Page 1

HT46R46/C46/R47/C47/R48A/C48A/R49

Cost-Effective A/D Type 8-Bit MCU

Rev. 1.41 1 December 30, 2008

General Description

The Cost-Effective A/D Type MCU Devices are a series

of 8-bit high performance RISC architecture

microcontrollers, designed especially for applications

that interface directly to analog signals, such as those

from sensors. All devices include an integrated

multi-channel Analog to Digital Converter in addition to

one or two Pulse Width Modulation outputs. The usual

Holtek MCU features such as power down and wake-up

functions, oscillator options, programmable frequency

divider, etc. combineto ensure user applications require

a minimum of external components.

The benefits of integrated A/D and PWM functions, in

addition to low power consumption, high performance,

I/O flexibility and low-cost, provide these devices with

the versatility to suit a wide range of application possibilities such as sensor signal processing, motor driving, industrial control, consumer products, subsystem

controllers, etc. Many features are common to all devices, however, they differ in areas such as I/O pin

count, Program Memory capacity, A/D resolution, stack

capacity and package types.

Features

·

Operating voltage:

f

SYS

=4MHz: 2.2V~5.5V

f

SYS

=8MHz: 3.3V~5.5V

·

13 to 23 bidirectional I/O lines

·

External interrupt input shared with an I/O line

·

8-bit programmable Timer/Event Counter with overflow interrupt and 7-stage prescaler

·

On-chip crystal and RC oscillator

·

Watchdog Timer function

·

PFD for audio frequency generation

·

Power down and wake-up functions to reduce power

consumption

·

Up to 0.5ms instruction cycle with 8MHz system clock

at V

DD

=5V

·

4 or 6-level subroutine nesting

·

4 channels 8 or 9-bit resolution A/D converter

·

1 or2 channel 8-bit PWM output shared with I/O lines

·

Bit manipulation instruction

·

Table read instructions

·

63 powerful instructions

·

All instructions executed in one or two machine

cycles

·

Low voltage reset function

·

Range of packaging types

Page 2

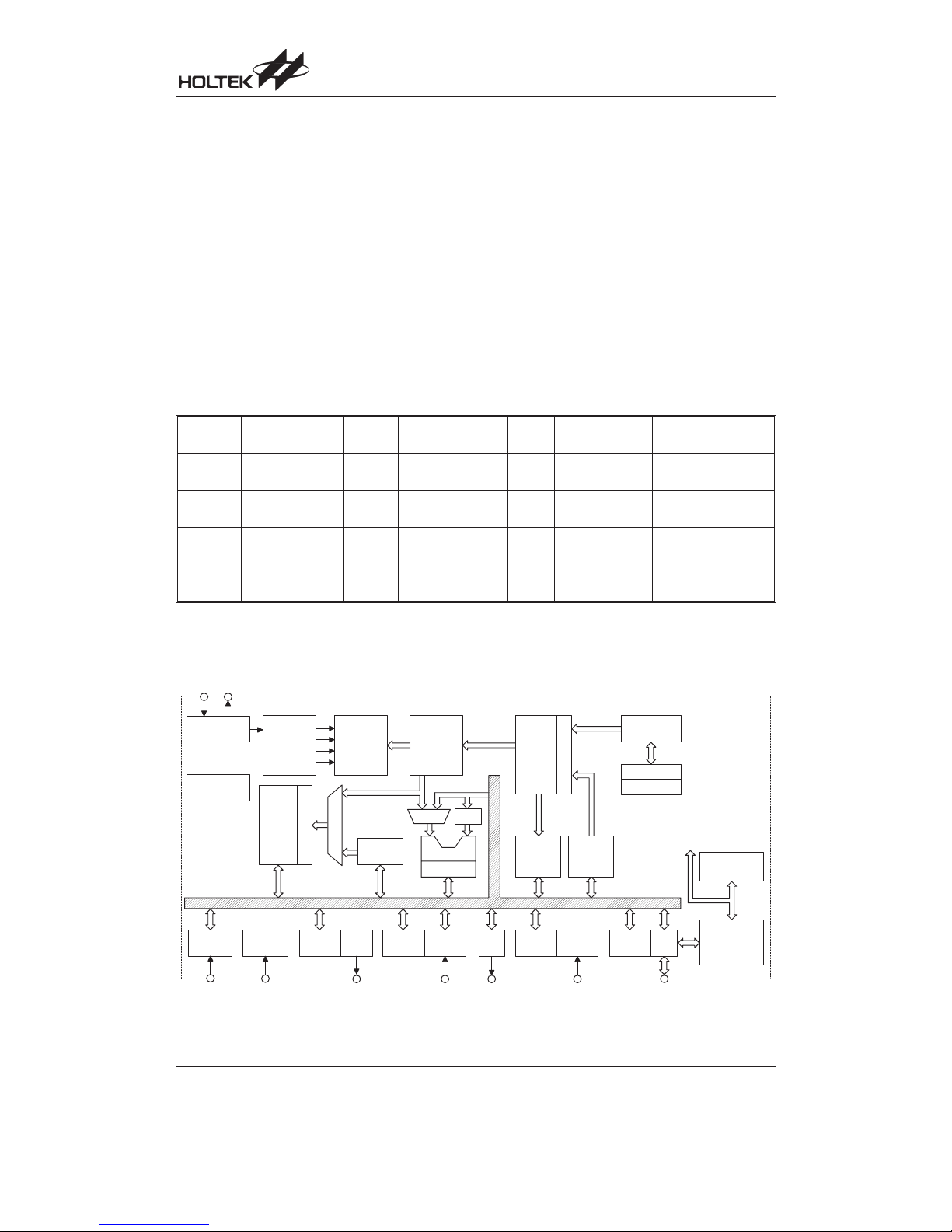

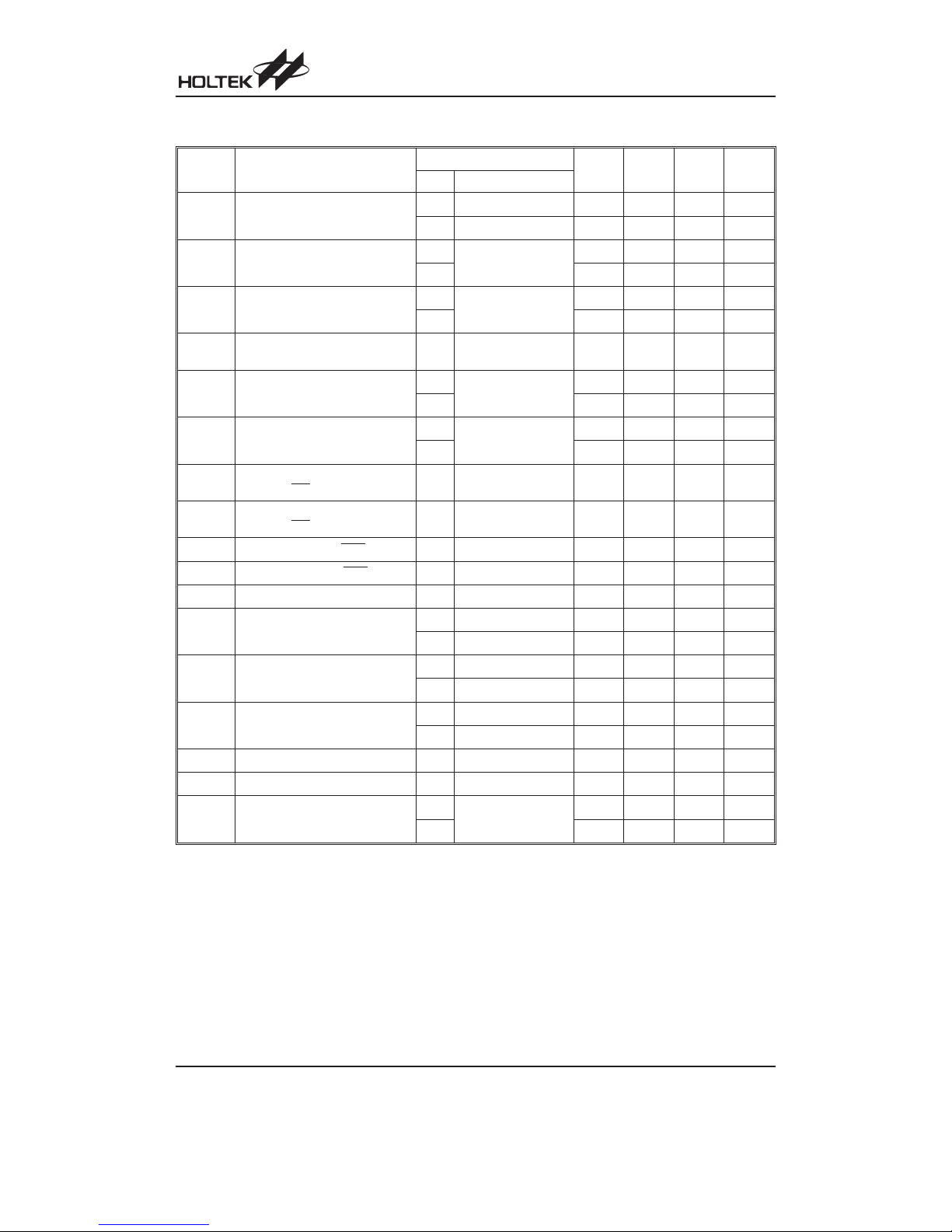

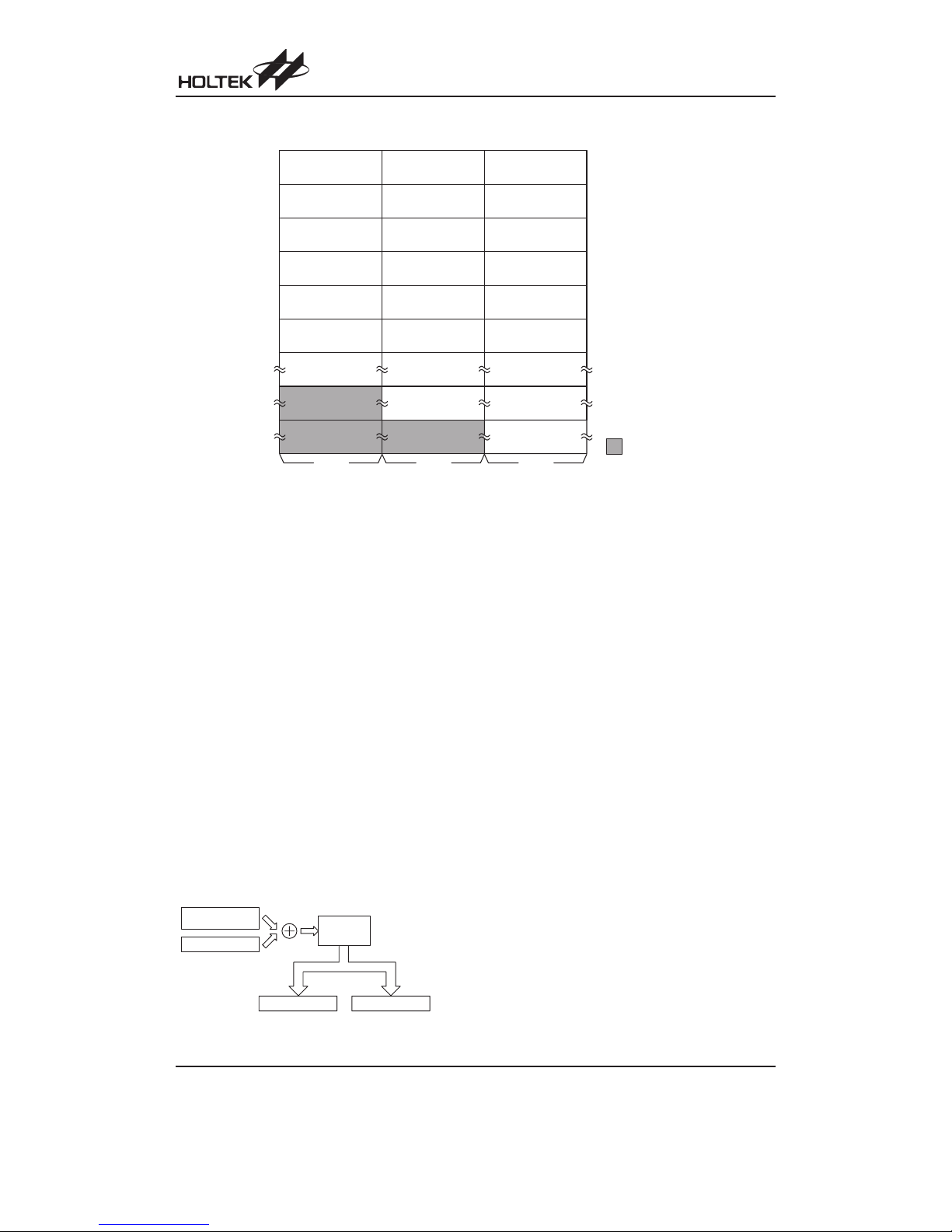

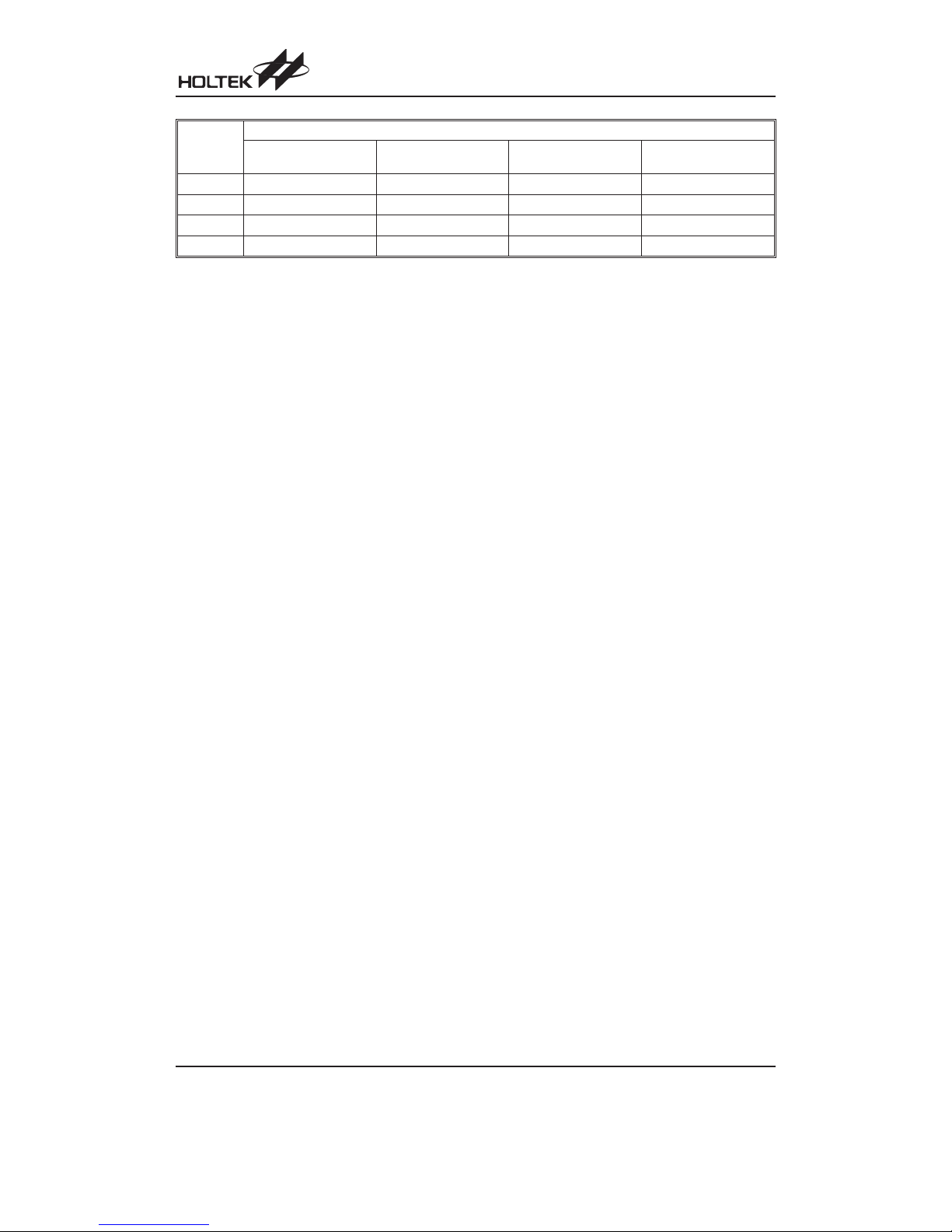

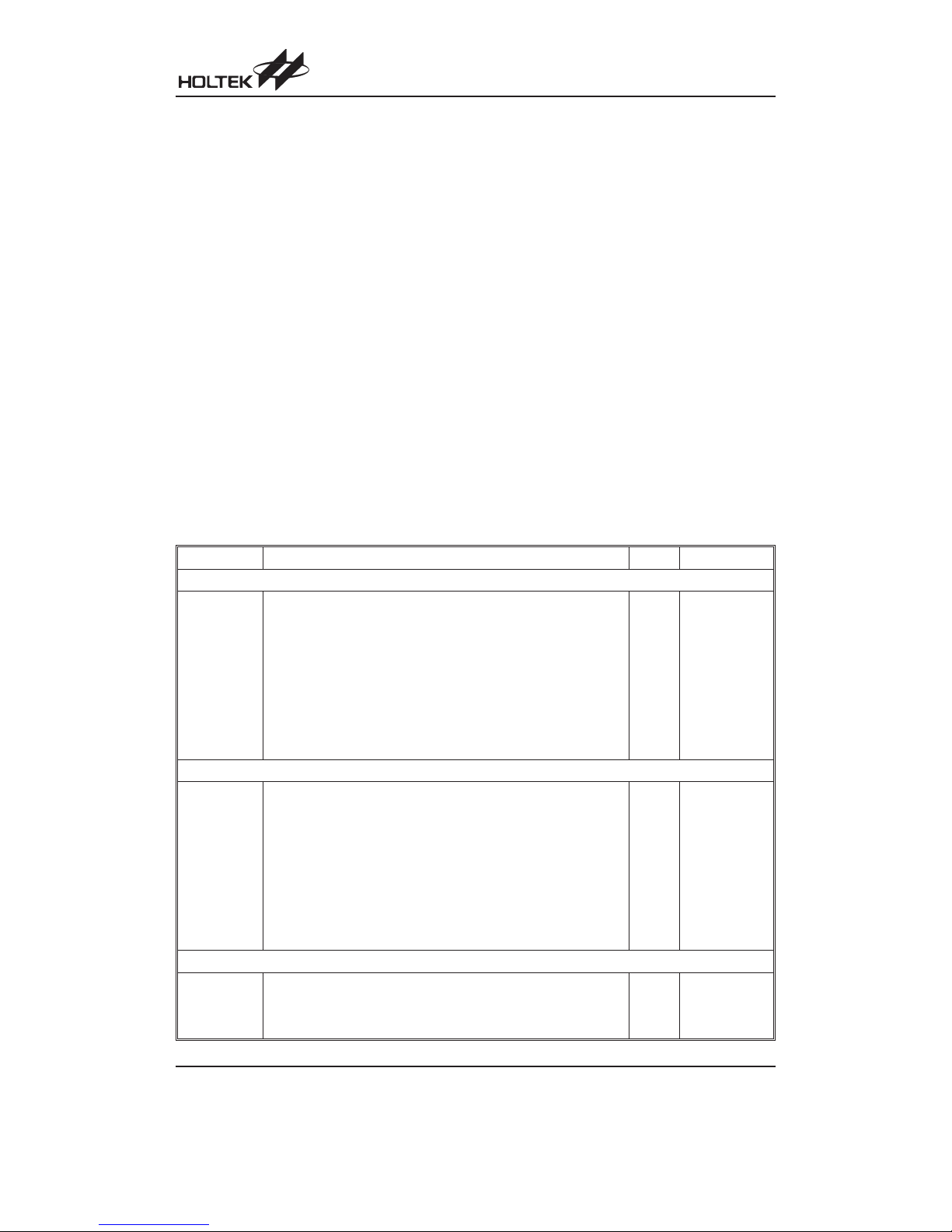

Part No. VDD

Program

Memory

Data

Memory

I/O Timer Int. A/D PWM Stack Package Types

HT46R46

HT46C46

2.2V~

5.5V

1K´14 64´8

13

8-bit´1

3

8-bit´4 8-bit´1

4

16NSOP, 18DIP/SOP,

20SSOP

HT46R47

HT46C47

2.2V~

5.5V

2K´14 64´8

13

8-bit´1

3

9-bit´4 8-bit´1

6

16NSOP, 18DIP/SOP,

20SSOP

HT46R48A

HT46C48A

2.2V~

5.5V

2K´14 88´8

19

8-bit´1

3

9-bit´4 8-bit´1

6

20DIP/SOP,

24SKDIP/SOP/SSOP

HT46R49

2.2V~

5.5V

4K´15 128´8

23

8-bit´1

3

9-bit´4 8-bit´2

6

20DIP/SOP,

24/28SKDIP/SOP

Note:

Part numbers including ²C² are mask version devices, ²R² are OTP devices.

For devices that exist in two package formats, the table reflects the situation for the larger package.

