Page 1

Contact Toaster

Owner’s Manual

Models

SCT4000, SCT4000E

This manual includes material related to installation,

use , cleaning, and care. Exploded view[s], as well

as any available parts list[s] pertaining to the unit

covered by this manual are also included.

This manual must be read and understood by all

persons using or installing this appliance. Contact

your Star dealer if you have any questions concerning

installation, use, or maintenance of this equipment.

DO NOT DISCARD THIS MANUAL.

SCT4000E

M-Z21667 • Rev. C • 03.2017

2

Page 2

LIMITED EQUIPMENT WARRANTY

Star Manufacturing [as well as its subsidiaries] warranties new products

to be free from defects in material and/or workmanship for a period

of one [1] year from the date of original installation, except as noted

below. Defects that occur as a result of normal use, within the time

period and limitations defi ned in this warranty, will at Star’s discretion

have the parts replaced or repaired by Star or a Star-authorized service

agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Starauthorized service agency. Star will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Star-authorized service agency must be used.

Star will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the reponsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specifi c

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid.

PORTABLE EQUIPMENT EXAMPLES

• 514LL fryer • J4R popcorn machine

• 15MC and 18MCP hot food • 12NCPW and 15NCPW nacho

merchandisers merchandisers

• QCS1, QCS2, and RCS2 toasters • nacho cheese warmers except

• 16PD-A pretzel merchandisers 11WLA-series models

• condiment dispensers except • specialty food warmers except

HPD- and SPD-series models 130R, 11RW, and 11WSA models

• all pop-up toasters • all butter dispensers

• all pastry display cabinets • all nacho chip merchandisers

• all heat lamps • all accessories

CO N TAC T

Should you require any assistance regarding the operation or

maintenance of any Star equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone Star/Toasmaster 314.678.6306 Lang 314.678.6315

Fax 314.781.2714

Email customerservice@star-mfg.com

www.star-mfg.com • www.langworld.com • www.toastmastercorp.com

WARRANTY EXCLUSIONS

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been used, maintained, or installed

in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual, including incorrect

gas or electrical connection. Star is not liable for any unit which

has been mishandled, abused, misapplied, subjected to harsh

chemicals, modifi ed by unauthorized personnel, damaged

by fl ood, fi re, or other acts of nature [or God], or which have

an altered or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls,

air and gas burner/bypass/pilot adjustments, gas or electrical

system checks, voltage and phase conversions, cleaning

of equipment, or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety

controls, or reset buttons.

• Replacement of broken or damaged glass components, quartz

heating elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and

hotplates, including but not limited to burners, grates, and

radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform

service.

• Replacement of items subject to normal wear or items that can

easily be replaced during a daily cleaning routine, such as but not

limited to knobs, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Any loss of business or profi ts.

ADDITIONAL WARRANTIES

Specialty/chain specifi c versions may also have additional warranties.

