Page 1

GSE

Model 370 & Model 375

Precision Counting Scale

Technical Reference Manual

Version 1.0

Page 2

Page 3

Model 370 &

Model 375

Technical Reference Manual

Version 1.0

Page 4

GSE 370 / 375 Precision Parts Counter Technical Reference Manual

Copyright © 2004 GSE Scale Systems. All rights reserved.

Published by:

GSE Scale Systems

42860 Nine Mile Road

Novi, MI 48375

USA

Information in this Technical Reference Manual is subject to change without notice due to

correction or enhancement. The information described in this manual is solely the property of

GSE. No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording and sold for any monetary figure

without the express written permission of GSE.

GSE LOCATIONS

GSE Scale Systems

42860 Nine Mile Road

Novi, MI 48375

U.S.A.

Phone: (800) 755-7875

www.gse-inc.com

GSE Canada, Inc.

617 East Lake Road

Airdrie, Alberta Canada T4B 2B8

Phone:(403) 948-9921

Fax: (403) 948-1449

SPX GSE Amprobe Europe GmbH

Phone: +49 (0) 2161-59906-11

Fax: +49 (0) 2161-59906-20

Your Distributor is:

Page 5

Table of Contents

CHAPTER 1: INTRODUCTION ............................................................................................................... 1

E

NCLOSURE

L

OAD CELL REPLACEMENT

Load Cell Connections ........................................................................................................................... 2

K

EYPAD

Model 370............................................................................................................................................... 2

MODEL 375........................................................................................................................................... 3

D

ISPLAY

Annunciators .......................................................................................................................................... 5

R

EAR PANEL CONNECTIONS

Communication Port 1............................................................................................................................ 6

Remote Display Connections.................................................................................................................. 6

CHAPTER 2: OPTION INSTALLATION................................................................................................ 7

C

OMMUNICATION

RS-485 Networking................................................................................................................................. 7

20 mA Current Loop Option................................................................................................................... 9

A

NALOG OUTPUT OPTION

S

ETPOINT OPTION

Setpoint Card Connections................................................................................................................... 13

O

PTION MOUNTING BRACKET

CHAPTER 3: SCALE CONFIGURATION............................................................................................ 15

E

NTERING THE SETUP MODE (MODEL

E

NTERING THE SETUP MODE (MODEL

S

ELECTING A PARAMETER

C

HANGING A PARAMETER VALUE

Selection Parameters............................................................................................................................ 17

S

AVING PARAMETERS

F

ACTORY DEFAULT

L

IST OF PARAMETERS

Parameter Map Details........................................................................................................................ 23

P

RINTING

Preset Transmit Selections................................................................................................................... 29

Custom Transmit .................................................................................................................................. 31

A

NALOG OUTPUT PARAMETER SETUP

Analog Output Example........................................................................................................................ 35

S

ETPOINT CONFIGURATION

Activation Methods (General).............................................................................................................. 37

Percentage Check-Weighing ................................................................................................................ 39

Fill........................................................................................................................................................ 40

Batch..................................................................................................................................................... 41

Discharge ............................................................................................................................................. 43

Both ...................................................................................................................................................... 45

Absolute Check-Weighing..................................................................................................................... 46

Independent Setpoint Operation........................................................................................................... 47

Target Deviation Check-Weighing....................................................................................................... 49

P

ARTS COUNTING

R

EMOTE SERIAL OPERATION

DISPLAY CAPTURE UTILITY............................................................................................................. 51

T

IME AND DATE SETUP (MODEL

................................................................................................................................................. 1

......................................................................................................................... 1

...................................................................................................................................................... 2

...................................................................................................................................................... 5

........................................................................................................................ 5

........................................................................................................................................ 7

......................................................................................................................... 11

..................................................................................................................................... 12

................................................................................................................... 13

370)............................................................................................... 15

375)............................................................................................... 16

......................................................................................................................... 16

............................................................................................................. 17

............................................................................................................................... 19

................................................................................................................................... 20

................................................................................................................................20

................................................................................................................................................... 29

....................................................................................................... 35

....................................................................................................................... 36

...................................................................................................................................... 50

..................................................................................................................... 51

370)....................................................................................................... 52

i

Page 6

T

IME AND DATE SETUP (MODEL

U

PGRADE MODEL

Prepare For Upgrade........................................................................................................................... 54

Load Flash File .................................................................................................................................... 54

R

EMOTE DISPLAY CONFIGURATION

Master To Remote (Slave) Configuration............................................................................................. 55

Setup Master Unit................................................................................................................................. 55

Setup Remote Unit............................................................................................................................... 56

Access The Setup Mode from the Remote Display Mode...................................................................... 58

300 S

ERIES COMMAND CODES

ID N

UMBER ENTRY

370/375 F

................................................................................................................................... 60

375)....................................................................................................... 53

IRMWARE

.................................................................................................................. 59

..................................................................................................... 53

.......................................................................................................... 55

CHAPTER 4: CALIBRATION................................................................................................................. 61

S

ETUP MODE CALIBRATION

Fast Calibration................................................................................................................................... 61

Performing Calibration........................................................................................................................ 61

First Zero.............................................................................................................................................. 62

Last Zero............................................................................................................................................... 63

False Zero............................................................................................................................................. 65

Only Zero.............................................................................................................................................. 66

Reset Calibration.................................................................................................................................. 67

M

ULTI-POINT LINERIZATION

E

XAMINING CALIBRATION RESULTS

Establishing A Span.............................................................................................................................. 70

E

XITING CALIBRATION

A

NALOG OUTPUT CALIBRATION

CHAPTER 5: TROUBLESHOOTING....................................................................................................73

E

RROR MESSAGES

Operational Errors.............................................................................................................................. 73

Setup Mode Errors ............................................................................................................................... 74

Hardware Errors.................................................................................................................................. 74

Calibration Errors................................................................................................................................ 75

Communication Errors......................................................................................................................... 75

Miscellaneous Errors ........................................................................................................................... 75

Viewing Setup....................................................................................................................................... 75

Information Mode Parameters (370 and 375)...................................................................................... 76

A/D C

ALIBRATION PROCEDURE

A

NALOG BOARD DIAGNOSTICS AND TEST PROCEDURES

..................................................................................................................................... 73

...................................................................................................................... 61

.................................................................................................................... 69

......................................................................................................... 70

.............................................................................................................................. 71

............................................................................................................... 71

................................................................................................................ 77

.......................................................................... 77

ii

Page 7

Chapter 1: INTRODUCTION

This chapter describes the components of the Model 370/375 such as keypad, e nclosure and

display. Also included is wiring for the load cell and communication port.

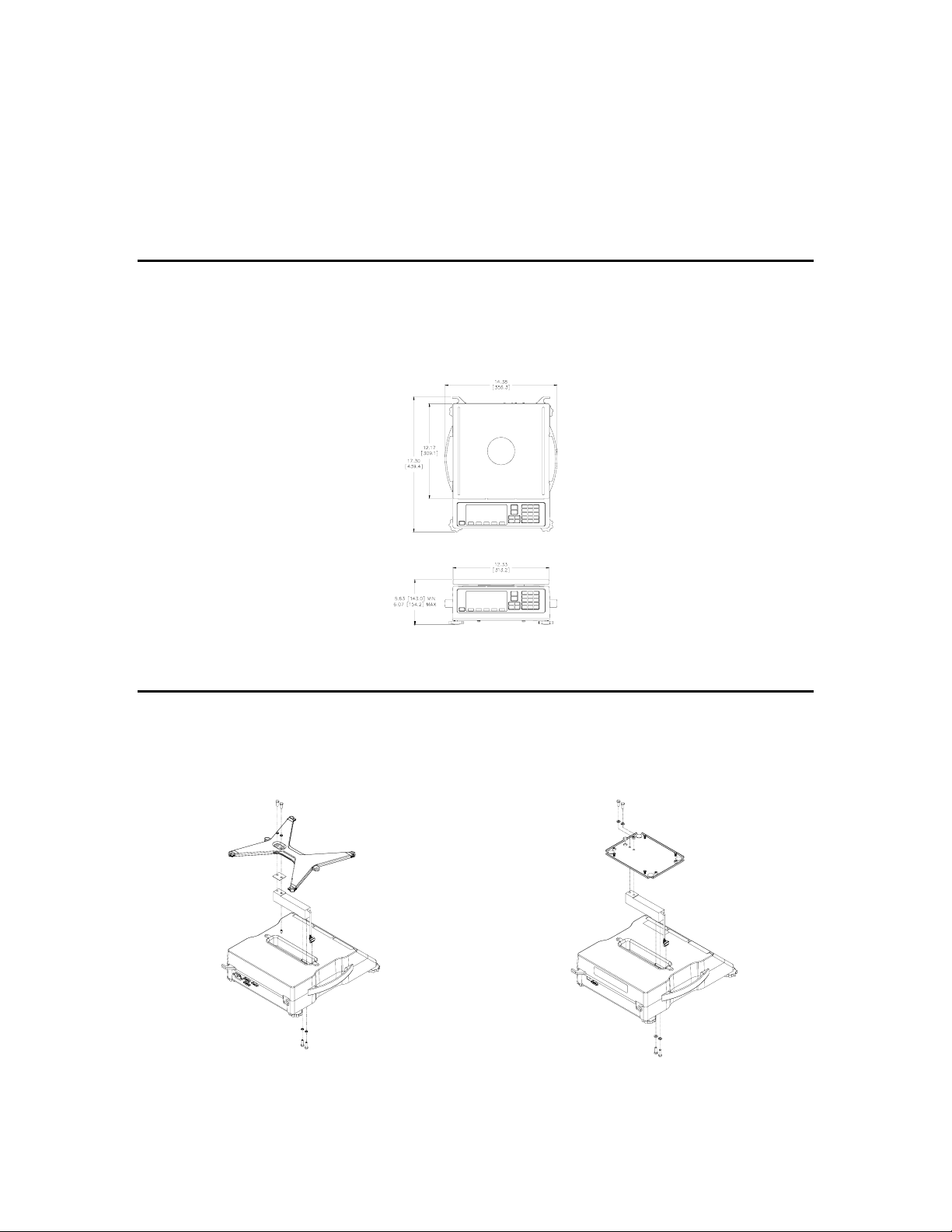

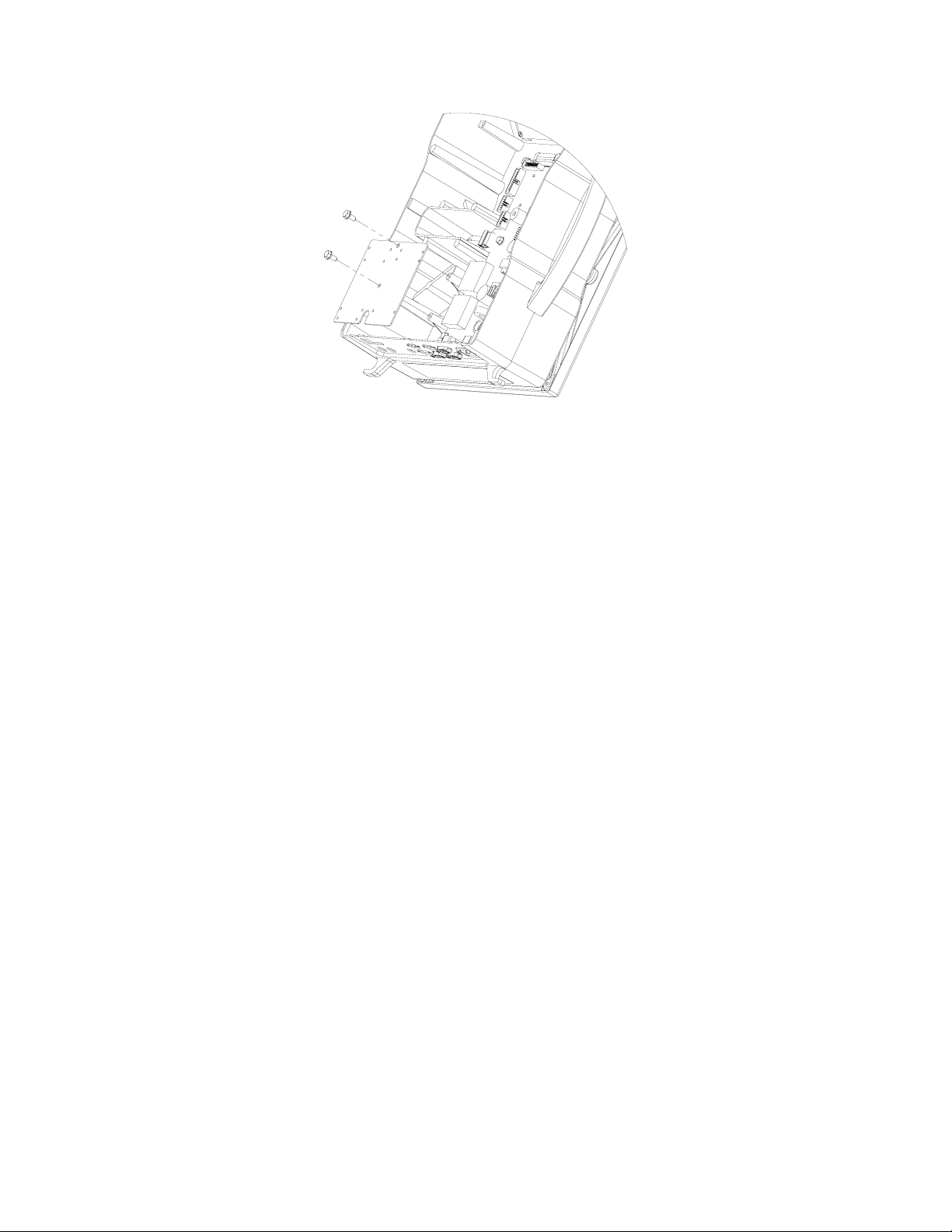

EEnncclloossuurree

The enclosure is made of die cast aluminum with rib enforcement that includes built in carrying

handles and a line cord wrap for ease of portability. This design provides extra strength and

durability. The enclosure is painted with powder coat and the counting surface is stainless steel.

LLooaadd CCeellll RReeppllaacceemmeenntt

Figure 1-1: Model 370 and Model 375 Enclosure

The load cell can be exchanged by removing two M6 1x 20mm (size) bolts from the bottom plate

and two M6 1 x 16mm (size) bolts from the top spider assembly.

Figure 1-2: 15 lb – 100 lb Load Cell Installation Figure 1-3: 6 lb Load Cell Installation

1

Page 8

Install the new load cell by placing it in the load cell cavity. Fasten the load cell by installing the

bolts on the bottom plate. Reinstall the spider assembly. NOTE: When exchanging a load cell

with another, the overload stop and corner overloads must be reset. Refer to Table 1-1 for

setting values.