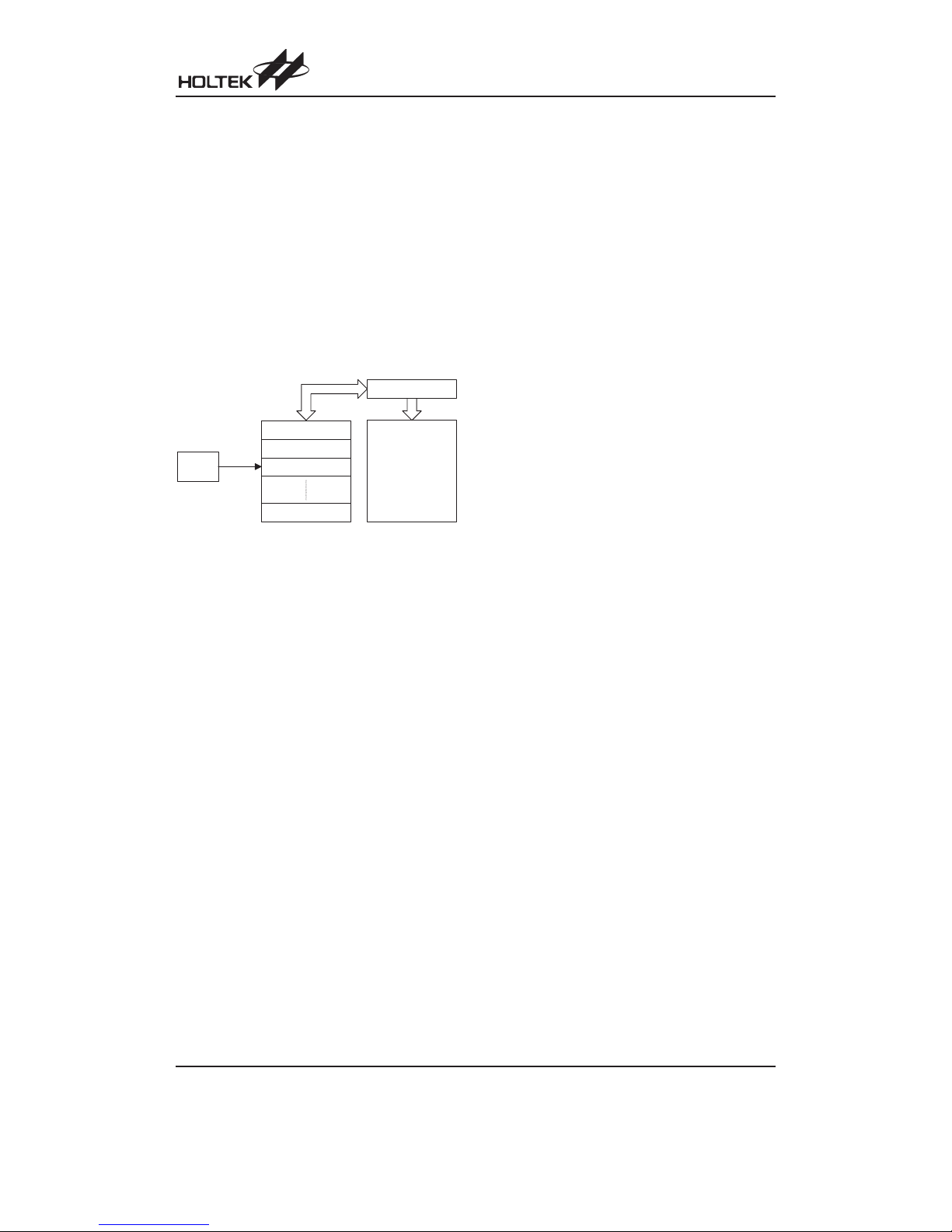

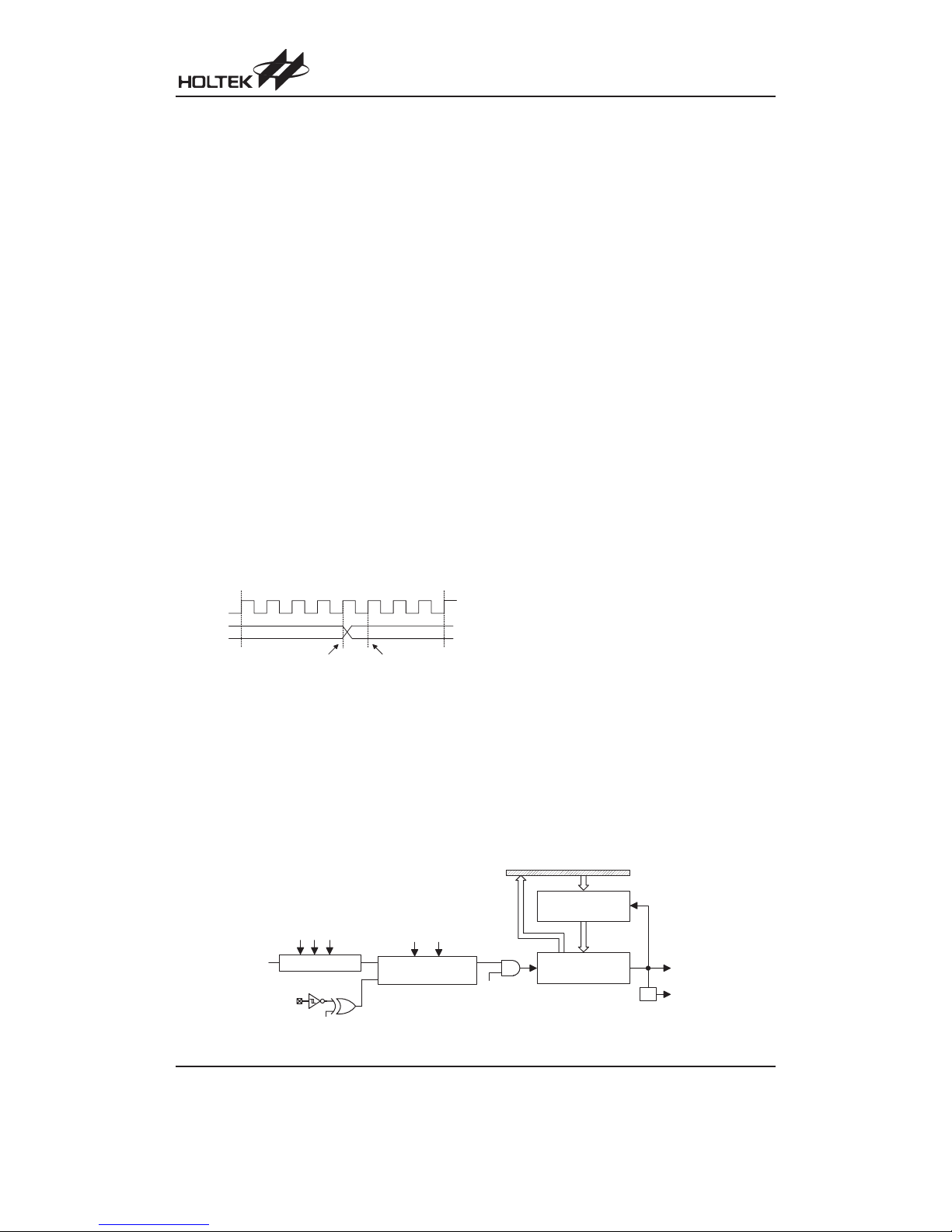

Block Diagram

Note: This block diagram represents the OTP devices, for the mask devices there is no Device Programming

Circuitry.

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 2 December 30, 2008

T i m i n g

G e n e r a t o r

S y s t e m R C /

X ' t a l O s c i l l a t o r

I n s t r u c t i o n

D e c o d e r

I n s t r u c t i o n

R e g i s t e r

W D T

O s c i ll a t o r

D a t a

M e m o r y

A d d r e s s D e c o d e r

M e m o r y

P o i n t e r

M U X

A C C

L o o k - u p

T a b l e

R e g i s t e r

R e s e t &

L V R

C o n f i g .

R e g i s t e r

T i m e r /

C o u n t e r

C o n f i g .

R e g i s t e r

I n t e r r u p t

C i r c u i t

C o n f i g .

R e g i s t e r

I / O

P o r t s

D e v i c e

P r o g r a m m i n g

C i r c u i t r y

C o n f i g u r a t i o n

O p t i o n

P r o g r a m

M e m o r y

A d d r e s s D e c o d e r

S t a c k

S t a c k P o i n t e r

P r o g r a m

C o u n t e r

L o o k - u p

T a b l e

P o i n t e r

T o P r o g r a m

M e m o r y

A L U

S h i f t e r

M

U

X

C o n f i g .

R e g i s t e r

P W M

P F D

A / D

C o n v e r t e r

Device Types

Devices which have the letter ²R² within their part number, indicate that they are OTP devices offering the advantages

of easy and effective program updates, using the Holtek range of development and programming tools. These devices

provide the designer with the means for fast and low-cost product development cycles. Devices which have the letter

²C² within their part number indicate that they are mask version devices. These devices offer a complementary device

for applications that are at a mature state in their design process and have high volume and low cost demands.

Fully pin and functionally compatible with their OTP sister devices, the mask version devices provide the ideal substi

-

tute for products which have gone beyond their development cycle and are facing cost-down demands.

In this datasheet, for convenience, when describing device functions, only the OTP types are mentioned by name,

however the same described functions also apply to the Mask type devices.

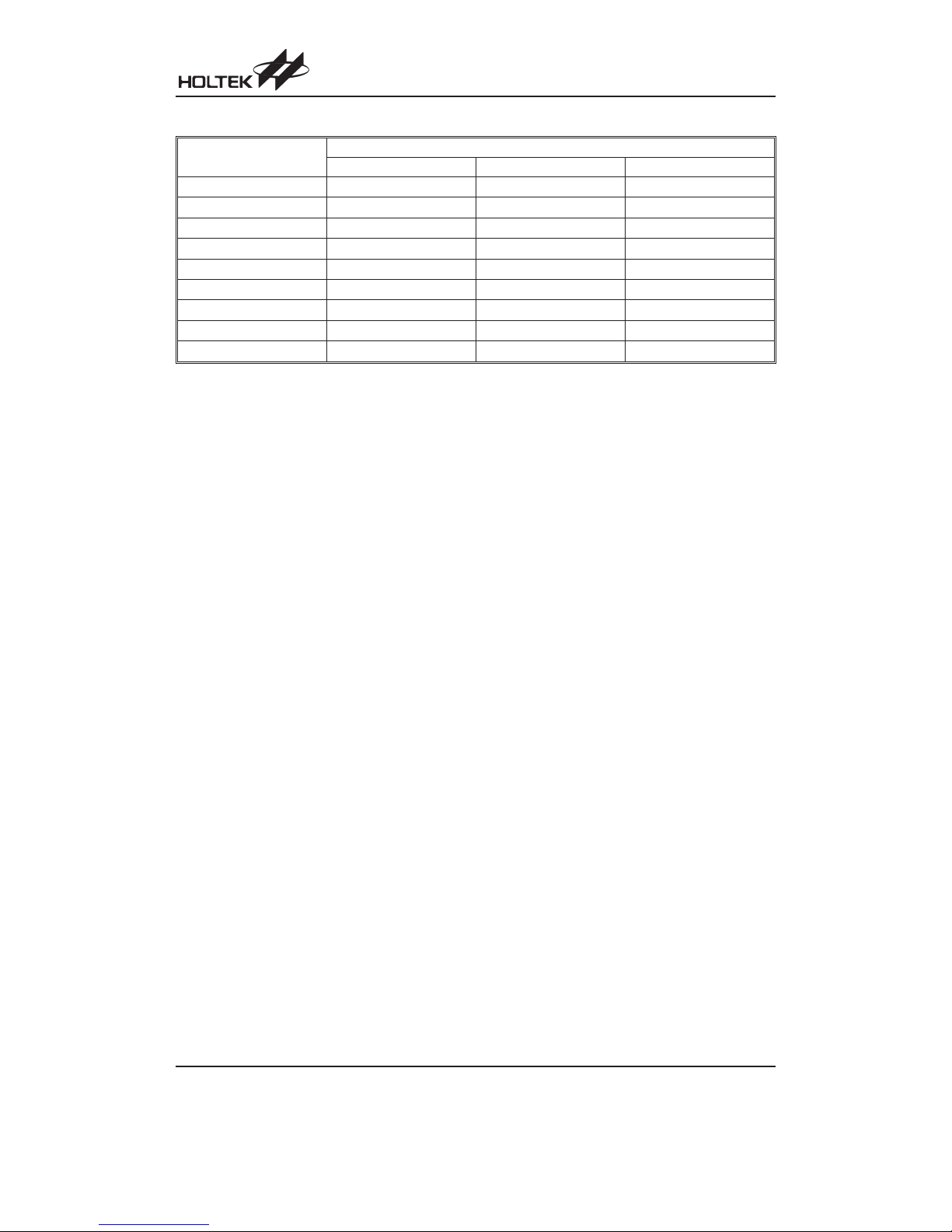

Selection Table

Most features are common to all devices, the main feature distinguishing them are Program Memory capacity, I/O

count, A/Dresolution, stack capacityand package types.The following table summarises the main features of each de

-

vice.

