Page 1

HT48C50-1

8-Bit Microcontroller

1 June 14, 2000

General Description

The device is an 8-bit high performance

RISC-like microcontroller designed for multi

ple I/O product applications. The device is particularly suitable for use in products such as

remote controllers, fan/light controllers, wash

-

ing machine controllers, scales, toys and vari

ous subsystem controllers. A HALT feature is

included to reduce power consumption.

Features

·

Operating voltage:

f

SYS

=4MHz: 2.4V~5.5V

f

SYS

=8MHz: 4.5V~5.5V

·

Low voltage reset function

·

35 bidirectional I/O lines (max.)

·

1 interrupt input shared with an I/O line

·

8-bit programmable timer/event counter with

overflow interrupt and 8-stage prescaler

·

16-bit programmable timer/event counter

and overflow interrupts

·

On-chip RC oscillator, external crystal and

RC oscillator

·

32768Hz crystal oscillator for timing

purposes only

·

Watchdog Timer

·

4096´15 program memory ROM

·

160´8 data memory RAM

·

Buzzer driving pair and PFD supported

·

Halt function and wake-up feature reduce

power consumption

·

6-level subroutine nesting

·

Up to 0.5ms instruction cycle with 8MHz

system clock at V

DD

=5V

·

Bit manipulation instruction

·

15-bit table read instruction

·

63 powerful instructions

·

All instructions in one or two machine

cycles

·

28-pin SKDIP and 40-pin DIP package

Preliminary

Page 2

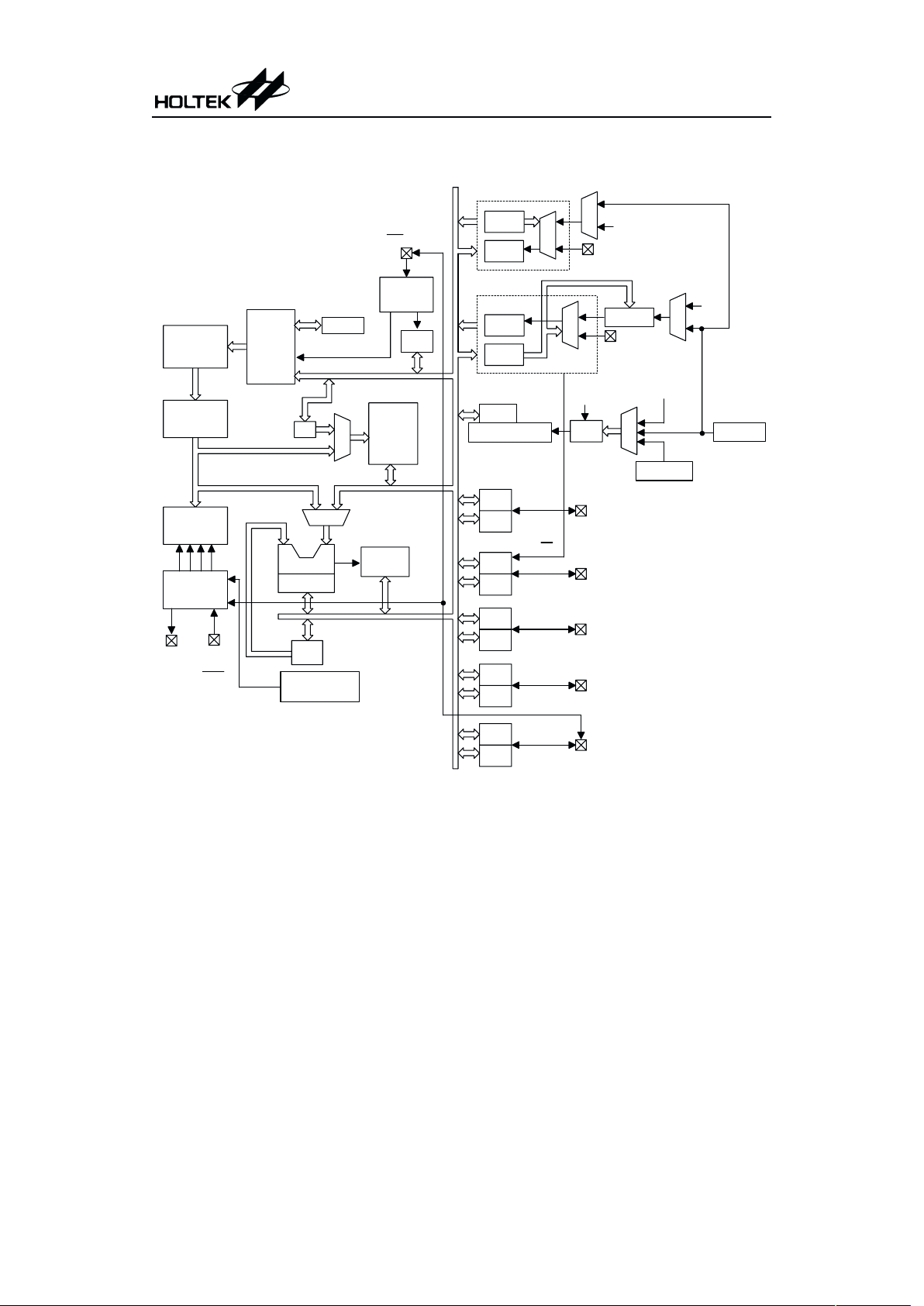

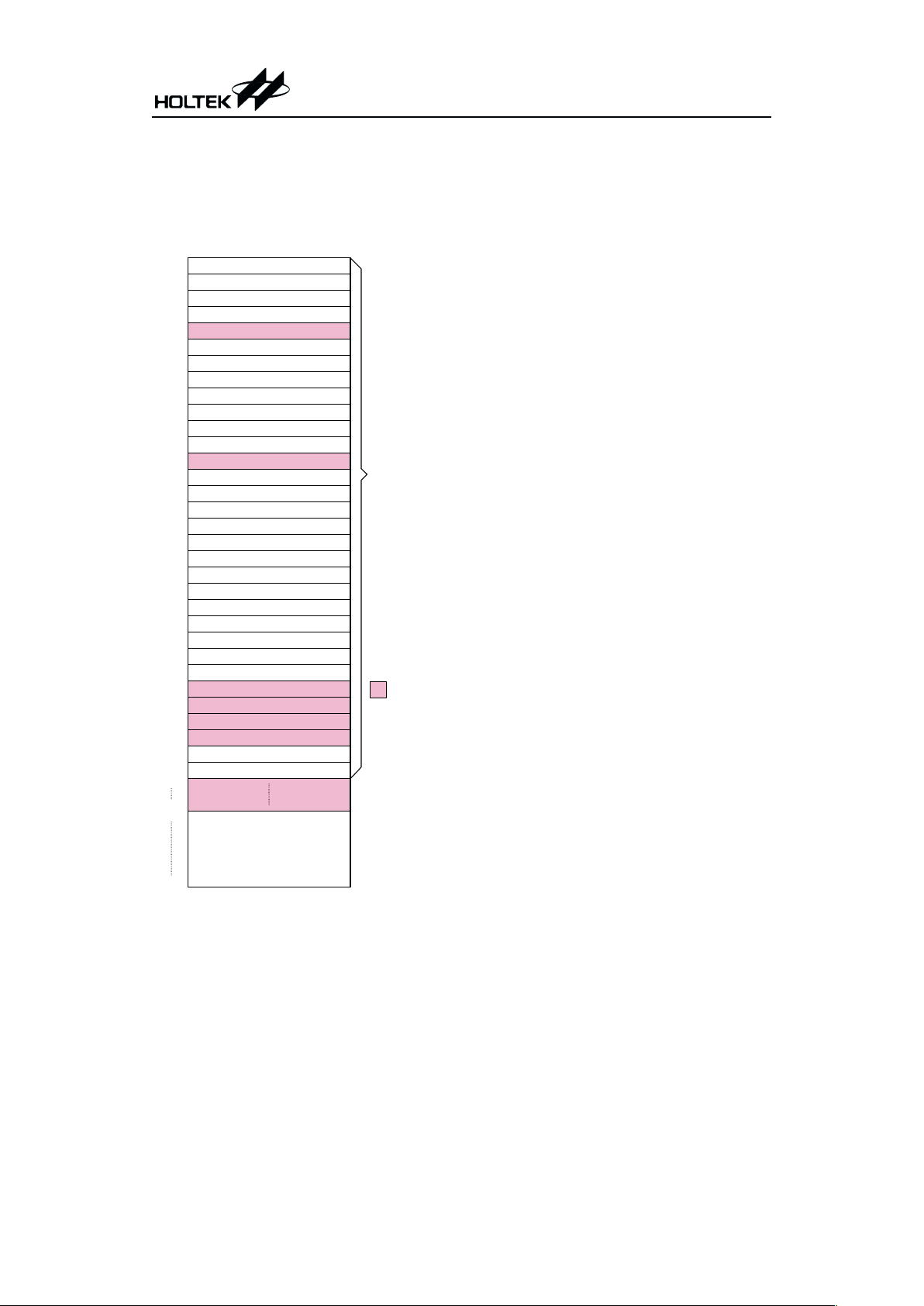

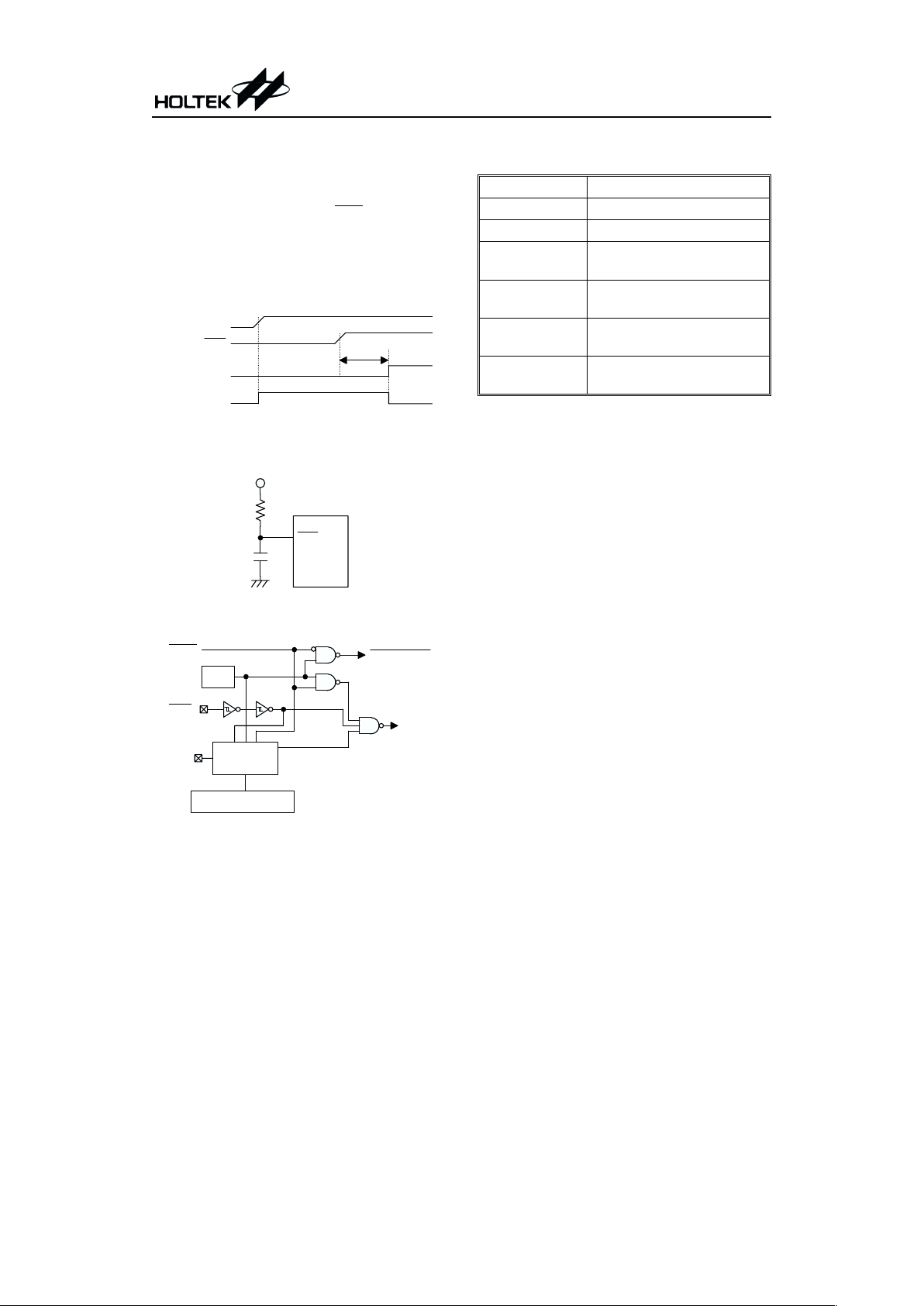

Block Diagram

HT48C50-1

2 June 14, 2000

Preliminary

IN T /P G 0

OSC2/

PG2

OSC1/

PG1

RES

VDD

MUX

TM R 0

TM R 0C

TM R 0

VSS

P re scaler

f

SYS

PG0

Program

ROM

Program

C ounter

Interrupt

Circuit

STACK

IN T C

DATA

Memory

In struction

R egister

M

U

X

In struction

D ecoder

STATUS

ALU

Shifter

Tim ing

G enerator

ACC

M

U

X

MP

S Y S C L K /4

WDTS

WDT

WDT OSC

W D T P rescale r

M

U

X

RTC OSC

E N /D IS

PG1

PG2

In te rn a l

RC OSC

PDC

PORT D

PD0~PD7

PGC

PG

PORT G

PG0~PG2

PBC

PORT B

PB0~PB7

BZ/BZ

PB

PAC

PORT A

PA0~PA7

PA

PD

PC

PORT C

PC0~PC7

PCC

TM R 1C

TM R 1

M

U

X

M

U

X

TM R 1

f

SYS

/4

M

U

X

Page 3

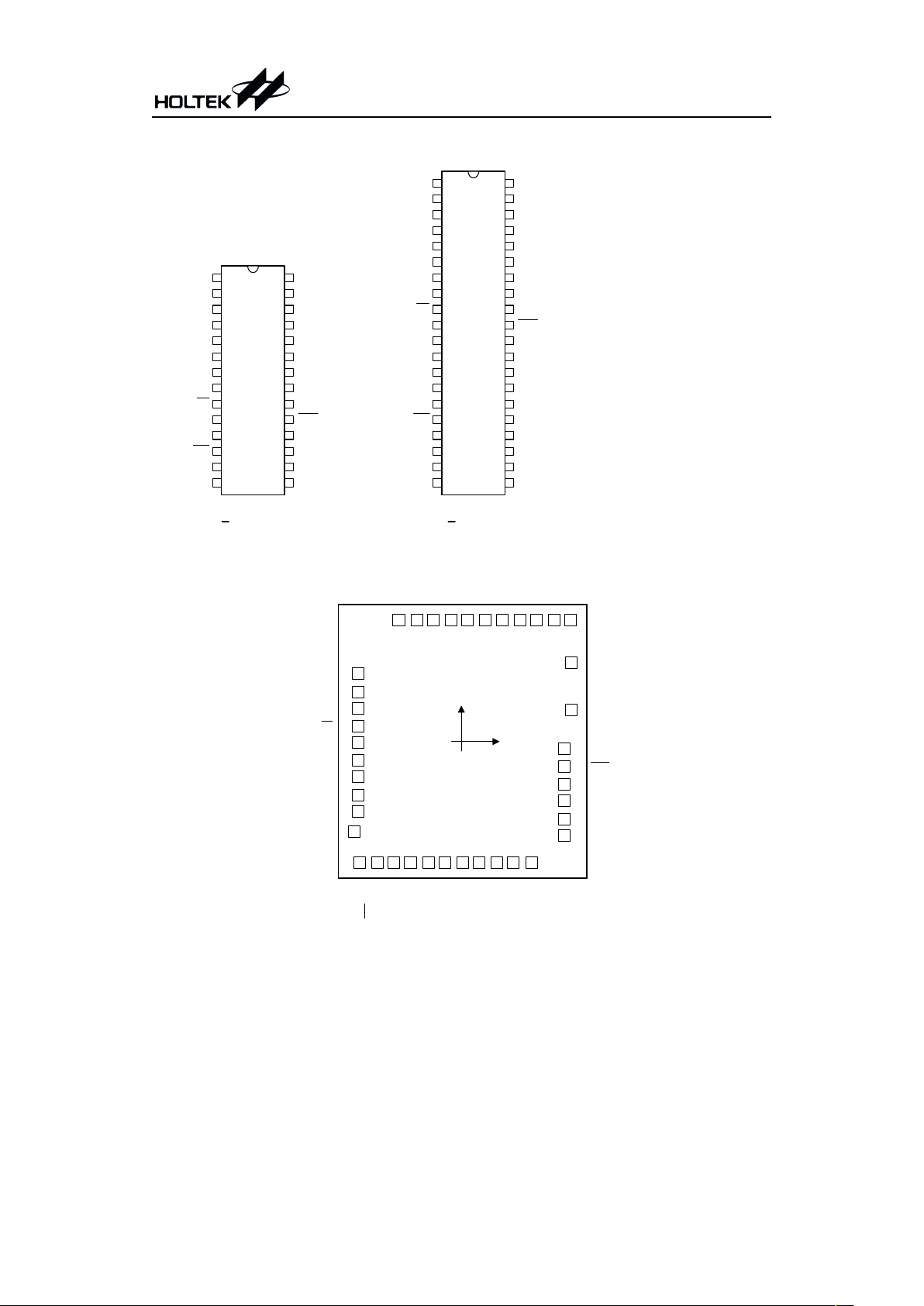

Pin Assignment

Pad Assignment

* The IC substrate should be connected to VSS in the PCB layout artwork.

