Page 1

High Voltage Touch A/D Flash MCU with HVIO

BS86DH12C

Revision: V1.00 Date: October 26, 2018

Page 2

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Table of Contents

Features ................................................................................................................. 7

CPU Features ...............................................................................................................................7

Peripheral Features ....................................................................................................................... 7

General Description .............................................................................................. 8

Block Diagram ....................................................................................................... 9

Pin Assignment ..................................................................................................... 9

Pin Descriptions ................................................................................................. 11

Absolute Maximum Ratings ............................................................................... 14

D.C. Electrical Characteristics ........................................................................... 15

Operating Voltage Characteristics ...............................................................................................15

Operating Current Characteristics ...............................................................................................15

Standby Current Characteristics .................................................................................................16

A.C. Characteristics ............................................................................................ 16

High Speed Internal Oscillator – HIRC – Frequency Accuracy ...................................................16

Internal Low Speed Oscillator Characteristics – LIRC ................................................................17

External Low Speed Oscillator Characteristics – LXT ................................................................. 17

Operating Frequency Characteristic Curves ............................................................................... 17

System Start Up Time Characteristics ........................................................................................18

Input/Output Characteristics ............................................................................. 19

Memory Characteristics ..................................................................................... 19

LVD/LVR Electrical Characteristics ................................................................... 20

A/D Converter Electrical Characteristics .......................................................... 20

Internal Reference Voltage Characteristics ...................................................... 21

High Voltage I/O Electrical Characteristics ...................................................... 21

Voltage Detector Electrical Characteristics .................................................................................21

High Voltage I/O Other Electrical Characteristics ........................................................................22

Low Dropout Regulator Electrical Characteristics .......................................... 22

OCP Electrical Characteristics .......................................................................... 24

OVP Electrical Characteristics ..........................................................................24

Power-on Reset Characteristics ........................................................................ 25

System Architecture ........................................................................................... 25

Clocking and Pipelining ............................................................................................................... 25

Program Counter ......................................................................................................................... 26

Stack ...........................................................................................................................................27

Arithmetic and Logic Unit – ALU .................................................................................................27

Flash Program Memory ...................................................................................... 28

Structure ...................................................................................................................................... 28

Special Vectors ...........................................................................................................................28

Rev. 1.00 2 October 26, 2018 Rev. 1.00 3 October 26, 2018

Page 3

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Look-up Table .............................................................................................................................. 28

Table Program Example .............................................................................................................. 29

In Circuit Programming – ICP .....................................................................................................30

On-Chip Debug Support – OCDS ...............................................................................................31

Data Memory ....................................................................................................... 31

Structure ...................................................................................................................................... 31

Data Memory Addressing ............................................................................................................ 32

General Purpose Data Memory ..................................................................................................32

Special Purpose Data Memory ...................................................................................................32

Special Function Register Description ............................................................. 34

Indirect Addressing Registers – IAR0, IAR1, IAR2 .....................................................................34

Memory Pointers – MP0, MP1L/MP1H, MP2L/MP2H ................................................................. 34

Accumulator – ACC .................................................................................................................... 35

Program Counter Low Register – PCL .......................................................................................36

Look-up Table Registers – TBLP, TBHP, TBLH .......................................................................... 36

Status Register – STATUS .........................................................................................................36

EEPROM Data Memory ....................................................................................... 38

EEPROM Data Memory Structure ..............................................................................................38

EEPROM Registers ....................................................................................................................38

Reading Data from the EEPROM ...............................................................................................39

Writing Data to the EEPROM ......................................................................................................40

EEPROM Interrupt ......................................................................................................................40

Programming Considerations ...................................................................................................... 40

Oscillators ...........................................................................................................42

Oscillator Overview .....................................................................................................................42

System Clock Congurations ...................................................................................................... 42

Internal High Speed RC Oscillator – HIRC .................................................................................43

Internal 32kHz Oscillator – LIRC ................................................................................................. 43

External 32.768 kHz Crystal Oscillator – LXT .............................................................................43

Operating Modes and System Clocks .............................................................. 45

System Clocks ............................................................................................................................45

System Operation Modes ............................................................................................................ 46

Control Registers ........................................................................................................................47

Operating Mode Switching .......................................................................................................... 49

Standby Current Considerations ................................................................................................. 53

Wake-up ......................................................................................................................................53

Watchdog Timer .................................................................................................. 54

Watchdog Timer Clock Source .................................................................................................... 54

Watchdog Timer Control Register ............................................................................................... 54

Watchdog Timer Operation ......................................................................................................... 55

Reset and Initialisation ....................................................................................... 56

Reset Functions ..........................................................................................................................56

Reset Initial Conditions ...............................................................................................................59

Page 4

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Input/Output Ports .............................................................................................. 63

Pull-high Resistors ......................................................................................................................63

Port A Wake-up ...........................................................................................................................64

I/O Port Control Registers ........................................................................................................... 64

I/O Port Source Current Selection ...............................................................................................64

I/O Port Sink Current Selection ................................................................................................... 66

Pin-shared Functions ..................................................................................................................68

I/O Pin Structures ........................................................................................................................ 72

Programming Considerations ...................................................................................................... 72

High Voltage I/O Port .......................................................................................... 73

High Voltage I/O Registers ..........................................................................................................74

Voltage Detector ..........................................................................................................................75

Short-circuit Protection Function ................................................................................................. 76

Low Dropout Regulator – LDO .......................................................................... 77

Timer Modules – TM ...........................................................................................77

Introduction .................................................................................................................................77

TM Operation ..............................................................................................................................77

TM Clock Source ......................................................................................................................... 78

TM Interrupts ............................................................................................................................... 78

TM External Pins ......................................................................................................................... 78

Programming Considerations ...................................................................................................... 79

Compact Type TM – CTM ................................................................................... 80

Compact Type TM Operation ......................................................................................................80

Compact Type TM Register Description......................................................................................81

Compact Type TM Operation Modes ..........................................................................................84

Periodic Type TM – PTM ..................................................................................... 90

Periodic TM Operation ................................................................................................................90

Periodic Type TM Register Description .......................................................................................90

Periodic Type TM Operation Modes ............................................................................................95

Analog to Digital Converter ............................................................................. 104

A/D Overview ............................................................................................................................104

A/D Converter Register Description .......................................................................................... 105

A/D Converter Reference Voltage .............................................................................................107

A/D Converter Input Signals ...................................................................................................... 108

A/D Converter Operation ........................................................................................................... 108

Conversion Rate and Timing Diagram ......................................................................................109

Summary of A/D Conversion Steps ...........................................................................................110

Programming Considerations .................................................................................................... 111

A/D Transfer Function ............................................................................................................... 111

A/D Programming Examples ..................................................................................................... 112

Touch Key Function ......................................................................................... 114

Touch Key Structure .................................................................................................................. 114

Touch Key Register Denition ................................................................................................... 114

Rev. 1.00 4 October 26, 2018 Rev. 1.00 5 October 26, 2018

Page 5

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Touch Key Interrupt ................................................................................................................... 120

Programming Considerations .................................................................................................... 120

Over Current Protection – OCP ....................................................................... 121

Over Current Protection Operation ...........................................................................................121

Over Current Protection Registers ............................................................................................ 122

Input Voltage Range ..................................................................................................................124

Input Offset Calibration .............................................................................................................125

Over Voltage Protection – OVP ........................................................................ 126

Over Voltage Protection Operation ...........................................................................................126

Over Voltage Protection Registers ............................................................................................127

Comparator Input Offset Cancellation ......................................................................................128

I2C Interface ....................................................................................................... 129

I2C Interface Operation .............................................................................................................. 129

I2C Registers .............................................................................................................................131

I2C Bus Communication ............................................................................................................133

I2C Time-out Control ..................................................................................................................137

UART Interface .................................................................................................. 138

UART External Pins ..................................................................................................................139

UART Data Transfer Scheme....................................................................................................139

UART Status and Control Registers..........................................................................................139

Baud Rate Generator ................................................................................................................ 145

UART Setup and Control...........................................................................................................145

UART Transmitter...................................................................................................................... 146

UART Receiver .........................................................................................................................148

Managing Receiver Errors ........................................................................................................149

UART Interrupt Structure...........................................................................................................150

UART Power Down and Wake-up ............................................................................................. 151

Low Voltage Detector – LVD ............................................................................ 152

LVD Register ............................................................................................................................. 152

LVD Operation ........................................................................................................................... 153

Interrupts ........................................................................................................... 154

Interrupt Registers ..................................................................................................................... 154

Interrupt Operation .................................................................................................................... 158

External Interrupt ....................................................................................................................... 159

Touch Key Module Interrupt ......................................................................................................160

Time Base Interrupt ...................................................................................................................160

Multi-function Interrupts ............................................................................................................. 161

I2C Interrupt ............................................................................................................................... 161

UART Transfer Interrupt ............................................................................................................162

LVD Interrupt ............................................................................................................................. 162

A/D Converter Interrupt ............................................................................................................. 162

EEPROM Interrupt ....................................................................................................................162

Over Voltage Protection Interrupt ..............................................................................................163

Page 6

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Over Current Protection Interrupt .............................................................................................. 163

High Voltage Short Circuit Interrupt ...........................................................................................163

TM Interrupts ............................................................................................................................. 163

Interrupt Wake-up Function .......................................................................................................163

Programming Considerations .................................................................................................... 164

Conguration Options ...................................................................................... 164

Application Circuits .......................................................................................... 165

Instruction Set ................................................................................................... 166

Introduction ...............................................................................................................................166

Instruction Timing ......................................................................................................................166

Moving and Transferring Data ...................................................................................................166

Arithmetic Operations ................................................................................................................ 166

Logical and Rotate Operation ...................................................................................................167

Branches and Control Transfer .................................................................................................167

Bit Operations ...........................................................................................................................167

Table Read Operations .............................................................................................................167

Other Operations ....................................................................................................................... 167

Instruction Set Summary ................................................................................. 168

Table Conventions .....................................................................................................................168

Extended Instruction Set ........................................................................................................... 170

Instruction Denition ........................................................................................ 172

Extended Instruction Denition .................................................................................................181

Package Information ........................................................................................ 188

20-pin SOP (300mil) Outline Dimensions .................................................................................189

28-pin SOP (300mil) Outline Dimensions .................................................................................190

44-pin LQFP (10mm×10mm) (FP2.0mm) Outline Dimensions .................................................191

Rev. 1.00 6 October 26, 2018 Rev. 1.00 7 October 26, 2018

Page 7

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Features

CPU Features

• Operating voltage

♦

f

=8/12/16MHz, using internal LDO: VDD=5V (Typ.)

SYS

♦

High Voltage Driver: VCC=7V~10V

• Up to 0.25μs instruction cycle with 16MHz system clock at VDD=5V

• Power down and wake-up functions to reduce power consumption

• Oscillator types

♦

Internal High Speed 8/12/16MHz RC – HIRC

♦

Internal Low Speed 32kHz RC – LIRC

♦

External Low Speed 32.768kHz Crystal – LXT

• Multi-mode operation: FAST, SLOW, IDLE and SLEEP

• Fully integrated internal oscillators require no external components

• All instructions executed in 1~3 instruction cycles

• Table read instructions

• 115 powerful instructions

• 8-level subroutine nesting

• Bit manipulation instruction

Peripheral Features

• Flash Program Memory: 8K×16

• Data Memory: 512×8

• True EEPROM Memory: 64×8

• 12 touch key functions – fully integrated without requiring external components

• Watchdog Timer function

• 22 bidirectional I/O lines

• 6 bidirectional High Voltage I/O lines with short circuit protection function

• Programmable I/O port source current and sink current for LED driving applications

• Single external interrupt line shared with I/O pin

• Multiple Timer Modules for time measurement, input capture, compare match output or PWM

output or single pulse output function

• Single Time-Base function for generation of xed time interrupt signals

• 8 external channels 12-bit resolution A/D converter with internal reference voltage V

• Over Current Protection function – OCP

• Over Voltage Protection function – OVP

• Internal 5V LDO with driving current of up to 500mA, providing power supply for MCU and

external components

• I2C interface

• Fully-duplex Universal Asynchronous Receiver and Transmitter Interface – UART

• Low voltage reset function

BG

Page 8

• Low voltage detect function

• Package types: 20/28-pin SOP, 44-pin LQFP

General Description

The device is a Flash Memory type 8-bit high performance RISC architecture microcontroller with

fully integrated touch key functions. With all touch key functions provided internally and with the

convenience of Flash Memory multi-programming features, the device has all the features to offer

designers a reliable and easy means of implementing touch keys within their products applications.

The touch key functions are fully integrated, completely eliminating the need for external

components. In addition to the Flash program memory, other memory includes an area of RAM

Data Memory as well as an area of true EEPROM memory for storage of non-volatile data such as

serial numbers, calibration data etc. Analog feature includes a multi-channel 12-bit A/D converter

and an internal LDO for power supply. Protective features such as an internal Watchdog Timer, Low

Voltage Reset, Low Voltage Detector, Over Current Protection and Over Voltage Protection coupled

with excellent noise immunity and ESD protection ensure that reliable operation is maintained in

hostile electrical environments.

A full choice of external low, internal high and low speed oscillators are provided including fully

integrated system oscillators which require no external components for its implementation. The

ability to operate and switch dynamically between a range of operating modes using different

clock sources gives users the ability to optimise microcontroller operation and minimise power

consumption. Easy communication with the outside world is provided using the internal I2C and

UART interfaces, while the inclusion of exible I/O programming features, Time-Base function,

Timer Modules and many other features further enhance device functionality and exibility.

This device contains programmable I/O port source current and sink current functions which are

used to implement LED driving function. The High Voltage I/O function specic to high voltage and

high current applications is also fully integrated within the device.

The touch key device will find excellent use in a huge range of modern Touch Key product

applications such as sensor signal processing, household appliances, health care products, industrial

control, consumer products, subsystem control to name but a few.