Page 3

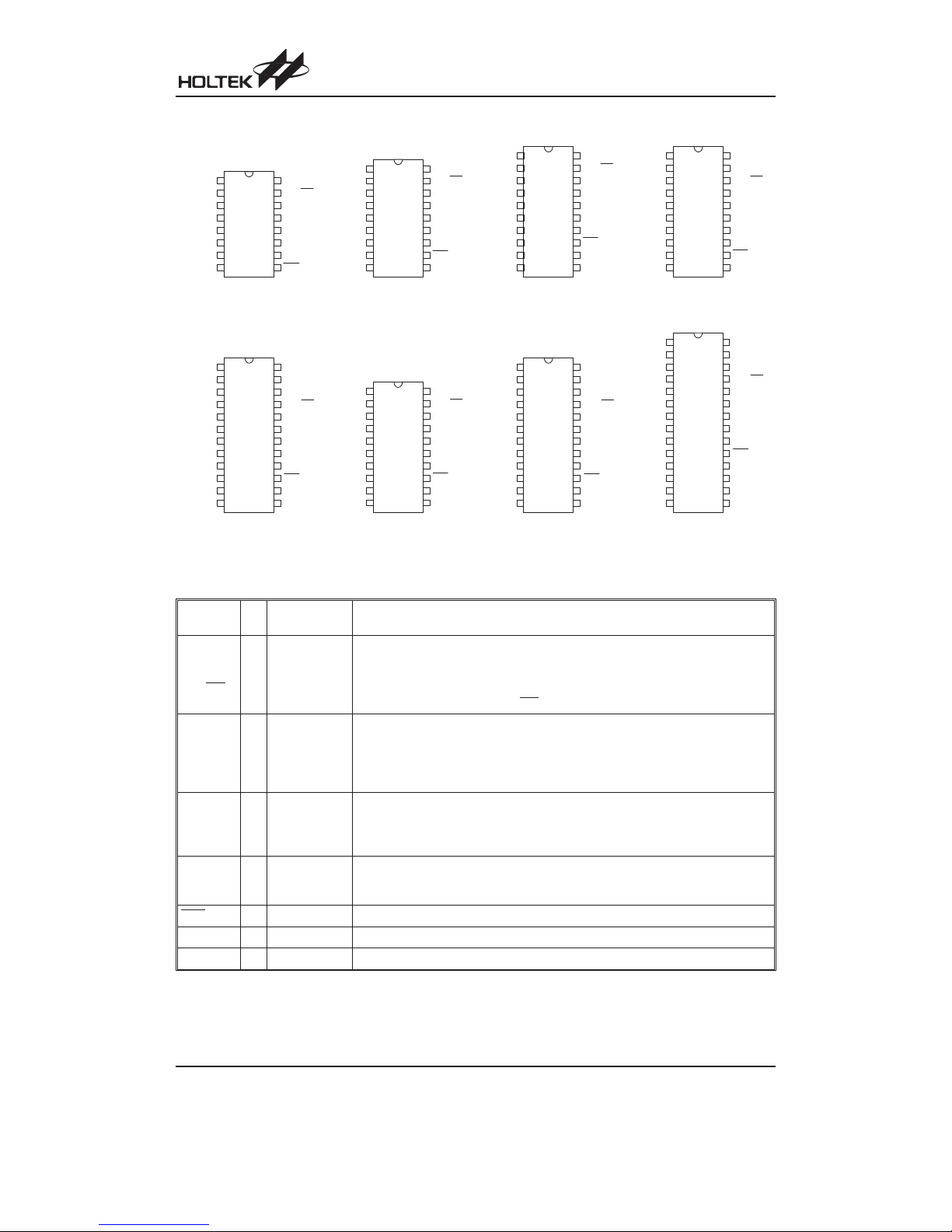

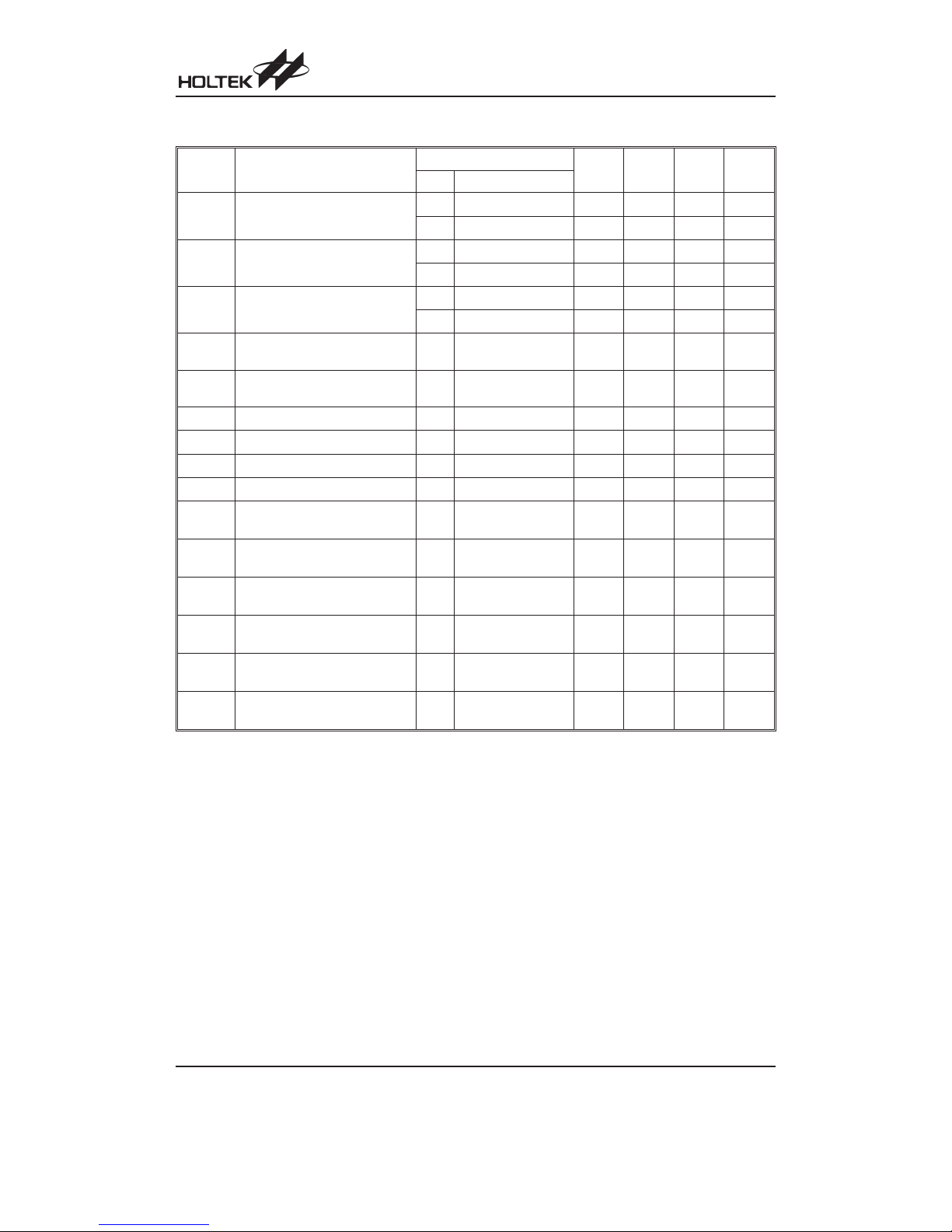

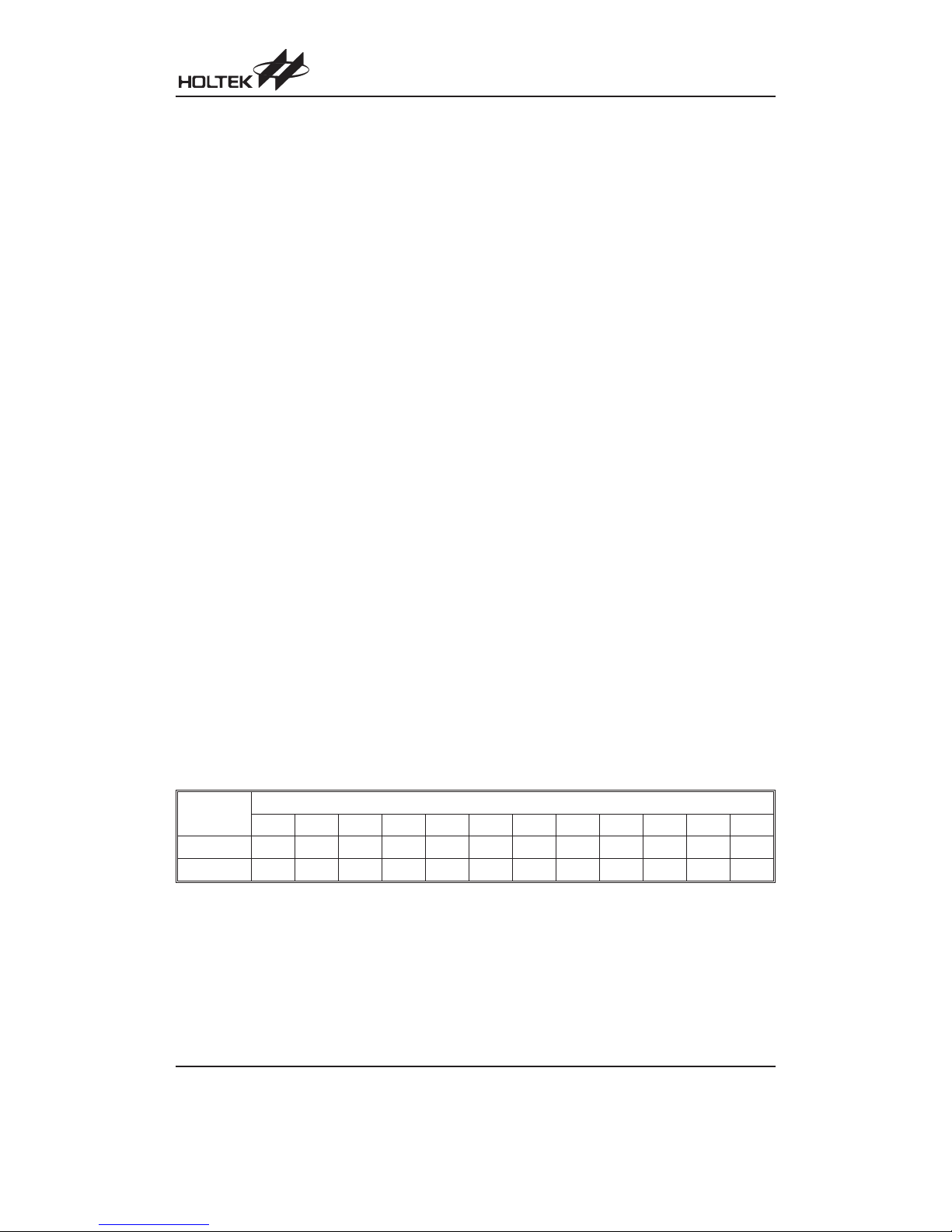

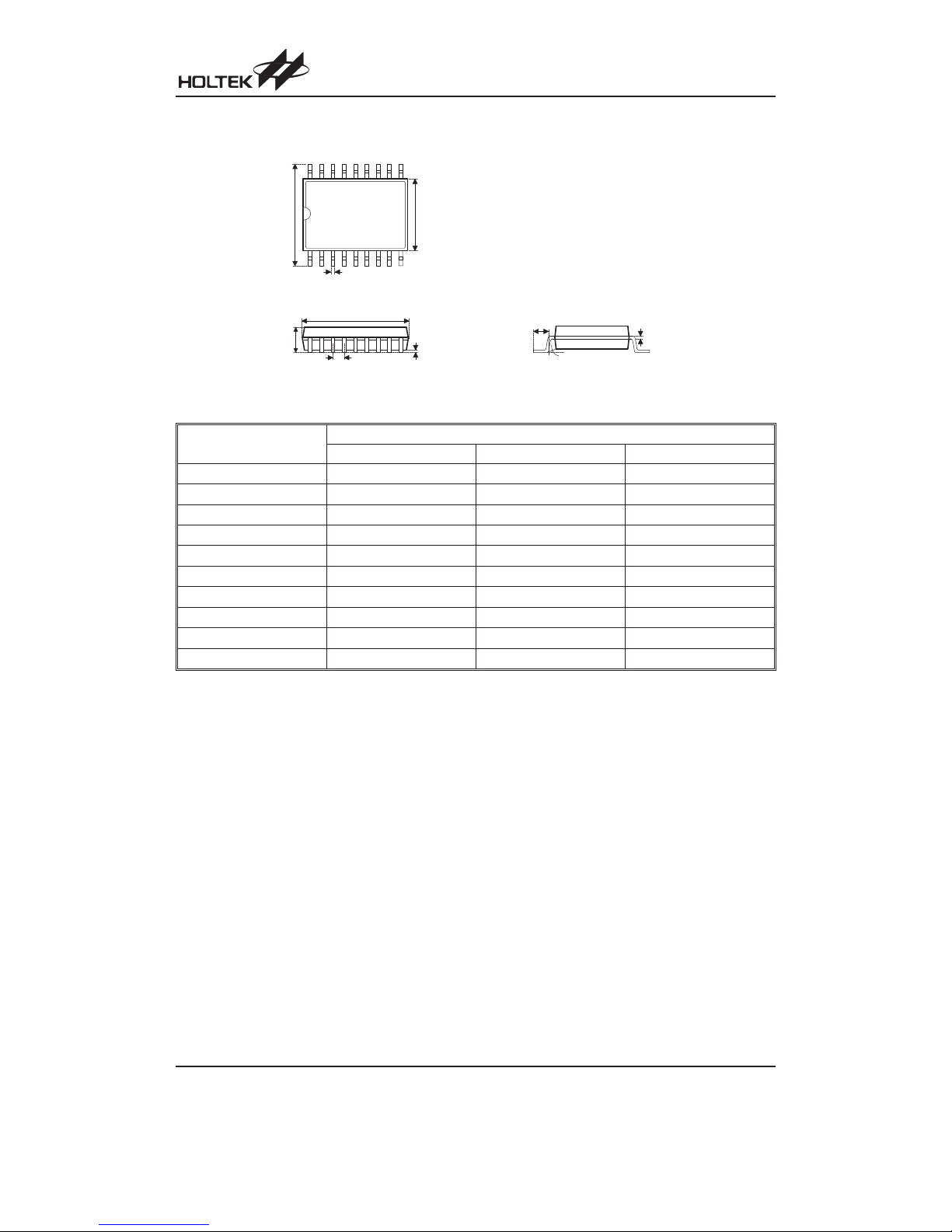

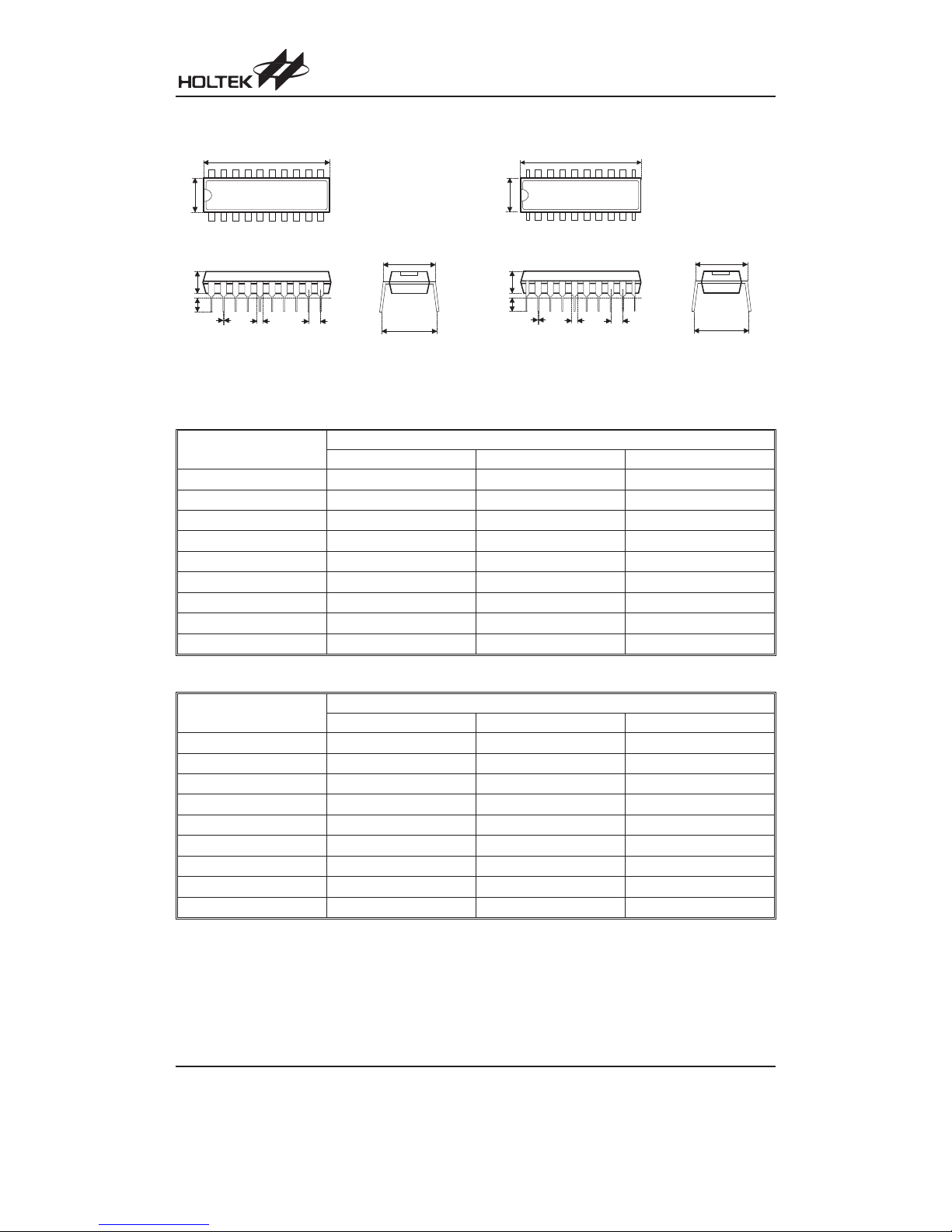

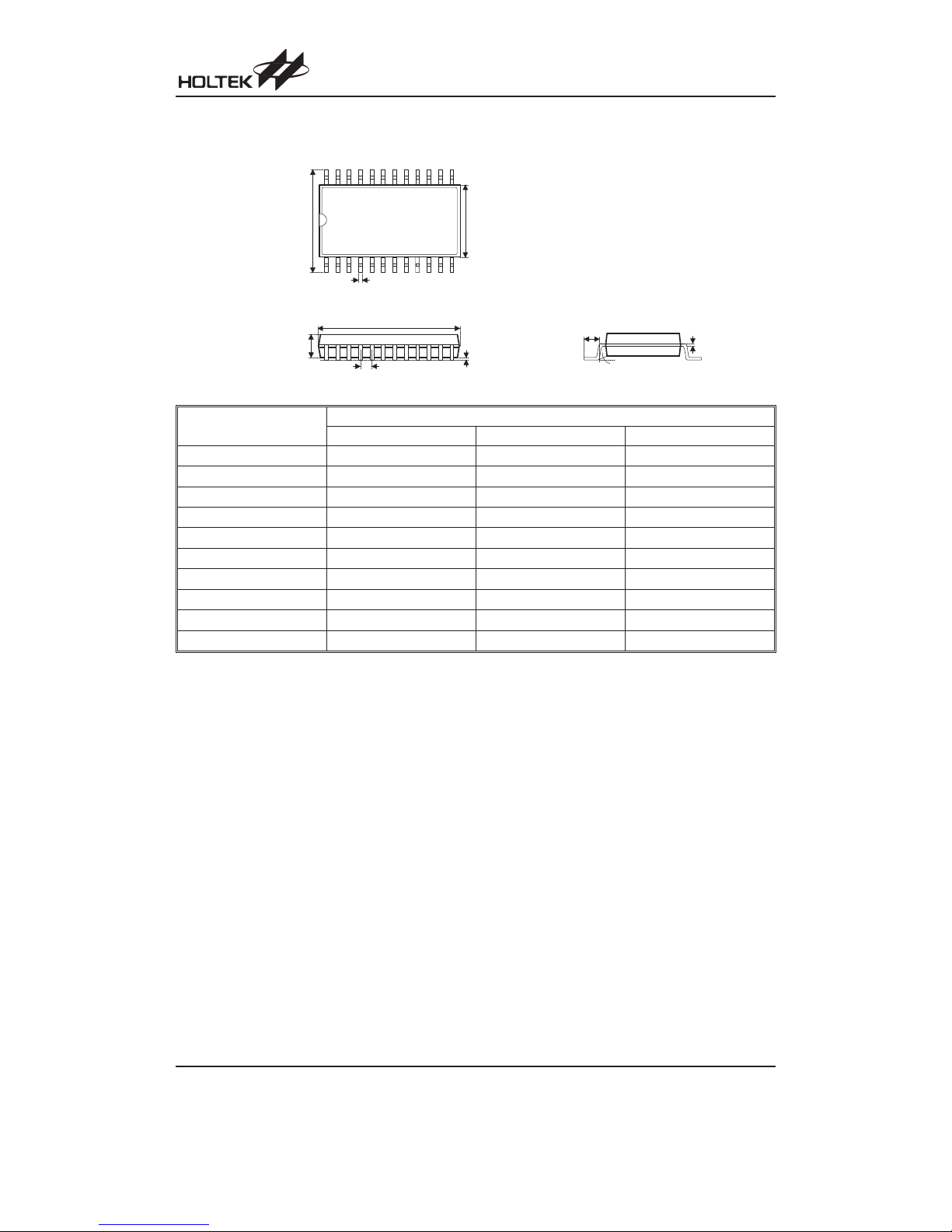

Pin Assignment

Pin Description

HT46R46, HT46R47

Pin Name I/O

Configuration

Option

Description

PA0~PA2

PA3/PFD

PA4/TMR

PA5/INT

PA6~PA7

I/O

Pull-high

Wake-up

PA3 or

PFD

Bidirectional 8-bit input/output port. Each individual pin on this port can be configured as a wake-up input by a configuration option. Software instructions determine

if the pin is a CMOS output or Schmitt Trigger input. Configuration options determine which pins on the port have pull-high resistors. Pins PA3, PA4 and PA5 are

pin-shared with PFD, TMR and INT

, respectively.

PB0/AN0

PB1/AN1

PB2/AN2

PB3/AN3

I/O Pull-high

Bidirectional 4-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration options determine which pins

on the port have pull-high resistors. PB is pin-shared with the A/D input pins. The

A/D inputs are selected via software instructions. Once selected as an A/D input,

the I/O function and pull-high resistor options are disabled automatically.

PD0/PWM I/O

Pull-high

PD0 or

PWM

Bidirectional 1-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input.

A configuration option determines if this pin has a pull-high resistor. The PWM out

-

put is pin-shared with pin PD0 selected via a configuration option.

OSC1

OSC2

I

O

Crystal

or RC

OSC1, OSC2 are connected to an external RC network or external crystal, deter

-

mined by configuration option, for the internalsystem clock. If the RC system clock op

-

tion is selected, pin OSC2 can beused to measure the system clock at 1/4frequency.

RES I

¾

Schmitt Trigger reset input. Active low.

VDD

¾¾

Positive power supply

VSS

¾¾

Negative power supply, ground

Note: 1. Each pin on PA can be programmed through a configuration option to have a wake-up function.

2. Individual pins can be selected to have a pull-high resistor.

3. Pins PB2/AN2~PB3/AN3 exist but are not bonded out on the 16-pin package.

4. unbonded pins should be setup as outputs or as inputs with pull-high resistors to conserve power.

