Page 1

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

FOR SERVICE INFORMATION

U.S. AND CANADA CALL: 1-800-264-7827

24 HOURS/DAY 7 DAYS/WEEK

TABLE OF CONTENTS

UNCRATING AND INSPECTION PAGE 1

ASSEMBLY AND INSTALLATION PAGE 1

POWER SAVER SWITCH PAGE 2

SECURITY FEATURES PAGE 2A

COOKING PROCEDURES PAGE 3, 4

CLEANING PROCEDURES PAGE 4

TROUBLESHOOTING GUIDE PAGE 5, 6

MAINTENANCE PROCEDURES PAGE 7, 8, 9

PARTS LIST/EXPLODED VIEW PAGE 10, 11, 12, 13

DRAWINGS

CRUMB TRAY PAGE 1

LOAD AND UNLOAD TRAYS PAGE 1

ADJ. HEAT SHIELD, FRONT VIEW PAGE 3

COMPONENT ARRANGEMENT PAGE 6

HEATER TUBE INSTALLATION PAGE 7

DRIVE SYSTEM PAGE 9

WIRING DIAGRAMS [T710(H,TW)] PAGE 15, 16

WIRING DIAGRAMS [T714(H,TW)] PAGE 16, 17

WIRING DIAGRAMS [B710(H)] PAGE 18

WIRING DIAGRAMS [S710(H), Jamba Juice] PAGE 19

WIRING DIAGRAMS [S714(H)] PAGE 20

2M-HG0102

REV. 1/31/2011

Page 2

