CMOS 2K 3-Wire Serial EEPROM

Features

·

Operating voltage: 2.2V~5.5V

·

Low power consumption

-

Operating: 5mA max.

-

Standby: 10mA max.

·

User selectable internal organization

-

2K(HT93LC56): 256´8or128´16

·

3-wire Serial Interface

·

Write cycle time: 5ms max.

General Description

The HT93LC56 is a 2K-bit low voltage nonvolatile, serial

electrically erasable programmable read only memory

device using the CMOS floating gate process. Its 2048

bits of memory are organized into 128 words of 16 bits

each when the ORG pin is connected to VCC or orga

nized into 256 words of 8 bits each when it is tied to

HT93LC56

·

Automatic erase-before-write operation

·

Word/chip erase and write operation

·

Write operation with built-in timer

·

Software controlled write protection

·

10-year data retention after 100K rewrite cycles

·

106rewrite cycles per word

·

Commercial temperature range (0°Cto+70°C)

·

8-pin DIP/SOP/TSSOP package

VSS. The device is optimized for use in many industrial

and commercial applications where low power and low

voltage operation are essential. By popular

microcontroller, the versatile serial interface including

chip select (CS), serial clock (SK), data input (DI) and

data output (DO) can be easily controlled.

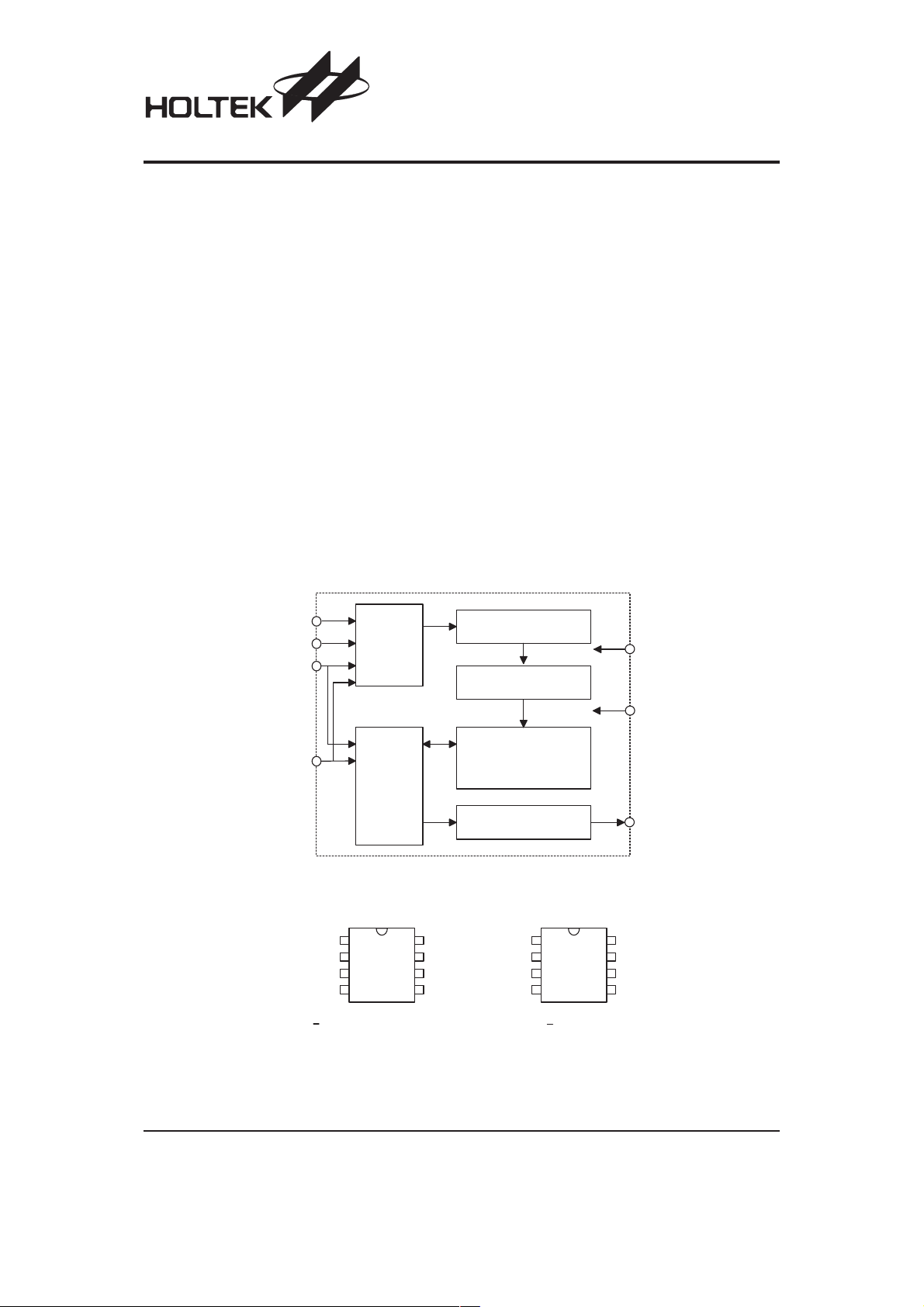

Block Diagram

Pin Assignment

C S

S K

O R G

D I

C S

1

S K

2

3

D I

4

D O

H T 9 3 L C 5 6

8 D I P - A / S O P - A / T S S O P - A

C o n t r o l

L o g i c

a n d

C l o c k

G e n e r a t o r

D a t a