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 3 December 30, 2008

H T 4 6 R 4 6 / H T 4 6 C 4 6

H T 4 6 R 4 7 / H T 4 6 C 4 7

2 0 S S O P - A

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 0 / P W M

N C

2 0

1 9

1 8

1 7

1 6

1 5

1 4

1 3

1 2

1 1

1

2

3

4

5

6

7

8

9

1 0

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

N C

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

H T 4 6 R 4 6 / H T 4 6 C 4 6

H T 4 6 R 4 7 / H T 4 6 C 4 7

1 8 D I P - A / S O P - A

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 0 / P W M

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

1 8

1 7

1 6

1 5

1 4

1 3

1 2

1 1

1 0

1

2

3

4

5

6

7

8

9

H T 4 6 R 4 8 A / H T 4 6 C 4 8 A

2 0 D I P - A / S O P - A

P B 5

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 0 / P W M

2 0

1 9

1 8

1 7

1 6

1 5

1 4

1 3

1 2

1 1

1

2

3

4

5

6

7

8

9

1 0

P B 4

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

H T 4 6 R 4 8 A / H T 4 6 C 4 8 A

2 4 S K D I P - A / S O P - A / S S O P - A

P B 5

P B 4

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

P C 0

P B 6

P B

7

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 0 / P W M

P C 1

2 4

2 3

2 2

2 1

2 0

1 9

1 8

1 7

1 6

1 5

1 4

1 3

1

2

3

4

5

6

7

8

9

1 0

1 1

1 2

H T 4 6 R 4 9

2 8 S K D I P - A / S O P - A

P B 6

P B 7

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 1 / P W M 1

P D 0 / P W M 0

P C 4

P C 3

2 8

2 7

2 6

2 5

2 4

2 3

2 2

2 1

2 0

1 9

1 8

1 7

1 6

1 5

1

2

3

4

5

6

7

8

9

1 0

1 1

1 2

1 3

1 4

P B 5

P B 4

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

P C 0

P C 1

P

C 2

P B 5

P B 4

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

P C 0

P B 6

P B 7

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 1 / P

W M 1

P D 0 / P W M 0

2 4

2 3

2 2

2 1

2 0

1 9

1 8

1 7

1 6

1 5

1 4

1 3

1

2

3

4

5

6

7

8

9

1 0

1 1

1 2

H T 4 6 R 4 9

2 4 S K D I P - B / S O P - B

H T 4 6 R 4 6 / H T 4 6 C 4 6

H T 4 6 R 4 7 / H T 4 6 C 4 7

1 6 N S O P - A

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P A 3 / P F D

P A 2

P A 1

P A 0

P B 1 / A N 1

P B 0 / A N 0

V S S

1 6

1 5

1 4

1 3

1 2

1 1

1 0

9

1

2

3

4

5

6

7

8

P D 0 / P W M

H T 4 6 R 4 9

2 0 D I P - A / S O P - A

P A 4 / T M R

P A 5 / I N T

P A 6

P A 7

O S C 2

O S C 1

V D D

R E S

P D 1 / P W M 1

P D 0 / P W M 0

2 0

1 9

1 8

1 7

1 6

1 5

1 4

1 3

1 2

1 1

1

2

3

4

5

6

7

8

9

1 0

P A 3 / P F D

P A 2

P A 1

P A 0

P B 3 / A N 3

P B 2 / A N 2

P B 1 / A N 1

P B 0 / A N 0

V S S

P C 0

Page 4

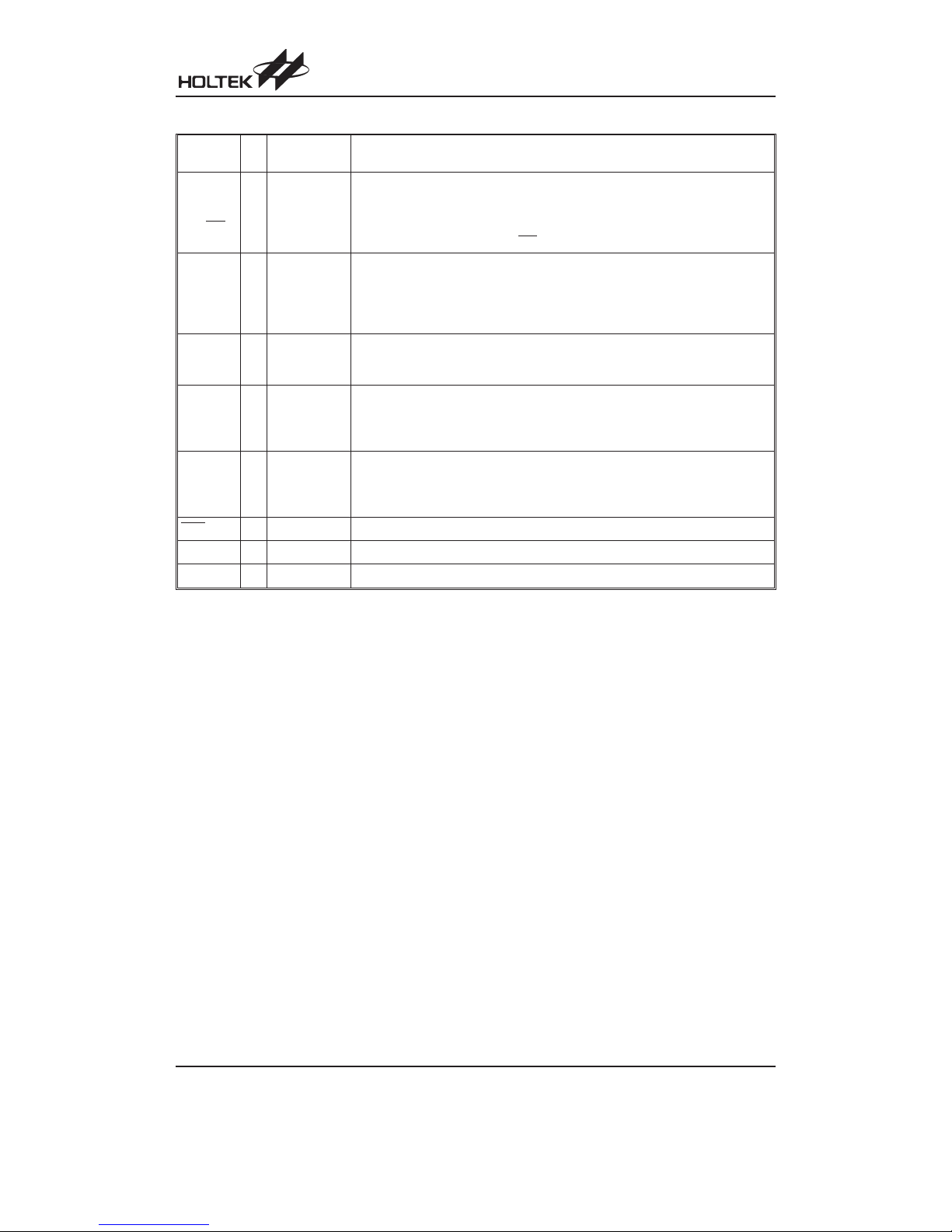

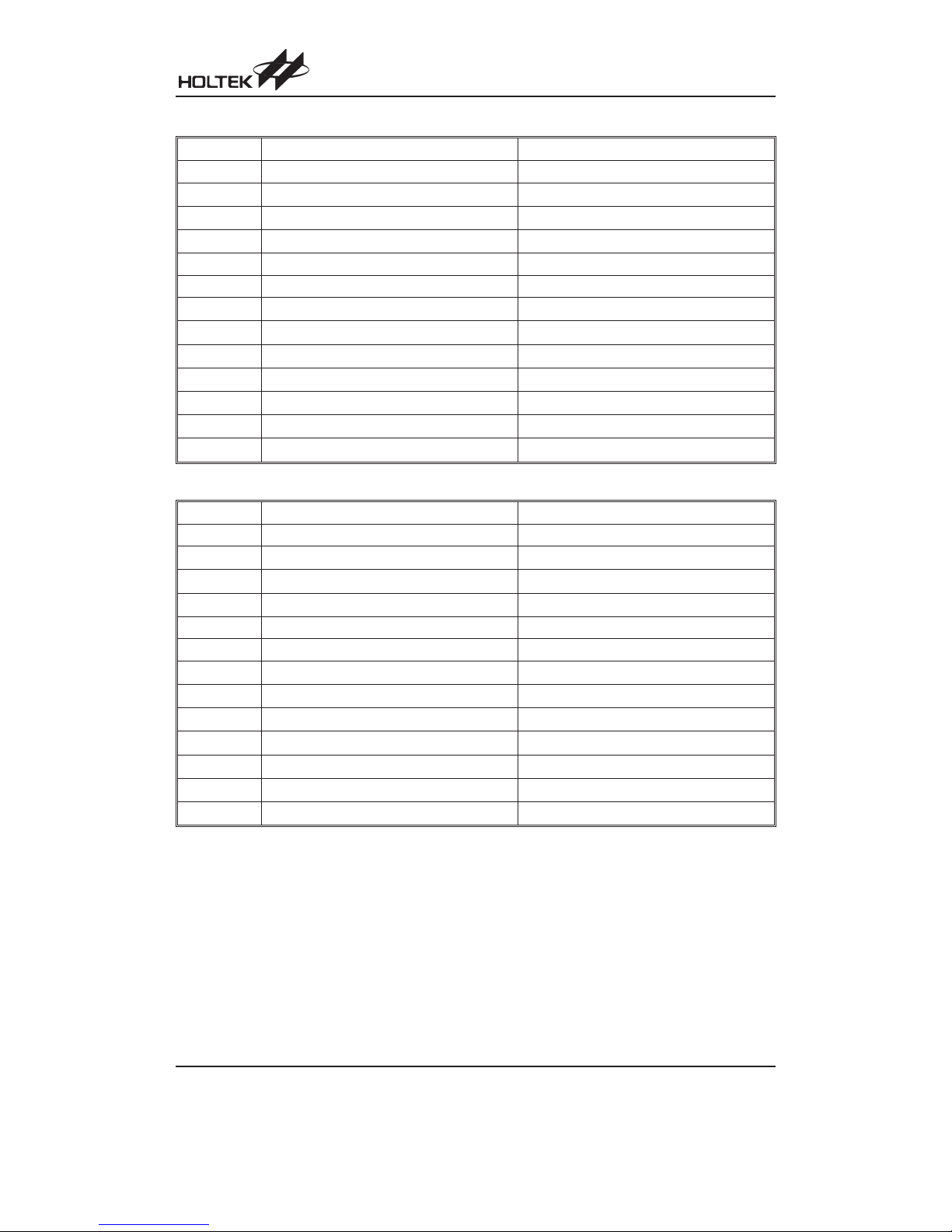

HT46R48A

Pin Name I/O

Configuration

Option

Description

PA0~PA2

PA3/PFD

PA4/TMR

PA5/INT

PA6~PA7

I/O

Pull-high

Wake-up

PA3 or PFD

Bidirectional 8-bit input/output port. Each individual pin on this port can be config

ured as a wake-up input by a configuration option. Software instructions determine

if the pin is a CMOS output or Schmitt Trigger input. Configuration options deter

mine which pins on the port have pull-high resistors. Pins PA3, PA4 and PA5 are

pin-shared with PFD, TMR and INT

, respectively.

PB0/AN0

PB1/AN1

PB2/AN2

PB3/AN3

PB4~PB7

I/O Pull-high

Bidirectional 8-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration options determine which pins

on the port have pull-high resistors. PB is pin-shared with the A/D input pins. The

A/D inputs are selected via software instructions. Once selected as an A/D input,

the I/O function and pull-high resistor options are disabled automatically.

PC0~PC1 I/O Pull-high

Bidirectional 2-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration options determine which pins

on the port have pull-high resistors.

PD0/PWM I/O

Pull-high

I/O or PWM

Bidirectional 1-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration option determines if this pin

has a pull-high resistor. The PWM output is pin-shared with pin PD0 selected via a

configuration option.

OSC1

OSC2

I

O

Crystal or RC

OSC1, OSC2 are connected to an external RC network or external crystal, deter

mined by configuration option, for the internal system clock. If the RC system clock

option is selected, pin OSC2 can be used to measure the system clock at 1/4 fre

quency.

RES I

¾

Schmitt Trigger reset input. Active low.

VDD

¾¾

Positive power supply

VSS

¾¾

Negative power supply, ground

Note: 1. Each pin on PA can be programmed through a configuration option to have a wake-up function.

2. Individual pins can be selected to have a pull-high resistor.

3. Pins PB4~PB7 exist but are not bonded out on the 20-pin package.

4. Unbonded pins should be setup as outputs or as inputs with pull-high resistors to conserve power.

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 4 December 30, 2008

Page 5

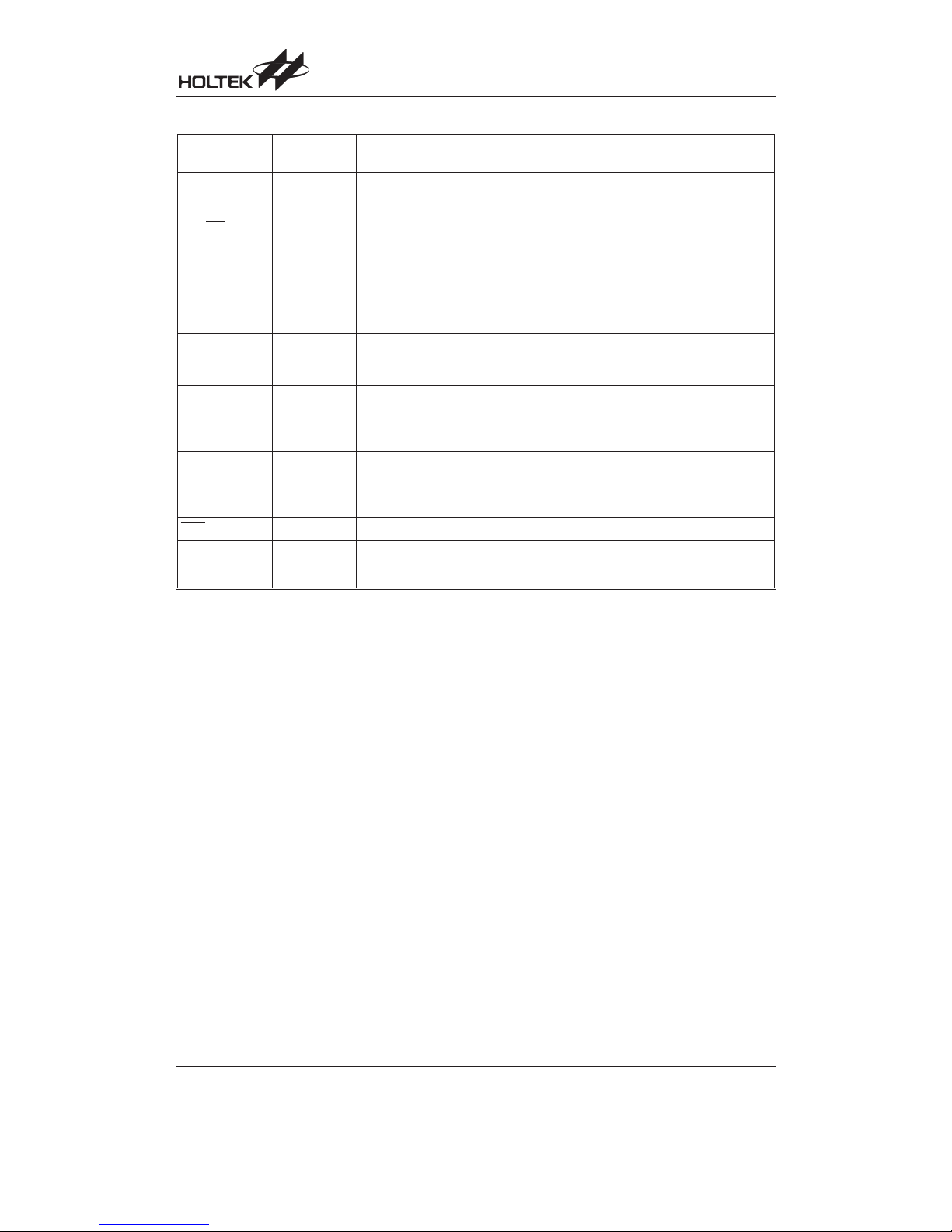

HT46R49

Pin Name I/O

Configuration

Option

Description

PA0~PA2

PA3/PFD

PA4/TMR

PA5/INT

PA6~PA7

I/O

Pull-high

Wake-up

PA3 or PFD

Bidirectional 8-bit input/output port. Each individual pin on this port can be config

-

ured as a wake-up input by a configuration option. Software instructions deter

-

mine if the pin is a CMOS output or Schmitt Trigger input. Configuration options

determine which pins on the port have pull-high resistors. Pins PA3, PA4 and PA5

are pin-shared with PFD, TMR and INT

, respectively.

PB0/AN0

PB1/AN1

PB2/AN2

PB3/AN3

PB4~PB7

I/O Pull-high

Bidirectional 8-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration options determine which

pins on the port have pull-high resistors. PB is pin-shared with the A/D input pins.

The A/D inputs are selected via software instructions. Once selected as an A/D in

-

put, the I/O function and pull-high resistor options are disabled automatically.

PC0~PC4 I/O Pull-high

Bidirectional 5-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration options determine which

pins on the port have pull-high resistors.

PD0/PWM0

PD1/PWM1

I/O

Pull-high

I/O or PWM

Bidirectional 2-bit input/output port. Software instructions determine if the pin is a

CMOS output or Schmitt Trigger input. Configuration option determines if this pin

has a pull-high resistor. The PWM output are pin-shared with pins PD0 and PD1

selected via a configuration option.

OSC1

OSC2

I

O

Crystal or RC

OSC1, OSC2 are connected to an external RC network or external crystal, deter

-

mined by configuration option, for the internal system clock. If the RC system

clock option is selected, pin OSC2 can be used to measure the system clock at

1/4 frequency.

RES I

¾

Schmitt Trigger reset input. Active low.

VDD

¾¾

Positive power supply

VSS

¾¾

Negative power supply, ground

Note: 1. Each pin on PA can be programmed through a configuration option to have a wake-up function.

2. Individual pins can be selected to have a pull-high resistor.

3. Pins PC1~PC4 exist but are not bonded out on the 20-pin and 24-pin package.

Pins PB4~PB7 exist but are not bonded out on the 20-pin package.

4. Unbonded pins should be setup as outputs or as inputs with pull-high resistors to conserve power.

Absolute Maximum Ratings

Supply Voltage...........................VSS-0.3V to VSS+6.0V

Storage Temperature ............................-50°Cto125°C

Input Voltage..............................V

SS

-0.3V to VDD+0.3V

Operating Temperature...........................-40°Cto85°C

I

OL

Total ..............................................................150mA

I

OH

Total............................................................-100mA

Total Power Dissipation .....................................500mW

Note: These are stress ratings only. Stresses exceeding the range specified under ²Absolute Maximum Ratings² may

cause substantial damage to the device. Functional operation of this device at other conditions beyond those listed

in the specification is not implied and prolonged exposure to extreme conditions may affect device reliability.

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 5 December 30, 2008

Page 6

D.C. Characteristics

Ta=25°C

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

V

DD

Operating Voltage

¾

f

SYS

=4MHz

2.2

¾

5.5 V

¾

f

SYS

=8MHz

3.3

¾

5.5 V

I

DD1

Operating Current

(Crystal OSC)

3V

No load, f

SYS

=4MHz

ADC disable

¾

0.6 1.5 mA

5V

¾

24mA

I

DD2

Operating Current

(RC OSC)

3V

No load, f

SYS

=4MHz

ADC disable

¾

0.8 1.5 mA

5V

¾

2.5 4 mA

I

DD3

Operating Current

(Crystal OSC, RC OSC)

5V

No load, f

SYS

=8MHz

ADC disable

¾

48mA

I

STB1

Standby Current

(WDT Enabled)

3V

No load,

system HALT

¾¾

5

mA

5V

¾¾

10

mA

I

STB2

Standby Current

(WDT Disabled)

3V

No load,

system HALT

¾¾

1

mA

5V

¾¾

2

mA

V

IL1

Input Low Voltage for I/O Ports,

TMR and INT

¾¾

0

¾

0.3V

DD

V

V

IH1

Input High Voltage for I/O Ports,

TMR and INT

¾¾

0.7V

DD

¾

V

DD

V

V

IL2

Input Low Voltage (RES)

¾¾

0

¾

0.4V

DD

V

V

IH2

Input High Voltage (RES)

¾¾

0.9V

DD

¾

V

DD

V

V

LVR

Low Voltage Reset

¾¾

2.7 3.0 3.3 V

I

OL

I/O Port Sink Current

3V

V

OL

=0.1V

DD

48

¾

mA

5V

V

OL

=0.1V

DD

10 20

¾

mA

I

OH

I/O Port Source Current

3V

V

OH

=0.9V

DD

-2 -4 ¾

mA

5V

V

OH

=0.9V

DD

-5 -10 ¾

mA

R

PH

Pull-high Resistance

3V

¾

20 60 100

kW

5V

¾

10 30 50

kW

V

AD

A/D Input Voltage

¾¾

0

¾

V

DD

V

E

AD

A/D Conversion Error

¾¾ ¾±0.5 ±1

LSB

I

ADC

Additional Power Consumption

if A/D Converter is Used

3V

¾

¾

0.5 1 mA

5V

¾

1.5 3 mA

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 6 December 30, 2008

Page 7

A.C. Characteristics

Ta=25°C

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

f

SYS

System Clock

¾

2.2V~5.5V 400

¾

4000 kHz

¾

3.3V~5.5V 400

¾

8000 kHz

f

TIMER

Timer I/P Frequency

(TMR)

¾

2.2V~5.5V 0

¾

4000 kHz

¾

3.3V~5.5V 0

¾

8000 kHz

t

WDTOSC

Watchdog Oscillator Period

3V

¾

45 90 180

ms

5V

¾

32 65 130

ms

t

WDT1

Watchdog Time-out Period

(RC)

¾¾

2

15

¾

2

16

t

WDTOSC

t

WDT2

Watchdog Time-out Period

(System Clock)

¾¾

2

17

¾

2

18

t

SYS

t

RES

External Reset Low Pulse Width

¾¾

1

¾¾ms

t

SST

System Start-up Timer Period

¾

Wake-up from HALT

¾

1024

¾

*t

SYS

t

LVR

Low Voltage Reset Time

¾¾

0.25 1 2 ms

t

INT

Interrupt Pulse Width

¾¾

1

¾¾ms

t

AD1

A/D Clock Period HT46R46

¾¾

0.5

¾¾ms

t

AD2

A/D Clock Period HT46R47/HT46R48A/HT46R49

¾¾

1

¾¾ms

t

ADC1

A/D Conversion Time HT46R46

¾¾ ¾64¾

t

AD1

t

ADC2

A/D Conversion Time HT46R47/HT46R48A/HT46R49

¾¾ ¾76¾

t

AD2

t

ADCS1

A/D Sampling Time HT46R46

¾¾ ¾32¾

t

AD1

t

ADCS2

A/D Sampling Time HT46R47/HT46R48A/HT46R49

¾¾ ¾32¾

t

AD2

Note: *t

SYS

=1/f

SYS

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 7 December 30, 2008

Page 8

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 8 December 30, 2008

System Architecture

A key factor in the high-performance features of the

Holtek range of Cost-Effective A/D Type

microcontrollers is attributed to the internal system ar

chitecture. The range of devices take advantage of the

usual features found within RISC microcontrollers pro

viding increased speed of operation and enhanced per

formance. The pipelining scheme is implemented in

such a way that instruction fetching and instruction exe

cution are overlapped, hence instructions are effectively

executed in one cycle, with the exception of branch or

call instructions. An 8-bit wide ALU is used in practically

all operations of the instruction set. It carries out arith

metic operations, logic operations, rotation, increment,

decrement, branch decisions, etc. The internal data

path is simplified by moving data through the Accumula

tor and the ALU. Certain internal registers are imple

mented in the Data Memory and can be directly or

indirectly addressed. The simple addressing methods of

these registers along with additional architectural fea

tures ensure that a minimum of external components is

required to provide a functional I/O and A/D control sys

tem with maximum reliability and flexibility. This makes

these devices suitable for low-cost, high-volume pro

duction for controller applications requiring from 1K up

to 4K words of Program Memory and 64 to 128 bytes of

Data Memory storage.

