Page 1

P ROGRAMMABLE I NDICATORS AND P ROCESS

C ONTROLLERS

60 SERIES

User Guide

Version 3.0

Page 2

60 SERIES

User Guide

Version 3.0

Page 3

GSE 60 Series User Guide

Copyright © 2000 GSE Scale Systems. All rights reserved.

Published by:

GSE Scale Systems

42860 Nine Mile Road

Novi, MI 48375

USA

Information in this User Guide is subject to change without notice due to correction

or enhancement. The information described in this manual is solely the property of

GSE. No part of this manual may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording and sold for

any monetary figure without the express written permission of GSE.

GSE Locations Worldwide

GSE Scale Systems

42860 Nine Mile Road

Novi, MI 48375

U.S.A.

Phone: (800) 755-7875

www.gse-inc.com

GSE Canada, Inc.

617 East Lake Road

Airdrie, Alberta Canada T4B 2B8

Phone:(403) 948-9921

Fax: (403) 948-1449

Page 4

Page 5

CONTENTS

1 CHAPTER 1: INTRODUCTION................................................................ 1

COMMON WEIGHING APPLICATIONS................................................................. 1

FEATURES .........................................................................................................2

CONTROLLER DESCRIPTIONS ............................................................................2

DISPLAY ........................................................................................................... 3

KEYPAD ............................................................................................................ 5

OPTIONS ........................................................................................................... 9

SPECIFICATIONS..............................................................................................11

2 CHAPTER 2: INSTALLATION ............................................................... 15

TABLE-TOP USE..............................................................................................15

PANEL MOUNT USE ........................................................................................15

PERMANENT MOUNTING................................................................................. 15

ENVIRONMENT SUITABILITY...........................................................................15

Model 460 Outline Drawings ...........................................................................17

Model 465, 560, 562, 660, 661, 662 Outline Drawings ...................................18

Model 663 Outline Drawings ...........................................................................19

Model 665 Outline drawings ............................................................................ 20

Panel Mount Cutouts ........................................................................................21

3 CHAPTER 3: CALIBRATION ................................................................. 23

QUICK CALIBRATION ...................................................................................... 23

New Zero?......................................................................................................... 24

Last Zero?.........................................................................................................25

Temp Zero?..................................................................................................... 26

Only Zero? ...................................................................................................... 26

Cal Reset ......................................................................................................... 27

Known Load Cell? ......................................................................................... 28

SAVE CALIBRATION ........................................................................................ 29

4 CHAPTER 4: COUNTING MODE .......................................................... 31

COUNTING MODE (KEY OPERATION) ..............................................................31

Sampling to Determine a Piece Weight ............................................................ 31

Negative Sampling to Determine a Piece Weight ............................................. 32

PIECE WEIGHT ENHANCEMENT........................................................................32

KNOWN CONTAINER WEIGHT ......................................................................... 33

AUTOMATIC SCALE SELECT (WITH MORE THAN ONE WEIGHING PLATFORM)33

COUNTING MODE LISTING .............................................................................. 34

5 CHAPTER 5: ACCUMULATION MODE .............................................. 35

i

Page 6

60 SERIES I NDICATORS

PERFORMING ACCUMULATIONS...................................................................... 35

INITIALIZING ACCUMULATION TOTALS .......................................................... 35

6 CHAPTER 6: ADDITIONAL OPERATING MODES............................37

PIECE WEIGHT DATABASE MODE – APW LOOKUP .......................................37

Store APW – Store a specific APW to the database – Must Perform a sample

before using.

Get APW – Retrieve a specific APW from the database................................... 37

Print APW’s – Prints all stored records in row/column format. ...................... 38

Clear One APW – Clears current record from the database. .......................... 38

Clear All APW’s – Clears all records from the database................................. 38

TRUCK IN/OUT (MODELS 465,560,562 AND 660 SERIES)............................... 39

................................................................................................... 37

TRUCK IN...................................................................................................... 39

TRUCK OUT ................................................................................................. 39

PRINT ID’S? ................................................................................................ 39

CLEAR ONE ID............................................................................................ 39

CLEAR ALL.................................................................................................. 40

TORE TRUCK IN TARE WEIGHT .............................................................40

S

CHECK WEIGH ABSOLUTE AND PERCENTAGE OPERATION ............................. 41

Set the Hi and Lo weights (460) .......................................................................41

Use Check Weigh (460) .................................................................................... 41

Set the Hi and Lo weights (465,560,562 and 660 Series)................................. 41

Use Check Weigh.............................................................................................. 41

BATCHING OPERATION (465,560 AND 562) - FILL ......................................... 42

Setting setpoints, preact, and dribbles.............................................................. 42

Batching............................................................................................................ 42

7 CHAPTER 7: TIME AND DATE (CLOCK FEATURE)........................43

VIEWING TIME AND DATE .............................................................................. 43

ENTERING A NEW TIME AND DATE (EXCLUDING MODEL 460) .......................43

ENTERING A NEW TIME AND DATE (MODEL 460)........................................... 44

8 CHAPTER 8: LEGAL-FOR-TRADE........................................................45

OIML AND INTERNATIONAL OPERATION .......................................................45

NTEP .............................................................................................................46

Enabling NTEP Operation ...............................................................................46

NTEP Custom Setup .........................................................................................47

Sealing and Audit Trails................................................................................... 49

9 CHAPTER 9: TROUBLESHOOTING .....................................................57

OPERATIONAL MODE ERROR MESSAGES........................................................ 57

ii

Page 7

C HAPTER 1:INTRODUCTION

SETUP MODE ERROR MESSAGES.....................................................................58

HARDWARE PROBLEM ERROR MESSAGES ...................................................... 59

CALIBRATION ERROR MESSAGES....................................................................60

GENERAL ERROR MESSAGES ..........................................................................61

MISCELLANEOUS MESSAGES ..........................................................................62

COMMUNICATIONS ERROR MESSAGES............................................................ 62

TROUBLE-SHOOTING ......................................................................................63

SERVICE.......................................................................................................... 63

iii

Page 8

Page 9

1CHAPTER 1: INTRODUCTION

GSE 60 Series programmable indicators come standard with a number of

features that make them the most versatile and powerful systems in their

price class. Accurate and durable, 60 Series controllers will provide you

with years of quality weighing service even in the most demanding industrial

environments.

This User Guide contains basic operating information. Subjects covered

include controller installation, operation modes, custom transmits, variable

or string operations, the clock feature, legal-for-trade issues, and

troubleshooting.

Subjects such as the Setup Mode and the macro programming language are

beyond the scope of a User Guide. For more detailed operating instructions,

a 60 Series Technical Reference Manual is available. Contact your GSE

Distributor for more information.

COMMON WEIGHING APPLICATIONS

Typical weighing applications for GSE 60 Series controllers include:

• Small parts weighing

• Large parts weighing

• Parts counting

• Vehicular truck loading (truck in

/ truck out)

• Tank weighing

• Process control

• Inventory control

• Order picking

• Floor and hopper scales control

• Conveyor weigh systems control

• Batching (mixing)

Figure 1: Model 660

1

Page 10

60 SERIES I NDICATORS

FEATURES

GSE 60 Series controllers share the following standard features:

• Sealed elastomer keypad for protection against harsh environments

• Capability to power as many as 14 350-ohm load cells for demanding

applications (12 350-ohm load cells on 460 and 465)

• AC/DC power operation

• Front panel calibration and linearization execution

• Full scale response time from 0.06 to 8 seconds

• Selectable weighing units: pounds, kilograms, ounces, grams, etc.

• Programmable RS-232 communications software

• Remote display support capability

• Expandable memory for increased data storage

• Battery-backed time and date clock

• Weighing increments of 1, 2, or 5 units, from .00001 to 500

CONTROLLER DESCRIPTIONS

All 60 Series models excluding the 663 come with a swivel bracket for

positioning on a tabletop or mounting to any fixed surface. They are also

available in panel-mount versions.

A stainless steel NEMA 4X enclosure for washdown environments comes

standard on all 60 Series models. The model 663 is also available in a

powder coat mild steel enclosure.

GSE offers many options to enhance the 60 Series of controllers. The

number of options that can be used varies among the different models.

See the Specifications section on page 11 for enclosure dimensions.

2

Page 11

C HAPTER 1:INTRODUCTION

DISPLAY

Display types differ according to model. The table below describes the

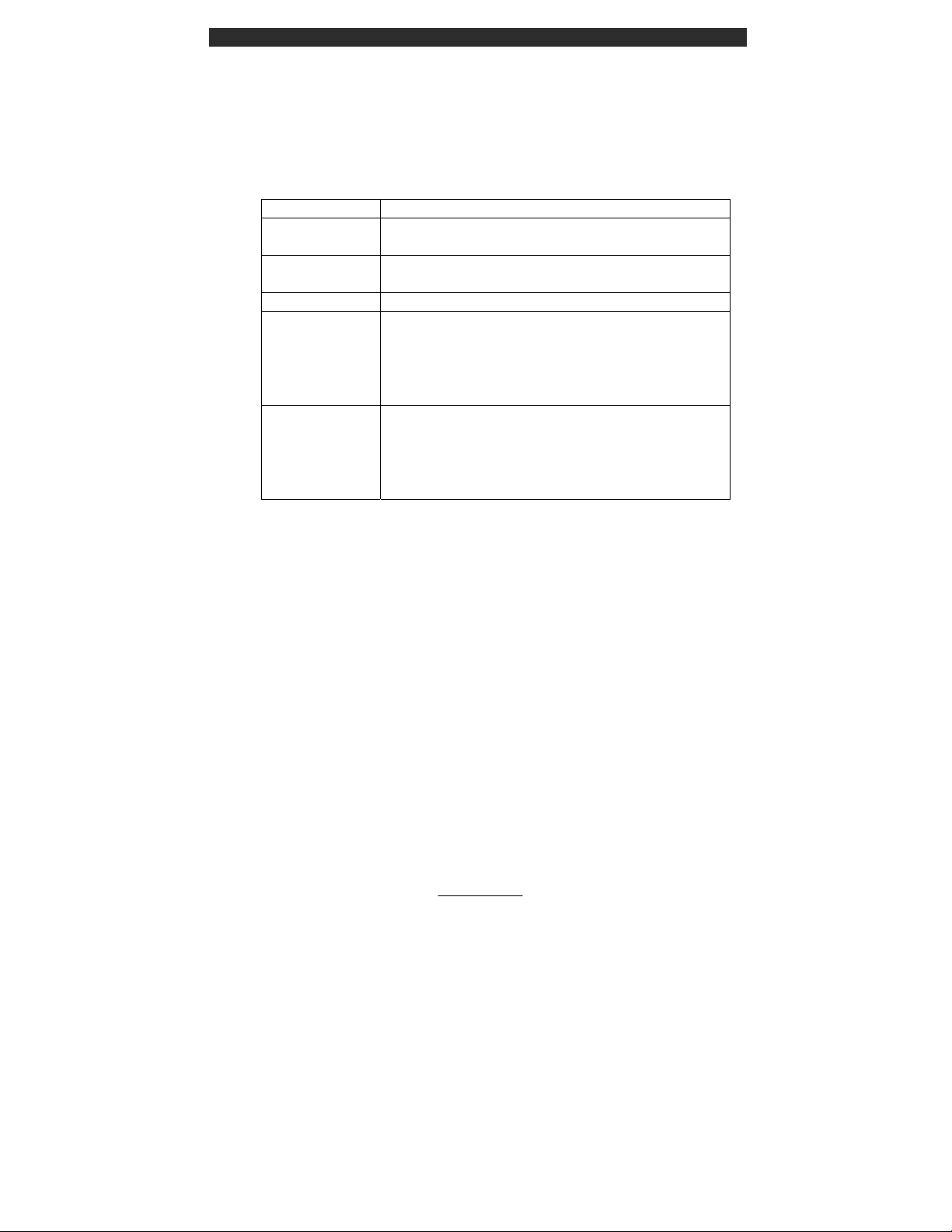

display(s) offered for each controller.