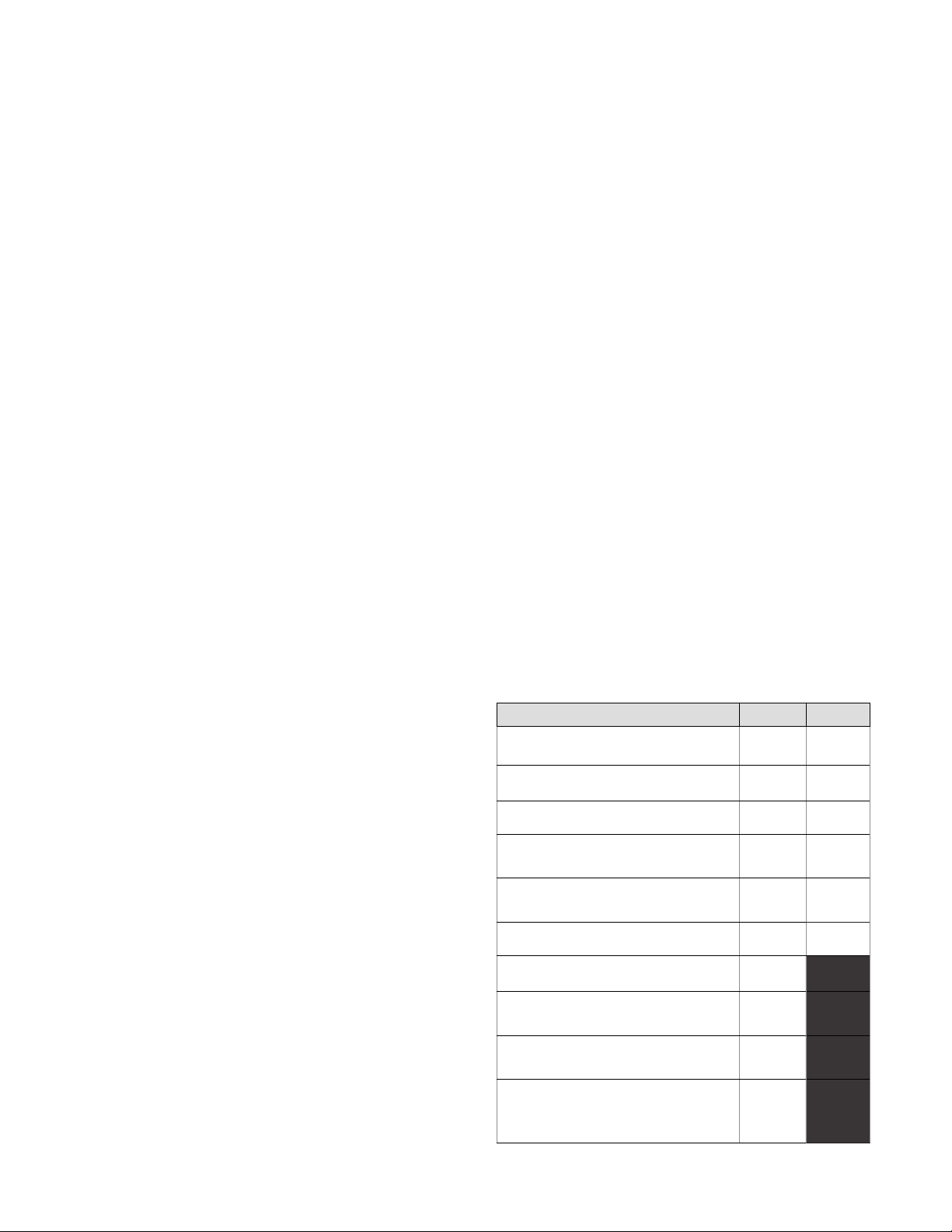

PRODUCTS PARTS LABOR

Lang Chef-Series™ convection ovens 3 years 2 years

Lang Strato-Series™ convection ovens 2 years 2 years

Lang convection oven doors lifetime 4 years

Lang LG and Star Ultra-Max®

griddles, charbroilers, and hotplates

Star-Max ® fryers, griddles,

charbroilers, and hotplates

3 years 3 years

2 years 2 years

Jetstar® popcorn poppers 2 years 2 years

Staltek™ roller grill coatings 5 years

chrome griddle surfaces [against

peeling]

lava rock charbroiler grates, burners,

and burner shields

5 years

180 days

original Star, Lang, or Toastmaster

parts sold to repair Star, Lang, or

90 days

Toastmaster equipment

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z216 47 • Rev A • 08.2016

i

Page 3

TABLE OF CONTENTS

Warranty i

General Information and Installation 1–2

Folding Conveyors Out 3

Bun Height Adjustment 3

PTFE Sheet Replacement 3

Daily Operation 4

Cleaning 5

Additional Electronic Settings 6–7

Control Label Replacement 8

Exploded Views 8–9

Parts List 10–11

Wiring Diagrams 12-13

Specifications 14

2M-Z21667 Rev C Owner's Manual for SCT4000 and SCT4000E Contact Toaster

Page 4

NOTES

iii

Page 5

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

SAFETY SYMBOLS

These symbols are intended to alert the user to the

presence of important operating and maintenance

instructions in the manual accompanying the appliance.

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to ensure delivery of your unit

in perfect condition. However, there are instances in which the unit may be damaged in transit. In the

event you discover any type of damage to your product upon receipt, you must immediately contact

the transportation company who delivered the item to you and initiate your claim with that company.