Table 1-1: Load Cell Overload Settings

Load Cell Stop Set to

Load Cell Center Overload 120 % of full scale

Corner Overloads 60 % of full scale

LOAD CELL CONNECTIONS

The load cell cable connects to J10 of the main board. The J10 connector is accessible from the

load cell cavity of the Model 370/375 enclosure.

Table 1-2: Load Cell Connection to Main Board

Pin Designation Function

1 Shield

2 - Sense

3 + Sense

4 - Signal

5 + Signal

6 - Excitation

7 + Excitation

KKeeyyppaadd

All of the keys perform different functions. Some keys have more than one function.

MODEL 370

The Model 370 offers a 6-button durable and versatile Polymeric switch plate with large keys for

ease of use. The keypad is easily cleaned with a damp cloth or non-abrasive cleaner. Each key is

assigned two distinct functions. Various key combinations are also used. Each key has secondary

functions; allowing an operator to enter target values, perform piece samples, access setup

parameters, etc.

Figure 1-4: Model 370 Keypad

Functions

The Model 370 keypad performs different functions in the Weigh Mode, the Setup Mode, and the

Calibration Mode. Secondary functions for each key allow you to perform additional tasks.

2

Page 9

Key Press Weigh Mode Count Mode Setup Mode

Performs a gross zero

<

=

:

>

9

<>

:>

<:

<=

function and/or clears an

entry in progress. Hold

this key on power-up to

turn on the display

regardless of P420.

Performs a print function

and/or ‘scrolls’ through

digits during setpoint

entry.

Toggles between ‘lb’, ‘kg’

third unit (if enabled)

and/or advances cursor to

next entry position.

Performs an auto-tare

function (if enabled)

and/or accepts an entry in

progress.

Toggles between display

modes and/or restores

power to the Model

370/375 (if auto-shutoff

enabled).

Goes to the count mode

Access Setup Mode.

Break out of remote

display mode.

No function. No function.

Absolute clear – clears an

entry in progress and/or

clears the value of a

parameter.

Backspace – erases the

right-most digit during

data entry.

Performs a quantity zero

function and/or clears an

entry in progress.

Performs a print function

and/or ‘scrolls’ through

digits during setpoint

entry.

Toggles through standard

sample sizes during a

sample and/or begins a

new sample entry.

Performs an auto-tare

function and/or accepts an

entry in progress.

Toggles between display

modes and/or restores

power to the Model

370/375 (if auto-shutoff

enabled) and/or toggles

through standard sample

sizes during a sample.

Performs a sample for an

accurate part count and

calculates an average

piece weight.

Access Setup Mode.

Break out of remote

display mode.

No function. Clears any entry in progress.

Backspace – erases the

right-most digit during

sample entry.

Exits the Setup Mode and/or

answers “NO” to query

prompts and/or clears an entry

in progress.

‘Scrolls’ through digits during

data entry.

Advances cursor to next entry

position and/or cycles prompts.

Accepts an entry in progress

and/or ‘scrolls’ through

parameter sub-set selections

and/or answers ‘YES’ to query

prompts.

Advances to the next setup

parameter.

Accepts an entry in progress

and/or ‘scrolls’ through

parameter sub-set selections

and/or answers ‘YES’ to query

prompts.

No function.

Return to the previous setup

parameter.

Backspace – erases right-most

digit during data entry.

=>

=

Extended gross. Extended gross. Shows parameter number.

Reverse character scroll

during data entry.

Reverse character scroll

during sample entry.

Reverse character scroll

during data entry.

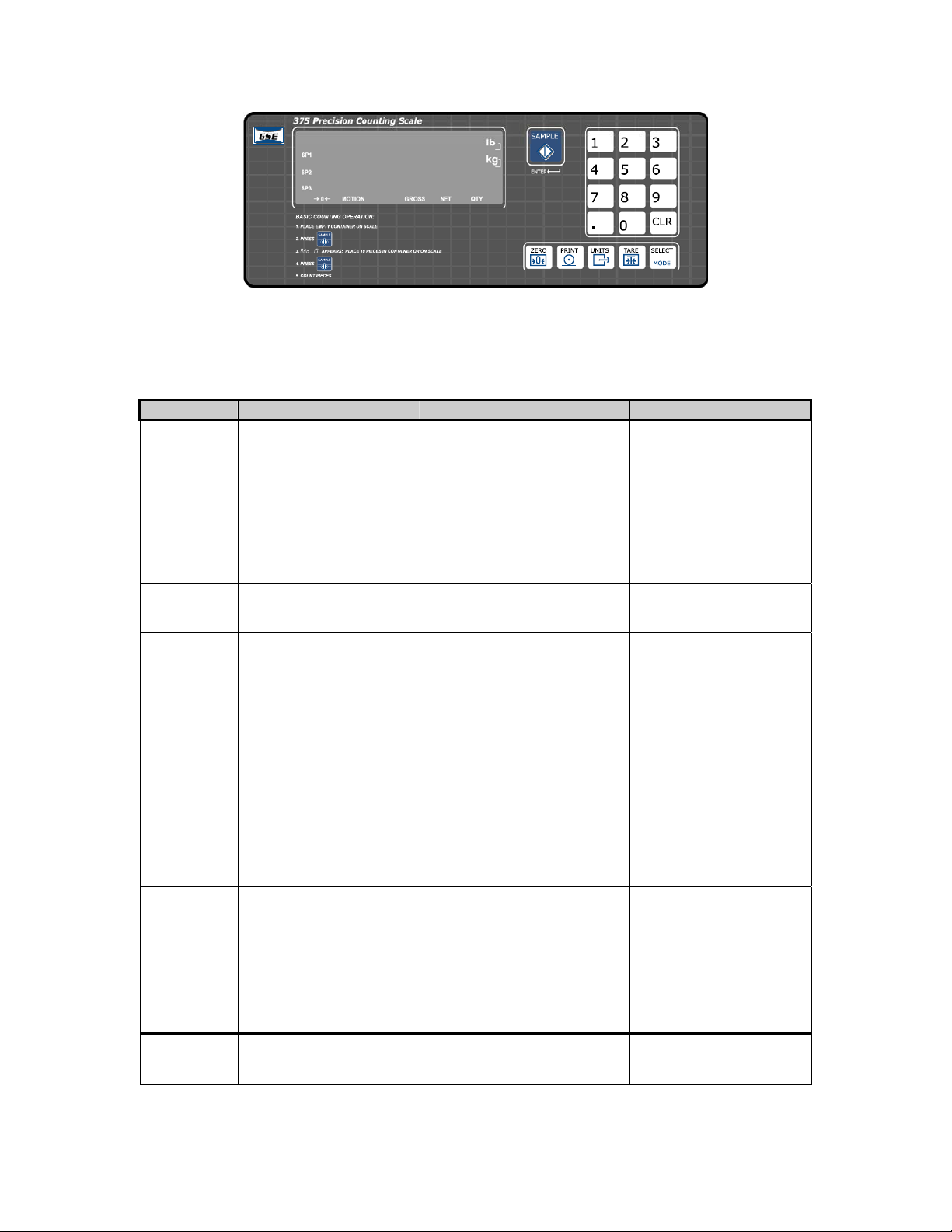

MODEL 375

The Model 375 offers an 18-button durable and versatile Polymeric switch plate with large keys

for ease of use. The keypad is easily cleaned with a damp cloth or non-abrasive cleaner. The

number keys make entering a tare value or average piece weight easier. Each key is assigned at

least one distinct function.

3

Page 10

Figure 1-5: Model 375 Keypad

Functions

All of the keys perform different functions. Some keys have more than one function.

Key Press Weigh Mode Count Mode Setup Mode

<

=

:

>

J-H,

I

K

9

<>

Performs a gross zero

function and/or clears an

entry in progress. Hold

this key on power-up to

turn on the display

regardless of P420.

Performs a print function

and/or ‘scrolls’ through

digits during setpoint or

time/date entry.

Toggles between ‘lb’, ‘kg’

or third unit (if enabled).

Performs an auto-tare

function (if enabled).

Toggles between display

modes and/or restores

power to the Model

370/375 (if auto-shutoff

enabled).

Numeric keys used to

manually enter a value for

tare weight or target

value.

Absolute clear – clears an

entry in progress and/or

clears the value of a

parameter.

Enters the counting mode

and/or accepts an entry in

progress.

Access Setup Mode.

Break out of remote

display mode.

Performs a quantity zero

function and/or clears an entry

in progress.

Performs a print function.

Toggles through standard

sample sizes.

Performs an auto-tare function

and requests a piece sample

and/or accepts an entry in

progress.

Toggles between display

modes and/or restores power

to the Model 370/375 (if autoshutoff enabled) and/or toggles

through standard sample sizes

during a sample.

Numeric keys used to

manually enter a value for tare

weight, average piece weight,

sample size etc.

Clears any entry in progress or

abort a sample.

Performs a sample for an

accurate part count and

calculates an average piece

weight and/or accepts an entry

in progress.

Access Setup Mode. Break

out of remote display mode.

Exits the Setup Mode

and/or answers “NO” to

query prompts and/or

clears an entry in

progress.

Return to the previous

setup parameter.

Shows the current

parameter number

Accepts an entry in

progress and/or ‘scrolls’

through parameter sub-set

selections and/or answers

‘YES’ to query prompts.

Advances to the next

setup parameter.

Numeric keys used to

manually enter a value.

Clears any entry in

progress.

Accepts an entry in

progress and/or ‘scrolls’

through parameter sub-set

selections and/or answers

‘YES’ to query prompts.

No function.