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Rev. 1.00 8 October 26, 2018 Rev. 1.00 9 October 26, 2018

Page 9

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

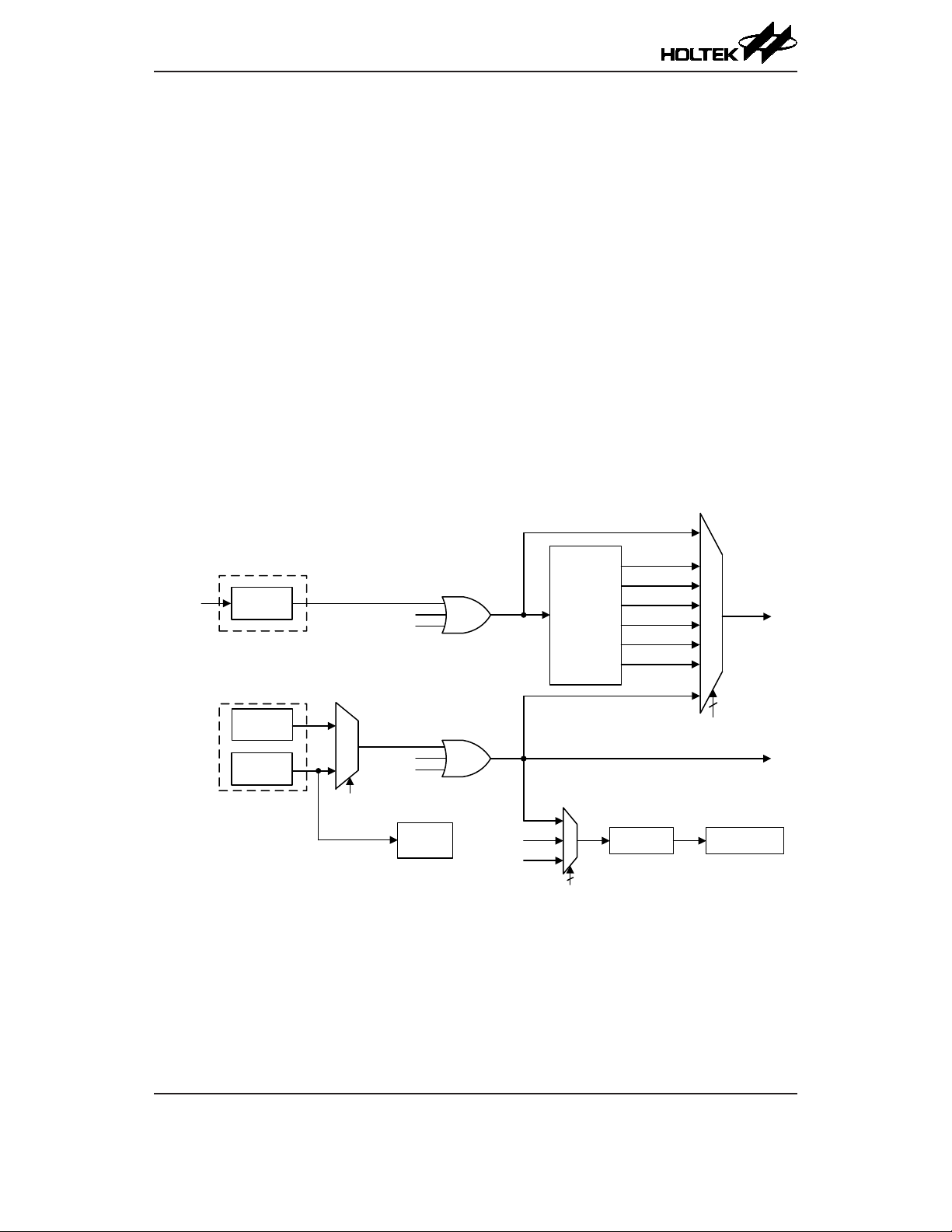

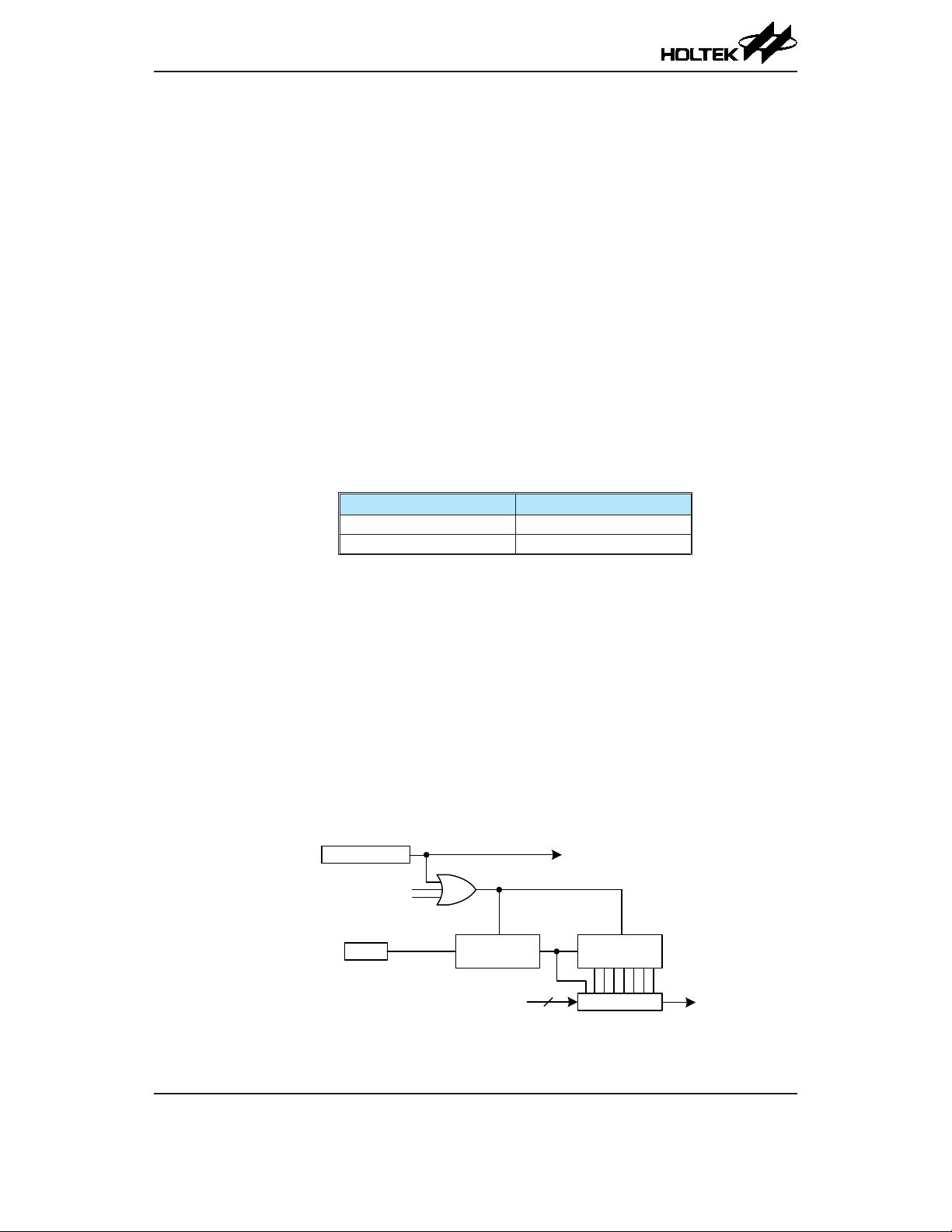

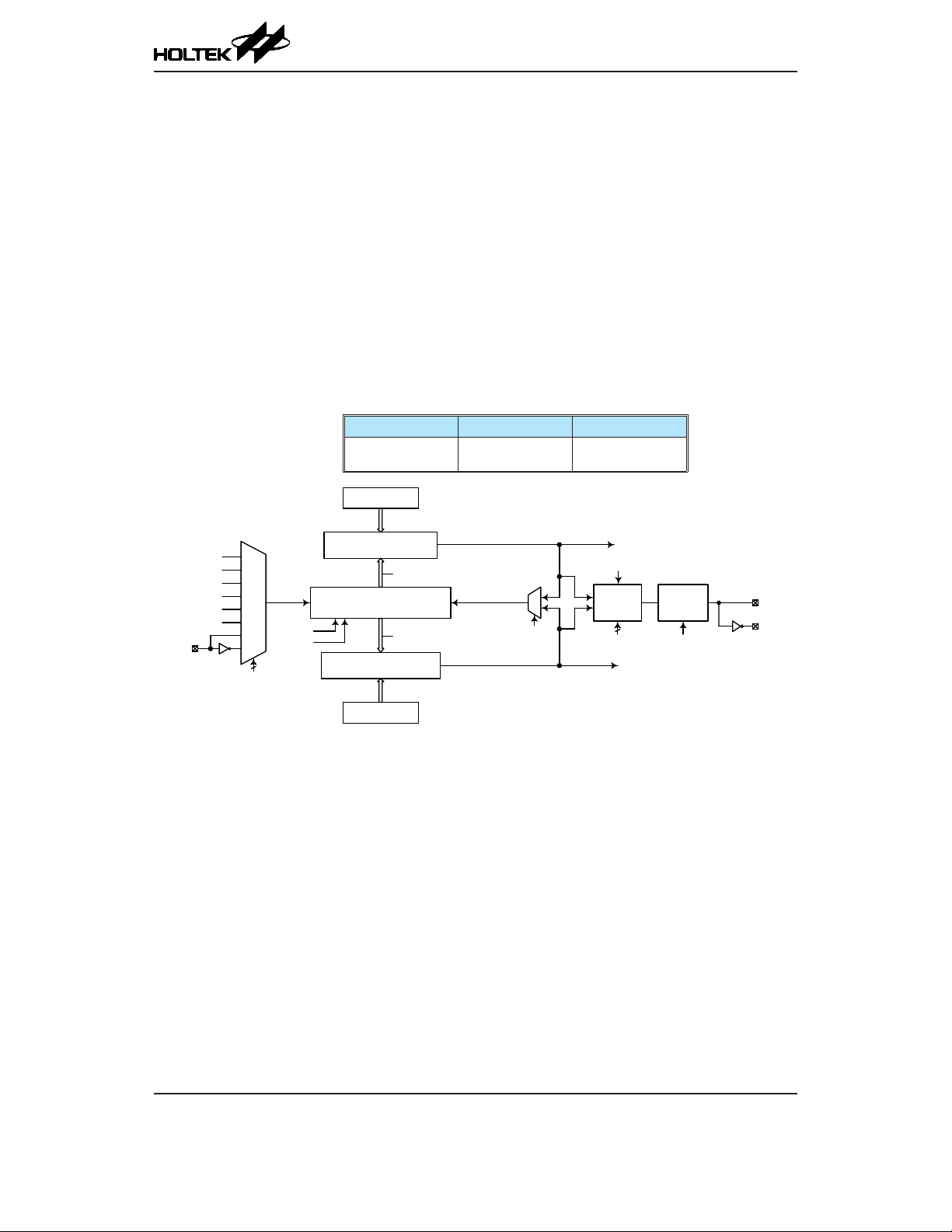

Block Diagram

VLDO

VCC1

HVSS

VCC2

PD0~PD5

VDD/AVDD/

VLDO

VSS/AVSS/

IOVSS/HVSS

Reset

Circuit

Pin-Shared

With Port C

Time Base

XT1

XT2

Pin-Shared

With Port A

Port D

Driver

V

DD

V

SS

Interrupt

Controller

8/12/16MHz

High Voltage Analog Peripherals

INT

: Bus Entry : Pin-Shared Node

8K × 16

EEPROM

Watchdog

LIRC

32kHz

LXT

HIRC

Clock System

LDO

(5V)

HV I/O

ROM

64 × 8

Timer

HT8 MCU Core

RAM

512 × 8

Stack

8-Level

LVR/LVD

MUX

Bus

Analog to Digital Converter

Over Current

Protection Circuit

Over Voltage

Protection Circuit

Touch Key Module 2

Touch Key Module 1

Touch Key Module 0

C to F

Circuit

Touch Key Function

Timers

I2C

12-bit

ADC

+

_

+

_

Analog Peripherals

I/O

UART

Digital Peripherals

MUX

MUX

8-bit

DAC

8-bit

DAC

V

V

V

V

Pin-Shared

BG

CC1O

CC2O

OCPAO

Function

AV

DD

OPA

Pin-Shared

With Port A, B & C

Port A

Driver

Port B

Driver

Port C

Driver

VREF

Pin-Shared

With Port A

AN0~AN7

Pin-Shared

With Port A & B

OCPAO

OCPI

Pin-Shared

With Port A & B

OVPI0

OVPI1

Pin-Shared

With Port A, B & C

KEY1~KEY12

PA0~PA7

PB0~PB7

PC0~PC5

Pin Assignment

PB0/RX/CTCK0/OCPI/KEY1 PA6/CTCK1/PTPI/CTP0/PTPB/XT1

PA1/PTCK/SCL/OVPI1/KEY3

PA3/PTPI/SDA/VREF/KEY4 PA0/RX/CTP1/OCPVR/ICPDA/OCDSDA

PD3 VCC2

PD2 VCC1

PD1 VDD/VLDO/AVDD

PD0 PA7/CTCK0/PTCK/PTP/XT2

PA4/AN0/KEY5

PA5/AN1/KEY6 PB2/SCL/AN6/KEY9

20

1

19

2

18

3

17

4

16

5

6

7

8

9

10

VSS/AVSS/IOVSS/HVSSPB1/TX/CTCK1/OVPI0/KEY2

15

PA2/TX/CTP1B/OCPI/ICPCK/OCDSCK

14

13

PB3/SDA/AN7/KEY10

12

11

BS86DH12C/BS86DHV12C

20 SOP-A

Page 10

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

PB0/RX/CTCK0/OCPI/KEY1

PB1/TX/CTCK1/OVPI0/KEY2

PA1/PTCK/SCL/OVPI1/KEY3

PA3/PTPI/SDA/VREF/KEY4

PA4/AN0/KEY5

PA5/AN1/KEY6

PB4/CTP0/AN2/KEY7

PB5/CTP0B/AN3/KEY8

PB6/CTP1/AN4/OCPAO

PB7/CTP1B/AN5/OVPCOUT

NC

NC

NC

PB0/RX/CTCK0/OCPI/KEY1

PB1/TX/CTCK1/OVPI0/KEY2

PA1/PTCK/SCL/OVPI1/KEY3

PA3/PTPI/SDA/VREF/KEY4

PA4/AN0/KEY5

PA5/AN1/KEY6

PB4/CTP0/AN2/KEY7

PB5/CTP0B/AN3/KEY8

PD3

1

28

PD2

2

27

PD1

3

26

PD0

4

25

5

24

6

23

7

22

8

21

9

20

10

19

11

18

12

17

13

16

14

15

BS86DH12C/BS86DHV12C

28 SOP-A

V

VCC2

C

P

P

P

PD0

PD1

P

D

D

D

4

3

2

1

2

3

4

5

BS86DH12C/BS86DHV12C

6

7

8

9

10

11

44 LQFP-A

12 13 14 15 16 1718 19 20 21 22

NC

NC

NC

P

P

B

B

7

6

/

/

C

C

T

T

P

P

1

1

B

/

A

/

A

N

N

4

/

5

O

/

O

C

V

P

P

A

C

O

O

U

T

NC

C

D

1

5

PB3/SDA/AN7/KEY10

P

P

P

B

C

C

2

5

4

/

S

C

L

/

A

N

6

/

K

E

Y

9

VCC2

VCC1

VDD/VLDO/AVDD

PA7/CTCK0/PTCK/PTP/XT2

PA6/CTCK1/PTPI/CTP0/PTPB/XT1

VSS/AVSS/IOVSS/HVSS

PC3/CTP0/SDA/TX

PC2/CTP1/SCL/RX

PA2/TX/CTP1B/OCPI/ICPCK/OCDSCK

PA0/RX/CTP1/OCPVR/ICPDA/OCDSDA

PC1/INT/PTPB/OVPI1/KEY12

PC0/PTP/OVPI0/KEY11

PB3/SDA/AN7/KEY10

PB2/SCL/AN6/KEY9

NC

NC

3435363738394041424344

VDD/VLDO/AVDD

33

NC

32

NC

31

NC

30

PA7/CTCK0/PTCK/PTP/XT2

29

PA6/CTCK1/PTPI/CTP0/PTPB/XT1

28

VSS/AVSS/IOVSS/HVSS

27

PC3/CTP0/SDA/TX

26

PC2/CTP1/SCL/RX

25

PA2/TX/CTP1B/OCPI/ICPCK/OCDSCK

24

PA0/RX/CTP1/OCPVR/ICPDA/OCDSDA

23

PC1/INT/PTPB/OVPI1/KEY12

PC0/PTP/OVPI0/KEY11

Note: 1. If the pin-shared pin functions have multiple outputs, the desired pin-shared function is determined by the

corresponding software control bits.

2. The OCDSDA and OCDSCK pins are supplied for the OCDS dedicated pins and as such only available

for the BS86DHV12C device which is the OCDS EV chip for the BS86DH12C device.

3. For less pin-count package types there will be unbonded pins which should be properly congured to

avoid unwanted current consumption resulting from floating input conditions. Refer to the “Standby

Current Considerations” and “Input/Output Ports” sections.

Rev. 1.00 10 October 26, 2018 Rev. 1.00 11 October 26, 2018

Page 11

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Pin Descriptions

With the exception of the power pins, all pins on the device can be referenced by their Port name, e.g.

PA0, PA1 etc., which refer to the digital I/O function of the pins. However these Port pins are also

shared with other function such as the Touch Key function, Timer Module pins etc. The function of

each pin is listed in the following table, however the details behind how each pin is congured is

contained in other sections of the datasheet.

As the Pin Description table shows the situation for the package with the most pins, not all pins in

the table will be available on smaller package sizes.