If this procedure is not followed, it may aff ect the warranty status of the unit. If damage or loss is not

apparent until after equipment is unpacked, a request for inspection of concealed damage must be

made with carrier within 15 days. Please record the model number, serial number, voltage, and purchase

date in the area below at the time of receipt..

Model Number

Serial Number

Voltage

Purchase Date

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance. Please have the

information in the above fi elds ready when you call to ensure a faster service.

Using any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.

Due to periodic changes in designs, methods, procedures, policies, and regulations, the specifi cations

contained in this document are subject to change without notice. Star reserves the right to change

product specifi cations and design without notice. In regards to previously purchased equipment,

such revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements. While Star International Holdings Inc. exercises good faith eff orts to provide information

that is accurate, we are not responsible for errors or omissions in information provided or conclusions

reached as a result of using the specifi cations. By using the information provided, the user assumes

all risks in connection with such use.

PLEASE REFER TO THE WARRANTY PAGE FOR SPECIFIC WARRANTY INFORMATION.

AUTHORIZED SERVICE AGENT LISTING

Reference the listing provided with the unit or for an updated listing go to the website or call customer

service to fi nd an agent.

Business hours: 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone: 314-678-6303

Fax: 314-781-2714

Email: customerservice@star-mfg.com

Website: www.star-mfg.com

Please visit www.starwebconnect.com/manuals.aspx for digital versions of any documents associated

with this unit.

1

Page 6

GENERAL SAFETY INFORMATION

This equipment is designed and sold for commercial use only, and is intended for use by personnel

trained and experienced in its operation. This is not sold for consumer use in and around the home

nor for use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions and labels associated

with the unit prior to putting it into operation. Make sure all people associated with its use understand

the units operation and safety before they use the unit.

GENERAL INSTALLATION INFORMATION

The unit is shipped fully assembled and ready to plug into a standard outlet specified for its voltage

and amp draw. If improper electrical supply can be determined through troubleshooting, contact

a qualified electrician prior to using the unit. Removal or replacement of the power cord or plug will

void the warranty. Should you require assistance, contact your local authorized service agent for any

service or required maintenance.

Allow enough space around the toaster for adequate ventilation. Make certain this unit is not located

near other appliances which may produce grease vapor, such as fryers, griddles, etc. In the event this

is unavoidable, ducting will be necessary to supply this unit with an adequate amount of clean, cool

air. It is recommended that you leave at least a one [1] inch (25 mm) gap on each side. Do not operate

the unit without the PTFE sheet and belts properly positioned. If operated improperly, bun sticking

and poor toasting may occur.

Before using the unit for the first time, ensure to clean the toaster properly. Refer to the Cleaning

Procedure document for cleaning instructions.

ELECTRICAL CONNECTION

Before making any electrical connection to this unit, check that the power supply is adequate for

the voltage, amperage, and requirements stated on the rating plate. Make certain to disconnect

the unit from the power source before installing or removing any parts. Be absolutely sure that

the ground connection for the receptacle is properly wired. Do not connect equipment to power

without proper ground connections. Improper grounding may result in personal injury or fatality.

DO NOT CUT OR REMOVE THE PLUG OR ELECTRICAL REQUIREMENTS

GROUNDING PRONG FROM THE PLUG. 208–240 volts and a NEMA 6-15P

or CEE7-7 receptacle are required

CONNECT/PLUG UNIT INTO DEDICATED

AC LINE ONLY SPECIFIED ON THE DATA

PLATE OF THE UNIT.

DO NOT IMMERSE OR LET THE UNIT STAND

IN WATER.

DO NOT HOSE DOWN THE UNIT OR THE

TABLE/COUNTER IF THE UNIT IS ON THE

TABLE/COUNTER.

depending

on model.

6-15P CEE7-7

KEEP AWAY FROM RUNNING WATER.

2

Page 7

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

FOLDING OUT CONVEYORS

THESE PARTS GET VERY HOT WHILE IN USE, SO PLEASE

MAKE CERTAIN THAT THE UNIT HAS COOLED BEFORE

ATTEMPTING THE BELOW PROCEDURES. IF THERE IS

AN IMMEDIATE NEED TO PERFORM THIS PROCEDURE

WHILE THE UNIT IS STILL HOT, MAKE CERTAIN TO WEAR

APPROPRIATE THERMAL PROTECTION.

i. The outer conveyor cover on the front and back fold down

by lifting up on the cover and pulling outward from the top

so that the cover swings down on its pivot point.

ii. Once the cover has been folded down, one side of the

conveyor on each side will be visible. In order to rotate

the conveyor[s] down, pull the conveyor outward.

iii. At this time, you will be able to view the other side of the

belt and the platen/PTFE sheet as well.

iv. Once you have finished cleaning/inspecting the unit, fold

the conveyor assemblies up first, ensuring they lock into

the proper place.

vi. Finally rotate the covers back up and lock them in place.

