb

PRINT/ACCUMULATE

has been pressed

1000 lb

ACCUM TOTAL: 1950 lb

1500 lb

ACCUM TOTAL: 3450 lb

Page 14 of 44

Page 15

PT300 Users manual

scale

scales

this session

1500

15001500

1500

this session

AC

ACAC

AC

.

3

3 3

3

1500

15001500

1500

3450

34503450

3450

Rev G, Feb 2011

Once a successful accumulation has occurred, press the LOCAL/TOTAL button to toggle

the display through the current local weight, current total weight, accumulated total, and the

number of accumulations that make up the total.

Current local

weight on this

Note: The scale will not accumulate and will display the error message “Ac

current weight is negative, zero, or if the weight is in motion. These Protections are added

to ensure that only valid readings are accumulated into the total. Also, after a successful

accumulation, ALL scales in the system must return to zero before you accumulate the next

weight. If you attempt to accumulate the next weight before allowing the scale(s) to return

to zero, the error message “Ac

The accumulated total weight can be viewed only on the scale you are accumulating from.

After the PRINT/ACCUMULATE button is first pushed; the display will show “Ac

system will accumulate the next reading and send it to print. (X will show the number of

accumulations this session) Once a successful accumulation has occurred, pressing the

LOCAL/TOTAL button will cycle the display to show number of accumulations, current local

weight, current total weight on all scales, and the accumulated total. When the local

weight, current total weight, or accumulated total is displayed, the total icon will be lit up,

flashing, or off. (as shown in the display description).

Note: In print-mode 3 it can accumulate either in local or total weight, but not when viewing

the accumulated total.

To clear the accumulated total weight, press and hold the ZERO button until the display

shows “CLr

CLr.tttt“.

CLrCLr

Current total

weight on all

Ac.Err

AcAc

Err” will be displayed.

ErrErr

Total weight of

accumulations

Total number of

accumulations

Ac.Err

AcAc

Err” if the

ErrErr

Ac. X” as the

AcAc

Accumulating Procedure:

1. With your system setup correctly, decide which scale you will accumulate from. This can be

2. With the first group of items stable on the scales, press the PRINT/ACCUMULATE button. If

any scale, but once you choose, you must only accumulate with that scale until the weighing

is complete. This scale needs to be set to your desired accumulate mode, 2 or 3 (See “Serial

Output Setup”). If you are using a printer, select the scale directly connected to the printer.

you are using a printer, a print ticket with all weights will now be printed. The display will

return to the setting that the accumulation was taken from. This first group’s weight will

become the accumulated total, which can be seen on the display by pressing the

LOCAL/TOTAL button as described in the previous section with the TOTAL icon flashing.

Another accumulation can not be made in the standard mode if the scale is in the

Page 15 of 44

Page 16

PT300 Users manual

Rev G, Feb 2011

Accumulation Print mode. (TOTAL icon flashing). After accumulation, remove the first group

of items from the scale(s).

3. With the next group of items stable on the scale(s), press the PRINT/ACCUMULATE button.

This will add the total weight to the accumulated total. If you are using a printer, a print ticket

with all weights will now be printed.

4. Repeat step 3 as needed. If the accumulated total becomes too large to display, the “diSP

diSP”

diSPdiSP

message and error icon will be displayed.

5. When finished, you may clear the accumulated total weight by pressing and holding the ZERO

button until the display show “CLr

CLr.tttt“. The display will clear the accumulated total and the

CLrCLr

number of accumulations.

Note: The scale will not accumulate when the weight is negative, zero, or if the weight is in

motion. A display message “Ac

Ac.Err

Err” with error icon will be displayed if any of those

AcAc

ErrErr

conditions are present. After a successful accumulation the scale must return to zero

before you accumulate the next weight. If you attempt to accumulate the next weight

before allowing the scale to return to zero, a display message “Ac

Ac.Err

Err” with error icon will

AcAc

ErrErr

be displayed.

Page 16 of 44

Page 17

PT300 Users manual

Rev G, Feb 2011

Weighing procedures

The PT300 platforms can be used separately, in pairs, or in groups of 4, 6, or more to measure

a support load, wheel load, axle load, axle group load, or the total weight of a multi-axle truck

in one measuring procedure.

Ideally, all wheels of a vehicle should be measured at the same time in order to avoid

measuring errors due to the suspension system.

If you are not able to weigh the wheels of a tandem or triple axle simultaneously, the difference

in height must be compensated for by using dummy plates (grids, wood or rubber plates) of the

same height. The wheel load scales are put in front of the wheels of a vehicle, the driver then

drives on the scales/plates and stops within the active weighing area. To avoid improper

weighing which might be caused by wheel or axle load displacements, the vehicle brakes

should be released before reading the weight values.

NOTES:

1. It is recommended to weigh the wheels of one axle at the same time.

2. The dummy plates can be omitted if the scales are embedded in recesses in the road surface

at the same levels as the road surface.

Please see tables on the following page

Page 17 of 44

Page 18

Table 1: Weighing Combinations

PT300 Users manual

Rev G, Feb 2011

Page 18 of 44

Page 19

Typical Scale Layouts

PT300 Users manual

Rev G, Feb 2011

Page 19 of 44

Page 20

PT300 Users manual

Rev G, Feb 2011

Mode Menu

Mode Menu

To access the mode menu simultaneously press the PRINT/ACCUMULATE and ZERO buttons.