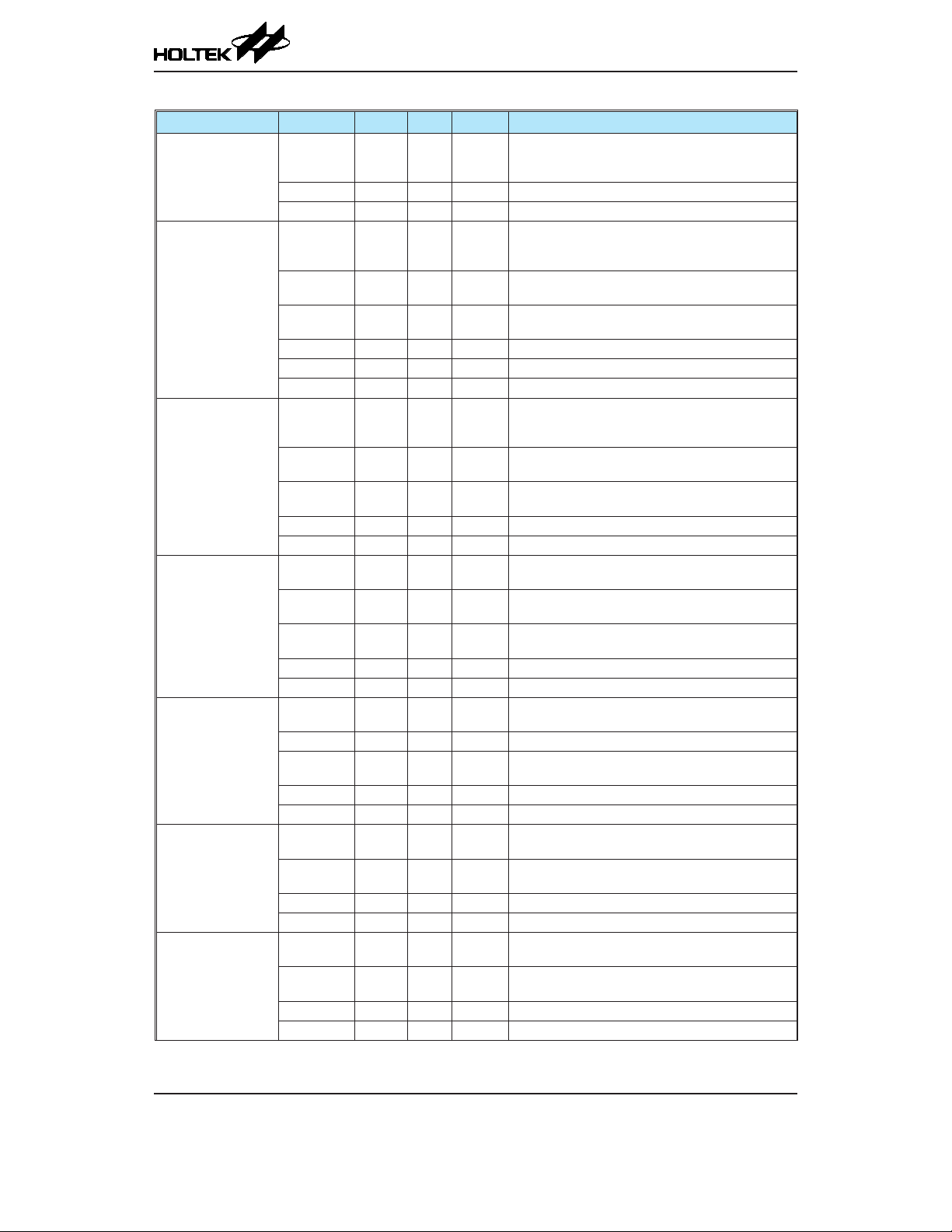

Pin Name Function OPT I/T O/T

PA0/RX/CTP1/

OCPVR/ICPDA/

OCDSDA

PA1/PTCK/SCL/

OVPI1/KEY3

PA2/TX/CTP1B/

OCPI/ICPCK/

OCDSCK

PA3/PTPI/SDA/

VREF/KEY4

PA4/AN0/KEY5

PA0

RX

CTP1 PAS0 — CMOS CTM1 output

OCPVR PAS0 AN — OCP D/A converter reference voltage input

ICPDA — ST CMOS ICP data/address

OCDSDA — ST CMOS OCDS data/address, for EV chip only

PA1

PTCK

SCL

OVPI1 PAS0 AN — OVP input 1

KEY3 PAS0 NSI — Touch key input

PA2

TX PAS0 — CMOS UART data transmit pin

CTP1B PAS0 — CMOS CTM1 inverted output

OCPI PAS0 AN — OCP input

ICPCK — ST — ICP clock

OCDSCK — ST — OCDS clock, for EV chip only

PA3

PTPI

SDA

VREF PAS0 AN — A/D converter external input channel

KEY4 PAS0 NSI — Touch key input

PA4

AN0 PAS1 AN — A/D converter external input channel

KEY5 PAS1 NSI — Touch key input

PAPU

PAWU

PAS0

PAS0

IFS0

PAPU

PAWU

PAS0

PAS0

IFS1

PAS0

IFS0

PAPU

PAWU

PAS0

PAPU

PAWU

PAS0

PAS0

IFS1

PAS0

IFS0

PAPU

PAWU

PAS1

ST CMOS

ST — UART data receive pin

ST CMOS

ST — PTM clock input

ST NMOS I2C clock line

ST CMOS

ST CMOS

ST — PTM capture input

ST NMOS I2C data line

ST CMOS

General purpose I/O. Register enabled pull-up and

wake-up

General purpose I/O. Register enabled pull-up and

wake-up

General purpose I/O. Register enabled pull-up and

wake-up

General purpose I/O. Register enabled pull-up and

wake-up

General purpose I/O. Register enabled pull-up and

wake-up

Description

Page 12

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Pin Name Function OPT I/T O/T

PAPU

PAWU

PAS1

PAPU

PAWU

PAS1

PAS1

IFS1

PAS1

IFS1

PAPU

PAWU

PAS1

PAS1

IFS1

PAS1

IFS1

PBPU

PBS0

PBS0

IFS0

PBS0

IFS1

PBPU

PBS0

PBS0

IFS1

PBPU

PBS0

PBS0

IFS0

PBPU

PBS0

PBS0

IFS0

PA5/AN1/KEY6

PA6/CTCK1/PTPI/

CTP0/PTPB/XT1

PA7/CTCK0/PTCK/

PTP/XT2

PB0/RX/CTCK0/

OCPI/KEY1

PB1/TX/CTCK1/

OVPI0/KEY2

PB2/SCL/AN6/KEY9

PB3/SDA/AN7/

KEY10

PA5

AN1 PAS1 AN — A/D converter external input channel

KEY6 PAS1 NSI — Touch key input

PA6

CTCK1

PTPI

CTP0 PAS1 — CMOS CTM0 output

PTPB PAS1 — CMOS PTM inverted output

XT1 PAS1 LXT — LXT oscillator pin

PA7

CTCK0

PTCK

PTP PAS1 — CMOS PTM output

XT2 PAS1 — LXT LXT oscillator pin

PB0

RX

CTCK0

OCPI PBS0 AN — OCP input

KEY1 PBS0 NSI — Touch key input

PB1

TX PBS0 — CMOS UART data transmit pin

CTCK1

OVPI0 PBS0 AN — OVP input 0

KEY2 PBS0 NSI — Touch key input

PB2

SCL

AN6 PBS0 AN — A/D converter external input channel

KEY9 PBS0 NSI — Touch key input

PB3

SDA

AN7 PBS0 AN — A/D converter external input channel

KEY10 PBS0 NSI — Touch key input

Description

ST CMOS

ST CMOS

ST — CTM1 clock input

ST — PTM capture input

ST CMOS

ST — CTM0 clock input

ST — PTM clock input

ST CMOS General purpose I/O. Register enabled pull-up

ST — UART data receive pin

ST — CTM0 clock input

ST CMOS General purpose I/O. Register enabled pull-up

ST — CTM1 clock input

ST CMOS General purpose I/O. Register enabled pull-up

ST NMOS I2C clock line

ST CMOS General purpose I/O. Register enabled pull-up

ST NMOS I2C data line

General purpose I/O. Register enabled pull-up and

wake-up

General purpose I/O. Register enabled pull-up and

wake-up

General purpose I/O. Register enabled pull-up and

wake-up

Rev. 1.00 12 October 26, 2018 Rev. 1.00 13 October 26, 2018

Page 13

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Pin Name Function OPT I/T O/T

PB4

PB4/CTP0/AN2/

KEY7

PB5/CTP0B/AN3/

KEY8

PB6/CTP1/AN4/

OCPAO

PB7/CTP1B/AN5/

OVPCOUT

PC0/PTP/OVPI0/

KEY11

PC1/INT/PTPB/

OVPI1/KEY12

PC2/CTP1/SCL/RX

PC3/CTP0/SDA/TX

PC4~PC5 PC4~PC5 PCPU ST CMOS General purpose I/O. Register enabled pull-up

PD0~PD5 PD0~PD5 — ST CMOS High voltage I/O port

VDD/AVDD/VLDO

CTP0 PBS1 — CMOS CTM0 output

AN2 PBS1 AN — A/D converter external input channel

KEY7 PBS1 NSI — Touch key input

PB5

CTP0B PBS1 — CMOS CTM0 inverted output

AN3 PBS1 AN — A/D converter external input channel

KEY8 PBS1 NSI — Touch key input

PB6

CTP1 PBS1 — CMOS CTM1 output

AN4 PBS1 AN — A/D converter external input channel

OCPAO PBS1 AN — OCP operational amplier output

PB7

CTP1B PBS1 — CMOS CTM1 inverted output

AN5 PBS1 AN — A/D converter external input channel

OVPCOUT PBS1 — CMOS OVP comparator output

PC0

PTP PCS0 — CMOS PTM output

OVPI0 PCS0 AN — OVP input 0

KEY11 PCS0 NSI — Touch key input

PC1

INT

PTPB PCS0 — CMOS PTM inverted output

OVPI1 PCS0 AN — OVP input 1

KEY12 PCS0 NSI — Touch key input

PC2

CTP1 PCS0 — CMOS CTM1 output

SCL

RX

PC3

CTP0 PCS0 — CMOS CTM0 output

SDA

TX PCS0 — CMOS UART data transmit pin

VDD — PWR — Digital positive power supply

AVDD — PWR — Analog positive power supply

VLDO — — PWR LDO output voltage

PBPU

PBS1

PBPU

PBS1

PBPU

PBS1

PBPU

PBS1

PCPU

PCS0

PCPU

PCS0

PCS0

INTC0

INTEG

PCPU

PCS0

PCS0

IFS0

PCS0

IFS0

PCPU

PCS0

PCS0

IFS0

ST CMOS General purpose I/O. Register enabled pull-up

ST CMOS General purpose I/O. Register enabled pull-up

ST CMOS General purpose I/O. Register enabled pull-up

ST CMOS General purpose I/O. Register enabled pull-up

ST CMOS General purpose I/O. Register enabled pull-up

ST CMOS General purpose I/O. Register enabled pull-up

ST — External interrupt input

ST CMOS General purpose I/O. Register enabled pull-up

ST NMOS I2C clock line

ST — UART data receive pin

ST CMOS General purpose I/O. Register enabled pull-up

ST NMOS I2C data line

Description

Page 14

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Pin Name Function OPT I/T O/T

VSS — PWR — Digital negative power supply, ground

VSS/AVSS/IOVSS/

HVSS

VCC1 VCC1 — PWR —

VCC2 VCC2 — PWR —

NC NC — — — Unused

AVSS — PWR — Analog negative power supply, ground

IOVSS — PWR — I/O port negative power supply, ground

HVSS — PWR — High voltage negative power supply, ground

Provides high voltage positive power supply for

LDO input

Provides high voltage positive power supply for

High Voltage I/O and Level Shifter

Legend: I/T: Input type; O/T: Output type;

OPT: Optional by register selection;

PWR: Power; ST: Schmitt Trigger input;

CMOS: CMOS output; NMOS: NMOS output;

AN: Analog signal; NSI: Non-standard input;

LXT: Low frequency crystal oscillator.

Absolute Maximum Ratings

Supply Voltage (VCC) ................................................................................................VSS-0.3V to 10.0V

Supply Voltage (VDD) .........................................................................................VSS-0.3V to VSS+6.0V

High Voltage Input Voltage ............................................................................... VSS-0.3V to VCC+0.3V

Input Voltage .....................................................................................................VSS-0.3V to VDD+0.3V

Storage Temperature .....................................................................................................-50°C to 125°C

Operating Temperature ................................................................................................... -40°C to 85°C

High Voltage IOH Total ..............................................................................................................-150mA

IOH Total ......................................................................................................................................-80mA

High Voltage IOL Total ............................................................................................................... 150mA

IOL Total ....................................................................................................................................... 80mA

Total Power Dissipation ........................................................................................................... 500mW

Description

Note: These are stress ratings only. Stresses exceeding the range specified under “Absolute

Maximum Ratings” may cause substantial damage to this device. Functional operation of

this device at other conditions beyond those listed in the specification is not implied and

prolonged exposure to extreme conditions may affect device reliability.

Rev. 1.00 14 October 26, 2018 Rev. 1.00 15 October 26, 2018

Page 15

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

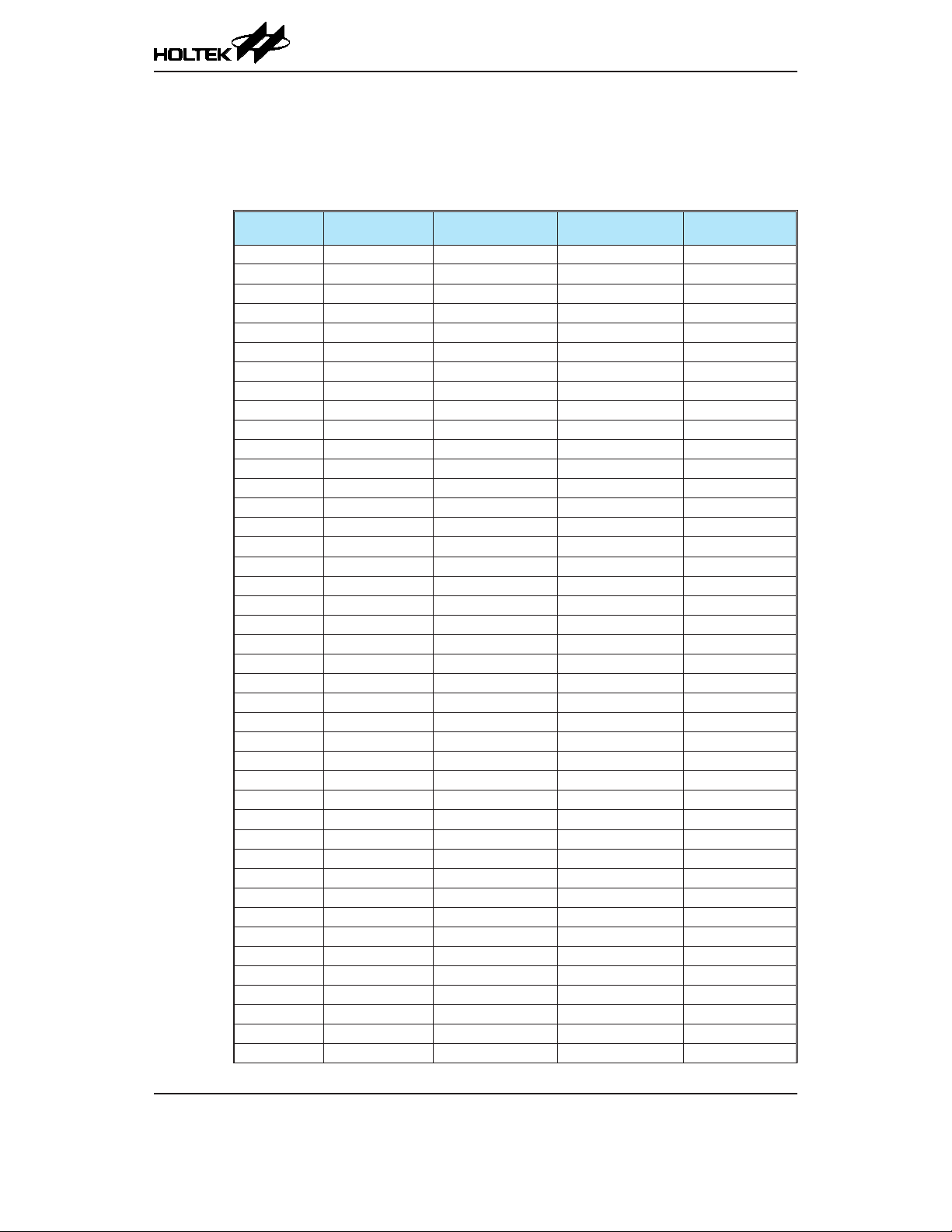

D.C. Electrical Characteristics

For data in the following tables, note that factors such as oscillator type, operating voltage, operating

frequency, pin load conditions, temperature and program instruction type, can all exert an inuence

on the measured values.