R e g i s t e r

A d d r e s s

R e g i s t e r

V C C

A d d r e s s

D e c o d e r

V S S

M e m o r y C e l l

A r r a y

2 K : ( 2 5 6

V C C

8

N C

7

6

O R G

5

V S S

8 o r 1 2 8 ´ 1 6 )

´

O u t p u t

B u f f e r

N C

1

V C C

2

3

C S

4

S K

H T 9 3 L C 5 6

8 S O P - B

D O

O R G

8

V S S

7

6

D O

5

D I

Rev. 1.30 1 March 15, 2006

HT93LC56

Pin Description

Pin Name I/O Description

CS I Chip select input

SK I Serial clock input

DI I Serial data input

DO O Serial data output

VSS

ORG I

NC

VCC

Absolute Maximum Ratings

Operation Temperature (Commercial)..........................................................................................................0°Cto70°C

Applied V

Applied Voltage onany Pin with Respect to VSS

Note: These are stress ratings only. Stresses exceeding the range specified under ²Absolute Maximum Ratings² may

Voltage with Respectto VSS ...................................................................................VSS-0.3V toVSS+6.0V

CC

cause substantial damage to the device. Functional operation of this device at other conditions beyond those

listed in the specification is not implied and prolonged exposure to extreme conditions may affect device reliability.

Negative power supply, ground

¾

Internal Organization

When ORG is connected to VDD or ORG is floated, the (´16) memory organization is se

lected. When ORG is tied to VSS, the (´8) memory organization is selected. There is an in

ternal pull-up resistor on the ORG pin. (HT93LC56-A)