Table 1: 60 Series Displays

Model Display

460, 465, 560

660

661 4-line by 20-character alphanumeric VF display

562, 662 240 x 64 backlit LCD graphic, 3 font sizes

663 Available in two versions:

665 Available in two versions:

The vacuum fluorescent (VF) display is divided into two sections: a large,

six-digit numeric area to the left, and a smaller, two-line-by-five-character

dot matrix area to the right.

6 digit, Vacuum Florescent display (VFD)

0.75” (19mm) height with 2X5 matrix

(8mm)

• 6 digit, Vacuum Florescent display (VFD) and

4x20 character alphanumeric VF display

OR

• 240x128 backlit LCD display

• 6 digit, Vacuum Florescent display (VFD) and

4x20 character alphanumeric VF display

OR

• 240x128 backlit LCD display

The large digit area displays numeric data, such as Gross Weight, Net

Weight or Tare Weight. The dot matrix area has several purposes:

• The first two characters on the upper line show the weighing units of the

displayed data.

• The last three characters on the upper line show a CENTER ZERO (->0< --) condition at times.

• The lower line of the dot matrix area specifies the type of data, such as

Gross, Net, Tare, etc.

The dot matrix area also displays specific messages during controller

operation and setup.

3

Page 12

60 SERIES I NDICATORS

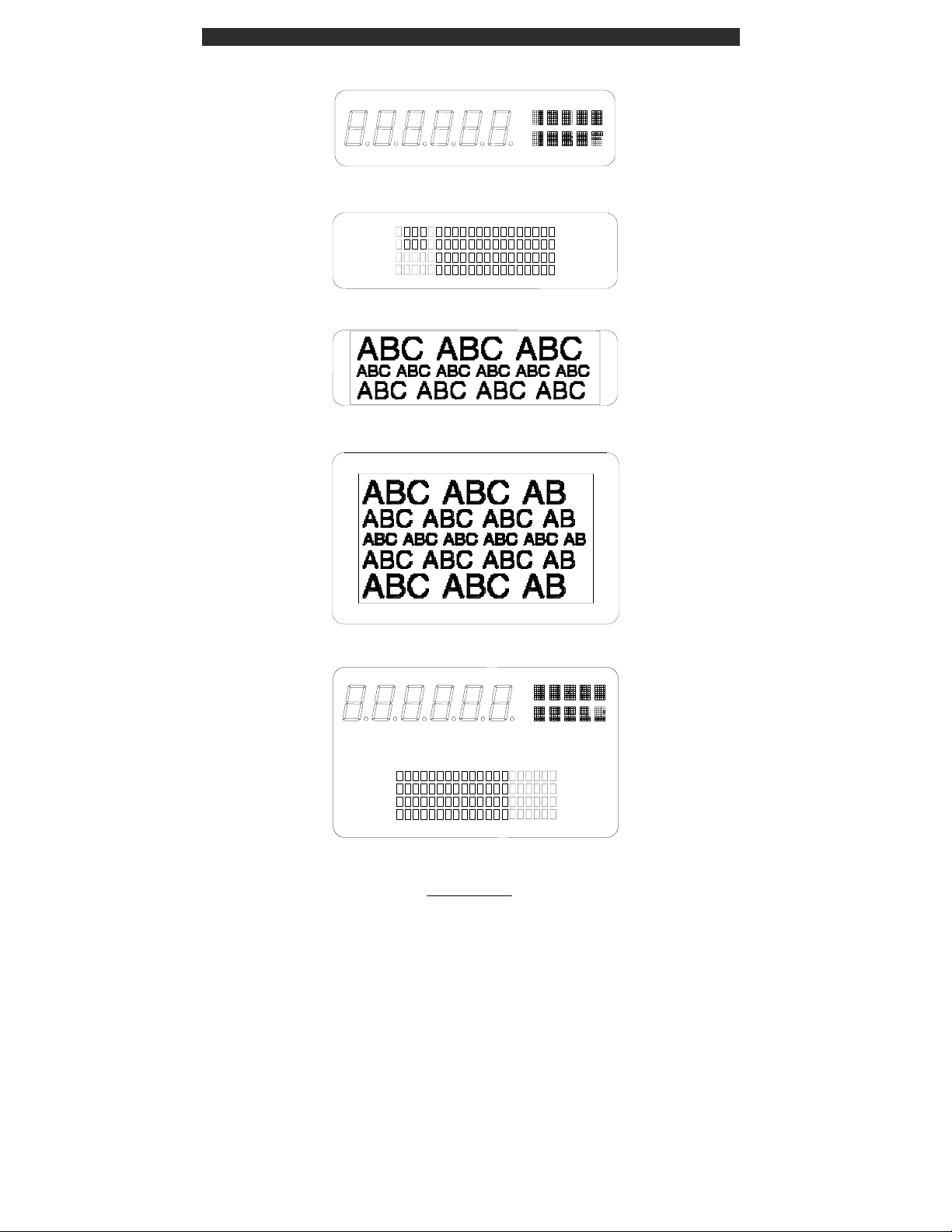

Figure 2: 6 Digit Vacuum Fluorescent Display (VFD)

Figure 3: 4x20 Vacuum Fluorescent Display (VFD)

