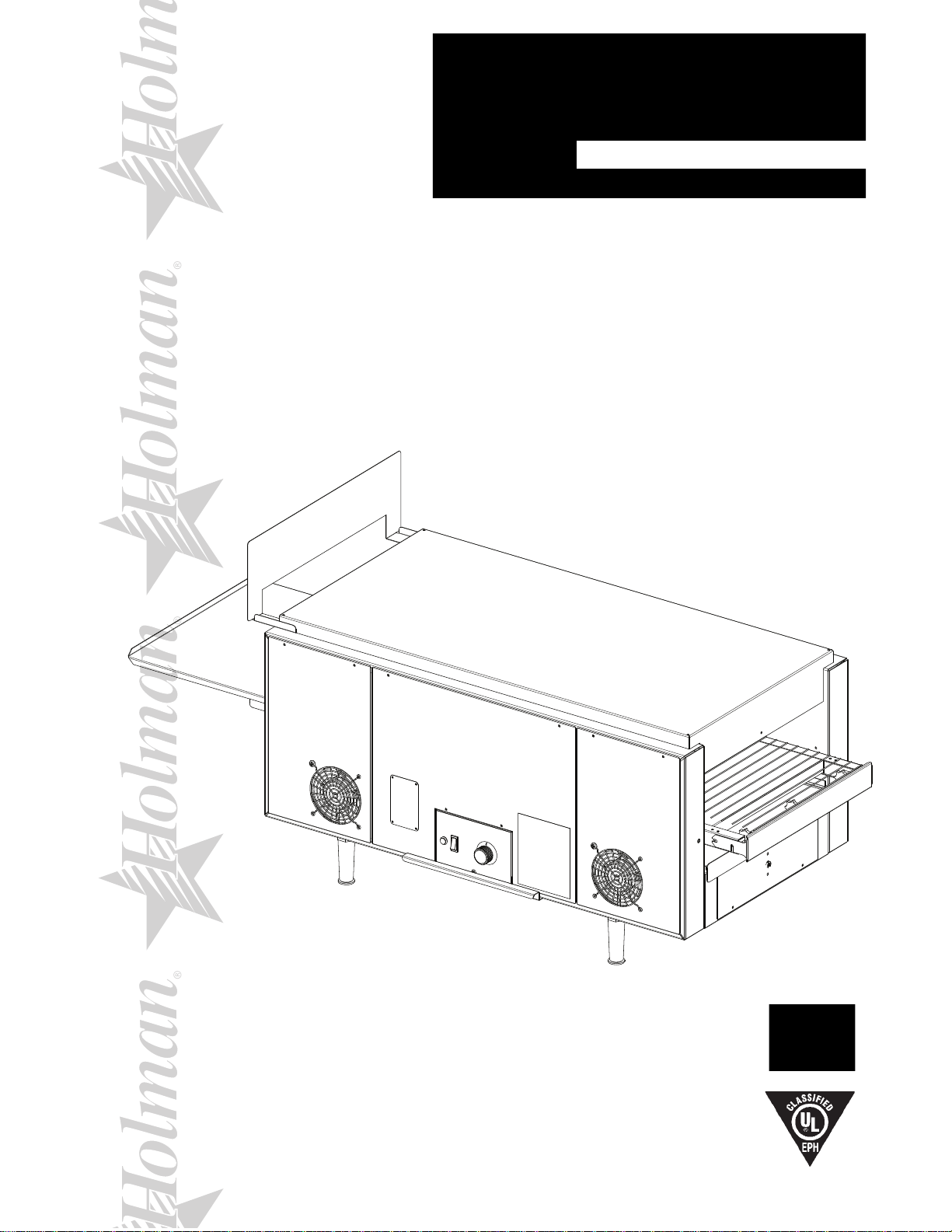

Holman Cooking/Star Mfg QT14B, QT14BR, QT14BW, QT14BWR Operation Manual

®

®

®

®

®

CONVEYOR

SANDWICH TOASTER

MODEL

QT14B, QT14BR,

QT14BW, QT14BWR

Installation and

Operation

Instructions

2M-Z9702 Rev. I 8/19/11

QT14BR

1

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business

8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 264-7827 Local (314) 684-6303