HT48C50-1

3 June 14, 2000

Preliminary

1

21

2

22

3

23

4

24

5

25

6

26

7

27

8

28

9

29

10

301131

1232133314341535163617371838193920

40

(0 , 0 )

PA0

PB3

PB2

PB0/BZ

PD7

PD6

PD5

PD4

VSS

TM R 0

PC0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

PD0

P G 0 /IN T

VDD

TM R 1

PD3

PD2

PD1

RES

OSC1/PG1

OSC2/PG2

PA7

PA6

PA5

PA4

PB7

PB6

PB5

PB4

PA3

PA2

PA1

PB1/BZ

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PB6

PB7

PA4

PA5

PA6

PA7

OSC2/PG2

OSC1/PG1

VDD

RES

PC5/TM R 1

PC4

PC3

PC2

PB5

PB4

PA3

PA2

PA1

PA0

PB3

PB2

PB1/BZ

PB0/BZ

VSS

P G 0 /IN T

PC0/TM R 0

PC1

H T48C 50-1-A

2 8 S K D IP

H T48C 50-1

4 0 D IP

PB6

PB7

PA4

PA5

PA6

PA7

OSC2/PG2

OSC1/PG1

VDD

RES

TM R1

PD3

PD2

PD1

PD0

PC7

PC6

PC5

PC4

PC3

PB5

PB4

PA3

PA2

PA1

PA0

PB3

PB2

PB1/BZ

PB0/BZ

PD7

PD6

PD5

PD4

VSS

PG0/INT

TM R0

PC0

PC1

PC2

Page 4

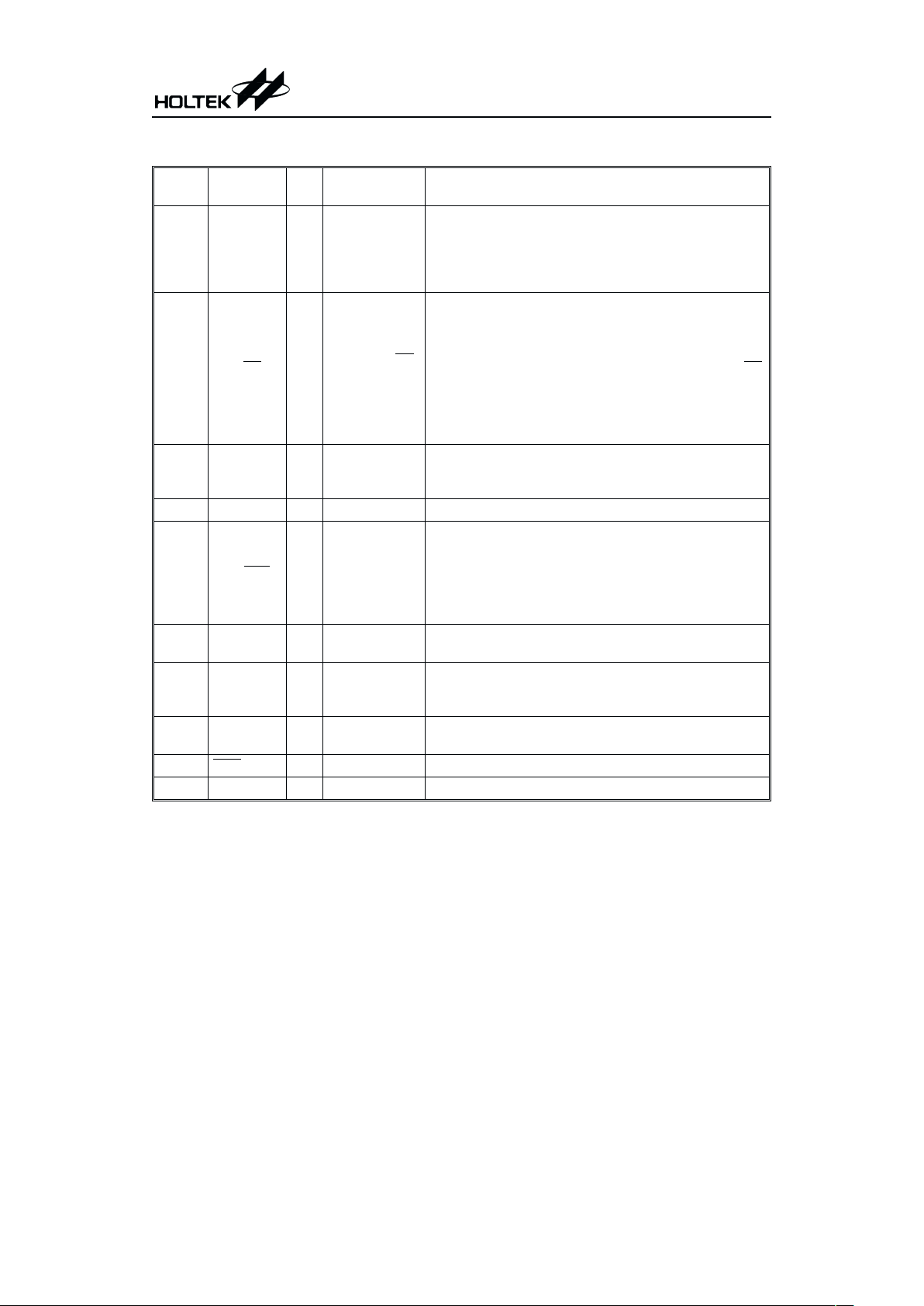

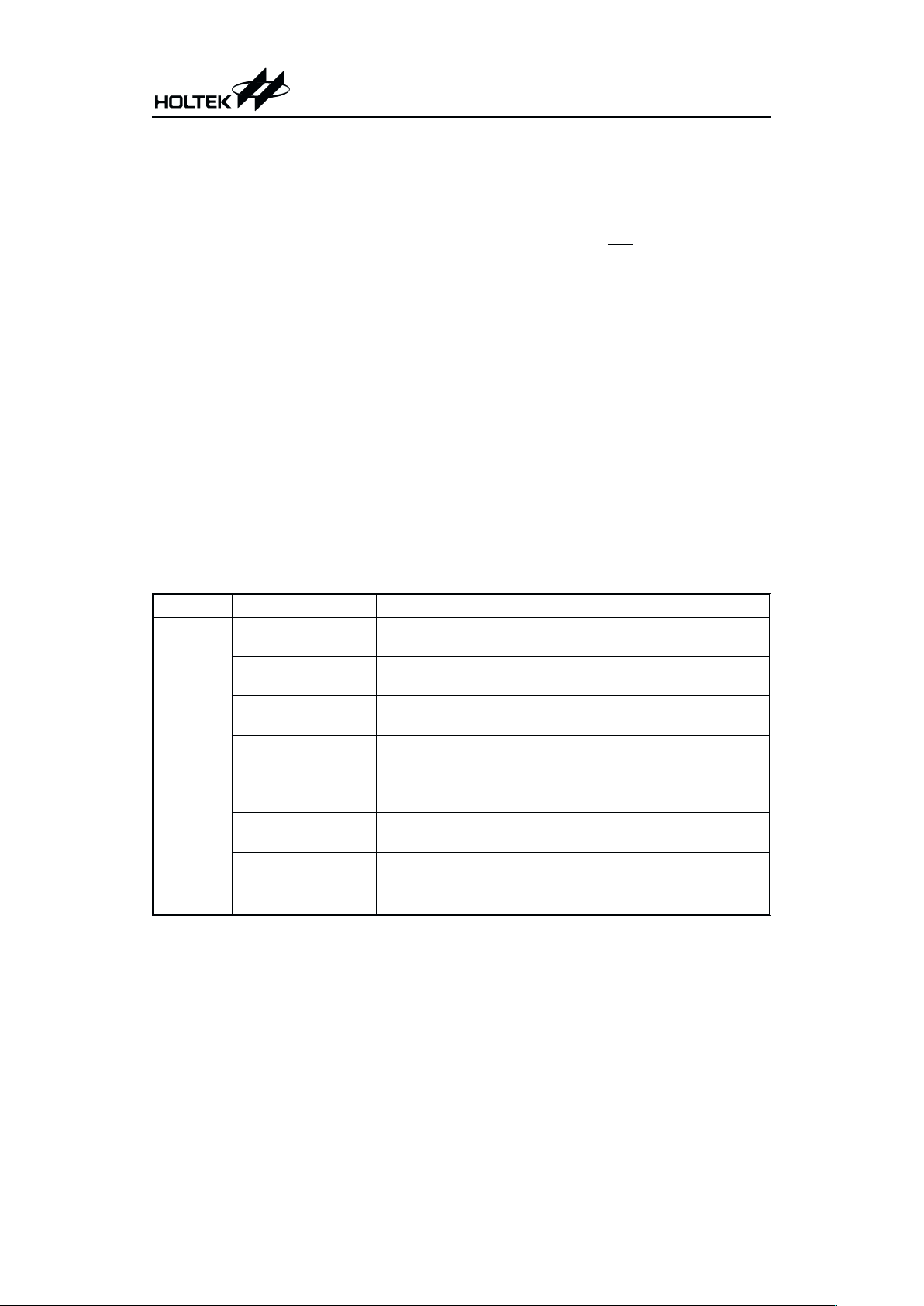

Pad Description

Pad

No.

Pad Name I/O Mask Option Description

1,

40~38,

33~30

PA0~PA7 I/O

Pull-high*

Wake-up

CMOS/schmitt

trigger input

Bidirectional 8-bit input/output port. Each bit can be

configured as a wake-up input by mask option. Soft

ware instructions determine the CMOS output or

schmitt trigger or CMOS input with pull-high resistor

(determined by pull-high options).

5

4

3, 2,

37~34

PB0/BZ

PB1/BZ

PB2~PB7

I/O

Pull-high*

I/O or BZ/BZ

CMOS/schmitt

trigger input

Bidirectional 8-bit input/output port. Software in

structions determine the CMOS output or schmitt

trigger input with pull-high resistor (determined by

pull-high options).

The PB0 and PB1 are pin-shared with the BZ and BZ

,

respectively. Once the PB0 and PB1 are selected as

buzzer driving outputs, the output signals come from

an internal PFD generator (shared with timer/event

counter 0).

21~24,

9~6

PD0~PD7 I/O

Pull-high*

CMOS/schmitt

trigger input

Bidirectional I/O lines. Software instructions deter

mine the CMOS output or schmitt trigger input with

pull-high resistor (determined by pull-high options).

10 VSS

¾¾

Negative power supply, ground

11 PG0/INT

I/O Pull-high*

Bidirectional I/O lines. Software instructions deter

mine the CMOS output or schmitt trigger input with

pull-high resistor (determined by pull-high options).

This external interrupt input is pin-shared with PG0.

The external interrupt input is activated on a high to

low transition.

12 TMR0 I

¾

Timer/event counter 0 schmitt trigger input (without

pull-high resistor)

13~20 PC0~PC7 I/O

Pull-high*

CMOS/schmitt

trigger input

Bidirectional I/O lines. Software instructions determine the CMOS output or schmitt trigger input with

pull-high resistor (determined by pull-high options).

25 TMR1 I

¾

Timer/event counter 1 schmitt trigger input (without

pull-high resistor)

26 RES

I

¾

Schmitt trigger reset input. Active low

27 VDD

¾¾

Positive power supply

HT48C50-1

4 June 14, 2000

Preliminary

Page 5

Pad

No.

Pad Name I/O Mask Option Description

28

29

OSC1/PG1

OSC2/PG2IO

Pull-high*

Crystal

or RC

or Int. RC+I/O

or Int.

RC+RTC

OSC1, OSC2 are connected to an RC network or Crys

tal (determined by mask option) for the internal sys

tem clock. In the case of RC operation, OSC2 is the

output terminal for 1/4 system clock. These two pins

can also be optioned as an RTC oscillator (32768Hz) or

I/O lines. In these two cases, the system clock comes

from an internal RC oscillator whose frequency has 4

options (3.2MHz, 1.6MHz, 800kHz, 400kHz). If the I/O

option is selected, the pull-high options can also be en

abled or disabled. Otherwise the PG1 and PG2 are

used as internal registers (pull-high resistors are al

ways disabled).

Note: * The pull-high resistors of each I/O port (PA, PB, PC, PD, PG) are controlled by options.

Absolute Maximum Ratings

Supply Voltage ...............VSS-0.3V to VSS+5.5V

Storage Temperature.................-50°Cto125°C

Input Voltage.................V

SS

-0.3V to VDD+0.3V

Operating Temperature ..............-40°Cto85°C

Note: These are stress ratings only. Stresses exceeding the range specified under "Absolute Maxi

mum Ratings" may cause substantial damage to the device. Functional operation of this device

at other conditions beyond those listed in the specification is not implied and prolonged expo

sure to extreme conditions may affect device reliability.

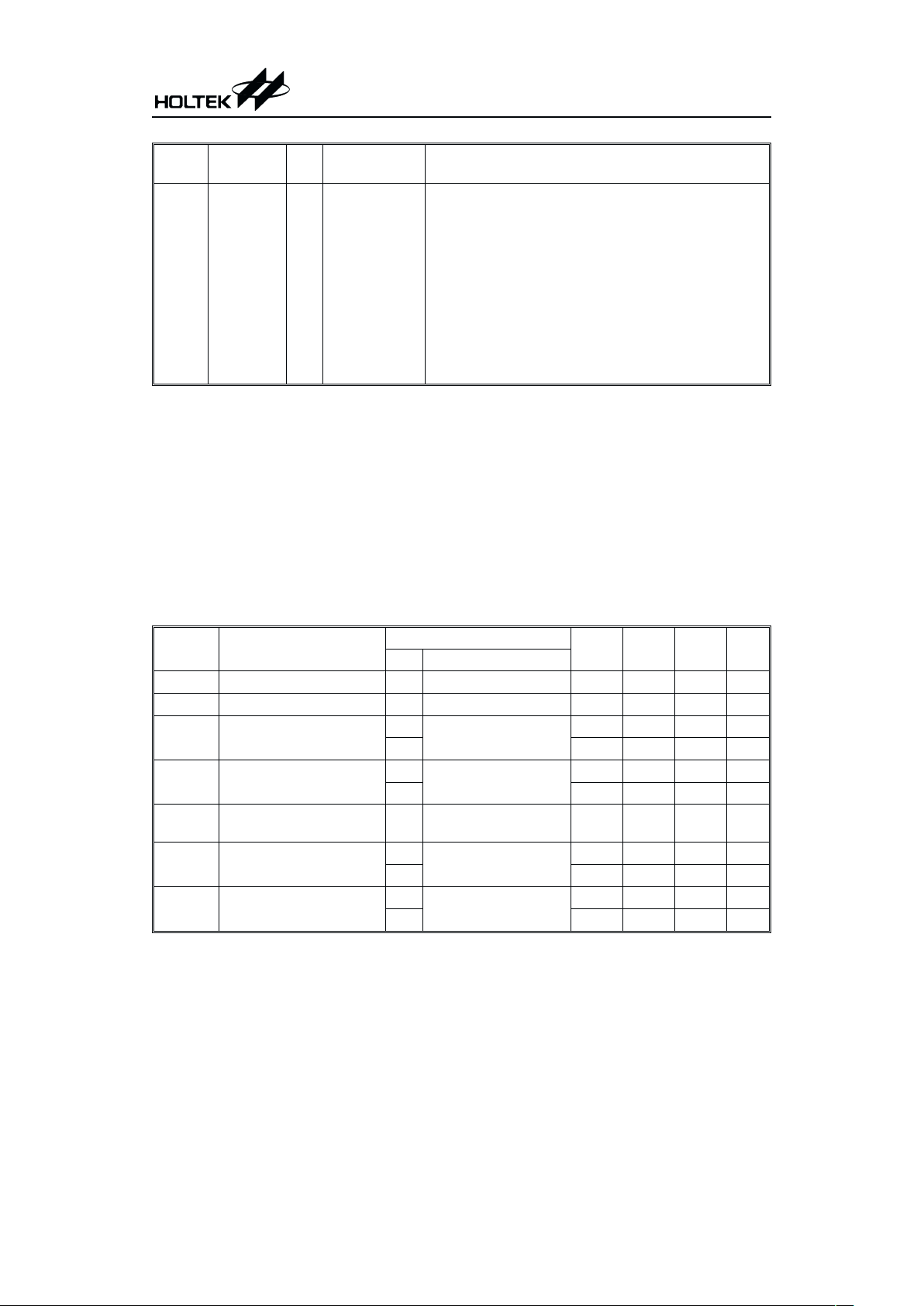

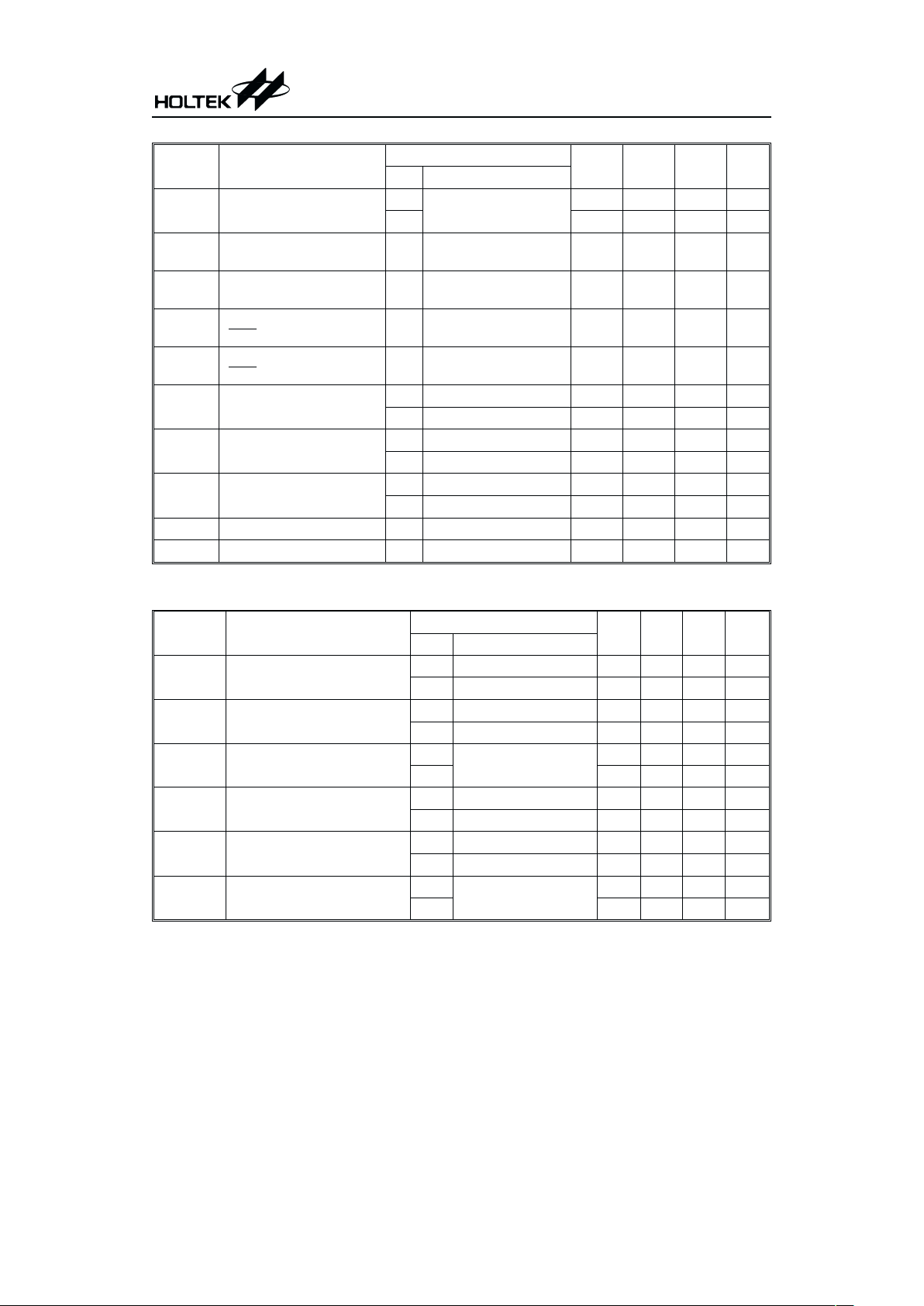

D.C. Characteristics

Ta=25°C

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

V

DD1

Operating Voltage

¾

f

SYS

=4MHz

2.4

¾

5.5 V

V

DD2

Operating Voltage

¾

f

SYS

=8MHz

4.5

¾

5.5 V

I

DD1

Operating Current

(Crystal OSC)