Figure 4: 240x64 Backlit LCD Display

Figure 5: 240x128 Backlit LCD Display

Figure 6: 6 Digit VFD and 4x20 VFD

4

Page 13

C HAPTER 1:INTRODUCTION

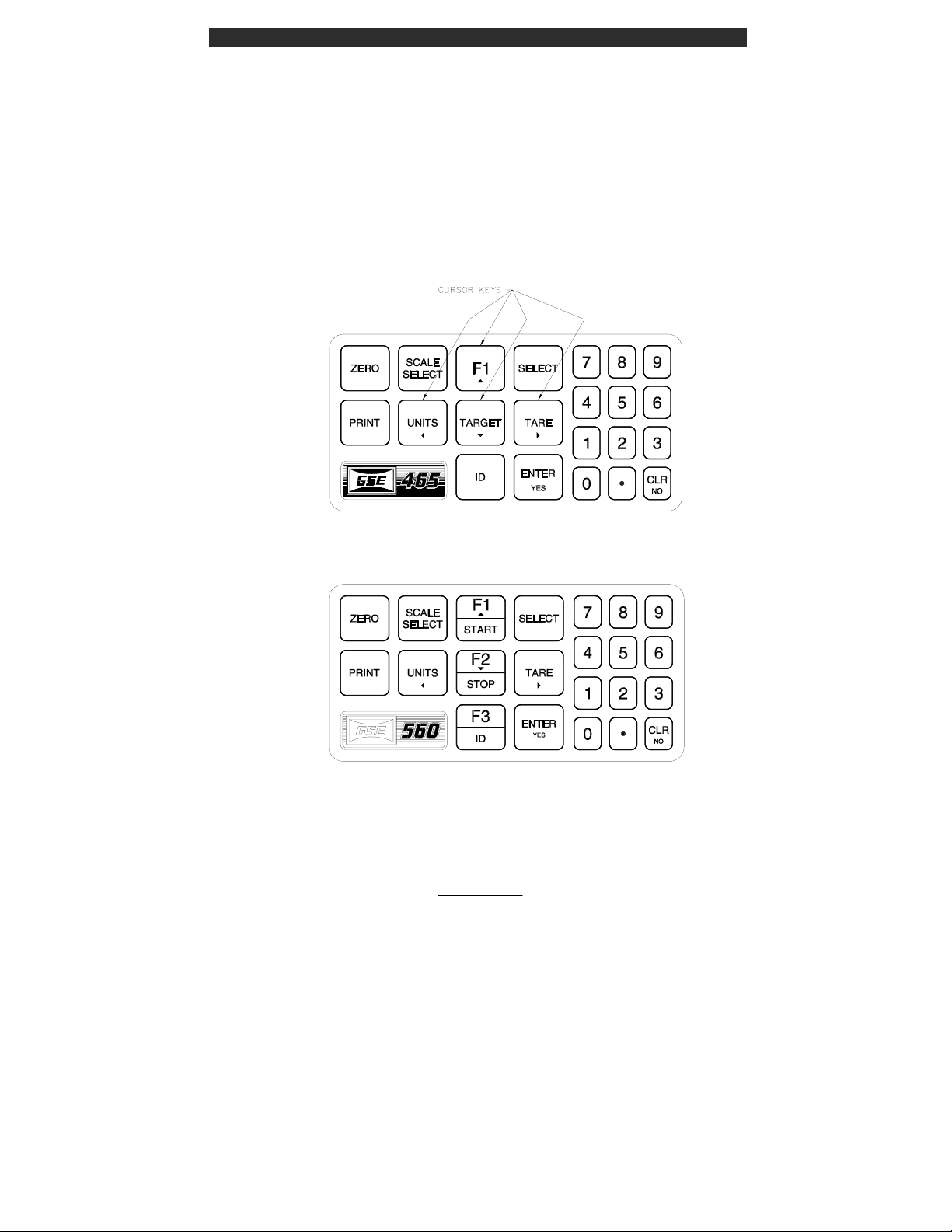

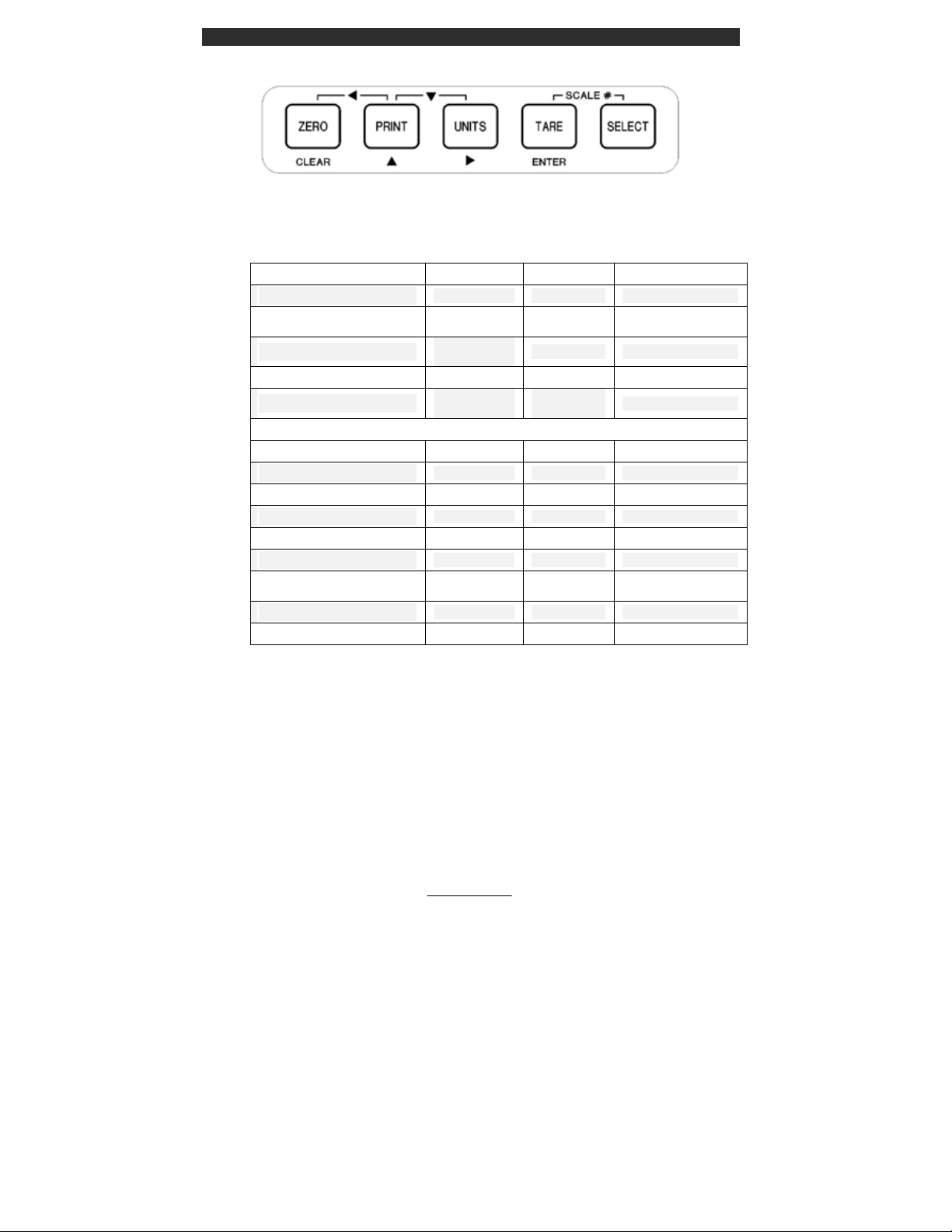

KEYPAD

A sealed elastomer keypad comes standard on all 60 Series controllers. A

TTL alpha keypad is also available as an option on the model 663 controller.

For more information on the alpha keypad option, please refer to the 60

Series Technical Reference Guide.

Detailed descriptions of each key and its associated function follow below.

Figure 7: 465 Keypad

Figure 8:560/562 Series Keypad

5

Page 14

60 SERIES I NDICATORS

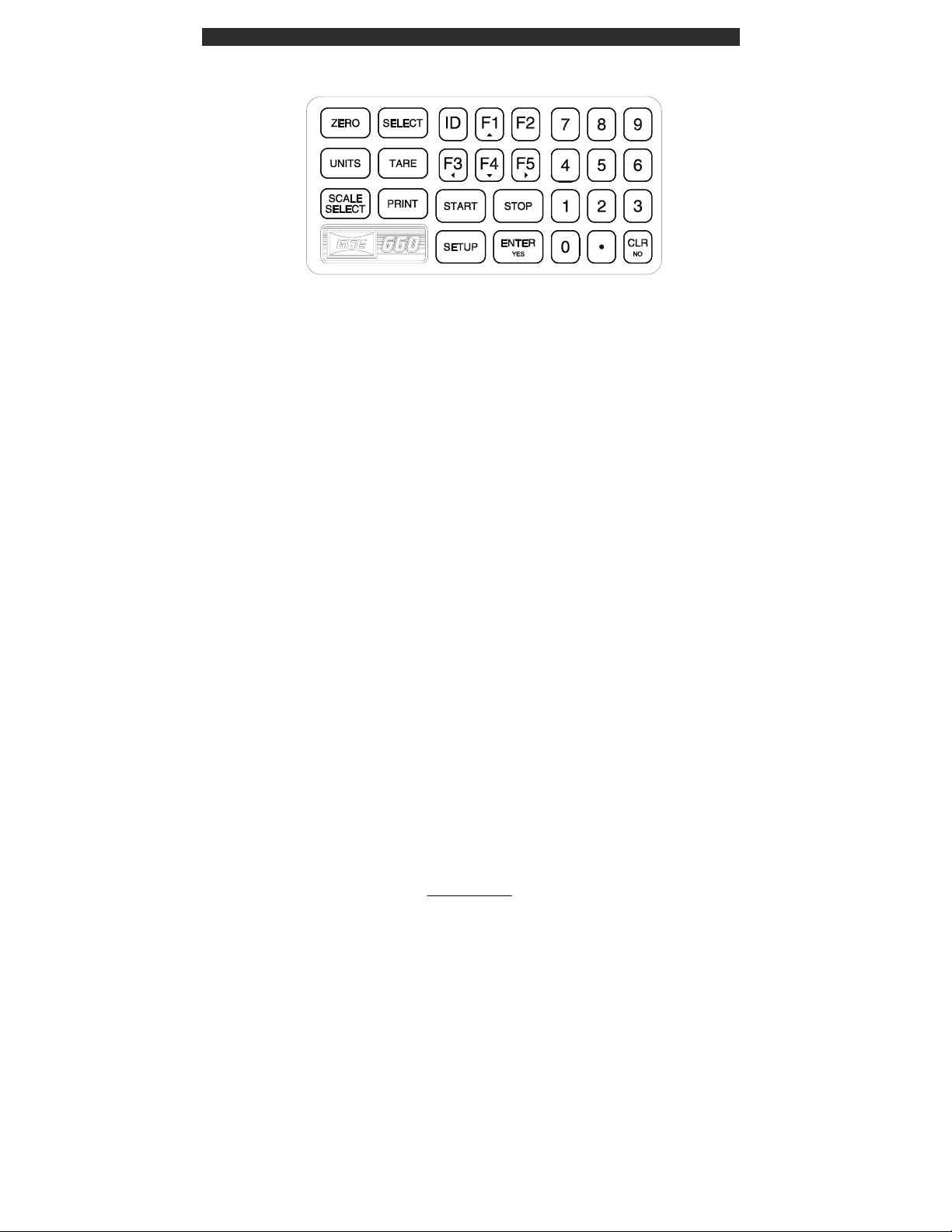

Figure 9: 660 Series Keypad

ZERO Press [ZERO] to zero the current quantity/weight reading.

When the meter is at Center Zero center-of-zero indication

will appear on the upper line of the dot matrix display. If a

Custom Unit’s name is greater than 2 characters, the Center

Zero indication is not displayed. If in the quantity mode,

pressing [ZERO] will set the current mode to a gross zero

quantity. If in the Weigh Mode, pressing [ZERO] sets the

current mode to Gross Weight.

UNITS

Pressing [UNITS] from the Weigh Mode will toggle the

displayed units through the available selections. Converted

units are automatically rounded to the appropriate

increment.

SELECT Pressing [SELECT] will toggle you through the Net

Weight, Tare Weight and Gross Weight or other enabled

operating modes.

TARE Pressing [TARE] by itself will perform an auto-tare. A Net

Zero is then displayed. You can enter a known Tare weight

by keying in the number and pressing [TARE]. In either

case, the indicator will be placed in the Net Mode, unless

you are in the Tare Mode.

ENTER/YES Press the [ENTER] key following certain numeric entries.

Doubles as a [YES] key for answering operator prompts.

PRINT

ID

Press to send data to a printer, computer or other device.

Used for entering ID numbers.

[F1c] The [F1c] key is used as an up arrow key for scrolling or

as a function key (such as accessing a menu or starting a

process). Not available on Model 460.

6

Page 15

C HAPTER 1:INTRODUCTION

[F2] The [F2] key is used as a function key (such as accessing a

menu or starting a process). 560 and 660 Series only. Not

available on Model 460 or Model 465.

[F3e] The [F3e] key is used as a left arrow key for scrolling or

as a function key (such as accessing a menu or starting a

process). Not available on Model 460 or Model 465.

[F4d] The [F4d] key is used as a down arrow key for scrolling or

as a function key(such as accessing a menu or starting a

process) . Not available on 460 or 560 Series.

[F5f] The [F5f] key is used as a down arrow key for scrolling or

as a function key (such as accessing a menu or starting a

process) . Not available on 460 Series or 560 Series.

TARGET

Only available on the Model 465. Used as a function key

and a down arrow key.

START The [START] key is used as a function key. 560 and 660

Series only. Not available on 460 Series.

STOP The [STOP] key is used as a function key. 560 and 660

Series only. Not available on 460 Series.

SETUP The [SETUP] key is used as a function key. 660 Series

only. Not available on 460 Series or 560 Series.

0 - 9 & .

Press the numeric keys to enter numeric values 0 through 9.

Press [.] to establish a decimal point or perform an

accumulation in the weigh or count mode. Not available on

Model 460.

CLR

Press this key to clear a numeric entry mistake prior to

entering it into memory. Also doubles as a [NO] key for

answering questions.

SCALE

SELECT

Pressing [SCALE SELECT] will toggle through all the

enabled scale inputs. Not available on Model 460.

7

Page 16

60 SERIES I NDICATORS

Figure 10: 460 Keypad

Table 2: 460 Key Functions

KEYPRESS GROSS/NET QTY OTHER MODES

[ZERO / CLEAR]

[PRINT]

[UNITS]

[TARE / ENTER]

[SELECT]

Zero Scale Zero Quantity ZERO * CLEAR

Print custom

transmit

Toggle though

enabled units

Tares Scale Tares Scale ENTER

Selects

Parameters

Print custom

transmit

N/A

Selects

Parameters

Character Entry

Space ►

SELECT

†

▲

Multiple Key Combinations

[ZERO] + [PRINT]

[ZERO] + [TARE]

[ZERO] + [UNITS]

[PRINT] + [UNITS]

[PRINT] + [SELECT]

[TARE] + [SELECT]

[UNITS] + [SELECT]

[UNITS] + [TARE]

[PRINT] + [TARE]

◄ ◄ ◄

N/A N/A Clear Entry

N/A N/A N/A

▼ ▼ ▼

ext. res. OIML ext. res. OIML ext. res. OIML

Scale Select Scale Select Move backwards

Performs an

Accumulation

N/A N/A N/A

N/A N/A N/A

Performs an

Accumulation

ENTER

* = No entry in progress

= Entry in progress

8

Page 17

OPTIONS

Numerous hardware options that maximize the capabilities and functions of

the standard 60 Series controllers are available. These options can be

installed by your GSE distributor when you order your controller or added

later. All options must be installed by your GSE distributor or a qualified

technician. Please do not return the controller to GSE for installation of

options. Consult your GSE products distributor for installation instructions.

4-Position I/O Board

60 Series supports the eight following 4-position I/O boards:

• Low Voltage AC 2 input 2 output

• High Voltage AC 2 input 2 output

• AC 4 output

• Low Voltage AC 4 input

• High Voltage AC 4 input

• DC 2 input 2 Output

• DC 4 output

• DC 4 input

16-Position I/O Board

The 16-position I/O board can be used in combination with the 4-position

boards listed above. As many as 128 I/O circuits can be configured.

Alpha Keypad (663 only)

Allows easy entry of alphanumeric characters.

Alphanumeric Serial Keyboard Converter Kit

Adapts PC keyboard to the indicator serial port (includes keyboard).

Analog Output

Up to 8 analog output cards can be added for analog output signals of each

scale value or any other independent variable.

Database

Adds capability for creating database records, consisting of fields, for data

storage and retrieval. Battery-backed SRAM increases internal storage to

256K, 1M, or 2M.

C HAPTER 1:INTRODUCTION

9

Page 18

60 SERIES I NDICATORS

DeviceNet Module

Provides a communication path between multiple end-points (Devices). The

GSE indicator will act as a slave on the network device layer.