The display will show “bbbb.LitE

scale is in the RUN position. (shorting pins 2 and 3(RUN)

At times it will be necessary to enter up to a five digit number. When this is necessary the current

number will be displayed with the right most digit flashing. The flashing digit may be incremented

by pressing the LOCAL/TOTAL button. To move one digit to the left, press the ZERO key. When

you have finished entering a number press the PRINT/ ACCUMULATE button. The settings are

saved once PRINT/ACCUMLATE is pressed to advance the menu, and the scale can then be

turned off.

Step Function Note

bbbb.LitE

LitE

LitELitE

SEtP1

SEtP1

SEtP1SEtP1

SEtP2

SEtP2

SEtP2SEtP2

vEr

vEr.

vErvEr

AAAA. rt

rt

rtrt

AAAA.tHrS

tHrS

tHrStHrS

A off

A off

A offA off

Prt t

Prt t

Prt tPrt t

Pbaud

Pbaud

PbaudPbaud

Units

Units

UnitsUnits

Proto

Proto

ProtoProto

iiii.baud

baud

baudbaud

radio

radio

radioradio

Rf CH

Rf CH

Rf CHRf CH

Rf

Rf.pan

pan

RfRf

panpan

Rf

Rf.eCp

eCp

RfRf

eCpeCp

Rf

Rf.def

def

RfRf

defdef

LitE”. If it doesn’t, go to Calibration Enable Jumper section and verify the

LitELitE

Default

Backlight

Set Point 1 0 to 199999

Set Point 2 0 to 199999

Firmware Version View only XXXXX

Average rate 1 to 120

Average threshold 1 to 10000

Auto off 000 = off, 1 to 240

Print Mode 0 = On-demand, 1 = Continuous,

Printer baud rate 1200, 2400, 4800, 9600, 19200,

Measurement units lb or kg lb

Protocol

Interface baud rate 9600 or 115200

Radio Enable Yes or no

Radio Channel 01 to 12

Radio Network ID 0 to 65534

Radio encryption enable Yes or no

Radio Encryption Key 0 to 65534

Restore Radio Defaults 0 or 3

Auto

Auto, on

on, oFF

AutoAuto

2 = Accumulating Total Axle,

3 = Accumulating Total Standard

or 38400, 57600, 115200

StAnd

StAnd, Lo Pr

StAndStAnd

oFF

onon

oFFoFF

Lo Pr, CCCC.L00P

Lo PrLo Pr

L00P, or none

L00PL00P

none

nonenone

Auto

Auto

AutoAuto

199999

199999

199999199999

199999

199999

199999199999

008

008

008008

200

200

200200

060

060

060060

0000

9600

9600

96009600

Lo Pr

Lo Pr

Lo PrLo Pr

9600

9600

96009600

no

no

nono

1111

8000

8000

80008000

no

no

nono

00000

00000

0000000000

0000

Page 20 of 44

Page 21

PT300 Users manual

Rev G, Feb 2011

Setting the Mode Menu Parameters

1. Simultaneously press the PRINT/ACCUMULATE and ZERO buttons. The display will show

“bbbb.LitE

LitE”. Press the PRINT/ACCUMULATE button. The flashing display shows the current

LitELitE

setting. Press the ZERO or the LOCAL/TOTAL buttons to toggle between Auto, on, and

off. With ‘Auto’ selected (default), the backlight will automatically light up when low level

light conditions are detected. When the desired setting is displayed, press the PRINT/

ACCUMULATE button.

2. The display will show “SEtP1

shows the current setting. When the weight displayed is equal to or greater than the set

point, the corresponding icon is displayed on the LCD. During normal weighing mode, the

S1 icon on the display will light when the weight is greater than or equal to set point 1. Use

the LOCAL/TOTAL button the advance the number and the ZERO button to move the

number flashing to the left. When the display shows the desired number, press the

PRINT/ACCUMULATE button.

3. The display will show “SEtP2

shows the current setting. During normal weighing mode, the S2 icon on the display will

light when the weight is greater than or equal to set point 2. Use the LOCAL/TOTAL button

the advance the number and the ZERO button to move the number flashing to the left.

When the display shows the desired number, press the PRINT/ACCUMULATE button.

4. The display will show “vEr

show the current version of firmware loaded in the scale. Press the PRINT/ACCUMULATE

button.

5. The display will show “AAAA. rt

shows the current setting. This number is how many readings will be averaged together

before the reading is sent to the display. Higher values will result in a more stable reading,

but will take longer to settle to the final value. Note that the scale updates at 4Hz, so an

Average Rate of ‘8’ equates to 2 seconds of averaging. Enter a ‘1’ to effectively disable

averaging. Use the Lb/Kg button the advance the number and the ZERO button to move

the number flashing to the left. When the display shows the desired number, press the

PRINT/ACCUMULATE button.

6. The display will show “AAAA.tHrS

shows the current Average Threshold setting. This setting enables dynamic averaging,

which can improve the settling time of a large Average Rate. If the scale senses a large

weight change, it will temporarily suspend averaging, jump to the new weight, and resume

averaging. Enter a value of 1-10000 to set the threshold (in display divisions) at which the

dynamic averaging triggers. Enter ‘0’ to disable dynamic averaging. When disabled, the

averaging will never be suspended. When the display shows the desired number, press

the PRINT/ACCUMULATE button.