3V

No load, f

SYS

=4MHz

¾

12mA

5V

¾

35mA

I

DD2

Operating Current

(RC OSC)

3V

No load, f

SYS

=4MHz

¾

12mA

5V

¾

35mA

I

DD3

Operating Current

(Crystal OSC)

5V

No load, f

SYS

=8MHz

¾

48mA

I

STB1

Standby Current

(WDT Enabled RTC Off)

3V

No load, system HALT

¾¾

5

mA

5V

¾¾

10

mA

I

STB2

Standby Current

(WDT Disabled RTC Off)

3V

No load, system HALT

¾¾

1

mA

5V

¾¾

2

mA

HT48C50-1

5 June 14, 2000

Preliminary

Page 6

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

I

STB3

Standby Current

(WDT Disabled, RTC On)

3V

No load, system HALT

¾¾

5

mA

5V

¾¾

10

mA

V

IL1

Input Low Voltage for

I/O Ports

¾¾

0

¾

0.2V

DD

V

V

IH1

Input High Voltage for

I/O Ports

¾¾

0.8V

DD

¾

V

DD

V

V

IL2

Input Low Voltage

(RES

)

¾¾

0

¾

0.4V

DD

V

V

IH2

Input High Voltage

(RES

)

¾¾

0.9V

DD

¾

V

DD

V

I

OL

I/O Port Sink Current

3V

V

OL

=0.1V

DD

612

¾

mA

5V

V

OL

=0.1V

DD

10 25

¾

mA

I

OH

I/O Port Source

Current

3V

V

OH

=0.9V

DD

-3 -6 ¾

mA

5V

V

OH

=0.9V

DD

-5 -10 ¾

mA

R

PH

Pull-high Resistance

3V

¾

40 60 80

kW

5V

¾

10 30 50

kW

V

LVR1

Low Voltage Reset

¾

2.2V option 2.0 2.2 2.4 V

V

LVR2

Low Voltage Reset

¾

3.3V option 3.0 3.3 3.6 V

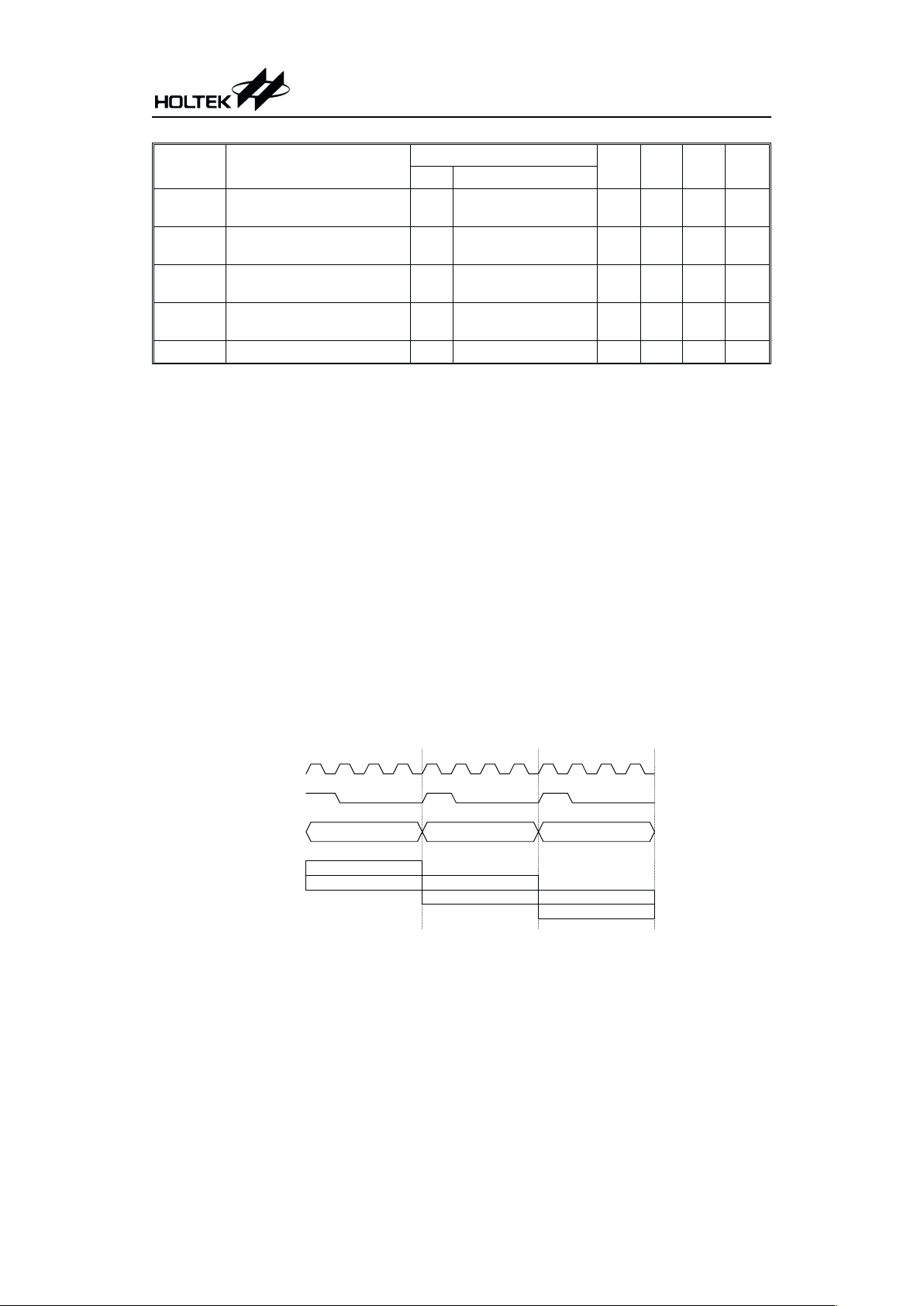

A.C. Characteristics

Ta=25°C

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

f

SYS1

System Clock

(Crystal OSC)

3V

¾

400

¾

4000 kHz

5V

¾

400

¾

8000 kHz

f

SYS2

System Clock (RC OSC)

3V

¾

400

¾

4000 kHz

5V

¾

400

¾

8000 kHz

f

SYS3

System Clock (Internal RC)

3V

3.2MHz option

1600 2500 3500 kHz

5V 2000 3200 4500 kHz

f

TIMER

Timer I/P Frequency

(TMR0/TMR1)

3V

¾

0

¾

4000 kHz

5V

¾

0

¾

8000 kHz

t

WDTOSC

Watchdog Oscillator

3V

¾

43 86 168

ms

5V

¾

35 65 130

ms

t

WDT1

Watchdog Time-out Period

(WDT OSC)

3V

Without WDT

prescaler

11 22 43 ms

5V 9 17 35 ms

HT48C50-1

6 June 14, 2000

Preliminary

Page 7

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

t

WDT2

Watchdog Time-out Period

(System Clock)

¾

Without WDT

prescaler

¾

1024

¾

t

SYS

t

WDT3

Watchdog Time-out Period

(RTC OSC)

¾

Without WDT

prescaler

¾

7.812

¾

ms

t

RES

External Reset Low Pulse

Width

¾¾

1

¾¾ms

t

SST

System Start-up Timer

Period

¾

Power-up, reset or

wake-up from HALT

¾

1024

¾

t

SYS

t

INT

Interrupt Pulse Width

¾¾

1

¾¾ms

Functional Description

HT48C50-1

7 June 14, 2000

Preliminary

Execution flow

The system clock for the microcontroller is de

rived from either a crystal or an RC oscillator.

The system clock is internally divided into four

non-overlapping clocks. One instruction cycle

consists of four system clock cycles.

Instruction fetching and execution are

pipelined in such a way that a fetch takes an in

struction cycle while decoding and execution

takes the next instruction cycle. However, the

pipelining scheme causes each instruction to effectively execute in a cycle. If an instruction

changes the program counter, two cycles are required to complete the instruction.

Program counter - PC

The program counter (PC) controls the sequence in which the instructions stored in the

program ROM are executed and its contents

specify a full range of program memory.

After accessing a program memory word to fetch

an instruction code, the contents of the program

counter are incremented by one. The program

counter then points to the memory word contain

-

ing the next instruction code.

When executing a jump instruction, conditional

skip execution, loading PCL register, subrou

-

tine call, initial reset, internal interrupt, exter

nal interrupt or return from subroutine, the PC

manipulates the program transfer by loading

the address corresponding to each instruction.

The conditional skip is activated by instructions. Once the condition is met, the next instruction, fetched during the current

instruction execution, is discarded and a

dummy cycle replaces it to get the proper instruction. Otherwise proceed with the next instruction.

T1 T2 T3 T4 T1 T2 T3 T4 T1 T2 T3 T4

F e tc h IN S T (P C )

Execute IN S T (P C -1)

F e tc h IN S T (P C + 1 )

Execute IN S T (P C )

F e tc h IN S T (P C + 2 )

Execute IN S T (P C + 1)

PC PC+1 PC+2

S ystem C lock

OSC2 (RC only)

PC

Execution flow

Page 8

HT48C50-1

8 June 14, 2000

Preliminary

The lower byte of the program counter (PCL) is

a readable and writeable register (06H).

Moving data into the PCL performs a short

jump. The destination will be within 256 loca

-

tions.

When a control transfer takes place, an addi

-

tional dummy cycle is required.

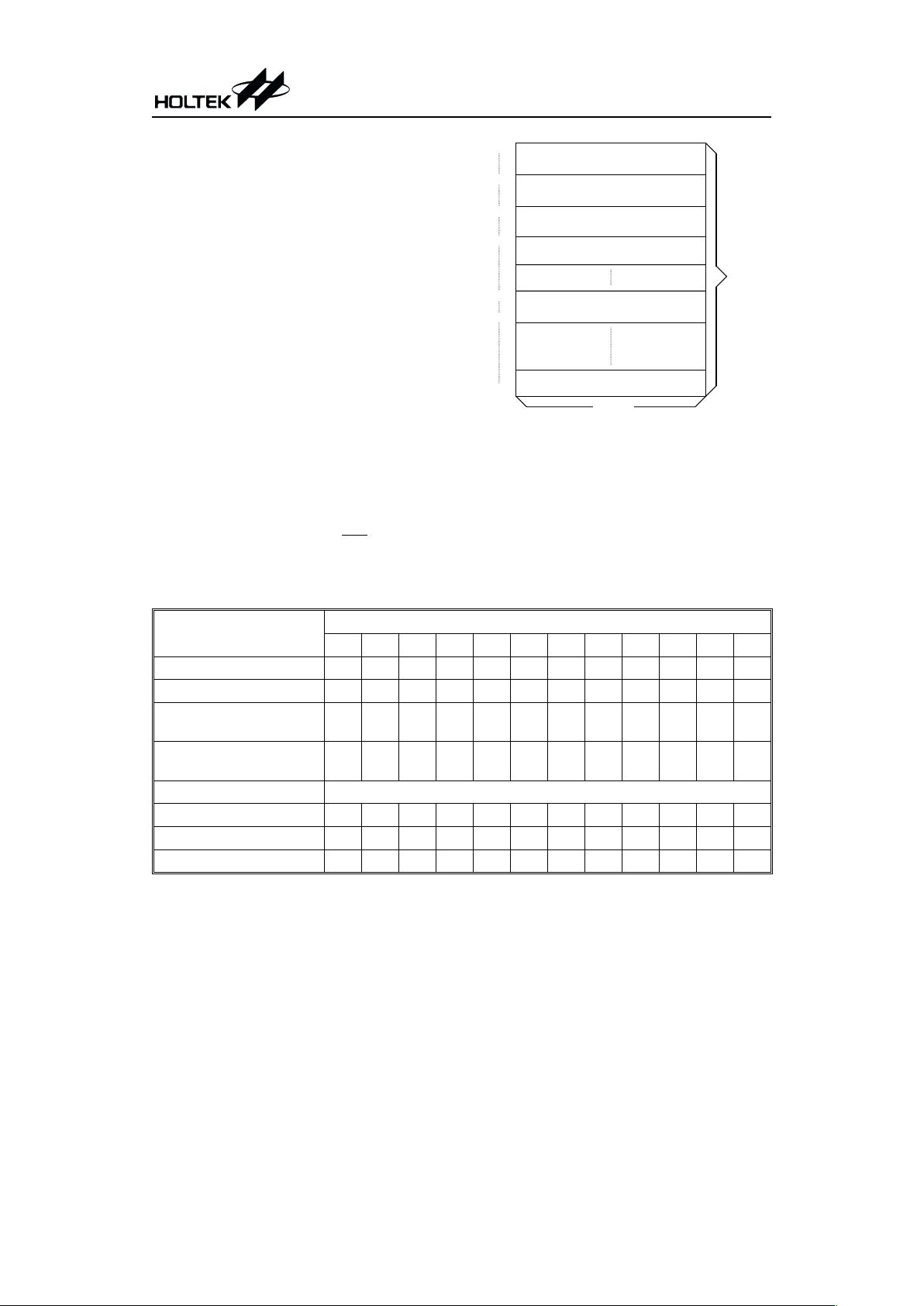

Program memory - ROM

The program memory is used to store the pro

gram instructions which are to be executed. It

also contains data, table, and interrupt entries,

and is organized into 4096´15 bits, addressed

by the program counter and table pointer.

Certain locations in the program memory are

reserved for special usage:

·

Location 000H

This area is reserved for program initializa

-

tion. After chip reset, the program always be

-

gins execution at location 000H.

·

Location 004H

This area is reserved for the external inter

-

rupt service program. If the INT

input pin is

activated, the interrupt is enabled and the

stack is not full, the program begins execution

at location 004H.

·

Location 008H

This area is reserved for the timer/event coun

-

ter 0 interrupt service program. If a timer inter

rupt results from a timer/event counter 0

overflow, and if the interrupt is enabled and the

stack is not full, the program begins execution

at location 008H .

Mode

Program Counter

*11 *10 *9 *8 *7 *6 *5 *4 *3 *2 *1 *0

Initial Reset 000000000000

External Interrupt 000000000100

Timer/Event Counter 0

Overflow

000000001000

Timer/Event Counter 1

Overflow

000000001100

Skip PC+2

Loading PCL *11 *10 *9 *8 @7 @6 @5 @4 @3 @2 @1 @0

Jump, Call Branch #11 #10 #9 #8 #7 #6 #5 #4 #3 #2 #1 #0

Return from Subroutine S11 S10 S9 S8 S7 S6 S5 S4 S3 S2 S1 S0

Program counter

Note: *11~*0: Program counter bits S11~S0: Stack register bits

#11~#0: Instruction code bits @7~@0: PCL bits

15 bits

FFFH

nFFH

Program

Memory

D evice Initia liza tion P rogram

E x te rn a l In te rr u p t S u b ro u tin e

Tim er/E vent C ounter 0

Interrupt Subroutine

Look-up Table (256 words)

Look-up Table (256 words)

N ote: n ranges from 0 to F

00C H

n00H

008H

004H

000H

Tim er/E vent C ounter 1

Interrupt Subroutine

Program memory

Page 9

HT48C50-1

9 June 14, 2000

Preliminary

Instruction

Table Location

*11 *10 *9 *8 *7 *6 *5 *4 *3 *2 *1 *0

TABRDC [m] P11 P10 P9 P8 @7 @6 @5 @4 @3 @2 @1 @0

TABRDL [m] 1 1 1 1 @7 @6 @5 @4 @3 @2 @1 @0

Table location

Note: *11~*0: Table location bits P11~P8: Current program counter bits

@7~@0: Table pointer bits

·

Location 00CH

This location is reserved for the timer/event

counter 1 interrupt service program. If a

timer interrupt results from a timer/event

counter 1 overflow, and the interrupt is en

abled and the stack is not full, the program

begins execution at location 00CH.

·

Table location

Any location in the ROM space can be used as

look-up tables. The instructions "TABRDC

[m]" (the current page, 1 page=256 words)

and "TABRDL [m]" (the last page) transfer

the contents of the lower-order byte to the

specified data memory, and the higher-order

byte to TBLH (08H). Only the destination of

the lower-order byte in the table is

well-defined, the other bits of the table word

are transferred to the lower portion of TBLH,

and the remaining 1-bit words are read as "0".

The Table Higher-order byte register (TBLH)

is read only. The table pointer (TBLP) is a

read/write register (07H), which indicates the

table location. Before accessing the table, the

location must be placed in the TBLP. The

TBLH is read only and cannot be restored. If

the main routine and the ISR (Interrupt Service Routine) both employ the table read instruction, the contents of the TBLH in the

main routine are likely to be changed by the

table read instruction used in the ISR. Errors

can occur. In other words, using the table read

instruction in the main routine and the ISR

simultaneously should be avoided. However,

if the table read instruction has to be applied

in both the main routine and the ISR, the interrupt is supposed to be disabled prior to the

table read instruction. It will not be enabled

until the TBLH has been backed up. All table

related instructions require two cycles to com

plete the operation. These areas may function

as normal program memory depending upon

the requirements.

Stack register - STACK

This is a special part of the memory which is

used to save the contents of the program coun

-

ter (PC) only. The stack is organized into 6 lev

-

els and is neither part of the data nor part of the

program space, and is neither readable nor

writeable. The activated level is indexed by the

stack pointer (SP) and is neither readable nor

writeable. At a subroutine call or interrupt ac

-

knowledge signal, the contents of the program

counter are pushed onto the stack. At the end of

a subroutine or an interrupt routine, signaled

by a return instruction (RET or RETI), the pro

-

gram counter is restored to its previous value

from the stack. After a chip reset, the SP will

point to the top of the stack.

If the stack is full and a non-masked interrupt

takes place, the interrupt request flag will be

recorded but the acknowledge signal will be in

-

hibited. When the stack pointer is decremented

(by RET or RETI), the interrupt will be serviced. This feature prevents stack overflow allowing the programmer to use the structure

more easily. In a similar case, if the stack is full

and a "CALL" is subsequently executed, stack

overflow occurs and the first entry will be lost

(only the most recent 6 return addresses are

stored).

Page 10

HT48C50-1

10 June 14, 2000

Preliminary

Data memory - RAM

The data memory is designed with 184´8 bits.

The data memory is divided into two func

-

tional groups: special function registers and

general purpose data memory (160´8). Most

are read/write, but some are read only.