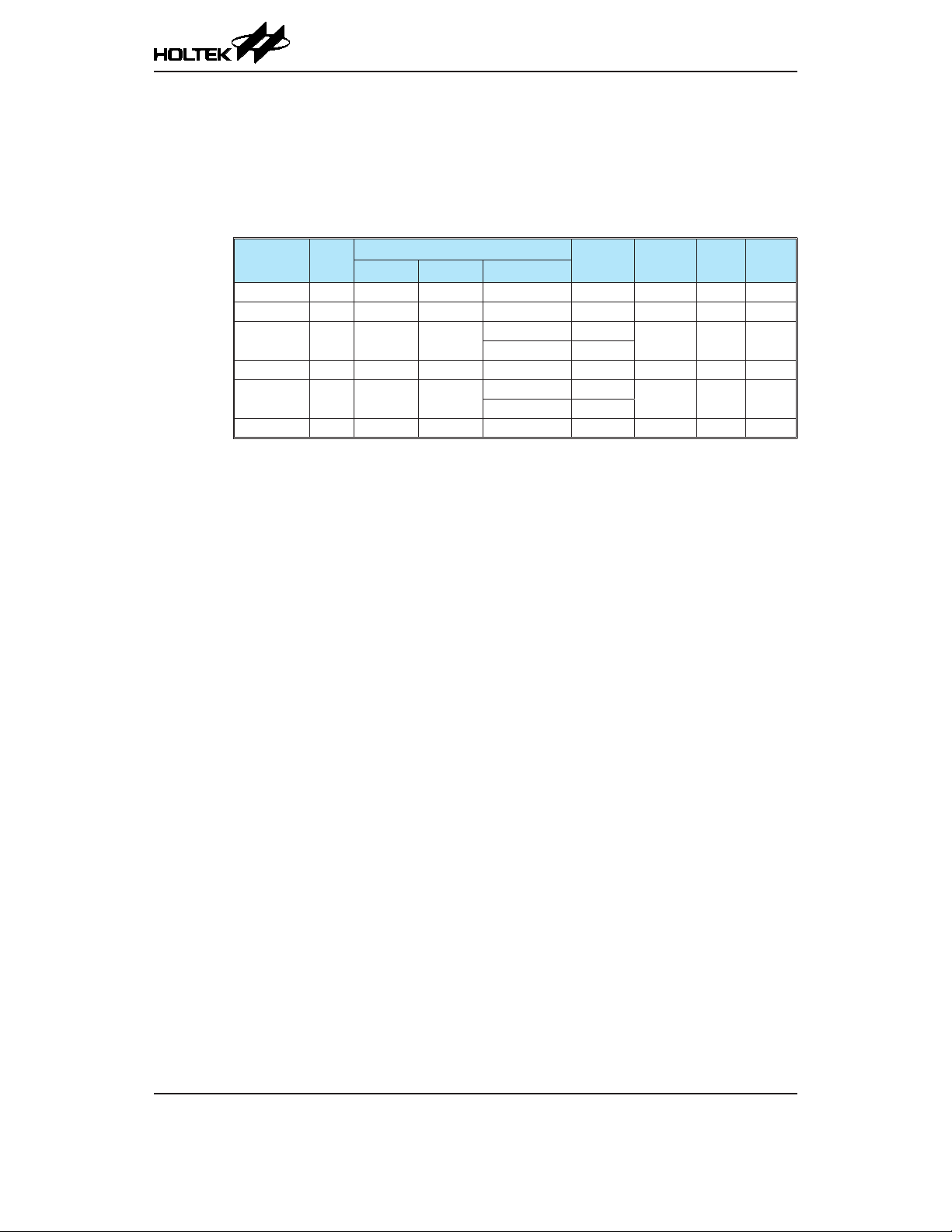

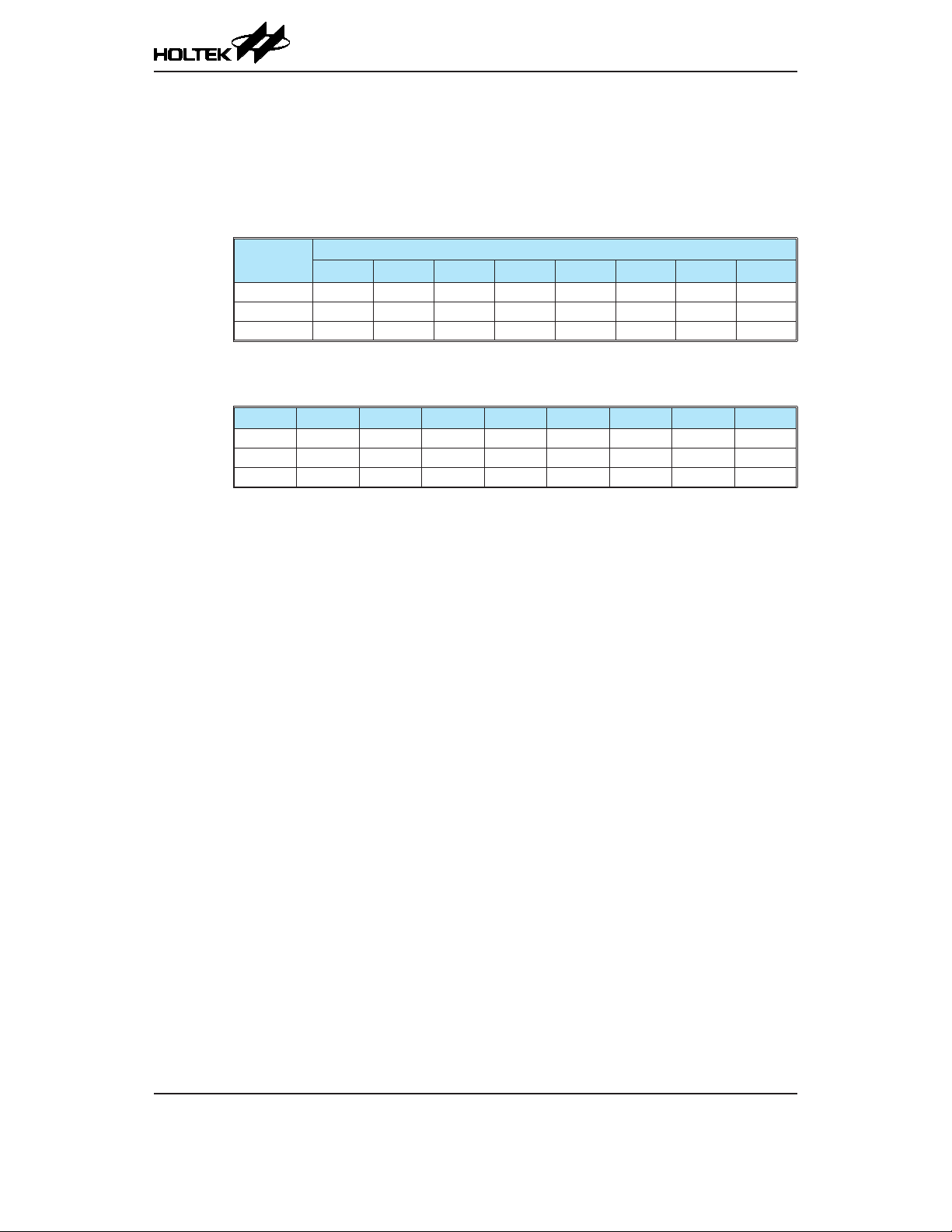

Operating Voltage Characteristics

Ta=25°C

Symbol Parameter Test Conditions Min. Typ. Max. Unit

f

=8MHz 4.5 — 5.5

SYS=fHIRC

Operating Voltage – HIRC

V

DD

Operating Voltage – LIRC f

Operating Voltage – LXT f

Operating Current Characteristics

Symbol Parameter

SLOW Mode – LIRC 5V

SLOW Mode – LXT 5V

I

DD

FAST Mode – HIRC 5V

f

SYS=fHIRC

f

SYS=fHIRC

SYS=fLIRC

SYS=fLXT

Test Conditions

V

DD

f

SYS=fLIRC

consumption included

f

SYS=fLXT

consumption included

f

SYS=fHIRC

consumption included

f

SYS=fHIRC

consumption included

f

SYS=fHIRC

consumption included

=12MHz 4.5 — 5.5

=16MHz 4.5 — 5.5

=32kHz 4.5 — 5.5 V

=32.768kHz 4.5 — 5.5 V

Ta=25°C

Conditions

=32kHz, LDO current

=32768Hz, LDO current

=8MHz, LDO current

=12MHz, LDO current

=16MHz, LDO current

Min. Typ. Max. Unit

— 180 200 μA

— 180 200 μA

— 1.6 2.4

— 2.4 3.6

— 6.0 9.0

V

mA

Note: When using the characteristic table data, the following notes should be taken into consideration:

1. Any digital input is set in a non-oating condition.

2. All measurements are taken under conditions of no load and with all peripherals in an off state.

3. There are no DC current paths.

4. All Operating Current values are measured using a continuous NOP instruction program loop.

Page 16

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Standby Current Characteristics

Ta=25°C, unless otherwise specied

Symbol Parameter

SLEEP Mode 5V

IDLE0 Mode – LIRC 5V

IDLE0 Mode – LXT 5V

I

STB

IDLE1 Mode – HIRC 5V

V

Test Conditions

DD

Conditions

WDT on, LDO current

consumption included

f

on, LDO current

SUB

consumption included

f

on, LDO current

SUB

consumption included

f

on, f

SUB

=8MHz, LDO

SYS

current consumption included

f

on, f

SUB

=12MHz, LDO

SYS

current consumption included

f

on, f

SUB

=16MHz, LDO

SYS

current consumption included

Min. Typ. Max.

— 160 200 210 μA

— 165 200 215 μA

— 165 200 215 μA

— 1.0 1.8 2.0

— 1.5 2.6 3.0

— 2.0 3.5 4.0

Note: When using the characteristic table data, the following notes should be taken into consideration:

1. Any digital input is set in a non-oating condition.

2. All measurements are taken under conditions of no load and with all peripherals in an off state.

3. There are no DC current paths.

4. All Standby Current values are taken after a HALT instruction executed thus stopping all instruction

execution.

Max.

@85°C

Unit

mA

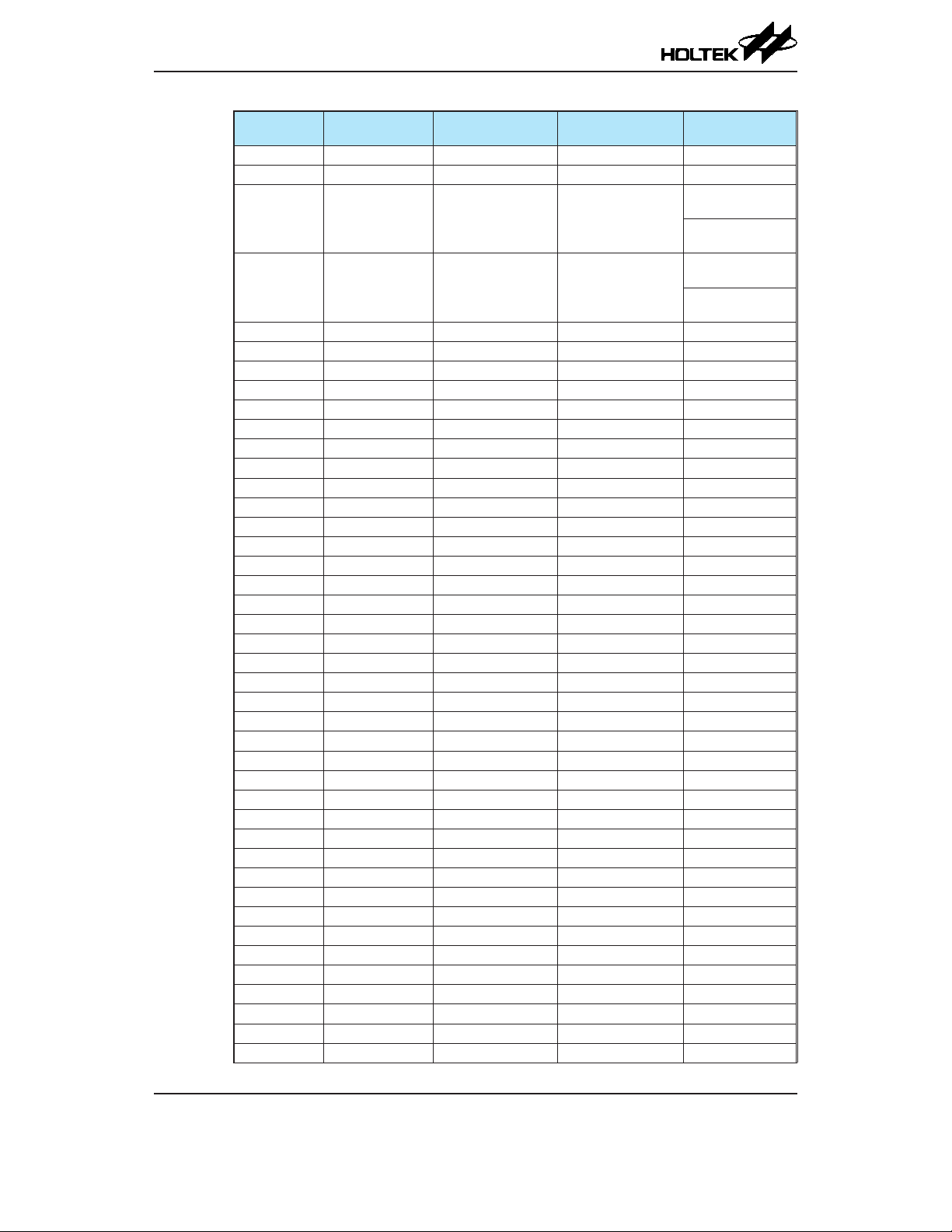

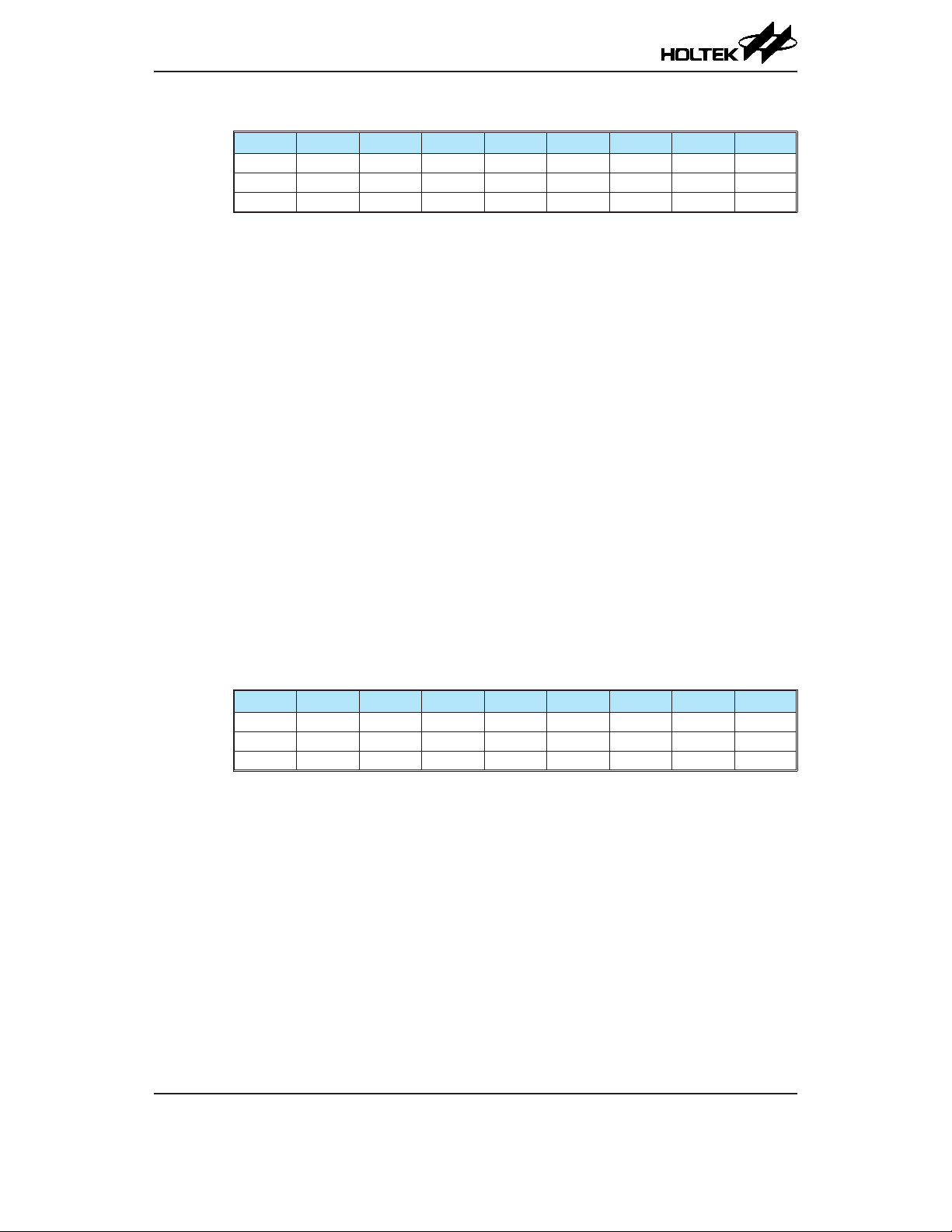

A.C. Characteristics

For data in the following tables, note that factors such as oscillator type, operating voltage, operating

frequency and temperature etc., can all exert an inuence on the measured values.