4

Page 11

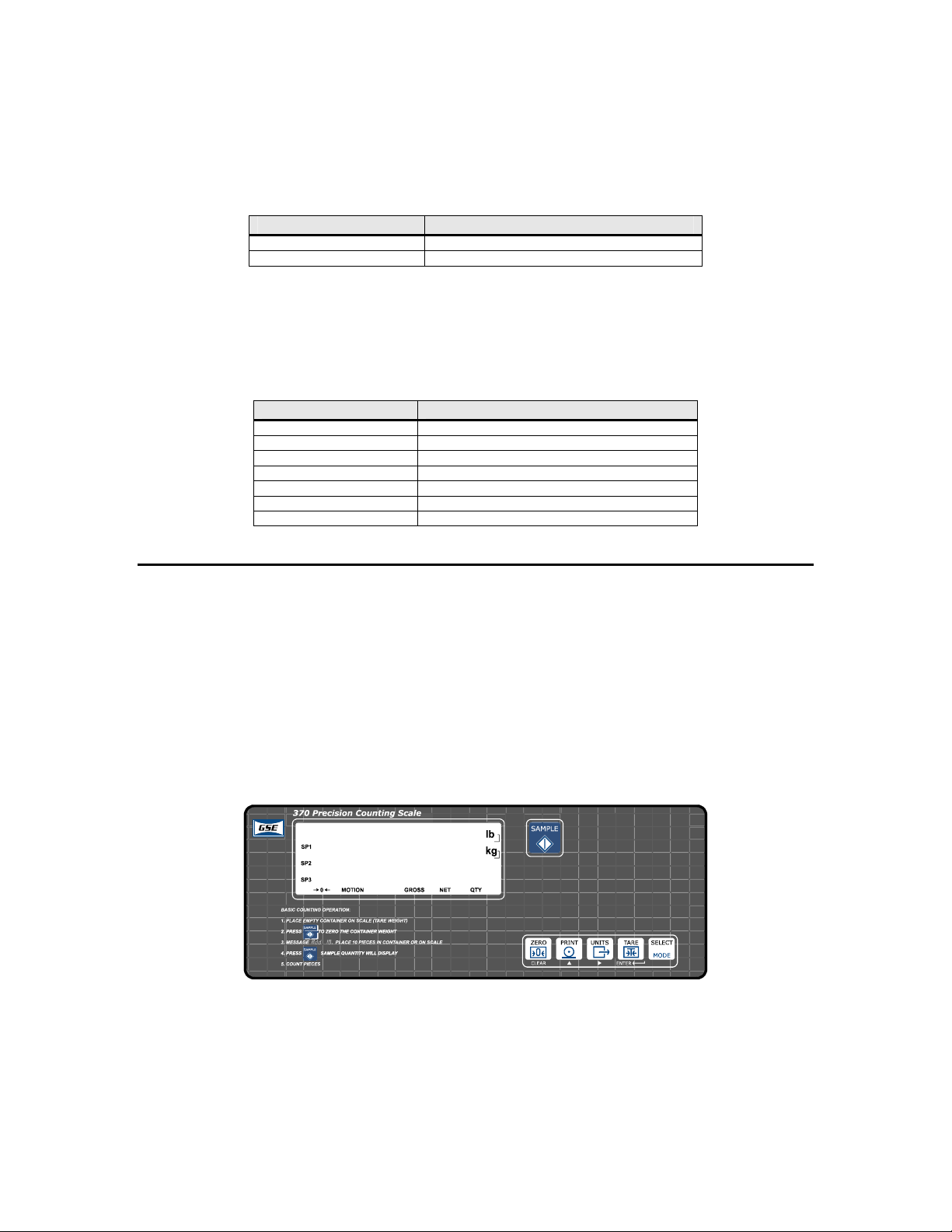

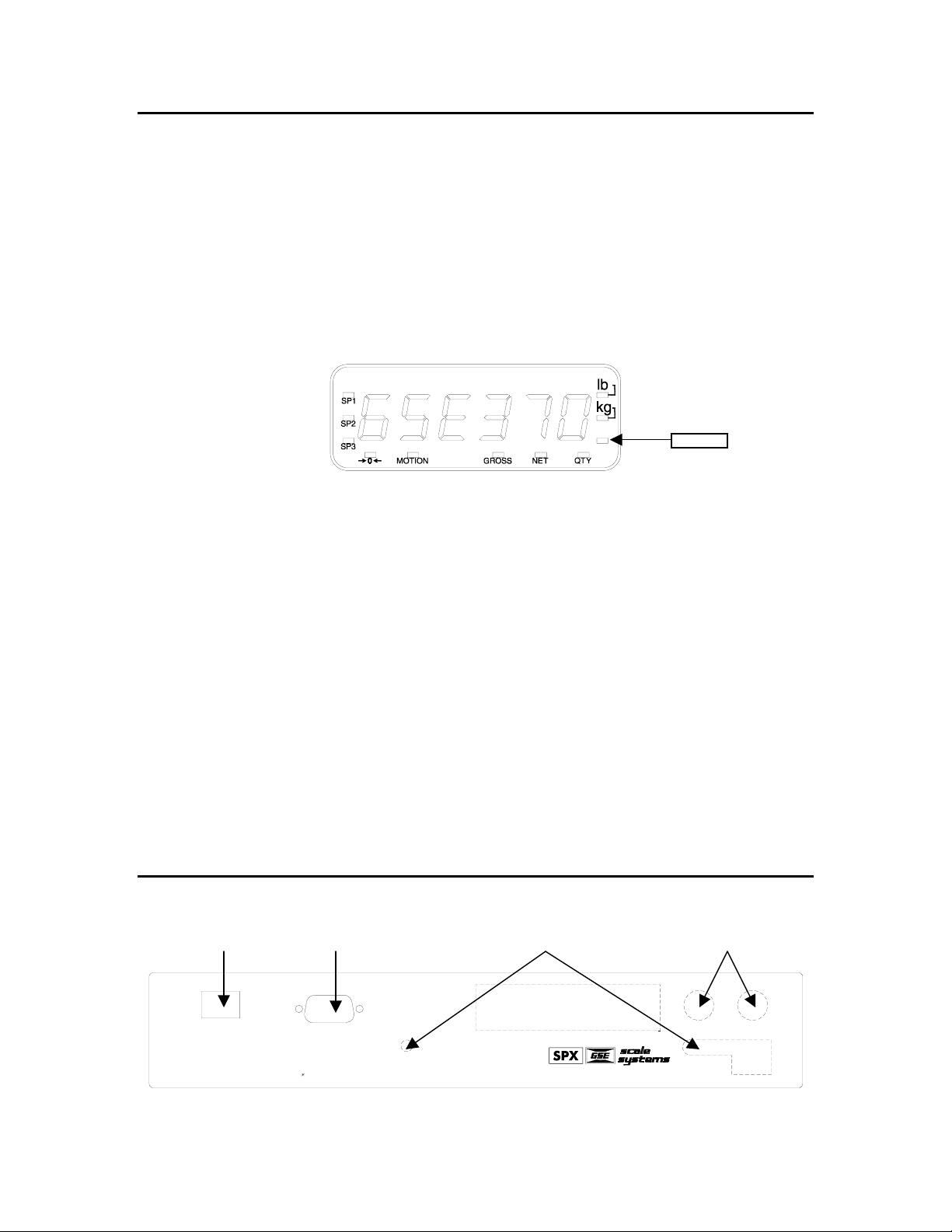

DDiissppllaayy

The Model 370 and Model 375 come standard with a six digit, 7-segment bright green LED

display. The Model 370 and Model 375 will display alphanumeric data, but due to the nature of 7segment LED and the limitation of six digits, some information is abbreviated.

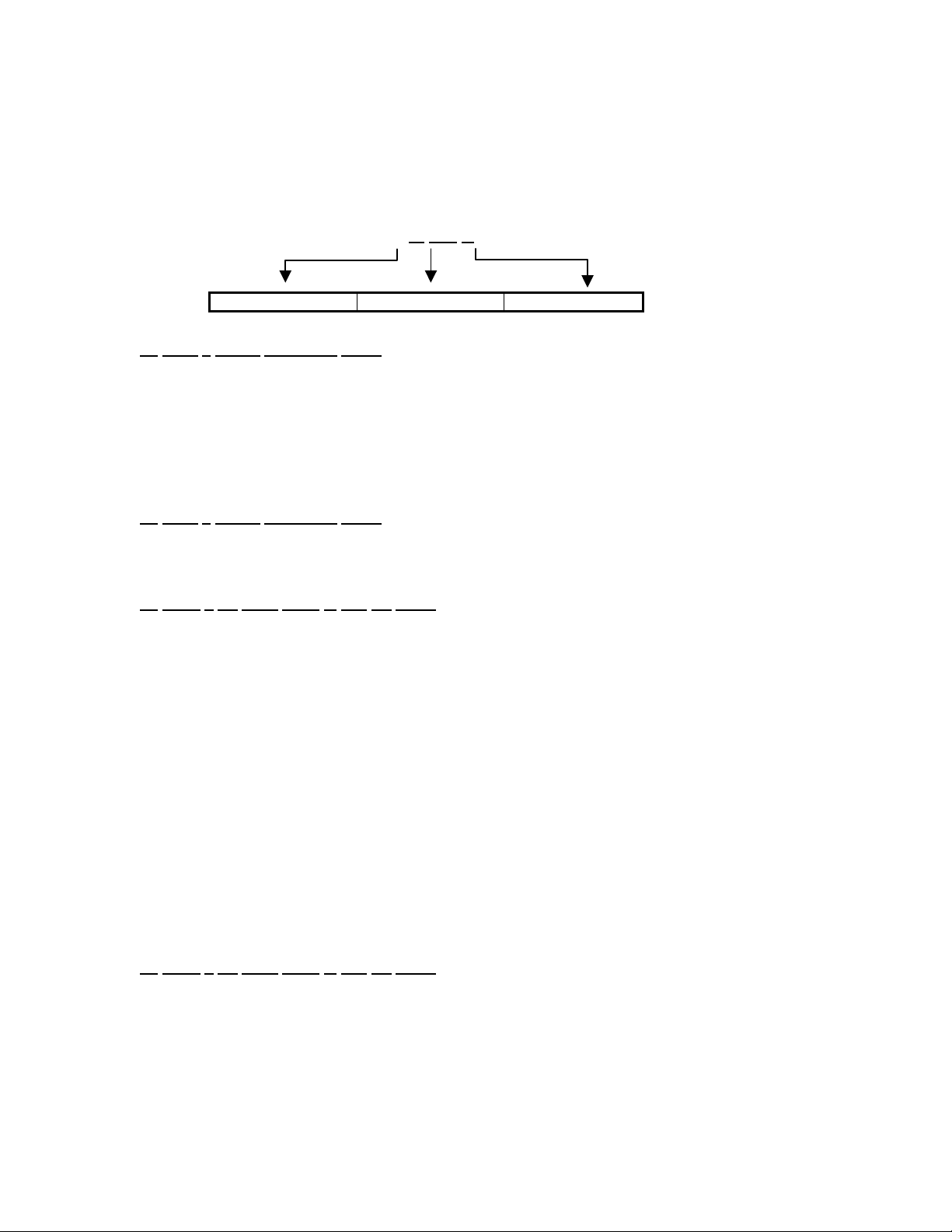

The display also has 11 annunciators to show weight and status information. The SP1, SP2, and

SP3 annunciators are red, green, and yellow. Also there is an annunciator for a third unit under

kg. Place the third unit label above the third Annunciator (refer to Figure 1-6). See page 24 for

third unit setup.

All segments and annunciators are illuminated for a brief display test upon power up. The current

gross weight is then displayed in default units.

Third Unit

Figure 1-6: Model 370 and Model 375 LED Display

ANNUNCIATORS

Annunciators provide mode and status information. When illuminated, they indicate the following

conditions:

SP1 Setpoint #1 activated (relay 1 closed)

SP2 Setpoint #2 activated (relay 2 closed)

SP3 Setpoint #3 activated (relay 3 closed)

0

MOTION

GROSS Displayed value represents the current gross weight

NET Displayed value represents the current net weight

QTY Displayed value represents the current piece quantity (Count)

lb The displayed value is represented in pounds

kg The displayed value is represented in kilograms

Oz, lb oz, g The displayed value is represented in either ounces, pound ounces or grams

RReeaarr PPaanneell CCoonnnneeccttiioonnss

AC Power Com 1 Options Future Option

Displayed weight is at center-of-zero (± ¼ display graduation)

Scale is in motion. Motion inhibited transmits and motion inhibited setpoint activation will be delayed

until motion ceases

COM 1

PLACE 370/375 BARCODE HERE

POWER (15W MAX)

50-60 Hz 12-20 VAC

DC 12-36V

1 NONE

6 GND

2 RXD

7 RTS

3 TXD

8 CTS

4 *

9 +5V

5 GND

5 GND

MOVE JUMBER E6

FOR +5V ON PIN 4

BATTERY

ON/OFF

www.gse-inc.com Novi, MI USA

Figure 1-7: Rear Panel

AUX 2

AUX 3

ETHERNET

5

Page 12

COMMUNICATION PORT 1

Comm1 is standard with the Model 370/375. Connector pin outs for Comm 1 (DB9) are provided

in Table 1-3 below.

Table 1-3: Communication Port Pin Out

Pin Designation Description Remote Display

1 No connection

2 RXD

3 TXD

4 VCC (+ 5V)

5 Ground / ISO Ground

6 Ground

7 RTS

8 CTS

9 VCC (+ 5V)

√

√

√

REMOTE DISPLAY CONNECTIONS

It is possible to connect a Model 370/375 to another 300 Series or 60 Series indicator and ha ve

the remote indicator display a copy of the master indicator or customize the display of the remote

(slave) indicator. The remote (slave) indicator’s keypad will operate the master indicator. Refer to

page 55 to configure the master and remote (slave) displays. There are several different

configurations for Master to remote (slave) indicator connection and setup. Refer to Table 1-3 for

comm port connections.

Supply Voltage Jumper (E6)

This allows for a choice in scanner power supply pins and to minimize modifications to a cable or

connector.

Comm port 1 has two pins on the DB 9 connector which provide + 5 volts to supply power to a

scanner. The jumpers located on E6 of the main board will reroute the power (+ 5 volt) to either

pin 9 or pin 4 depending on jumper orientation.

Pin 9 (Default) Pin 4

The power (+ 5 volt) and remote key pins are switched. Refer to Figure 1-8 for the jumper

location on the main board. Refer to the Barcode Scanner manual for the power pin location.

Figure 1-8: Comm Port 1 Supply Voltage Jumper Location

6

Page 13

Chapter 2: O

This chapter will provide detailed instructions on installing each option. Additional hardware may

be needed for the Model 370/375 depending on which options you will be installing.

Also this chapter provides instructions on how to configure all Model 370 / 375 options. This

includes setup mode parameters, connections, calibration and testing.

PTION INSTALLATION

CCoommmmuunniiccaattiioonn

RS-485 NETWORKING

The module converts the standard RS-232 communication on comm port 1 to RS-485. However

the advantage of using the RS-485 module, aside from the ability to transmit over long distances,

is the ability to network multiple indicators or parts counters using the same communication wires.

When networking indicators or parts counter, it is necessary to set up a network address for each

scale. The network module itself does not require addressing, rather each indicator or pa rts

counter must be enabled for network addressing in the setup mode. Refer to page 26 for details

on the RS-485 enable parameter (P250) and the network address parameter (P251).

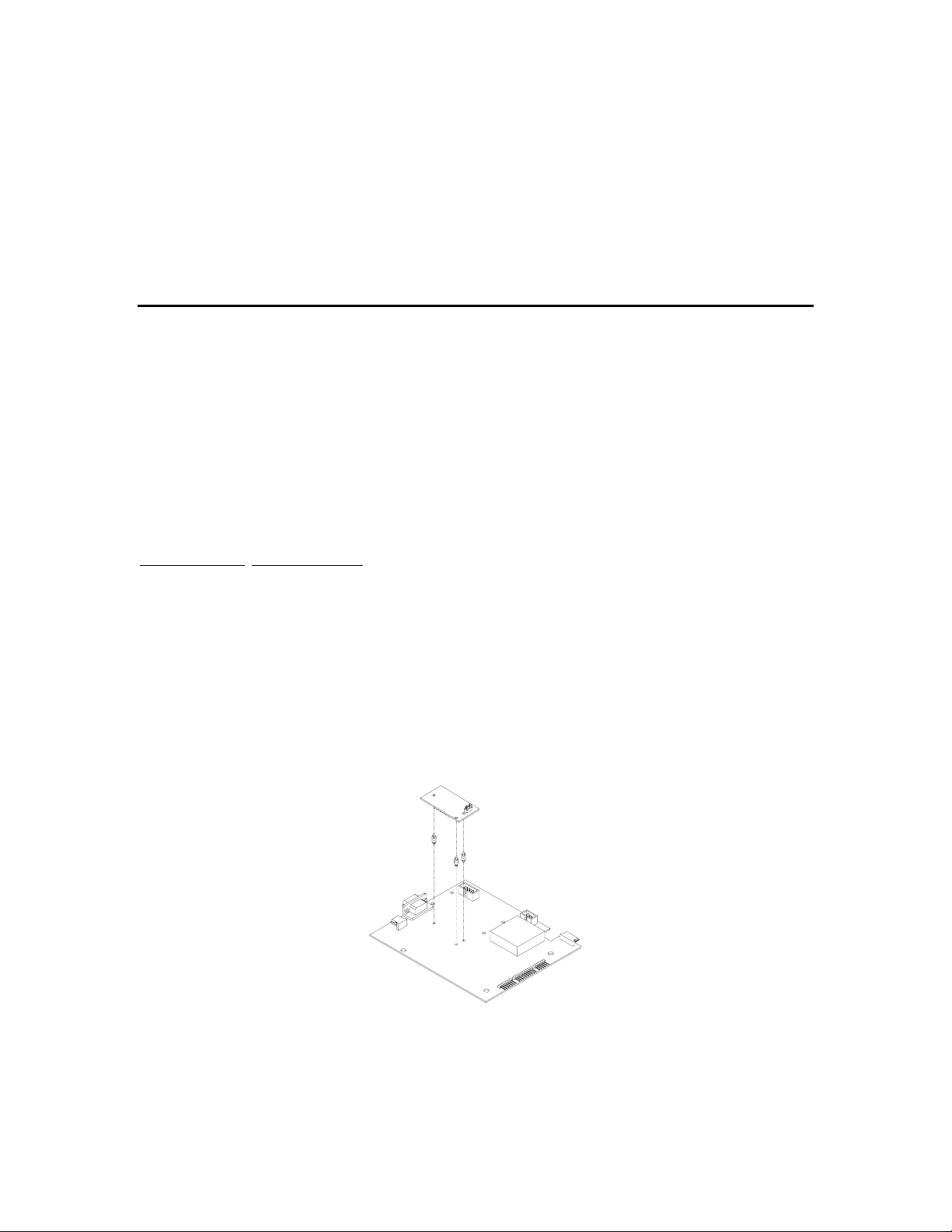

Installation Instructions

1. DISCONNECT POWER! UNPLUG THE MODEL 370/375 TO INSURE DAMAGE WILL NOT

OCCUR DURING OPTION INSTALLATION.

2. Remove the six 8 mm screws (size) from the bottom plate. Separate the top enclosure from

the bottom plate.

3. Remove the IC chip and white jumper from the U4 socket on the main board.

4. Snap in the plastic spacers into the three mounting holes surrounding the U4 socket. Refer

to Figure 2-1.

5. Gently press the option board into the socket and make sure the board snaps onto the

standoffs.