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

UNCRATING AND INSPECTION

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

Unpack unit and components from container. Remove all visible packing

material, inspect unit for damage. If damage is discovered, file a claim

ASSEMBLY AND INSTALLATION

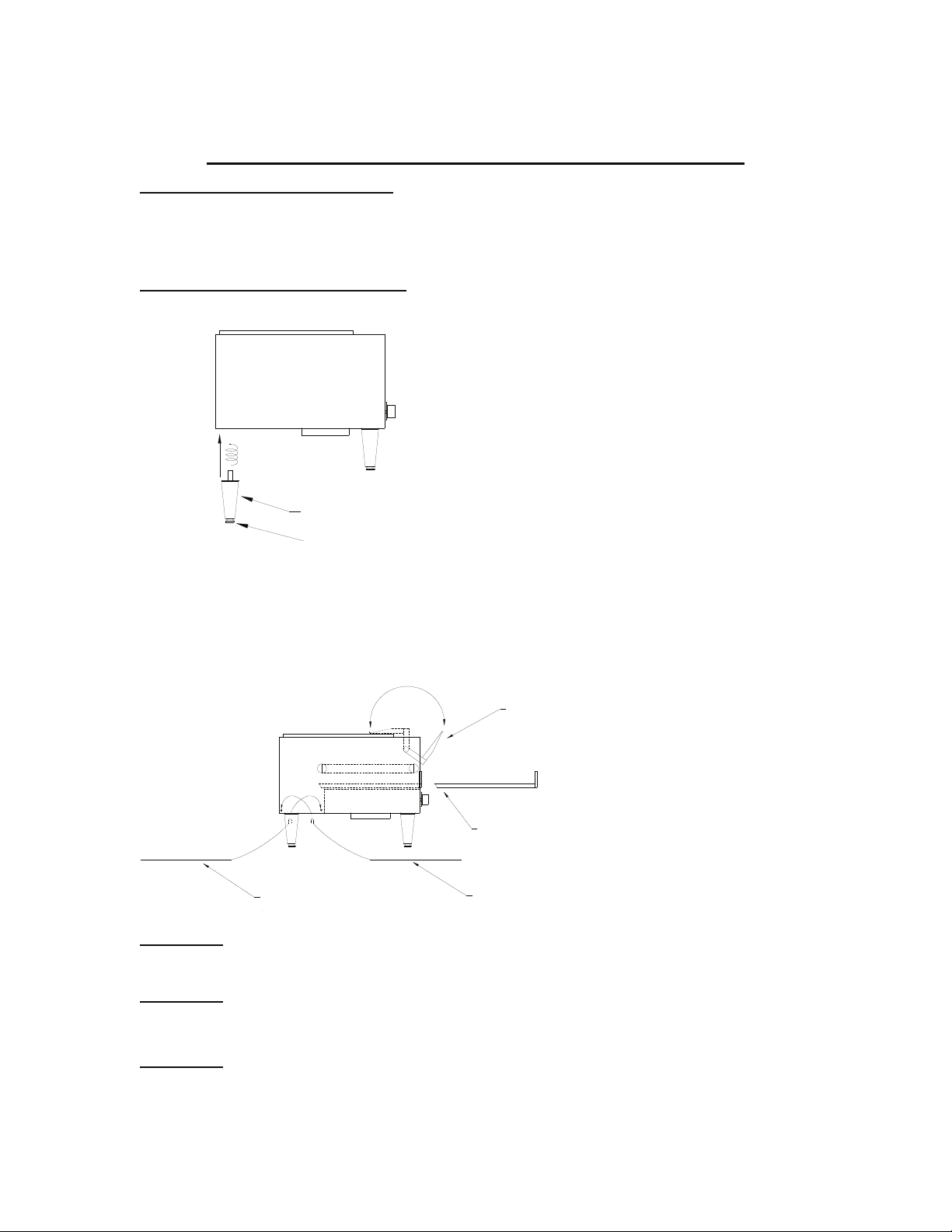

A. Attach legs by screwing into weld nuts, as shown below.

immediately with the carrier that handled the shipment.

Page 1

ADJUSTABLE LEG: SCREWS INTO WELD NUT LOCATED

AT EACH CORNER ON BOTTOM SIDE OF TOASTER

LEVELING OF THE TOASTER CAN BE DONE BY TURNING

THE FOOT SECTION OF THE LEG COUNTER CLOCKWISE

B. Anti Skid pads are available at no charge and may be adhered to the foot

section of each leg to prevent sliding. Call 1-800-225-3958 for details.

WARNING: the National Sanitation Foundation does not approve Use of

these pads.