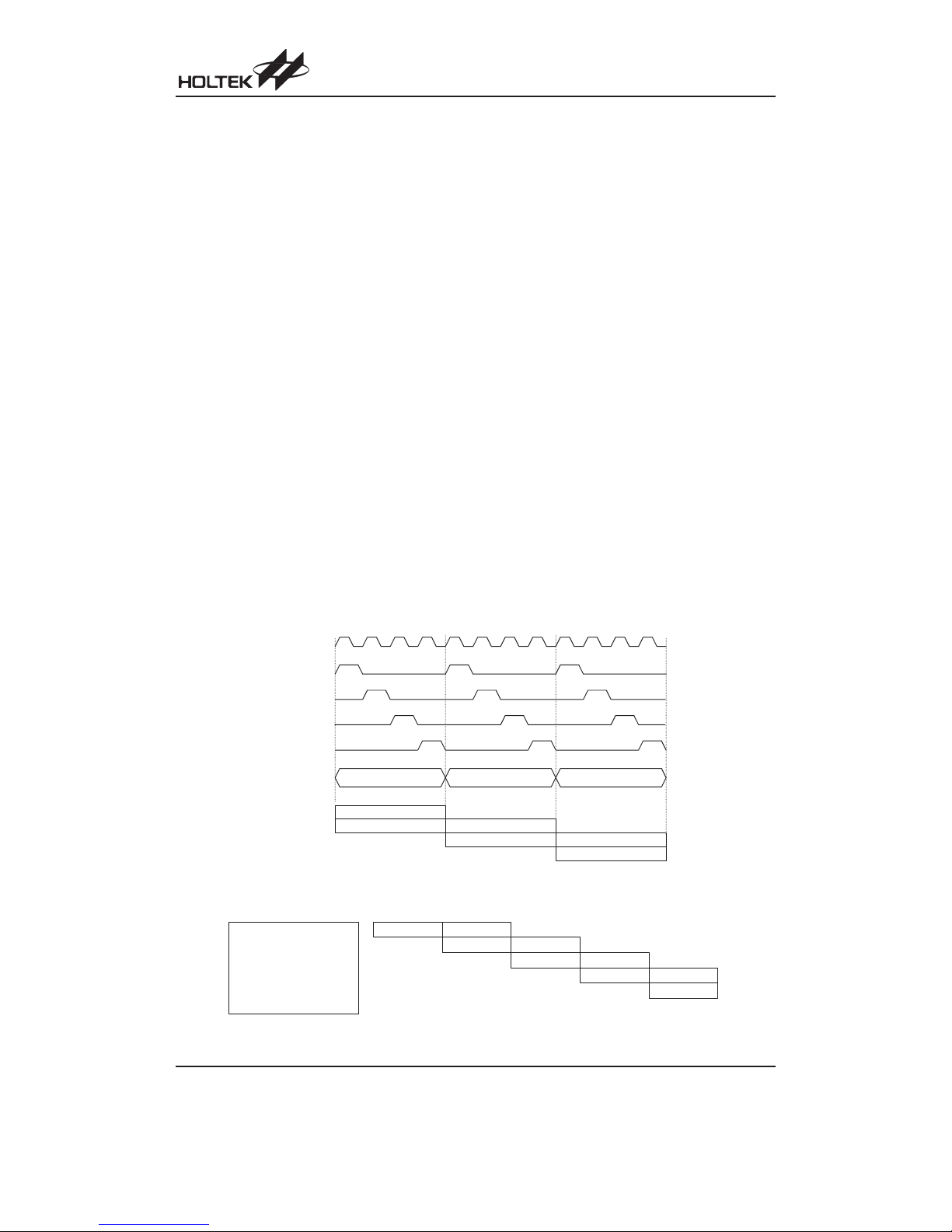

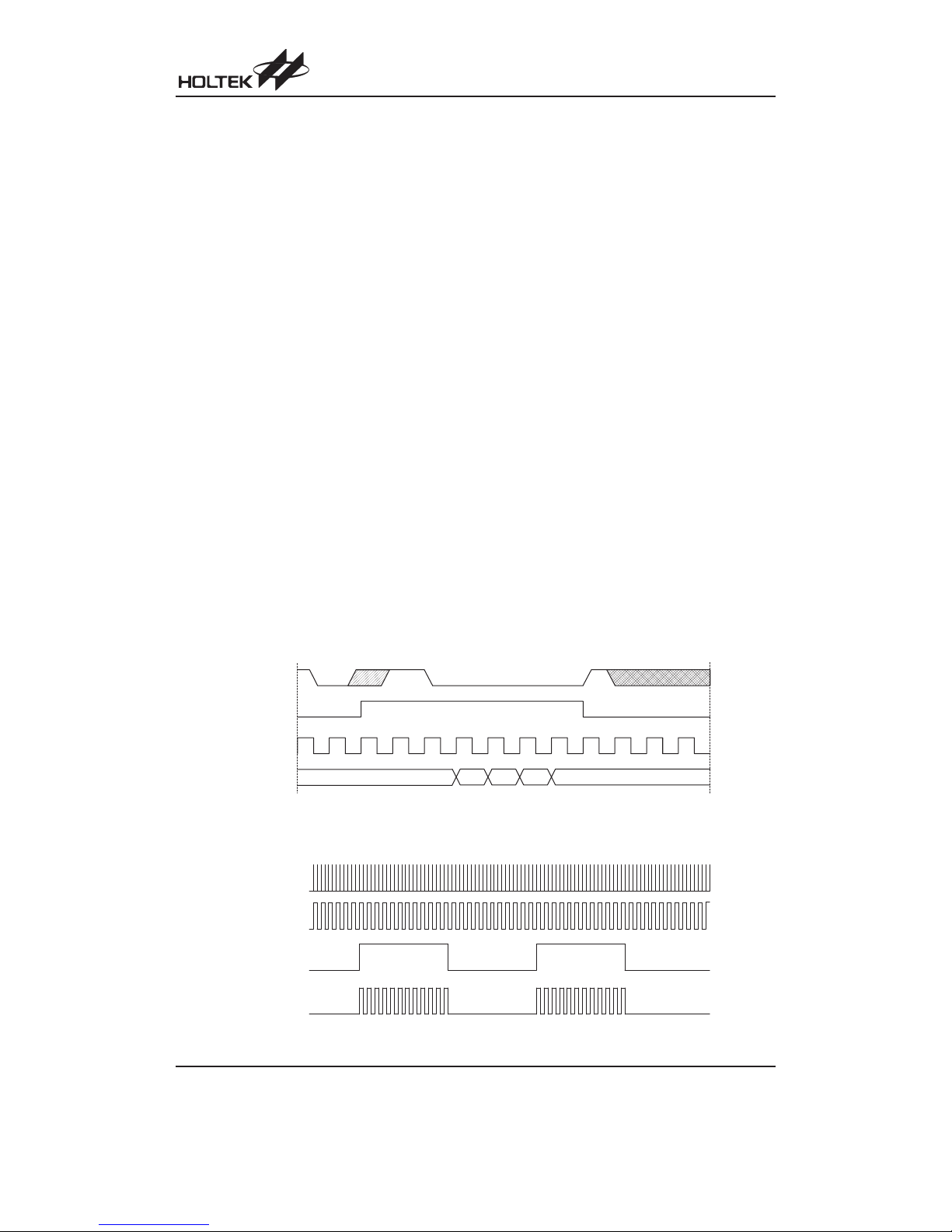

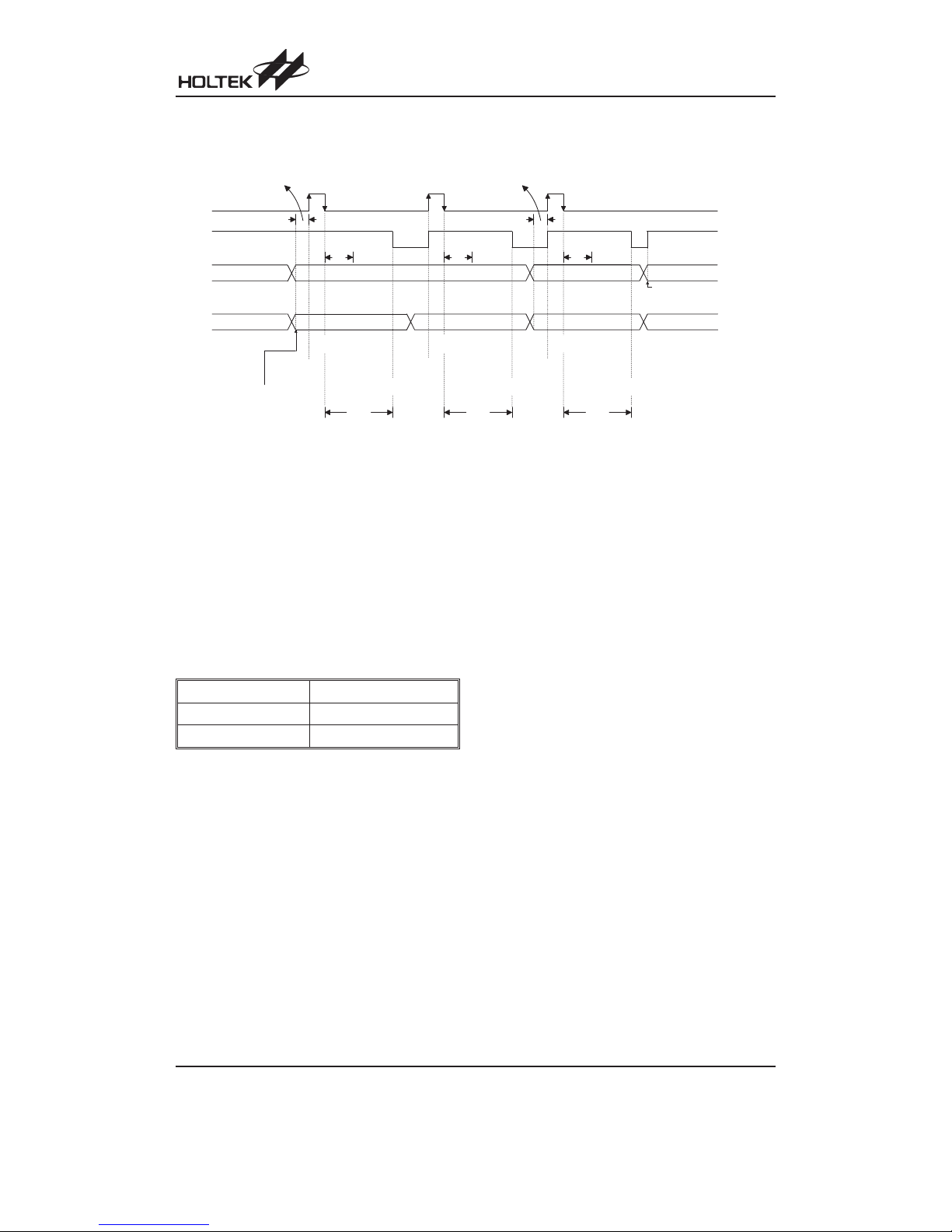

Clocking and Pipelining

The main system clock, derived from either a Crys

-

tal/Resonator or RC oscillator is subdivided into four in

ternally generated non-overlapping clocks, T1~T4. The

Program Counter is incremented at the beginning of the

T1 clock during which time a new instruction is fetched.

The remaining T2~T4 clocks carry out the decoding and

execution functions. In this way, one T1~T4 clock cycle

forms one instruction cycle. Although the fetching and

execution of instructions takes place in consecutive in

struction cycles, the pipelining structure of the

microcontroller ensures that instructions are effectively

executed in one instruction cycle. The exception to this

are instructions where the contents of the Program

Counter are changed, such as subroutine calls or

jumps, in which case the instruction will take one more

instruction cycle to execute.

When the RC oscillator is used, OSC2 is freed for use as

a T1 phase clock synchronizing pin. This T1 phase clock

has afrequency of f

SYS

/4 witha 1:3 high/low duty cycle.

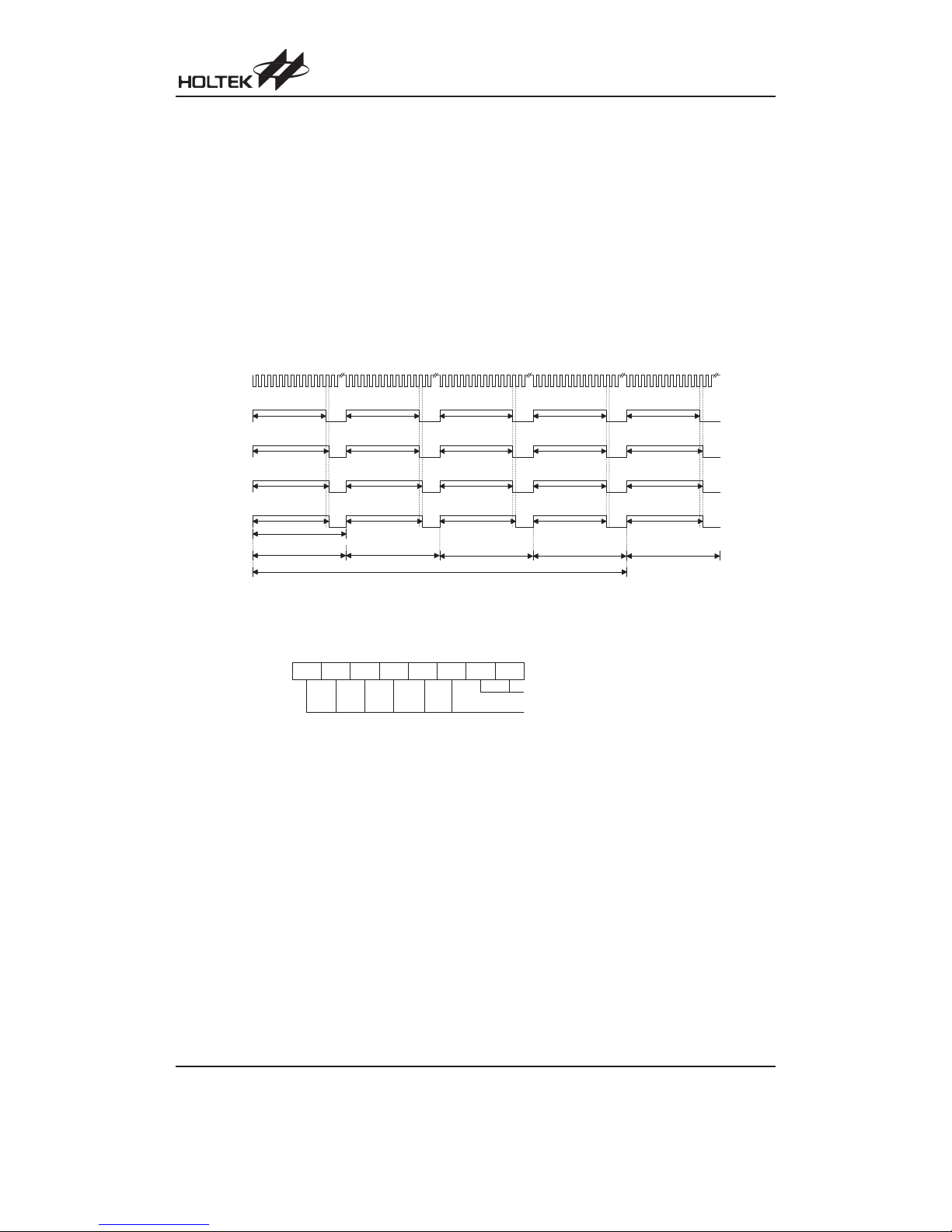

For instructions involving branches, such as jump or call

instructions, two machine cycles are required to com

plete instruction execution. An extra cycle is required as

the program takes one cycle to first obtain the actual

jump or call address and then another cycle to actually

execute the branch. The requirement for this extra cycle

should be taken into account by programmers in timing

sensitive applications

F e t c h I n s t . ( P C )

E x e c u t e I n s t . ( P C - 1 )

F e t c h I n s t . ( P C + 1 )

E x e c u t e I n s t . ( P C )

F e t c h I n s t . ( P C + 2 )

E x e c u t e I n s t . ( P C + 1 )

P C P C + 1 P C + 2

O s c i l l a t o r C l o c k

( S y s t e m C l o c k )

P h a s e C l o c k T 1

P r o g r a m C o u n t e r

P h a s e C l o c k T 2

P h a s e C l o c k T 3

P h a s e C l o c k T 4

P i p e l i n i n g

System Clocking and Pipelining

F e t c h I n s t . 1 E x e c u t e I n s t . 1

F e t c h I n s t . 2

F l u s h P i p e l i n e

1

2

3

4

5

6

D E L A Y :

M O V A , [ 1 2 H ]

C A L L D E L A Y

C P L [ 1 2 H ]

:

:

N O P

E x e c u t e I n s t . 2

F e t c h I n s t . 3

F e t c h I n s t . 6 E x e c u t e I n s t . 6

F e t c h I n s t . 7

Instruction Fetching

Page 9

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 9 December 30, 2008

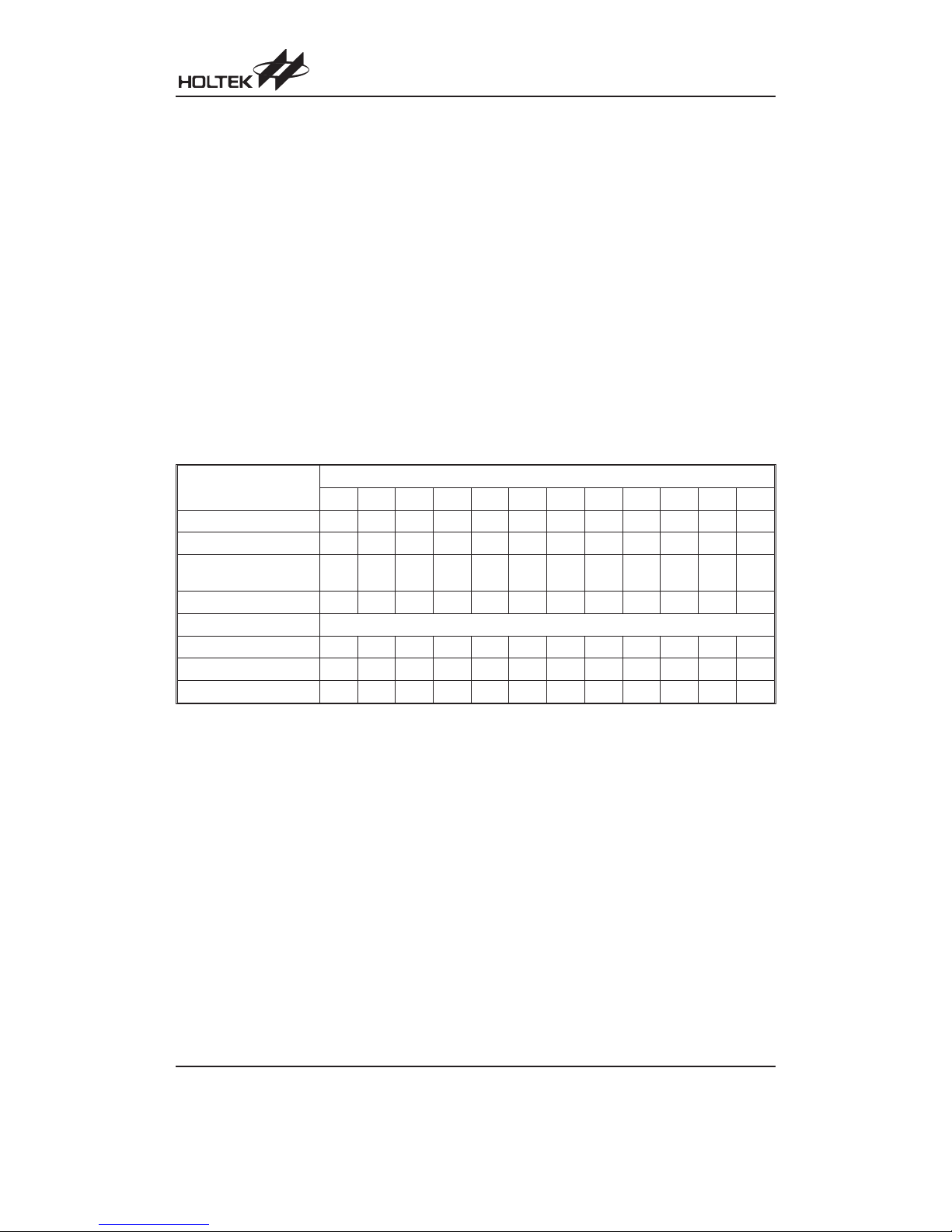

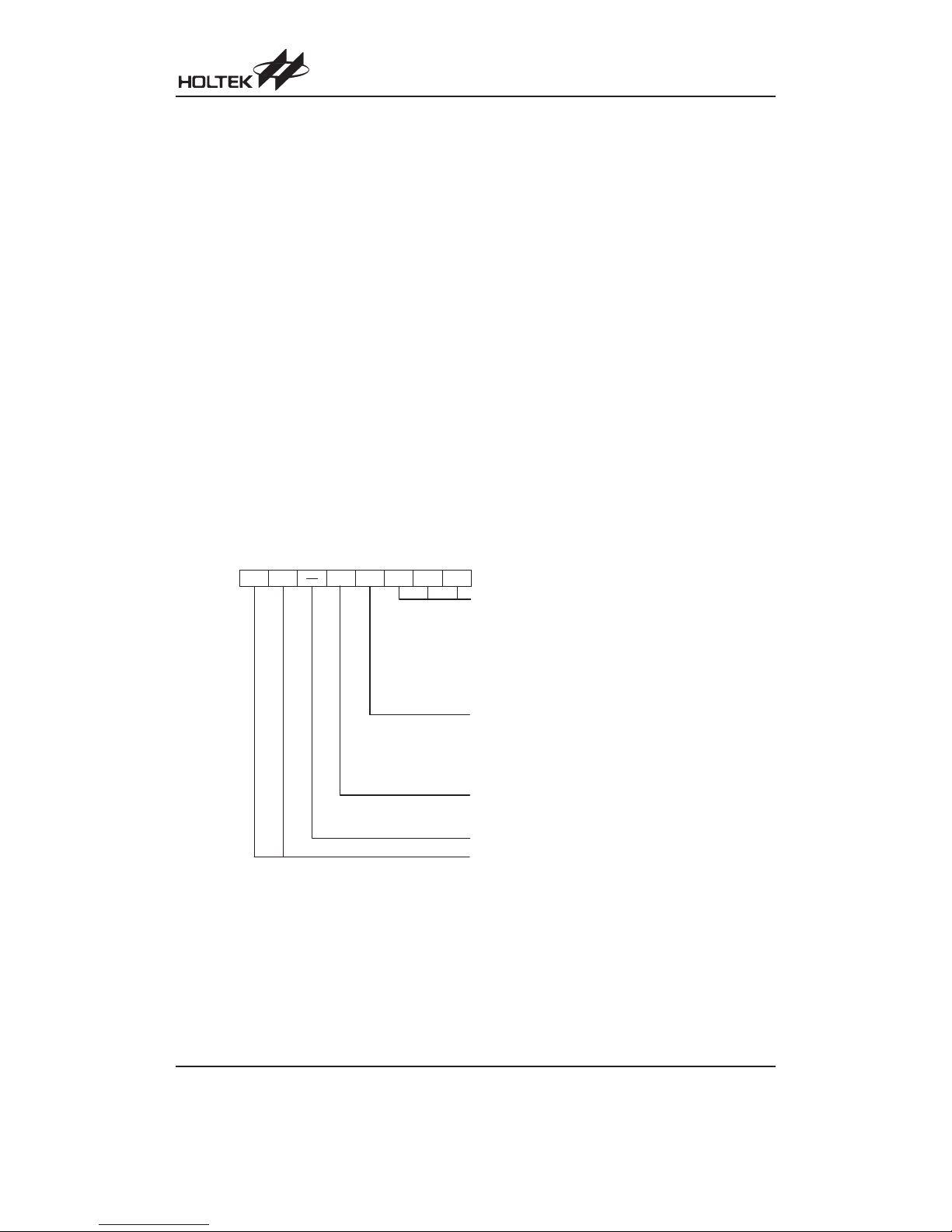

Program Counter

During program execution, the Program Counter is used

to keep track of the address of the next instruction to be

executed. It is automatically incremented by one each

time an instruction is executed except for instructions,

such as ²JMP² or ²CALL² that demand a jump to a

non-consecutive Program Memory address. For the

Cost-Effective A/D Type series of microcontrollers, note

that the Program Counter width varies with the Program

Memory capacity depending upon which device is se

lected. However, it must be noted that only the lower 8

bits, known as the Program Counter Low Register, are

directly addressable by user.