6. Reinstall the enclosure bottom plate.

Figure 2-1: RS-485 / 20 mA Option Installation

RS-485 Connections (Comm Port 1)

The Model 370/375 will be connected to a peripheral via the DB 9 connector on comm port 1.

Refer to Table 2-1 for wiring connections.

7

Page 14

Table 2-1: RS-485 Comm Port 1 Connections

Comm port 1 pin out Connection

1 No connection

2 TX (B+)

3 TX (A-)

4 VCC

5 ISO ground

6 Ground

7 RX (A-)

8 RX (B+)

9 VCC

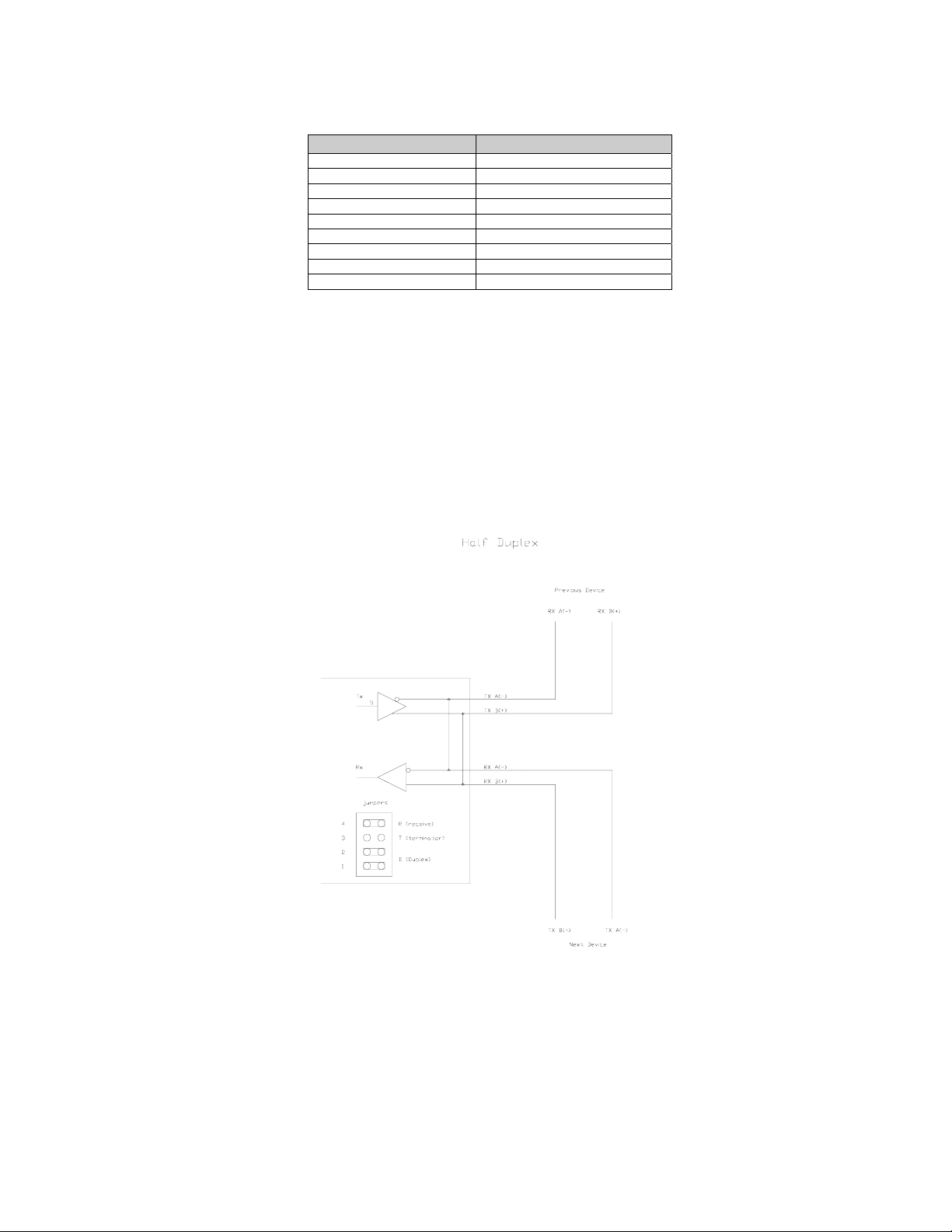

Half Duplex (2-wire)

Installing jumpers 1, 2 and 4 on the RS-485 option board electrically connects pin RX B(+) to pin

TX B(+), and pin RX A(-) to pin TX A(-) on the option board. This effectively provides two + and

two - pin connections, enabling easy connection of network lines in parallel from device to d evice

without having to position two wires into the same lever socket. A B(+) line from each device on

the network should be connected in parallel to the next device on the network. This is also true for

all A(-) lines.

The units inside the two end-points of the network loop will utilize both A(-) pin connections and

both B(+) pin connections. The units at the end-points of the network will utilize only one A(-) pin

connection and one B (+) pin connection.

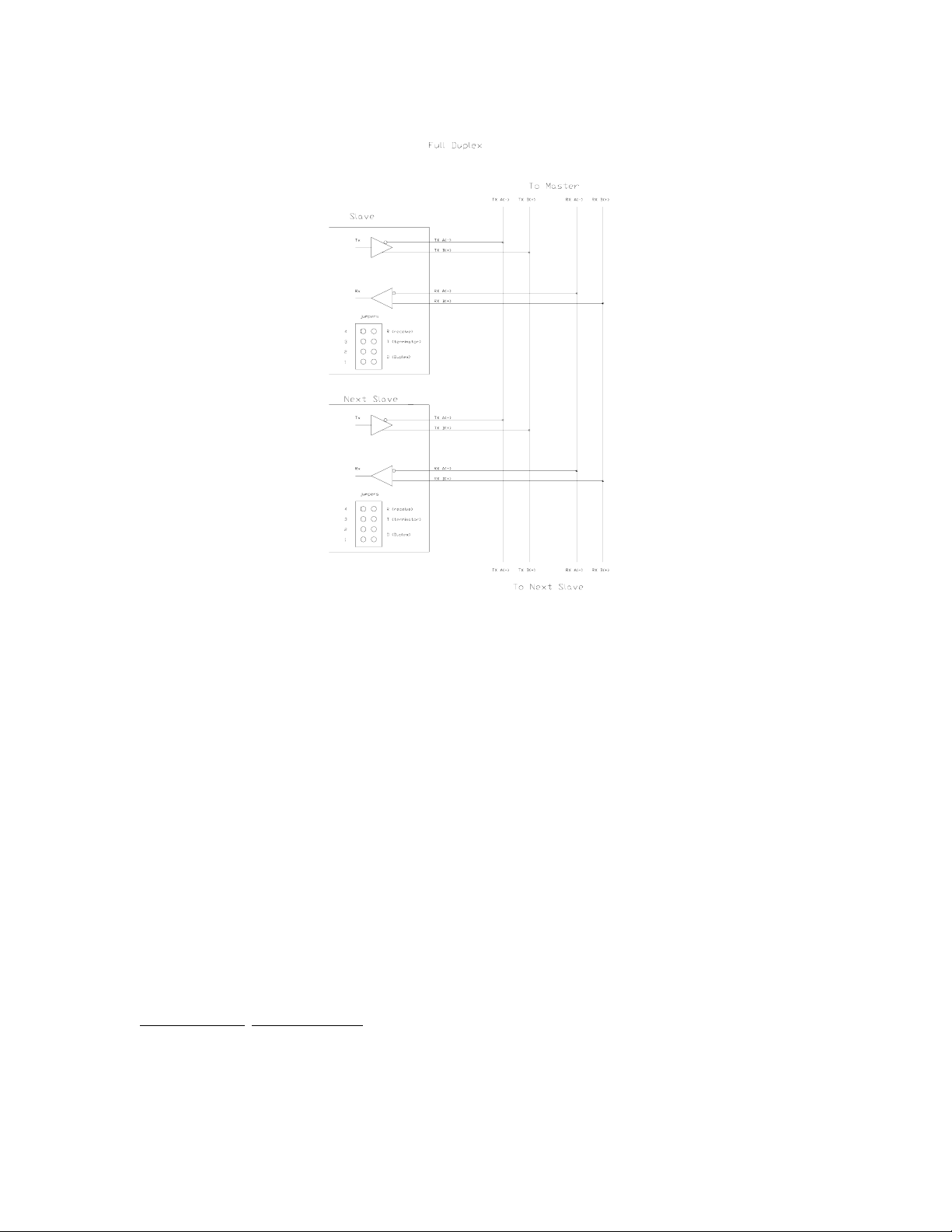

Full Duplex (4-wire)

Removing jumpers 1, 2 and 4 on the RS-485 option board requires that the transmit and receive

lines be wired independently of one another. The RX B(+) and RX A(-) receive lines must be

wired in parallel to the next device's RX B(+) and RX A(-) receive lines and the TX B(+) and TX A

(-) transmit lines must be wired in parallel to the next device's TX B(+) and TX A(-) transmit lines.

8

Page 15

In order to connect network lines in parallel from device to device it is necessary to position two

wires into the same lever socket. This requires that the wire used to build the network be 24 AWG

or smaller to allow both wires to fit into the same lever socket.

Both Half Duplex and Full Duplex

The network boards on both end-points should install jumper 3 on the RS-485 option board to

engage the 120 W termination resistor (R8). The boards between the two en d-points should

remove jumper 3 on the RS-485 option board.

The isolated ground (ISO GND) should be connected in parallel from unit to unit. A shielded

twisted two pair cable is recommended throughout the network.

20 MA CURRENT LOOP OPTION

This option will convert the comm port 1 to a 20 mA current loop instead of an RS-232. This is a

digital communication signal and should not be confused with a 4 to 20-mA (or 0-20 mA), which

are analog output signals. The intended use is primarily printers and scoreboard displays.

This option will mount into the socket for the comm port RS-232 chip on the main board. This

option will exclude the use of the RS-485 option board. (I.e. only the RS-485 OR the 20 mA

option can be installed into a Model 370/375).

Installation Instructions

1. DISCONNECT POWER! UNPLUG THE MODEL 370/375 TO INSURE DAMAGE WILL

NOT OCCUR DURING OPTION INSTALLATION.

2. Remove the six 8 mm screws (size) from the bottom plate. Separate the top enclosure

from the bottom plate.

9

Page 16

3. Remove U4 and the white jumper from the socket of the main board.

4. Snap in the plastic spacers into the three mounting holes surrounding the U4 socket.

Refer to Figure 2-1.

5. Gently press the option board into the socket and make sure the board snaps onto the

standoffs.

6. Reinstall the enclosure bottom plate.

BI-Directional

Both the transmit output and the receive input of the Model 370/375 are available as 20 mA

signals. None of the handshake signals are supported for the 20-mA current loop operation.

Baud

Only baud rates of 9600 baud and less are supported.

Active/Passive

The Tx output may be used as an active or passive output from the Model 370/375. Either active

or passive is chosen depending upon which terminals are used for the connections. In active

mode the Model 370/375 supplies the current. In passive mode, the external device supplies the

current. The Rx input is available in passive mode only.

Isolation

The input and output are electrically isolated from the main board as well as earth ground and

each other, for both passive and active modes of operation. Isolation is a minimum of 1000v.

Max Voltage

Active mode Tx current loop provides a driving voltage of 12v. This will allow 20 mA current flow

with up to a 600 ohm load. Passive mode will work with an external driving voltage of up to 50v.

Connections

The field connections to the 20 mA circuitry will be made at the 9 pin 'D' connector on the rear of

the Model 370/375.

Transmit Current Input Active = TA

Transmit Current Input Passive = TP

Transmit Output = TXO

Receive Current Input = RXI

Receive Current Output = RX

Comm port 1 pin out Connection

1 No connection

2 RX IN

3 RX Pass

4 VCC

5 TX Active

6 Ground

7 TX OUT

8 TX Pass

9 VCC

Cable

The length for the current loop is 1000 ft. maximum. This is for the entire loop, not from device to

device. Example: 1 transmitter and 1 receiver can have a maximum of 500 ft. of 2 conductor

cable between them.

10

Page 17

Connected Devices

While 20 mA current loops can allow for more than one transmitter and/or receiver, the Model

370/375 and/or option board do not include any address recognition or collision avoidance and/or

detection to promote this usage. If the 20-mA loop is intended to be used in this manner, proper

planning for these issues is required.

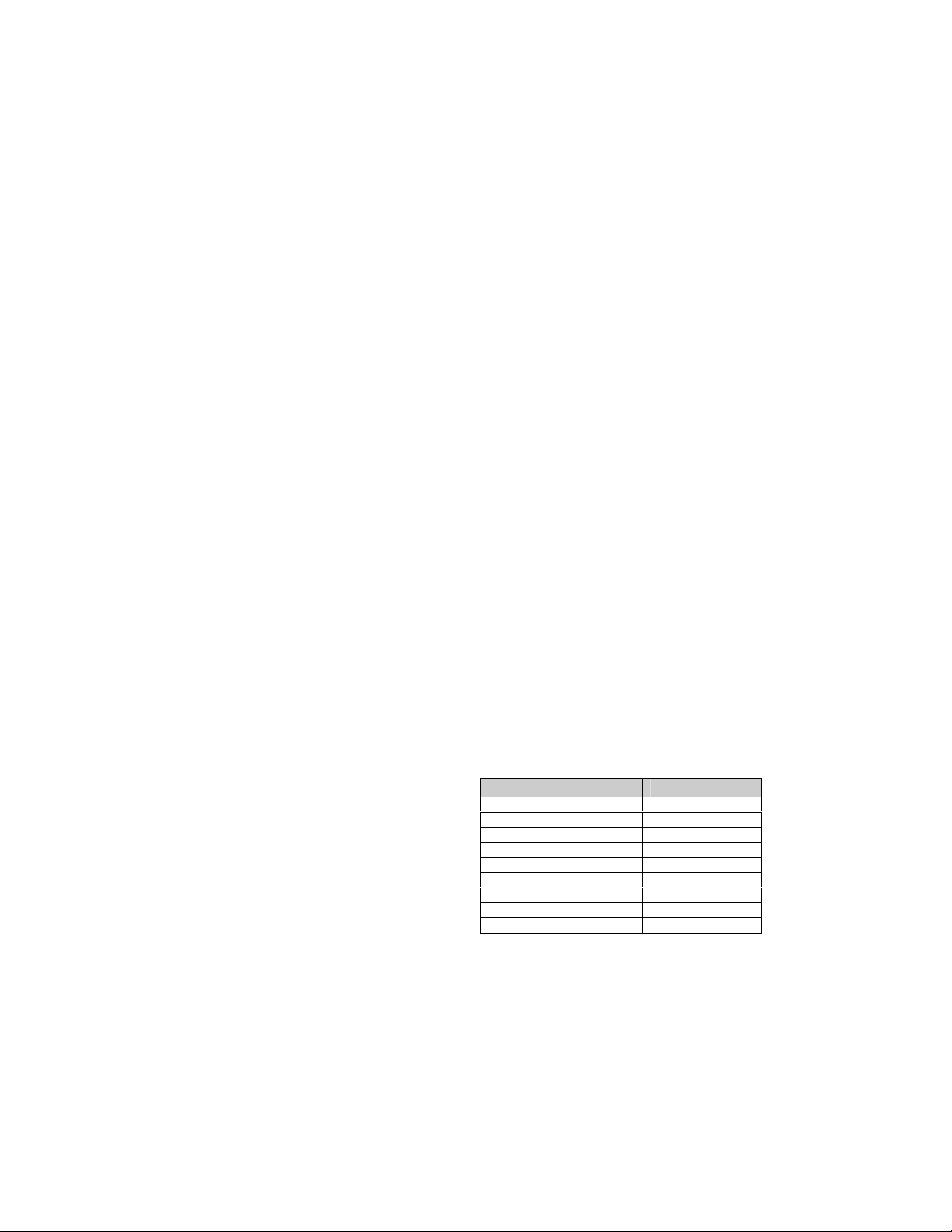

Table 2-2: Connecting to External Devices

Typical Installations

Model 370/375 External Device

Passive 20 mA Output

Passive 20 mA Input

Active 20 mA Output

TP RX+

TXO RXRXI RX+

RX RXTXO RX+

TA RX-

Active 20 mA Input

Active 20 mA Output

Passive 20 mA Input

AAnnaalloogg OOuuttppuutt OOppttiioonn

This section provides procedures for installing and configuring the analog output module.