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

TABLE OF CONTENTS

PAGE

Star Contact Information 2

Specications 3

General Information Data 4

Inspection & Assembly 4

Assembly and Installation 4-5

Electrical Connection 5

Oven Components 5

Stacking Ovens 6

Daily Operation 6

Cleaning

Daily 7

Weekly 8

Monthly 9

Maintenance and Repairs 10-11

Troubleshooting Guide 12

Limited Equipment Warranty 13

Wiring Diagrams 14-16

Exploded View Illustration & Parts List 18-21

SPECIFICATIONS

QT14B,

Rating/Connection: 7,800 Watts

NEMA Plug: N/A

Electrical Supply: Separate service per toaster - 37.5 Amp, 208 VAC, 1 phase, 60 Hz

Separate service per toaster - 32.5 Amp, 240 VAC, 1 phase, 60/50 Hz

Separate service per toaster - 21.7 Amp, 208 VAC, 3 phase, 60 Hz

Approximate Weight (QT14B Oven with Legs): Installed - 170 Lbs (77.1 kg)

Dimensions: Width: 55" (139.7 cm) - Oven with Trays

Depth: 24" (60.9 cm)

Height: 20" (50.8 cm) - Single Oven with Legs

QT14BR, QT14BW, QT14BWR

QT14B, QT14BR, QT14BW, QT14BWR

Rating/Connection: 7,950 Watts

NEMA Plug: N/A 3 Phase: N/A

Electrical Supply: Separate service per toaster - 36.1 Amp, 220 VAC, 1 phase, 60 Hz

Separate service per toaster - 20.9 Amp, 220 VAC, 3 phase, 50 Hz

Separate service per toaster - 12.1 Amp, 380 VAC, 3 phase, 50 Hz

Approximate Weight (QT14B Oven with Legs): Installed - 170 Lbs (77.1 kg)

Dimensions: Width: 55" (139.7 cm) - Oven with Trays

Depth: 24" (60.9 cm)

Height: 20" (50.8 cm) - Single Oven with Legs

3

IL1150

CAUTION

GENERAL INSTALLATION DATA

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand the

units operation & safety before they use the unit.

INSPECTION & ASSEMBLY

All shipping containers should be checked for freight damage both visible and concealed. This

unit has been tested and carefully packaged to insure delivery of your unit in perfect condition. If

equipment is received in damaged condition, either apparent or concealed, a claim must be made

with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain

to retain all contents plus external and internal packaging materials for inspection. The carrier will

make an inspection and will supply necessary claim forms.

UN CRATING AND INSPECTING

Unpack the unit and components from the shipping container. Remove all visible packing material.

Ifdamageisdiscovered,leaclaimimmediatelywiththecarrierthathandledtheshipment.DO

NOT operate the unit if it was damaged during shipping.

The following should be included: Holman Conveyor Sandwich Toaster, Stainless Steel Unload Tray,

(four) 4 Stainless Steel Legs, extra Motor, and Magnetic Bake Aid w/Bracket.