The special function registers include the indi

-

rect addressing registers (00H, 02H),

timer/event counter 0 (TMR0;0DH),

timer/event counter 0 control register

(TMR0C;0EH), timer/event counter 1 higher

order byte register (TMR1H;0FH), timer/event

counter 1 lower order byte register

(TMR1L;10H), timer/event counter 1 control

register (TMR1C;11H), program counter

lower-order byte register (PCL;06H), memory

pointer registers (MP0;01H, MP1;03H), accu

-

mulator (ACC;05H), table pointer

(TBLP;07H), table higher-order byte register

(TBLH;08H), status register (STATUS;0AH),

interrupt control register (INTC;0BH), Watch

-

dog Timer option setting register

(WDTS;09H), I/O registers (PA;12H, PB;14H,

PC;16H, PD;18H, PG;1EH) and I/O control

registers (PAC;13H, PBC;15H, PCC;17H,

PDC;19H, PGC;1FH). The remaining space be

-

fore the 60H is reserved for future expanded

usage and reading these locations will get

"00H". The general purpose data memory, ad

-

dressed from 60H to FFH, is used for data and

control information under instruction com

-

mands.

All of the data memory areas can handle arithmetic, logic, increment, decrement and rotate

operations directly. Except for some dedicated

bits, each bit in the data memory can be set and

reset by "SET [m].i" and "CLR [m].i". They are

also indirectly accessible through memory

pointer registers (MP0 or MP1).

Indirect addressing register

Location 00H and 02H are indirect addressing

registers that are not physically implemented.

Any read/write operation of [00H] ([02H]) will

access data memory pointed to by MP0 (MP1).

Reading location 00H (02H) itself indirectly

will return the result 00H. Writing indirectly

results in no operation.

The memory pointer registers (MP0 and MP1)

are 8-bit registers.

G eneral P urpose

DATA M EM ORY

(160 B ytes)

Special P urpose

DATA M EM ORY

00H

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0C H

0D H

0EH

0FH

10H

11H

12H

13H

14H

15H

16H

17H

18H

19H

1AH

1BH

1C H

1D H

1EH

1FH

FFH

: U n u s e d

R ead as "00"

5FH

60H

20H

Indirect Addressing R egister 0

MP0

Indirect Addressing R egister 1

MP1

ACC

PCL

TBLP

TBLH

WDTS

STATUS

IN T C

TM R 0

TM R 0C

TM R 1H

TM R 1L

TM R 1C

PA

PAC

PB

PBC

PC

PCC

PD

PDC

PG

PGC

RAM mapping

Page 11

HT48C50-1

11 June 14, 2000

Preliminary

Accumulator

The accumulator is closely related to ALU oper

ations. It is also mapped to location 05H of the

data memory and can carry out immediate data

operations. The data movement between two

data memory locations must pass through the

accumulator.

Arithmetic and logic unit - ALU

This circuit performs 8-bit arithmetic and logic

operations. The ALU provides the following func

tions:

Arithmetic operations (ADD, ADC, SUB, SBC,

DAA)

·

Logic operations (AND, OR, XOR, CPL) Rota

-

tion (RL, RR, RLC, RRC)

·

Increment and Decrement (INC, DEC)

·

Branch decision (SZ, SNZ, SIZ, SDZ ....)

The ALU not only saves the results of a data op

eration but also changes the status register.

Status register - STATUS

This 8-bit register (0AH) contains the zero flag

(Z), carry flag (C), auxiliary carry flag (AC),

overflow flag (OV), power down flag (PD), and

watchdog time-out flag (TO). It also records the

status information and controls the operation

sequence.

With the exception of the TO and PD flags,

bits in the status register can be altered by

instructions like most other registers. Any

data written into the status register will not

change the TO or PD flag. In addition opera

tions related to the status register may give

different results from those intended. The

TO flag can be affected only by system

power-up, a WDT time-out or executing the

"CLR WDT" or "HALT" instruction. The PD

flag can be affected only by executing the

"HALT" or "CLR WDT" instruction or during

a system power-up.

The Z, OV, AC and C flags generally reflect the

status of the latest operations.

In addition, on entering the interrupt sequence

or executing the subroutine call, the status reg

ister will not be pushed onto the stack automat

ically. If the contents of the status are

important and if the subroutine can corrupt the

status register, precautions must be taken to

save it properly.

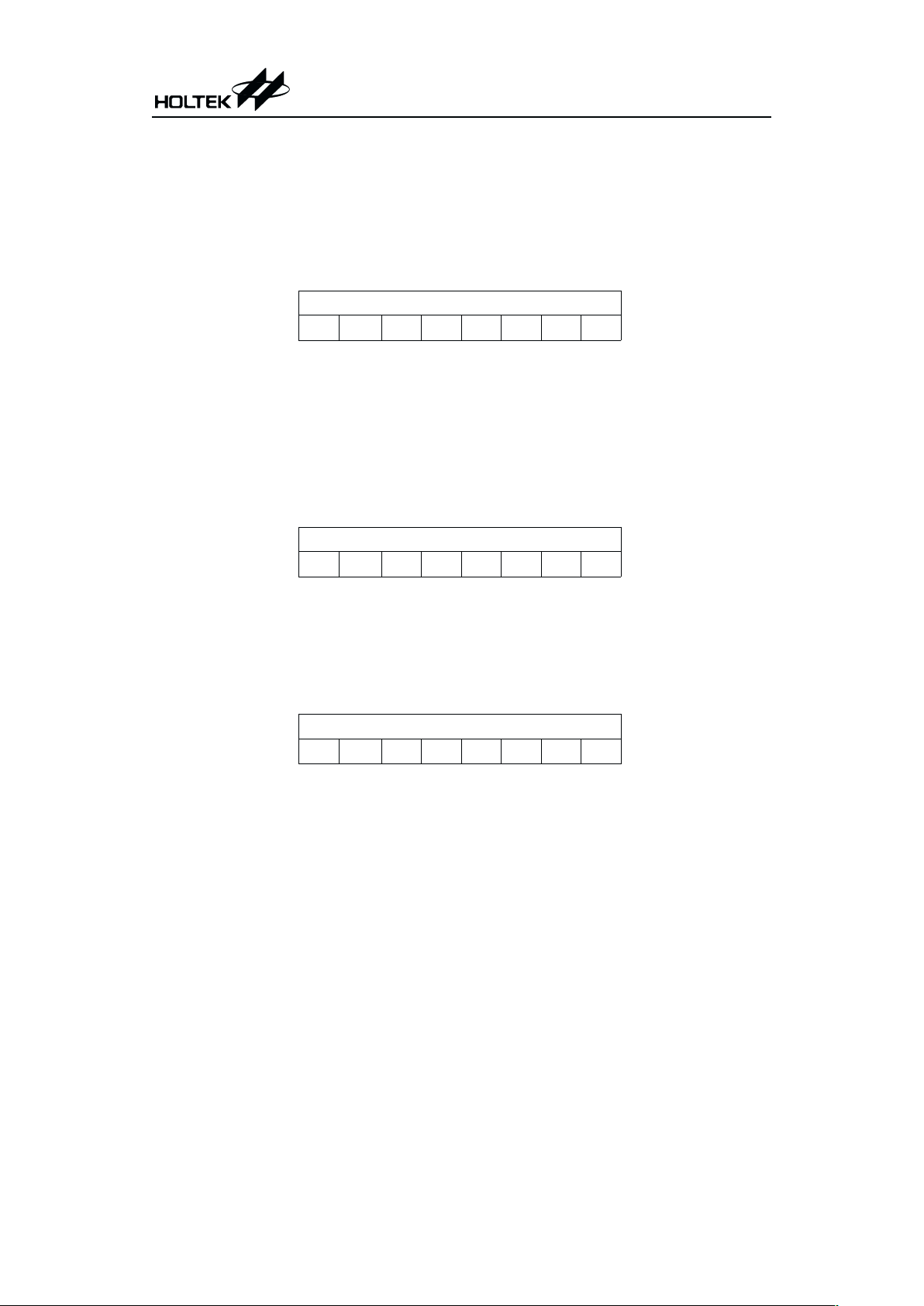

Labels Bits Function

C

0

C is set if the operation results in a carry during an addition operation or if a borrow does not take place during a subtraction operation; otherwise C is cleared. C

is also affected by a rotate through carry instruction.

AC

1

AC is set if the operation results in a carry out of the low nibbles in addition or no

borrow from the high nibble into the low nibble in subtraction; otherwise AC is

cleared.

Z

2

Z is set if the result of an arithmetic or logic operation is zero; otherwise Z is

cleared.

OV

3

OV is set if the operation results in a carry into the highest-order bit but not a

carry out of the highest-order bit, or vice versa; otherwise OV is cleared.

PD

4

PD is cleared by system power-up or executing the "CLR WDT" instruction. PD

is set by executing the "HALT" instruction.

TO

5

TO is cleared by system power-up or executing the "CLR WDT" or "HALT" in

-

struction. TO is set by a WDT time-out.

¾

6 Undefined, read as "0"

¾

7 Undefined, read as "0"

Status register

Page 12

HT48C50-1

12 June 14, 2000

Preliminary

Interrupt

The device provides an external interrupt and

internal timer/event counter interrupts. The

Interrupt Control Register (INTC;0BH) con

-

tains the interrupt control bits to set the en

-

able/disable and the interrupt request flags.

Once an interrupt subroutine is serviced, all

the other interrupts will be blocked (by clearing

the EMI bit). This scheme may prevent any fur

-

ther interrupt nesting. Other interrupt re

quests may occur during this interval but only

the interrupt request flag is recorded. If a cer

-

tain interrupt requires servicing within the ser

vice routine, the EMI bit and the corresponding

bit of the INTC may be set to allow interrupt

nesting. If the stack is full, the interrupt request

will not be acknowledged, even if the related in

terrupt is enabled, until the SP is decremented.

If immediate service is desired, the stack must

be prevented from becoming full.

All these kinds of interrupts have a wake-up ca

pability. As an interrupt is serviced, a control

transfer occurs by pushing the program counter

onto the stack, followed by a branch to a sub

routine at specified location in the program

memory. Only the program counter is pushed

onto the stack. If the contents of the register or

status register (STATUS) are altered by the in

-

terrupt service program which corrupts the de

sired control sequence, the contents should be

saved in advance.

External interrupts are triggered by a high to

low transition of the INT

and the related inter

rupt request flag (EIF; bit 4 of INTC) will be set.

When the interrupt is enabled, the stack is not

full and the external interrupt is active, a sub

routine call to location 04H will occur. The in

terrupt request flag (EIF) and EMI bits will be

cleared to disable other interrupts.

The internal timer/event counter 0 interrupt is

initialized by setting the timer/event counter 0

interrupt request flag (T0F; bit 5 of INTC),

caused by a timer 0 overflow. When the inter

rupt is enabled, the stack is not full and the T0F

bit is set, a subroutine call to location 08H will

occur. The related interrupt request flag (T0F)

will be reset and the EMI bit cleared to disable

further interrupts.

The internal timer/even counter 1 interrupt is

initialized by setting the timer/event counter 1

interrupt request flag (T1F;bit 6 of INTC),

caused by a timer 1 overflow. When the inter-

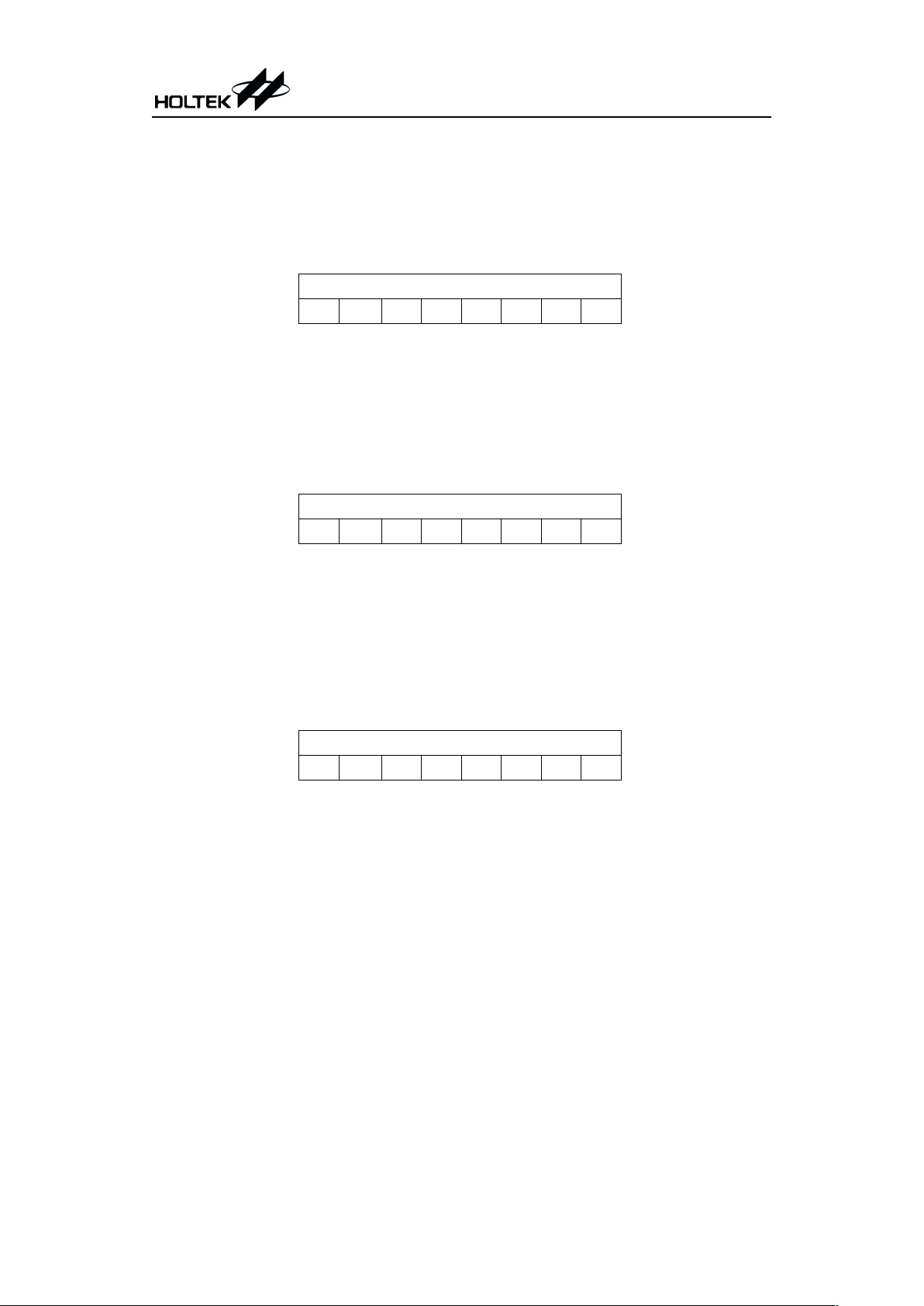

Register Bit No. Label Function

INTC

(0BH)

0 EMI

Controls the master (global) interrupt

(1= enabled; 0= disabled)

1 EEI

Controls the external interrupt

(1= enabled; 0= disabled)

2 ET0I

Controls the timer/event counter 0 interrupt

(1= enabled; 0= disabled)

3 ET1I

Controls the timer/event counter 1 interrupt

(1= enabled; 0= disabled)

4 EIF

External interrupt request flag

(1= active; 0= inactive)

5 T0F

Internal timer/event counter 0 request flag

(1= active; 0= inactive)

6 T1F

Internal timer/event counter 1 request flag

(1= active; 0= inactive)

7

¾

Unused bit, read as "0"

INTC register

Page 13

HT48C50-1

13 June 14, 2000

Preliminary

rupt is enabled, the stack is not full and the T1F

is set, a subroutine call to location 0CH will oc

cur. The related interrupt request flag (T1F)

will be reset and the EMI bit cleared to disable

further interrupts.

During the execution of an interrupt subroutine,

other interrupt acknowledge signals are held

until the "RETI" instruction is executed or the

EMI bit and the related interrupt control bit are

set to 1 (if the stack is not full). To return from

the interrupt subroutine, "RET" or "RETI" may

be invoked. RETI will set the EMI bit to enable

an interrupt service, but RET will not.

Interrupts, occurring in the interval between

the rising edges of two consecutive T2 pulses,

will be serviced on the latter of the two T2

pulses, if the corresponding interrupts are en

abled. In the case of simultaneous requests the

following table shows the priority that is ap

plied. These can be masked by resetting the

EMI bit.

No. Interrupt Source Priority Vector

a External Interrupt 1 04H

b

Timer/event

Counter 0 Overflow

2 08H

c

Timer/event

Counter 1 Overflow

3 0CH

The timer/event counter 0/1 interrupt request

flag (T0F/T1F), external interrupt request flag

(EIF), enable timer/event counter 0/1 interrupt

bit (ET0I/ET1I), enable external interrupt bit

(EEI) and enable master interrupt bit (EMI)

constitute an interrupt control register (INTC)

which is located at 0BH in the data memory.

EMI, EEI, ET0I and ET1I are used to control

the enabling/disabling of interrupts. These bits

prevent the requested interrupt from being ser

viced. Once the interrupt request flags (T0F,

T1F, EIF) are set, they will remain in the INTC

register until the interrupts are serviced or

cleared by a software instruction.

It is recommended that a program does not

use the "CALL subroutine" within the inter

rupt subroutine. Interrupts often occur in an

unpredictable manner or need to be serviced

immediately in some applications. If only one

stack is left and enabling the interrupt is not

well controlled, the original control sequence will

be damaged once the "CALL" operates in the in

terrupt subroutine.