The analog output modules enable the Model 370/375 to generate a 0-10VDC, active 0-20mA or

active 4-20mA output signal corresponding to the value of most operating parameters. For

parameter setup see page 35. For details on testing and troubleshooting see page 77. For

analog output calibration see page 71. Requires an option mounting bracket kit (24370B-300A0)

for internal installation.

Installation Instructions

1. DISCONNECT POWER! UNPLUG THE MODEL 370/375 TO INSURE DAMAGE WILL NOT

OCCUR DURING OPTION INSTALLATION

2. Remove the (6) 38-31-8710 M5 x 0.8 x 10 mm screws from the enclosure bottom plate and

set it aside.

3. Discard the mounting hardware provided with the analog output kit and use the hardware

provided with the option-mounting bracket kit. Refer to page 13 for parts included with this

kit.

4. Snap in the (4) nylon spacers in the 4 holes either to the right of the notch or the left of the

notch in the option mounting bracket.

5. Position the Analog Output Option Board on the spacers so the ribbon cable points away

from the notch on the option-mounting bracket. Carefully press the analog output option onto

the spacers.

6. Install the (4) nylon hex nuts to secure the option board. Refer to Figure 2-3 for details.

7. If a setpoint option is also being used, connect the 6" option ribbon cable from J1 of the

analog output option board to J1 of the setpoint option board.

8. Connect the 22-30-25520 6.5" ribbon cable (optional) to from J2 of the analog output board to

J3 of the main board.

9. Install the option-mounting bracket in the Model 370/375 enclosure. Refer to page 13 for

option mounting bracket installation instructions.

10. Connect all necessary wiring to the Analog Output Option Board.

11. Reinstall the enclosure bottom plate.

11

Page 18

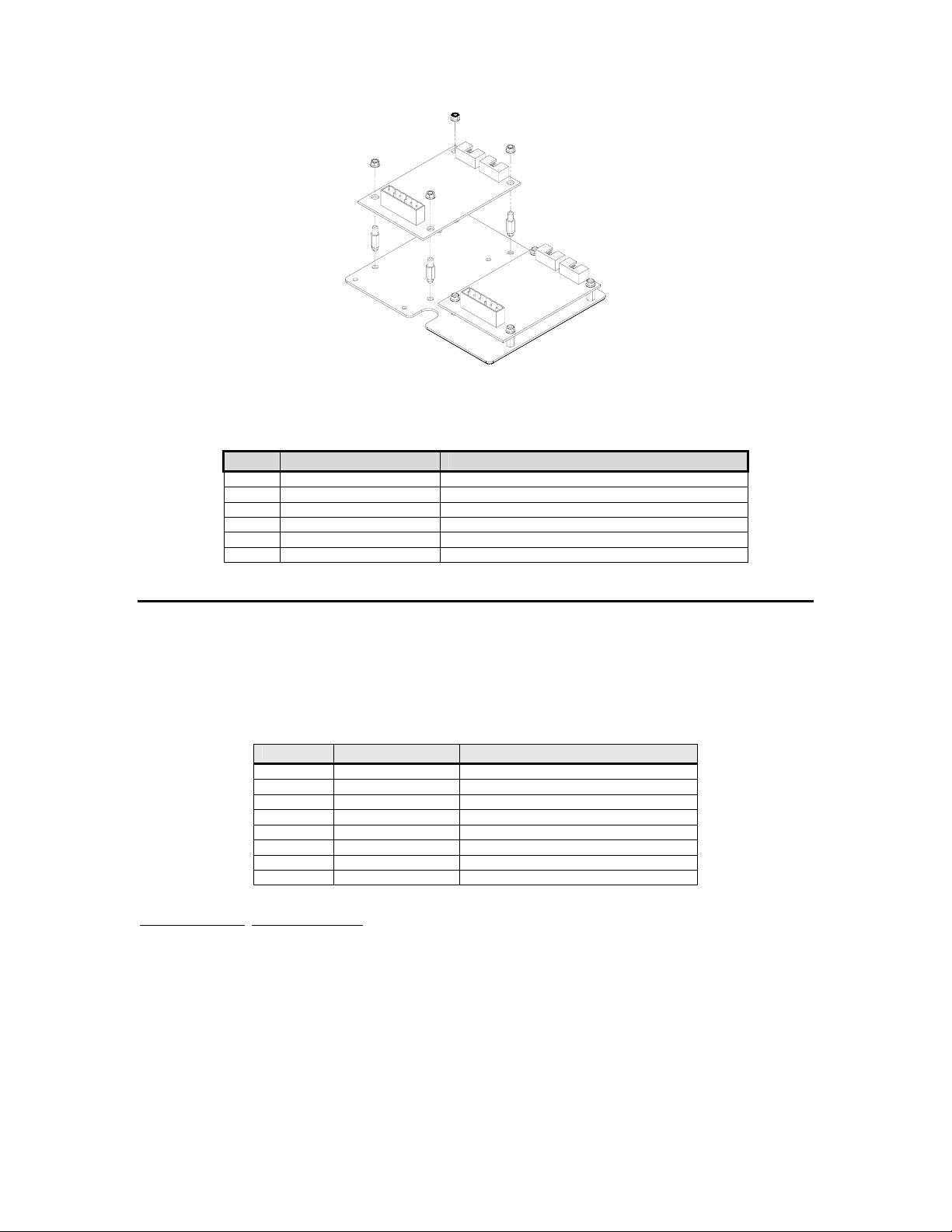

Figure 2-2: Model 370/375 Analog Output and Setpoint Option Installation

Analog Output Connections

Pin Connection Name Description

1 Earth Ground Non-isolated earth ground (future use).

2 + 5 VDC Isolated 5 volt source (future use).

3 Isolated Ground Provides an isolated ground connection.

4 Vout Used for the 0-10 VDC analog signal output.

5 Isolated Ground Provides an isolated ground connection.

6 Iout Used for 4-20 or 0-20 mA analog signal output.

SSeettppooiinntt OOppttiioonn

The setpoint option provides the ability to running a process, turning on stack lights or anything

else that may require an output signal. Eight different configurations are offered. Requires an

option mounting bracket kit (24370B-300A0) for internal installation.

Table 2-3: Setpoint Option Board Part Numbers

Quantity Part Number Description

1 420925-36594 DC 4 output

1 420926-36589 DC 4 input

1 420924-36584 CD 2/in - 2/out

1 420923-36574 Low voltage AC, 4 input

1 420918-36536 Low voltage AC, 2/in - 2/out

1 420922-36579 AC 4 output

1 420923-37093 High voltage AC, 4 input

1 420918-37092 High voltage AC, 2/in - 2/out

Installation Instructions

1. DISCONNECT POWER! UNPLUG THE MODEL 370/375 TO INSURE DAMAGE WILL NOT

OCCUR DURING OPTION INSTALLATION

2. Remove the (6) 38-31-8710 M5 x 0.8 x 10 mm screws from the enclosure bottom plate and

set it aside.

3. Discard the mounting hardware provided with the setpoint option kit and use the hardware

provided with the option-mounting bracket kit. Refer to page 13 for parts included with this

kit.

4. Snap in the (4) nylon spacers in the 4 holes either to the right of the notch or the left of the

notch in the option mounting bracket.

12

Page 19

5. Position the setpoint option board on the spacers so the ribbon cable points away from the

notch on the option-mounting bracket. Carefully press the analog output option onto the

spacers.

6. Install the (4) nylon hex nuts to secure the option board. Refer to Figure 2-3 for details.

7. If an analog output option is also being used, connect the 6" option ribbon cable from J1 of

the setpoint option board to J1 of the analog output option board.

8. Connect the 22-30-25520 6.5" ribbon cable (optional) to from J2 of the setpoint board to J3

of the main board.

9. Install the option-mounting bracket in the Model 370/375 enclosure. Refer to page 13 for

option mounting bracket installation instructions.

10. Connect all necessary wiring to the setpoint option board.

11. Reinstall the enclosure bottom plate.

SETPOINT CARD CONNECTIONS

Using one of the software setpoint configurations (see General Setpoint Setup on page 36) in

conjunction with the setpoint option board gives the Model 370/375 the ability to directly control

external devices such as valves, relays, actuators, etc.

There are up to three setpoint outputs available. The activation and deactivation is controlled by

the setpoint configuration. The outputs are capable of driving up to one Amp at 20-280VAC & 2

Amp at 3-60VDC. The solid state relays are normally open (NO) contacts.

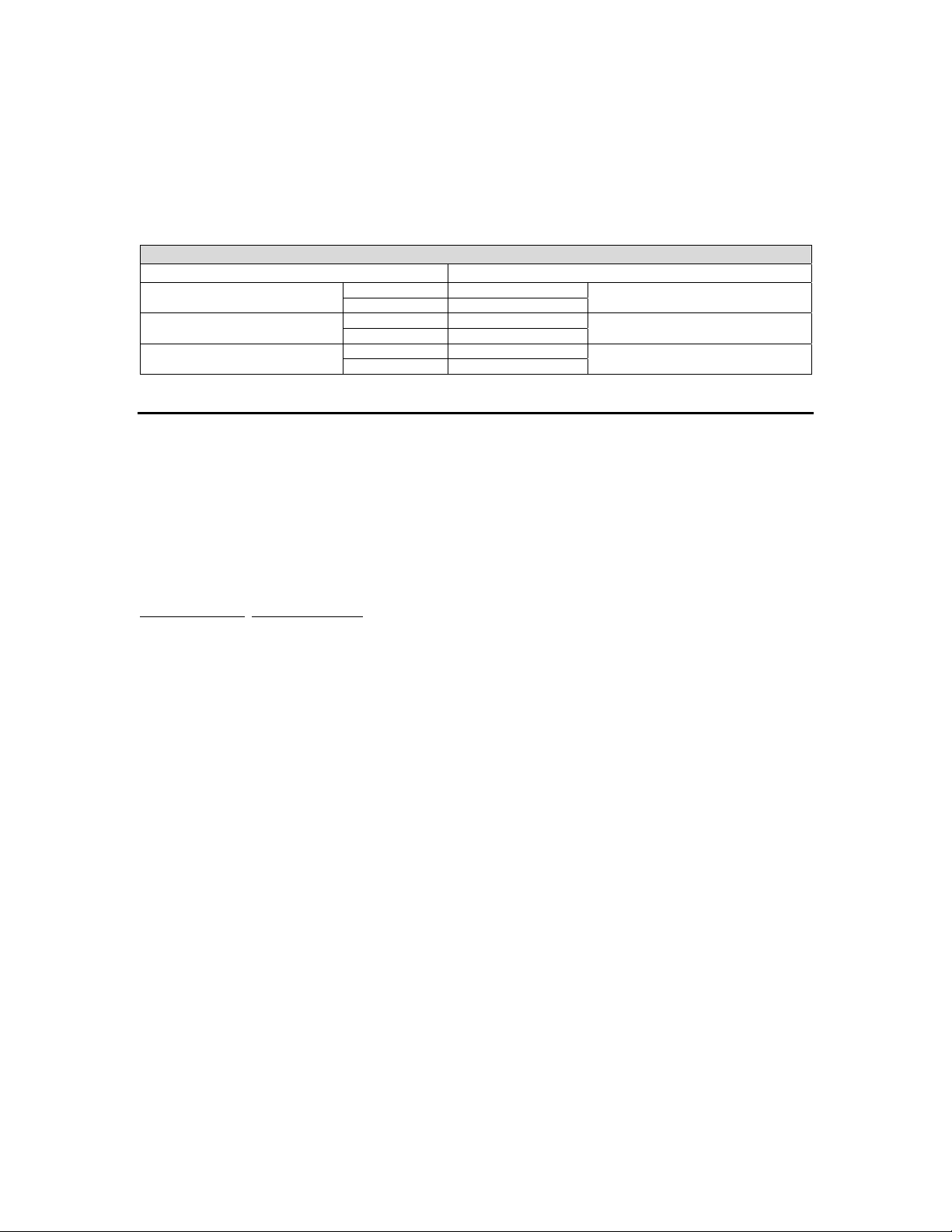

OOppttiioonn MMoouunnttiinngg BBrraacckkeett

The option mounting bracket kit (24370B-300A0) is required for option installation. The bracket

will accommodate up to four options. The options installed on the option-mounting bracket are the

Analog Output and Setpoint. The options mount on the bracket with the hardware provided with

each option kit.

Quantity Part Number Description

1 44-25-43147 Mounting Plate

8 17-20-2107 Nylon spacers

2 38-31-8710 Mounting Plate bolts

8 38-24-1500 Nylon nuts

Installation Instructions

1. DISCONNECT POWER! UNPLUG THE MODEL 370/375 TO INSURE DAMAGE WILL NOT

OCCUR DURING OPTION INSTALLATION.

2. Install all options on the mounting bracket. Refer to the specific option section for installation

instructions.

3. Remove the (6) 38-31-8710 M5 x 0.8 x 10 mm screws from the enclosure bottom plate and

set it aside.