7. The display will show “AAAA. oFF

shows the current setting. The number displayed is the minutes that the scale can remain

idle before it automatically shuts down. Setting this number to “000

SEtP1”. Press the PRINT/ACCUMULATE button. The flashing digit

SEtP1SEtP1

SEtP2”. Press the PRINT/ACCUMULATE button. The flashing digit

SEtP2SEtP2

vEr”. Press the PRINT/ACCUMULATE button and the display will

vErvEr

rt”. Press the PRINT/ACCUMULATE button. The flashing digit

rt rt

tHrS”. Press the PRINT / ACCUMULATE button. The flashing digit

tHrStHrS

oFF”. Press the PRINT/ACCUMULATE button. The flashing digit

oFF oFF

000” will disable the

000000

Page 21 of 44

Page 22

function, meaning the scale will never shut itself off. Use the LOCAL/TOTAL button the

advance the number and the ZERO button to move the number flashing to the left. When

the display shows the desired number, press the PRINT/ACCUMULATE button.

8. The display will show “Prt t

Prt t”. Press the PRINT/ACCUMULATE button. The flashing digit

Prt tPrt t

shows the current setting. The number enables the scales different print modes. (0 for ondemand, 1 for continuous, 2 for accumulating total axle format, and 3 for accumulating total

standard format) Use the LOCAL/TOTAL button to increment and the ZERO button to

decrement the number. When the display shows the desired number, press the

PRINT/ACCUMULATE button.

9. The display will show “PbAUd

PbAUd”. Press the PRINT/ACCUMULATE button. The flashing

PbAUdPbAUd

display shows the current setting of the printer baud rate. The baud rates available are:

1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200. Use the LOCAL/TOTAL

button or the ZERO button to toggle through the available rates. When the display shows

the desired number, press the PRINT/ACCUMULATE button.

10. The display will show “UnitS

UnitS”. Press the PRINT/ACCUMULATE button. The lb or the kg

UnitSUnitS

icon will flash in the upper left of the display. This will set the scale to measure pounds (lb)

or kilograms (kg). Use the LOCAL/TOTAL button or the ZERO button to toggle between

the settings. When the desired icon is flashing, press the PRINT/ACCUMULATE button.

11. The display will show “Proto

Proto”. Press the PRINT/ACCUMULATE button. The flashing

ProtoProto

display shows the current setting. There are 4 protocol settings for the scale, Standard

(“StAnd

StAnd”), Low Power (“Lo Pr

StAndStAnd

Lo Pr”), Current Loop (“CCCC.L00P

Lo PrLo Pr

Standard is a setting for use in specific wireless and wired scale networks. Low Power

will significantly improve the wireless battery life for all non-‘host’ scales (maximum number

of scales in this mode is 32).

Current Loop is used when connecting to older legacy PT300 scales. The legacy cables

(part #’s 100488, 100489, or 100490) must be used when in this communication mode.

See section titled “Totalizing/Printing in Current Loop Mode” for more information.

When scales are not part of a totalizing network, battery life will be improved if “nonE

chosen. Use the LOCAL/TOTAL button or the ZERO button to cycle through the settings.

When the desired protocol is flashing, press the PRINT/ ACCUMULATE button.

12. The display will show “iiii.bAud

bAud”. Press the PRINT/ACCUMULATE button. The display will

bAudbAud

show the current setting flashing. This is the setting of the interface baud rate. There are

two settings available, 9600 and 115200. Use the LOCAL/TOTAL button or the ZERO

button to toggle between the settings. When the desired baud rate is flashing, press the

PRINT/ ACCUMULATE button.

13. The display will show “rAdio

rAdio”. Press the PRINT/ACCUMULATE button. The display will

rAdiorAdio

show the current setting flashing. This is the radio enable status and is either on or off.

Use the LOCAL/TOTAL button or the ZERO button to toggle between the settings. When

the desired status is flashing, press the PRINT/ ACCUMULATE button. If you select “no”

the scale will skip the rest of the settings and return to normal weighing.

L00P”), or “None

L00PL00P

None”.

NoneNone

PT300 Users manual

Rev G, Feb 2011

nonE” is

nonEnonE

Page 22 of 44

Page 23

14. The display will show “rF CH

rF CH”. Press the PRINT/ACCUMULATE button. The flashing digit

rF CHrF CH

shows the current setting. All scales in a system must be set to the same radio channel

setting in order to communicate with each other. Use the LOCAL/TOTAL button to

increment and the ZERO button to move the number flashing to the left. When the display

shows the desired number, press the PRINT/ACCUMULATE button.

15. The display will show “rF

rF.PAn

PAn”. Press the PRINT/ACCUMULATE button. The display will

rFrF

PAnPAn

show the current setting with the number on the right flashing. All scales in a system must

be set to the same Personal Area Network ID setting in order to communicate with each

other. Use the LOCAL/TOTAL button to increment and the ZERO button to move the

number flashing to the left. When the display shows the desired number, press the

PRINT/ACCUMULATE button.

16. The display will show “rF

rF.ECP

ECP”. Press the PRINT/ACCUMULATE button. The display will

rFrF

ECPECP

show the current setting flashing. This is the encryption enable status and is either on or

off. Use the LOCAL/TOTAL button or the ZERO button to toggle between the settings.