No connection

¾

Positive power supply

¾

..................................................................................................VSS

-0.3V toVCC+0.3V

-

-

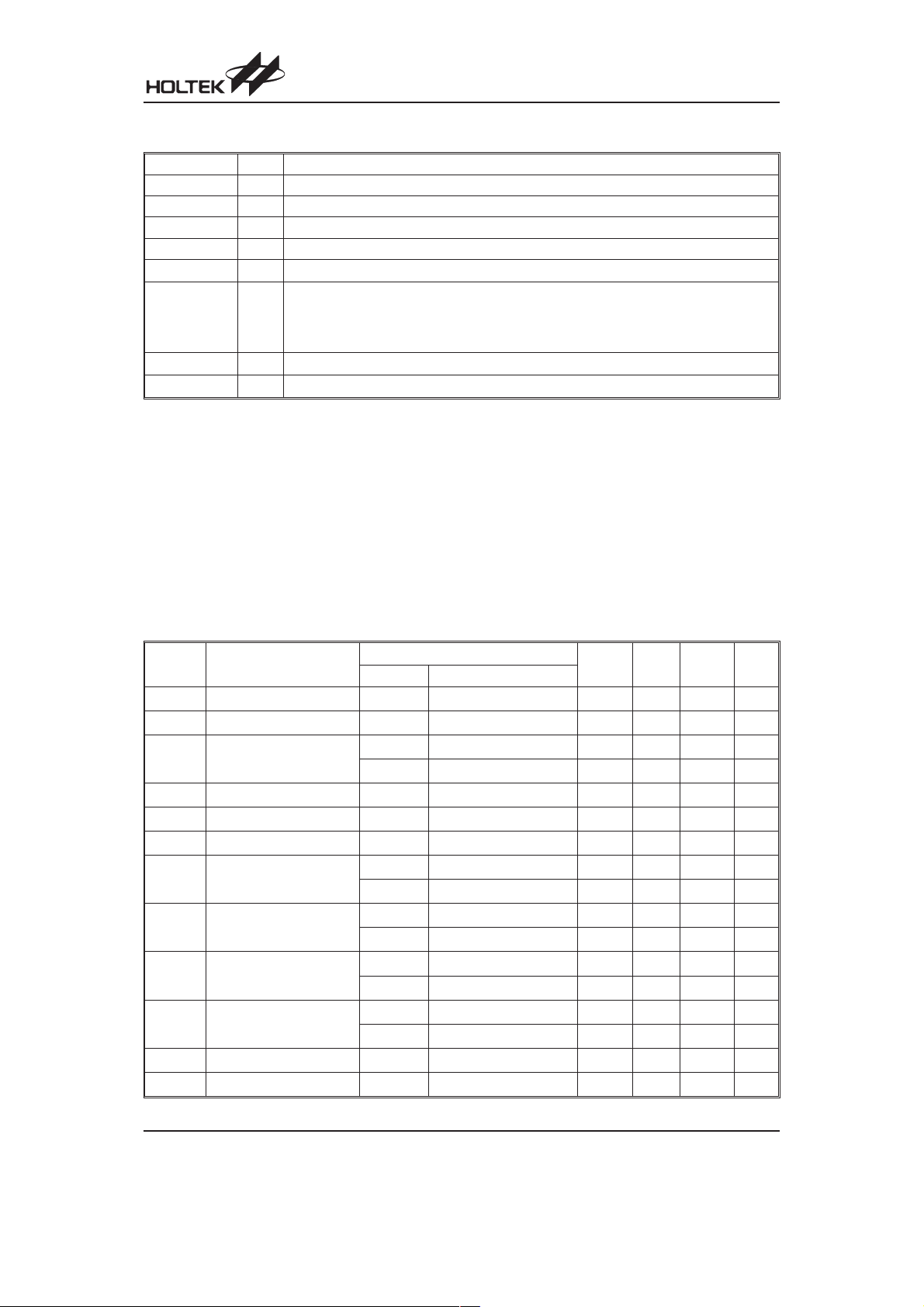

D.C. Characteristics

Symbol Parameter

V

I

I

I

I

I

V

V

V

V

C

C

CC1

CC2

STB

LI

LO

Operating Voltage

CC

Operating Current (TTL) 5V DO unload, SK=1MHz

Operating Current

(CMOS)