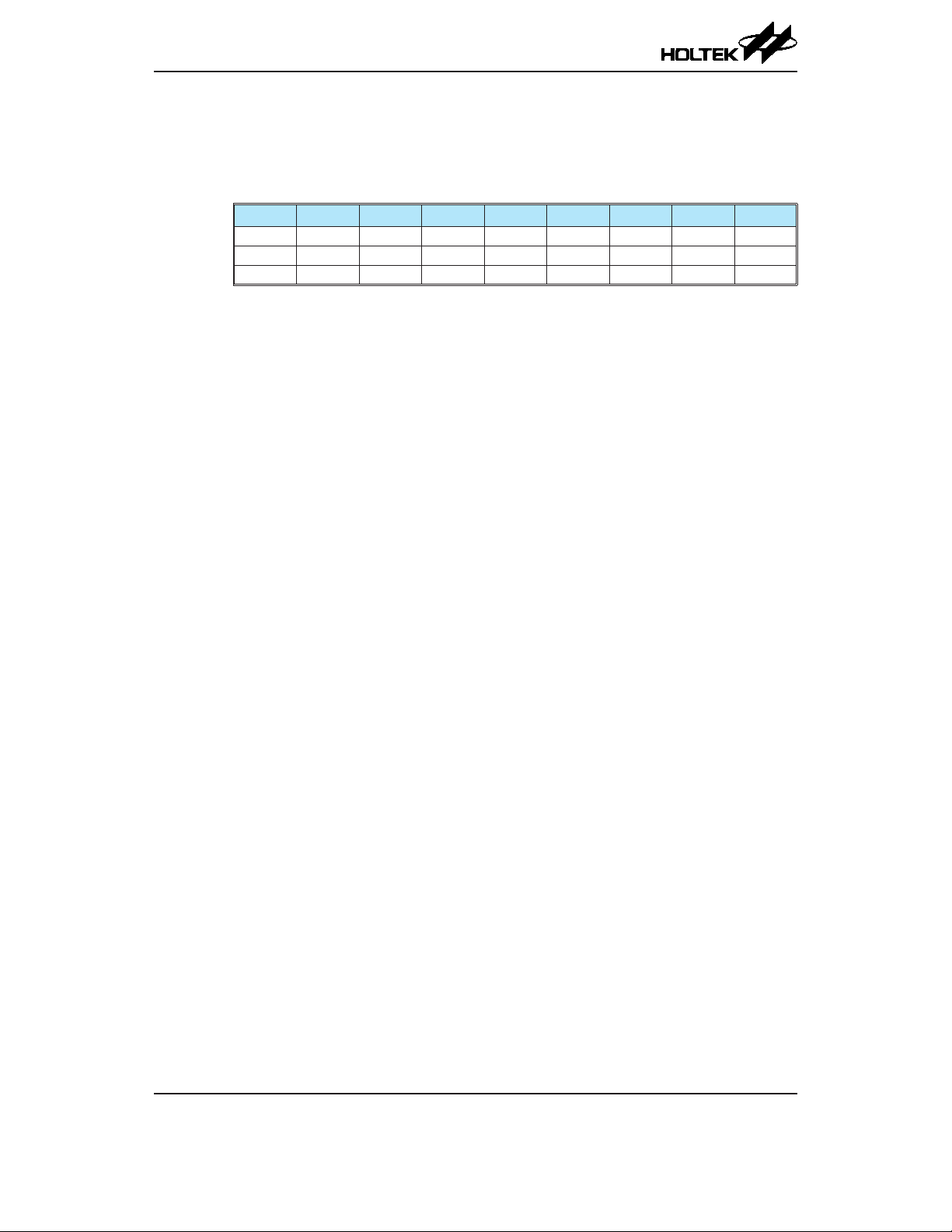

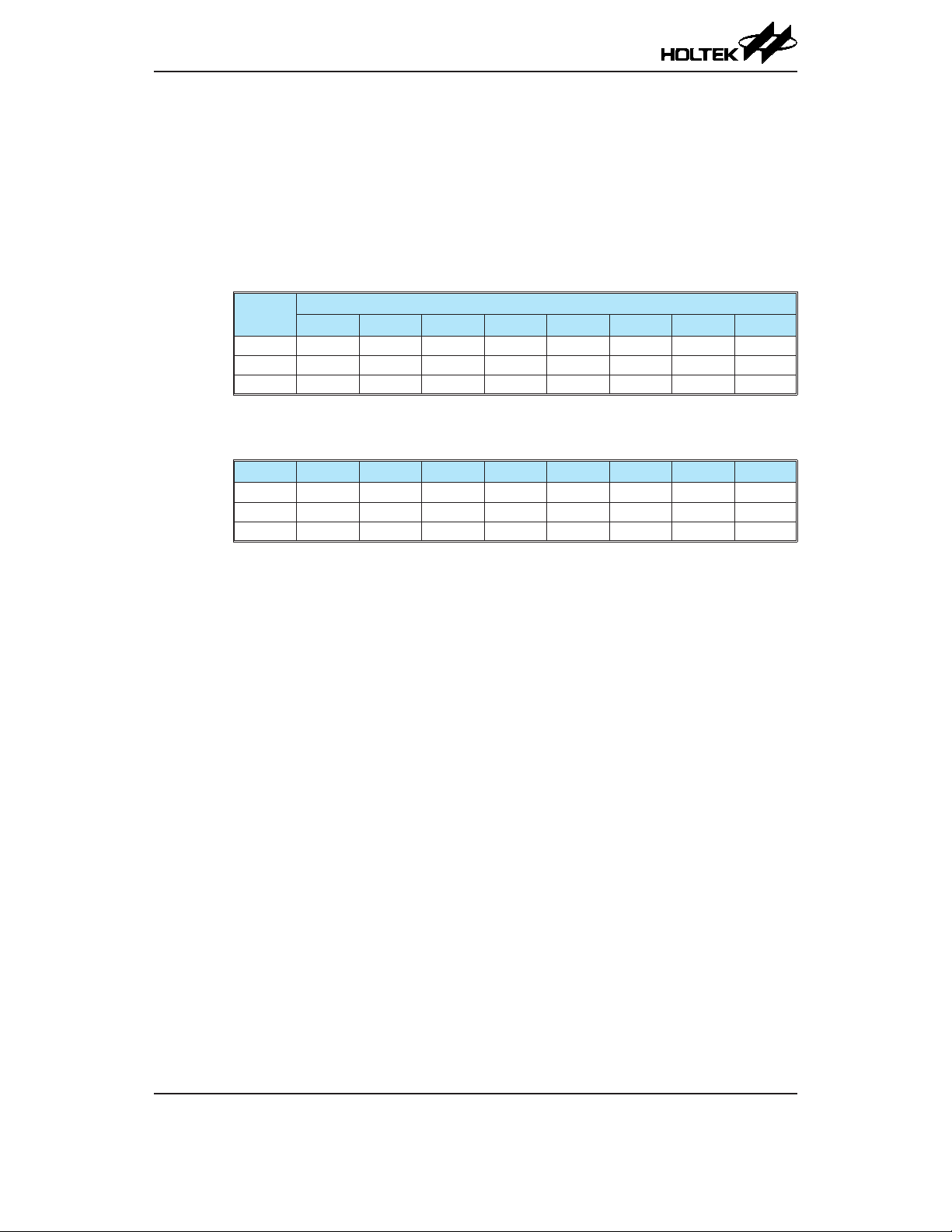

High Speed Internal Oscillator – HIRC – Frequency Accuracy

During the program writing operation the writer will trim the HIRC oscillator at a user selected

HIRC frequency and user selected voltage of 5V.

Symbol Parameter

8MHz Writer Trimmed HIRC Frequency

f

HIRC

12MHz Writer Trimmed HIRC Frequency

16MHz Writer Trimmed HIRC Frequency

Note: 1. The 5V values for VDD are provided as this is the xed voltage at which the HIRC frequency is trimmed

by the writer.

2. The row below the 5V trim voltage row is provided to show the values for the full VDD range operating

voltage. It is recommended that the trim voltage is xed at 5V for application voltage ranges from 3.3V

to 5.5V.

Test Conditions

V

DD

5V

4.5V~5.5V

5V

4.5V~5.5V

5V

4.5V~5.5V

Temp.

Min. Typ. Max. Unit

25°C -1% 8 +1%

-40°C~85°C -2% 8 +2%

25°C -2.5% 8 +2.5%

-40°C~85°C -3% 8 +3%

25°C -1% 12 +1%

-40°C~85°C -2% 12 +2%

25°C -2.5% 12 +2.5%

-40°C~85°C -3% 12 +3%

25°C -1% 16 +1%

-40°C~85°C -2% 16 +2%

25°C -2.5% 16 +2.5%

-40°C~85°C -3% 16 +3%

MHz

MHz

MHz

Rev. 1.00 16 October 26, 2018 Rev. 1.00 17 October 26, 2018

Page 17

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

3. The minimum and maximum tolerance values provided in the table are only for the frequency at which

the writer trims the HIRC oscillator. After trimming at this chosen specific frequency any change in

HIRC oscillator frequency using the oscillator register control bits by the application program will give a

frequency tolerance to within ±20%.

Internal Low Speed Oscillator Characteristics – LIRC

Symbol Parameter

f

LIRC

t

START

LIRC Frequency 4.5V~5.5V

LIRC Start Up Time — 25°C — — 500 μs

Test Conditions

V

DD

25°C -10% 32 +10%

-40°C~85°C -50% 32 +60%

Temp.