Dura-Shield

A clear weatherable film lexan that adheres over the keypad and display.

Recommended when high-pressure washdown, petroleum distillates or harsh

cleaning agents are present. (Not available for the 663).

Ethernet Module

Communicate via internet or intranet connection.

Memory Expansion (Not available for 460 Series)

An 8Kmemory chip can replace each of the two standard 2K memory chips,

increasing internal E2 memory from the standard 4K to 16K maximum.

Multi-Scale

Enables the use of as many as seven additional scale platforms per

controller.

Network Module

Addressable RS-485 network card. Full or half duplex.

Profibus Module

Allows joint operation of several systems with their distributed peripherals

on one bus. The GSE indicator acts as a slave on the network line.

SCR Module

DIN rail mount controller suitable for controlling AC devices such as

vibratory feeders.

Severe Transient Voltage Suppression

Protects the controller from power line transient damage.

Splash Guards

A clear flexible vinyl cover for use in harsh environments. It will keep the

indicator well protected and looking like new.

10

Page 19

C HAPTER 1:INTRODUCTION

SPECIFICATIONS

Performance

• Full Scale Selectable

• Resolution 100,000 displayed (+/-500,000 internal)

• Display Update Selectable 0.05-20 seconds

• A/D Conversion 60 Hz

• Non-Linearity 0.005% of full scale (input dependent)

• Zero Track 0.05-20.0 displayed divisions

• Zero Range Selectable from 0.01-100% of full scale

• Calibration Selectable, 5 multi-point calibration for

linearization

• Division Size .00001 through 500

• Warranty 2 year

Electrical

• Power input 90-250 VAC, 50/60 Hz; 10-32 VDC

• Fuse 0.8 amp time lag

Load Cell Input

• Connections 4 lead or 6 lead with sense, jumper selectable

• Power 14 350-ohm cells (560 and 660 Series)

• Power 12 350-ohm cells (460 Series)

• Signal Range 0.1 to 20 mV/V at full scale

• Excitation 10 VDC, short circuit protected

• Current 400 mA maximum

Communications

• Bi-directional RS-232 serial ports

• Independent custom transmit tables for labels, reports, transmitting

control characters, etc.

• Transmit output: continuous transmit, on request, motion inhibited

• Selectable baud rate

• Selectable protocol

11

Page 20

60 SERIES I NDICATORS

• Selectable data formatting

Display

• Vacuum fluorescent, 0.75 in. high digits

• 240x64 LCD display, 5 in. x 1.34 in. usable area

• 240 x 128 LCD display, 4.72 in. x 2.52 in. usable area

• Four-line by 20-character alphanumeric display, 0.20 in. high digits

• Increments 1,2, 5, 10, 20, 50, 100, 500

• Selectable decimal point

• Display values -99,999 through 999,999

• Polarity "-" sign to left of most significant active digit

• Status indicator 10-character dot matrix prompting display

Enclosure Dimensions

Model Width Height Depth

465/560/562//660/661/662

460

460 Panel Mount

465/560/562/660/661/662

Panel Mount

663

663 Big Box

665

mm =millimeter; in = inch

*Includes mounting stand.

**Includes mounting flange.

11 in*

(279 mm)

11 in*

(279 mm)

10 in**

(254 mm)

10 in**

(254 mm)

16.18 in**

(411 mm)

24 in**

(609 mm)

11.07 in*

(281.20 mm)

12

9 in*

(228 mm)

8 in*

(203 mm)

7 in**

(177 mm)

9 in**

(228 mm)

22.5 in**

(571.5 mm)

32 in**

(812 mm)

12.16 in*

(308.9 mm)

4.4 in*

(112 mm)

4 in*

(101 mm)

4 in**

(101 mm)

4.4 in**

(112 mm)

9.28 in**

(235.7 mm)

9.28 in**

(235.7 mm)

4.70 in*

(119.4 mm)

Page 21

C HAPTER 1:INTRODUCTION

13

Page 22

Page 23

2CHAPTER 2: INSTALLATION

This chapter outlines the basic installation of the 60 Series instruments.

Please take the time to review these important guidelines.

IMPORTANT!

The 60 Series indicators do not include an on/off switch, and therefore

must be installed near a power outlet socket that is easily accessible and in

keeping with UL/CSA safety standards.

TABLE-TOP USE

All models excluding the model 663 have been designed with a swivel

bracket, which lets you tilt the instrument face to any desired angle. When

the instrument is placed on a table, the non-slip rubber feet prevent

scratching and slipping across the surface when keys are pressed.

PANEL MOUNT USE

All models excluding the Model 663 are available in panel mount versions.

When properly installed, the units are suitable for washdown environments.

The panel mount version functions identically to the table top version. The

only difference between the two package types is the mechanical aspects of

the enclosure and the positioning of the main board and display. Refer to the

60 Series Technical Reference Manual for further panel mount version

installation procedures and available options.

PERMANENT MOUNTING

Refer to pages 21 - 24 for panel mount cutout and mounting hole

dimensions.

ENVIRONMENT SUITABILITY

60 Series instruments are supplied in a NEMA 4X (IP66) enclosure and may

be used in a washdown environment. Care must be taken to ensure that the

AC power socket outlet is properly protected.

The keypad is made of silicon rubber. It may be cleaned periodically with a

soft damp non-abrasive cloth. The display window is made from a

15

Page 24

60 SERIES I NDICATORS

polycarbonate material, which may scratch due to aggressive cleaning. Care

must be taken to avoid such damage.

Connections from the load cell to the single channel input require gaining

access to J1 inside the sealed enclosure. In addition, peripherals and

options can be interfaced to 60 Series instruments by means of connections

within the enclosure. However, physically accessing the unit may void the

warranty. Refer to the Technical Reference Manual or contact your local

GSE distributor.

Calibrating the unit requires entering the Setup Mode and selecting the

calibration parameters specific to your application needs. Contact your

local GSE distributor for calibration service.

16

Page 25

C HAPTER 2:INSTALLATION

MODEL 460 OUTLINE DRAWINGS

Figure 11: 460 Standard Enclosure

Figure 12: 460 Panel Mount Enclosure

17

Page 26

60 SERIES I NDICATORS

MODEL 465, 560, 562, 660, 661, 662 OUTLINE DRAWINGS

Figure 13: Standard Enclosure (excluding 460, 663, 665)

Figure 14: Panel Mount Enclosure (excluding 460, 663, 665)

18

Page 27

C HAPTER 2:INSTALLATION

MODEL 663 OUTLINE DRAWINGS

Figure 15: Model 663 Standard Enclosure

Figure 16: Model 663 Big Box Enclosure

19

Page 28

60 SERIES I NDICATORS

MODEL 665 OUTLINE DRAWINGS

Figure 17: Model 665 Standard Enclosure

Figure 18: Model 665 Panel Mount Enclosure

20

Page 29

C HAPTER 2:INSTALLATION

PANEL MOUNT CUTOUTS

Figure 19: Model 460 Panel Mount Cutout

Figure 20: Model 465, 560, 562, 660, 661, 662 Panel Mount Cutout

21

Page 30

60 SERIES I NDICATORS

Figure 21: Model 665

22

Page 31

3CHAPTER 3: CALIBRATION

The 60 Series indicators can be calibrated several ways. The following

method is a quick calibration procedure and assumes that the necessary

parameters are selected before the actual calibration is performed (i.e. full

scale value, graduation size, etc.). Your local GSE distributor will normally

set up these parameters.

QUICK CALIBRATION

A certified weight is required to perform a calibration. Serious

inaccuracies could result from using non-certified standards for calibration.

To access calibration on the Model 460:

• From the Weigh Mode press

[ZERO]+[SELECT]

[ZERO] [PRINT] [UNITS] [TARE/ENTER]

To access calibration on all other 60 Series indicators:

• From the Weigh Mode press

[100] [SELECT] [5 4 3 2 1] [ID] [ENTER]

The controller will briefly prompt you with QUICK CAL! And then New

Zero?. If multiple scales are enabled, the controller will prompt you with

Keyin Scl #. Key in the scale number being calibrated and press [ENTER].

Use the [PRINT] and [UNITS] keys to enter the scale number on the Model

460. Refer to Table 2: 460 Key Functions on page 8. After the scale number

is entered the New Zero? prompt will be displayed.

Press the [SELECT] key to toggle through the available calibration

selections, and [ENTER] when the desired calibration method is displayed.

Press [ENTER] to begin calibration when the desired calibration selection is

displayed. Pressing the [CLR] key at any point in the calibration routine will

back you up one step.

23

Page 32

60 SERIES I NDICATORS

The calibration selections are as follows, starting with New Zero?:

• New Zero?

• Last Zero?

• Temp Zero?

• Only Zero?

• Cal Reset

• Known Load Cell

•

NEW ZERO?

New Zero? is the selection for establishing the first or a new calibration. If

New Zero? is selected, the controller displays the dead load (which might

not be in precise units) that is present on the scale. The controller assumes a

“NO LOAD” condition.

Remove the load, and press [ENTER]. As soon as [ENTER] is pressed, a

new zero is established. This is reflected on the main display with the

prompt Adj’g Zero followed by the prompt Keyin CalWt.

At this point, the controller is waiting for the actual calibration value to be

entered. Place the calibration weight on the platform, key in the weight

value, and press [ENTER].

If you key in a cal weight and press [ENTER] without adding any weight

since the last calibration weight, the controller will prompt you to add

CalWT. Add the weight and press [ENTER].

NTERING NUMERIC VALUES

E

Where appropriate, you can use the numeric keypad to enter numeric values.

Use the [PRINT] and [UNITS] keys to enter numeric values on the Model

460. Refer to Table 2: 460 Key Functions on page 8. If an error is made

while entering data, press [CLR] before you press [ENTER]. The controller

will perform the calibration, display the value of the calibration weight, and

prompt CAL OK?. At this point, you can check the accuracy of the

calibration by weight without leaving the Calibration Mode.

• If the calibration was accurate, press [ENTER].

• The controller will prompt you to save the new calibration plus any

other changes you have made. Press [ENTER] twice to save and exit.

24

Page 33

C HAPTER 3:CALIBRATION

• If the calibration is not accurate, press [CLR].

The controller will return to the New Zero? prompt. Repeat the above

steps to calibrate.

If the calibration weight was less than 5% of capacity, or if there was a

large change in the calibration, the controller prompts ReCal Req’d. Press

[ENTER] and repeat the calibration, or press [CLR] to obtain the CAL

OK? prompt as described above and override the re-calibration

requirement.

LAST ZERO?

The Last Zero procedure allows recalibration of the weighing device using

an existing test load. This is especially beneficial when checking high

capacity applications such as tank weighing to minimize the task of placing

and removing test weights.

1. Remove all weight from the scale

2. Press [ZERO] to zero the scale in the weigh mode.

3. Apply the calibration test weight.

4. Access the Calibration Mode (see page 23).

5. Use the [SELECT] key to toggle to Last Zero?.

6. At the Last Zero? prompt, the [ENTER] key is pressed.

7. Key in the calibration weight value in terms of the default calibration

units and press [ENTER]. For the Model 460, use the [PRINT] and

[UNITS] keys to enter numeric values. Refer to Table 2: 460 Key

Functions on page 8.

8. After establishing span, Cal OK? is displayed. Or if Recal ??? is

displayed, repeat the calibration process.

9. Press [ENTER] to save the calibration.

10. At the prompts Save Mods? and Enter = Save are displayed, [ENTER]

is pressed to save the new calibration factors.