Standby Current (CMOS) 5V CS=SK=DI=0V

Input Leakage Current 5V

Output Leakage Current 5V

Input Low Voltage

IL

IH

OL

OH

IN

OUT

Input High Voltage

Output Low Voltage

Output High Voltage

Input Capacitance

Output Capacitance

Test Conditions

V

CC

Conditions

¾¾

5V DO unload, SK=1MHz

2.2V~5.5V DO unload, SK=250kHz

V

IN=VSS~VCC

, CS=0V

¾

¾

¾

¾

5V

2.2V~5.5V

5V

2.2V~5.5V

5V

2.2V~5.5V

5V

2.2V~5.5V

¾

¾

V

OUT=VSS~VCC

=2.1mA

I

OL

=10mA ¾¾

I

OL

=-400mA

I

OH

I

=-10mAV

OH

=0V, f=250kHz

V

IN

=0V, f=250kHz

V

OUT

Min. Typ. Max. Unit

2.2

¾

¾¾

¾¾

¾¾

¾¾

0

0

0

0

2

0.9V

CC

¾

¾

¾

¾

¾

¾

¾¾

5.5 V

5mA

5mA

5mA

10

1

1

0.8 V

0.1V

CC

V

CC

V

CC

0.4 V

0.2 V

2.4

CC

¾¾

¾¾

¾¾

-0.2 ¾¾

5pF

5pF

mA

mA

mA

V

V

V

V

V

Rev. 1.30 2 March 15, 2006

A.C. Characteristics

Symbol Parameter

f

t

t

t

t

t

t

t

t

t

t

t

t

SK

SKH

SKL

CSS

CSH

CDS

DIS

DIH

PD1

PD0

SV

HV

PR

Clock Frequency 0 2000 0 500 0 250 kHz

SK High Time 250

SK Low Time 250

CS Setup Time 50

CS Hold Time 0

CS Deselect Time 250

DI Setup Time 100

DI Hold Time 100

DO Delay to ²1²¾

DO Delay to ²0²¾

Status Valid Time

DO Disable Time 100

Write Cycle Time

VCC=5V±10% VCC=3V±10%

VCC=2.2V

Min. Max. Min. Max. Min. Max.

¾

¾

¾

¾

¾

¾

¾

250

250

¾

250

¾

¾

5

1000

1000

200

0

250

200

200

¾

¾

¾

400

¾

¾

¾

¾

¾

¾

¾

¾

1000

1000

250

¾

5

2000

2000

200

0

1000

400

400

¾

¾

¾

¾

¾

¾

¾

¾

¾

2000 ns

2000 ns

¾¾

400

¾

¾¾

HT93LC56

Unit

ns

ns

ns

ns

ns

ns

ns

ns

ns

ms

A.C. Test Conditions

Input rise and fall time: 5ns (1V to 2V)

Input and output timing reference levels: 1.5V

Output load circuit: See Figure below.

V C C = 1 . 9 5 2 V

8 0 0

W

D O

1 0 0 p F *

* Including Scope and Jig

t

C S

S K

D I

D O

C S S

t

D I S

H i - Z

t

t

D I H

V a l i d D a t a

S K H

t

P D 0

t

C D S

t

S K L

V a l i d D a t a

t

P D 1

t

C S H

Rev. 1.30 3 March 15, 2006

Functional Description

The HT93LC56 is accessed via a three-wire serial com

munication interface. The device is arranged into 128

words by 16 bits or 256 words by 8 bits depending whether

the ORG pin is connected to VCC or VSS. The HT93LC56

contains seven instructions: READ, ERASE, WRITE,

EWEN, EWDS, ERAL and WRAL. When the user

selectable internal organization is arranged into

128´16 (256´8), these instructions are all made up of

11(12) bits data: 1 start bit, 2 op code bits and 8(9) address

bits.

By using the control signal CS, SK and data input signal

DI, these instructions can be given to the HT93LC56.

These serial instruction data presented at the DI input

will be written into the device at the rising edge of SK.

During the READ cycle, DO pin acts as the data output

and during the WRITE or ERASE cycle, DO pin indi

cates the BUSY/READY status. When the DO pin is ac

tive for read data or as a BUSY/READY indicator the CS

pin must be high; otherwise DO pin will be in a

high-impedance state. For successful instructions, CS

must be low once after the instruction is sent. After

power on, the device is by default in the EWDS state.

And, an EWEN instruction must be performed before

any ERASE or WRITE instruction can be executed. The

following are the functional descriptions and timing diagrams of all seven instructions.