At this time the toaster would be ready to use again.

BUN HEIGHT ADJUSTMENT KNOB

Bun height adjustment controlled with a simple knob in six steps ranging from [setting 1] 0.3125 in. (8 mm)

to [setting 6] 1.075 in. (27 mm) [adjusted independently front and rear]. Simply push the knob in to release

it from the current position, slide up or down to the desired position, and release the handle to lock into the

desired slot.

PTFE [NON-STICK] SHEET REPLACEMENT

The PTFE sheet is secured with two tabs on the front and two on the back. With the conveyors up,

they will be accessible from the bottom. Simply pull the sheet off of two tabs to release the tension

on the sheet, then pull the sheet off the other tabs. Lift the sheet off from the top of the unit. Place

the new sheet in position and clip over one set of tabs. Gently pull the other side and slip the slots

on it over the other tabs. Once the sheet is over all the tabs, the process is complete.

3

Page 8

DAILY OPERATION

CERTAIN SURFACES ARE EXTREMELY HOT DURING

OPERATION AND CARE SHOULD BE TAKEN WHILE

USING THIS UNIT.

DO NOT LEAVE THE UNIT IN OPERATION WITHOUT

AN ATTENDANT.

DO NOT LEAVE THE UNIT AT HIGH TEMPERATURE

WHEN NOT IN USE OR DURING IDLE PERIODS.

MAIN MENU

i. DISPL AY—Once the toaster has been pre-heated,

menu products will appear in two lists on the display

separated into a front and back side. The front conveyor

BACKFRONT

CROISSANTBAGEL

CROISSAN

T MUFFIN

MUFFIN FLATBREAD

and heaters are controlled

by the left side buttons

and the back side is

controlled by the right

side buttons.

ELECTRONIC VERSION [SCT4000E]

upper ▲ button

upper ▼ button

display screen

lower ▼ button [LIGHTER]

START UP / PREHEAT

i. When the toaster has been plugged into a suitable

outlet and power supply, the power switch can be

flipped to turn the unit on.

ii. The toaster will enter into its PREHEAT mode and

a percentage will appear on the screen. The fan and

belts will turn on and the platen will begin to heat up.

iii. The unit will, by default, use the belt speed and set

point settings last used before the previous

shutdown.

lower ▲ button [DARKER]

[PROGRAM] button

LIGHT DARK LIGHT DARK

ii. UPPER ▲/▼ ARROWS—The selected preset can be

changed simply by pressing the upper ▲ or ▼ on

the corresponding side until the desired preset is

highlighted. The speed setting change will occur

instantly.

iii. DARKER/LIGHTER—The “DARKER” and “LIGHTER”

▲ and ▼ buttons can be pressed up to ten [10] times

in each direction to activate a conveyor speed

adjustment mode from the main menu. The “DARKER”

and “LIGHTER” ▲ and ▼ buttons will cause the belt

to slow down or speed up on the corresponding side

allowing quick adjustments in toasting color. Selecting

“LIGHTER” will increase speed, while selecting “DARKER”

will decrease speed. Adjustments made here will reset

to the original time after the cycle time has finished.

ANALOG VERSION [SCT4000]

START UP / PREHEAT

i. When the toaster has been plugged into a suitable

outlet and power supply, the power switch can be

flipped to turn the unit on.

ii. Turn the thermostat to the desired set point and

allow 20-30 minutes of preheat time to ensure the

proper temperature can has been reached before

beginning to pass product through the toaster.

SHUTDOWN

Disconnect power to the unit with the power button

at the end of each day of operation.

4

Page 9

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

COOLDOWN

14 : 55

OTHER TOASTER FUNCTIONS [SCT4000E ONLY]

COOLDOWN MODE

COOLDOWN mode can be activated by holding the PG

button and the both upper ▼ buttons for a few seconds.