Min. Typ. Max. Unit

kHz

External Low Speed Oscillator Characteristics – LXT

C1=C2=10pF, RP=10MΩ (C1, C2 and RP are external components), CL=7pF, ESR=30kΩ

Symbol Parameter

f

LXT

t

START

LXT Frequency 4.5V~5.5V — — 32768 — Hz

LXT Start Up Time 5V — — — 1000 μs

Test Conditions

V

DD

Conditions

Min. Typ. Max. Unit

Duty Cycle Duty Cycle — — 40 — 60 %

R

NEG

Negative Resistance 5V — 3×ESR — — Ω

Ta=25°C

Operating Frequency Characteristic Curves

System Operating Frequency

16MHz

12MHz

8MHz

~

~

~

~

~

~

4.5V 5.5V

Operating Voltage

Page 18

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

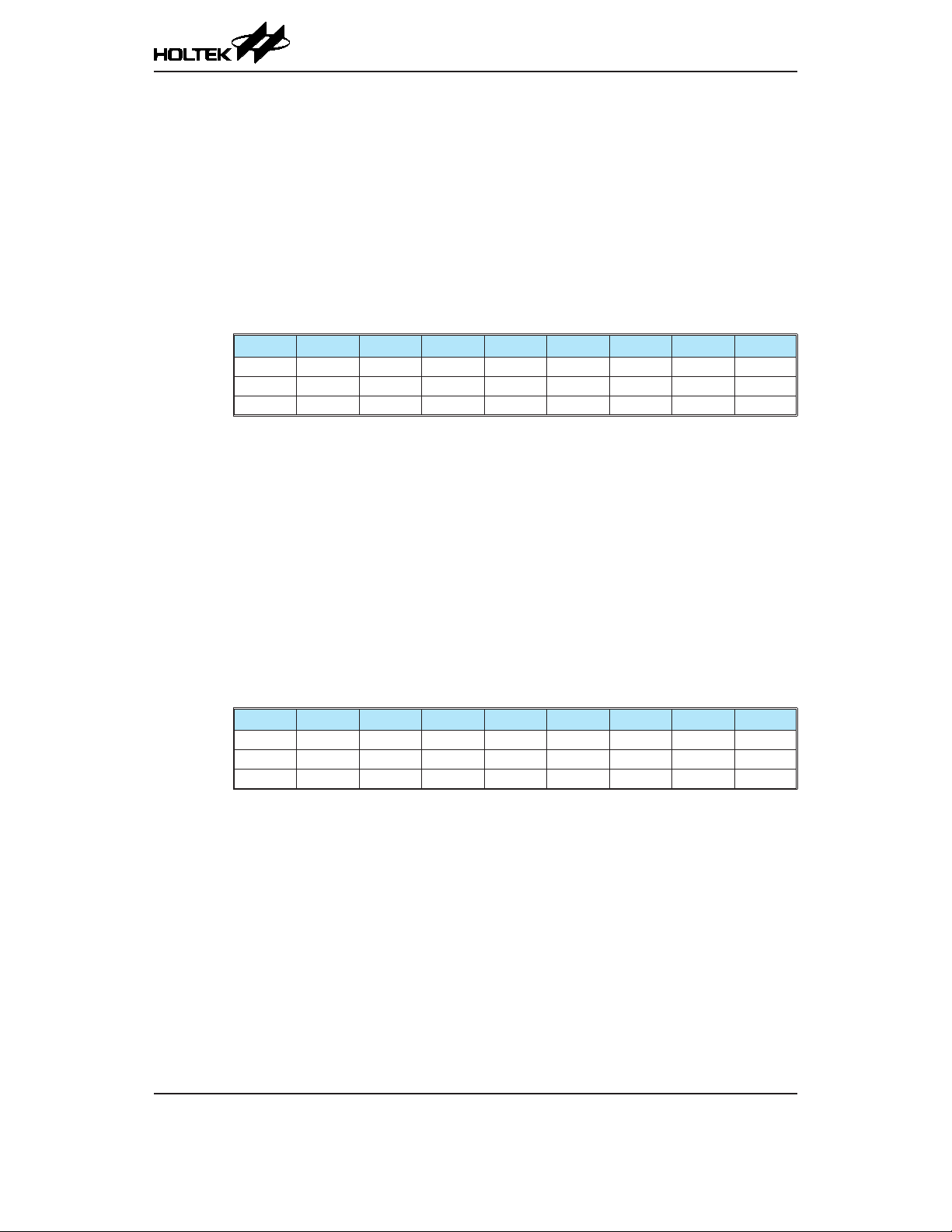

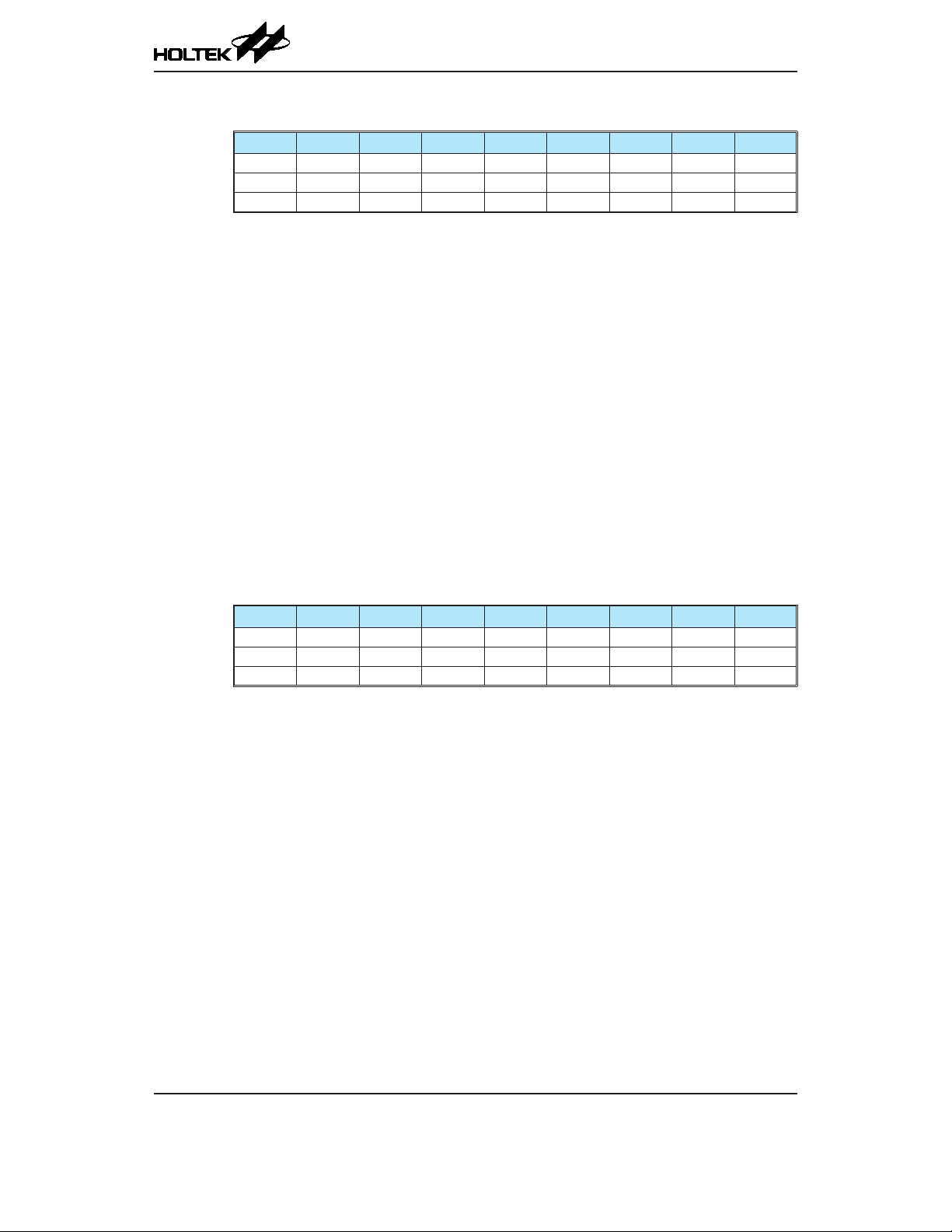

System Start Up Time Characteristics

Symbol Parameter

System Start-up Time

Wake-up from Condition where f

t

SST

System Start-up Time

Wake-up from Condition where f

SYS

SYS

is Off

is On

System Speed Switch Time

FAST to SLOW Mode or

SLOW to FAST Mode

System Reset Delay Time

Reset Source from Power-on Reset or

LVR Hardware Reset

t

RSTD

System Reset Delay Time

LVRC/WDTC/RSTC Software Reset

System Reset Delay Time

Reset Source from WDT Overow

t

SRESET

Minimum Software Reset Width to Reset — — 45 90 180 μs

Note: 1. For the System Start-up time values, whether f

f

system oscillator. Details are provided in the System Operating Modes section.

SYS

2. The time units, shown by the symbols t

HIRC

, t

as provided in the frequency tables. For example t

3. If the LIRC is used as the system clock and if it is off when in the SLEEP Mode, then an additional LIRC

start up time, t

, as provided in the LIRC frequency table, must be added to the t

START

above.

4. The System Speed Switch Time is effectively the time taken for the newly activated oscillator to start up.

V

DD

— f

— f

— f

— f

— f

— f

— f

— RR

SYS=fH~fH

SYS=fSUB=fLXT

SYS=fSUB=fLIRC

SYS=fH~fH

SYS=fSUB=fLIRC

HIRC

LXT

Test Conditions

Conditions

/64, fH=f

HIRC

/64, fH=f

HIRC

or f

LXT

switches from off → on — 16 — t

switches from off → on — 1024 — t

=5V/ms

POR

Min. Typ. Max. Unit

— 16 — t

— 1024 — t

— 2 — t

— 2 — t

— 2 — t

30 48 72 ms

— —

— — 10 16 24 ms

is on or off depends upon the mode type and the chosen

SYS

etc. are the inverse of the corresponding frequency values

SYS

=1/f

, t

=1/f

HIRC

HIRC

SYS

SYS

etc.

time in the table

SST

Ta=25°C

HIRC

LXT

LIRC

H

SUB

HIRC

LXT

Rev. 1.00 18 October 26, 2018 Rev. 1.00 19 October 26, 2018

Page 19

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Input/Output Characteristics

Ta=25°C

Symbol Parameter

V

V

I

OL

I

OH

R

I

LEAK

t

TCK

t

TPI

t

INT

Input Low Voltage for I/O Ports

IL

Input High Voltage for I/O Ports

IH

Sink Current for I/O Ports

(PA, PB, PC)

Source Current for I/O Ports

(PA, PB, PC)

Pull-high Resistance for I/O Ports

PH

(Note)

Input Leakage Current 5V VIN=VDD or VIN=V

TM Clock Input Pin Minimum Pulse Width — — 0.3 — — μs

TM Capture Input Pin Minimum Pulse Width — — 0.3 — — μs

External Interrupt Minimum Pulse Width — — 10 — — μs

Note: The RPH internal pull high resistance value is calculated by connecting to ground and enabling the input pin

with a pull-high resistor and then measuring the pin current at the specied supply voltage level. Dividing

the voltage by this measured current provides the RPH value.

Test Conditions

V

DD

5V

— 0 — 0.2V

5V

— 0.8VDD— V

Conditions

—

—

VOL=0.1VDD,

PxNS=0, x=A, B or C

5V

VOL=0.1VDD,

PxNS=1, x=A, B or C

Min. Typ. Max. Unit

0 — 1.5

DD

3.5 — 5.0

DD

32 64 —

mA

50 100 —

VOH=0.9VDD,

SLEDCn[m+1:m]=00B

-1.5 -2.9 —

(n=0, 1; m=0, 2, 4 or 6)

VOH=0.9VDD,

SLEDCn[m+1:m]=01B

(n=0, 1; m=0, 2, 4 or 6)

5V

VOH=0.9VDD,

SLEDCn[m+1:m]=10B

-2.5 -5.1 —

mA

-3.6 -7.3 —

(n=0, 1; m=0, 2, 4 or 6)

VOH=0.9VDD,

SLEDCn[m+1:m]=11B

-8 -16 —

(n=0, 1; m=0, 2, 4 or 6)

5V — 10 30 50 kΩ

SS

— — ±1 μA

V

V

Memory Characteristics

Symbol Parameter

V

Flash Program / Data EEPROM Memory

t

DEW

I

DDPGM

E

t

RETD

RAM Data Memory

V

VDD for Read / Write — — V

RW

Erase / Write Cycle Time – Flash Program

Memory

Write Cycle Time – Data EEPROM Memory — — — 4 6 ms

Programming / Erase Current on V

Cell Endurance — — 100K — — E/W

P

ROM Data Retention Time — Ta=25°C — 40 — Year

RAM Data Retention Voltage — Device in SLEEP Mode 1.0 — — V

DR

Ta=-40°C~85°C, unless otherwise specied

Test Conditions

V

DD

Conditions

Min. Typ. Max. Unit

DDmin

— V

DDmax

V

— — — 2 3 ms

DD

— — — — 5.0 mA

Page 20

High Voltage Touch A/D Flash MCU with HVIO

LVD/LVR Electrical Characteristics

Symbol Parameter

V

V

t

t

t

LVDS

LVR

LVD

Low Voltage Reset Voltage

LVR

Low Voltage Detection Voltage

LVD

LVDO Stable Time —

Minimum Low Voltage Width to Reset — — 120 240 480 μs

Minimum Low Voltage Width to Interrupt — — 60 120 240 μs

V

BS86DH12C

Test Conditions

DD

Conditions

— LVR enable, voltage select 2.1V

— LVR enable, voltage select 2.55V 2.55

— LVR enable, voltage select 3.15V 3.15

— LVR enable, voltage select 3.8V 3.8

— LVD enable, voltage select 2.0V

— LVD enable, voltage select 2.2V 2.2

— LVD enable, voltage select 2.4V 2.4

— LVD enable, voltage select 2.7V 2.7

— LVD enable, voltage select 3.0V 3.0

— LVD enable, voltage select 3.3V 3.3

— LVD enable, voltage select 3.6V 3.6

— LVD enable, voltage select 4.0V 4.0

For LVR enable, VBGEN=0,

LVD off → on

Min. Typ. Max. Unit

2.1

-5%

2.0

-5%

— — 15 μs

Ta=25°C

+5% V

+5% V

A/D Converter Electrical Characteristics

Symbol Parameter

V

V

V

A/D Converter Operating Voltage — — 4.5 — 5.5 V

DD

A/D Converter Input Voltage — — 0 — V

ADI

A/D Converter Reference Voltage — — 2 — V

REF

DNL A/D Converter Differential Non-linearity 5V

INL A/D Converter Integral Non-linearity 5V

I

ADC

t

ADCK

t

ON2ST

t

ADS

t

ADC

Additional Current Consumption for A/D

Converter Enable

A/D Converter Clock Period — — 0.5 — 10 μs

A/D Converter On-to-Start Time — — 4 — — μs

A/D Converter Sampling Time — — — 4 — t

A/D Conversion Time

(Including A/D Sampling and Hold Time)

Test Conditions

V

DD

V

V

V

V

5V No load, t

— — — 16 — t

Conditions

REF=VDD

REF=VDD

REF=VDD

REF=VDD

Ta=-40°C~85°C

Min. Typ. Max. Unit

, t

=0.5μs

ADCK

, t

=10μs

ADCK

, t

=0.5μs

ADCK

, t

=10μs

ADCK

=0.5μs — 1.5 3.0 mA

ADCK

-3 — +3 LSB

-4 — +4 LSB

REF

DD

V

V

ADCK

ADCK

Rev. 1.00 20 October 26, 2018 Rev. 1.00 21 October 26, 2018

Page 21

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Internal Reference Voltage Characteristics

Ta=25°C

Symbol Parameter

V

t

BG

BGS

Bandgap Reference Voltage — — -5% 1.04 +5% V

VBG Turn-on Stable Time — No load — — 150 μs

Test Conditions

V

DD

Conditions

Min. Typ. Max. Unit

Note: 1. All the above parameters are measured under conditions of no load condition unless otherwise described.

2. A 0.1μF ceramic capacitor should be connected between VDD and GND.

3. The VBG voltage is used as the A/D converter internal signal input.

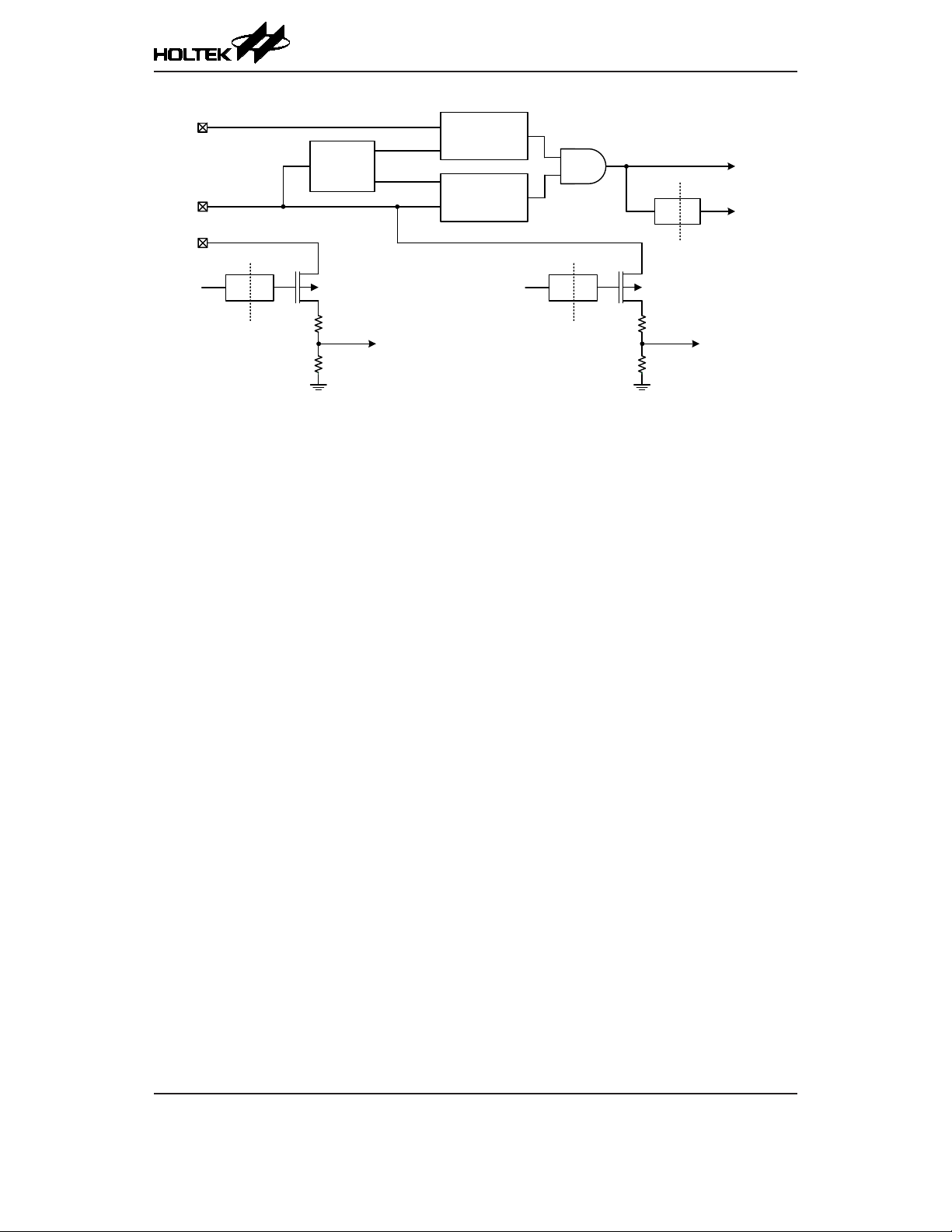

High Voltage I/O Electrical Characteristics

VDD=5V, Ta=25°C, unless otherwise specied

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

V

V

I

OH

I

OL

t

SF

Input Voltage — V

IN

Input High Voltage for High Voltage I/O Ports — 0.6VIN— V

IH

Input Low Voltage for High Voltage I/O Ports — 0 — 0.3VINV

IL

DET1

Source Current for High Voltage I/O Ports VOH=0.9×VIN, VIN=10V -40 -70 — mA

Sink Current for High Voltage I/O Ports VOL=0.1×VIN, VIN=10V 50 80 — mA

SFRTC=0, Ta=25°C 2 — 3

Short Circuit Flag Response Time

SFRTC=0, Ta=-40°C~85°C 1.5 — 3.9

SFRTC=1, Ta=25°C 1.0 — 1.5

SFRTC=1, Ta=-40°C~85°C 0.75 — 1.85

— 10 V

IN

V

ms

Voltage Detector Electrical Characteristics

Symbol Parameter

V

IN

V

DET1

V

RLS1

V

HYS1

V

DET2

V

RLS2

V

HYS2

Input Voltage — — V

V

Detect Level

CC2

V

Release Level

CC2

Hysteresis — VIN=10V ↔ 5V 100 750 1000 mV

VDD Detect Level — VDD=0V → 5V

VDD Release Level

Hysteresis — VDD=0V ↔ 5V 100 250 500 mV

(Note)

(Note)

(Note)

V

DD

— VIN=0V → 10V

— VIN=10V → 0V V

— VDD=5V → 0V V

Test Conditions

Conditions

Ta=25°C

Min. Typ. Max. Unit

DET1

Typ.-

0.5

Typ.