READ

The READ instruction will stream out data at a specified

address on the DO pin. The data on DO pin changes

during the low-to-high edge of SK signal. The 8 bits or

16 bits data stream is preceded by a logical ²0² dummy

bit. Irrespective of the condition of the EWEN or EWDS

instruction, the READ command is always valid and in

dependent of these two instructions. After the dataword

has been read the internal address will be automatically

incremented by 1 allowing the next consecutive data

word to be read out without entering further address

data. The address will wrap around with CS High until

CS returns to LOW.

HT93LC56

ERASE

-

The ERASE instruction erases data at the specified ad

dresses in the programming enable mode. After the

ERASE op-code and the specified address have been

issued, the data erase is activated by the falling edge of

CS. Since the internal auto-timing generator provides all

timing signals for the internal erase, so the SK clock is

not required. During the internal erase, we can verify the

busy/ready status if CS is high. The DO pin will remain

low butwhen the operation is over, the DO pin will return

to high and further instructions can be executed.

WRITE

The WRITE instruction writes data into the device at the

specified addresses in the programming enable mode.

After the WRITE op-code and the specified address and

data have been issued, the data writing is activated by

the falling edge of CS. Since the internal auto-timing

generator provides all timing signal for the internal writ

ing, so the SK clock is not required. The auto-timing

write cycle includes an automatic erase-before-write ca

pability. So, it is not necessary to erase data before the

WRITE instruction. During the internal writing, we can

verify the busy/ready status if CS is high. The DO pin will

remain low but when the operation is over, the DO pin

will return to high and further instructions can be executed.

ERAL

The ERALinstruction erases the entire 128´16 or 256´8

memory cellsto logical ²1² state in the programming enable mode. After the erase-all instruction set has been

issued, the data erase feature is activated by the falling

edge of CS. Since the internal auto-timing generator

provides all timing signal for the erase-all operation, so

the SK clock is not required. During the internal erase-all

operation, we can verify the busy/ready status if CS is

high. The DO pin will remain low but when the operation

is over, the DO pin will return to high and further instruc

tion can be executed.

-

-

-

-

EWEN/EWDS

The EWEN/EWDS instruction will enable or disable the

programming capabilities. At both the power on and

power off state the device automatically entered the dis

able mode. Before a WRITE, ERASE, WRAL or ERAL in

struction is given, the programming enable instruction

EWEN must be issued, otherwise the ERASE/WRITE in

struction is invalid. After the EWEN instruction is issued,

the programming enable condition remains until power is

turned off or an EWDS instruction is given. No data can be

written into the device in the programming disabled state.

By so doing, the internal memory data can be protected.

Rev. 1.30 4 March 15, 2006

WRAL

The WRAL instruction writes data into the entire 128´16

or 256´8 memory cells in the programming enable

-

mode. After the write-all instruction set has been issued,

-

the data writing is activated by the falling edge of CS.

Since the internal auto-timing generator provides all tim

-

ing signals for the write-all operation, so the SK clock is

not required. During the internal write-all operation, we

can verify the busy/ready status if CS is high. The DO

pin will remain low but when the operation is over the

DO pin will return to high and further instruction can be

executed.

-

Timing Diagrams

READ

C S

S K

D I

D O

* A d d r e s s p o i n t e r a u t o m a t i c a l l y c y c l e s t o t h e n e x t w o r d

EWEN/EWDS

( 1 )

S t a r t b i t

t

C D S

0

1

H i g h Z H i g h - Z

A N

A 0

t

0

D 0

D X

D X

H Z

*

M o d e

( X 1 6 )

A N

D X

A 6

D 1 5

HT93LC56

( X 8 )

A 7

D 7

WRITE

C S

S t a n d b y

S K

D I

( 1 )

S t a r t b i t

1 1 = E W E N

0

0

0 0 = E W D S

t

C D S

C S

v e r i f y

S t a n d b y

S K

A N - 1

D I

D O

( 1 )

S t a r t b i t

H i g h - Z

A N - 2

A N

1

0

A 1

A 0 D X

D 0

t

S V

r e a d y

b u s y

t

P R

t

H Z

Rev. 1.30 5 March 15, 2006

ERASE

ERAL

HT93LC56

t

C S

S K

A N - 1

D I

D O

( 1 )