When the desired status is flashing, press the PRINT/ ACCUMULATE button. If “Yes

selected go to the next step. If “no

17. The display will show “00000

00000” with the number on the right flashing. Use the

0000000000

no” was selected got to step 17.

nono

LOCAL/TOTAL button to increment and the ZERO button to move the number flashing to

the left. Enter any number from 0 to 65534. This is the encryption key. For security

purposes, this setting is not accessible to view and will always show as “00000

don’t want to change the key enter “00000

00000” to leave it unchanged. All scales in a system

0000000000

must be set to the same encryption key setting in order to communicate with each other.

When the desired encryption key is displayed, press the PRINT/ ACCUMULATE button.

18. The display will show “rF

rF.dEF

dEF”. Press the PRINT/ACCUMULATE button. The display will

rFrF

dEFdEF

show “0000” with the number flashing. Use the LOCAL/TOTAL button to increment and the

ZERO button to decrement the number. Setting the number to 3 will restore the default

radio settings. All other numbers will have no affect on the radio set-up. When the desired

number is flashing, press the PRINT/ ACCUMULATE button. The scale will return to

normal weighing.

If the scale does not have the radio option installed, the “rF CH

rF CH”, “rF Pan

rF CHrF CH

Encryption key will be view only.

PT300 Users manual

00000”. If you

0000000000

rF Pan”, “rF ECP

rF PanrF Pan

rF ECP” and the

rF ECPrF ECP

Rev G, Feb 2011

Yes” was

YesYes

Page 23 of 44

Page 24

Cabled Scale Usage

Legacy PT300

PT300 Users manual

Rev G, Feb 2011

Totalizing/Printing in Current Loop Mode

To use your next generation PT300 scales with the older legacy PT300 scales, the scales need to

be set to Current Loop (“CCCC.L00P

Before you attempt to do either of these, a few terms and definitions must be understood. These

terms only apply to scales that are cabled together. Also, legacy cables (part #’s 100488,

100489, 100490) are wired differently than the next generation PT300 cables (part #’s 101029,

101032, 101035) and must be used in Current Loop communication mode.

Master Scale: If more than one scale is being used, the first scale in line is referred to as

the Master Scale. Normally these scales have continuous output, If you requested a

demand output use the print button on this scale when printing or totalizing.

Slave Scale: If more than one scale is being used, any scale that is not the master scale

is referred to as a Slave Scale.

Master Slave Slave Slave

scale A scale B scale C scale D

L00P”) mode. Change the protocol (“Proto

L00PL00P

Proto”) option in the mode menu.

ProtoProto

Printer

Example of Master/Slave designations

The master and slave designations are determined by the cable and not the scale itself. The cable

also determines if the scale transmits data on demand (when the print button is pushed) or

continuously. If continuous, the print button doesn't have to be activated to totalize or print.

Please refer to the cabling diagrams

Page 24 of 44

Page 25

PT300 Users manual

Rev G, Feb 2011

Totalizing

When more than one scale is being used, the last one in line can be used to show the total

weight of all the scales added together. To totalize, turn on the scales in sequential order

starting with the master scale (“scale A") and make sure all of the slave scales are in the total

mode. The indicating bar on the upper left side of the display is on when in the total mode. This

does not mean that the scale is receiving; only that it is capable of receiving.

If transmitting on demand, press the print button on the master scale and the last scale in line

(slave scale D in the diagram) will show the total weight of all the scales.

Example: Scale A will display the total of A only.

Scale B will display the total of A + B.

Scale C will display the total of A + B + C.

Scale D will display the total of A + B + C + D.

Printing

Use the print button on the master scale when printing. If more than one scale is being used,

put the slave scale(s) in the total mode. This will allow the printer to print the total weight of all

the scales.

NOTE: The important thing to remember is that the printer will print whatever is displayed

on the last scale in line before the printer.

In addition to the weight, the printer will print a letter that signifies the number of scales that it

printed the weight from.

Example: The letter A signifies the weight is from one scale. The letter B signifies the weight is

from two scales etc..

Page 25 of 44

Page 26

PT300 Users manual

Rev G, Feb 2011

Data Interface

Serial ASCII

20 mA current loop, active or passive. (The PT300 supplies the current for active current loop,

and an external current is used for passive current loop. Passive is preferred for longer battery

use between charges.)

1200 Baud

8 data bits

1 start bit

2 stop bits

no parity

M Kg

Transmission Format: A_O_-XXXXXXX._Lb<CR><LF>

Z

Format explanation: A = Scale code (Signifies the scale, could be

A for scale A, B for scale B etc..)

Space

M,O,Z = Error code (M = motion, O = over-capacity,

Z = zero, space = no error)

Space

Minus sign if negative, space if positive.

8 data bits

Space

Pounds/Kilograms

Carriage return

Line feed

Page 26 of 44

Page 27

PT300 Users manual

1

2

Rev G, Feb 2011

Calibration

Note: The PT300 scale is calibrated by the factory prior to shipment.

Note: The calibration will achieve the best accuracy if calibration loads are applied to PT300

platform through a metal block, separated from the platform by a thick piece of firm rubber; this

setup best simulates the load applied by a tire. Loading without a block can damage the scale.