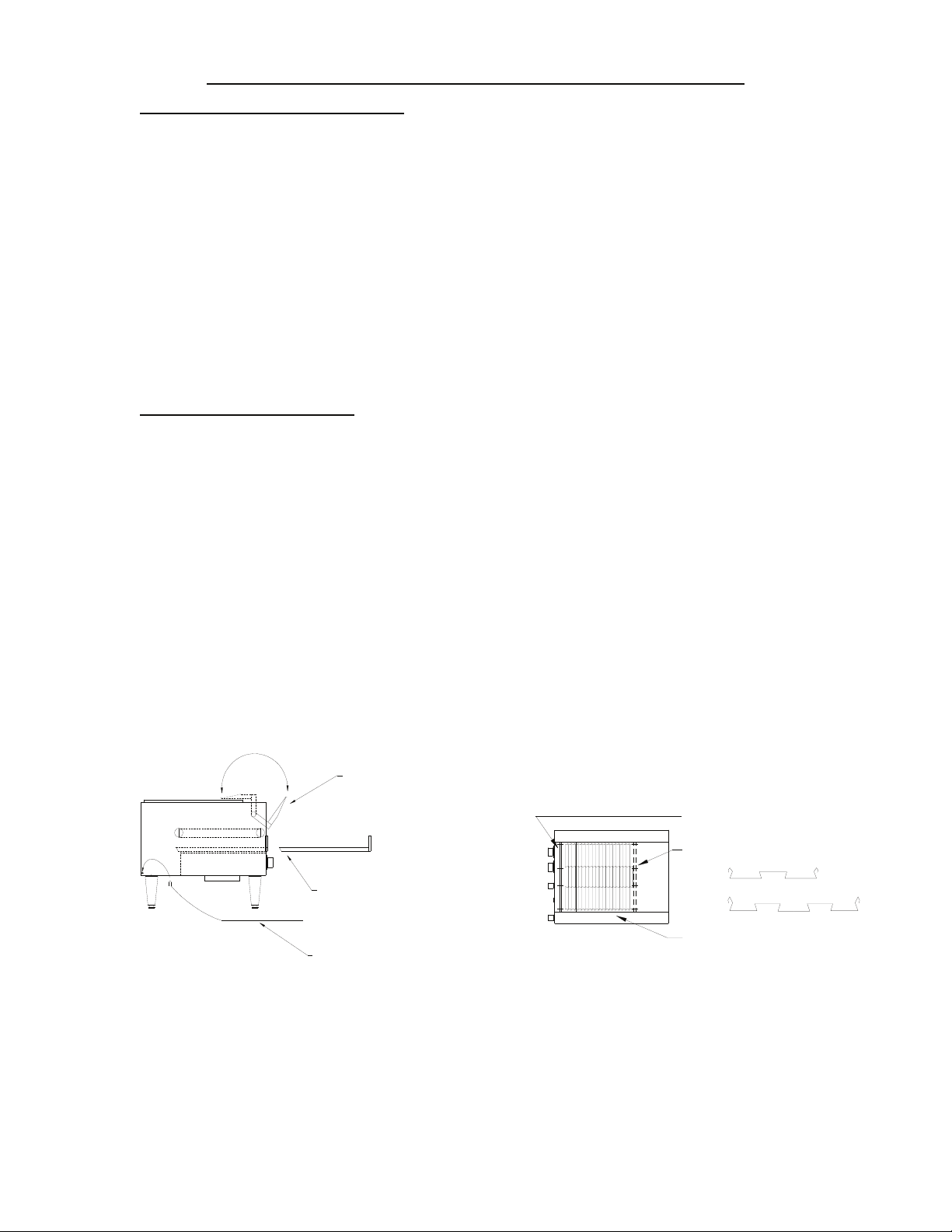

C. Place load and unload trays as shown below.

LOAD UP TRAY

HEAT REFLECTOR / CRUMB TRAY

(REAR DISCHARGE)

TOAST CHUTETOAST CHUTE

CAUTION: DO NOT OPERATE UNIT WITHOUT

CRUMB TRAY PROPERLY POSITIONED

AS THIS WILL CAUSE OVERHEATING IN THE

CONTROL BOX.

WARNING: MAKE SURE ALL INPUT POWER IS OFF BEFORE INSTALLING/REMOVING

WARNING

WARNING

ANY PARTS.

: BEFORE INSTALLING UNIT(S), CHECK WITH LOCAL POWER COMPANY TO

DETERMINE ACTUAL VOLTAGE AT JOB SITE. NEVER PLUG A 208-VOLT UNIT

INTO 240 VOLTS OR A 240 VOLT UNIT INTO 208 VOLTS.

: BE ABSOLUTELY SURE THE GROUND CONNECTION FOR THE RECEPTACLE

IS PROPERLY WIRED. NEVER CONNECT UNIT TO POWER WITHOUT

PROPER GROUND CONNECTIONS. IMPROPER GROUND MAY RESULT IN

SEVERE INJURY OR FATALITY.

REVISED 9/10/2008

Page 3

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

OPERATION

Your Holman toaster may be equipped with a Power Saver Switch, details are as

follow;

Page 2

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

POWER SAVER

SWITCH

FULL

POWER

OFF

1/4 POWER

STAND BY

TOGGLE POWER SAVER

FULL POWER

OFFOFF

1/4 POWER

STAND BY

ROTARY POWER SAVER

USING YOUR POWER SAVER SWITCH

Power Saver

Switch Positions

FULL POWER- When in this position your unit is at Full Power and ready to use.

Adjust the Top and Bottom Variable Heat Controls and Conveyor

Belt Speed Control to your desired settings.

OFF-ROTARY: Two off positions are provided so that a single rotation to either

direction will result in the unit being turned OFF.

OFF-TOGGLE: The center position of the toggle switch turns the unit completely

OFF regardless of heat and speed control settings.