CAUTION

CAUTION

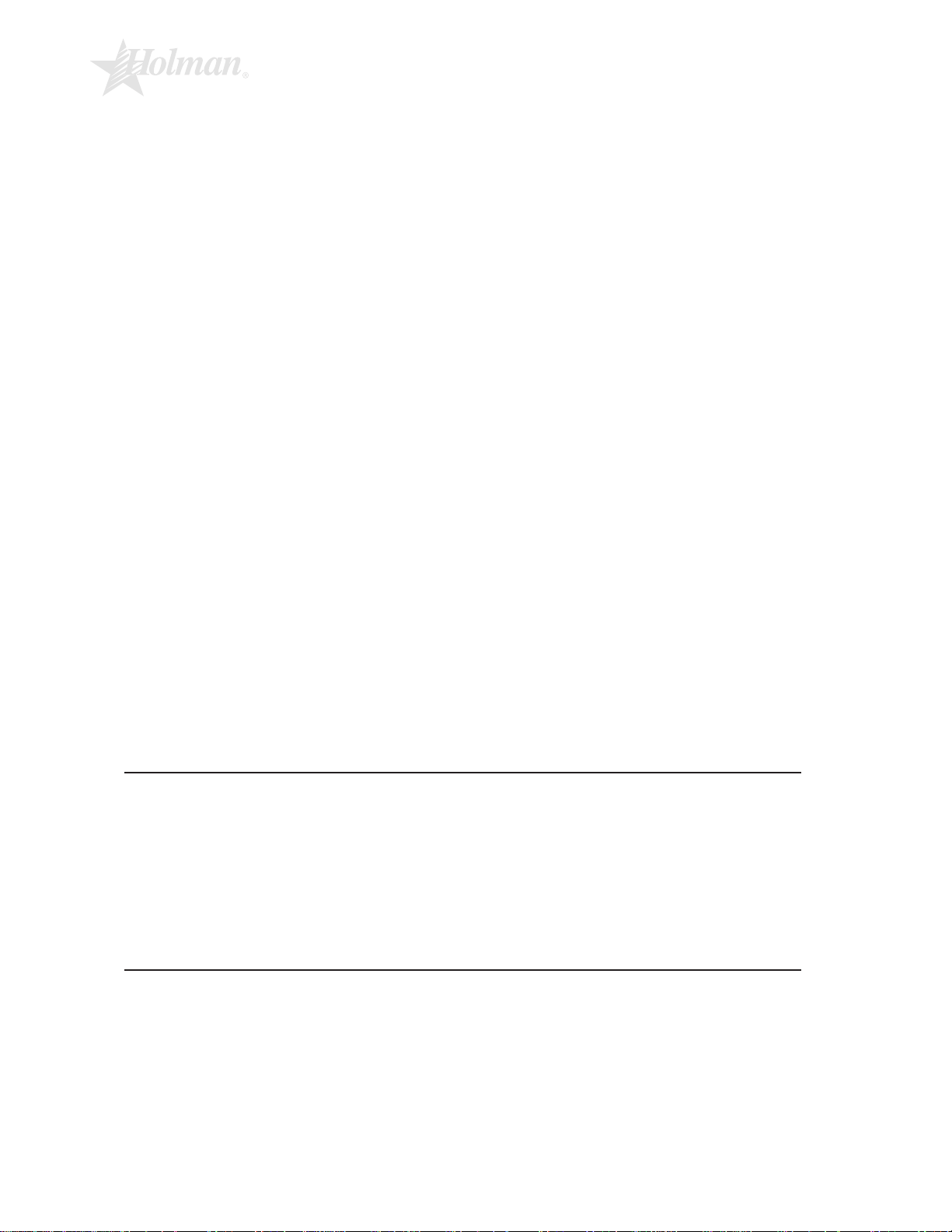

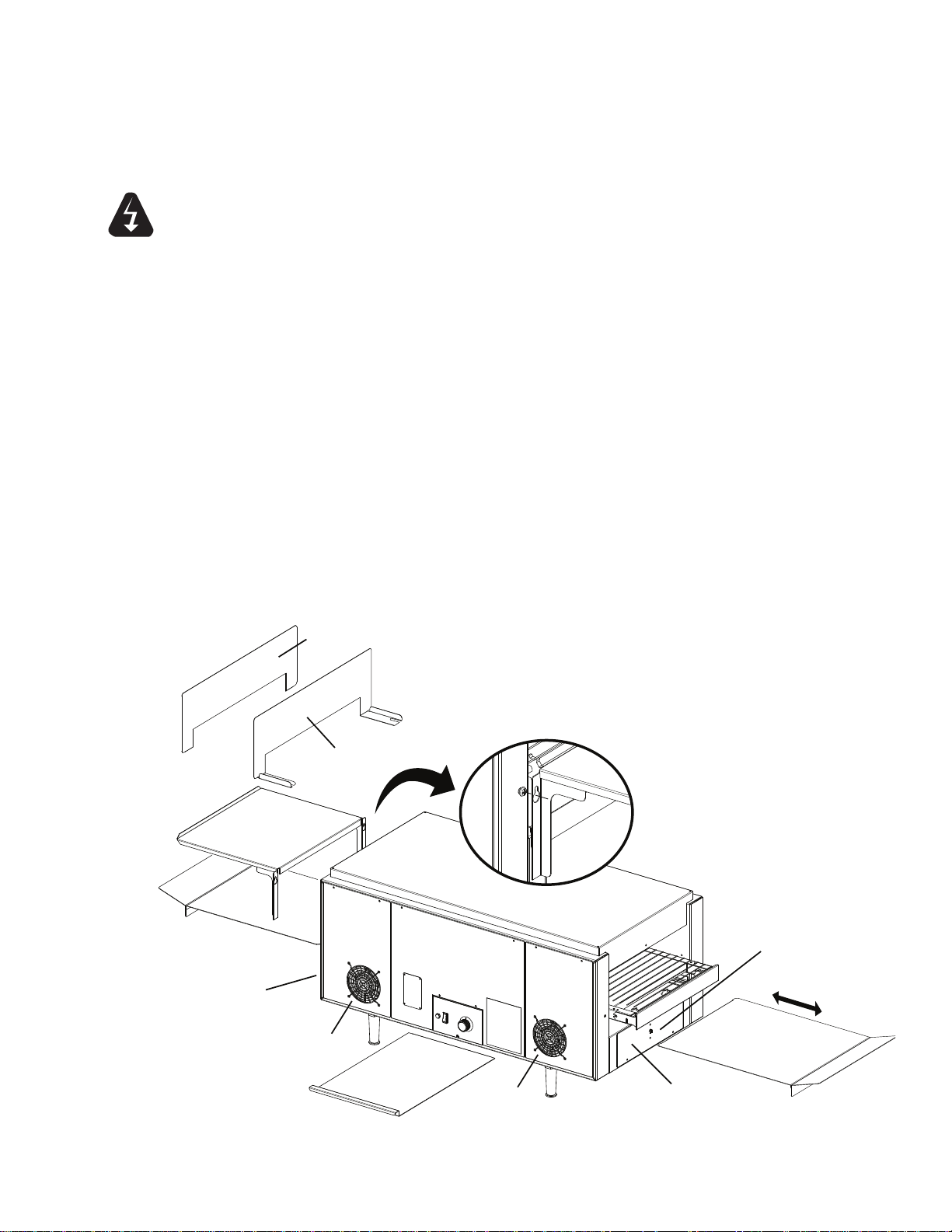

ASSEMBLY AND INSTALLATION

The unit was shipped with certain assembly required.

DO NOT PLACE THE UNIT ON ITS SIDE. FAILURE

TO COMPLY MAY RESULT IN DAMAGE TO

EQUIPMENT.

To attach the four 4 legs, with assistance place the unit on

its end as shown (damage to the elements can occur when

the unit is placed on its side) insert the legs by screwing

them into the weld nuts located on the bottom of the unit.

When completed and with help, carefully turn the unit

upright.

NEVER OPERATE UNIT WITHOUT PROPER LEGS

IN PLACE.

Install unit in its operating position. Level unit by adjusting

the feet. Both ends must be at least 6" from any vertical

combustiblesurface.Allowsufcientspaceforoperating

personnel.

The Unload Tray has a keyhole slot on the tray that will

slide over the two screw heads on the end of the toaster as

shown int the Toaster Components Iluustration.

The crumb tray slides into each end of the toaster under

the conveyor. The slot is formed by two pieces of metal on

each side, under the toaster. They keep the interior of the machine clean

andreectheatawayfromthecontrolsandbackuptothesandwiches.