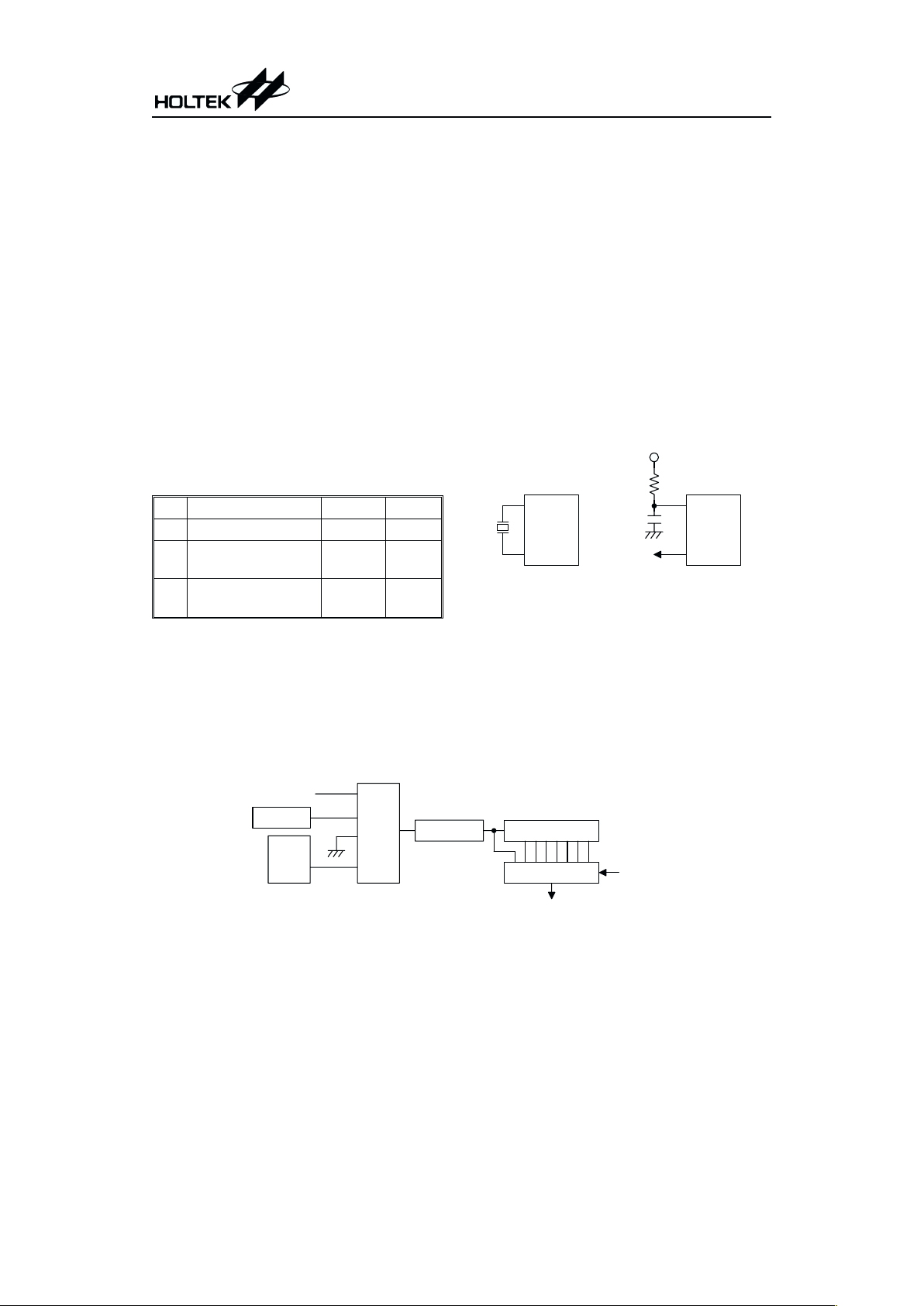

Oscillator configuration

There are 3 oscillator circuits in the

microcontroller.

All of them are designed for system clocks,

namely the external RC oscillator, the external

Crystal oscillator and the internal RC

oscillator, which are determined by mask option. No matter what oscillator type is selected,

the signal provides the system clock. The HALT

mode stops the system oscillator and ignores an

external signal to conserve power.

S ystem C lo ck/4

8-bit C ounter

W D T P rescaler

7-bit C ounter

8-to-1 M U X

W D T T im e-out

WS0~WS2

ROM

C ode

Option

Select

WDT

OSC

RTC O SC

Watchdog Timer

C rystal O scilla to r

(Include 32768H z)

R C O s c illa to r

OSC1

OSC2

N M O S O p e n D r a in

OSC2

f

SYS

/4

470pF

V

DD

OSC1

System oscillator

Page 14

HT48C50-1

14 June 14, 2000

Preliminary

If an RC oscillator is used, an external resistor

between OSC1 and VDD is required and the

resistance must range from 51kW to 1MW. The

system clock, divided by 4, is available on

OSC2, which can be used to synchronize exter

nal logic. The RC oscillator provides the most

cost effective solution. However, the frequency

of oscillation may vary with VDD, tempera

tures and the chip itself due to process varia

tions. It is, therefore, not suitable for timing

sensitive operations where an accurate oscilla

tor frequency is desired.

If the Crystal oscillator is used, a crystal across

OSC1 and OSC2 is needed to provide the feed

back and phase shift required for the oscillator.

No other external components are required. In

stead of a crystal, a resonator can also be con

nected between OSC1 and OSC2 to get a fre

quency reference, but two external capacitors

in OSC1 and OSC2 are required. If the internal

RC oscillator is used, the OSC1 and OSC2 can

be selected as general I/O lines or an 32768Hz

crystal oscillator (RTC OSC). Also, the frequen

cies of the internal RC oscillator can be

3.2MHz, 1.6MHz, 800kHz and 400kHz (de

-

pends on the options).

The WDT oscillator is a free running on-chip RC

oscillator, and no external components are required. Even if the system enters the power down

mode, the system clock is stopped, but the WDT

oscillator still works within a period of 78ms. The

WDT oscillator can be disabled by mask option to

conserve power.

Watchdog Timer - WDT

The WDT clock source is implemented by a ded

icated RC oscillator (WDT oscillator), RTC

clock or instruction clock (system clock divided

by 4), determines the mask option. This timer is

designed to prevent a software malfunction or

sequence from jumping to an unknown location

with unpredictable results. The Watchdog

Timer can be disabled by mask option. If the

Watchdog Timer is disabled, all the executions

related to the WDT result in no operation. The

RTC clock is enabled only in the internal

RC+RTC mode.

Once the internal WDT oscillator (RC oscillator

with a period of 65ms/5V normally) is selected, it

is first divided by 256 (8-stage) to get the nomi

nal time-out period of 16.6ms/5V. This time-out

period may vary with temperatures, VDD and

process variations. By invoking the WDT

prescaler, longer time-out periods can be real

ized. Writing data to WS2, WS1, WS0 (bit 2,1,0

of the WDTS) can give different time-out periods.

If WS2, WS1, and WS0 are all equal to 1, the divi

sion ratio is up to 1:128, and the maximum

time-out period is 2.2s/5V seconds. If the WDT os

cillator is disabled, the WDT clock may still come

from the instruction clock and operates in the

same manner except that in the HALT state the

WDT may stop counting and lose its protecting

purpose. In this situation the logic can only be re

started by external logic. The high nibble and bit

3 of the WDTS are reserved for user's defined

flags, which can be used to indicate some speci

fied status.

If the device operates in a noisy environment, us

ing the on-chip RC oscillator (WDT OSC) or

32kHz crystal oscillator (RTC OSC) is strongly

recommended, since the HALT will stop the sys

tem clock.

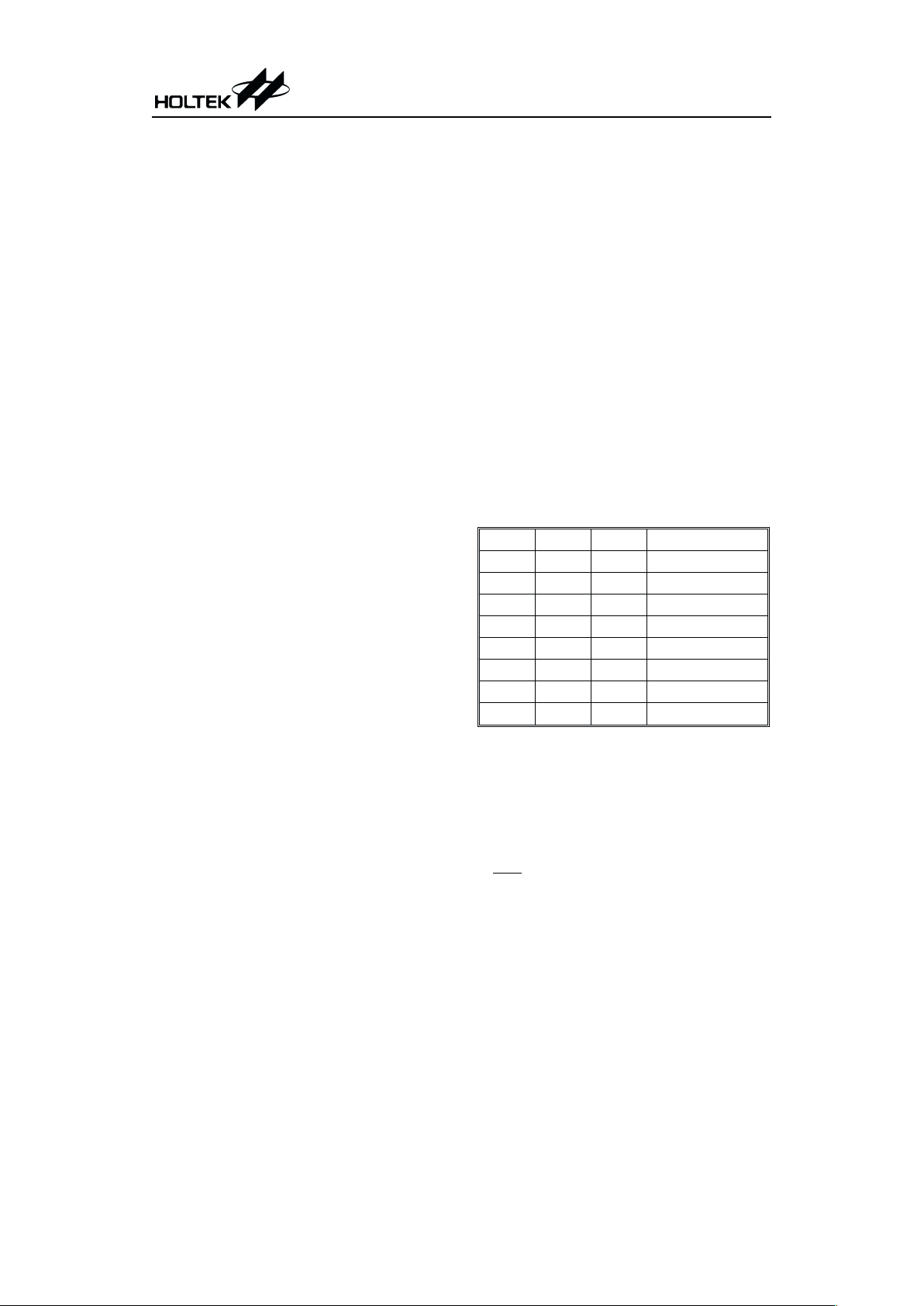

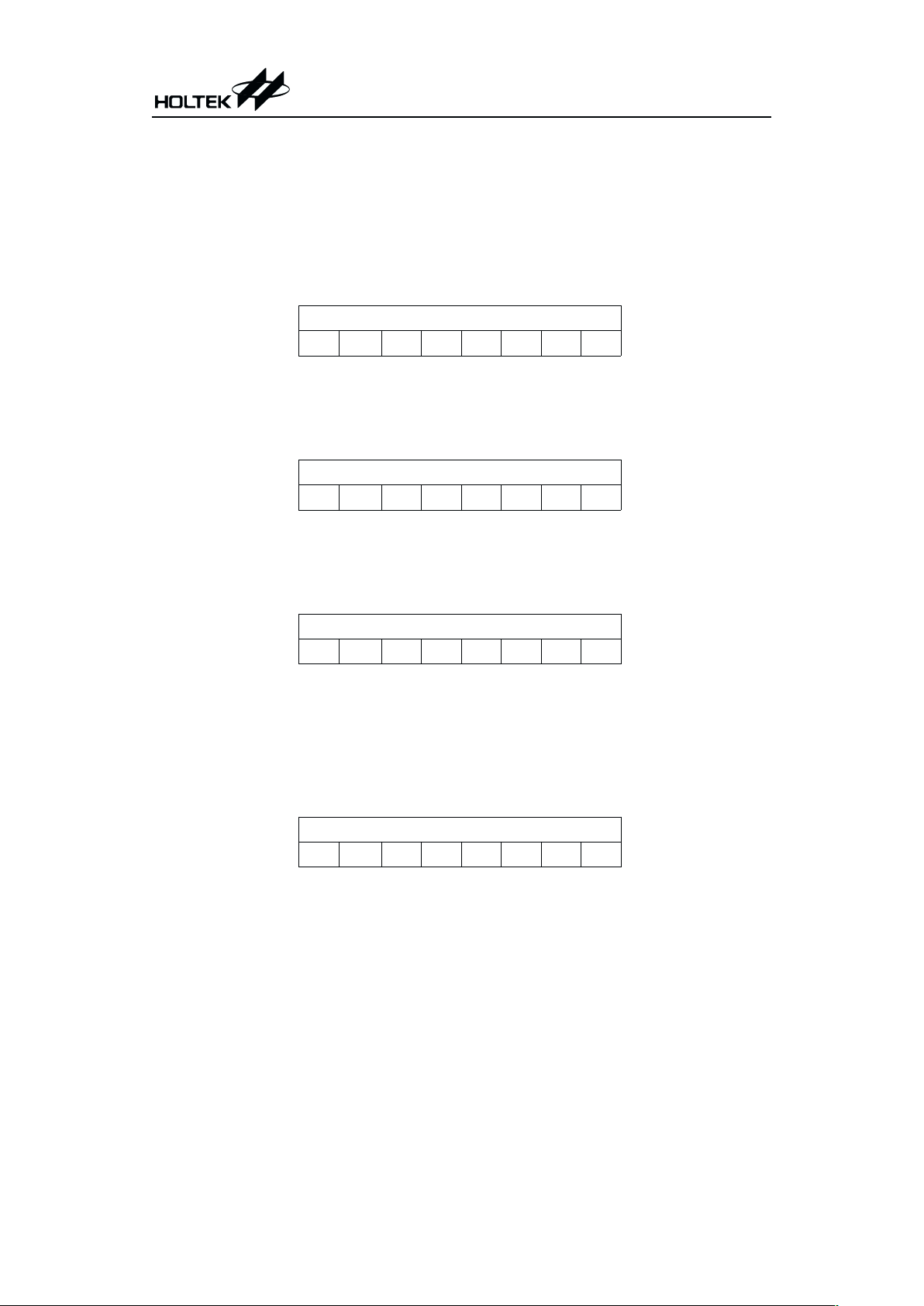

WS2 WS1 WS0 Division Ratio

000 1:1

001 1:2

010 1:4

011 1:8

1 0 0 1:16

1 0 1 1:32

1 1 0 1:64

1 1 1 1:128

WDTS register

The WDT overflow under normal operation will

initialize "chip reset" and set the status bit

"TO". But in the HALT mode, the overflow will

initialize a ²warm reset² and only the PC and

SP are reset to zero. To clear the contents of

WDT (including the WDT prescaler), three

methods are adopted; external reset (a low level

to RES

), software instruction and a "HALT" in

struction. The software instruction include

"CLR WDT" and the other set - "CLR WDT1"

and "CLR WDT2". Of these two types of instruc

-

Page 15

HT48C50-1

15 June 14, 2000

Preliminary

tion, only one can be active depending on the

mask option - "CLR WDT times selection op

tion". If the "CLR WDT" is selected (i.e.

CLRWDT times equal one), any execution of

the "CLR WDT" instruction will clear the WDT.

In the case that "CLR WDT1" and "CLR WDT2"

are chosen (i.e. CLRWDT times equal two),

these two instructions must be executed to

clear the WDT; otherwise, the WDT may reset

the chip as a result of time-out.

Power down operation - HALT

The HALT mode is initialized by the "HALT" in

struction and results in the following...

·

The system oscillator will be turned off but

the WDT oscillator remains running (if the

WDT oscillator is selected).

·

The contents of the on chip RAM and regis

-

ters remain unchanged.

·

WDT and WDT prescaler will be cleared and

recounted again (if the WDT clock is from the

WDT oscillator).

·

All of the I/O ports maintain their original sta

-

tus.

·

The PD flag is set and the TO flag is cleared.

The system can leave the HALT mode by means

of an external reset, an interrupt, an external

falling edge signal on port A or a WDT overflow.

An external reset causes a device initialization

and the WDT overflow performs a "warm reset". After the TO and PD flags are examined,

the reason for chip reset can be determined.

The PD flag is cleared by system power-up or

executing the "CLR WDT" instruction and is set

when executing the "HALT" instruction. The

TO flag is set if the WDT time-out occurs, and

causes a wake-up that only resets the PC and

SP; the others remain in their original status.

The port A wake-up and interrupt methods can

be considered as a continuation of normal exe

cution. Each bit in port A can be independently

selected to wake up the device by mask option.

Awakening from an I/O port stimulus, the pro

gram will resume execution of the next instruc

tion. If it awakens from an interrupt, two

sequence may occur. If the related interrupt is

disabled or the interrupt is enabled but the

stack is full, the program will resume execution

at the next instruction. If the interrupt is en

-

abled and the stack is not full, the regular inter

rupt response takes place. If an interrupt

request flag is set to "1" before entering the

HALT mode, the wake-up function of the re

lated interrupt will be disabled. Once a

wake-up event occurs, it takes 1024 t

SYS

(sys

tem clock period) to resume normal operation.

In other words, a dummy period will be inserted

after a wake-up. If the wake-up results from an

interrupt acknowledge signal, the actual inter

rupt subroutine execution will be delayed by

one or more cycles. If the wake-up results in the

next instruction execution, this will be executed

immediately after the dummy period is fin

ished.

To minimize power consumption, all the I/O

pins should be carefully managed before enter

ing the HALT status. The RTC oscillator still

runs in the HALT mode (if the RTC oscillator is

enabled).

Reset

There are three ways inwhich a reset canoccur:

·

RES reset during normal operation

·

RES reset during HALT

·

WDT time-out reset during normal operation

The WDT time-out during HALT is different

from other chip reset conditions, since it can

perform a "warm reset" that resets only the PC

and SP, leaving the other circuits in their original state. Some registers remain unchanged

during other reset conditions. Most registers

are reset to the ²initial condition² when the reset conditions are met. By examining the PD

and TO flags, the program can distinguish between different "chip resets".

TO PD RESET Conditions

0 0 RES

reset during power-up

u u RES

reset during normal operation

0 1 RES

wake-up HALT

1u

WDT time-out during normal

operation

1 1 WDT wake-up HALT

Note: "u" stands for "unchanged"

Page 16

HT48C50-1

16 June 14, 2000

Preliminary

To guarantee that the system oscillator is

started and stabilized, the SST (System

Start-up Timer) provides an extra-delay of 1024

system clock pulses when the system reset

(power-up, WDT time-out or RES

reset) or the

system awakes from the HALT state.

When a system reset occurs, the SST delay is

added during the reset period. Any wake-up

from HALT will enable the SST delay.

The functional unit chip reset status are shown

below.