STANDBY- The standby position reduces the power to the unit to 1/4, and

therefore saves 75% of the energy consumption. In this position

your unit will stay warm and reduce the reheat time when switched

to Full Power to 20 to 30 seconds.

REVISED 9/10/2008

Page 4

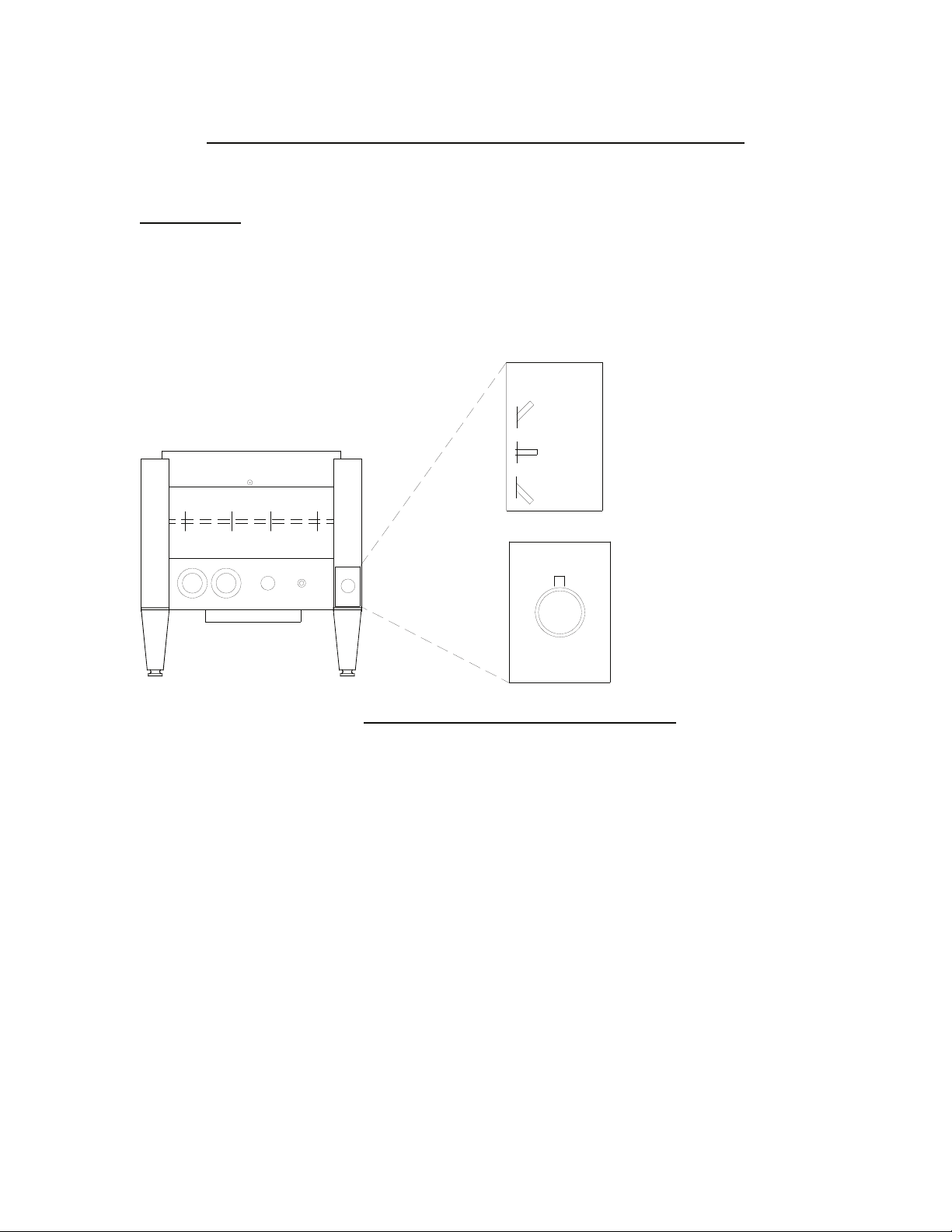

FULL KEY LOCKING COVER

FITS OVER CONTROLS AND

SIDE PANELS TO PREVENT

TAMPERING

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS S710(H), S714(H)

SECURITY COVER :

Your Holman models S710 and S714 are quipped

with a full front key locking cover (fig.1). This over fits

over the front and sides of the unit. The security

cover must be removed with a key in order to gain

access to the controls, side panels, legs and toast

chute to be removed.