11. At the Enter = Exit prompt, [ENTER] is pressed again and the

controller returns to the Weigh Mode.

25

Page 34

60 SERIES I NDICATORS

TEMP ZERO?

Temp Zero? is used to recalibrate without establishing a new zero. In some

applications you might want to perform a calibration without removing the

currently applied load. This is particularly useful in tank weighing

applications where it is both time-consuming and costly to drain the tank

being weighed.

During the calibration procedure, at the Temp Zero? prompt you press

[ENTER]. This action causes the controller to zero the displayed weight

temporarily so additional weight can be added to assure system calibration.

The zero determined during the previous calibration is not affected.

1. Access the Calibration Mode (see page 23).

2. Use the [SELECT] key to toggle to Temp Zero?.

3. At the Temp Zero? prompt, press [ENTER].

The displayed value will zero out.

4. Apply the calibration weight.

5. Key in the value of the calibration weight: for example, 1 0 0 0

[ENTER]. For the Model 460, use the [PRINT] and [UNITS] keys to

enter numeric values. Refer to Table 2: 460 Key Functions on page 8.

The numeric display should show the entered value.

6. Remove the calibration weight. The display should return to zero. If the

display reads as specified, at the Cal OK? prompt press [ENTER]. To

repeat the calibration process, press [CLR], and then repeat steps 2

through 5.

7. Save the newly determined calibration weight: At the Enter = Save

prompt, press [ENTER]

8. To return to the Weighing Mode, at the ENTER = EXIT prompt, press

[ENTER].

ONLY ZERO?

Only Zero is used to establish a new calibration zero without affecting the

span. This is useful for correcting changes to the scale’s dead load, for

example in tank weighing applications where the re-zero parameter (P118) is

set very low in order to prevent inadvertent re-zeroing. A build-up of sludge

can be zeroed out in this manner.

26

Page 35

C HAPTER 3:CALIBRATION

1. Remove all weight from the scale.

2. Access the Calibration Mode (see page 23).

3. Press [SELECT] to toggle to the Only Zero? routine.

4. At the Only Zero? prompt, press [ENTER].

The displayed value zeroes out. Adj Zero! is displayed briefly, followed

by CAL OK?.

5. Press [ENTER] to accept the newly established zero, or [CLR] to

repeat the calibration.

9. At the Enter = Save prompt, press [ENTER]

10. To return to the Weighing Mode, at the ENTER = EXIT prompt, press

[ENTER].

C

AL RESET

Cal Reset may be necessary when an over-load or under-load condition

exists, preventing the completion of the calibration process. Calibration

Reset adjusts the zero and gain factors of the A/D amplifier to factory

default values for maximum sensitivity.

After performing a calibration reset, a complete recalibration is required.

The effects of a calibration reset do not take effect until the indicator is

recalibrated and calibration information has been saved.

If Code 02 (under-load) or Code 03 (over-load) is displayed during

calibration, press [CLR] to perform a calibration reset.

When reset, these parameters are adjusted to the lowest possible values.

Contact your GSE Distributor regarding Information Parameters for a more

detailed explanation on the gain factors.

Normally, a Cal Reset is performed if the amplifier is locked in at an

extremely high gain factor and will not allow a new calibration to be

performed.

1. Access the Calibration Mode (see page 23).

2. Press [SELECT] to toggle to the Cal Reset.

27

Page 36

60 SERIES I NDICATORS

Once the Cal Reset is performed, the controller returns to the New Zero?

prompt. Press [SELECT] to toggle to the desired calibration routine.

Following a Cal Reset, a re-calibration should be performed before exiting

the calibration or Setup Modes. The reset will not be saved unless a recalibration is performed and changes are saved.

KNOWN LOAD CELL?

Known Load Cell is used to calibrate without test weights. The exact full

scale mV/V rating must be known for each load cell. All load cells must be

of the same full scale capacity. This procedure works best for hopper scales

where weight is evenly distributed and signal trimming is not required.

1. Access the calibration mode (see page 23).

2. Press [SELECT] to toggle to the Known LCOut routine.

3. Press [ENTER] at the Known LCOut prompt to display #of LC.

The number of load cells specified during the last calibration will also

be displayed. A value of zero (0) indicates that this calibration method

has not yet been performed.

4. Key in the number of load cells and press [ENTER]. For the Model

460, use the [PRINT] and [UNITS] keys to enter numeric values. Refer

to Table 2: 460 Key Functions on page 8.

- or -

Press [ENTER] to accept the displayed value.

5. The display prompts LC#x mVv (where ‘x’ is the load cell number) and

then shows the mV/V value (0.1 Æ 5.0) last entered for this load cell.

6. Key in the load cell’s mV/V value and press [ENTER]. For the Model

460, use the [PRINT] and [UNITS] keys to enter numeric values. Refer

to Table 2: 460 Key Functions on page 8.

- or -

Press [ENTER] to accept the displayed value.

7. Steps 5-6 will be repeated for as many load cells as specified in step 4.

8. The display prompts LC FS showing the value last entered for the load

cell full scale.

28

Page 37

C HAPTER 3:CALIBRATION

9. Key in the full scale capacity for the load cell(s) and press [ENTER].

For the Model 460, use the [PRINT] and [UNITS] keys to enter

numeric values. Refer to Table 2: 460 Key Functions on page 8.

- or -

Press [ENTER] to accept the displayed value.

10. The display briefly shows Updtg Gains as it updates the gain values,

then prompts CurWt Zero?.

11. Press [ENTER] to establish the current input signal as the zero

reference.

- or -

Press [SELECT] to display Zero=0mVv?. Press [ENTER] to use a

0mV/V output as the zero reference.

- or -

Press [SELECT] to display Keyin CurWt. Key in the known gross

weight already applied to the scale and press [ENTER].

- or -

Press [CLR] to bypass the zeroing option.

12. The display shows CAL OK? suggesting that the calibration is

acceptable.

Accept the calibration by pressing [ENTER] at the CAL OK? prompt.

- or -

Repeat the calibration by pressing [CLR] at the CAL OK? prompt.

13. Once the calibration is accepted, press [ENTER] at the ENTER=SAVE

prompt and again at the ENTER=EXIT prompt to save the new

calibration and exit the calibration mode.

- or -

To exit the calibration mode without

[CLR] at the ENTER=SAVE prompt. Then press [ENTER] at the

ENTER=UNDO

exit the calibration mode.

prompt and again at the ENTER=EXIT prompt to

saving the new calibration, press

SAVE CALIBRATION

The indicator will perform the calibration, display the value of the

calibration weight, and display the prompt, CAL OK?. At this point, you can

29

Page 38

60 SERIES I NDICATORS

check the accuracy of the calibration by weight without leaving the

Calibration Mode.

If the calibration was accurate, press [ENTER]. The indicator will prompt

you to save the new calibration plus any other changes you made. Press

[ENTER] to save, then [ENTER] again to exit. If the calibration is not

accurate, press [CLR]. The indicator will return to the New Zero? prompt.

If the calibration weight is less than 5% of capacity or if there is a large

change in the calibration, the indicator will prompt ReCal Req'd. Press

[ENTER] and you will be returned to the beginning of the calibration

selections, or press [CLR] to obtain the CAL OK? prompt as described

above and override the re-calibration requirement.

A variation of the calibration process is the linearization procedure.

Linearization is useful in improving the absolute accuracy of large-capacity

systems, which often exhibit poor linearity. This feature is documented in

the 60 Series Technical Reference Manual.

30

Page 39

4CHAPTER 4: COUNTING MODE

The front panel keys on the 60 Series take on different functions depending

on the selected mode. This chapter will define the front panel key operation

for the Counting Mode.

COUNTING MODE (KEY OPERATION)

To activate the counting operation, the indicator must be in the Quantity

mode. To access the Quantity mode on a Model 460, the quantity mode must

be in the selectable modes of instrument operation. Simply press the

[SELECT] key to step through all enabled modes of instrument operation.

The Quantity mode may be accessed directly by pressing [30] [SELECT]

(not available on the Model 460).

SAMPLING TO DETERMINE A PIECE WEIGHT

Although the sampling process may be performed in a number of ways, the

recommended method is to first access the Quantity mode, then place an

empty box or empty container on the scale platform, and press [ENTER].

The first time a sample is performed, the display will read Must Sampl and

press [ENTER]. The indicator will then perform an auto-tare resulting in a

zero net weight. The display will prompt you to Add xx, where the "xx" is

the sample quantity of parts (sample size)—the manufacturer default setting

is 10 pieces. Add the requested number of parts to the scale and press the

[ENTER] key.

If the sample's total weight was sufficient, the piece weight will be

calculated and the sample quantity will be displayed. Otherwise, you may

be prompted to add additional parts. The exact prompts will depend on

whether the auto-enhance and/or minimum accuracy assurance features have

been enabled. The minimum amount of weight required for the sample

routine to meet the selected accuracy requirements for the specified scale

capacity is considered.

If the weight of the sample is un-detectable or barely detectable then the

message Code 32 ADD MORE! is displayed briefly. This will most often

occur when the [ENTER] key is pressed without adding any parts. If the

parts were in fact placed on the scale, either the parts are too light to count

on that capacity platform or a much larger quantity of parts must be hand

counted in order to perform the sample.

31

Page 40

60 SERIES I NDICATORS

EGATIVE SAMPLING TO DETERMINE A PIECE WEIGHT

N

In order to perform a negative sample routine, access the Quantity mode,

place a full or partially full container of parts on the scale, and press

[ENTER].

The indicator will then perform an auto-tare resulting in a zero net weight.

The display will then prompt you to Add xx where the "xx" is the sample

size. In this case, the prompt Add xx actually means take parts from the

container. Proceed to remove the requested number of parts, and then press

the [ENTER] key. If the sample's total weight was sufficient, the piece

weight will be calculated and the sample quantity will be displayed (-10

parts). Otherwise, you may be prompted to take additional parts. The exact

prompts will depend on whether the auto-enhance and/or minimum accuracy

assurance features have been enabled.

If the weight of the sample removed was un-detectable or barely detectable

then the message Code 32 ADD MORE! is displayed briefly. This indicates

that more weight must be removed adding to the overall sample weight.

This occurs most often when the [ENTER] key is pressed without taking out

any parts. If the parts were in fact taken from the scale, either the parts are

too light to count on that capacity platform or a much larger quantity of parts

must be hand counted out in order to perform the sample.

The first method is recommended to avoid the possibility that inappropriate

tare weights may affect the piece weight calculation.

When the Quantity mode is accessed and the residing piece weight value is

“0.00”, the prompt Must Sampl will be displayed. Press the [ENTER] key

to proceed with the sampling to determine a piece weight.

PIECE WEIGHT ENHANCEMENT

The presence of this feature depends on the internal setup of your

controller. It is intended for the accurate counting of extremely light parts.

1. Access the quantity mode.

2. Place an empty container on the platform (optional).

32

Page 41

C HAPTER 4:COUNTING M ODE

3. Press [ENTER]. The indicator tares to a zero net weight. The display

shows the current net weight and the prompt: Add 10.

4. Place the specified number of parts on the scale.

5. Press [ENTER]. The indicator then calculates the piece weight of the

sample parts and momentarily displays the maximum number of parts

which may be added for a piece weight enhancement to occur. The

minimum achieved accuracy is then displayed.

6. If a greater accuracy is desired, add additional parts but not more than

the maximum enhanceable quantity.