See Tool List below for complete specifications.

Procedure: Calibration (Verification)

Check front/back load cell balance

Tools required

Twenty thousand pound calibration press.

1.5" x 1.5" x 12" aluminum loading block.

Static dissipation station.

#2 Phillips screwdriver for bezel and board mounts.

Small slotted blade screwdriver.

Torque-seal potentiometer shaft sealer.

Caution:

The following procedure must be performed at a static controlled workstation.

Load cell locations used in the following procedure are shown below.

Load Cell Placement

Page 27 of 44

Page 28

PT300 Users manual

Rev G, Feb 2011

1. Position the corner fixture with rubber pad on the scale position #1. Apply 2500 lbs to the

loading block. Annotate the reading.

2. Repeat for the #2 position.

3. If all readings are within 5 pounds and the previous calibration passed all of the readings

continue with the rest of the calibration verification. If the corner check fails go to the corner

adjust calibration procedure.

Scale Span Calibration

Tools required:

•

Calibration force generator; press or deadweights. This calibration source must cover the

range of 10% to 100% of nominal capacity with an accuracy of 0.25% of reading or better.

PT300

•

100027 - 8" (± 0.25") x 8" (± 0.25") x 1.75" (minimum) aluminum loading block.

•

100028-A - 8" (± 0.25") x 8" (± 0.25") x 0.5" (± 0.125") rubber loading scale. (40 to 70 Shore A

rating)

PT300DW

•

100029

•

100030-A

A rating)

4. Bring the scales to the calibration site. If there is more than 5°F difference in temperature

between the scale temperature and the calibration site allow the scales to reach room

temperature.

5. Place scale on calibration fixture. Turn scale on. Wait 3 minutes for warm-up.

6. Apply test forces every 10% of the scales capacity and verify that the reading falls within 1% of

the applied force or 1 display division whichever is greater as shown in the sample table below.

7. If any value is out of acceptable limits proceed to the adjust calibration procedure.

8. If all values are within acceptable limits unit passes calibration verification.

- 12" (± 0.25") x 12" (± 0.25") x 1.75" (minimum) aluminum loading block.

- 12" (± 0.25") x 12" (± 0.25") x 0.5" (± 0.125") rubber loading scale. (40 to 70 Shore

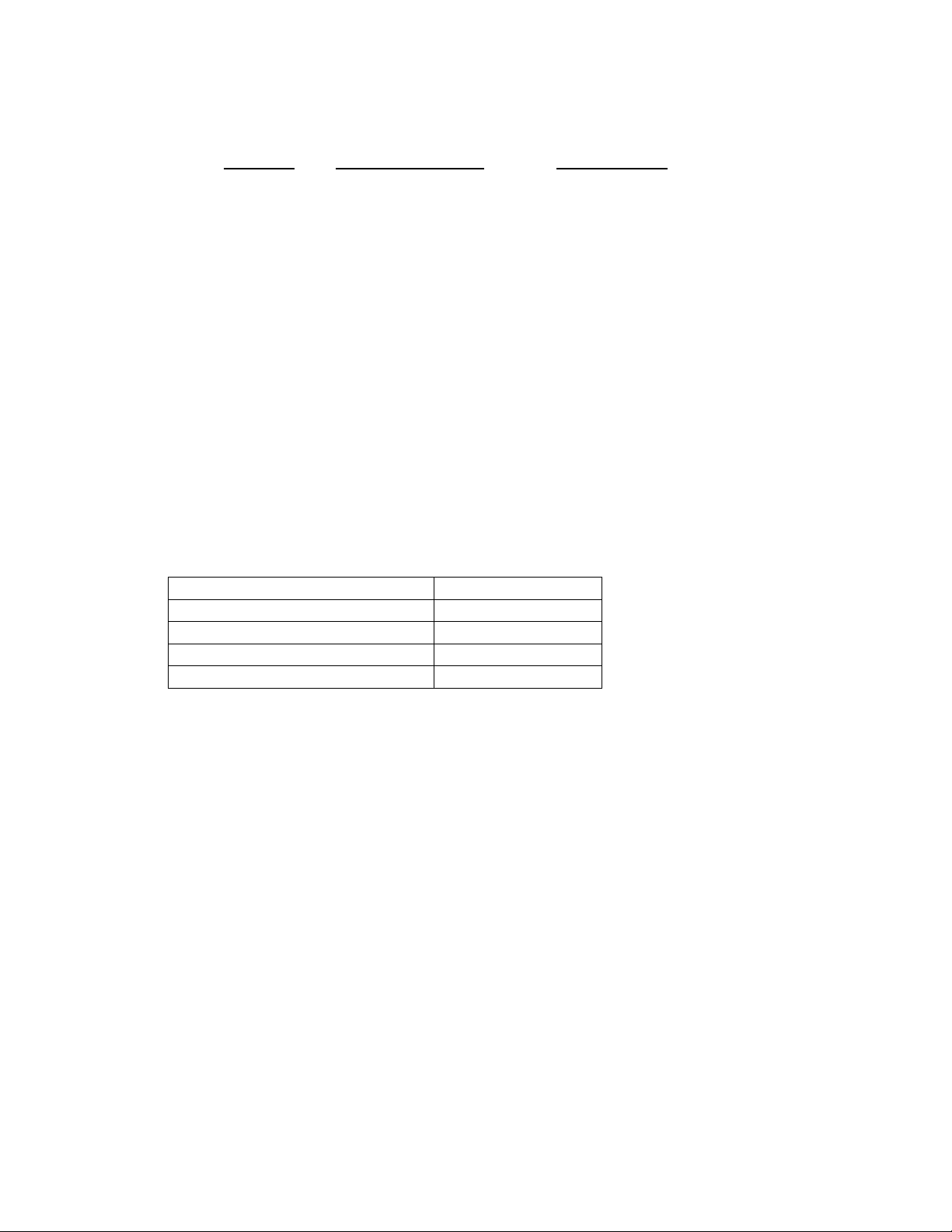

20K Capacity

Test

force

(lb)