S t a r t b i t

H i g h - Z

A N - 2

A N

1

1

A 1

A 0

C S

S K

C D S

v e r i f y

b u s y

t

P R

t

C D S

v e r i f y

S t a n d b y

t

S V

r e a d y

t

H Z

S t a n d b y

D I

( 1 )

S t a r t b i t

D O

1000

H i g h - Z

t

S V

r e a d y

b u s y

t

P R

t

H Z

WRAL

t

C D S

C S

S K

0

00

D I

D O

( 1 )

S t a r t b i t

1

H i g h - Z

D X

D 0

v e r i f y

b u s y

t

P R

S t a n d b y

t

S V

r e a d y

t

H Z

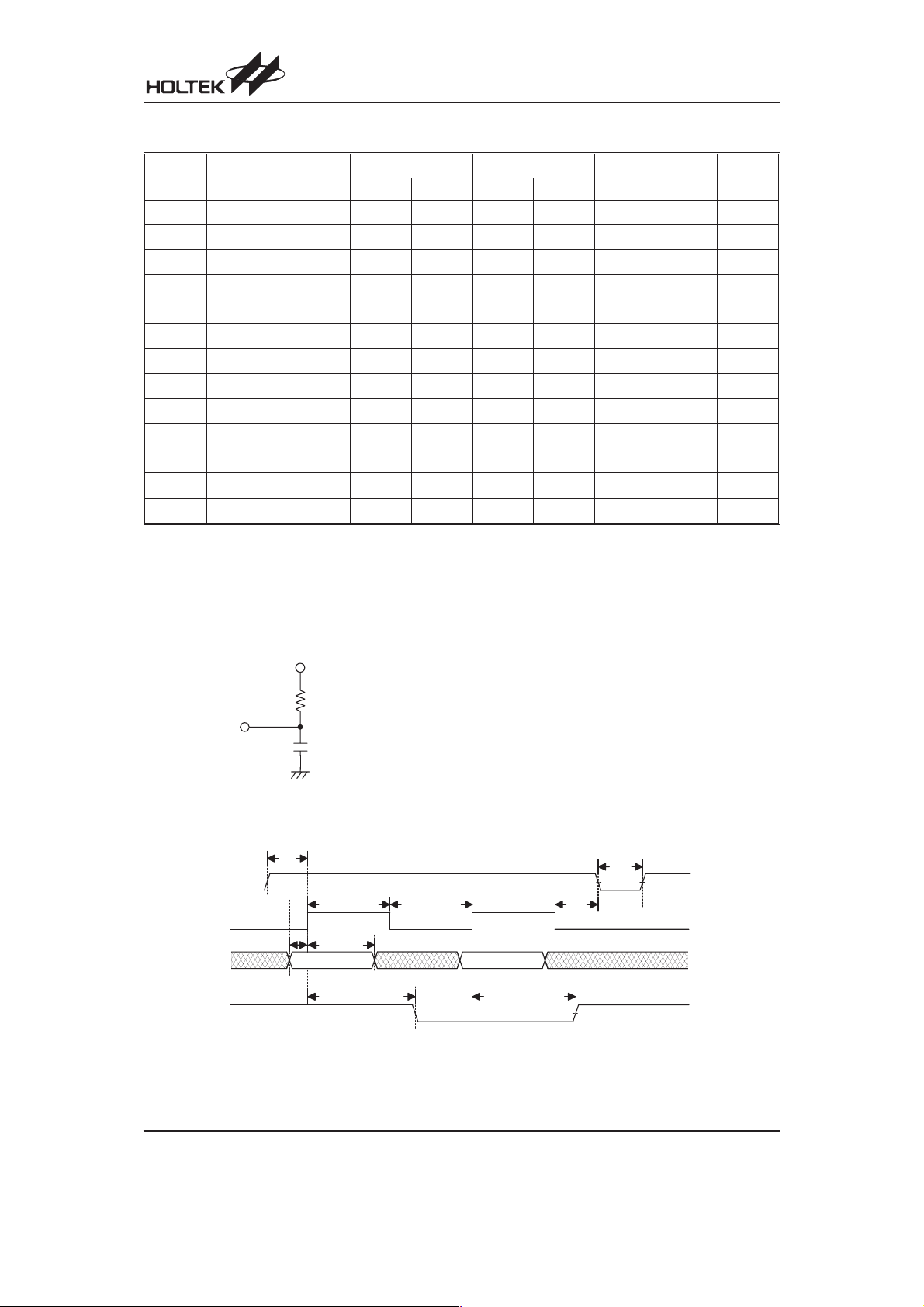

Instruction Set Summary

Instruction Comments

Start

bitOpCode

READ Read data 1 10 XA7~A0 XA6~A0 D7~D0 D15~D0

ERASE Erase data 1 11 XA7~A0 XA6~A0

WRITE Write data 1 01 XA7~A0 XA6~A0 D7~D0 D15~D0

EWEN Erase/Write Enable 1 00 11XXXXXXX 11XXXXXX

EWDS Erase/Write Disable 1 00 00XXXXXXX 00XXXXXX

ERAL Erase All 1 00 10XXXXXXX 10XXXXXX

WRAL Write All 1 00 01XXXXXXX 01XXXXXX D7~D0 D15~D0

Note: ²X² stands for ²don¢t care²

Address Data

ORG=0

X8

ORG=1

X16

ORG=0X8ORG=1

¾¾

¾¾

¾¾

¾¾

X16

Rev. 1.30 6 March 15, 2006

Package Information

8-pin DIP (300mil) Outline Dimensions

B

C

D

E

HT93LC56

A

8

5

4

1

H

G

F

a

I

Symbol

Min. Nom. Max.

A 355

B 240

C 125

D 125

E16

F50

G

¾

H 295

I 335

Dimensions in mil

¾

¾

¾

¾

¾

¾

100

¾

¾

a 0°¾15°

375

260

135

145

20

70

¾

315

375