To remove, unlock the cover using the key. Pull

locked side of cover out and away from the unit. The

right side will release at the same time.

HOLMAN

To replace the cover, Hook the right side of the cover

over the latch on right front of the unit while sliding

the left side of the cover over the lock. Secure cover

using key.

Page 2A

Fig. 1

SECURITY TOAST

CHUTE MOUNTING

ROD

S710CHUT.WMF

Fig. 2

COTTER PIN

S710LEG.WMF

Fig. 3

S710LOK.WMK

TOAST CHUTE MOUNTING ROD

SLIDES THOUGH MOUNTING HOLE

IN CHASSIS AND THROUGH LOOP IN

TOP OF TOAST CHUTE

H

O

L

M

A

N

SECURITY COUNTER MOUNTING

BRACKET ATTACHES TO LEG FOOT

AND IS SECURED TO COUNTER

WITH A SCREW.

COTTER PIN

MOUNTING

BRACKET

LEG SCREWS

INTO THE BOTTOM

OF TOASTER

FOOT SCREWS

INTO BOTTOM

OF LEG

KEY LOCK

OPERATOR'S MANUAL

TOAST CHUTE ;

To install the toast chute (fig. 2), Remove the left side

panel by removing two screws and pulling the top

part of the panel out while lifting up. Remove the

mounting rod by sliding it through chassis.

Next, place the toast chute beneath toaster as

shown. Line up the looped end of toast chute with

holes in the rear of toaster as shown. Insert mounting

rod through the holes in chassis and the toast chute

(If legs have not been installed, do so now).

Reinstall side panel and secure with screws. Toast

chute is now ready for use.

LEGS :

To secure the toaster to the counter (fig.3), Remove

both side panels by removing two screws and pulling

the top of the panel out while lifting up. Unscrew the

foot of each leg and slide counter-mounting brackets

onto the legs. Screw the foot back onto each leg and

install legs onto the toaster. Place the small cotter pin

through the holes in threaded portion of each leg.

Secure the mounting brackets to the counter with a

screw or bolt. Reinstall both side panels and secure

with screws.

NOTE: Security models are not supplied with a

power saver switch.

REVISED 9/10/2008

PAGE 3

Page 5

HOLMAN CONVEYOR TOASTERS

COOKING PROCEDURES

A. BREAD TOASTING

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

NOTE: Models TX710(H) and TX714(H) have an extended conveyor belt in

lue of a load up tray. Place (do not press) the product on the

extended conveyor belt for toasting or heating. Follow the

instructions listed below for cooking and operation procedures.

1. On models T710H, TX710(H), T714H, TX714(H) and B710H, S710(H),

S714(H) lower the front heat shield all the way down, leave just enough

clearance for bread slices to pass under the shield into the cooking

cavity (See illustration below).

ADJUSTABLE HEAT SHUTTER

2. Turn top and bottom heat controls to HI; turn conveyor speed control to

50.

3. Allow warm up time of 5 to 10 minutes.

4. Test with a slice of bread.

a. If toast is too light, turn conveyor speed control counterclockwise to a

slower speed.

b. If toast is too dark, turn conveyor speed control clockwise to a faster

speed.

B. MODELS T710(H), TX710H, T714(H), TX714H, S710(H), S714(H)-BUN TOASTING

1. Buns may be top or bottom toasted. Turn appropriate heat control to HI,

set conveyor speed control to 50.