When executing instructions requiring jumps to

non-consecutive addresses such as a jump instruction,

a subroutine call, interrupt or reset, etc., the

microcontroller manages program control by loading the

required address into the Program Counter. For condi

tional skip instructions, once the condition has been

met, the next instruction, which has already been

fetched during the present instruction execution, is dis

-

carded and a dummy cycle takes its place while the cor

-

rect instruction is obtained.

The lower byte of the Program Counter, known as the

Program Counter Low register or PCL, is available for

program control and is a readable and writable register.

By transferring data directly into this register, a short

program jump can be executed directly, however, as

only this low byte is available for manipulation, the

jumps are limited to the present page of memory, that is

256 locations. When such program jumps are executed

it should also be noted that a dummy cycle will be in

-

serted.

The lower byte of the Program Counter is fully accessi

ble under program control. Manipulating the PCL might

cause program branching, so an extra cycle is needed

to pre-fetch. Further information on the PCL register can

be found in the Special Function Register section.

Mode

Program Counter Bits

b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Initial Reset 000000000000

External Interrupt 000000000100

Timer/Event Counter

Overflow

000000001000

A/D Converter Interrupt 000000001100

Skip Program Counter + 2

Loading PCL PC11 PC10 PC9 PC8 @7 @6 @5 @4 @3 @2 @1 @0

Jump, Call Branch #11 #10 #9 #8 #7 #6 #5 #4 #3 #2 #1 #0

Return from Subroutine S11 S10 S9 S8 S7 S6 S5 S4 S3 S2 S1 S0

Program Counter

Note: PC11~PC8: Current Program Counter bits

@7~@0: PCL bits

#11~#0: Instruction code address bits

S11~S0: Stack register bits

For the HT46R49, the Program Counter is 12 bits wide, i.e. from b11~b0.

For the HT46R47 and HT46R48A, the Program Counter is 11 bits wide, i.e. From

b10~b0, therefore the b11 column in the table is not applicable.

For the HT46R46, the Program Counter is 10 bits wide, i.e. from b9~b0, therefore the b11 and

b10 the columns in the table are not applicable.

Page 10

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 10 December 30, 2008

Stack

This is a special part of the memory which is used to

save the contents of the Program Counter only. The

stack can have either 4 or 6 levels depending upon

which device is selected and is neither part of the data

nor part of the program space, and is neither readable

nor writable. The activated level is indexed by the Stack

Pointer, SP, and is neither readable nor writable. At a

subroutine call or interrupt acknowledge signal, the con

tents of the Program Counter are pushed onto the stack.

At the end of a subroutine or an interrupt routine, sig

naled by a return instruction, RET or RETI, the Program

Counter is restored to its previous value from the stack.

After a device reset, the Stack Pointer will point to the

top of the stack.

If the stack is full and an enabled interrupt takes place,

the interrupt request flag will be recorded but the acknowledge signal will be inhibited. When the Stack

Pointer is decremented, by RET or RETI, the interrupt

will be serviced. This feature prevents stack overflow allowing the programmer to use the structure more easily.

However, when the stack is full, a CALL subroutine instruction can still be executed which will result in a stack

overflow. Precautions should be taken to avoid such

cases which might cause unpredictable program

branching.

Note: Forthe HT46R46, 4levels of stackare available

and for the HT46R47,HT46R48A and

HT46R49, 6 levels of stack are available.

Arithmetic and Logic Unit - ALU

The arithmetic-logic unit or ALU is a critical area of the

microcontroller that carries out arithmetic and logic op

erations of the instruction set. Connected to the main

microcontroller data bus, the ALU receives related in

struction codes and performs the required arithmetic or

logical operations after which the result will be placed in

the specified register. As these ALU calculation or oper

ations may result in carry, borrow or other status

changes, the status register will be correspondingly up

dated to reflect these changes. The ALU supports the

following functions:

·

Arithmetic operations: ADD, ADDM, ADC, ADCM,

SUB, SUBM, SBC, SBCM, DAA

·

Logic operations: AND, OR, XOR, ANDM, ORM,

XORM, CPL, CPLA

·

Rotation RRA, RR, RRCA, RRC, RLA, RL, RLCA,

RLC

·

Increment and Decrement INCA, INC, DECA, DEC

·

Branch decision, JMP, SZ, SZA, SNZ, SIZ, SDZ,

SIZA, SDZA, CALL, RET, RETI

Program Memory

The Program Memory is the location wherethe user code

or program is stored. For microcontrollers, two types of

Program Memory are usually supplied. The first type is

the One-Time Programmable, OTP, memory where us

ers can program their application code into the device.

Devices with OTP memory are denoted by having an ²R²

within their device name. By using the appropriate pro

gramming tools, OTP devices offer users the flexibility to

freely develop their applications which may be useful

during debug or for products requiring frequent upgrades

or program changes. OTP devices are also applicable for

use in applications that require low or medium volume

production runs. The other type of memory is the mask

ROM memory, denoted by having a ²C² within the device

name. These devices offer the most cost effective solu

tions for high volume products.

Structure

The Program Memory has a capacity of 1K by 14, 2K by

14 or 4K by 15 bits depending upon which device is selected. The Program Memory is addressed by the Program Counter and also contains data, table information

and interrupt entries. Table data, which can be setup in

any location within the Program Memory, is addressed

by separate table pointer registers.

Special Vectors

Within the Program Memory, certain locations are re

served for special usage such as reset and interrupts.

·

Location 000H

This vector is reserved for use by the device reset for

program initialisation. After a device reset is initiated, the

program will jump to this location and begin execution.

·

Location 004H

This vector is used by the external interrupt. If the ex

-

ternal interrupt pin on the device goes low, the pro

-

gram will jump to this location and begin execution if

the external interrupt is enabled and the stack is not

full.

·

Location 008H

This internal vector is used by the Timer/Event Coun

-

ter. If a counter overflow occurs, the program will jump

to this location and begin execution if the timer/event

counter interrupt is enabled and the stack is not full.

·

Location 00CH

This internal vector is used by the A/D converter.

When an A/D conversion cycle is complete, the pro

-

gram will jump to this location and begin execution if

the A/D interrupt is enabled and the stack is not full.

P r o g r a m C o u n t e r

S t a c k L e v e l 1

S t a c k L e v e l 2

S t a c k L e v e l 3

S t a c k L e v e l N

P r o g r a m

M e m o r y

T o p o f S t a c k

S t a c k

P o i n t e r

B o t t o m o f S t a c k

Page 11

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 11 December 30, 2008

Look-up Table

Any location within the Program Memory can be defined

as a look-up table where programmers can store fixed

data. To use the look-up table, the table pointer must

first be setup by placing the lower order address of the

look up data to be retrieved in the table pointer register,

TBLP. This register defines the lower 8-bit address of

the look-up table.

After setting up the table pointer, the table data can be

retrieved from the current Program Memory page or last

Program Memory page using the ²TABRDC[m]² or

²TABRDL[m]² instructions, respectively. When these in

structions are executed, the lower order table byte from

the Program Memory will be transferred to the user de

fined Data Memory register [m] as specified in the in

struction. The higher order table data byte from the

Program Memory will be transferred to the TBLH special

register. Any unused bits in this transferred higher order

byte will be read as ²0².

The following diagram illustrates the addressing/data

flow of the look-up table:

Table Program Example

The following example shows how the table pointer and

table data is defined and retrieved from the HT46R47

microcontroller. This example uses raw table data located in the last page which is stored there using the

ORG statement. The value at this ORG statement is

²700H² which refers to the start address of the last page

within the 2K Program Memory of the HT46R47

microcontroller. The table pointer is setup here to have

an initial value of ²06H². This will ensure that the first

data read from the data table will be at the Program

Memory address ²706H² or 6 locations after the start of

the last page. Note that the value for the table pointer is

referenced to the first address of the present page if the

²TABRDC [m]² instruction is being used. The high byte

of the table data which in this case is equal to zero will

be transferred to the TBLH register automatically when

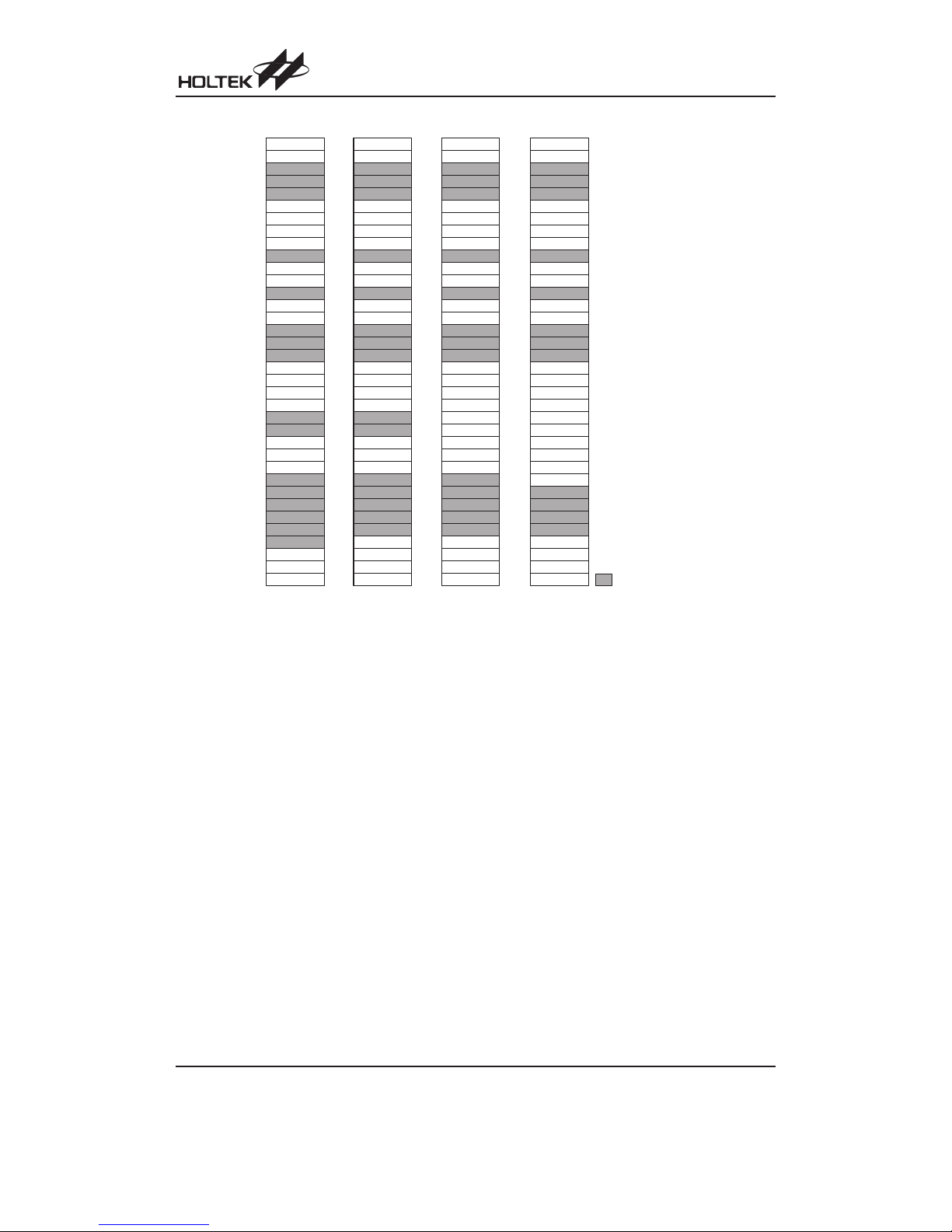

the ²TABRDL [m]² instruction is executed.

3 F F H

N o t I m p l e m e n t e d

1 5 b i t s

1 4 b i t s1 4 b i t s

8 0 0 H

F F F H

0 1 4 H

I n i t i a l i s a t i o n

V e c t o r

E x t e r n a l

I n t e r r u p t V e c t o r

I n i t i a l i s a t i o n

V e c t o r

E x t e r n a l

I n t e r r u p t V e c t o r

T i m e r / E v e n t C o u n t e r

I n t e r r u p t V e c t o r

I n i t i a l i s a t i o n

V e c t o r

E x t e r n a l

I n t e r r u p t V e c t o r

T i m e r / E v e n t C o u n t e r

I n t e r r u p t V e c t o r

H T 4 6 R 4 7

H T 4 6 R 4 8 A H T 4 6 R 4 9H T 4 6 R 4 6

A / D C o n v e r t e r

I n t e r r u p t V e c t o r

A / D C o n v e r t e r

I n t e r r u p t V e c t o r

A / D C o n v e r t e r

I n t e r r u p t V e c t o r

T i m e r / E v e n t C o u n t e r

I n t e r r u p t V e c t o r

0 0 0 H

0 0 4 H

0 0 8 H

0 0 C H

0 1 0 H

3 0 0 H

7 F F H

4 0 0 H

Program Memory Structure

P r o g r a m

M e m o r y

P r o g r a m C o u n t e r

H i g h B y t e

T B L P

T B L H S p e c i f i e d b y [ m ]

T a b l e C o n t e n t s H i g h B y t e

T a b l e C o n t e n t s L o w B y

t e

Page 12

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 12 December 30, 2008

tempreg1 db ? ; temporary register #1

tempreg2 db ? ; temporary register #2

:

:

mov a,06h ; initialise table pointer - note that this address

; is referenced

mov tblp,a ; to the last page or present page

:

:

tabrdl tempreg1 ; transfers value in table referenced by table pointer

; to tempregl

; data at prog. memory address ²706H² transferred to

; tempreg1 and TBLH

dec tblp ; reduce value of table pointer by one

tabrdl tempreg2 ; transfers value in table referenced by table pointer

; to tempreg2

; data at prog.memory address ²705H² transferred to

; tempreg2 and TBLH

; in this example the data ²1AH² is transferred to

; tempreg1 and data ²0FH² to register tempreg2

; the value ²00H² will be transferred to the high byte

; register TBLH

:

:

org 700h ; sets initial address of last page (for HT46R47)

Dc 00Ah, 00Bh, 00Ch, 00Dh, 00Eh, 00Fh, 01Ah, 01Bh

:

:

Because the TBLH register is a read-only register and

cannot be restored, care should be taken to ensure its

protection if both the main routine and Interrupt Service

Routine use table read instructions. If using the table

read instructions, the Interrupt Service Routines may

change the value of the TBLH and subsequently cause

errors if used again by the main routine. As a rule it is

recommended that simultaneous use of the table read

instructions should be avoided. However, in situations

where simultaneous use cannot be avoided, the interrupts should be disabled prior to the execution of any

main routine table-read instructions. Note that all table

related instructions require two instruction cycles to

complete their operation.

Data Memory

The Data Memory is a volatile area of 8-bit wide RAM

internal memory and is the location where temporary information is stored. Divided into two sections, the first of

these is an area of RAM where special function registers

are located. These registers have fixed locations and

are necessary for correct operation of the device. Many

of these registers can be read from and written to directly under program control, however, some remain

protected from user manipulation. The second area of

Data Memory is reserved for general purpose use. All

locations within this area are read and write accessible

under program control.

Instruction

Table Location Bits

b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

TABRDC

[m] PC11 PC10 PC9 PC8 @7 @6 @5 @4 @3 @2 @1 @0

TABRDL

[m]1111@7@6@5@4@3@2@1@0

Table Location

Note: PC11~PC8: Current Program Counter bits

@7~@0: Table Pointer TBLP bits

For the HT46R49 the Table address location is 12 bits, i.e. from b11~b0.

For the HT46R47 and HT46R48A, the Table address location is 11 bits, i.e. from b10~b0.

For the HT46R46, the Table address location is 10 bits, i.e. from b9~b0.

Page 13

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 13 December 30, 2008

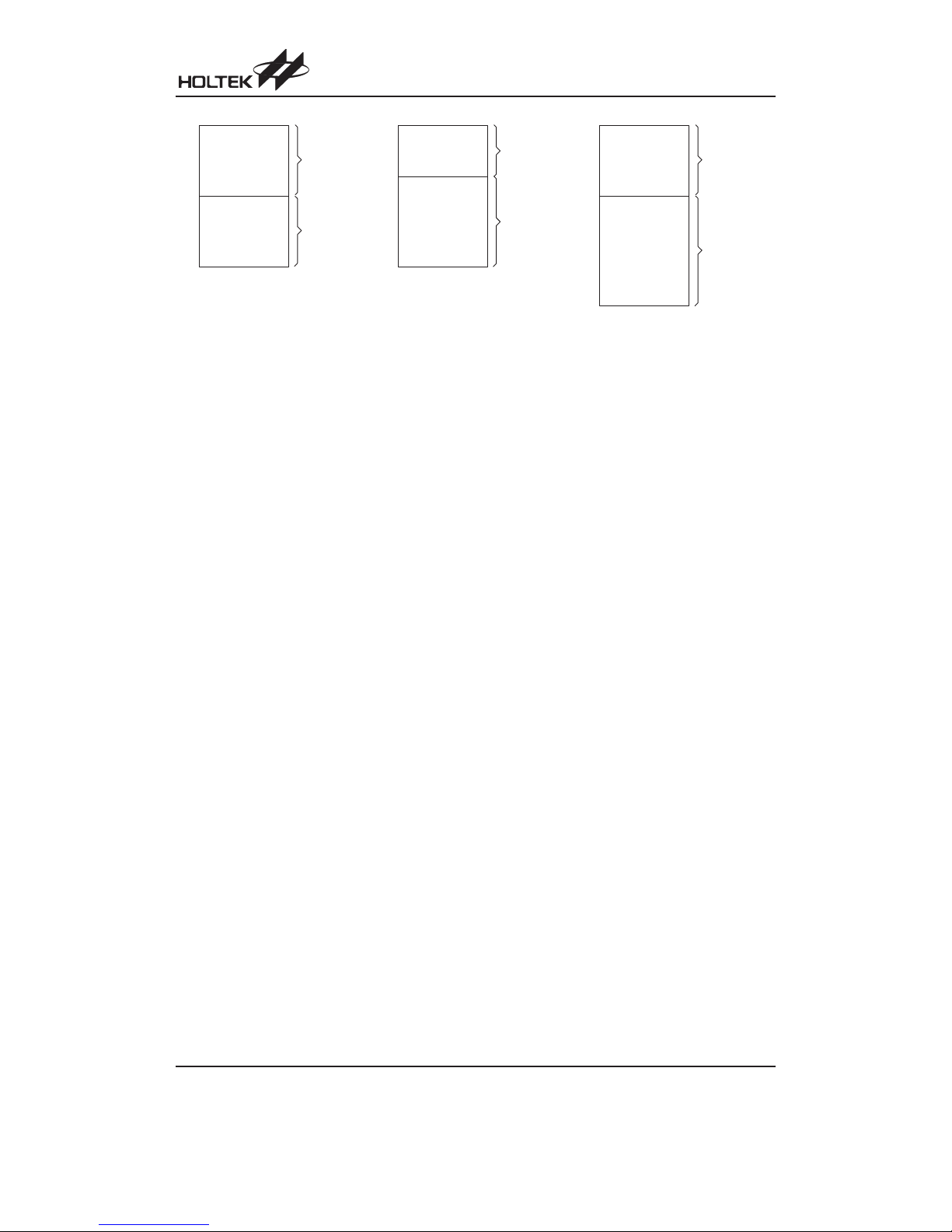

Structure

The two sections of Data Memory, the Special Purpose

and General Purpose Data Memory are located at con

secutive locations. All are implemented in RAM and are

8 bits wide but the length of each memory section is dic

tated by the type of microcontroller chosen. The start

address of the Data Memory for all devices is the ad

-

dress ²00H². Registers which are common to all

microcontrollers, such as ACC, PCL, etc., have the

same Data Memory address.

General Purpose Data Memory

All microcontroller programs require an area of

read/write memory where temporary data can be stored

and retrieved for use later. It is this area of RAM memory

that is known as General Purpose Data Memory. This

area of Data Memory is fully accessible by the user pro

gram for both read and write operations. By using the

²SET [m].i² and ²CLR [m].i² instructions individual bits

can be set or reset under program control giving the

user a large range of flexibility for bit manipulation in the

Data Memory.

Special Purpose Data Memory

This area of Data Memory is where registers, necessary

for the correct operation of the microcontroller, are

stored. Most of the registers are both readable and

writable but some are protected and are readable only,

the details of which are located under the relevant Spe

cial Function Register section. Note that for locations

that areunused, any readinstruction to these addresses

will return the value ²00H².

Special Function Registers

To ensure successful operation of the microcontroller,

certain internal registers are implemented in the Data

Memory area. These registers ensure correct operation

of internal functions such as timers, interrupts, etc., as

well as external functions such as I/O data control and

A/D converter operation. The location of these registers

within the Data Memory begins at the address 00H. Any

unused Data Memory locations between these special

function registers and the point where the General Pur

pose Memory begins is reserved for future expansion

purposes, attempting to read data from these locations

will return a value of 00H.