COOLDOWN mode causes the heaters to be turned o,

but the conveyors, display, and fan to continue functioning.

This mode can be used for cleaning or simply cooling o

the unit.

DO NOT IMMERSE THE UNIT IN WATER

OR LET THE UNIT STAND IN WATER.

DO NOT USE A NON-STICK SPRAY

ON THE CONVEYOR BELT, IT WILL

CAUSE A STICKY BUILD-UP AND

INCREASE STICKING.

DO NOT HOSE DOWN THE UNIT OR

THE TABLE/COUNTER IF THE UNIT

IS ON THE TABLE/COUNTER.

CLEANING

SUGGESTED CLEANING SUPPLIES

i. mild dish detergent and water

ii. surface sanitizer

iii. white polishing pad

iv. clean cloth rag

CLEANING PROCEDURE

Preventive maintenance for your toaster consists

of the following recommended cleaning procedures.

To keep your toaster in its best operating condition,

these steps should be performed on a daily or weekly

basis as required.

i. Turn the toaster o. On the electronic version, you can

also activate COOLDOWN mode by pressing and holding

the PG button and the upper left and upper right ▼ buttons.

This causes the toaster to turn o the heating elements

but keep power to all other parts and the display.

ii. Once cool, open the conveyor cover on each side. Apply

a mixture of dish soap and water to the white polishing

pad. Gently scrub each side of the conveyor belt and the

PTFE non-stick sheet to clean residual debris/buildup

from them.

iii. Rinse the pad and repeat as necessary until clean

of noticeable debris.

iv. Rinse the non-scratch pad to remove all detergent and

then soak with clean, warm water. Ring the pad out so

that it is only damp, and wipe down the areas until it

is clean of any detergent.

v. Wipe the belts and PTFE with a clean cloth dampened

with sanitizer solution. Allow to air dry.

vi. Rinse the non-scratch pad and then soak with clean

warm water. Ring the pad out so that it is only damp,

and wipe exterior areas of the toaster.

vii. Once dry, the unit is ready for use.

5

Page 10

DON’T REMOVE

USB FLASH

DRIVE OR TURN OFF

POWER UNTIL THE

PROGRAMMING IS

COMPLETE. CAUTION

TOASTER MAY NOT

FUNCTION PROPERLY.

PRODUCT SETTINGS AND ADJUSTMENTS [SCT4000E ONLY]

The Star contact toaster comes with pre-programmed factory default settings

for toasting some products, although the settings will need to be adjusted to

accurately toast your specific buns. User defined settings can be saved with no

set limit to the variations that can be used. Users can customize product names

and belt speed.

CHANGING CONVEYOR SPEED [TOAST TIME]

i. To adjust the conveyor speed [toast time], begin by pressing the PG button.

ii. Using the upper, left ▲ and ▼ buttons, select the product to be adjusted.

iii. Using the upper, right ▲ and ▼ buttons, change the speed [toast time].

iv. Hit PG again to save changes.

CHANGING PLATEN TEMPERATURE

i. To adjust the platen temperature, begin by simultaneously pressing the

PGbutton and the lower, right ▲ button.

ii. Using the upper, right ▲ and ▼ buttons, change the platen temperature.

iii. Hit PG again to save changes.

PROGRAMMING

LOADING A PRODUCT FILE

i. Ensure the toaster is powered on before beginning.

ii. Plug a USB flash drive containing the desired .csv file into the receptacle.

iii. The display will automatically search for all files with the correct .csv extension.

These will then be shown on the display.

iv. Select the desired file to upload with the upper right side ▲ and ▼ buttons and

the PG button.

v. Programming may take up to several minutes. The display will reset when finished,

and the toaster will resume normal operation.

EDIT PRODUCT SETTINGS [ON TOASTER]

THE SETUP MENU IS USED TO EDIT THE PRODUCT NAME, CONVEYOR SPEED,

OR HEATER SETTING FOR ANY EXISTING PRODUCTS.

i. To access the setup menu, while on the main screen, press and hold the PG

button for a few seconds until the setup screen appears.

ii. The selected product can be changed using the ▲ and ▼ buttons on the upper

left side.

iii. The right “DARKER” and “LIGHTER” ▲ and ▼ buttons are used to cycle between

the other settings.

iv. The belt speed values can be changed using the upper right side ▲ and ▼

buttons. All values are set in whole numbers.

v. Once finished, press the PG button to exit to the main menu. Settings update

instantly.