0 0 0

2000

4000

6000

8000

10000

12000

14000

16000

18000

20000

0 -20 20

Lower

limit

(lb)

1980

3960

5940

7920

9900

11880

13860

15840

17820

19800

Upper

Limit

(lb)

2020

4040

6060

8080

10100

12120

14140

16160

18180

20200

Page 28 of 44

Page 29

PT300 Users manual

Rev G, Feb 2011

Procedure: Calibration (Adjustment)

Tools required:

•

Calibration force generator; press or deadweights. This calibration source must cover the

range of 10% to 100% of nominal scale capacity with a certified accuracy of 0.25% of reading

or better.

PT300

•

100027 - 8" (± 0.25") x 8" (± 0.25") x 1.75" (minimum) aluminum loading block.

•

100028-A - 8" (± 0.25") x 8" (± 0.25") x 0.5" (± 0.125") rubber loading scale. (40 to 70 Shore A

rating)

PT300DW

•

100029

•

100030-A

A rating)

•

140208 - #2 Phillips screwdriver.

•

140210 - Static dissipation station.

- 12" (± 0.25") x 12" (± 0.25") x 1.75" (minimum) aluminum loading block.

- 12" (± 0.25") x 12" (± 0.25") x 0.5" (± 0.125") rubber loading scale. (40 to 70 Shore

Page 29 of 44

Page 30

PT300 Users manual

Rev G, Feb 2011

Calibration Enable Jumper

To access the calibration mode the shorting strap labeled “RUN/CAL”, located on the right-middle

of the circuit board (Intercomp, A/D 20 BIT rev E), it must be moved from shorting pins 2 and

3(RUN); to shorting pins 1 and 2(CAL). To access the shorting strap, remove the 10 screws on

the outside edges of the display assembly. Carefully lift the display assembly up and place the

assembly, display side down, on top of the weighing platform.

Following calibration, replace the strap to shorting pins 2 and 3 (RUN); replace the assembly and

reattach the assembly with the screws. This will ensure that the calibration information of the

scale is protected from being changed.

Note: Care must be taken to ensure the wire harness is seated properly to prevent it from

being pinched between the display assembly and the scale casing.

Page 30 of 44

Page 31

PT300 Users manual

Rev G, Feb 2011

Calibration menu

To initiate calibration simultaneously press the PRINT/ACCUMULATE and ZERO buttons. The

display will show “StEP

calibration. Return to ‘Calibration Enable Jumper’ section to verify correct setting. Press the

PRINT/ACCUMULATE button to access the parameter setting.

At times it will be necessary to enter up to a five digit number. When this is necessary the current

number will be displayed with the right most digit flashing. The flashing digit may be incremented

by pressing the LOCAL/TOTAL button. To move one digit to the left, press the ZERO key. When

you have finished entering a number press the PRINT/ ACCUMULATE button. The settings are

saved once PRINT/ACCUMLATE is pressed to advance the menu, and the scale can then be

turned off.