Indirect Addressing Register - IAR

The IAR register, located at Data Memory address

²00H², is not physically implemented. This special register allows what is known as indirect addressing, which

permits data manipulation using Memory Pointers instead of the usual direct memory addressing method

where the actual memory address is defined. Any ac

tions on the IAR register will result in corresponding

read/write operations to the memory location specified

by the Memory Pointer MP. Reading the IAR register in

-

directly will return a result of ²00H² and writing to the

register indirectly will result in no operation.

Memory Pointer - MP

One Memory Pointer, known as MP, is physically imple

mented in Data Memory. The Memory Pointer can be

written to and manipulated in the same way as normal

registers providing an easy way of addressing and

tracking data. When using any operation on the indirect

addressing register IAR, it is actually the address speci

fied by the Memory Pointer that the microcontroller will

be directed to.

For devices with 64 or 88 bytes of RAM Data Memory,

bit 7 of the Memory Pointer is not implemented. How

ever, it must be noted that when the Memory Pointer for

these devices is read, bit 7 will be read as high.

G e n e r a l P u r p o s e

D a t a M e m o r y

S p e c i a l P u r p o s e

D a t a M e m o r y

0 0 H

4 0 H

B F H

3 F H

G e n e r a l P u r p o s e

D a t a M e m o r y

S p e c i a l P u r p o s e

D a t a M e m o r y

0 0 H

4 0 H

7 F H

3 F H

H T 4 6 R 4 6 a n d H T 4 6 R 4 7

H T 4 6 R 4 9

G e n e r a l P u r p o s e

D a t a M e m o r y

S p e c i a l P u r p o s e

D a t a M e m o r y

0 0 H

2 8 H

7 F H

2 7 H

H T 4 6 R 4 8 A

Data Memory Structure

Note:

Most ofthe Data Memorybits can be directly manipulated using the ²SET [m].i² and ²CLR [m].i² with the excep

-

tion ofa few dedicated bits. The Data Memory can also be accessed through thememory pointer register MP.

Page 14

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 14 December 30, 2008

The following example shows how to clear a section of four RAM locations already defined as locations adres1 to

adres4.

data .section ¢data¢

adres1 db ?

adres2 db ?

adres3 db ?

adres4 db ?

block db ?

code .section at 0 ¢code¢

org 00h

start:

mov a,04h ; setup size of block

mov block,a

mov a,offset adres1 ; Accumulator loaded with first RAM address

mov mp,a ; setup memory pointer with first RAM address

loop:

clr IAR ; clear the data at address defined by MP

inc mp ; increment memory pointer

sdz block ; check if last memory location has been cleared

jmp loop

continue:

The importantpoint to note here is that in the example shownabove, no reference is made to specific RAM addresses.

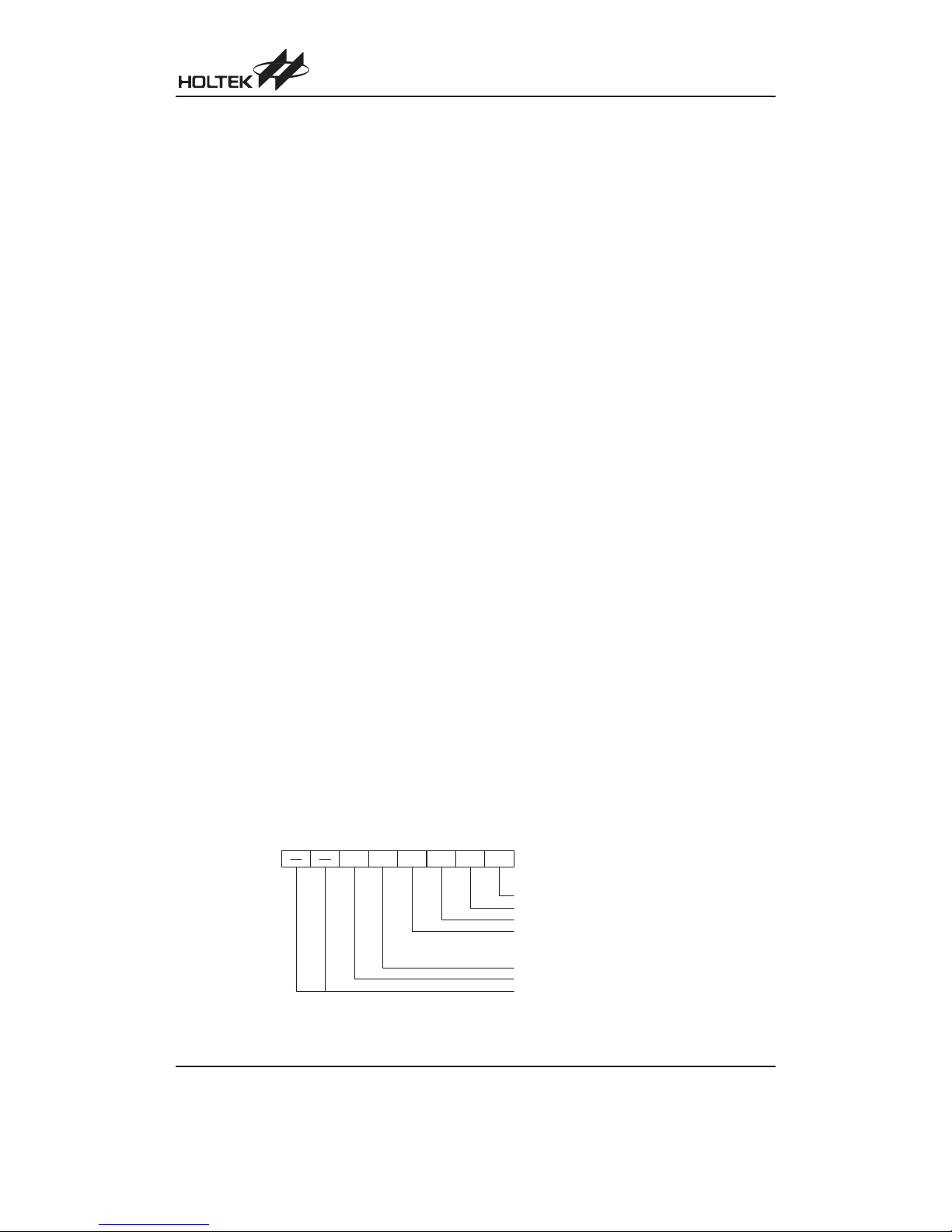

0 0 H

0 1 H

0 2 H

0 3 H

0 4 H

0 5 H

0 6 H

0 7 H

0 8 H

0 9 H

0 A H

0 B H

0 C H

0 D H

0 E H

0 F H

1 0 H

1 1 H

1 2 H

1 3 H

1 4 H

1 5 H

1 6 H

1 7 H

1 8 H

1 9 H

1 A H

1 B H

1 C H

1 D H

1 E H

1 F H

2 0 H

2 1

H

2 2 H

2 3 H : U n u s e d , r e a d a s " 0 0 "

I A R

M P

A C C

P C L

T B L P

T B L H

S T A T U S

I N T C

T M R

T M R C

P A

P A C

P B

P B C

P D

P D C

P W M

A D R

A D C R

A C S R

H T 4 6 R 4 6

I A R

M P

A C C

P C L

T B L P

T B L H

S T A T U S

I N T C

T M R

T M R C

P A

P A C

P B

P B C

P D

P D C

P W M

A D R L

A D R H

A D C R

A C S R

H T 4 6 R 4 7

I A R

M P

A C C

P C L

T B L P

T B L H

S T A T U S

I N T C

T M R

T M R C

P A

P A C

P B

P B C

P C

P C C

P D

P D C

P W M

A D R L

A D R H

A D C R

A C S R

H T 4 6 R 4 8 A

I A R

M P

A C C

P C L

T B L P

T B L H

S T A T U S

I N T C

T M R

T M R C

P A

P A C

P B

P B C

P C

P C C

P D

P D C

P W M 0

P W M 1

A D R L

A D R H

A D C R

A C S R

H T 4 6 R 4 9

Special Purpose Data Memory

Page 15

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 15 December 30, 2008

Accumulator - ACC

The Accumulator is central to the operation of any

microcontroller and is closely related with operations

carried out by the ALU. The Accumulator is the place

where all intermediate results from the ALU are stored.

Without the Accumulator it would be necessary to write

the result of each calculation or logical operation such

as addition, subtraction, shift, etc., to the Data Memory

resulting in higher programming and timing overheads.

Data transfer operations usually involve the temporary

storage function of the Accumulator; for example, when

transferring data between one user defined register and

another, it is necessary to do this by passing the data

through the Accumulator as no direct transfer between

two registers is permitted.

Program Counter Low Register - PCL

To provide additional program control functions, the low

byte of the Program Counter is made accessible to pro

grammers by locating it within the Special Purpose area

of the Data Memory. By manipulating this register, direct

jumps to other program locations are easily imple

mented. Loading a value directly into this PCL register

will cause a jump to the specified Program Memory lo

cation, however, as the register is only 8-bit wide, only

jumps within the current Program Memory page are permitted. When such operations are used, note that a

dummy cycle will be inserted.

Look-up Table Registers - TBLP, TBLH

These two special function registers are used to control

operation of the look-up table which is stored in the Program Memory. TBLP is the table pointer and indicates

the location where the table data is located. Its value

must be setup before any table read commands are ex

ecuted. Its value can be changed, for example using the

²INC² or ²DEC² instructions, allowing for easy table data

pointing and reading. TBLH is the location where the

high order byte of the table data is stored after a table

read data instruction has been executed. Note that the

lower order table data byte is transferred to a user de

fined location.

Status Register - STATUS

This 8-bit register contains the zero flag (Z), carry flag

(C), auxiliary carry flag (AC), overflow flag (OV), power

down flag (PDF), and watchdog time-out flag (TO).

These arithmetic/logical operation and system manage

ment flagsare used to record the status and operation of

the microcontroller.

With the exception of the TO and PDF flags, bits in the

status register can be altered by instructions like most

other registers. Any data written into the status register

will not change the TO or PDF flag. In addition, opera

tions related to the status register may give different re

sults due to the different instruction operations. The TO

flag can be affected only by a system power-up, a WDT

time-out or by executing the ²CLR WDT² or ²HALT² in

struction. The PDF flag is affected only by executing the

²HALT² or ²CLR WDT² instruction or during a system

power-up.

The Z, OV, AC and C flags generally reflect the status of

the latest operations.

¨

C is set if an operation results in a carry during an

addition operation or if a borrow does not take place

during a subtraction operation; otherwise C is

cleared. C is also affected by a rotate through carry

instruction.

¨

AC is set if an operation results in a carry out of the

low nibbles in addition, or no borrow from the high

nibble into the low nibble in subtraction; otherwise

AC is cleared.

¨

Z is set if the result of an arithmetic or logical operation is zero; otherwise Z is cleared.

¨

OV is set if an operation results in a carry into the

highest-order bit but not a carry out of the highest-order bit,or vice versa; otherwise OV is cleared.

¨

PDF is cleared by a system power-up or executing

the ²CLR WDT² instruction. PDF is set by executing

the ²HALT² instruction.

¨

TO is cleared by a system power-up or executing

the ²CLR WDT² or ²HALT² instruction. TO is set by

a WDT time-out.

T O P D F O V Z A C C

S T A T U S R e g i s t e r

A r i t h m e t i c / L o g i c O p e r a t i o n F l a g s

C a r r y f l a g

A u x i l i a r y c a r r y f l a g

Z e r o f l a g

O v e r f l o w f l a g

S y s t e m M a n a g e m e n t F l a g s

P o w e r d o w n f l a g

W a t c h d o g t i m e - o u t f l a g

N o t i m p l e m e n t e d , r e a d a s " 0 "

b 7 b 0

Status Register

Page 16

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 16 December 30, 2008

In addition, on entering an interrupt sequence or execut

ing a subroutine call, the status register will not be

pushed onto the stack automatically. If the contents of

the status registers are important and if the subroutine

can corrupt the status register, precautions must be

taken to correctly save it.

Interrupt Control Register - INTC

This 8-bit register, known as the INTC register, controls

the operation of both external and internal timer inter

rupts. By setting various bits within this register using

standard bit manipulation instructions, the enable/disable

function of each interrupt can be independently con

trolled. A master interrupt bit within this register, the EMI

bit, acts like a global enable/disable and is used to set all

of the interrupt enable bits on or off. This bit is cleared

when an interrupt routine is entered to disable further in

-

terrupt and is set by executing the ²RETI² instruction.

Timer/Event Counter Registers - TMR, TMRC

All devices possess a single internal 8-bit count-up

timer. An associated register known as TMR is the loca

-

tion where the timer¢s 8-bit value is located. This register

can also be preloaded with fixed data to allow different

time intervals to be setup. An associated control regis

ter, known as TMRC, contains the setup information for

this timer, which determines in what mode the timer is to

be used as well as containing the timer on/off control

function.

Input/Output Ports and Control Registers

Within the area of Special Function Registers, the I/O

registers and their associated control registers play a

prominent role. All I/O ports have a designated register

correspondingly labeled as PA, PB, PC and PD. These

labeled I/O registers are mapped to specific addresses

within the Data Memory as shown in the Data Memory

table, which are used to transfer the appropriate output

or input data on that port. With each I/O port there is an

associated control register labeled PAC, PBC, PCC and

PDC, also mapped to specific addresses with the Data

Memory. The control register specifies which pins of that

port are set as inputs and which are set as outputs. To

setup a pin as an input, the corresponding bit of the con

-

trol register must be set high, for an output it must be set

low. During program initialization, it is important to first

setup the control registers to specify which pins are out

puts and which are inputs before reading data from or

writing data to the I/O ports. One flexible feature of these

registers is the ability to directly program single bits us

-

ing the ²SET [m].i² and ²CLR [m].i² instructions. The

ability to change I/O pins from output to input and vice

versa by manipulating specific bits of the I/O control reg

isters during normal program operation is a useful fea

ture of these devices.

Pulse Width Modulator Registers PWM, PWM0, PWM1

Each device in the Cost-Effective A/D Type

microcontroller range contains either one or two Pulse

Width Modulators. Each one has its own related inde

pendent control register. For devices with a single PWM

function this is register is known as PWM, while for de

vices with two PWM functions, their control register

names are PWM0 and PWM1. The 8-bit contents of

these registers, defines the duty cycle value for the

modulation cycle of the corresponding Pulse Width

Modulator.

A/D Converter Registers ADR, ADRL, ADRH, ADCR, ACSR

Each device in the Cost-Effective A/D Type

microcontroller range contains a 4-channel 8-bit or 9-bit

A/D converter. The correct operation of the A/D requires

the use of one or two data registers, a control register

and a clock source register. For the HT46R46 device,

which has an 8-bit A/D converter, there is a single data

register, known as ADR. For the other devices, which

contain a 9-bit A/D converter, there are two data regis

ters, a high byte data register known as ADRH, and a

low byte data register known as ADRL. These are the

register locations where the digital value is placed after

the completion of an analog to digital conversion cycle.

The channel selection and configuration of the A/D con

verter is setup via the control register ADCR while the

A/D clock frequency is defined by the clock source reg

ister, ACSR.

Page 17

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 17 December 30, 2008

Input/Output Ports

Holtek microcontrollers offer considerable flexibility on

their I/Oports. With theinput or output designation of ev

-

ery pin fully under user program control, pull-high op

tions for all ports and wake-up options on certain pins,

the user is provided with an I/O structure to meet the

needs of a wide range of application possibilities.

Depending upon which device or package is chosen,

the microcontroller range provides from 13 to 23

bidirectional input/output lines labeled with port names

PA, PB, PC and PD. These I/O ports are mapped to the

RAM Data Memory with specific addresses as shown in

the Special Purpose Data Memory table. All of these I/O

ports can be used for input and output operations. For

input operation, these ports are non-latching, which

means the inputs must be ready at the T2 rising edge of

instruction ²MOV A,[m]², where m denotes the port ad

dress. For output operation, all the data is latched and

remains unchanged until the output latch is rewritten.

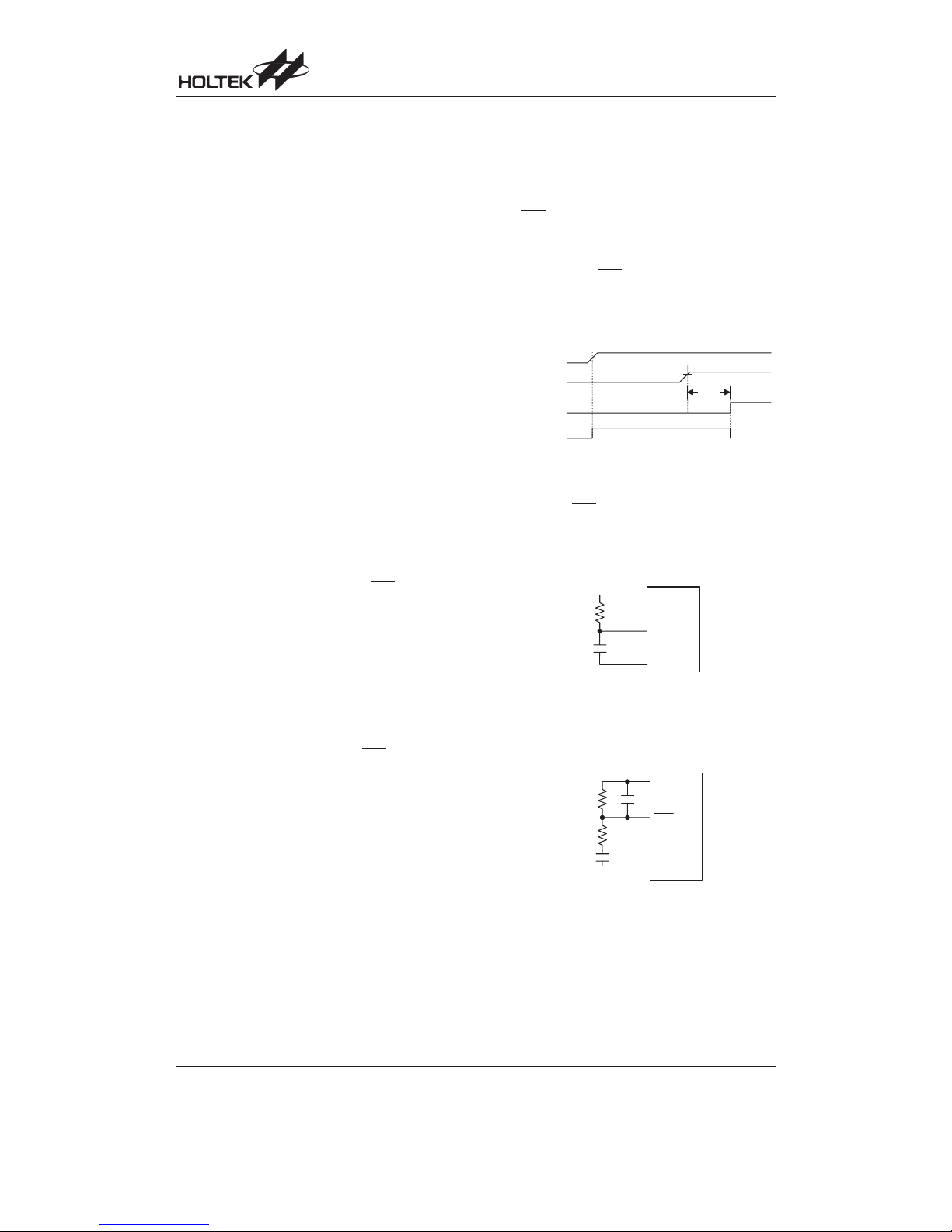

Pull-high Resistors

Many product applications require pull-high resistors for

their switch inputs usually requiring the use of an exter

nal resistor. To eliminate the need for these external re

sistors, all I/O pins, when configured as an input have

the capability of being connected to an internal pull-high

resistor. These pull-high resistors are selectable via

configuration options and are implemented using a

weak PMOS transistor.

Port A Wake-up

Each device has a HALT instruction enabling the

microcontroller to enter a Power Down Mode and preserve power, a feature that is important for battery and

other low-power applications. Various methods exist to

wake-up the microcontroller, one of which is to change

the logic condition on one of the Port Apins from high to

low. After a ²HALT² instruction forces the microcontroller

into entering a HALT condition, the processor will re

main idle or in a low-power state until the logic condition

of the selected wake-up pin on Port Achanges from high

to low. This function is especially suitable for applica

tions that can be woken up via external switches. Note

that each pin on Port A can be selected individually to

have this wake-up feature.

I/O Port Control Registers

Each I/O port has its own control register PAC, PBC,

PCC and PDC, to control the input/output configuration.

With this control register, each CMOS output or input

with or without pull-high resistor structures can be re

configured dynamicallyunder software control.Each pin

of the I/O ports is directly mapped to a bit in its associ

ated port control register. For the I/O pin to function as

an input, the corresponding bit of the control register

must be written as a ²1². This will then allow the logic

state of the input pin to be directly read by instructions.

When the corresponding bit of the control register is

written as a ²0², the I/O pin will be setup as a CMOS out

put. If the pin is currently setup as an output, instructions

can still be used to read the output register. However, it

should be noted that the program will in fact only read

the status of the output data latch and not the actual

logic status of the output pin.