7. As soon as motion ceases, the indicator will recalculate the piece weight

and then briefly display the new maximum number of pieces which can

be added and still accurately enhance the piece weight.

8. Repeat as many times as necessary to achieve the desired accuracy.

KNOWN CONTAINER WEIGHT

Place the full container of parts on the weigh platform. At any point in the

counting process, the known weight of a container can be keyed in followed

by the [TARE] key in order to cancel the affect of the container. Make

certain that the weighing units of your entry are consistent with the current

unit selection (lb, kg, etc.)

AUTOMATIC SCALE SELECT (WITH MORE

THAN ONE WEIGHING PLATFORM)

The 60 Series has the capability of automatically selecting a predetermined

scale before and after the sample routine. One or more multi-scale option

cards must be installed for this feature to work.

One scale will be a pre sample and the other will be an after sample. During

operation, press the [ENTER] key and the indicator will automatically select

the predetermined sample scale. The prompt add XX will be displayed.

Place the specified number of pieces on the sample scale and again press

[ENTER]. The average piece weight having been established, the indicator

automatically selects the appropriate “bulk” scale for higher capacity

counting.

33

Page 42

60 SERIES I NDICATORS

COUNTING MODE LISTING

The [SELECT] key will advance to the next mode. Alternatively, keying a

mode number then pressing [SELECT] will change the current mode to be

the mode whose number was keyed in. The following six modes are

counting related. Any one of these parameter numbers listed may be printed

out on a ticket.

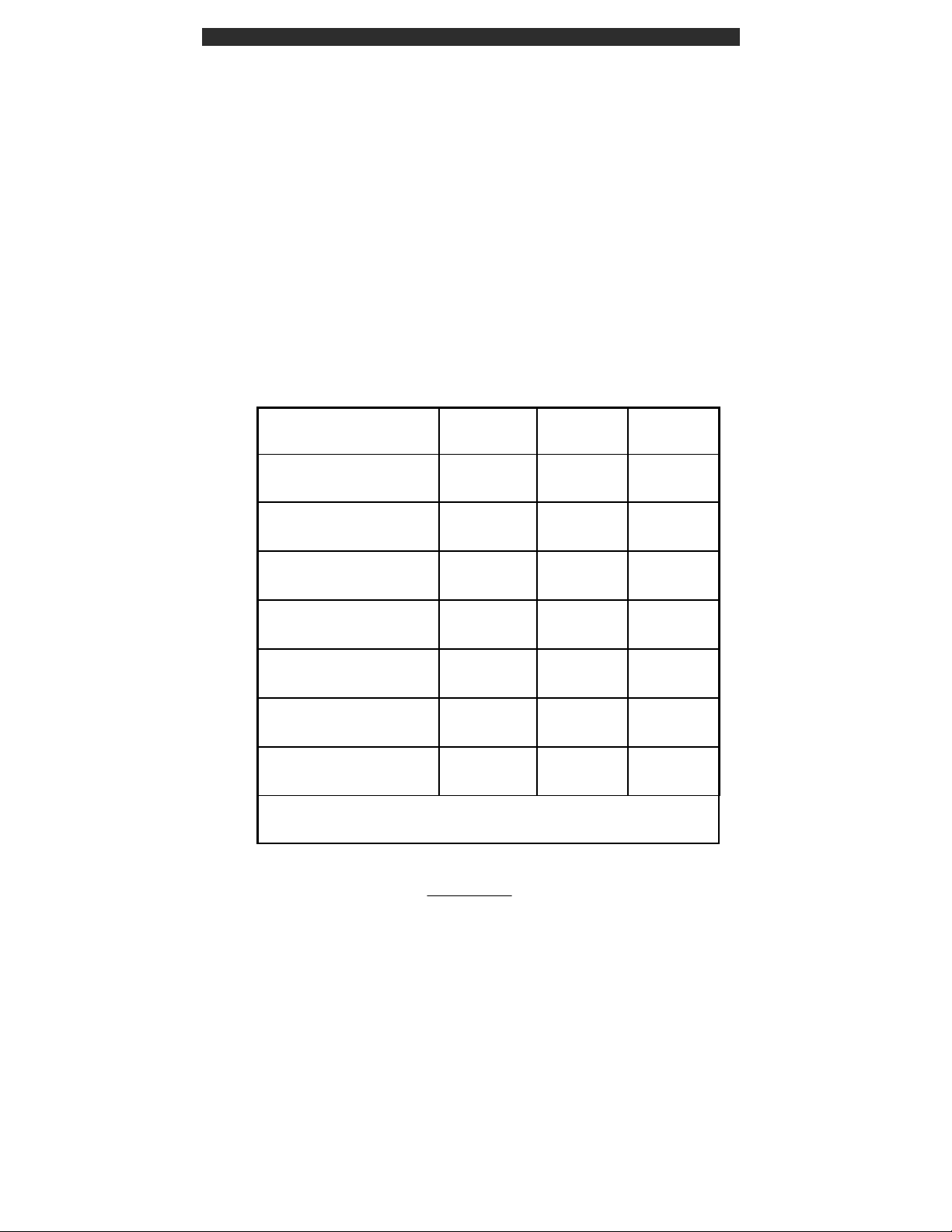

Table 3: Counting Mode Parameter Numbers

Mode Number Description

30 Quantity

31 Quantity Total

34 Piece Weight

35 Piece Weight x 1000

36 Percentage Accuracy Achieved

37 Last Sampled Amount

34

Page 43

5CHAPTER 5: ACCUMULATION MODE

60 Series controllers offer three main memory registers into which weighing

data may be accumulated. The three registers are the Gross Total, Net Total

and the Quantity Total.

PERFORMING ACCUMULATIONS

First, enter the desired “Accumulation Mode” either by pressing the

[SELECT] key until one of the Accumulation Modes appears on the display

or key in one of the accumulation parameters directly. Refer to Table 4:

Accumulation Mode Numbers on page 36. Once in an Accumulation Mode,

press [UNITS] + [SELECT] on the Model 460 or [.] [ENTER] on all other

60 Series indicators to add the displayed value to the accumulated total.

Accumulate operations are motion delayed. If motion is occurring when an

accumulation is requested, the Mot'n Delay prompt is displayed until motion

ceases. If motion does not stop, press [CLR] to abort the accumulation.

There are six Accumulation Modes with corresponding Mode Numbers as

shown in Table 4. When an accumulation is made, both the Gross and Net

totals are affected. After an accumulation occurs, these values are frozen at

their new accumulate total values until the Gross Weight returns to zero. The

weight must return to zero before another accumulation is allowed. At that

time, these values again resume their active state. This feature prevents

double accumulations. A CLEAR WGHT prompt appears to warn of such

situations.

INITIALIZING ACCUMULATION TOTALS

The Accumulation Registers may be reset to a new number. This would

permit you to enter a total from the previous day or shift to continue the

accumulation, or to reset the number to “0”. Access the Accumulation Mode

by keying in the single or two-digit mode number from Table 4 and pressing

[SELECT] (not available on the Model 460). If the mode is one of the preprogrammed selectable modes simply toggle to the corresponding mode

using the [SELECT] key. Key in the desired reset value and press

[ENTER]. You will then be prompted to confirm the accumulation

modification by a display of MOD AC? for 1 second followed by ENTER

=MOD. Press [ENTER] to confirm the change or any other key to abort the

modification of the accumulation total.

35

Page 44

60 SERIES I NDICATORS

The [ZERO] + [ENTER] keys on the Model 460 or the [CLR] key on all

other 60 Series may be used to reset both the net and Gross Totals to zero.

The prompt CLEAR ACS? will appear briefly followed by ENTER =CLR!.

Press [ENTER] to complete the clearing or press any other key to abort the

clear operation.

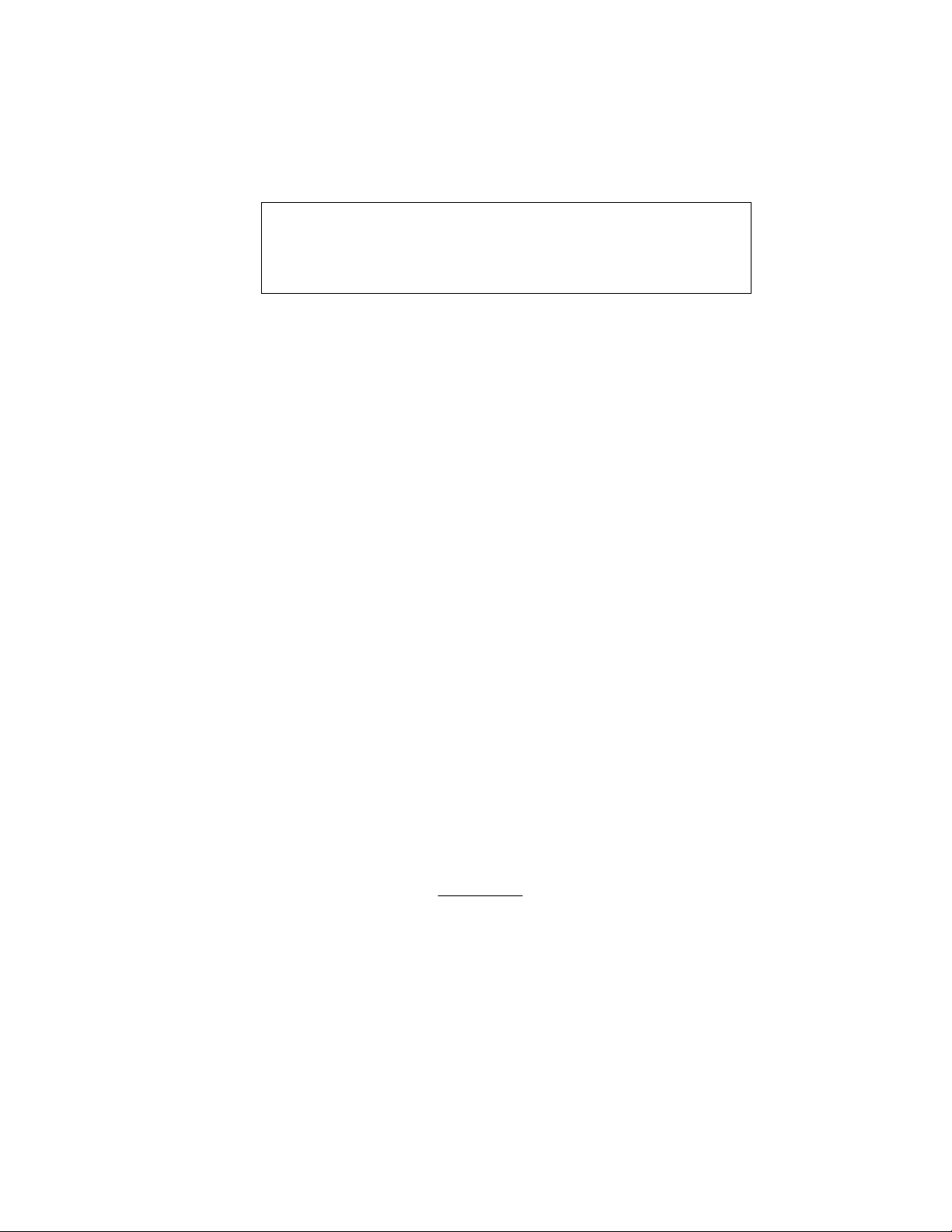

Table 4: Accumulation Mode Numbers

Mode Number Description

3 Gross Total (GrTOT)

6 Net Total (GrTOT)

9 Accumulation Counter (# Accum)

31 Quantity Total (QtTOT)

36

Page 45

6CHAPTER 6: ADDITIONAL OPERATING MODES

We have taken popular application files and incorporated them into the

firmware in an easy to use menu format. Use the arrow keys to scroll

through the choices or the [SELECT] key on the Model 460 and press

[ENTER] to setup the chosen application file. An explanation of each

application file can be found at the bottom of the display on the LCD models

only. With 5 different display choices available on the 60 series instruments,

menu selections may vary in appearance. Operator prompts will also vary

with display type.