4. Use the (2) M5 self-tapping screws to fasten the option-mounting bracket to the Model

370/375 enclosure. For the installation drawing refer to Figure 2-3.

5. Reinstall the enclosure bottom plate.

13

Page 20

Figure 2-3: Option Bracket Installation

14

Page 21

Chapter 3: S

This chapter will cover the configuration of the scale parameters and how to configure options

such as analog output, setpoint and communication modules.

CALE CONFIGURATION

EEnntteerriinngg tthhee SSeettuupp MMooddee ((MMooddeell 337700))

To prevent accidental changes to the Model 370/375 Setup, a sequence of keystrokes is used to

gain access to the Setup Mode. If the Model 370 is set for remote display, unplug the unit and

press [ZERO] + [SELECT] upon power up. Follow the instructions below to a ccess the setu p

mode.

[ZERO] + [SELECT]

[SELECT], [ZERO], [PRINT], [UNITS], [TARE]

These keystrokes must be made within five seconds, or the Model 370 will return to the Weigh

Mode.

To

access the Setup Mode:

1. From the Weigh Mode, press [ZERO] + [SELECT]

DISPLAY READS Setup ~ Enter Code

2. Press [SELECT]

DISPLAY READS .

3. Press [ZERO]

DISPLAY READS ..

4. Press [PRINT]

DISPLAY READS …

5. Press [UNITS]

DISPLAY READS ….

6. Press [TARE]

DISPLAY READS Chgs ~ Poss!

P110.- - ~ F.S.= ~ 100

To

access Setup in a view-only mode:

1. From the Weigh Mode, press [ZERO] + [SELECT]

DISPLAY READS Setup ~ Enter Code

2. Press [TARE]

DISPLAY READS No ~ Chgs

P110.- - ~ F.S.= ~ 100

When exiting the Setup Mode, the Model 370/375 prompts whether to enter the Calibration

Mode. (See page 61 for Calibration Mode procedures). The display will then prompt to save

any changes.

15

Page 22

EEnntteerriinngg tthhee SSeettuupp MMooddee ((MMooddeell 337755))

To prevent accidental changes to the Model 370/375 Setup, a sequence of keystrokes is used to

gain access to the Setup Mode. If the Model 375 is set for remote display, unplug the unit and

press [ZERO] + [SELECT] upon power up. Follow the instructions below to a ccess the setu p

mode.

100 [SELECT]

23640 [SAMPLE/Enter]

These keystrokes must be made within five seconds, or the Model 375 will return to the Weigh

Mode.

To

access the Setup Mode:

1. From the Weigh Mode, key in 100 [SELECT]

DISPLAY READS Setup ~ Enter Code

2. Key in 23640 [SAMPLE/Enter]

DISPLAY READS Chgs ~ Poss!

P110.- - ~ F.S.= ~ 100

To

access Setup in a view-only mode:

1. From the Weigh Mode, key in 100 [SELECT]

DISPLAY READS Setup ~ Enter Code

2. Press [SAMPLE/Enter]

DISPLAY READS No ~ Chgs

P110.- - ~ F.S.= ~ 100

SSeelleeccttiinngg aa PPaarraammeetteerr

To advance to the next parameter (Model 370 and Model 375):

1. Press [SELECT]

DISPLAY READS P111.09 ~ 1Grad ~ 0.01

2. Press [SELECT]

DISPLAY READS P112.05 ~ Ztrac ~ 0.5 d

3. Continue pressing [SELECT] to advance through all setup parameters.

To

access the previous parameter (Model 370):

1. Press [PRINT]

DISPLAY READS .

2. Press [SELECT]

DISPLAY READS P111.09 ~ 1Grad ~ 0.01

3. Repeat [PRINT] + [SELECT] to back up one parameter.

To

access the previous parameter (Model 375):

1. Press [.]

DISPLAY READS .

2. Press [SELECT]

DISPLAY READS P111.09 ~ 1Grad ~ 0.01

3. Repeat [.][SELECT] to back up one parameter.

16

Page 23

When accessing a parameter, the parameter number appears briefly. The display then toggles between

the parameter name and selection. Pressing [UNITS] will again briefly display the parameter number.

access a specific parameter (for example P200) (Model 370):

To

1. Press [PRINT] four times to select the first digit.

DISPLAY READS 2

2. Press [UNITS] to advance to the next digit.

DISPLAY READS 2.

3. Press [PRINT] once to select the next digit.

DISPLAY READS 20

4. Press [UNITS] to advance to the next digit.

DISPLAY READS 20.

5. Press [PRINT] once to select the next digit.

DISPLAY READS 200

6. Press [SELECT] to advance to the parameter.

DISPLAY READS P200.00 ~ Baud ~ 9600

To

access a specific parameter (for example P200) (Model 375):

1. Key in 200 [SELECT]

DISPLAY READS P200.00 ~ Baud ~ 9600

CChhaannggiinngg aa PPaarraammeetteerr VVaalluuee

SELECTION PARAMETERS

Selection parameters have a pre-defined list of choices to pick from. Each choice is numbered

and corresponds to a certain value. The choice number is shown to the right of the decimal point

within the parameter number. Repeatedly pressing [TARE] (Model 370) or [SAMPLE/Enter]

(Model 375) while viewing a selection parameter cycles through the available choices, or you can

key in the choice number.

P 200.00

Indicates Parameter Parameter Number Choice Number

For example, parameter 200 (P200) is a selection parameter that holds the baud rate for the

serial port. This is a selection parameter because a choice number between 00 and 12 must be

used. Each choice number corresponds to a different baud rate. To change the baud rate from

the default value of 9600 to 4800, perform the following steps from the Setup Mode.

To

change the baud rate from the default value of 9600 to 4800:

1. Key in 200 [SELECT]

DISPLAY READS P200.00 ~ Baud ~ 9600

2. Press [TARE] (Model 370) or [SAMPLE/Enter] (Model 375) once.

DISPLAY READS P200.01 ~ Baud ~ 4800

17

Page 24

Key-In Parameters

Key-In Parameters are not limited to a list of choices, although there may be upper and lower

value limits. A Key-In Parameter requires that a numeric value be entered using the front panel

keys. Key-In Parameters are shown with two hyphens after a decimal point within the parameter

number.

P 110.--

Indicates Parameter Parameter Number Denotes “Key In”

To

enter a Key-In Parameter (370):

1. Press [PRINT]. A decimal point is used to represent the entry position.

2. Press [PRINT] until the desired character appears.

3. Press [UNITS]. Another decimal point indicates the next entry position.

4. Repeat steps 1 and 2 until your desired entry value is shown.

5. Press [TARE] to enter your numerical value.

To

enter a Key-In Parameter (375):

1. Key in the number by using the numeric keys.

2. Press [SELECT] to accept the entry.

To

setup a full scale value of 250 lbs (370):

1. Access the setup mode.

DISPLAY READS P11 0.- - ~ F.S.= ~ 100

2. Press [PRINT] four times to select the first digit.

DISPLAY READS 2

3. Press [UNITS] to advance to the next digit.

DISPLAY READS 2.

4. Press [PRINT] six times to select the next digit.

DISPLAY READS 25

5. Press [UNITS] to advance to the next digit.

DISPLAY READS 25.

6. Press [PRINT] once to select the next digit.

DISPLAY READS 250

7. Press [TARE] to enter the value.

DISPLAY READS P11 0.- - ~ F.S.= ~ 250

To

setup a full scale value of 250 lbs (375):

1. Access the setup mode.

DISPLAY READS P110.- - ~ F.S.= ~ 100

2. Key in 250 [SELECT] to accept the entry.

DISPLAY READS P11 0.- - ~ F.S.= ~ 250

18

Page 25

SSaavviinngg PPaarraammeetteerrss

To exit the Setup Mode and save changes (370):

1. Press [ZERO] to begin exiting Setup Mode.

DISPLAY READS Enter ~ =CAL!

2. Press [ZERO] to bypass Calibration Mode.

DISPLAY READS Enter ~ =Stor

3. Press [TARE] to save setup changes.

DISPLAY READS Enter ~ =End

4. Press [TARE] to complete exit.

DISPLAY READS 0.00

To

exit the Setup Mode and save changes (375):

1. Press [ZERO] to begin exiting Setup Mode.

DISPLAY READS Enter ~ =CAL!

2. Press [CLR] to bypass Calibration Mode.

DISPLAY READS Enter ~ =Stor

3. Press [SAMPLE/Enter] to save setup changes.

DISPLAY READS Enter ~ =End

4. Press [SAMPLE/Enter] to complete exit.

DISPLAY READS 0.00

To

exit the Setup Mode from the view-only mode (370 and 375):

1. Press [ZERO] to begin exiting Setup Mode.

DISPLAY READS Enter ~ =End

2. Press [TARE] (370) or [SAMPLE/Enter] (375) to complete exit.

DISPLAY READS 0.00

To

exit the Setup Mode without saving changes (370):

1. Press [ZERO] to begin exiting Setup Mode.

DISPLAY READS Enter ~ =CAL!

2. Press [ZERO] to bypass Calibration Mode.

DISPLAY READS Enter ~ =Stor

3. Press [ZERO] to exit without saving changes.

DISPLAY READS Enter ~ =Undo

4. Press [TARE] to undo changes.

DISPLAY READS Enter ~ =End

5. Press [TARE] to complete exit.

DISPLAY READS 0.00

To

exit the Setup Mode without saving changes (375):

1. Press [ZERO] to begin exiting Setup Mode.

DISPLAY READS Enter ~ =CAL!

2. Press [CLR] to bypass Calibration Mode.

DISPLAY READS Enter ~ =Stor

19

Page 26

3. Press [CLR] to exit without saving changes.

DISPLAY READS Enter ~ =Undo

4. Press [SAMPLE/Enter] to undo changes.

DISPLAY READS Enter ~ =End

5. Press [SAMPLE/Enter] to complete exit.

DISPLAY READS 0.00

FFaaccttoorryy DDeeffaauulltt

Parameter 65001 and 65002 are available to return the Model 370/375 to factory settings.

Parameter 65001 will reset parameters including the calibration, while parameter 65002 resets all

parameters except the calibration.

After a factory default is performed and saved the Model 370/375 will be in the Quantity mode.

The display will show ‘do APS’ which means an average piece weight needs to be established.

Either perform a sample (refer to page 50) or press [SELECT] to chose another mode.

Return

1. Access the setup mode. See page 15.

2. Key in 65001 or 65002 [SELECT]

3. Press [TARE] once.

4. Press [TARE] once.

5. Press [ZERO] [ZERO] [TARE] [TARE]

Return

1. Access the setup mode. See page 15.

2. Key in 65001 or 65002 [SELECT]

to factory default (370):

DISPLAY READS P65002~default-Cal

DISPLAY READS Are U sure?~default=Enter

DISPLAY READS Setup done~P65002~default-Cal

DISPLAY READS do APS

to factory default (375):

DISPLAY READS P65002~default-Cal

3. Press [SAMPLE/Enter] once.

DISPLAY READS Are U sure?~default=Enter

4. Press [SAMPLE/Enter] once.

DISPLAY READS Setup done~P65002~default-Cal

5. Press [ZERO] [CLR] [SAMPLE/Enter] [SAMPLE/Enter]

DISPLAY READS do APS

LLiisstt ooff PPaarraammeetteerrss

The Model 370 and Model 375 have several parameters that can be configured to your sp ecific

application. Table 3-1 is a complete list of the available parameters. Also refer to page 23 for

explanations of each parameter. The parameters shaded in gray do not apply to the Model

370/375.