PC 000H

Interrupt Disable

Prescaler Clear

WDT

Clear. After master reset,

WDT begins counting

Timer/event

Counter

Off

Input/output

Ports

Input mode

SP

Points to the top of

the stack

V

DD

RES

Reset circuit

W arm R eset

WDT

HALT

Cold

Reset

RES

System R eset

SST

10-bit R ipple

C ounter

OSC1

Reset configuration

t

SST

RES

VDD

SS T T im e-out

C hip R eset

Reset timing chart

Page 17

HT48C50-1

17 June 14, 2000

Preliminary

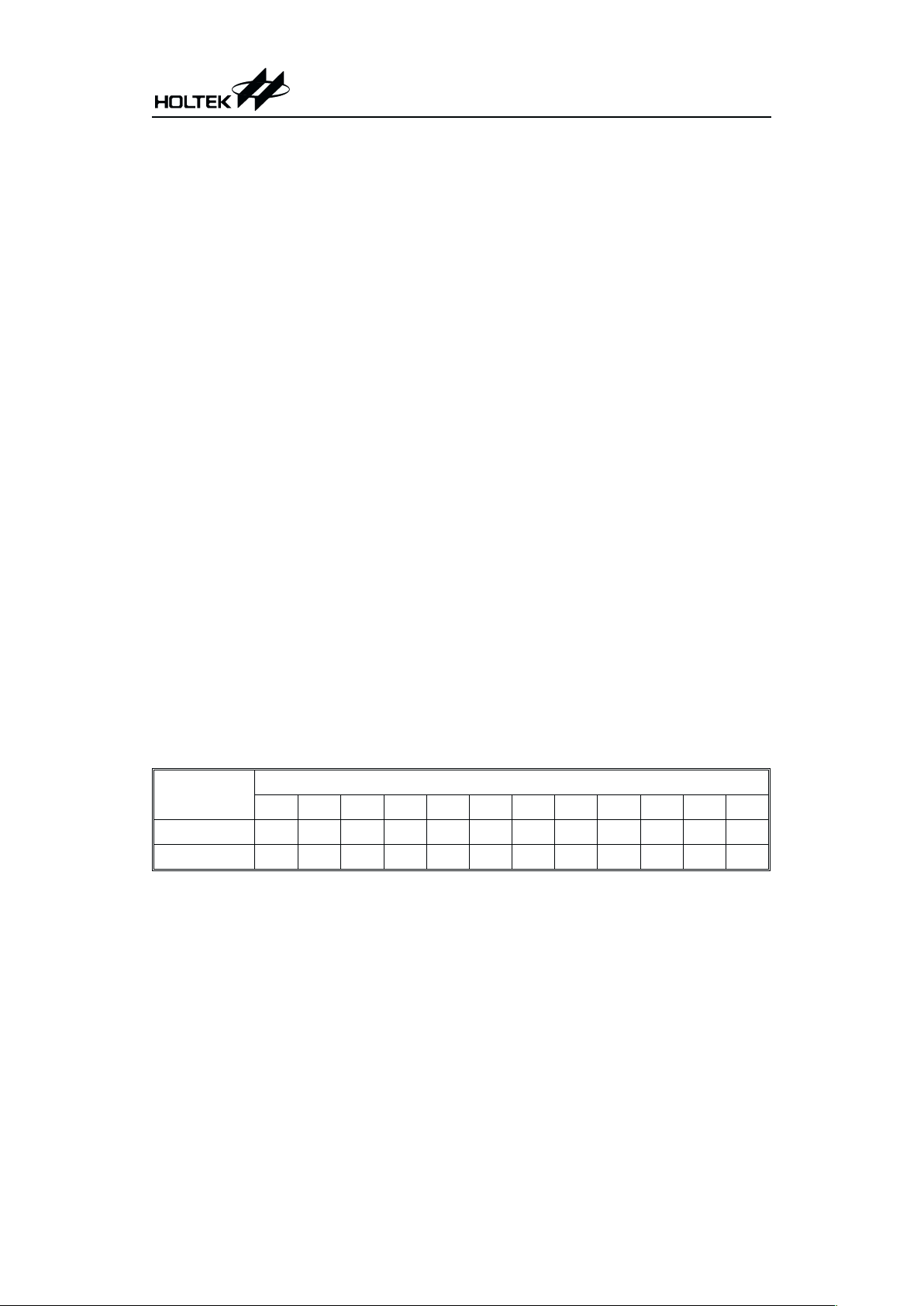

The states of the registers is summarized in the table.

Register

Reset

(Power On)

WDT Time-out

(Normal

Operation)

RES

Reset

(Normal

Operation)

RES

Reset

(HALT)

WDT

Time-out

(HALT)*

TMR0 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TMR0C 00-0 1000 00-0 1000 00-0 1000 00-0 1000 uu-u uuuu

TMR1H xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TMR1L xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TMR1C 00-0 1--- 00-0 1--- 00-0 1--- 00-0 1--- uu-u u---

Program

Counter

000H 000H 000H 000H 000H

MP0 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

MP1 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

ACC xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TBLP xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TBLH -xxx xxxx -uuu uuuu -uuu uuuu -uuu uuuu -uuu uuuu

STATUS --00 xxxx --1u uuuu --uu uuuu --01 uuuu --11 uuuu

INTC -000 0000 -000 0000 -000 0000 -000 0000 -uuu uuuu

WDTS 0000 0111 0000 0111 0000 0111 0000 0111 uuuu uuuu

PA 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PAC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PB 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PBC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PCC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PD 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PDC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PG ---- -111 ---- -111 ---- -111 ---- -111 ---- -uuu

PGC ---- -111 ---- -111 ---- -111 ---- -111 ---- -uuu

Note: "*" stands for "warm reset"

"u" stands for "unchanged"

"x" stands for "unknown"

Page 18

HT48C50-1

18 June 14, 2000

Preliminary

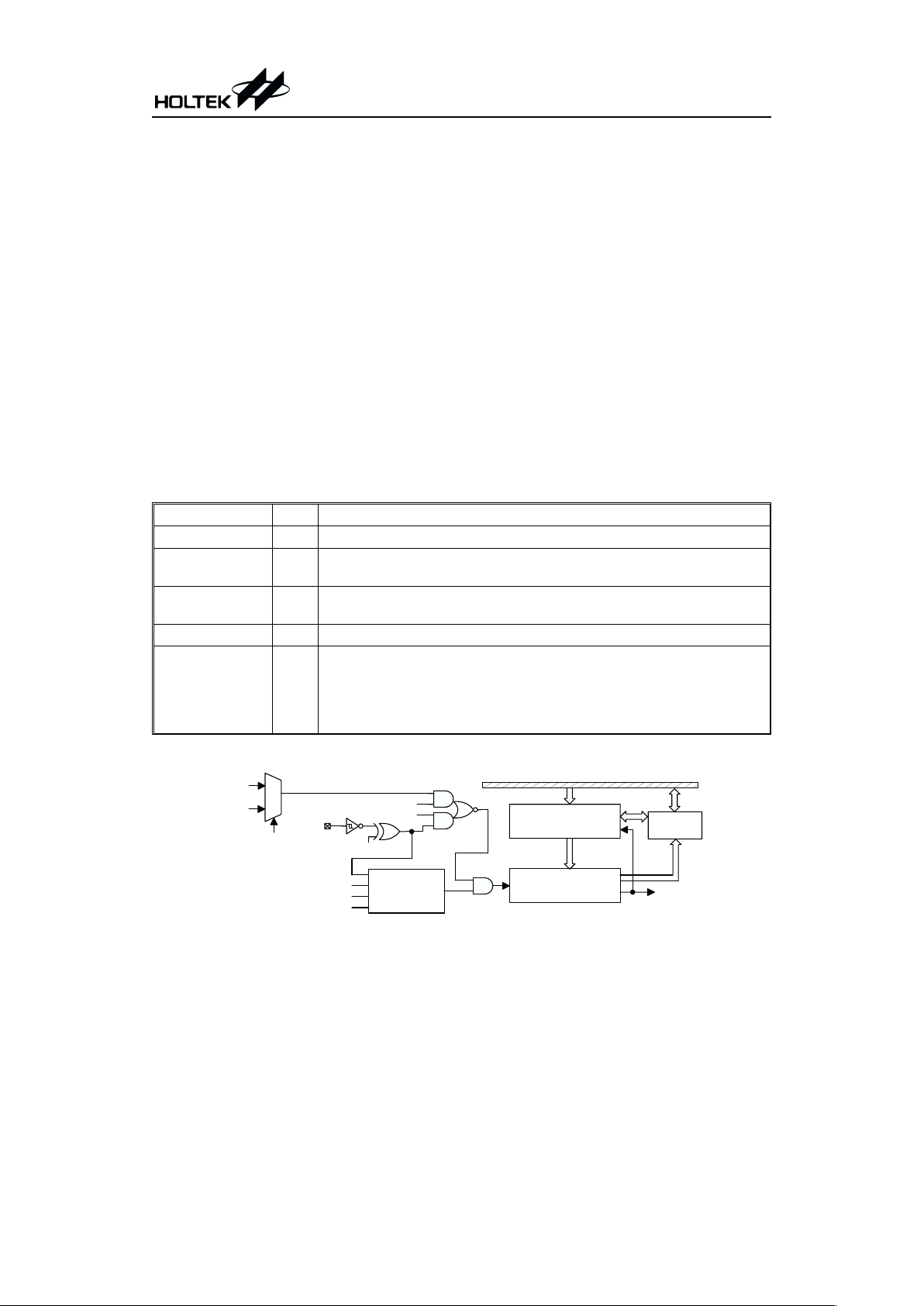

Timer/event counter

Two timer/event counters (TMR0, TMR1) are

implemented in the microcontroller. The

timer/event counter 0 contains an 8-bit pro

grammable count-up counter and the clock may

come from an external source or from the system

clock or RTC.

The timer/event counter 1 contains an 16-bit

programmable count-up counter and the clock

may come from an external source or from the

system clock divided by 4 or RTC.

Using the internal clock sources, there are 2

reference time-bases for timer/event counter 0.

The internal clock source can be selected as

coming from f

SYS

(can always be optioned) or

f

RTC

(enabled only system oscillator in the Int.

RC+RTC mode) by mask option. The external

clock input allows the user to count external

events, measure time intervals or pulse widths,

Label (TMR0C) Bits Function

PSC0~PSC2 0~2

To define the prescaler stages, PSC2, PSC1, PSC0=

000: f

INT=fSYS

/2 or f

RTC

/2

001: f

INT=fSYS

/4 or f

RTC

/4

010: f

INT=fSYS

/8 or f

RTC

/8

011: f

INT=fSYS

/16 or f

RTC

/16

100: f

INT=fSYS

/32 or f

RTC

/32

101: f

INT=fSYS

/64 or f

RTC

/64

110: f

INT=fSYS

/128 or f

RTC

/128

111: f

INT=fSYS

/256 or f

RTC

/256

TE 3

To define the TMR0 active edge of timer/event counter 0

(0=active on low to high; 1=active on high to low)

TON 4

To enable/disable timer 0 counting

(0=disabled; 1=enabled)

¾

5 Unused bit, read as"0"

TM0

TM1

6

7

To define the operating mode

01=Event count mode (external clock)

10=Timer mode (internal clock)

11=Pulse width measurement mode

00=Unused

TMR0C register

TM 1

TM 0

TM R 0

TE

TM 1

TM 0

TO N

Pulse W idth

M easurem ent

M ode C ontrol

Tim er/E vent C ounter 0

Preload R egister

Tim er/event

C ounter 0

Data Bus

R eload

O verflow

to Interrupt

1/2

BZ

BZ

8-stage prescaler

8-1 M U X

f

SYS

f

IN T

PSC2~PSC0

M

U

X

f

RTC

m ask optio n

Timer/event counter 0

Page 19

HT48C50-1

19 June 14, 2000

Preliminary

or to generate an accurate time base and PFD

signals.

Using the internal clock sources, there are 2

reference time-bases for timer/event counter 1.

The internal clock source can be selected as

coming from f

SYS

/4 (can always be optioned) or

f

RTC

(enable only the system oscillator in the

Int. RC+RTC mode) by mask option. The exter

nal clock input allows the user to count external

events, measure time intervals or pulse widths

or to generate an accurate time base.

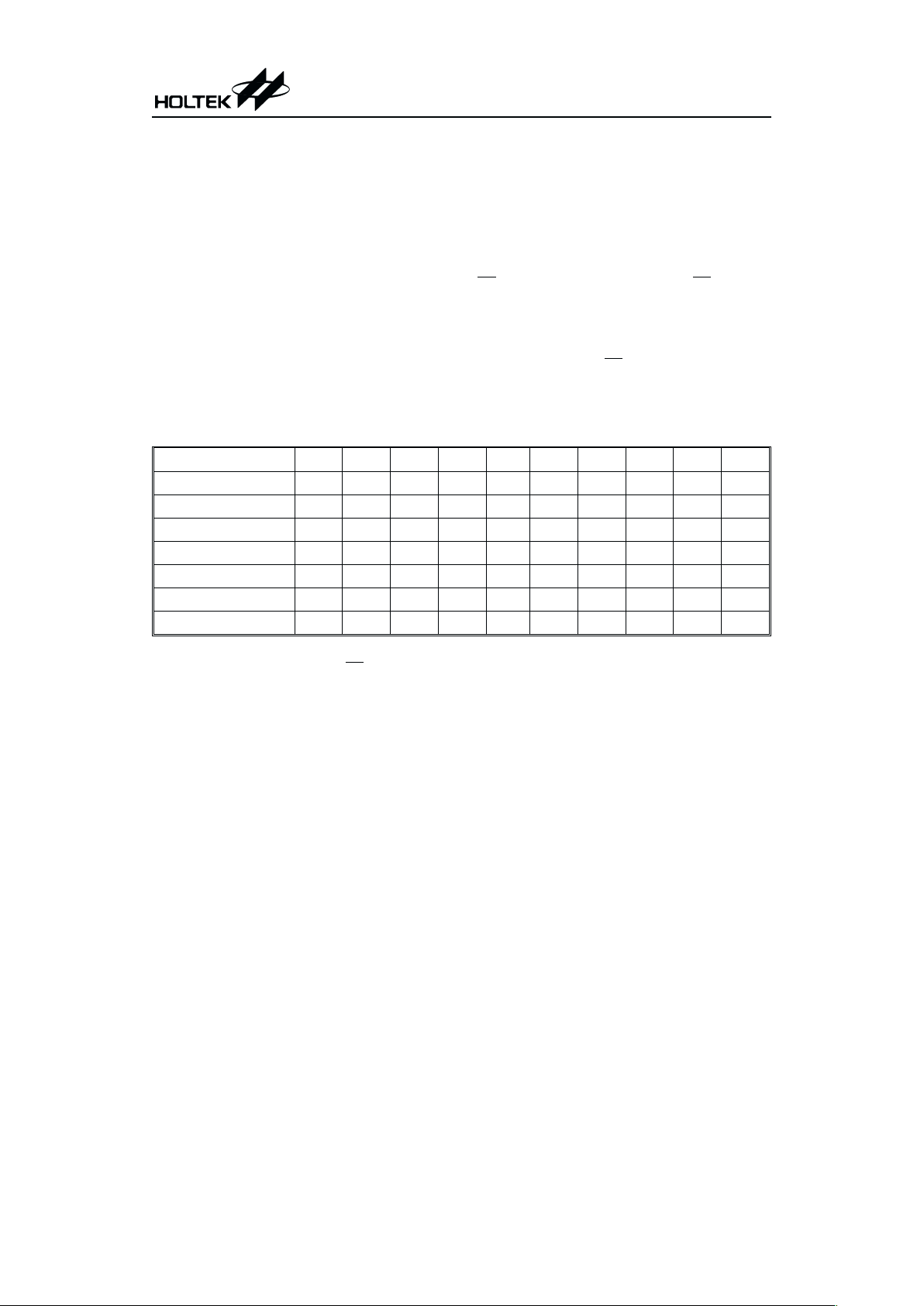

There are 2 registers related to the timer/event

counter 0; TMR0 ([0DH]), TMR0C ([0EH]). Two

physical registers are mapped to TMR0 location;

writing TMR0 makes the starting value be placed

in the timer/event counter 0 preload register and

reading TMR0 getsthe contents of the timer/event

counter 0. The TMR0C is a timer/event counter

controlregister,which defines some options.

There are 3 registers related to timer/event

counter 1; TMR1H (0FH), TMR1L (10H),

TMR1C (11H). Writing TMR1L will only put

the written data to an internal lower-order byte

buffer (8 bits) and writing TMR1H will transfer

the specified data and the contents of the

lower-order byte buffer to TMR1H and TMR1L

preload registers, respectively. The timer/event

counter 1 preload register is changed by each

writing TMR1H operations. Reading TMR1H

will latch the contents of TMR1H and TMR1L

counters to the destination and the lower-order

byte buffer, respectively. Reading the TMR1L

will read the contents of the lower-order byte

buffer. The TMR1C is the timer/event counter 1

control register, which defines the operating

mode, counting enable or disable and active

edge.

The TM0, TM1 bits define the operating mode.

The event count mode is used to count external

events, which means the clock source comes

from an external (TMR0/TMR1) pin. The timer

mode functions as a normal timer with the

clock source coming from the f

INT

clock/instruc

tion clock or RTC clock (Timer0/Timer1). The

pulse width measurement mode can be used to

count the high or low level duration of the external

signal (TMR0/TMR1). The counting is based on

the f

INT

clock/instruction clock or RTC clock

(Timer0/Timer1).

In the event count or timer mode, once the

timer/event counter 0/1 starts counting, it will

count from the current contents in the

timer/event counter 0/1 to FFH or FFFFH. Once

overflow occurs, the counter is reloaded from the

timer/event counter 0/1 preload register and gen

erates the interrupt request flag (T0F/T1F; bit

5/6 of INTC) at the same time.

In the pulse width measurement mode with

the TON and TE bits equal to one, once the

TMR0/TMR1 has received a transient from low

to high (or high to low if the TE bits is "0") it will

start counting until the TMR0/TMR1 returns to

the original level and resets the TON. The mea

sured result will remain in the timer/event

counter 0/1 even if the activated transient oc

curs again. In other words, only one cycle mea

surement can be done. Until setting the TON,

the cycle measurement will function again as

long as it receives further transient pulse. Note

that, in this operating mode, the timer/event

counter 0/1 starts counting not according to the

logic level but according to the transient edges.

In the case of counter overflows, the counter 0/1

is reloaded from the timer/event counter 0/1

preload register and issues the interrupt request just like the other two modes. To enable

the counting operation, the timer ON bit (TON;

bit 4 of TMR0C/TMR1C) should be set to 1. In

the pulse width measurement mode, the TON

will be cleared automatically after the measurement cycle is completed. But in the other

two modes the TON can only be reset by instructions. The overflow of the timer/event

counter 0/1 is one of the wake-up sources. No

matter what the operation mode is, writing a 0

to ET0I/ET1I can disable the corresponding in

terrupt services.

In the case of timer/event counter 0/1 OFF con

dition, writing data to the timer/event counter

0/1 preload register will also reload that data to

the timer/event counter 0/1. But if the

timer/event counter 0/1 is turned on, data writ

ten to it will only be kept in the timer/event

counter 0/1 preload register. The timer/event

counter 0/1 will still operate until overflow oc

curs (a timer/event counter 0/1 reloading will oc

-

Page 20

HT48C50-1

20 June 14, 2000

Preliminary

cur at the same time). When the timer/event

counter 0/1 (reading TMR0/TMR1) is read, the

clock will be blocked to avoid errors. As clock

blocking may results in a counting error, this

must be taken into consideration by the program

-

mer.

The bit0~bit2 of the TMR0C can be used to de

fine the pre-scaling stages of the internal clock

sources of timer/event counter 0. The defini

tions are as shown. The overflow signal of

timer/event counter 0 can be used to generate

PFD signals for buzzer driving.