PIECE WEIGHT DATABASE MODE – APW

L

OOKUP

A specific average piece weight may be recalled from a database. The

average piece weight will be associated with an ID#.

STORE APW – STORE A SPECIFIC APW TO THE DATABASE –

MUST PERFORM A SAMPLE BEFORE USING.

1. To store an average piece weight, Press [SELECT] until APW is

displayed. Key in the average piece weight and press [ENTER].

2. From the gross weight, press [F1]. Prompt = “Key In ID”.

3. Key-in the desired ID number.

4. Press [ENTER]. Prompt = “store new#?”.

5. Press [ENTER] to store the ID. Or [CLR] to abort.

6. Add sample parts (default value = 10) to the scale.

7. Press [ENTER] to store APW.

[CLR] will abort the process.

GET APW – RETRIEVE A SPECIFIC APW FROM THE DATABASE

1. Press [F1]. Prompt = “Key In ID”.

2. Key in the ID number. If the ID# exists, “Found ID#” will be

displayed briefly and then ID#.

3. The display will return to the QTY mode. Press [ENTER] to accept

entry.

4. The piece weight register is updated with the associated value.

37

Page 46

60 SERIES I NDICATORS

Note: If the ID# does not exist you will be prompted to add default number of

pieces to store a new APW.

[CLR] will abort the process.

PRINT APW’S – PRINTS ALL STORED RECORDS IN ROW/COLUMN

FORMAT

1. Press [TARGET] or [F2]. Prompt = “Delete ID# XXX?”.

2. Press [CLR/NO] to advance to print mode.

3. Press [ENTER] to print stored APW’s in row/column format.

4. Indicator returns to the gross mode.

.

CLEAR ONE APW – CLEARS CURRENT RECORD FROM THE

DATABASE

1. Press [TARGET] or [F2]. Prompt = “Delete ID# XXX?”.

2. Press [ENTER] at the prompt to confirm deletion.

Note: this will only remove the current APW from the database.

.

CLEAR ALL APW’S – CLEARS ALL RECORDS FROM THE

DATABASE

.

1. Press [TARGET] or [F2]. Prompt = “Delete ID# XXX?”.

2. Press [CLR/NO] until “Clear ALL?” is displayed.

3. Press [ENTER] to delete all ID#s from the database. Prompt = “Clear

SURE?”.

4. Press [ENTER] at the prompt to confirm deletion.

5. Indicator returns to the previous display mode.

38

Page 47

C HAPTER 6:ADDITIONAL O PERATING M ODES

TRUCK IN/OUT (MODELS 465,560,562 AND

660 SERIES)

Used for vehicle weighing where product is being loaded or unloaded.

TRUCK IN

Weigh the vehicle in.

1. With the truck on the scale. Press [F1]. Prompt = “Key In ID#”.

2. Press [ENTER] for Automatic ID# or key-in the ID number and press

[ENTER].

3. The indicator flashes Weigh In and returns to the gross mode.

4. If a printer is connected, a ticket will automatically be printed.

Note: look at ticket to find the trucks ID# if Automatic ID# is used.

TRUCK OUT

Weigh the vehicle out.

1. With the truck on the scale. Press [F1]. Prompt = “Key In ID#”.

2. Key-in truck ID#.

3. Press [ENTER] prompt flashes “Weigh Out”.

4. If a printer is connected, a ticket will automatically be printed.

PRINT ID’S?

Prints all ID’s in a row column with header format.

1. Press [TARGET] or [F2]. Prompt = “Print ID’s?”. All stored ID

numbers will be printed.

2. Press [ENTER]. Prompt = “Clear One?”.

3. Press [CLR/ NO]. Prompt = “Clear ALL?”.

4. Press [CLR/NO] indicator returns to previous display mode.

CLEAR ONE ID

Clears 1 record from the database.

39

Page 48

60 SERIES I NDICATORS

1. Press [TARGET] or [F2]. Prompt = “Print ID’s?”.

2. Press [CLR/NO]. Prompt = “Clear One?”.

3. Press [ENTER]. Prompt = “ID to Delet”.

4. Key in the ID number to be deleted and press [ENTER].

5. If the ID number is not stored in the database, “Not Found” will be

displayed briefly. The indicator returns to the weigh mode.

6. Otherwise, if the ID number was found “Done” will be displayed

briefly and the indicator will return to the weigh mode.

CLEAR ALL

Clears all records from the database.

1. Press [TARGET] or [F2]. Prompt = “Print ID’s?”.

2. Press [CLR/NO]. Prompt = “Clear One?”.

3. Press [CLR/NO]. Prompt = “Clear ALL?”.

4. Press [ENTER]. Prompt = “Clear Sure?”.

5. Press [ENTER] indicator returns to previous display mode.

Note: [CLR] will abort the process.

STORE TRUCK IN TARE WEIGHT

Make a permanent record in the database for a truck tare weight.

1. Press [F1]. Prompt = “KeyIn ID#”.

2. Press [TARE]. Prompt = “Press tare or KeyIn”.

3. Key-In tare weight of truck or have truck on the scale.

4. Press [TARE]. Prompt = “KeyIn ID#”.

5. Key in the ID number and press [ENTER].

40

Page 49

C HAPTER 6:ADDITIONAL O PERATING M ODES

CHECK WEIGH ABSOLUTE AND PERCENTAGE

OPERATION

The standard check-weigh operation is designed to check the weight of an

item against a given standard or target weight. In the check weigh absolute

mode, values are entered as target limits. In the check weigh percent mode,

the values are entered based on percentage.

SET THE HI AND LO WEIGHTS (460)

1. Press [SELECT] until prompt = “mName SETUP”.

2. Press [TARE] prompt =”10.00 High” (by default)

3. Use the [PRINT] key to enter a number ( [UNITS] key moves

placeholder over 1 spot)

4. Press [TARE] prompt = “5.00 Lo”.

5. Repeat steps 2 – 4 to enter in low value

6. Press [TARE] indicator returns to previous display mode.

USE CHECK WEIGH (460)

1. Press [SELECT] until prompt = “mName START”

2. Press [ENTER]. The display will return to the weigh mode.

3. To stop check-weighing, press [SELECT] until prompt = gross mode.

Note: if your weight is greater than your hi weight then the prompt = “OVER” is

displayed. If your weight is less than your Lo weight the prompt = “UNDER” is

displayed. If your weight is between the Hi and Lo then prompt = “GOOD” is

displayed.

SET THE HI AND LO WEIGHTS (465,560,562 AND 660 SERIES)

1. Press [TARGET] or [F2] prompt = “10.00 Hi”. (by default)

2. Key in the desired high value weight.

3. Press [ENTER] prompt = “5.00 Lo”. (by default)

4. Key in the low value weight.

5. Press [ENTER] indicator returns to previous display mode.

USE CHECK WEIGH

1. Press [F1] to start check-weighing

2. Add your weight to the scale.

3. Press [TARGET] or [F2] key to stop check-weighing

41

Page 50

60 SERIES I NDICATORS

Note: if the weight is greater than the high limit then the prompt OVER” is displayed.

If the weight is less than the low limit the prompt “UNDER” is displayed. If the

weight is between the high and low limits then prompt “GOOD” is displayed.

BATCHING OPERATION (465,560 AND 562) F

ILL

SETTING SETPOINTS, PREACT, AND DRIBBLES

1. Press [TARGET] or [F2] prompt = “current setpoint value + SP 1”.

2. Key in Setpoint value.

3. Press [ENTER] prompt = “ current setpoint value + PAct.”.

4. Key in Preact value (if enabled), zero (0) for no preact.

5. Press [ENTER] prompt = “current setpoint value + Drib”.

6. Key in Dribble value (if enabled), zero (0) for no dribble.

7. Repeat steps 2 – 6 for each setpoint your systems has.

8. Systems returns to previous display mode.

BATCHING

1. Press [ZERO] to zero the indicator

2. Press [F1]. Fill until the target is met. “Done” will be displayed when

cycle completes

3. Empty the scale

42

Page 51

7CHAPTER 7: TIME AND DATE (CLOCK FEATURE)

The 560 and 660 Series indicators include a battery backed time/date

feature. The 460/465 have an optional battery backed time/date module.

Without this option on the 460 Series, the time/date will be reset when

power is lost. This means that when the feature is used, the time and date

does not need to be entered every time the instrument is powered up. The

time/date feature permits printouts with time and day of the week and the

date in many possible formats. Consult with your local GSE distributor or

the 60 Series Technical Reference Manual for more information on time/date

configurations.

In the following discussion, HH is a 2-digit representation for hours, MM

is minutes, SS is seconds, MO is month, DA is day and YR is year. When

the 60 Series controller is powered up, the time and date clock is set to Jan

1, 1970, 00:00:00 am.

VIEWING TIME AND DATE

While in the Weigh Mode, the time and date can be displayed

simultaneously in the dot matrix and main displays. Press [SELECT] on the

Model 460 until the time/date is displayed or [11] [SELECT] on the other

models. The date is then displayed on the large numeric display in the format

"MM.DD.YY" (or DD.MM.YY for international style) and the time is

displayed on the dot matrix display in the format "HH:MM:SS". The time

may be displayed in a 24 or 12-hour format with an "am" or "pm" displayed

as appropriate, depending on the setup of time-date.

ENTERING A NEW TIME AND DATE

(EXCLUDING MODEL 460)

From the weigh mode, press [11] [SELECT] to access the time and date.

Press [ENTER] to invoke the date prompt. A new date is entered by keying

in "MM.DD.YY" (or "DD.MM.YY" if international format was selected)

followed by the [ENTER] key. Month, day and year entries must be

separated by decimal points. Leading zeroes need not be entered. For

example, if you enter "4.1.96" and press [ENTER] the date is set to

04/01/96. If the date is entered improperly, the prompt try m.d.y (or try

d.m.y for international format) is displayed. The word Date will then be

43

Page 52

60 SERIES I NDICATORS

displayed. Press [ENTER] if the date is correct and move to the Time

setting mode.

The new time is entered by keying in "HH.MM.SS" in a 24-hour format.

Hours and minutes entries must be separated by a decimal point. Seconds

entry is optional, and if omitted, they are set to zero. To specify seconds, it

also must be separated from minutes by a decimal point. Leading zeroes

need not be entered. For example, if you enter "8.9.45" and press

[ENTER], the time will be set to 08:09:45; if you enter "15.02" and press

[ENTER] the time is set to 15:02:00. If time is entered improperly, the

prompt try h.m.s is displayed. The word Time will then be displayed. Press

[ENTER] if the time is correct.