20

Page 27

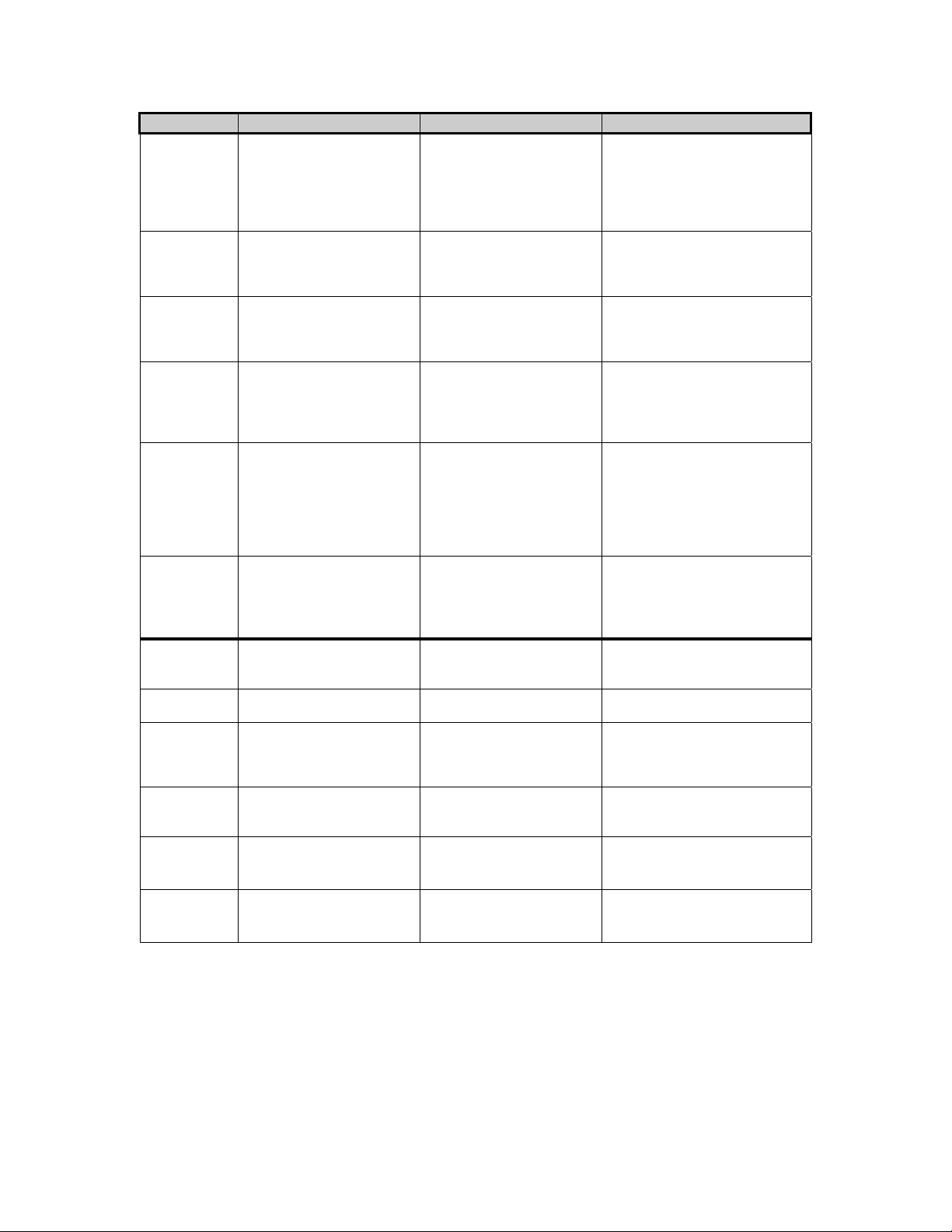

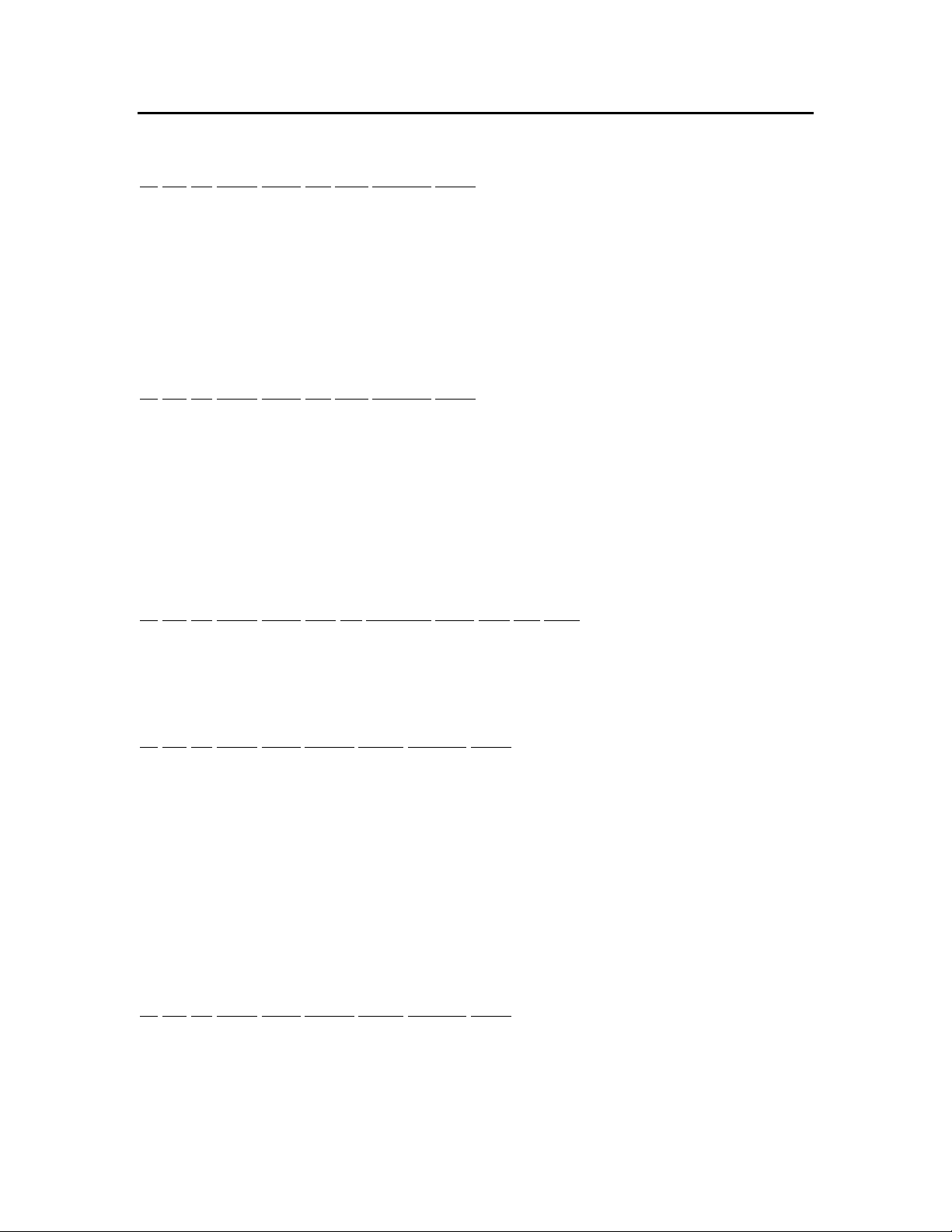

Table 3-1: Parameter Map

Parameter

Number

P110.-P111.06

P112.05

P114.10

P115.10

P116.04

P117.03

P118.12

P119.00

P150.00

P151.01

P152.00

P161.00

P166.01

P167.01

P169.00

P171.00

P179.01

P200.00

P201.01

P202.00

P203.00

P204.02

P210.01

P212.01

P213.01

P220.00

P221.01

P222.00

P223.00

P224.02

Display

Name

F.S.=

1Grad

Ztrac

Stabl

StDly

Filtr

Rate=

Zrang

LinrZ

Units

Unbut

Unit3

TarSa

AutoT

TarIn

AtClr

AnAlg

Count

Baud1

Data1

Par 1

Stop1

HndS1

Send1

Stbl1

Ttyp1

Baud2

Data2

Par 2

Stop2

HndS2

Default

Value

100.00

0.01

0.5d

1.0d

1 Sec

1 Sec

0.3 Sec

100%

Disable

lb

Enable

None

Disable

Enable

Disable (370)

Enable (375)

Disable

Disable

Enable

9600

8 Bits

None

1 Bit

Soft

Press

Delay

--2-9600

8 Bits

None

1 Bit

Soft

Valid Range/ Choices

.01 – 999,999

(Keyed In)

.00001 – 500

(24 Selections)

Off - 20.0d

(200 Selections)

Off – 20.0d

(200 Selections)

0.05 – 10.0 Sec

(101 Selections)

.06 – 8.00 Sec

(8 Selections)

0.05 – 20.0 Sec

(201 Selections)

.01 – 100%

(13 Selections)

Enable / Disable

(Toggle)

lb / kg / other

(Toggle)

Enable / Disable

(Toggle)

None / ounce / gram / lb oz

(4 Selections)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

150 – 115K

(13 Selections)

7 – 8 Bits

(2 Selections)

None – Odd

(3 Selections)

1 – 2 Bits

(2 Selections)

None – Both

(4 Selections)

Off – ID

(5 Selections)

Off – Delay

(Toggle)

1 – 16, Custom

(Selection)

150 – 115K

(13 Selections)

7 – 8 Bits

(2 Selections)

None – Odd

(3 Selections)

1 – 2 Bits

(2 Selections)

None – Soft

(2 Selections)

Parameter

Description

Full Scale

Count By (division size)

Zero Track Aperture

Stability Window

Stability (Motion) Delay

Filter Setting

Display Update

Zero Button Range

Linearization

Default (Calibration) Units

Units Button

Additional Unit

Tare Save

Auto Tare

Keyboard Tare

Auto Tare Clear

Analog Output Option

Counting Functions

Comm 1 Baud Rate

Comm 1 Data Bits

Comm 1 Parity

Comm 1 Stop Bits

Comm 1 Handshake

Comm 1 Transmit

Comm 1 Motion

Print Transmission

Comm 2 Baud Rate

Comm 2 Data Bits

Comm 2 Parity

Comm 2 Stop Bits

Comm 2 Handshake

Page

23

23

23

23

23

23

23

23

24

24

24

24

24

24

24

24

24

24

24

24

25

25

25

25

25

25

25

25

25

25

25

21

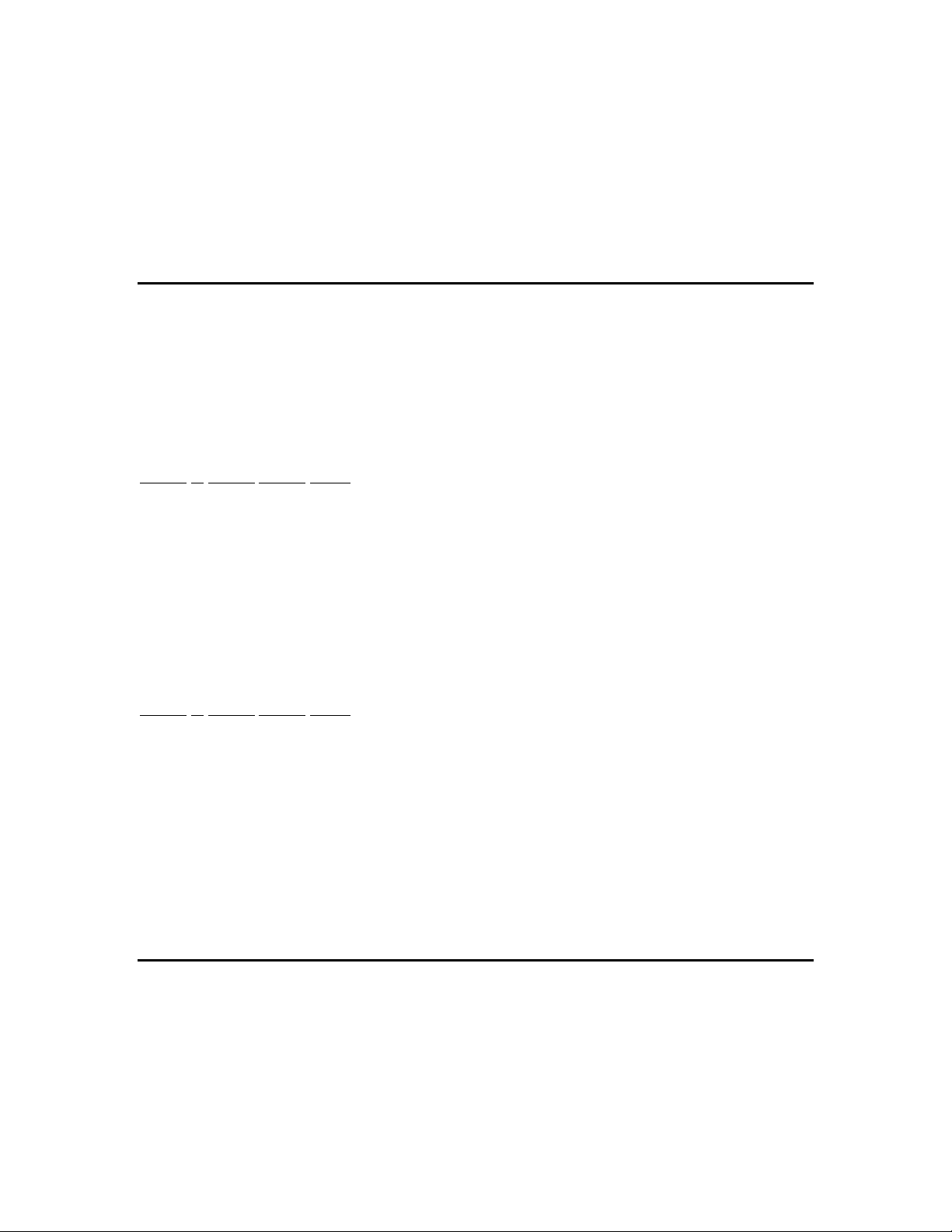

Page 28

Parameter

Number

P230.01

P232.01

P233.01

P250.00

P260.00

P290.00

P291.02

P292.03

P296.00

P410.-P412.00

P420.01

P426.00

P427.00

P440.00

P500--

P501-P502.00

P503.01

P504.00

P505.00

P800.07

P1000.--

P2000.-P5000.0 tArGt Disable

P5002.0 StoP Disable

P5003.0 StArt Disable

P5010.1

P5100.0

Display

Name

Send2

Stbl2

Ttyp2

RS485

Type

Echo

Start

End

EStyle

Euro

PrSEt

Dsply

Batt

Apo

rStrc

Tine

Date

disbl

t-dAt

12 hours

Style

TdSEL disbl

rbut 1

Cust.tran1

Cust.tran2

SPAnn

SetPt

Default

Value

Press

Delay

--1-Disable

350

None

<STX>

<ETX>

300

Disable

Disable

On

Disable

Off

Disable

12.00.00

01.01.70

Disable

12 hour

U.S.A

Disable

do APS

--

--

Enable

None

Valid Range/ Choices

Off – ID

(5 Selections)

Off – Delay

(Toggle)

1 – 16, Custom

(Selection)

Enable / Disable

(Toggle)

350 – Cntrl

(4 Selection)

None – Port 2

(3 Selections)

0 – 255

(256 Selections)

0 – 255

(256 Selections)

300 or 60

(2 Selections)

Enable / Disable

9991/9990 (Key In)

Enable / Disable

(Toggle)

Off – Auto

(3 Selections)

Enable / Disable

(Toggle)

Off – 60 minutes

(16 Selections)

Enable / Disable

(Toggle)

(Keyed In)

(Keyed In)

Enable / Disable

(Toggle)

12 hour/24 hour

U.S.A or International

Enable / Disable

(Toggle)

None - Qty

(9 Selections)

--

--

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

Enable / Disable

(Toggle)

None – Checb

(9 Selections)

Parameter

Description

Comm 2 Transmit

Comm 2 Motion

Print Transmission

Network Option

Remote Display Type

Remote Display – Master

Echo

Master Display Start

Character

Master Display Ending

Character

Remote Display Style

Echo Format

OIML Enforce

OIML Enforce

Display Function

Battery Option Annunciator

Auto Power for Battery

Option

NTEP Enforce

Time/Date Function

Time/Date Function

Time/Date Function

Time/Date Function

Time/Date Function

Time/Date Function

Remote Button Function

Custom Transmit 1

Custom Transmit 2

Target Key

Stop Key

Start Key

Setpoint Annunciators

Setpoint Operation

Page

25

25

26

26

26

26

26

26

26

26

27

27

27

27

27

27

27

28

28

28

28

28

28

28

28

28

28

28

29

22

Page 29

PARAMETER MAP DETAILS

P110 Full Scale Value (Key in)

Denotes the full-scale capacity. This value should not exceed the rated capacity of the weighing

device.

P111 Division Size (Selection)

Indicates the count-by and decimal point. Pressing [ZERO] + [TARE] (Model 370) or [CLR]

(Model 375) will automatically select the choice closest to 30,000 divisions without exceeding

30,000 divisions.

P112 Zero Track Aperture (Selection)

Set in terms of number of divisions. Zero tracking eliminates small weight deviations at or near

zero. Weight deviations within the selected window that have been stable for more than one

second are tracked off, maintaining a gross or net zero condition.

The sum of weight values zeroed with auto zero tracking and [ZERO] cannot exceed the

allowable zero range (P118).

To determine the proper setting in a counting application, divide the weight of the smallest

product counted by the division size (P111). Zero track should be set to 0 (off) for most setpoint

filling operations. This prevents tracking off any product trickle at the start of a fill process.