Rev. 1.30 7 March 15, 2006

8-pin SOP (150mil) Outline Dimensions

5

8

A

1

B

4

C

HT93LC56

C '

D

E

F

Symbol

Min. Nom. Max.

A 228

B 149

C14

C¢

189

D53

E

¾

F4

G22

H4

G

H

a

Dimensions in mil

¾

¾

¾

¾

¾

50

¾

¾

¾

a 0°¾10°

244

157

20

197

69

¾

10

28

12

Rev. 1.30 8 March 15, 2006

8-pin TSSOP Outline Dimensions

HT93LC56

58

E 1

1 4

E

L 1

Dimensions in mm

¾

¾

¾

0.25

¾

¾

¾

¾

0.65

¾

¾

q

A

e

R 0 . 1 0

( 4 C O R N E R S )

Symbol

A 1.05

A1 0.05

A2 0.95

B

C 0.11

D 2.90

E 6.20

E1 4.30

e

L 0.50

L1 0.90

y

D

A 2

A 1

B

y

L

C

Min. Nom. Max.

¾

¾

¾¾

q 0°¾8°

1.20

0.15

1.05

¾

0.15

3.10

6.60

4.50

¾

0.70

1.10

0.10

Rev. 1.30 9 March 15, 2006

Product Tape and Reel Specifications

Reel Dimensions

HT93LC56

T 2

A

B

T 1

D

SOP 8N, TSSOP 8L

Symbol Description Dimensions in mm

A Reel Outer Diameter

B Reel Inner Diameter

C Spindle Hole Diameter

D Key Slit Width

T1 Space Between Flange

T2 Reel Thickness

330±1.0

62±1.5

13.0+0.5

2.0±0.5

12.8+0.3

18.2±0.2

C

-0.2

-0.2

Rev. 1.30 10 March 15, 2006

Carrier Tape Dimensions

HT93LC56

D

E

F

PD 1

P 1P 0

W

A 0

B 0

C

SOP 8N

Symbol Description Dimensions in mm

W Carrier Tape Width

P Cavity Pitch

E Perforation Position

F Cavity to Perforation (Width Direction)