-0.2

— 10 V

Typ.

7

+0.5

DET1-VHYS1

2.5

DET2-VHYS2

Typ.

+0.2

V

V

V

V

Page 22

Note:

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

V

V

DET1

V

RLS1

V

DET2

V

RLS2

PWRRDY

Undefined

High Voltage I/O Other Electrical Characteristics

Symbol Parameter

V

V

V

IN

CC1O

CC2O

Input Voltage — — 7 — 10 V

V

Accuracy — VIN=10V -5% 0.2V

CC1O

V

Accuracy — VIN=10V -5% 0.2V

CC2O

Note: Divider 1: R11:R12=4:1(12kΩ/3kΩ), V

Divider 2: R21:R22=4:1(12kΩ/3kΩ), V

Test Conditions

V

DD

=R12/(R11+R12)×V

CC1O

=R22/(R21+R22)×V

CC2O

Conditions

CC1

CC2

Min. Typ. Max. Unit

IN

IN

=0.2V

=0.2V

CC1

CC2

.

.

V

IN

V

DD

t

t

Ta=25°C

+5% V

+5% V

Low Dropout Regulator Electrical Characteristics

C

=10μF+0.1μF, VIN=V

LOAD

Symbol Parameter

V

V

ΔV

V

I

OUT

IN

OUT

LOAD

DROP

Input Voltage — — 6 — 10 V

Output Voltage

Load Regulation

Dropout Voltage

Output Current

V

IN

—

—

(1)

(2)

— 1mA≤I

—

— VIN=V

— VIN=V

Test Conditions

Conditions

Ta=25°C,

I

=1mA, V

LOAD

OUT

Ta=-40°C~85°C, I

V

=5.0V

OUT

≤70mA, VIN=V

LOAD

ΔV

=2%, I

OUT

VIN=V

+1V

OUT

+1V, ΔV

OUT

+2V, ΔV

OUT

LOAD

=5.0V

LOAD

=1mA,

OUT

OUT

Rev. 1.00 22 October 26, 2018 Rev. 1.00 23 October 26, 2018

+1V, Ta=25°C, unless otherwise specied

OUT

Min. Typ. Max. Unit

-2% 5.0 +2% V

=1mA,

+1V — 0.015 0.033 %/mA

OUT

-5% 5.0 +5% V

— — 100 mV

=-3% 250 — — mA

=-3% 500 — — mA

Page 23

BS86DH12C

13

High Voltage Touch A/D Flash MCU with HVIO

Symbol Parameter

I

Q

ΔV

LINE

Quiescent Current 10V No load — 120 200 μA

Line Regulation — 6V≤VIN≤10V, I

V

IN

TC Temperature Coefcient — Ta=-40°C~85°C, I

ΔV

OUT_RIPPLE

RR Ripple Rejection

I

LIMIT

t

START

Output Voltage Ripple 6V I

(3)

—

Current Limit 6V ΔV

LDO Start Up Time 6V I

Test Conditions

Conditions

=1mA — — 0.2 %/V

LOAD

=10mA — ±1.5 ±2.0 mV/°C

LOAD

=10mA — — 40 mV

LOAD

VIN=10VDC+2V

P-P(AC)

, I

LOAD

≤50mA,

f=120Hz

=-10% 600 800 — mA

OUT

LOAD

=1mA, V

settle to ±5% — — 10 ms

OUT

Min. Typ. Max. Unit

35 — — dB

Note: 1. Load regulation is measured at a constant junction temperature, using pulse testing with a low ON time

and is guaranteed up to the maximum power dissipation. Power dissipation is determined by the input/

output differential voltage and the output current. Guaranteed maximum power dissipation will not be

available over the full input/output range. The maximum allowable power dissipation at any ambient temperature is PD=(T

J(MAX)-Ta

)/θJA.

2. Dropout voltage is dened as the input voltage minus the output voltage that produces a 2% change in the

output voltage from the value at appointed VIN.

3. Ripple rejection ratio measurement circuit. RR=20×log(ΔVIN/ΔV

OUT

).

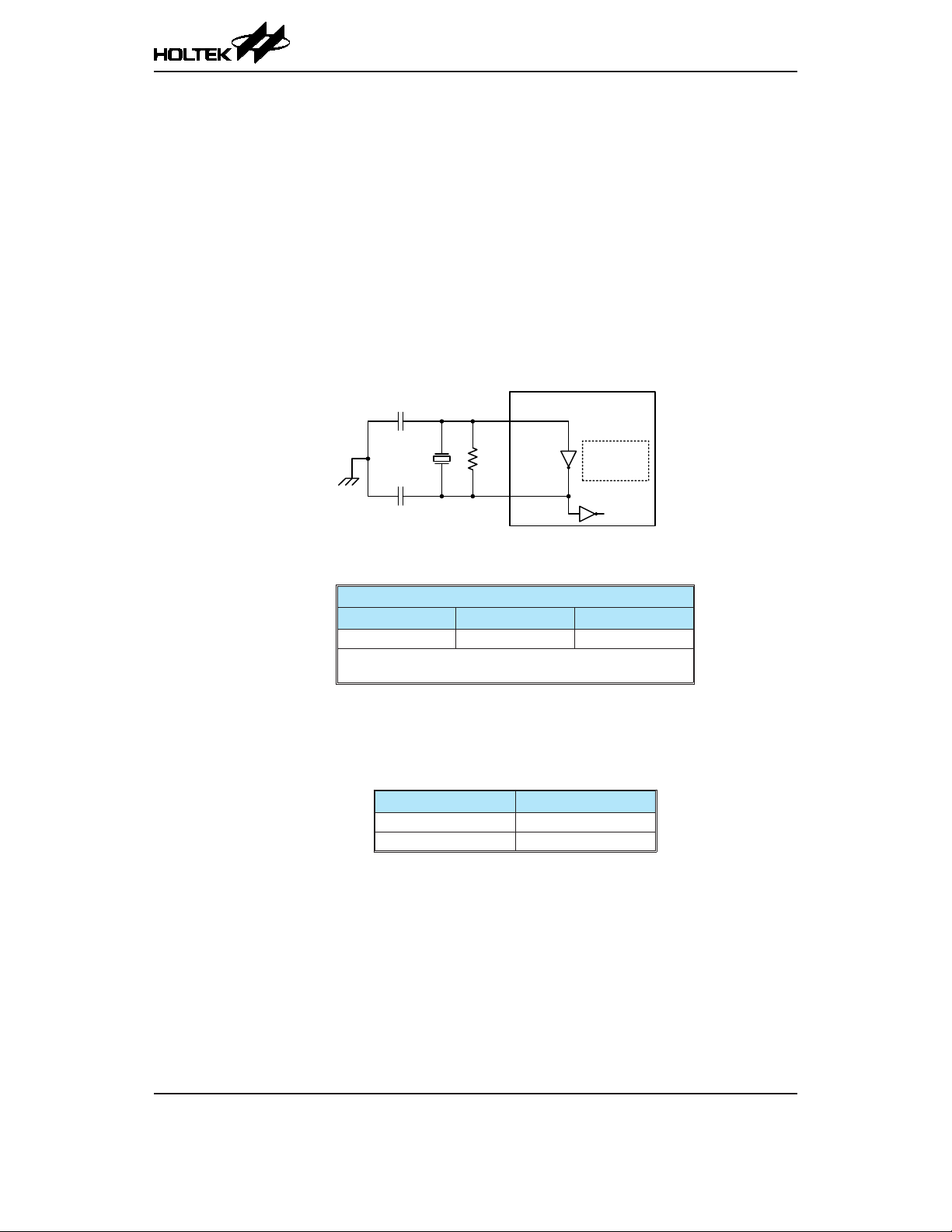

LDO

AC

0.33μF

V

IN

GND

V

OUT

2

10.1μF

R

Output

L

4. Application information for LDO load capacitor selection for stability:

Recommended Output Capacitor

Symbol Parameter

C

LOAD

Output Load Capacitor — Capacitor 4.7 10 — μF

In common with most regulators, the LDO requires an external capacitor connected between V

and ground for regulator stability. If the ESR is less than 10Ω, capacitor values of 4.7μF or large

are acceptable. Any aluminum electrolytic capacitor meeting the requirements described above is

suitable.

For better load transient response purposes, use a combination of a C

0.1μF capacitor on V

. Note that the 0.1μF capacitor is always required on V

OUT

recommended to be a multi-layer ceramic capacitor. The internal regulator is designed to be stable

with an output lter capacitor C

and ESR as recommended.

LOAD

Test Conditions

V

DD

Conditions

Min. Typ. Max.

10μF and an extra

LOAD

and is strong

OUT

Ta=25°C

Unit

OUT

Page 24

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

OCP Electrical Characteristics

Ta=25°C

Symbol Parameter

I

V

V

V

V

V

V

OCP

Operating Current 5V

Comparator Input Offset Voltage

OS_CMP

Hysteresis 5V — 10 40 60 mV

HYS

Comparator Common Mode Voltage

CM_CMP

Range

OPA Input Offset Voltage

OS_OPA

OPA Common Mode Voltage Range 5V — V

CM_OPA

OPA Maximum Output Voltage Range 5V — VSS+0.1 — VDD-0.1 V

OR

Ga PGA Gain Accuracy 5V All gains -5 — +5 %

V

D/A Converter Reference Voltage 5V OCPVRS=1 2 — V

REF

DNL Differential Non-linearity 5V DAC V

INL Integral Non-linearity 5V DAC V

Test Conditions

V

DD

Conditions

OCPEN[1:0]=01B,

DAC V

Without calibration

5V

(OCPCOF[4:0]=10000B)

REF

=2.5V

Min. Typ. Max. Unit

— 730 1250 μA

-15 — 15

5V With calibration -4 — 4

5V — V

Without calibration

5V

(OCPOOF[5:0]=100000B)

-15 — 15

— VDD-1.4 V

SS

5V With calibration -4 — 4

— VDD-1.4 V

SS

REF=VDD

REF=VDD

-1 — +1 LSB

-1.5 — +1.5 LSB

DD

mV

mV

V

OVP Electrical Characteristics

Symbol Parameter

I

V

V

V

OVP

Operating Current 5V OVPEN=1, DAC V

Input Offset Voltage 5V With calibration -2 — 2 mV

OS

Hysteresis 5V

HYS

Common Mode Voltage Range 5V — V

CM

DNL Differential Non-linearity 5V DAC V

INL Integral Non-linearity 5V DAC V

t

RP

OVP Response Time 5V

V

DD

HYS[1:0]=00B 0 0 5

HYS[1:0]=01B 15 30 45

HYS[1:0]=10B 40 60 80

HYS[1:0]=11B 60 80 100

OVPDA[7:0]=10000000B,

OVPDEB[2:0]=000B,

DAC V

OVP input=2.1V~3.6V

Test Conditions

Conditions

REF=VDD

REF=VDD

REF=VDD

,

REF=VDD

Ta=25°C

Min. Typ. Max. Unit

— 500 750 μA

mV

— VDD-1.4 V

SS

-1 — +1 LSB

-1.5 — +1.5 LSB

— 1.0 1.8 μs

Rev. 1.00 24 October 26, 2018 Rev. 1.00 25 October 26, 2018

Page 25

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

Power-on Reset Characteristics

Symbol Parameter

V

RR

t

POR

VDD Start Voltage to Ensure Power-on Reset — — — — 100 mV

POR

PORVDD

Rising Rate to Ensure Power-on Reset — — 0.035 — — V/ms

Minimum Time for VDD Stays at V

Power-on Reset

V

DD

to Ensure

POR

Test Conditions

V

— — 1 — — ms

DD

Conditions

Ta=25°C

Min. Typ. Max. Unit

System Architecture

A key factor in the high-performance features of the range of microcontrollers is attributed to their

internal system architecture. The device takes advantage of the usual features found within RISC

microcontrollers providing increased speed of operation and enhanced performance. The pipelining

scheme is implemented in such a way that instruction fetching and instruction execution are

overlapped, hence instructions are effectively executed in one or two cycles for most of the standard

or extended instructions respectively. The exceptions to this are branch or call instructions which need

one more cycle. An 8-bit wide ALU is used in practically all instruction set operations, which carries

out arithmetic operations, logic operations, rotation, increment, decrement, branch decisions, etc.

The internal data path is simplied by moving data through the Accumulator and the ALU. Certain

internal registers are implemented in the Data Memory and can be directly or indirectly addressed.

The simple addressing methods of these registers along with additional architectural features ensure

that a minimum of external components is required to provide a functional I/O and A/D control

system with maximum reliability and flexibility. This makes the device suitable for low-cost,

high-volume production for controller applications.

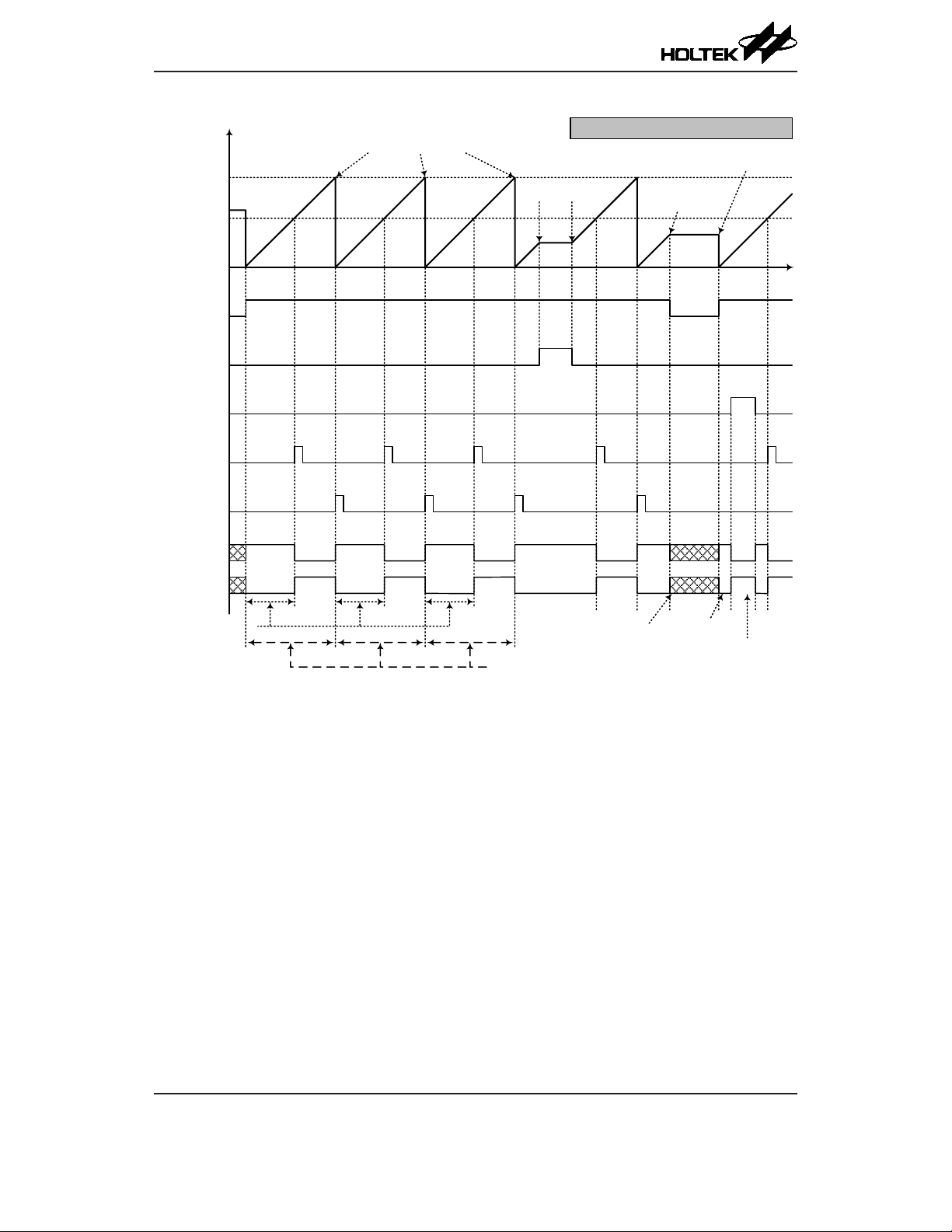

Clocking and Pipelining

The main system clock, derived from either a HIRC, LIRC or LXT oscillator is subdivided into four

internally generated non-overlapping clocks, T1~T4. The Program Counter is incremented at the

beginning of the T1 clock during which time a new instruction is fetched. The remaining T2~T4

clocks carry out the decoding and execution functions. In this way, one T1~T4 clock cycle forms

one instruction cycle. Although the fetching and execution of instructions takes place in consecutive

instruction cycles, the pipelining structure of the microcontroller ensures that instructions are

effectively executed in one instruction cycle. The exception to this are instructions where the

contents of the Program Counter are changed, such as subroutine calls or jumps, in which case the

instruction will take one more instruction cycle to execute.

t

POR

RR

POR

V

POR

Time

Page 26

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

f

(System Clock)

Phase Clock T1

Phase Clock T2

Phase Clock T3

Phase Clock T4

Program Counter PC PC+1 PC+2

SYS

Pipelining

For instructions involving branches, such as jump or call instructions, two machine cycles are

required to complete instruction execution. An extra cycle is required as the program takes one

cycle to rst obtain the actual jump or call address and then another cycle to actually execute the

branch. The requirement for this extra cycle should be taken into account by programmers in timing

sensitive applications.