P114 Stability (Selection)

Stability is defined as weight fluctuations within an aperture that can be regarded as being a

stable weight. Deviations outside this aperture are considered motion, and the motion

annunciator on the front panel will light accordingly. Once the scale settles within the stability

aperture, the Model 370/375 will wait for a period of time specified by the motion delay (P115)

before the Model 370/375 is considered stable.

Print operations configured as motion delayed (P114) will not send the specified data until the

weight reflects a stable reading as designated by this setting. Certain setpoint operations are also

considered motion delayed and will not change states until a no-motion condition exists.

P115 Stability Delay (Selection)

Selects the stability (motion) time delay to a resolution of 0.1 seconds. For example, an entry of

25 will be accepted as 2.5 seconds.

P116 Filter (Selection)

Sets the Model 370/375 response time in terms of seconds. Filtering determines how quickly the

Model 370/375 will respond to changing input signals. A low filter setting speeds the response, a

higher filter setting will 'dampen' the response.

Filtering is used to filter out weight fluctuations caused by outside sources, such as vibrations or

air currents.

P117 Rate (Selection)

Specifies how often the display is updated with new data and the rate of continuous transmits (if

P210 or P230 are enabled). For example, if 0.05 is selected, the Model 370/375 will write data to

the display and send continuous transmits 20 times a second. Selections from 0.05 to 20.0

seconds are available. The actual rate may be less than (P117). The actual rate depends on the

Model 370/375 speed (P60090), the size and number of transmits (P1000, P2000, P210, and

P230), and COM ports' speed (if echo (P290) is enabled or continuous transmits are enabled).

P118 Zero Range (Selection)

Specifies how many divisions can be zeroed in terms of a percentage of full scale (P110). The

sum of weight values zeroed through the [ZERO] key and auto zero tracking cannot exceed this

range.

23

Page 30

A zero range of 5% is commonly used with large tank scales to avoid accidental zeroing of a full

or partially full tank.

P119 Multi-Point Linearization (Toggle)

Enable the five-point linearization feature used during load cell calibration.

P150 Units (Toggle)

Set default units to 'lb', 'kg' or ‘other’ (third unit). The Model 370/375 must use the default units

during calibration procedures (see Chapter 4:). The default units are the displayed units upon

power-up. If ‘other’ is chosen, P152 must be set to one of the available unit selections.

P151 Units Button (Toggle)

When enabled, this parameter will allow [UNITS] to toggle between 'lb', 'kg' (1000g) or third unit.

When disabled, the Model 370/375 will show only the calibration units as determined by P150.

P152 Third Unit (Selection)

This parameter will allow the choice of three additional units (ounces, grams or lb oz) that may be

accessed with the [UNITS] key. Only one unit will be available at a time. The third unit can only

be selected if P151 is enabled. The third unit will be identified by an annunciator on the display

below the ‘kg’ annunciator.

P161 Tare Save (Toggle)

Enabling Tare Save allows the Model 370/375 to retain the tare value in the event of power loss.

The correct net weight is restored upon power-up.

P166 Auto Tare (Toggle)

When enabled, pressing [TARE] will wait for a no-motion condition and then bring the scale to a

net zero reading. Disabling will prevent keypad tare operations.

P167 Keyboard Tare (Toggle)

If P167 is disabled, then the user cannot view tare using the select key. Also, it will block numeric

tare (manually entering tare) and show the message; "Funct" "disbl". The only way you can tare

is using the automatic tare (press [TARE] to tare the weight on the scale). When P167 is on, the

user can view tare using the select key (tare will follow Net). The unit will accept numeric tare. On

the Model 375, a known tare amount may be keyed in with the numeric keypad. On the Model

370, a known tare amount may be keyed in with the [PRINT] and [UNITS] keys.

P169 Auto Tare Clear (Toggle)

Enabling this feature will cause the current tare value to be cleared to zero every time the Model

370/375 stabilizes within ±5 graduations of gross zero

P171 Analog (Toggle)

Enable or disable the optional analog output module. See Analog Output Setup on page 35 for all

parameters associated with the Analog Output Module.

P179 Count (Toggle)

When enabled, the quantity mode becomes accessible via the [SAMPLE/Enter] or [SELECT]

key. The quantity mode is identified by the illumination of the QTY annunciator.

P200 Baud (Comm 1) (Selection)

Set the desired baud rate for the communication port. 150 - 115K bps

Note that if a setpoint activation method is set to [TARE], disabling Auto Tare will also disable

the activation of that setpoint.

P201 Data Bits (Comm 1) (Toggle)

Select 7 or 8 data bits for the transmission.

24

Page 31

P202 Parity (Comm 1) (Selection)

Select Odd, Even or None for the transmission parity.

P203 Stop Bits (Comm 1) (Toggle)

Select 1 or 2 stop bits for communication port transmissions.

P204 Comm Handshake (Comm 1) (Selection)

Select from None, Software (Xon/Xoff), Hardware (CTS/RTS), or Both.

P210 Send (Comm 1) (Selection)

Transmission Send options:

Choice Number Selection Name Description

P210.00 Off All transmissions disabled.

P210.01 Press Sends transmission with [PRINT] key.

P210.02 Cont. Sends transmissions continuously.

P210.03 Cycle

P210.04 ID Sends transmission with the stored ID.

Send single transmission after weight is reached and motion ceases. Must

return display value below 0.1% of F.S. to reset for next transmission.

P212 Send Stability (Comm 1) (Toggle)

Enabling Send Stability will delay any transmissions until a no-motion condition exists.

P213 Transmit Selection (Comm 1) (Selection)

Select desired print output (1 - 16 or custom). The transmission will be initiated by the selected

print operation (P210) and / or the Remote Key selection (P800). See page 29 for details on

preset formats or page 31 for details on custom transmit.

P220 Baud (Comm 2) (Selection)

Set the desired baud rate for the communication port. 150 - 115K bps

P221 Data Bits (Comm 2) (Toggle)

Select 7 or 8 data bits for the transmission.

P222 Parity (Comm 2) (Selection)

Select Odd, Even or None for the transmission parity.

P223 Stop Bits (Comm 2) (Toggle)

Select 1 or 2 stop bits for communication port transmissions.

P224 Comm Handshake (Comm 2) (Selection)

Select from None and Software (Xon/Xoff).

P230 Send (Comm 2) (Selection)

Transmission Send options:

Choice Number Selection Name Description

P230.00 Off All transmissions disabled.

P230.01 Press Sends transmission with [PRINT] key.

P230.02 Cont. Sends transmissions continuously.

P230.03 Cycle

P230.04 ID Sends transmission with the stored ID.

Send single transmission after weight is reached and motion ceases. Must

return display value below 0.1% of F.S. to reset for next transmission.

P232 Send Stability (Comm 2) (Toggle)

Enabling Send Stability will delay any transmissions until a no-motion condition exists.

25

Page 32

P233 Transmit Selection (Comm 2) (Selection)

Select desired print output (1 - 16 or custom). The transmission will be initiated by the selected

print operation (P210) and / or the Remote Key selection (P800). See page 29 for details on

preset formats or page 31 for details on custom transmit.

P250 RS-485 Multi-Drop Network (Toggle)

Enable / disable the RS-485 multi-drop network option. Requires that an RS-485 option board be

installed. This option allows up to 250 RS-485 devices to be networked together in either a half

duplex or full duplex wiring scheme. See the RS-485 Multi-Drop Network Setup and Operation

section beginning on page 35 for complete details on RS-485 setup and operation.

P251 Address (Key in) (Only displayed if P250 is enabled)

Specifies the address of the Model 370/375 for RS-485 multi-drop communications. Allowed

choices are 0 (disabled) and 4 - 254.

P260 Master, Remote Display or Safe Area Hub (Selection)

Select the mode of operation.

Choice Number Selection Name Description

P260.00 350 Sets indicator as the master device. Model 350/355/370/375.

P260.01 R-dsp

P260.02 Hub Sets the indicator to a safe area hub.

P260.03 Cntrl

Sets the indicator as a slave device. P261 – P283 will be

available.

Sets the indicator to the master controller for fiber-optic

interface to the safe area hub.

P290 Echo Display (Toggle)

Determines which comm port will be echoed to another device. Selections are None, port 1, port

2.

P291 Start Character (Key-in)

Set the start character for the master indicator. Choices are 0 – 255. Default value is 2 (STX).

The choice must match the start character at P274 of the remote display (slave). A value of 0

means that a byte with the value 0 will be sent for the character. Avoid using values of 17 or 19

when using software flow control. The values of 17 and 19 are Xon and Xoff codes and could

cause conflict.

P292 End Character (Key-in)

Set the end character for the master indicator. Choices are 0 – 255. Default value is 3 (ETX). The

choice must match the end character at P275 of the remote display (slave). A value of 0 means

that a byte with the value 0 will be sent for the character. Avoid using values of 17 or 19 when

using software flow control. The values of 17 and 19 are Xon and Xoff codes and could cause

conflict.

P296 Echo Style (Toggle)

Set the style of indicator the display will be echoed to. Choose from 300 or 60. The 300 choice is

for 350, 355, 350 I.S., 355 I.S., 351, 370, 375, ABS 4100. The 60 choice is for 460 series, 560

series and 660 series indicators.

P410 Euro (Toggle)

Enable/disable OIML legal-for-trade restrictions. To enable this parameter key in 9991

[SAMPLE/Enter]. To disable key in 9990 [SAMPLE/Enter].

If P410 is enabled the following will apply:

• An over-load condition will result when the gross weight exceeds nine graduations over

the full scale capacity.

26

Page 33

• Full scale capacity is always referenced from the last zero calibration reference, not the

last zero acquired by pressing [ZERO].

P412 Preset Character (Toggle)

If P412 is enabled, it will add a ‘P’ to the beginning of the tare parameter on the display and

transmits if the last tare value was entered manually by the user (numeric entry). P167 needs to

be enabled in order to key in a tare value. A ‘P’ will not be added if the last tare was performed by

pressing the tare key or if the tare value is zero (even if the zero value was manually entered by

the user). The ‘P’ prefix stands for “Preset”. When P412 is disabled, the unit will never show 'P'

before tare no matter how tare is entered.

P420 Display (Selection)

Select display control option. Choose from On, Off or Auto. The auto setting helps conserve

power for extended battery life. When the Model 370/375 display is off, the load cell(s) are still

powered.

If P420 is set to Off or selection 0, you can turn on the display by holding down the [ZERO] key

upon power up.

Parameter

Setting

P420.00 Off Shuts off the display.

P420.01 On Normal display operation.

P420.02 Auto

Choice Description

Shuts off the display when weight has stabilized within 6 divisions for 5 minutes.

Changing weight more than 6 divisions will re-enable the display. NOTE: The display

will turn back on if data is received via the RS-232 Port.

P426 Low Battery Indication (Toggle)

Press [TARE] to enable or disable this option from the gross or net modes. Low battery will be

indicated continuously if this feature is enabled without the battery option installed.

P427 Battery Option Automatic Shutdown (Selection)

Select duration of time for auto shutdown. Selections are off, 0.5, 1, 2, 3, 4, 5, 10, 15, 20, 25, 30,

35, 40, 45, and 60. Choices are in set in minutes.

P440 Legal For Trade Restrictions (Toggle)

Enable NTEP legal-for-trade restrictions. The Model 370/375 are not NTEP approved.

If P440 is enabled the following will apply:

• Serial data will not be received while in the Setup Mode.

• Received alpha characters will not be displayed.

• Numeric tare entries cannot be received through the serial port.

• Pressing [TARE] with a gross weight of zero (0) or keying in a tare value of zero (0) will

not automatically switch to the net mode.

• Negative tare values are not accepted.

• Tare rounding is enforced.

• When the tare value is zero, the net mode is not selectable.

P500 Time Setting (key in)

Enter the time in the form HH.MM.SS. Time is always shown in military format within this

parameter. P503 will determine how the time is displayed in the weigh mode.

P501 Date Setting (key in)

Enter the date in the form MM.DD.YY. P504 will determine the how the date is displayed in the

weigh mode.

27

Page 34

P502 Time/Date (toggle)

Enables or disables the time and date feature. If enabled the time and date will be accessible

from the weigh mode with the [SELECT] key. The weight will continue to be updated when

viewing the time or date. The time will be formatted as defined by P503 and the date will be

formatted as defined by P504. See page 52 for instructions on how to change the time and/or

date.

P503 Hours (toggle)

Determines the TIME format style, 12 hour or 24 hour. If in 12-hour mode the right most decimal

point on the display will become the PM indicator. Note: The time must be entered as military

time. If the mode is set for 12-hour, the time will be converted to a 12-hour clock.

P504 Sty l e (toggle)

Determines the DATE format style, U.S.A. or Int'l. If set for U.S.A, the date will resemble

01/26/01. If set for international, the date will resemble 26/01/01.

P505 Time/Date Select (toggle)

Enables or disables the editing of time and date the weigh mode.

P800 Remote Key 1 Operation (Selection)

A physical Remote Key closure does not exist and is not functional on the Model 370/375. The

remote key choice for activation within a setpoint will not work.

P1000 Custom Transmit 1

A custom transmit is a user-defined string of data that can be sent to the serial port. Parameter

P1000 is the beginning of the custom transmit table for transmit 1and must be enabled for

transmit by selecting “cust” at P213. Parameters use three bytes of memory; ASCII characters

and control codes use one byte. See P60001 for available memory. The custom transmit cannot

be viewed or altered from the Model 370/375. A custom transmit must be entered via the serial

port. See Custom Transmit Setup on page 31 for details on designing and loading a custom

transmit.

P2000 Custom Transmit 2

A custom transmit is a user-defined string of data that can be sent to the serial port. Parameter

P2000 is the beginning of the custom transmit table for transmit 2 and must be enabled for

transmit by selecting “cust” at P230. Parameters use three bytes of memory; ASCII characters

and control codes use one byte. See P60001 for available memory. The custom transmit cannot

be viewed or altered from the Model 370/375. A custom transmit must be entered via the serial

port. See Custom Transmit Setup on page 31 for details on designing and loading a custom

transmit.

P5000 Target Key (Toggle)

Although the target key is not physically on the keypad, a target value can be entered by sending

a %<CTRL A> using a serial device such as a computer. P5000 must be enabled and a setpoint

that uses a target value must be enabled before the target can be entered in this manner.

P5002 Stop Key (Toggle)

Although the stop key is not physically on the keypad, you can stop a setpoint remotely by

sending a %<CTRL F> using a serial device such as a computer. P5002 and a setpoint must be

enabled before the stop function will operate in this manner.

P5003 Start Key (Toggle)

Although the start key is not physically on the keypad, you can start a setpoint remotely by