ENTERING A NEW TIME AND DATE (MODEL

460)

From the weigh mode, [SELECT] until the time/date is displayed. Press

[ENTER] to invoke the date prompt. The [ENTER] key may be pressed to

bypass the date entry. A new date is entered by keying in "MM.DD.YY" (or

"DD.MM.YY" if international format was selected) followed by the

[ENTER] key. Month, day and year entries must be separated by decimal

points. Leading zeroes need not be entered. Using the combination of the

[PRINT] and [UNITS] keys, enter the in the date. If the date is entered

improperly, the prompt try m.d.y (or try d.m.y for international format) is

displayed. The word Date will then be displayed. Press [ENTER] if the

date is correct and [ENTER] again to move to the Time setting mode.

The [ENTER] key may be pressed to bypass the time entry. The new time is

entered by keying in "HH.MM.SS" in a 24-hour format. Hours and minutes

entries must be separated by a decimal point. Seconds entry is optional, and

if omitted, they are set to zero. To specify seconds, it also must be separated

from minutes by a decimal point. Leading zeroes need not be entered. Use

the [PRINT] and [UNITS] keys to enter time. If time is entered improperly,

the prompt try h.m.s is displayed. The word Time will then be displayed.

Press [ENTER] if the time is correct.

44

Page 53

8CHAPTER 8: LEGAL-FOR-TRADE

The 60 Series parameter setup does not ensure compliance with legal-fortrade installations as mandated by local weights and measures authorities.

This chapter explains how to configure the 60 Series controllers to comply

with various regulations and describes other features that will make your

controller suitable for installations worldwide.

Legal-for-trade requirements vary by location. Ensure that your controller is

installed in accordance with all local regulations.

OIML AND INTERNATIONAL OPERATION

The International Organization of Legal Metrology is an inter-governmental

body, which harmonizes the national metrology regulations of its worldwide

members. A list of regulation publications can be obtained from the Bureau

International de Métrologie Légale (BIML) in Paris, France.

In order to configure the your controller to comply with OIML requirements,

P410 must be enabled in the Setup Mode. Doing this will ensure the

following:

• An over-load condition will result when the gross weight exceeds nine

graduations over the full-scale capacity.

• Full scale capacity is always referenced from the last zero calibration

reference, not the last zero acquired by pressing [ZERO].

• The keypad is remapped for the international version.

• Presettable parameters will give indication that a value has been entered

manually.

Most NTEP requirements will also apply.

For detailed information on enabling OIML operation, please see the 60

Series Technical Reference Manual.

45

Page 54

60 SERIES I NDICATORS

NTEP

The National Type Evaluation Program (NTEP) is a widely accepted

weights and measures standard in the United States. Most states abide by

some or all of the requirements set forth by NTEP. A complete list of these

regulations is available in the “Handbook 44” publication distributed by the

National Institute of Standards and Technology (NIST). For more

information on this and other NIST publications, visit their web site at

http://www.nist.gov.

ENABLING NTEP OPERATION

In order to configure the 60 Series indicators to comply with NTEP

requirements, the NTEP parameter (P440) must be enabled in the Setup

Mode. This will have the following effects on the standard indicator’s

operation:

• Pressing [TARE] with a gross weight of zero (0) or pressing 0 [TARE]

will not automatically switch to the net mode.

• Negative tare values are not accepted regardless of the selection for the

“Negative Tare Enable” parameter (P162).

• Tare values are automatically rounded regardless of the selection for the

“Tare Rounding Enable” parameter (P163).

• Received serial data will not be processed while in the Setup Mode until

P440 is manually enabled.

• Accumulations using the . [ENTER] method can only be performed

from the gross, net or quantity mode.

• Printing using the [PRINT] key is only possible from the gross, net or

quantity mode.

• Weight values that exceed the minimum width specified at P240 will be

transmitted as dashes "-------".

Legal-for-trade installations using accumulations require the “number of

accumulations” parameter (9) to be accessible when not using a printer.

When using a printer, this parameter must be printed on the receipt.

46

Page 55

C HAPTER 8:LEGAL- FOR-TRADE

NTEP CUSTOM SETUP

The “Custom Setup” parameter, P60205 of the information parameters,

displays a list of parameters, which, if configured improperly, could

facilitate fraud in a legal-for-trade installation. A weights and measures

inspector might check this parameter and inquire about the configuration of

any parameters that appear in this list.

ACCESSING THE CUSTOM SETUP LIST

DO NOT ATTEMPT TO ACCESS THE CUSTOM SETUP LIST

DURING CRITICAL WEIGHT PROCESSING! It is important to note

that all functions of the operating mode will be suspended immediately upon

accessing the information parameters. This includes suspension of weight

conversions, deactivation of all setpoints and cancellation of custom

transmits.

The “Custom Setup” list may be accessed from the Weigh Mode. An access

code is not required to view this list.

To access the custom setup list:

1. From the Weigh Mode, key in 60205 [SELECT].

2. The Custom Setup list begins scrolling through each parameter to check.

If there are no parameters to check, Std. Setup is displayed.

3. The Custom Setup list may be repeated by pressing [ENTER] at

P60205.

4. Press [ZERO] to return to the Weigh Mode.

A setup parameter that appears in the “Custom Setup” does not imply that it

is improperly configured. Consider the application and refer to the

following descriptions to determine if the parameter is configured

appropriately.

P205 – Receive Mode

If the receive mode is enabled for any of the four communication ports, any

device connected to that port should not be used to transmit data to the

M660 which could facilitate fraud.

47

Page 56

60 SERIES I NDICATORS

P205 will appear in the “Custom Setup” list for each receive port enabled.

For example, if the receive mode is enabled for all four ports, the list will

display

P205—, P205˜, P205™, and P205š.

P240 – Minimum Transmit Width

A weight value that cannot be displayed due to the 6-digit limitation of the

standard VF display may not be printed. To ensure this is not possible, P240

must be set to a width of not greater than 7 (6 digits and a decimal point).

NTEP must also be enabled at P440. Any weight value that exceeds the

minimum width specified will be printed as dashes "-------".

P440 – NTEP Enable

P440 appears in the “Custom Setup” list if disabled. Refer to Enabling

NTEP Operation on page 46 for possible implications.

P9990 – Macro Instance Selection

P9990 appears in the “Custom Setup” list if at least one macro is configured.

Macro operation should be checked to verify its conformance to all

regulations.

ADDITIONAL CONFORMANCE CONSIDERATIONS

Several parameters must be considered on an individual basis as their

configuration may vary with different applications. These parameters

include, but are not limited to those listed in Table 5.

Table 5: Additional Conformance Parameters

PARAMETER DESCRIPTION COMMENT

P110 Full Scale Capacity Verify proper scale capacity.

P111 Division Size Verify allowable scale divisions.

P112 Zero Track Verify required selection.

P114 Motion Verify required selection.

P118 Zero Range Verify required selection.

P212 Print Stability Verify required selection.

P126 Æ P130 Multi-Range Verify proper configuration.

P151 Æ P154 Custom Units Verify name and conversion factor.

P600 Æ P646 Rename Parameters Verify acceptable names.

48

Page 57

C HAPTER 8:LEGAL- FOR-TRADE

SEALING AND AUDIT TRAILS

Most legal-for-trade installations will require the indicator to be sealed. A

sealed indicator cannot be accessed for setup or calibration changes without

breaking a physical seal or incrementing an event counter, thus providing

evidence that the unit has been tampered with. Each member of the 60

Series has two types of sealing provisions:

• Physical seal used in conjunction with an internal program jumper

• Three-event audit trail counter

Check with your local weights and measures authority to determine which

method(s) are required.

PHYSICAL SEAL

The most common sealing method is a lead-wire seal. All standard units

provide two tamper-proof screws used for sealing the rear panel to the front

of the enclosure. A lead-wire seal can be applied by passing the lead-wire

seal wire through a hole in these two screws, thus preventing the screws

from being removed without breaking the seal. The 60 Series panel mount

versions use a lead-wire seal and one screw. The Model 663 has a locking

clasp on the front door to which the seal can be applied, or the scale can be

sealed using the same method as that used with the panel mount versions.

49

Page 58

60 SERIES I NDICATORS

60 Series Standard Enclosure NTEP Seal

50

Page 59

C HAPTER 8:LEGAL- FOR-TRADE

Panel Mount NTEP Seal

51

Page 60

60 SERIES I NDICATORS

663 NTEP Seal

52

Page 61

C HAPTER 8:LEGAL- FOR-TRADE

665 NTEP Seal

53

Page 62

60 SERIES I NDICATORS

AUDIT TRAIL PARAMETERS

Three separate incrementing, non-resettable audit trail parameters are used

by the M660 to indicate changes to various parameters:

• P60201 – OIML

• P60203 – Calibration

• P60204 – Setup

An audit trail counter will increment only once upon exiting the Setup Mode

and saving changes regardless of how many settings were changed. Each

audit trail counter will increment to 99999 before beginning again at 00001.

DO NOT ATTEMPT TO ACCESS AUDIT TRAIL PARAMETERS

DURING CRITICAL WEIGHT PROCESSING! Weight conversions and

custom transmits will be suspended and all setpoints will be deactivated!

Accessing Audit Trails

The audit trails may be accessed from the Weigh Mode. An access code is

not required to view audit trail parameters.

To access audit trails:

1. Key in 60201 [SELECT] to access the OIML audit trail.

2. Key in 60203 [SELECT] to view the Calibration audit trail.

3. Key in 60204 [SELECT] to view the Setup audit trail.

4. Press [ZERO] to return to the Weigh Mode.

OIML Audit Trail

Changes to any of the following parameters will increment the OIML audit

trail at P60201:

• P109 Æ P119 Scale Setup

• P122 Return to Zero

• P131 Æ P134 Units

• P150 Æ P154 Calibration & Custom Units

• P162, P163 Negative Tare Enable, Tare Rounding Enable

• P300 Æ P309 Selectable Modes

54

Page 63

C HAPTER 8:LEGAL- FOR-TRADE

• P410, P412 OIML Enable, Preset Enable

• P420 Standard VF Display Mode

• P600 Æ P646 Rename Parameters

• P800 Æ P820 Key Functions

• P989 Æ P4999 Custom Transmit

• P61101 Æ P61140 Calibration & Linearization

• P65001, P65002 Default All, Default –Cal

Calibration Audit Trail

Any changes to the existing calibration will increment the Calibration audit

trail at P60203. This includes any changes to P60101 Æ P61140 of the

information parameters.

Setup Audit Trail

Changes to any of the Setup Mode parameters will increment the Setup audit

trail at P60204.

55

Page 64

Page 65

9CHAPTER 9: TROUBLESHOOTING

This chapter of the User Guide provides information on error messages and

trouble-shooting 60 Series controllers. Some information in this chapter

refers to parameters that are not discussed in this guide. They are provided

as a quick reference to problems and solutions. Please refer to the technical

reference manual or consult your GSE distributor for additional information.

All 60 Series error messages are listed below in numerical order. The

leading two digits will appear on the numerical portion of the display, and

the message will appear on the two lines of dot matrix display. Following

each message is a summation of possible causes and probable remedy.

OPERATIONAL MODE ERROR MESSAGES

02 UnderLoad!

03 Over-Load!

04 # > Dsply

05 Zero> Max.!

Input signal less than negative full scale.

Check the load cell connections. If a 4-wire

load cell cable is being used, check that the

sense jumpers are in place. Verify that the

capacity selection P110 is correct. Use the

information parameters, especially P61100 to

check the setup and input signal.

Input signal is greater than 104% of positive

full scale. Use same check as for underload.

Number to be displayed will not fit within 6

digits. This will not normally occur for the

Gross, Net or Tare Weights but may result

while displaying the accumulated totals if the

amount exceeds 999,999. Clear the totals or

settle for only being able to transmit the totals.