EDITING PRODUCT NAME

i. Once in the setup menu, press the left “LIGHTER” ▼ button on the product name

to begin editing.

ii. Use the upper right ▲ and ▼ buttons to cycle through characters and the upper

left ▲ and ▼ buttons to move selection from character to character. Spaces

cannot be used. Any characters after a space will not appear in the product

name in the menu. The name can be up to a maximum of nine [9] characters.

iii. Press the PG button to save and exit.

6

Page 11

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

ADVANCED PROGRAMMING [SCT4000E ONLY]

CREATING A NEW UPDATE FILE

i. If a .csv file with the correct format for uploading new preset names and settings into the toaster

has not already been loaded onto a USB flash drive, a file with the correct format can be generated

by plugging a USB flash drive into the toaster while it is on. A flash drive formatted in FAT32

is strongly suggested.

ii. A screen will appear prompting an upload or download option for the toaster. By pressing the

upper, left-side ▼ button, a csv file will be generated with the toaster’s current product settings

and names called “CONTACTD”.

iii. Remove the flash drive and insert it into a computer with Microsoft Excel or another application

capable of creating .csv files. Open the file and change the product names and settings to the

desired values. Save the file as a .csv file.

FILE REQUIREMENTS

• PRODUCT NAMES will only appear in upper case when uploaded and must be 9 characters or less.

• CYCLE TIME must be a whole number between 6 and 60.

• FILE NAME will only appear in upper case when uploaded, must be 8 characters or less.

7

Page 12

ELECTRONIC AND COMMON COMPONENTS

2

3

4

5

6

A

10

8

1

10

12

11

9

15

14

12

45

45

9

29

30

38

31

26

7

20

21

22

23

24

25

27

28

CONTROL LABEL REPLACEMENT

i. Remove the two [2] screws holding the bezel on.

ii. Lift o the bezel, gasket, and label.

iii. Place new label, bezel, and gasket in place in the

order displayed on the right.

iv. Tighten down the two [2] screws that hold the

bezel in place.