D Perforation Diameter

12.0+0.3

8.0±0.1

1.75±0.1

5.5±0.1

1.55±0.1

D1 Cavity Hole Diameter 1.5+0.25

P0 Perforation Pitch

P1 Cavity to Perforation (Length Direction)

A0 Cavity Length

B0 Cavity Width

K0 Cavity Depth

t Carrier Tape Thickness

4.0±0.1

2.0±0.1

6.4±0.1

5.2±0.1

2.1±0.1

0.3±0.05

C Cover Tape Width 9.3

t

K 0

-0.1

TSSOP 8L

Symbol Description Dimensions in mm

W Carrier Tape Width

P Cavity Pitch

E Perforation Position

F Cavity to Perforation (Width Direction)

12.0+0.3

-0.1

8.0±0.1

1.75±0.1

5.5±0.5

D Perforation Diameter 1.5+0.1

D1 Cavity Hole Diameter 1.5+0.1

P0 Perforation Pitch

P1 Cavity to Perforation (Length Direction)

A0 Cavity Length

B0 Cavity Width

K0 Cavity Depth

t Carrier Tape Thickness

4.0±0.1

2.0±0.1

7.0±0.1

3.6±0.1

1.6±0.1

0.3±0.013

C Cover Tape Width 9.3

Rev. 1.30 11 March 15, 2006

Holtek Semiconductor Inc. (Headquarters)

No.3, Creation Rd. II, Science Park, Hsinchu, Taiwan

Tel: 886-3-563-1999

Fax: 886-3-563-1189

http://www.holtek.com.tw

Holtek Semiconductor Inc. (Taipei Sales Office)

4F-2, No. 3-2, YuanQu St., Nankang Software Park, Taipei 115, Taiwan

Tel: 886-2-2655-7070

Fax: 886-2-2655-7373

Fax: 886-2-2655-7383 (International sales hotline)

HT93LC56

Holtek Semiconductor Inc. (Shanghai Sales Office)

7th Floor, Building 2, No.889, Yi Shan Rd., Shanghai, China 200233

Tel: 021-6485-5560

Fax: 021-6485-0313

http://www.holtek.com.cn

Holtek Semiconductor Inc. (Shenzhen Sales Office)

5/F, Unit A, Productivity Building, Cross of Science M 3rd Road and Gaoxin M 2nd Road, Science Park, Nanshan District,

Shenzhen, China 518057

Tel: 0755-8616-9908, 8616-9308

Fax: 0755-8616-9533

Holtek Semiconductor Inc. (Beijing Sales Office)

Suite 1721, Jinyu Tower, A129 West Xuan Wu Men Street, Xicheng District, Beijing, China 100031

Tel: 010-6641-0030, 6641-7751, 6641-7752

Fax: 010-6641-0125

Holtek Semiconductor Inc. (Chengdu Sales Office)

709, Building 3, Champagne Plaza, No.97 Dongda Street, Chengdu, Sichuan, China 610016

Tel: 028-6653-6590

Fax: 028-6653-6591

Holmate Semiconductor, Inc. (North America Sales Office)

46729 Fremont Blvd., Fremont, CA 94538

Tel: 510-252-9880

Fax: 510-252-9885

http://www.holmate.com

Copyright Ó 2006 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek as

sumes no responsibility arising from the use of the specifications described. The applications mentioned herein are used

solely for the purpose of illustration and Holtek makes no warranty or representation that such applications will be suitable

without further modification, nor recommends the use of its products for application that may present a risk to human life

due to malfunction or otherwise. Holtek¢s products are not authorized for use as critical components in life support devices

or systems. Holtek reserves the right to alter its products without prior notification. For the most up-to-date information,

please visit our web site at http://www.holtek.com.tw.

-

Rev. 1.30 12 March 15, 2006

Loading...

Loading...