StEP

StEP

StEPStEP

UUUU. EnA

bP 1

bP 1

bP 1bP 1

bP 2

bP 2

bP 2bP 2

bP 3

bP 3

bP 3bP 3

AdC

AdC.rt

AdCAdC

2Er0

2Er0.rrrr

2Er02Er0

ggggrAd

LL-01

LL-01

LL-01LL-01

HH

HH-01

HHHH

LL

LL-01

LLLL

HH

HH-02

HHHH

LL

LL-02

LLLL

HH

HH-03

HHHH

LL-03

LL-03

LL-03LL-03

HH-04

HH-04

HH-04HH-04

LL-04

LL-04

LL-04LL-04

StEP”, if it does not, the calibration strap is incorrectly placed to allow

StEPStEP

Step Function Note

skip 000= no skip

001= skip to Weight Calibration

003= skip to cornering routine

EnA

EnA EnA

A2t

A2t

A2tA2t

rAd

rAdrAd

CAP

CAP

CAPCAP

Unit enable Yes or no

grad break point 1 Enter weight

grad break point 2 Enter weight

grad break point 3 Enter weight

ADC rate 0 or 1

rt

rtrt

AZT (auto zero tracking) 1 d, 3 d, .5 d, oFF, or.6 d

Zero range 0= off, 1= 1%, 2= 2%, 3= 5%,

4 = 1%

graduation size 0.02, 0.05, 0.1, 0.2, 0.5, 1, 2, 5,

10, 20, 50, or 100

SAVE

SAVE

SAVESAVE

capacity Enter scale capacity

No weight applied

First weight Enter first weight

01

0101

First weight Load first weight

01

0101

Second weight Enter second weight

02

0202

Second weight Load second weight

02

0202

Third weight Enter third weight

03

0303

Third weight Load third weight

Fourth weight Enter fourth weight

Fourth weight Load fourth weight

10 points available to enter 3 minimum recommended

Displays for 1 sec and advances

Default

000

000

000000

YES

YES

YESYES

00000

00000

0000000000

00000

00000

0000000000

00000

00000

0000000000

1111

1 d

1 d

1 d1 d

0000

d 1

d 1

d 1d 1

20000

20000

2000020000

Page 31 of 44

Page 32

PT300 Users manual

Rev G, Feb 2011

Setting the Calibration Parameters

1. At any point in the following steps, data will be retained by the scale at the step completed if

the power is cycled off. To initiate calibration simultaneously press the PRINT/ACCUMULATE

and the ZERO buttons. The scale shows “StEP

The scale shows “000

000” with the far right number flashing. To go through all of the calibration

000000

parameters, press PRINT/ ACCUMULATE with the display showing “000

calibration parameters and proceed to step 11 enter “001

additional codes available. Use the LOCAL/TOTAL button to increment and the ZERO button

to decrement the number. Press the PRINT/ ACCUMULATE button when the desired number

is displayed.

3. The display shows “UUUU. EnA

ACCUMULATE button. The display will read “YES

button will toggle the display to “no

PRINT/ACCUMULATE button.

4. The display now shows “bP 1

the current setting with the far right number flashing. Use the LOCAL/TOTAL button to

advance the number and the ZERO button to move the number flashing to the left. When the

desired graduation break point is displayed press the PRINT/ ACCUMULATE button.

5. The display shows “bP 2

step 3 for graduation break point 2. When the desired graduation break point is displayed

press the PRINT/ACCUMULATE button.

6. The display shows “bP 3

step 3 for graduation break point 3. When the desired graduation break point is displayed

press the PRINT/ACCUMULATE button.

EnA” if proceeding through all parameters. Press the PRINT/

EnAEnA

no”. With the display showing “YES

nono

bP 1”. Press the PRINT/ACCUMULATE button. The display will read

bP 1bP 1

bP 2”. Press the PRINT/ACCUMULATE button. Repeat the process in

bP 2bP 2

bP 3”. Press the PRINT/ACCUMULATE button. Repeat the process in

bP 3bP 3

StEP”. Press the PRINT/ACCUMULATE button.

StEPStEP

000”. To skip the first 8

000000

001”. See Diagnostics section for

001001

YES”. Pressing LOCAL/TOTAL or the ZERO

YESYES

YES”, press the

YESYES

Multiple Graduation Break Points

The PT300 has the ability to have multiple graduation values set. Following is an example

of setting graduation break points. Example:

Grad = Initial graduation equals by 0.1 lb

Cap = 10000 (Capacity equals 10,000 lb)

bP 1

bP 1 = 1000

bP 1bP 1

bP 2

bP 2 = 2000

bP 2bP 2

bP 3

bP 3 = 5000

bP 3bP 3

Page 32 of 44

Page 33

PT300 Users manual

Rev G, Feb 2011

The scale would then display the following:

up to 1000 lb by 0.1 lb; up to 453.55 kg by 0.05 kg

1000+ to 2000 lb by 0.2 lb; 453.55+ to 907.1 kg by 0.1 kg

2000+ to 5000 lb by 0.5 lb; 907.1+ to 2267.8 kg by 0.2 kg

5000+ lb by 1.0 lb; 2267.8+ kg by 0.5 kg

To disable the breakpoints the graduation break points should be set to 110% of the

capacity. The scale uses the same graduation from zero to capacity. This turns off the

breakpoint feature.

7. The display shows “AdC

AdC.rt

rt”. Press the PRINT/ACCUMULATE button. The display shows the

AdCAdC

rtrt

current setting flashing. This sets the internal A/D conversion time at one of two choices. An

entry of ‘0’ results in the full conversion time for the most stable results. An entry of ‘1’ results

in a reduced conversion time which extends battery life. For the PT300 it is recommended to

leave this set to ‘1’. Note that if this setting is changed, the scale must be recalibrated. Use

the LOCAL/TOTAL button to increment and the ZERO button to decrement the number.

When the desired ADC rate is displayed press the PRINT/ACCUMULATE button.

8. The display shows “AZt

AZt”. Press the PRINT/ACCUMULATE button. The display shows the

AZtAZt

current setting. Press the LOCAL/TOTAL or the Zero button to cycle through the auto zero

tracking options. (1 d

1 d, 3 d

3 d, .5 d

1 d1 d

3 d3 d

5 d. oFF

oFF, or 6 d

5 d5 d

oFFoFF

6 d) If the displayed weight is less than the number

6 d6 d

of grads shown for a given amount of time, the weight will be zeroed off. When the desired

auto zero tracking setting is displayed press the PRINT/ACCUMULATE button.