A layer of aluminum foil on the tray (check that it does not interfere with the conveyor) will make the

traymorereectiveandmakecleanupeasier.

LEG INSTALLATION

4

ASSEMBLY AND INSTALLATION continued

UNLOAD TRAY

TYPICAL TOASTER COMPONENTS

IL1151A

CRUMB TRAY

CRUMB TRAY

HI-LIMIT RESET SWITCH

CLEAN

OPERATE

CRUMB TRAY

LOWER

AIR

INTAKE

ACCESS PANEL

ACCESS PANEL

AIR

INTAKE

“The Bake” Bracket

“The Bake” SIGN

WARNING

ELECTRICAL

CONNECTION

Have an electrician connect input power to the unit(s) in accordance with local electrical

codes. A connection terminal block is located inside an electrical box on the control side of

the unit. CORD & PLUG IS NOT PROVIDED.

VERIFY THE GROUND (EARTH) CONNECTION IS PROPERLY WIRED. NEVER

CONNECT UNIT TO POWER WITHOUT PROPER GROUND CONNECTIONS.

IMPROPER GROUND MAY RESULT IN SEVERE INJURY OR FATALITY.

MAKE SURE ALL INPUT POWER IS OFF BEFORE INSTALLING/REMOVING ANY

PARTS.

BEFORE INSTALLING UNIT, HAVE YOUR ELECTRICIAN CHECK WITH LOCAL

POWER COMPANY TO DETERMINE ACTUAL VOLTAGE AT THE STORE.

Before applying input power to the unit, check elements for breakage. DO NOT apply power to the

unit if a any elements are broken. If no broken elements are found, apply input power by switching

the ON/OFF toggle to the ON position. Turn conveyor belt speed control to the maximum setting

and check all elements and conveyor for proper operation.

Allow approximately 5 to 10 minutes for the twin-fan cooling system to come on. Check the air

intakefanareashownbelow,makingsurethereisasufcientowofairintotheunit.Restricting

theairowwillcausetheunittorunhotterthendesignedcausingdamagetotheunit.

If all heater and conveyor systems are operating properly, turn the master ON/OFF switch to the

OFF position and allow unit to cool. The fans will continue to circulate cool air throughout the unit

until the internal temperatures have been decreased.

If a problem is discovered during start up procedures, immediately turn the Master ON/OFF switch

to the OFF position and call the Star Service Help Desk at 1-800-807-9054.

5

TOASTER

TOASTER

STACKING LEGS

(QTY 4)