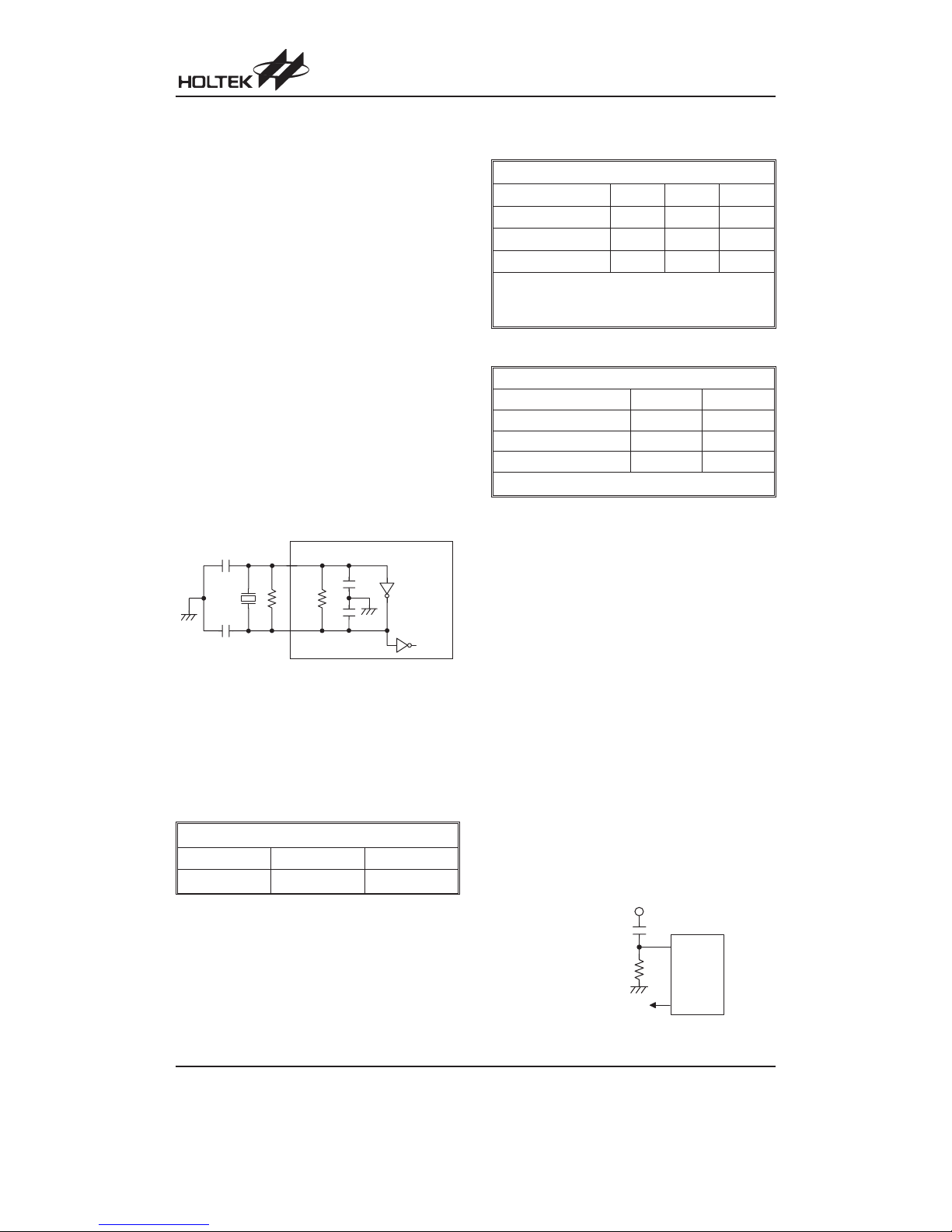

Pin-shared Functions

The flexibility of the microcontroller range is greatly en

hanced by the use of pins that have more than one func

tion. Limited numbers of pins can force serious design

constraints on designers but by supplying pins with

multi-functions, many of these difficulties can be over

come. For some pins, the chosen function of the

multi-function I/O pins is set by configuration options

while for others the function is set by application pro

gram control.

·

External Interrupt Input

The external interrupt pin INT

is pin-shared with the

I/O pin PA5. For applications not requiring an external

interrupt input, the pin-shared external interrupt pin

can be used as a normal I/O pin, however to do this,

the external interrupt enable bits in the INTC register

must be disabled.

·

External Timer Clock Input

The external timer pin TMR is pin-shared with the I/O

pin PA4. To configure it to operate as a timer input, the

corresponding control bits in the timer control register

must be correctly set. For applications that do not re

quire an external timer input, the pin can be used as a

normal I/O pin. Note that if used as a normal I/O pin

the timer mode control bits in the timer control register

must select the timer mode, which has an internal

clock source, to prevent the input pin from interfering

with the timer operation.

·

PFD Output

Each device contains a PFD function whose single

output is pin-shared with PA3. The output function of

this pin is chosen via a configuration option and re

mains fixed after the device is programmed. Note that

the corresponding bit of the port control register,

PAC.3, must setup the pin as an output to enable the

PFD output. If the PAC port control register has setup

the pin as an input, then the pin will function as a nor

mal logic input with the usual pull-high option, even if

the PFD configuration option has been selected.

Page 18

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 18 December 30, 2008

·

PWM Outputs

All devices contain one or two PWM outputs pin

shared with pins PD0 and PD1. The PWM output

functions are chosen via configuration options and re

main fixed after the device is programmed. Note that

the corresponding bit or bits of the port control regis

ter, PDC, must setup the pin as an output to enable

the PWM output. If the PDC port control register has

setup the pin as an input, then the pin will function as a

normal logic input with the usual pull-high option, even

if the PWM configuration option has been selected.

·

A/D Inputs

Each device has four A/D converter inputs. All of

these analog inputs are pin-shared with I/O pins on

Port B. If these pins are to be used as A/D inputs and

not as normal I/O pins then the corresponding bits in

the A/D Converter Control Register, ADCR, must be

properly set. There are no configuration options asso

ciated with the A/D function. If used as I/O pins, then

full pull-high resistor configuration options remain,

however if used as A/D inputs then any pull-high resis

tor options associated with these pins will be automat

ically disconnected.

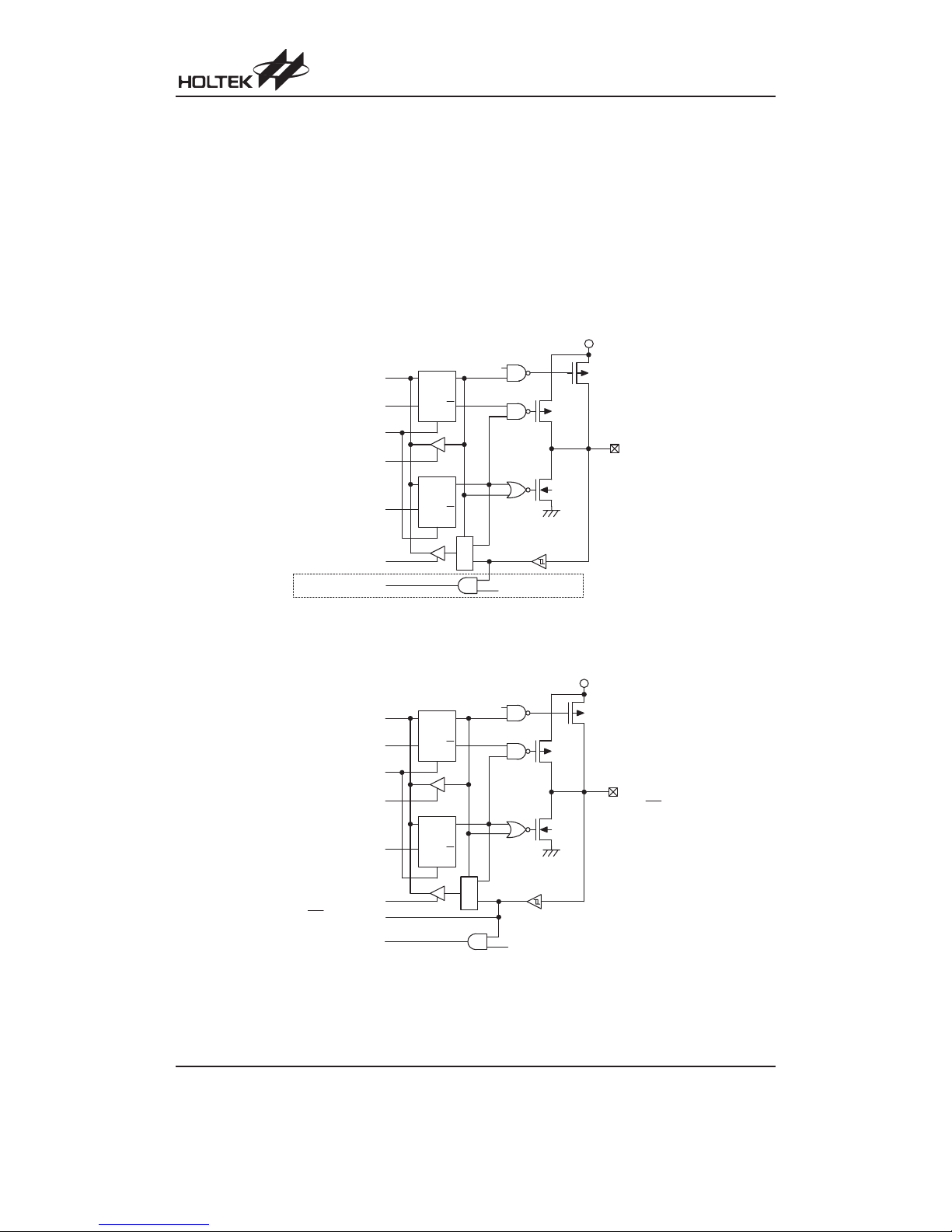

V

D D

M

U

X

W a k e - u p O p t i o n

S y s t e m W a k e - u p

R e a d D a t a R e g i s t e r

C o n t r o l B i t

P u l l - H i g h

O p t i o n

D a t a B u s

W r i t e C o n t r o l R e g i s t e r

C h i p R e s e t

R e a

d C o n t r o l R e g i s t e r

W r i t e D a t a R e g i s t e r

D a t a B i t

I / O P i n

W e a k

P u l l - u p

D

Q

C K

S

Q

D

Q

C K

S

Q

P A o n l y

Non-pin-shared Function Input/Output Ports

V

D D

M

U

X

R e a d D a t a R e g i s t e r

C o n t r o l B i t

P u l l - H i g h

O p t i o n

D a t a B u s

W r i t e C o n t r o l R e g i s t e r

C h i p R e s e t

R e a d C o n t r o l R e g i s t e r

W r i t e D a t a R e g i s t e r

D a t a B

i t

I N T f o r P A 5 o n l y

T M R f o r P A 4 o n l y

P A 4 / T M R

P A 5 / I N T

W a k e - u p O p t i o n

S y s t e m W a k e - u p

W e a k

P u l l - u p

D

Q

C K

S

Q

D

Q

C K

S

Q

PA4/PA5 Input/Output Ports

Page 19

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 19 December 30, 2008

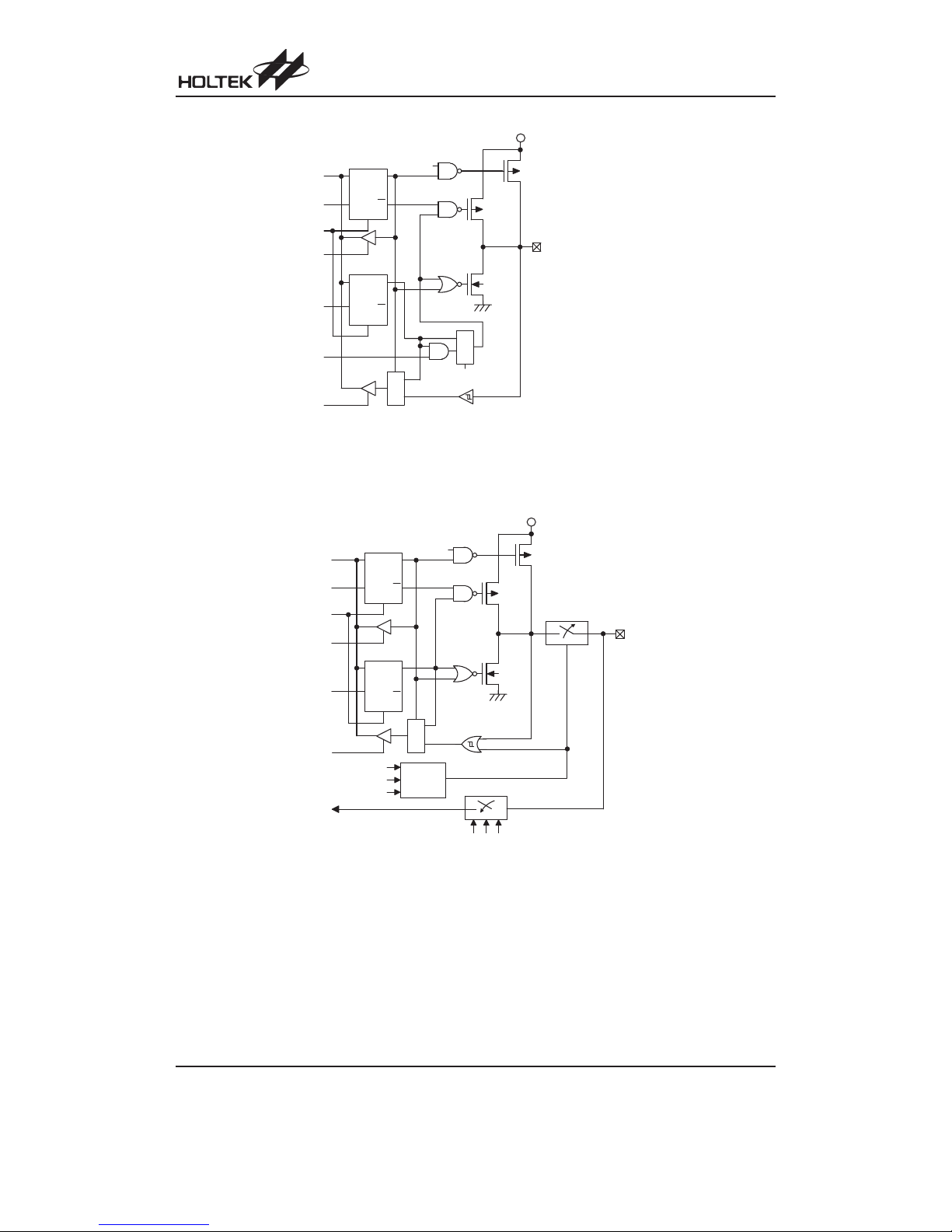

V

D D

M

U

X

R e a d D a t a R e g i s t e r

C o n t r o l B i t

P u l l - H i g h

O p t i o n

D a t a B u s

W r i t e C o n t r o l R e g i s t e r

C h i p R e s e t

R e a d C o n t r o l R e g i s t e r

W r i t e D a t a R e g i s t e r

D a t a B

i t

P B 0 / A N 0 ~ P B 3 / A N 3

A C S 2 ~ A C S 0

T o A / D C o n v e r t e r

P C R 2

P C R 1

P C R 0

W e a k

P u l l - u p

A n a l o g

I n p u t

S e l e c t o r

D

Q

C K

S

Q

D

Q

C K

S

Q

PB Input/Output Ports

V

D D

P F D o r P W M W a v e f o r m

M

U

X

R e a d D a t a R e g i s t e r

C o n t r o l B i t

P u l l - H i g h

O p t i o n

D a t a B u s

W r i t e C o n t r o l R e g i s t e r

C h i p R e s e t

R e a d C o n t r o l R e g i s t e r

W r i t e D a t a R e g i s t e r

D a t a B

i t

P F D / P W M O p t i o n

M

U

X

W e a k

P u l l - u p

D

Q

C K

S

Q

D

Q

C K

S

Q

P A 3 / P F D

P D 0 / P W M

P D 0 / P W M 0

P D 1 / P W M 1

( H T 4 6 R 4 9 2 8 - p i n p a c k a g e o n l y )

PA3/PFD and PD/PWM Input/Output Ports

Page 20

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 20 December 30, 2008

I/O Pin Structures

The following diagrams illustrate the I/O pin internal

structures. As the exact logical construction of the I/O

pin may differ from these drawings, they are supplied as

a guide only to assist with the functional understanding

of the I/O pins.

Programming Considerations

Within the user program, one of the first things to con

sider is port initialization. After a reset, all of the I/O data

and port control registers will be set high. This means

that all I/O pins will default to an input state, the level of

which depends on the other connected circuitry and

whether pull-high options have been selected. If the port

control registers, PAC, PBC, PCC and PDC, are then

programmed to setup some pins as outputs, these out

put pins will have an initial high output value unless the

associated port data registers, PA, PB, PC and PD, are

first programmed. Selecting which pins are inputs and

which are outputs can be achieved byte-wide by loading

the correct values into the appropriate port control regis

ter or by programming individual bits in the port control

register using the ²SET [m].i² and ²CLR [m].i² instruc

tions. Note that when using these bit control instruc

tions, a read-modify-write operation takes place. The

microcontroller must first read in the data on the entire

port, modify it to the required new bit values and then rewrite this data back to the output ports.

Port Ahas the additional capability of providing wake-up

functions. When the device is in the Power Down Mode,

various methods are available to wake the device up.

One of these is a high to low transition of any of the Port

A pins. Single or multiple pins on Port A can be setup to

have this function.

Note that some devices have different package types

which may result in some I/O pins not being bonded out.

If these pins are setup as inputs they may oscillate and

increase power consumption, especially notable if the

device isin the PowerDown Mode. It is therefore recom

-

mended that any unbonded pins should be setup as out

puts, or if setup as inputs, then they should be

connected to pull-high resistors.

Timer/Event Counters

The provision of timers form an important part of any

microcontroller giving the designer a means of carrying

out time related functions. Each device contains an in

ternal 8-bit count-up timer. With three operating modes,

the timers can be configured to operate as a general

timer, external event counter or as a pulse width mea

surement device. The provision of an internal 8-stage

prescaler to the timer clock circuitry gives added range

to the timer.

There are two registers related to the Timer/Event

Counter, TMR and TMRC. The TMR register is the reg

ister that contains the actual timing value. Writing to

TMR places an initial starting value in the Timer/Event

Counter preload register while reading TMR retrieves

the contents of the Timer/Event Counter. The TMRC

register is a Timer/Event Counter control register, which

defines the timer options, and determines how the timer

is to be used. The timer clock source can be configured

to come from the internal system clock source or from

an external clock on shared pin PA4/TMR.

Configuring the Timer/Event Counter Input Clock

Source

The internal timer¢s clock source can originate from either the system clock or from an external clock source.

The system clock input timer source is used when the

timer is in the timer mode or in the pulse width measure

ment mode. The internal timer clock also passes

through a prescaler, the value of which is conditioned by

the bits PSC0, PSC1 and PSC2.

An external clock source is used when the timer is in the

event counting mode, the clock source being provided

on pin-shared pin PA4/TMR. Depending upon the condi

tion of the TE bit, each high to low, or low to high transi

tion on the PA4/TMR pin will increment the counter by

one.

T 1 T 2

T 3 T 4

T 1 T 2

T 3 T 4

W r i t e t o P o r t R e a d f r o m P o r t

S y s t e m C l o c k

P o r t D a t a

Read/Write Timing

P A 4 / T M R I n p u t

T i m e r / E v e n t C o u n t e r

M o d e C o n t r o l

T O N

P r e l o a d R e g i s t e r

T i m e r / E v e n t C o u n t e r

D a t a B u s

R e l o a d

O v e r f l o w

t o I n t e r r u p t

2

8 - S t a g e P r e s c a l e r

P S C 2 ~ P S C 0

( 1 / 1 ~ 1 / 1 2 8 )

8 - B i t T i m e r / E v e n t C o u n t e r

T M 1 T M 0

f S Y S

P F D

¸

8-bit Timer/Event Counter Structure

Page 21

HT46R46/C46/R47/C47/R48A/C48A/R49

Rev. 1.41 21 December 30, 2008

Timer Register - TMR

The TMR register is an 8-bit special function register lo

cation within the special purpose Data Memory where

the actual timer value is stored. The value in the timer

registers increases by one each time an internal clock

pulse is received or an external transition occurs on the

PA4/TMR pin. The timer will count from the initial value

loaded by the preload register to the full count value of

FFH at which point the timer overflows and an internal

interrupt signal generated. The timer value will then be

reset with the initial preload register value and continue

counting. For a maximum full range count of 00H to FFH

the preload register must first be cleared to 00H. It

should be noted that after power-on the preload register

will be in an unknown condition. Note that if the

Timer/Event Counter is not running and data is written to

its preload register, this data will be immediately written

into the actual counter. However, if the counter is en

abled and counting, any new data written into the

preload register during this period will remain in the

preload register and will only be written into the actual

counter the next time an overflow occurs.

Timer Control Register - TMRC

The flexible features of the Holtek microcontroller

Timer/Event Counters enable them to operate in three

different modes, the options of which are determined by

the contents of the Timer Control Register TMRC. To

gether with the TMR register, these two registers control

the full operation of the Timer/Event Counters. Before

the timer can be used, it is essential that the TMRC reg

ister is fully programmed with the right data to ensure its