Input/output ports

There are 35 bidirectional input/output lines in

the microcontroller, labeled from PA to PD and

PG, which are mapped to the data memory of

[12H], [14H], [16H], [18H] and [1EH] respec

tively. All of these I/O ports can be used for input

and output operations. For input operation, these

ports are non-latching, that is, the inputs must be

ready at the T2 rising edge of instruction "MOV

A,[m]" (m=12H, 14H, 16H, 18H or 1EH). For out

put operation, all the data is latched and remains

unchanged until the output latch is rewritten.

Each I/O line has its own control register (PAC,

PBC, PCC, PDC, PGC) to control the input/out

put configuration. With this control register,

CMOS output or schmitt trigger input with or

without pull-high resistor structures can be re

configured dynamically (i.e. on-the-fly) under

software control. To function as an input, the

corresponding latch of the control register must

write "1". The input source also depends on the

control register. If the control register bit is "1",

the input will read the pad state. If the control

register bit is "0", the contents of the latches

will move to the internal bus. The latter is pos

sible in the "read-modify-write" instruction.

For output function, CMOS is the only configu

ration. These control registers are mapped to

locations 13H, 15H, 17H, 19H and 1FH.

TM 1

TM 0

TM R 1

TE

TM 1

TM 0

TO N

Pulse W idth

M easurem ent

M ode C ontrol

16 Bits

Tim er/E vent C ounter

Preload R egister

Data Bus

R eload

O verflow

to Interrupt

f

SYS/4

M

U

X

f

RTC

m ask optio n

16 Bits

Tim er/E vent C ounter

(TM R 1H /TM R 1L)

Low B yte

B u ffe r

Timer/event counter 1

Label (TMR1C) Bits Function

¾

0~2 Unused bit, read as"0"

TE 3

To define the TMR1 active edge of timer/event counter 1

(0=active on low to high; 1=active on high to low)

TON 4

To enable/disable timer 1 counting

(0=disabled; 1=enabled)

¾

5 Unused bit, read as"0"

TM0

TM1

6

7

To define the operating mode

01=Event count mode (external clock)

10=Timer mode (internal clock)

11=Pulse width measurement mode

00=Unused

TMR1C register

Page 21

HT48C50-1

21 June 14, 2000

Preliminary

After a chip reset, these input/output lines re

main at high levels or floating state (depending

on the pull-high options). Each bit of these in

put/output latches can be set or cleared by "SET

[m].i" and "CLR [m].i" (m=12H, 14H, 16H, 18H

or 1EH) instructions.

Some instructions first input data and then fol

low the output operations. For example, "SET

[m].i", "CLR [m].i", "CPL [m]", "CPLA [m]" read

the entire port states into the CPU, execute the

defined operations (bit-operation), and then

write the results back to the latches or the accu

mulator.

Each line of port A has the capability of wak

ing-up the device. The highest 5-bit of port G are

not physically implemented; on reading them a

"0" is returned whereas writing then results in

no-operation. See Application note.

There is a pull-high option available for all I/O

lines (bit option). Once the pull-high option of

an I/O line is selected, the I/O line have

pull-high resistor. Otherwise, the pull-high re

sistor is absent. It should be noted that a

non-pull-high I/O line operating in input mode

will cause a floating state.

The PB0 and PB1 are pin-shared with BZ and

BZ

signal, respectively. If the BZ/BZ option is

selected, the output signal in output mode of

PB0/PB1 will be the PFD signal generated by

timer/event counter 0 overflow signal. The in

-

put mode always remain in its original func

-

tions. Once the BZ/BZ

option is selected, the

buzzer output signals are controlled by the PB0

data register only. The I/O functions of

PB0/PB1 are shown below.

PB0I/O I I OOOOOOOO

PB1I/O I O I I IOOOOO

PB0 Mode x x C B B CBBBB

PB1 Mode x C x x x CCCBB

PB0 Data x x D 0 1 D

0

0101

PB1 Data x D x x x D

1

DD x x

PB0 Pad Status I I D 0 B D

0

0B0B

PB1 Pad Status I D I I I D

1

DD0 B

Note:

²I² input, ²O² output, ²D, D

0,D1

² data,

²B² buzzer option, BZ or BZ

, ²x² don't care

²C² CMOS output

Page 22

HT48C50-1

22 June 14, 2000

Preliminary

The PG0 is pin-shared with INT.

In case of ²Internal RC+I/O² system oscillator,

the PG1 and PG2 are pin-shared with OSC1

and OSC2 pins. Once the ²Internal RC+I/O²

mode is selected, the PC3 and PC4 can be used

as general purpose I/O lines. Otherwise, the

pull-high resistors and I/O functions of PG1

and PG2 will be disabled.

It is recommended that unused or not bonded

out I/O lines should be set as output pins by

software instruction to avoid consuming power

under input floating state.

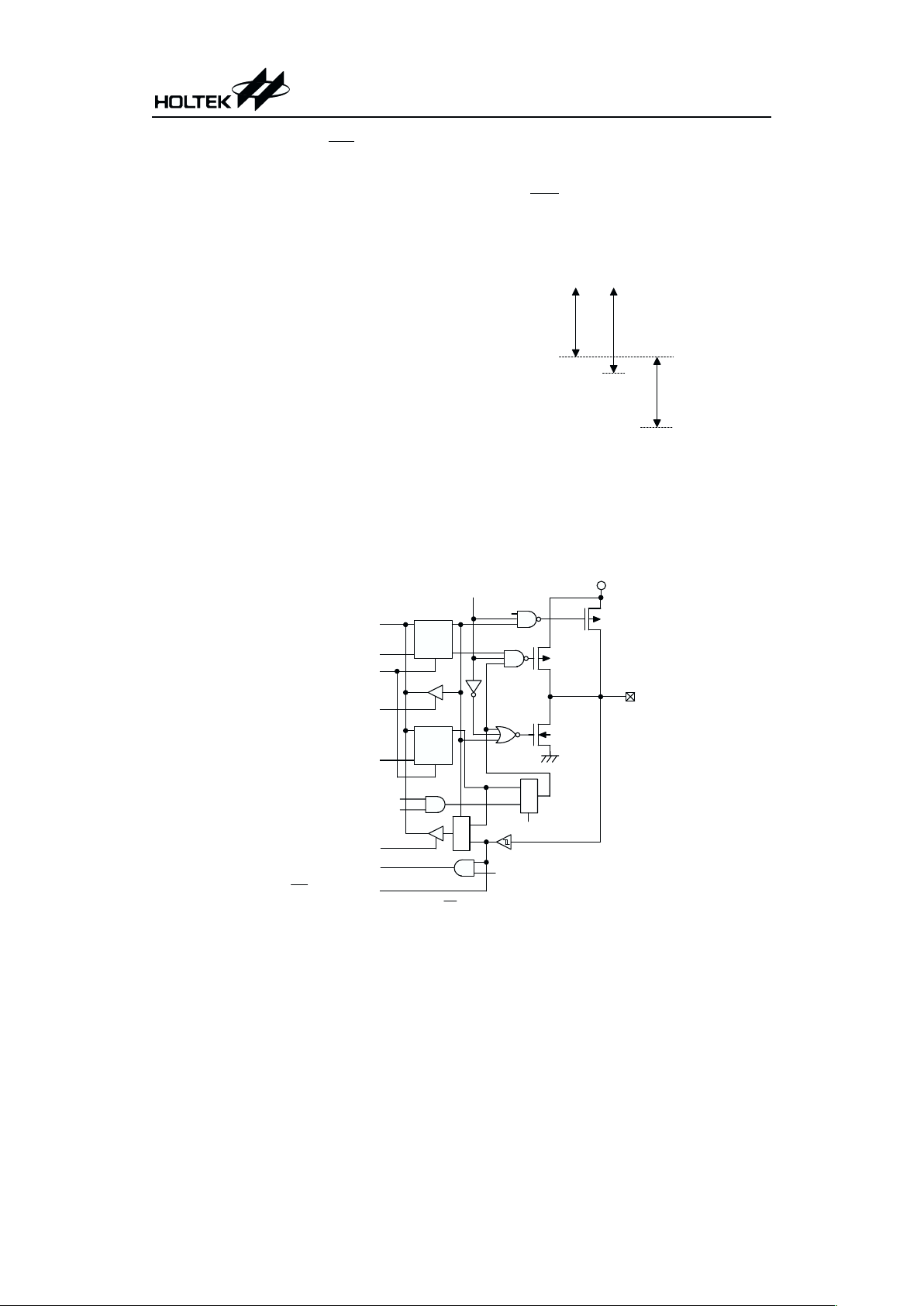

Low voltage reset - LVR

The microcontroller provides low voltage reset

circuit in order to monitor the supply voltage of

the device. If the supply voltage of the device is

within the range 0.9V~V

LVR

(2.2V or 3.3V),

such as changing a battery, the LVR will auto

-

matically reset the device internally.

The LVR includes the following specifications:

·

The low voltage (0.9V~V

LVR

) has to remain in

their original state to exceed 1ms. If the low

voltage state does not exceed 1ms, the LVR

will ignore it and do not perform a reset func

-

tion.

·

The LVR uses the ²OR² function with the ex

-

ternal RES

signal to perform chip reset.

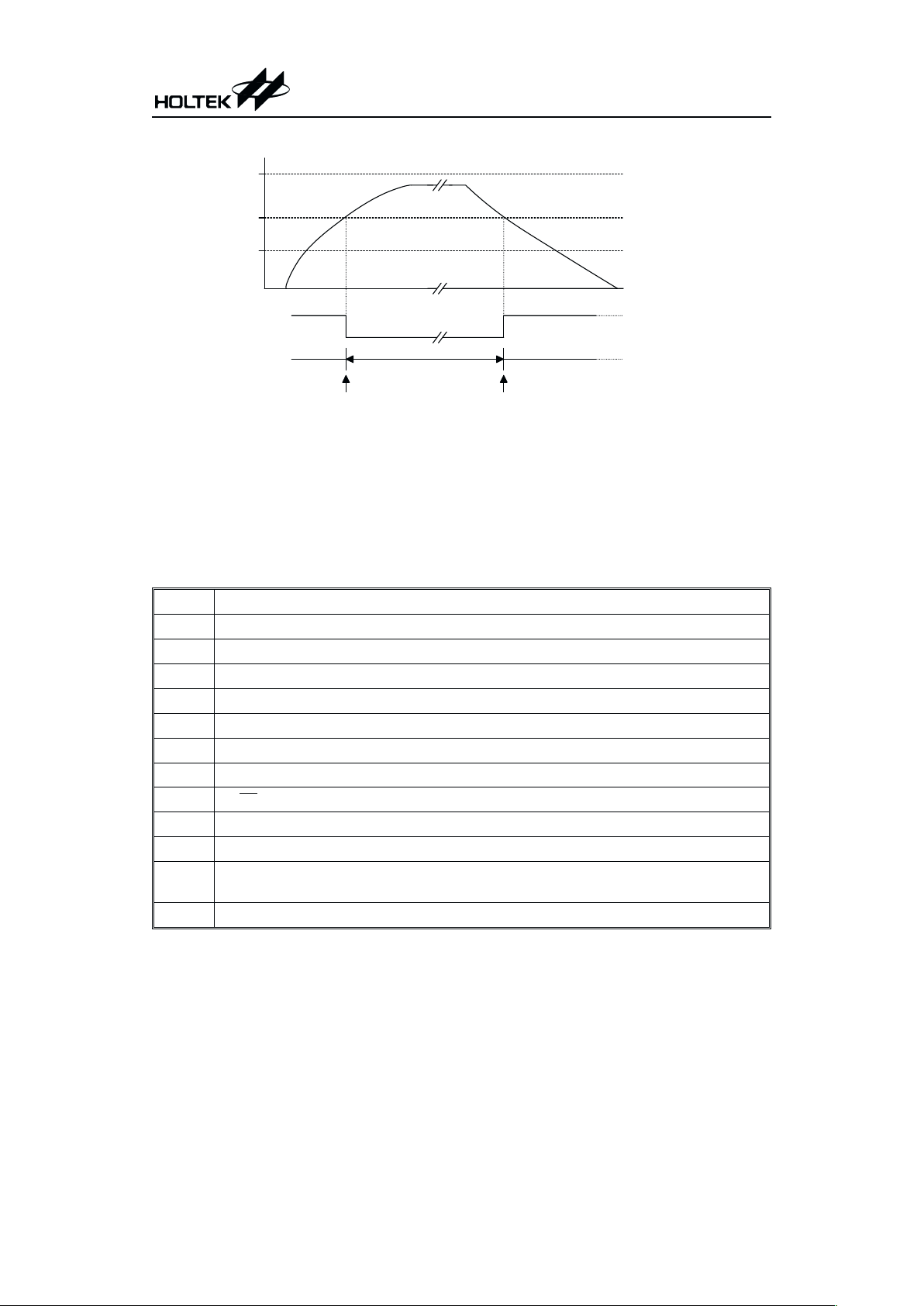

The relationship between V

DD

and V

LVR

is

shown below.

Note: V

OPR

is the voltage range for proper chip

operation at 4MHz system clock.

5.5V

2.2V or 3.3V

2.0V or 3.0V

0.9V

V

DDVOPR

V

LVR

5.5V

V

DD

PA0~PA7

PB0~PB7

PC0~PC7

PD0~PD7

PG0~PG2

M

U

X

M

U

X

EXTEN

(P B 0 , P B 1 O n ly)

OP0~OP7

IN T fo r P G 0 O n ly

System W ake-up

(P A o n ly)

R ead D ata R egister

PB0

EXT

(PB0, PB1 O nly)

D

Q

CK

QB

S

D

Q

CK

QB

S

C o n tro l B it

PU

Data Bus

W rite C ontrol R egister

C hip R eset

R ead C ontrol Register

W rite D ata R egister

Data Bit

EX T=BZ for P B 0 only, E X T =B Z for P B1 only, control=P B 0 data register

PG 1/P G 2 I/O m ode only

Input/output ports

Page 23

HT48C50-1

23 June 14, 2000

Preliminary

Mask option

The following table shows all kinds of mask option in the microcontroller. All of the mask options

must be defined to ensure proper system functioning.

Items Option

1 WDT clock source: WDTOSC/f

TID

/RTCOSC/disable

2 CLRWDT instructions: 1 or 2 instructions

3 Timer/event counter 0 clock sources: f

SYS

or RTCOSC

4 Timer/event counter 1 clock sources: f

SYS

/4 or RTCOSC

5 PA wake-up

6 PA, PB, PC, PD CMOS/SCHMITT input

7 PA, PB, PC, PD, PG pull-high enable/disable

8 BZ/BZ

enable/disable

9 LVR enable/disable

10 LVR voltage: 2.2V or 3.3V

11

System oscillator

Ext. RC, Ext.crystal, Int.RC+RTC or Int.RC+PC3/PC4

12 Int.RC frequency selection 3.2MHz, 1.6MHz, 800kHz or 400kHz

V

DD

5.5V

V

LVR

0.9V

0V

R eset S ignal

Reset

*1 *2

N o rm a l O p e ra tio n R e s e t

LVR D etect V oltage

Low voltage reset

Note: *1: To make sure that the system oscillator has stabilized, the SST provides an extra delay of

1024 system clock pulses before entering the normal operation.

*2: Since low voltage has to be maintained in its original state and exceed 1ms, therefore 1ms

delay enters the reset mode.

Page 24

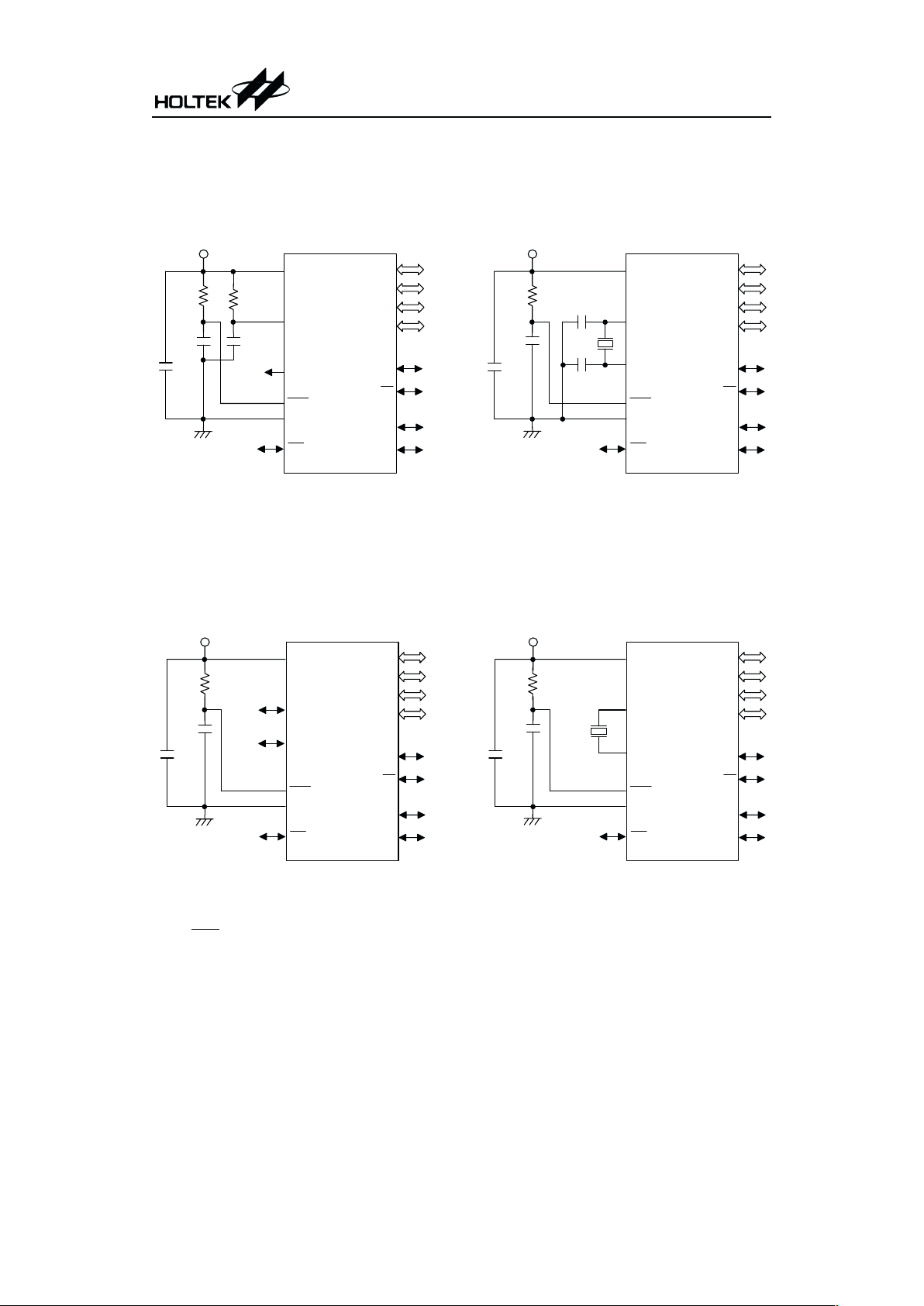

Application Circuits

HT48C50-1

24 June 14, 2000

Preliminary

V

DD

470pF

NMOS

open drain

0.1mF

100k

W

0.1mF

HT48C50-1

V

DD

0.1mF

100k

W

0.1mF

C1

C2

51kW~

1M

W

HT48C50-1

VDD

OSC1/PG1

OSC2/PG2

RES

VSS

IN T /P G 0

PA0~PA7

PB2~PB7

PC0~PC7

PD0~PD7

PB0/BZ

PB1/BZ

TM R 0

TM R 1

VDD

OSC1/PG1

OSC2/PG2

RES

VSS

IN T /P G 0

PA0~PA7

PB2~PB7

PC0~PC7

PD0~PD7

PB0/BZ

PB1/BZ

TM R 0

TM R 1

RC oscillator for multiple I/O applications Crystal or ceramic resonator for multiple I/O

applications

Internal RC oscillator for multiple I/O

applications

Internal RC oscillator with RTC for multiple I/O

applications

HT48C50-1

V

DD

0.1mF

100k

W

0.1mF

HT48C50-1

V

DD

0.1mF

100k

W

0.1mF

32768H z

VDD

OSC1/PG1

OSC2/PG2

RES

VSS

IN T /P G 0

PA0~PA7

PB2~PB7

PC0~PC7

PD0~PD7

PB0/BZ

PB1/BZ

TM R 0

TM R 1

VDD

OSC1/PG1

OSC2/PG2

RES

VSS

IN T /P G 0

PA0~PA7

PB2~PB7

PC0~PC7

PD0~PD7

PB0/BZ

PB1/BZ

TM R 0

TM R 1

Note: C1=C2=300pF if f

SYS

<1MHz

Otherwise, C1=C2=0

Note: The resistance and capacitance for reset circuit should be designed in such a way as to ensure

that the VDD is stable and remains within a valid operating voltage range before bringing

RES

to high.