IL1152

DRILL THROUGH

HOLES

®

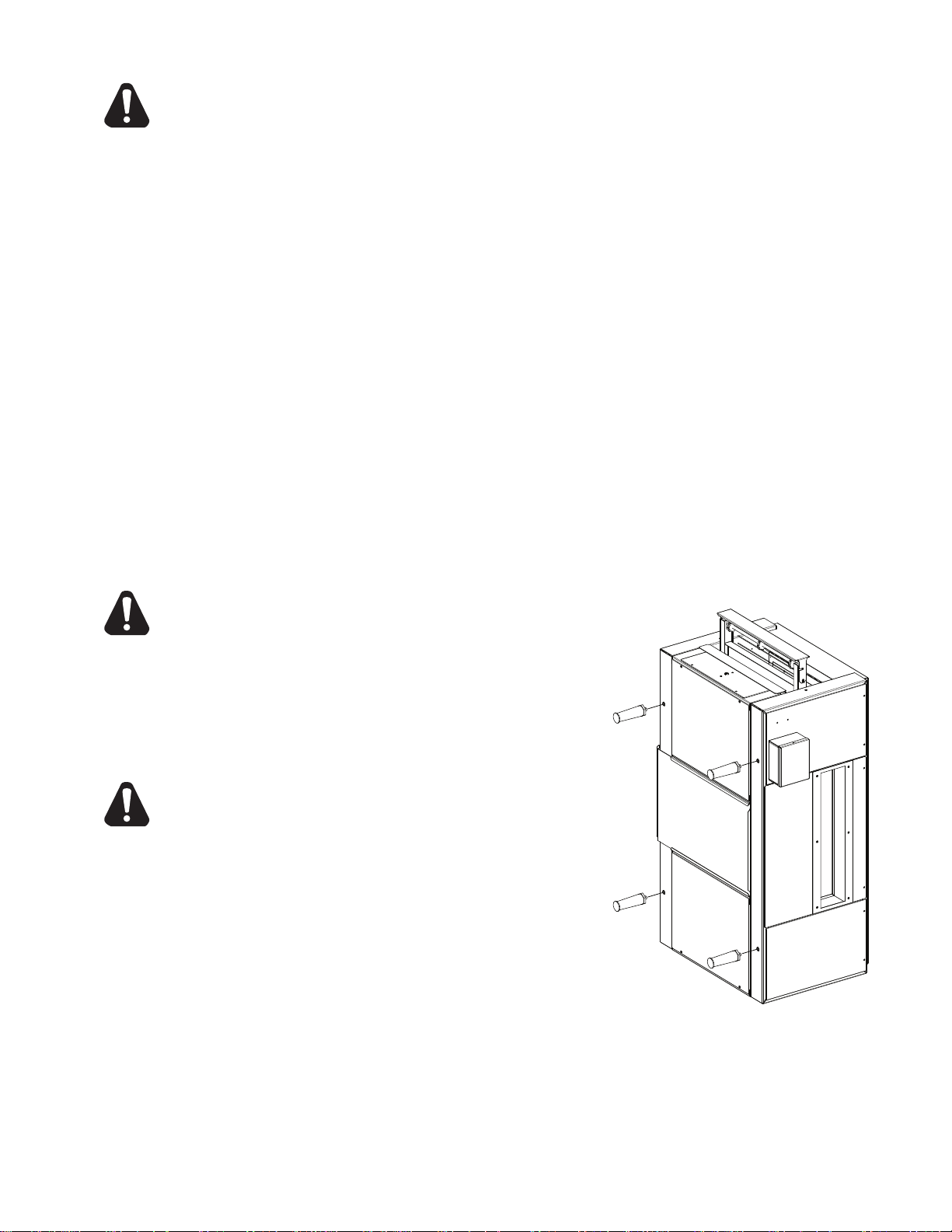

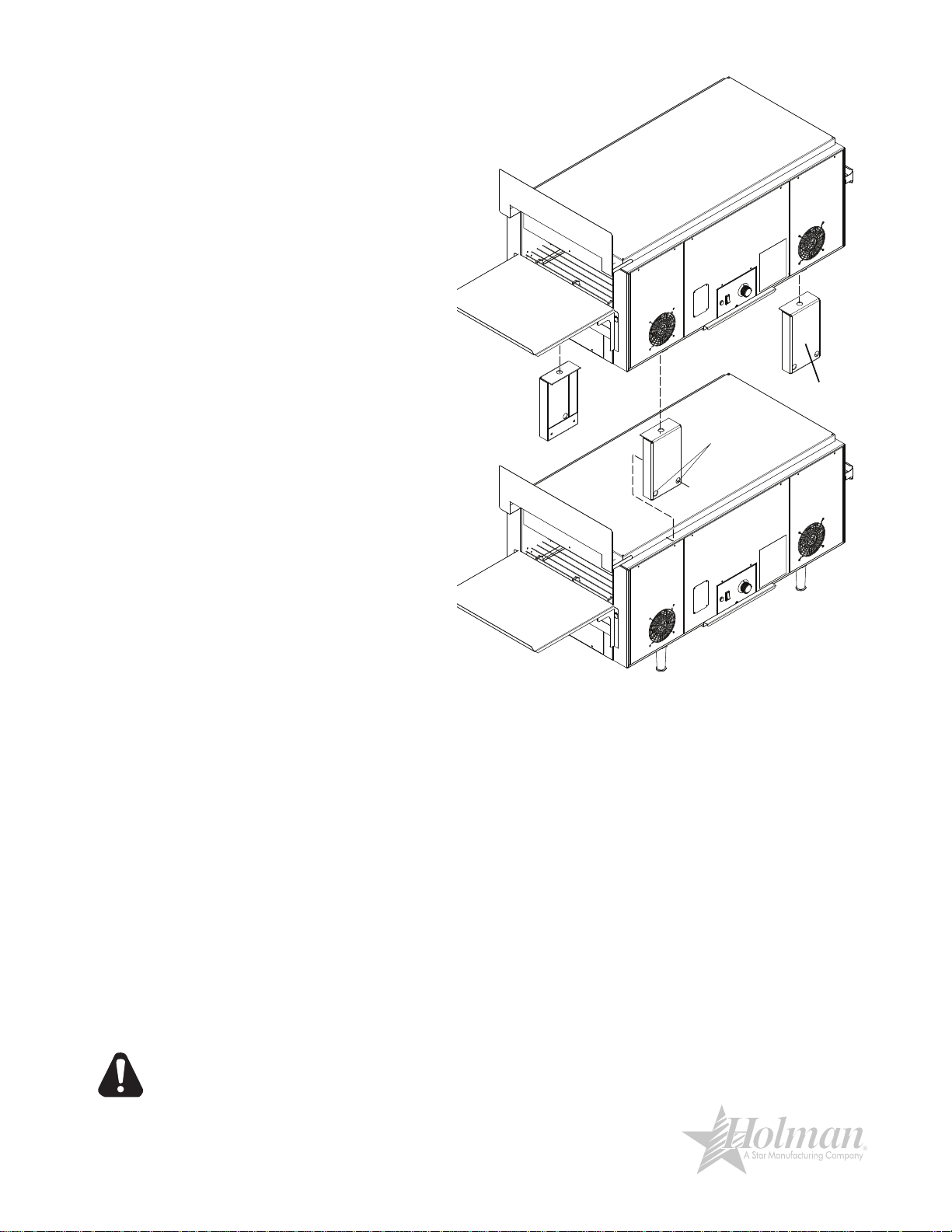

STACKING TOASTERS

When stacking two Holman QT14/

QT14B Conveyor Sandwich Toasters

a QT14 Stacking Legs Kit (part no.

PS-Z8977) MUST be used to prevent

overheating of the control box of the

top toaster.

1. Unplug BOTH UNIT power

cords from the wall receptacle,

and allow to cool.

2. Once cooled, stand the top unit

on end and remove all 4 feet.

Save them for possible future

use.

3.

Take one of the four (4) stacking

legs and bolt it in place of

previously removed leg.

T

ighten using wrench. Install

the remaining three.

4. Stand unit in its usable position

and verify the legs are stable.

5. Place the upper unit on top

of the other toaster, with the

controls facing the same

direction and lined up together.

6. Once in place, using a #29-drill

bit (.136"), drill holes into the

lower toaster by going through

the drill holes in the stacking leg

as shown. Do this in all four (4)

places.

Insert screws

7.

(provided)

holes

securing the two units together. Continue

until all four (4) are complete.

8. Plug in units and test for proper operation.

into the mounting

CAUTION

DAILY OPERATION

1. Turn On/Off switches to the ON position and variable speed control to the desired setting.

Allow 30-40 minutes for complete machine warm up.

2. Adjust speed as required during operation to achieve a good bake.

3. When done for the day, turn the On/Off switch to the OFF position. The conveyor

will

stop and the elements will go off. The two fans will continue to run to cool the machine.

The fans are controlled by a thermostat and will stop when the elements are cooled.

DO NOT begin to service or clean the machine until the fans have stopped.

CAUTION: Some parts of the machine will still be warm.

Refer to the Troubleshooting section if the machine is not performing as expected.

CERTAIN SURFACES ARE EXTREMELY HOT DURING OPERATION AND CARE

SHOULD BE TAKEN WHILE USING THIS UNIT.

6

Loading...

Loading...