11

32

33

34

13

37

39

40

6

5

36

35

8

Page 13

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

ANALOG COMPONENTS

23

41

28

6

5

16

30

42

37

17

18

19

44

43

31

9

Page 14

PARTS LIST

REF NO PART NUMBER MODEL DESCRIPTION QTY PAGE NO

1 HC-21450 ALL conveyor cover, rear 1 8

2 HC-120413 ALL rear conveyor assembly [INCLUDES PARTS 9–12] 1 8

3 2F-Z21590 ALL platen 1 8

4 2V-Z21506 ALL PTFE sheet bar 1 8

5 2C-35733 ALL 8-32 screw 2 8, 9

6 HC-Z21437 ALL side cover 2 8, 9

7 HC-Z21515 ALL conveyor cover, front 1 8

8 HC-120412 ALL front conveyor assembly [INCLUDES PARTS 9–12] 1 8

91 2V-Z21574 ALL conveyor drive rod 2 8

101 2M-Z22076 ALL bun thickness label 2 8

111 2A-Z12583 ALL 0.375-inch e-clip 8 8

121 2R-Z21448 ALL linkage handle 2 8

13 2A-Z11501 ALL foot 4 8

14 HC-Z21510 ALL discharge tray 1 8

15 HC-Z21511 ALL crossbar 1 8

16 2P-Z8779 SCT4000 sprocket [25p-11t] 1 9

17 2P-200645 SCT4000 sprocket [25B17] 2 9

18 HC-Z21531 SCT4000 sprocket mount bracket 1 9

19 2P-200650 SCT4000 sprocket [25B24] 1 9

20 HC-Z21513 SCT4000E guard 1 8

21 2E-Z21591 SCT4000E display board

22 HC-Z20995 SCT4000E control panel cover 1 8

2M-Z21066 SCT4000E

23

2M-Z22011 SCT4000 1 9

24 2I-Z21052 SCT4000E control bezel gasket 1 8

25 HC-Z20994 SCT4000E control panel bezel 1 8

26 2C-41620 ALL 8-32 screw 22 8

27 2C-Z21598 ALL pem stud 2 8

28 2E-Z21127 ALL rocker switch 1 8, 9

29 2M-Z22069 SCT4000E name label 1 8

30 2E-Z21585 ALL high limit thermostat 1 8, 9

2E-Z21523 SCT4000E stepper motor 2 8

31

2U-Z21534 SCT4000 A/C motor 1 9

32 2E-Z21593 SCT4000E motor board 1 8

33 2E-Z21586 SCT4000E CPU board 1 8

34 2E-Z21444 SCT4000E AC/DC converter 1 8

35 2E-Z21440 SCT4000E relay 1 8

36 2E-Z21003 SCT4000E cooling fan 1 8

control label overlay

1 8

1 8

1These parts are also included in assemblies HC-120412 and HC-120413.

10

Page 15

PARTS LIST

REF NO PART NUMBER MODEL DESCRIPTION QTY PAGE NO

37 2K-Y6764 ALL strain relief bushing 1 8, 9

38 HC-Z21524 SCT4000E motor mount 2 8

39 2E-Z21509 SCT4000E fan guard 1 8

40 2C-Z5883 SCT4000E 10-24 self-tapping screw 2 8

41 2R-Z22044 SCT4000 control knob 1 9

42 2T-Z21434 SCT4000 thermostat 1 9

43 HC-Z21532 SCT4000 motor mount bracket 1 9

44 2C-Z7165 ALL 8-32 keps nut 8 9

45 2H-Z21527 ALL PTFE platen insulation 4 8

46 2I-Z21439 ALL PTFE sheet 1 NP

47 2I-Z21454 ALL silicone belt 2 NP

48 2P-150015 SCT4000 drive chain 1 NP

OPTIONAL ACCESSORIES

9Y-SCTBWP ALL perforated butter wheel

9Y-SCTBWS ALL smooth butter wheel

9Y-SCTSHEET-D ALL pack of 10 replacement PTFE sheets for standard, dry use

9Y-SCTSHEET-B ALL pack of 10 replacement PTFE sheets for use with butter

2M-Z21001 Rev- Owner's Manual for IRCS4 Impingement/Radiant Split-Belt Conveyor Toaster

11

2M-Z21667 Rev B Owner’s Manual for SCT4000 and SCT4000E Contact Toaster

Page 16

R

T

H

IS

D

R

A

W

IN

G

C

O

N

T

A

IN

S

I

N

F

O

R

M

A

T

IO

N

C

O

N

F

ID

E

N

T

IA

L

T

O

S

T

A

R

M

F

G

. IN

T

'L

. IN

C

. N

O

R

E

P

R

O

D

U

C

T

IO

N

O

R

D

IS

C

L

O

S

U

R

E

O

F

IT

S

C

O

N

T

E

N

T

S

IS

P

E

R

M

IT

T

E

D

S

T

A

R

M

A

N

U

F

A

C

T

U

R

IN

G

IN

T

E

R

N

A

T

IO

N

A

L

IN

C

.

#

1

0

S

U

N

N

E

N

D

R

IV

E

S

T

. L

O

U

IS

, M

O

. 6

3

1

4

3

, U

S

A

D

E

S

C

R

I

P

T

I

O

N

O

F

C

H

A

N

G

E

D

A

T

E

L

T

R

C

K

.

R

E

V

I

S

I

O

N

S

T

O

L

E

R

A

N

C

E

U

N

L

E

S

S

N

O

T

E

D

:

.0

1

5

A

N

G

L

E

S

1

P

A

R

T

N

O

.

T

I

T

L

E

M

O

D

E

L

N

O

.

F

I

N

I

S

H

D

A

T

E

:

D

R

.