1 MOV A,[12H]

2 CALL DELAY

3 CPL [12H]

4 :

5 :

6 DELAY: NOP

Program Counter

During program execution, the Program Counter is used to keep track of the address of the next

instruction to be executed. It is automatically incremented by one each time an instruction is executed

except for instructions, such as “JMP” or “CALL” that demand a jump to a non-consecutive Program

Memory address. Only the lower 8 bits, known as the Program Counter Low Register, are directly

addressable by the application program.

When executing instructions requiring jumps to non-consecutive addresses such as a jump instruction,

a subroutine call, interrupt or reset, etc., the microcontroller manages program control by loading

the required address into the Program Counter. For conditional skip instructions, once the condition

has been met, the next instruction, which has already been fetched during the present instruction

execution, is discarded and a dummy cycle takes its place while the correct instruction is obtained.

Fetch Inst. (PC)

Execute Inst. (PC-1) Fetch Inst. (PC+1)

Execute Inst. (PC)

System Clocking and Pipelining

Fetch Inst. 1

Execute Inst. 1

Fetch Inst. 2 Execute Inst. 2

Fetch Inst. 3 Flush Pipeline

Instruction Fetching

Program Counter

High Byte Low Byte (PCL)

PC12~PC8 PCL7~PCL0

Program Counter

Fetch Inst. (PC+2)

Execute Inst. (PC+1)

Fetch Inst. 6 Execute Inst. 6

Fetch Inst. 7

The lower byte of the Program Counter, known as the Program Counter Low register or PCL, is

available for program control and is a readable and writeable register. By transferring data directly

into this register, a short program jump can be executed directly; however, as only this low byte

is available for manipulation, the jumps are limited to the present page of memory that is 256

locations. When such program jumps are executed it should also be noted that a dummy cycle

Rev. 1.00 26 October 26, 2018 Rev. 1.00 27 October 26, 2018

Page 27

BS86DH12C

High Voltage Touch A/D Flash MCU with HVIO

will be inserted. Manipulating the PCL register may cause program branching, so an extra cycle is

needed to pre-fetch.

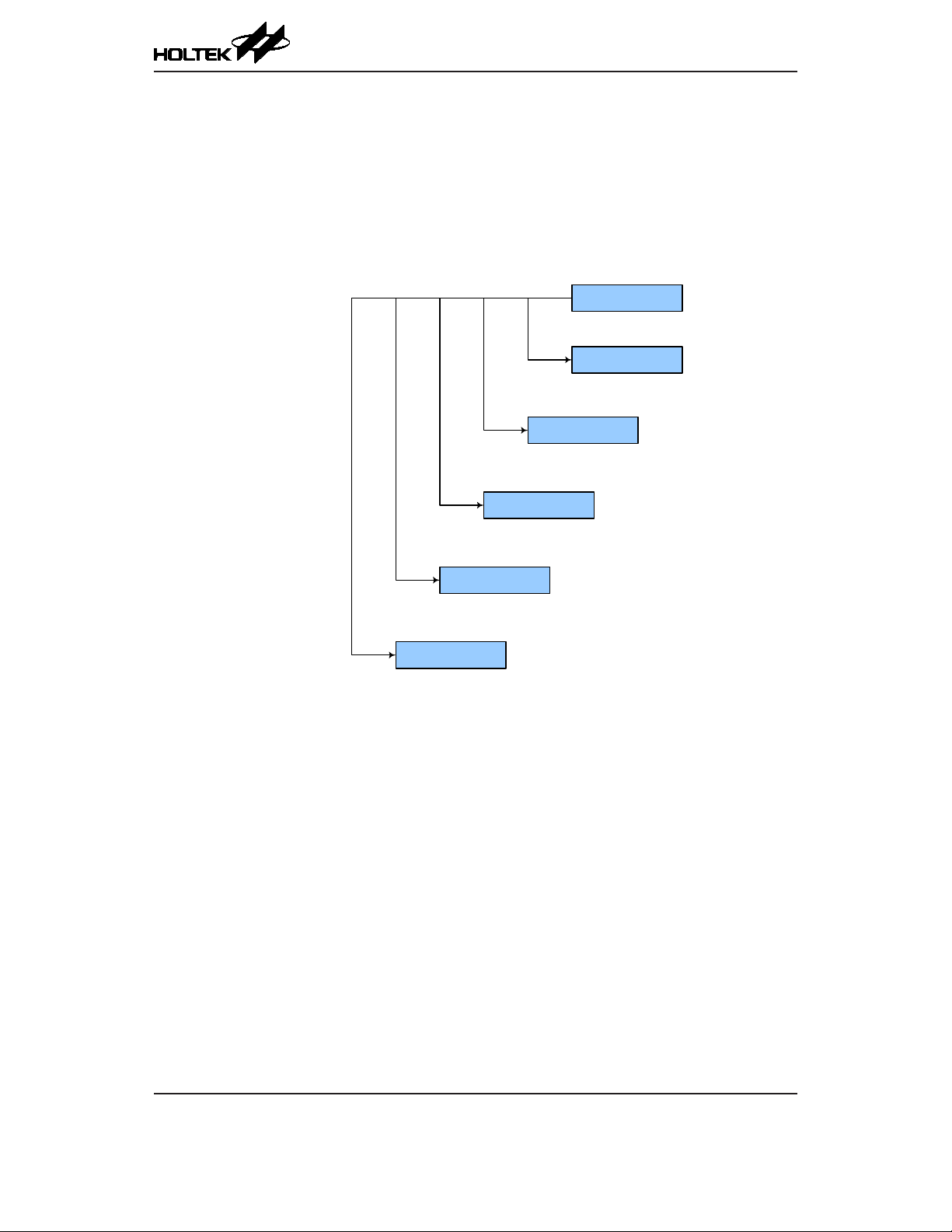

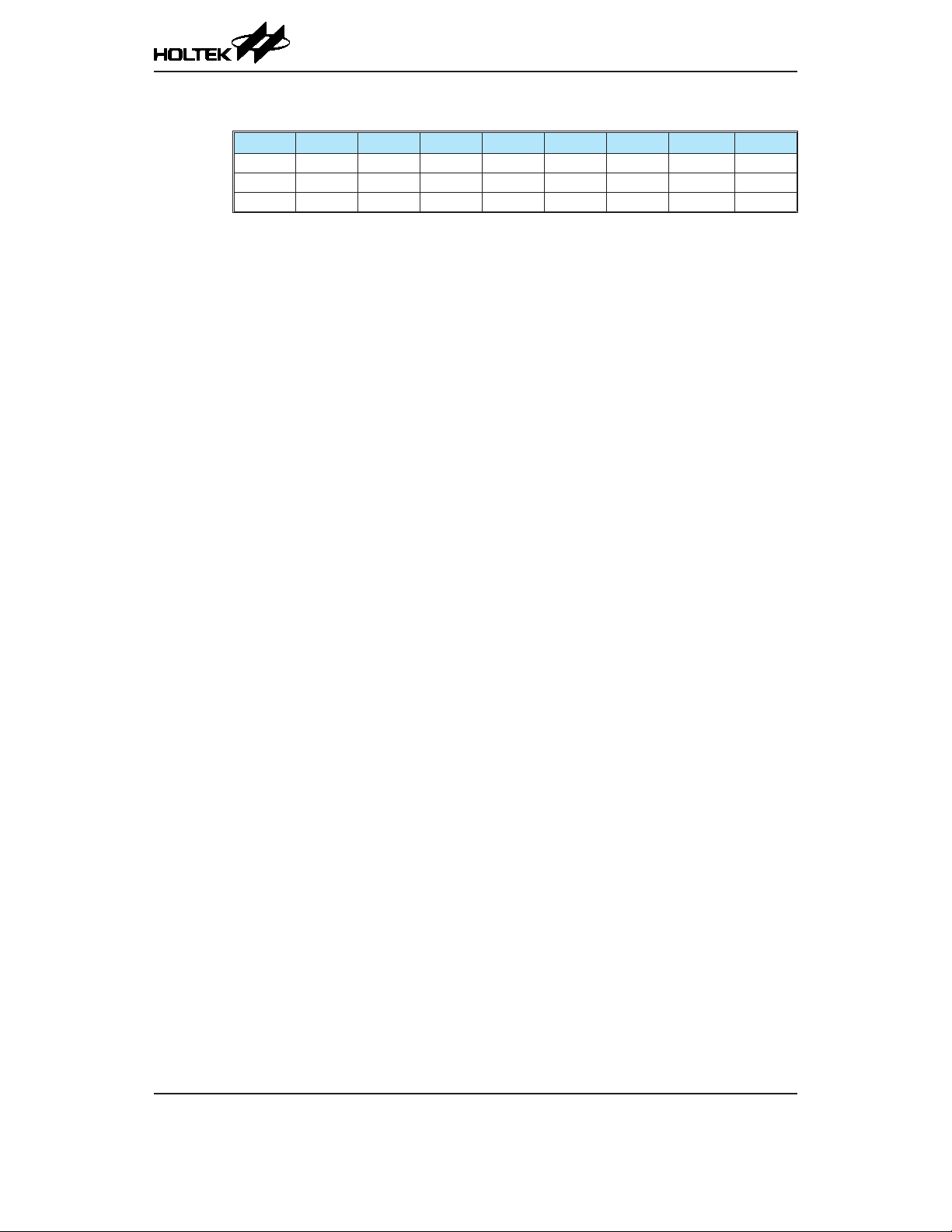

Stack

This is a special part of the memory which is used to save the contents of the Program Counter

only. The stack is organized into 8 levels and neither part of the data nor part of the program space,

and is neither readable nor writeable. The activated level is indexed by the Stack Pointer, and is

neither readable nor writeable. At a subroutine call or interrupt acknowledge signal, the contents of

the Program Counter are pushed onto the stack. At the end of a subroutine or an interrupt routine,

signaled by a return instruction, RET or RETI, the Program Counter is restored to its previous value

from the stack. After a device reset, the Stack Pointer will point to the top of the stack.

If the stack is full and an enabled interrupt takes place, the interrupt request ag will be recorded but

the acknowledge signal will be inhibited. When the Stack Pointer is decremented, by RET or RETI,

the interrupt will be serviced. This feature prevents stack overow allowing the programmer to use

the structure more easily. However, when the stack is full, a CALL subroutine instruction can still

be executed which will result in a stack overow. Precautions should be taken to avoid such cases

which might cause unpredictable program branching.

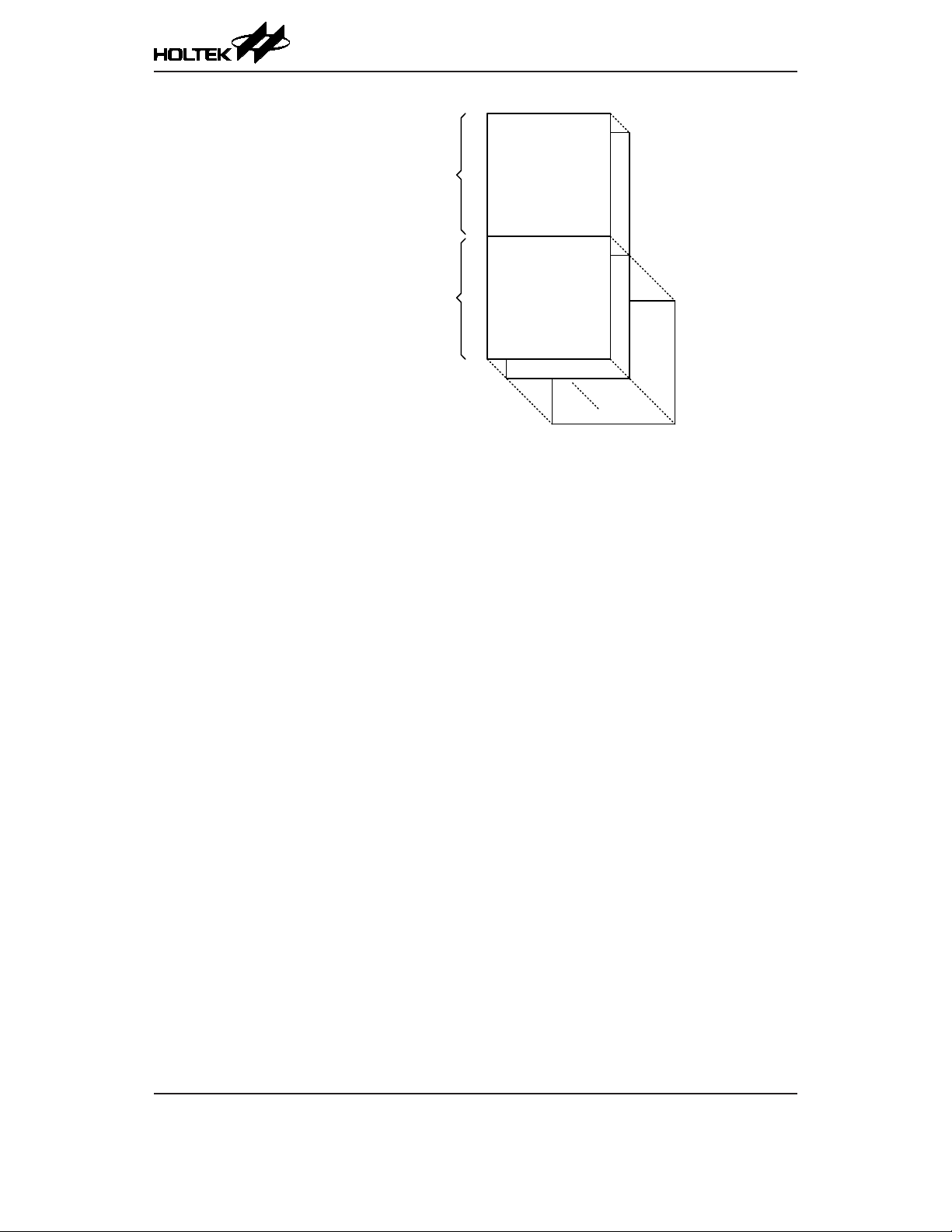

If the stack is overow, the rst Program Counter save in the stack will be lost.

Top of Stack

Stack

Pointer

Bottom of Stack

Arithmetic and Logic Unit – ALU

The arithmetic-logic unit or ALU is a critical area of the microcontroller that carries out arithmetic