9. The display shows “ZEr0

ZEr0.rrrr”. Press the PRINT/ACCUMULATE button. The display shows the

ZEr0ZEr0

current setting flashing. Use the LOCAL/TOTAL button to increment and the ZERO button to

decrement the number. The zero range is the percentage the zero can move from the original

zero obtained at calibration. The zero button will not work if outside the zero range; and the

display will show “ZEr0

ZEr0.rrrr” with the error icon lit if the zero range is set to 1, 2, or 3. If 4-6 is

ZEr0ZEr0

selected, the zero button will simply not function when an attempt is made to zero the scale

outside the range. When the number for desired zero range number is displayed press the

PRINT/ACCUMULATE button. (0=off, 1=1%, 2=2%, and 3=5%, 4=1%, 5=2%, 6=5%)

10. The display shows “GGGGrAd

rAd”. Press the PRINT/ACCUMULATE button. The display shows the

rAdrAd

current setting with the number flashing. Press the LOCAL/TOTAL or the Zero button to cycle

through the graduation options. When the desired graduation setting is displayed press the

PRINT/ACCUMULATE button. (grad options 0.02, 0.05, 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 50, or

100)

Note: The numbering for the “setting the calibration parameters” continues at Span

Calibration.

At this point the display will show “SAvE

SAvE” for about 1 second and advance to show “CAP

SAvESAvE

CAP”.

CAPCAP

Page 33 of 44

Page 34

PT300 Users manual

1

2

Rev G, Feb 2011

Weight Calibration

One to ten load weights need to be applied to calibrate the scale. Using multiple point calibration

allows the unit to weigh more accurately; by removing undesirable characteristics of load cells. A

typical weight calibration is a three point calibration. This means three different and optimal loads

are applied and entered (not including the zero point). If you do not conveniently have the three

different weights available, you may also use one or two point calibration. To calibrate with one

point, simply turn off the scale after completing step 13 as listed below. To calibrate with two

points, turn off the scale after completing step 15 as listed below. The PT300 has the capability to

apply and load up to 10 calibration points.

Corner Calibration (Both load cells)

Caution: Avoid directly touching any exposed circuitry. Use cotton gloves or similar protection.

Oils from the fingers will cause unacceptable performance in high humidity conditions. This

degradation may not be obvious at the time of contamination. If the circuitry becomes

contaminated it must be cleaned using isopropanol or an equivalent cleaner.

Note: If the scale fails corner verification perform the following routine. If the span is the

only thing that need to be calibrated skip this section and go to span calibration.

1. Turn scale ON.

2. Press the PRINT / ACCUMULATE button. The display should show “StEP

Cal Enable Switch Access section and press the cal enable switch. Press the PRINT /

ACCUMULATE button.

3. The display shows “000

button until the display shows “003

the PRINT / ACCUMULATE button.

4. The display shows “LLLLCCCC.bAL

show one digit flashing. This is the number of load cells in the scale. Increase the number

000” with the most right digit flashing. Increase the number with the Lb/Kg

000000

003”. This will access the Load Cell Balance routine. Press

003003

bAL”. Press the PRINT / ACCUMULATE button and the display will

bALbAL

Page 34 of 44

StEP”. If not return to the

StEPStEP

Page 35

PT300 Users manual

Rev G, Feb 2011

with the Lb/Kg button or decrease the number with the Zero button until the display shows “2222”.

This is the number of load cells in the PT300. (Unless you have a 30K or 40K PT300DW,

which has 4 load cells, enter “4444” in this case) If the number was changed the scale will save

and restart. If this happens go back to step 2. If the number isn’t changed the display will

show “LC 00

5. Press PRINT / ACCUMULATE to read the zero load. For this step it doesn’t matter if there are

loading blocks on the scale or not.

6. The display will show “LC1-0

as per figure above. With no weight on the scale except the loading block fixture, press the

PRINT ACCUMULATE button.

7. The display will show “LC1-L

same loading fixture. Once the load is applied press the PRINT ACCUMULATE button.

8. The display will show “LC2-0

as per figures 1 and 2 above. With no weight on the scale except the loading block fixture,

press the PRINT ACCUMULATE button.

9. The display will show “LC2-L

same loading fixture. Once the load is applied press the PRINT ACCUMULATE button.

10. The display will show “SAvE

been internally compensated and saved. Perform corner calibration verification in normal

weighing mode. This concludes the corner calibration.

11. To access the Span calibration, simultaneously press the PRINT/ACCUMULATE and the

ZERO buttons. The scale shows “StEP

shows “000

press PRINT/ ACCUMULATE with the display showing “000

parameters and proceed to span calibration enter “001

LC 00”.

LC 00LC 00

LC1-0”. Prepare load cell 1 using the loading block and the rubber pad

LC1-0LC1-0

LC1-L”. Apply ¼ of the capacity of the scale to load cell 1 using the

LC1-LLC1-L

LC2-0”. Prepare load cell 2 using the loading block and the rubber pad

LC2-0LC2-0

LC2-L”. Apply ¼ of the capacity of the scale to load cell 2 using the

LC2-LLC2-L

SAvE” and then return to normal weighing mode. The cornering has now

SAvESAvE

StEP”. Press the PRINT/ACCUMULATE button. The scale

StEPStEP

000” with the far right number flashing. To go through all of the calibration parameters,

000000

000”. To skip the first 8 calibration

000000

001”.

001001

Corner Calibration (Single load cell)

1. Position the scale, loading block and pad to apply weight on the corner requiring

adjustment.

2. Enter Cal mode.

3. Enter “20

the code as ‘x’. (Example: Enter “202