M

A

T

E

R

I

A

L

S

C

T

4

0

0

0

E

W

I

R

E

D

I

A

G

R

A

M

,

S

C

T

4

0

0

0

E

2

M

-

Z

2

1

4

5

8

1

/

1

7

/

2

0

1

7

m

m

a

r

a

g

n

i

WIRING DIAGRAM

SCT4000E

USB CONNECTOR

POWER CHORD

L

N

G

12

GROUND TO CHASSIS

WAGO CONNECTOR

WAGO CONNECTOR

DISPLAY BOARD

3

5

2

4

6

6

CAT 5E

CABLE

RTD

14

11

CPU BOARD

12

MOTOR WIRES

MOTOR BOARD

STEPPER MOTOR REAR

8

7

STEPPER MOTOR FRONT

POWER SWITCH

2

1

HEATER PLATEN

14

13

HIGH LIMIT THERMOSTAT

9 10

CAT 5E

CABLE

13

RELAY

12

5

COOLING FAN

POWER SUPPLY

3

4

7

8

9

10

11

FAN WIRES

Page 17

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

T

H

IS

D

R

A

W

IN

G

C

O

N

T

A

IN

S

IN

F

O

R

M

A

T

IO

N

C

O

N

F

ID

E

N

T

IA

L

T

O

S

T

A

R

M

F

G

. IN

T

'L

. I

N

C

. N

O

R

E

P

R

O

D

U

C

T

I

O

N

O

R

D

IS

C

L

O

S

U

R

E

O

F

IT

S

C

O

N

T

E

N

T

S

IS

P

E

R

M

IT

T

E

D

S

T

. L

O

U

IS

, M

O

. 6

3

1

4

3

, U

S

A

D

E

S

C

R

I

P

T

I

O

N

O

F

C

H

A

N

G

E

D

A

T

E

L

T

R

C

K

.

R

E

V

I

S

I

O

N

S

T

O

L

E

R

A

N

C

E

U

N

L

E

S

S

N

O

T

E

D

:

.0

1

5

A

N

G

L

E

S

1

T

I

T

L

E

D

A

T

E

:

D

R

.

W

I

R

I

N

G

D

I

A

G

R

A

M

,

S

C

T

4

0

0

0

1

/

1

8

/

2

0

1

7

m

m

a

r

a

g

n

i

WIRING DIAGRAM

SCT4000

POWER CHORD

L

N

G

GROUND TO CHASSIS

ADJUSTABLE THERMOSTAT

POWER

SWITCH

1

2

WAGO CONNECTOR

WAGO CONNECTOR

4

4

HEATER PLATEN

5

3

6

HIGH LIMIT THERMOSTAT

5

3

6

1

AC MOTOR

13

Page 18

SPECIFICATIONS

21.7 in.

(551 mm)

SCT4000E shown.

25.7 in.

(653 mm)

6.25 in.

(159 mm)

0.5 in.

(13 mm)

0.9 in.

(23 mm)

0.6 in.

(15 mm)

1 in.

(25 mm)

[toaster opening]

13 in.

(330 mm)

2.375 in.

(60 mm)

9.5 in.

(241 mm)

MODEL HEIGHT WIDTH DEPTH1 VO LTS AMPS WAT TS

SCT4000E

SCT4000

1without butter wheel [butter wheel extends out and adds 4.2 in. (107 mm) to unit depth].

25.7 in.

(653 mm)

25.7 in.

(653 mm)

21.7 in.

(551 mm)

21.7 in.

(551 mm)

9.5 in.

(241 mm)

9.5 in.

(241 mm)

208

230

240

208

230

240

0.6 in.

(15 mm)

9.6

10.6

11.1

9.9

11

11.5

CLEARANCE

Please allow at least one [1] inch (25mm) on each

side of unit and the rear of the unit.

NEMA

PLUG

2,000

2,446

2,663

2,065

2.525

2,750

6-15P

CEE7-7

6-15P

6-15P

CEE7-7

6-15P

APPROX. SHIP

WEIGHT

100 lb.

(45.4 kg)

100 lb.

(45.4 kg)

APPROX. WEIGHT

INSTALLED

75 lb.

(34 kg)

75 lb.

(34 kg)

CEE 7-7 6-15P

14

Page 19

2M-Z21667 Re

v C Owner

’s Manual for SCT4000 and SCT4000E Contact Toaster

NOTES

15

Page 20

STAR MANUFACTURING INTERNATIONAL INC.

10 Sunnen Drive

Telephone 800 264 7827 • Fax 314 781 5445

•

Saint Louis, Missouri 63143

www.star-mfg.com

Printed in the U.S.A. • 2M

Specifications are subjec t to change without notice.

-Z21667• Rev C • 03.2017

Loading...

Loading...