Page 25

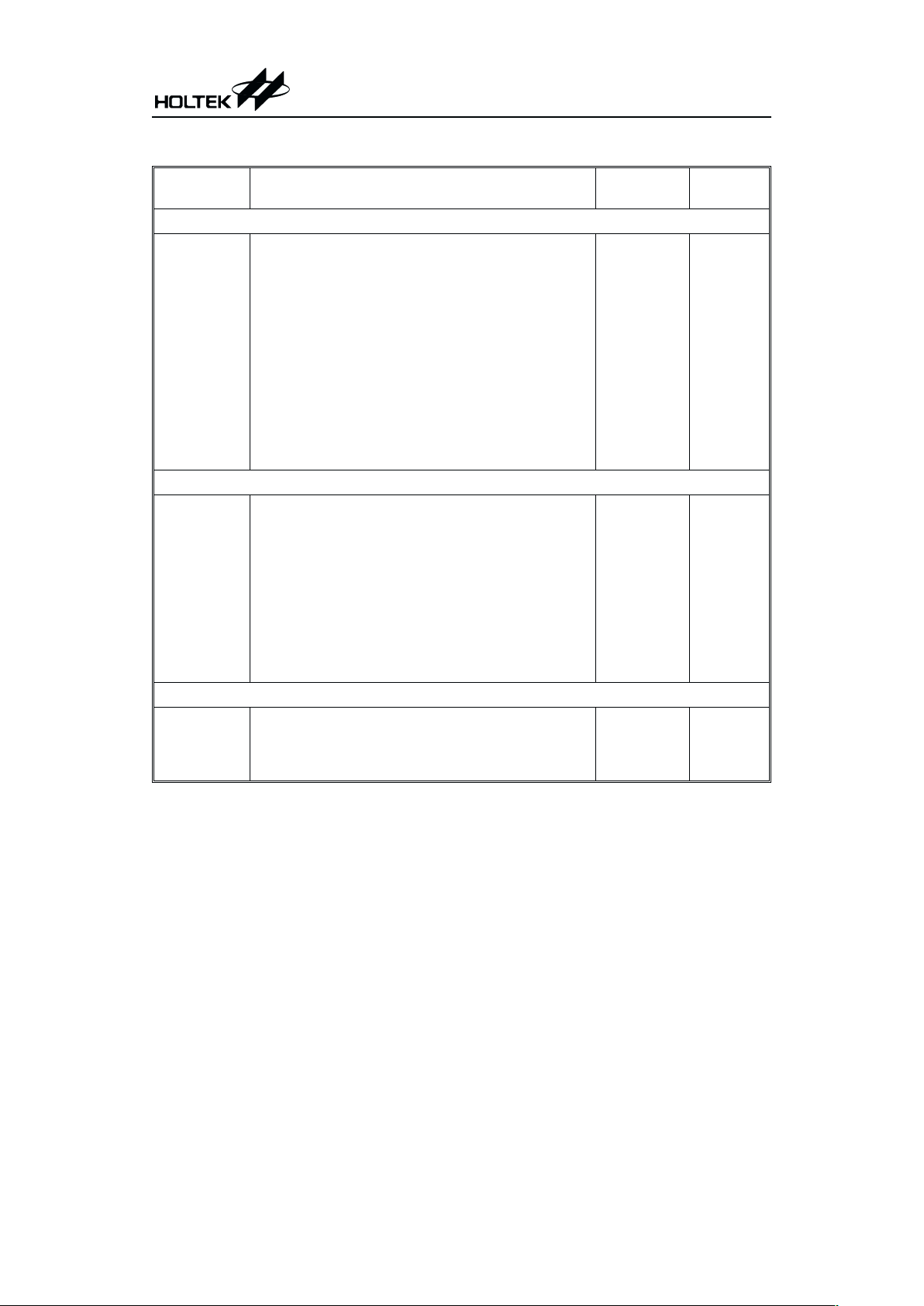

Instruction Set Summary

Mnemonic Description

Instruction

Cycle

Flag

Affected

Arithmetic

ADD A,[m]

ADDM A,[m]

ADD A,x

ADC A,[m]

ADCM A,[m]

SUB A,x

SUB A,[m]

SUBM A,[m]

SBC A,[m]

SBCM A,[m]

DAA [m]

Add data memory to ACC

Add ACC to data memory

Add immediate data to ACC

Add data memory to ACC with carry

Add ACC to register with carry

Subtract immediate data from ACC

Subtract data memory from ACC

Subtract data memory from ACC with result in data

memory

Subtract data memory from ACC with carry

Subtract data memory from ACC with carry and result

in data memory

Decimal adjust ACC for addition with result in data

memory

1

1

(1)

1

1

1

(1)

1

1

1

(1)

1

1(1)

1

(1)

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

Z,C,AC,OV

C

Logic Operation

AND A,[m]

OR A,[m]

XOR A,[m]

ANDM A,[m]

ORM A,[m]

XORM A,[m]

AND A,x

OR A,x

XOR A,x

CPL [m]

CPLA [m]

AND data memory to ACC

OR data memory to ACC

Exclusive-OR data memory to ACC

AND ACC to data memory

OR ACC to data memory

Exclusive-OR ACC to data memory

AND immediate data to ACC

OR immediate data to ACC

Exclusive-OR immediate data to ACC

Complement data memory

Complement data memory with result in ACC

1

1

1

1

(1)

1

(1)

1

(1)

1

1

1

1

(1)

1

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Z

Increment & Decrement

INCA [m]

INC [m]

DECA [m]

DEC [m]

Increment data memory with result in ACC

Increment data memory

Decrement data memory with result in ACC

Decrement data memory

1

1

(1)

1

1

(1)

Z

Z

Z

Z

HT48C50-1

25 June 14, 2000

Preliminary

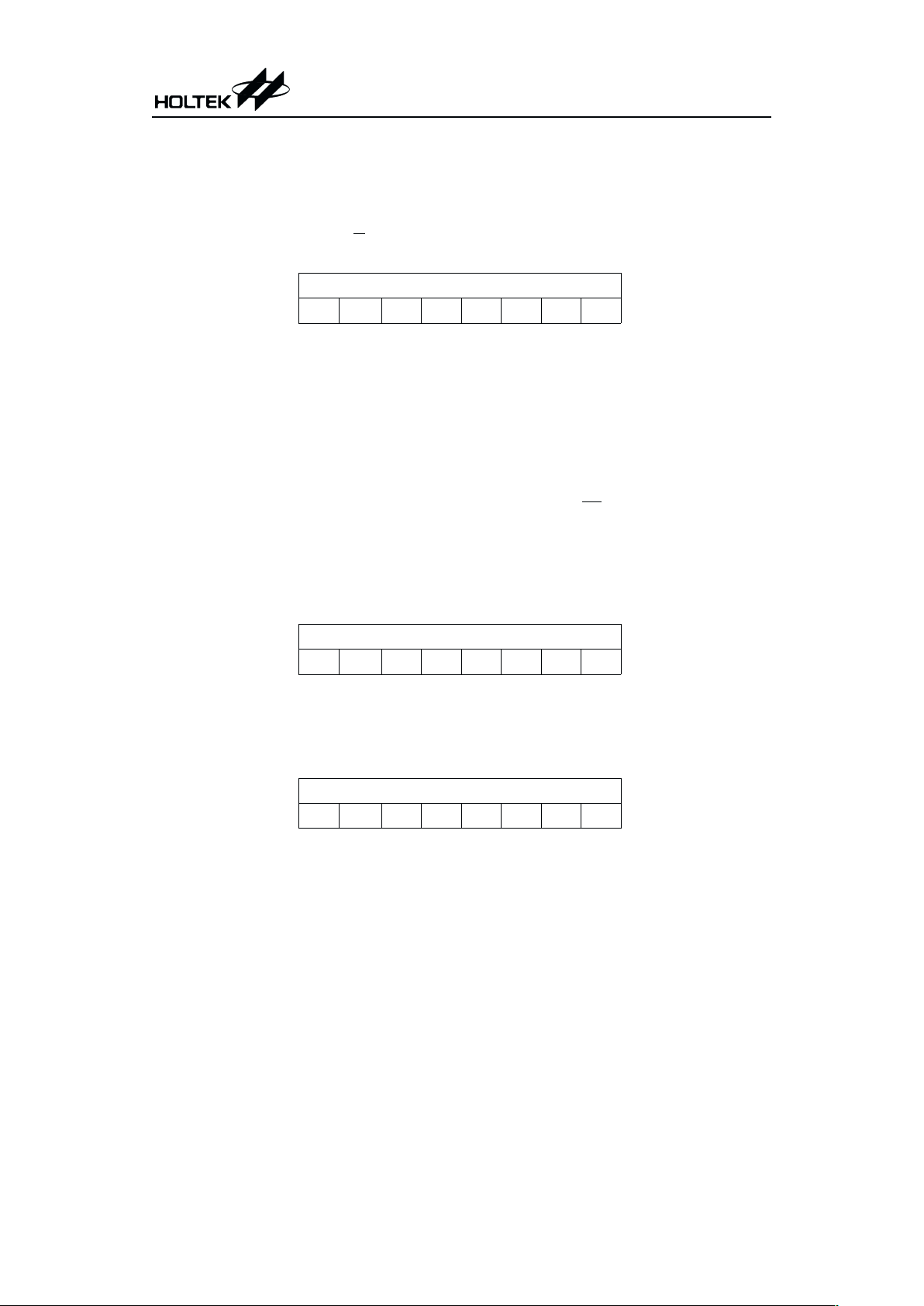

Page 26

Mnemonic Description

Instruction

Cycle

Flag

Affected

Rotate

RRA [m]

RR [m]

RRCA [m]

RRC [m]

RLA [m]

RL [m]

RLCA [m]

RLC [m]

Rotate data memory right with result in ACC

Rotate data memory right

Rotate data memory right through carry with result in

ACC

Rotate data memory right through carry

Rotate data memory left with result in ACC

Rotate data memory left

Rotate data memory left through carry with result in

ACC

Rotate data memory left through carry

1

1

(1)

1

1

(1)

1

1

(1)

1

1

(1)

None

None

C

C

None

None

C

C

Data Move

MOV A,[m]

MOV [m],A

MOV A,x

Move data memory to ACC

Move ACC to data memory

Move immediate data to ACC

1

1

(1)

1

None

None

None

Bit Operation

CLR [m].i

SET [m].i

Clear bit of data memory

Set bit of data memory

1

(1)

1

(1)

None

None

Branch

JMP addr

SZ [m]

SZA [m]

SZ [m].i

SNZ [m].i

SIZ [m]

SDZ [m]

SIZA [m]

SDZA [m]

CALL addr

RET

RET A,x

RETI

Jump unconditionally

Skip if data memory is zero

Skip if data memory is zero with data movement to

ACC

Skip if bit i of data memory is zero

Skip if bit i of data memory is not zero

Skip if increment data memory is zero

Skip if decrement data memory is zero

Skip if increment data memory is zero with result in

ACC

Skip if decrement data memory is zero with result in

ACC

Subroutine call

Return from subroutine

Return from subroutine and load immediate data to

ACC

Return from interrupt

2

1

(2)

1

(2)

1

(2)

1

(2)

1

(3)

1

(3)

1

(2)

1

(2)

2

2

2

2

None

None

None

None

None

None

None

None

None

None

None

None

None

HT48C50-1

26 June 14, 2000

Preliminary

Page 27

Mnemonic Description

Instruction

Cycle

Flag

Affected

Table Read

TABRDC [m]

TABRDL [m]

Read ROM code (current page) to data memory and

TBLH

Read ROM code (last page) to data memory and TBLH

2

(1)

2

(1)

None

None

Miscellaneous

NOP

CLR [m]

SET [m]

CLR WDT

CLR WDT1

CLR WDT2

SWAP [m]

SWAPA [m]

HALT

No operation

Clear data memory

Set data memory

Clear Watchdog Timer

Pre-clear Watchdog Timer

Pre-clear Watchdog Timer

Swap nibbles of data memory

Swap nibbles of data memory with result in ACC

Enter power down mode

1

1

(1)

1

(1)

1

1

1

1

(1)

1

1

None

None

None

TO,PD

TO

(4)

,PD

(4)

TO

(4)

,PD

(4)

None

None

TO,PD

Note: x: 8 bits immediate data

m: Data memory address

A: Accumulator

i: 0~7 number of bits

addr: Program memory address

Ö: Flag is affected

-: Flag is not affected

(1)

: If a loading to the PCL register occurs, the execution cycle of instructions will be delayed

for one more cycle (four system clocks).

(2)

: If a skipping to the next instruction occurs, the execution cycle of instructions will be de-

layed for one more cycle (four system clocks). Otherwise the original instruction cycle is un-

changed.

(3):(1)

and

(2)

(4)

: The flags may be affected by the execution status. If the Watchdog Timer is cleared by

executing the CLR WDT1 or CLR WDT2 instruction, the TO is set and the PD is cleared.

Otherwise the TO and PD flags remain unchanged.

HT48C50-1

27 June 14, 2000

Preliminary

Page 28

Instruction Definition

ADC A,[m] Add data memory and carry to the accumulator

Description The contents of the specified data memory, accumulator and the carry flag

are added simultaneously, leaving the result in the accumulator.

Operation

ACC ¬ ACC+[m]+C

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾ÖÖÖÖ

ADCM A,[m] Add the accumulator and carry to data memory

Description The contents of the specified data memory, accumulator and the carry flag

are added simultaneously, leaving the result in the specified data memory.

Operation

[m] ¬ ACC+[m]+C

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾ÖÖÖÖ

ADD A,[m] Add data memory to the accumulator

Description The contents of the specified data memory and the accumulator are added.

The result is stored in the accumulator.

Operation

ACC ¬ ACC+[m]

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾ÖÖÖÖ

ADD A,x Add immediate data to the accumulator

Description The contents of the accumulator and the specified data are added, leaving

the result in the accumulator.

Operation

ACC ¬ ACC+x

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾ÖÖÖÖ

HT48C50-1

28 June 14, 2000

Preliminary

Page 29

ADDM A,[m] Add the accumulator to the data memory

Description The contents of the specified data memory and the accumulator are added.

The result is stored in the data memory.

Operation

[m] ¬ ACC+[m]

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾ÖÖÖÖ

AND A,[m] Logical AND accumulator with data memory

Description Data in the accumulator and the specified data memory perform a bitwise

logical_AND operation. The result is stored in the accumulator.

Operation

ACC ¬ ACC "AND" [m]

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾¾Ö¾¾

AND A,x Logical AND immediate data to the accumulator

Description Data in the accumulator and the specified data perform a bitwise logi

-

cal_AND operation. The result is stored in the accumulator.

Operation

ACC ¬ ACC "AND" x

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾¾Ö¾¾

ANDM A,[m] Logical AND data memory with the accumulator

Description Data in the specified data memory and the accumulator perform a bitwise

logical_AND operation. The result is stored in the data memory.

Operation

[m] ¬ ACC "AND" [m]

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾¾Ö¾¾

HT48C50-1

29 June 14, 2000

Preliminary

Page 30

CALL addr Subroutine call

Description The instruction unconditionally calls a subroutine located at the indicated

address. The program counter increments once to obtain the address of the

next instruction, and pushes this onto the stack. The indicated address is

then loaded. Program execution continues with the instruction at this ad

-

dress.

Operation

Stack ¬ PC+1

PC ¬ addr

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾¾¾¾¾

CLR [m] Clear data memory

Description The contents of the specified data memory are cleared to 0.

Operation

[m] ¬ 00H

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾¾¾¾¾

CLR [m].i Clear bit of data memory

Description The bit i of the specified data memory is cleared to 0.

Operation

[m].i ¬ 0

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾¾¾¾¾¾¾

CLR WDT Clear Watchdog Timer

Description The WDT and the WDT Prescaler are cleared (re-counting from 0). The

power down bit (PD) and time-out bit (TO) are cleared.

Operation

WDT and WDT Prescaler ¬ 00H

PD and TO ¬ 0

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾

00

¾¾¾¾

HT48C50-1

30 June 14, 2000

Preliminary

Page 31

CLR WDT1 Preclear Watchdog Timer

Description The TD, PD flags, WDT and the WDT Prescaler has cleared (re-counting

from 0), if the other preclear WDT instruction has been executed. Only exe

cution of this instruction without the other preclear instruction just sets the

indicated flag which implies this instruction has been executed and the TO

and PD flags remain unchanged.

Operation

WDT and WDT Prescaler ¬ 00H*

PD and TO ¬ 0*

Affected flag(s)

TC2 TC1 TO PD OV Z AC C

¾¾

0* 0*

¾¾¾¾

CLR WDT2 Preclear Watchdog Timer

Description The TO, PD flags, WDT and the WDT Prescaler are cleared (re-counting

from 0), if the other preclear WDT instruction has been executed. Only exe

cution of this instruction without the other preclear instruction, sets the in