2. On models with high (3") clearance (T710H, TX710H, T714H, TX714H, S710H,

S714H), lower the front heat shield as far as possible, leave just enough

clearance for the bun half to pass under and into the cooking cavity.

3. Test with a half of a bun.

a. If bun half is too light, turn conveyor speed control counterclockwise

to a slower speed.

b. If bun half is too dark, turn conveyor speed control clockwise to a

faster speed.

Cooking procedures continued on page 4

REVISED 9/10/2008

PAGE 4

OPERATOR'S MANUAL

Page 6

HOLMAN CONVEYOR TOASTERS

COOKING PROCEDURES CONT.

C. MODEL B710(H)

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

The model B710(H) has higher wattage tubes on the top than on the bottom,

therefore when placing the bun halves on the conveyor you should place

them cut side up.

D. DEEP TOASTING OR BAKING (Units with Variable Heat Controls).

Food products that require deep heating without exterior toasting may be

heated by reducing the oven temperature (lowering the top and/or bottom

heat controls) and cooking at slower speeds. Some foods may require more

top heat than bottom heat or vice versa. Every product will require some

experimentation to arrive at the correct balance of heat control and conveyor

speed settings. Each time a setting is changed allow about 5 minutes for the

unit to stabilize.

CLEANING PROCEDURES

1. Turn top and bottom heat controls to the OFF position.

2. For lightly soiled conveyor belts, turn conveyor speed control to fastest

setting (100) and wipe with a damp cloth.

3. For heavily soiled conveyors, turn conveyor speed control to fastest setting

(100) and wipe with a light abrasive pad.

4. Turn conveyor speed control off.

5. After the unit cools, remove interior crumb tray (as shown below) and clean.

Slide crumb tray back into position. DO NOT OPERATE UNIT WITHOUT

CRUMB TRAY IN PLACE AS THIS CAUSES OVERHEATING IN THE

CONTROL BOX AND MAY ACTIVATE THE HEAT LIMIT SWITCH.

6. Wipe exterior surface of unit.

LUBRICATION OF DRIVE CHAIN WITH A GRAPHITE BASED LUBRICANT IS REQUIRED AS

PERIODIC MAINTENANCE. CALL HOLMAN FACTORY SERVICE DEPARTMENT FOR

DETAILS.

LOAD UP TRAY

CAUTION: DO NOT OPERATE UN

WITHOUT CRUMB TRAY AS

THIS CAUSES OVERHEATING IN

THE CONTROL BOX.

HEAT REFLECTOR / CRUMB TRAY

(TOP VIEW)

TOAST CHUTE

SHOWN WITHOUT TOP COVER

IDLER SHAFT

DRIVE SHAFT

CONVEYOR LINK, MODEL T710

CONVEYOR LINK, MODEL T714

CONVEYOR BELT

REVISED 9/10/2008

OPERATOR'S MANUAL

PAGE 5

Page 7

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

TROUBLESHOOTING GUIDE

A. UNIT WILL NOT HEAT, CONVEYOR WILL NOT TURN.

1. Be sure the main circuit breaker is switched to the ON position.

2. Check to see if the toaster is plugged in and all controls are turned to the

ON position.

B. UNIT WILL NOT HEAT, CONVEYOR TURNS PROPERLY.

1. Check to see if both top and bottom heat controls have been turned to

HI.

2. Push heat limit switch on front of control box as shown below.

If this reactivates the heater tubes, see HEAT LIMIT SWITCH in

section C.

C. HEAT LIMIT SWITCH

Your Holman conveyor toaster is equipped with an automatically activated

Heat Limit Switch that interrupts the heater tube connections if the ambient

temperature in the control box exceeds 190F (88C). This heat limit switch

can be reset manually by pushing the red button on the front of the control

box.

HEAT LIMIT SWITCH

CONVEYOR SPEED CONTROL

BOTTOM HEAT CONTROL

TOP HEAT CONTROL

THE HEAT LIMIT SWITCH IS ACTIVATED WHEN THERE IS NOT

SUFFICIENT AIR FLOW GENERATED BY THE COOLING FAN. WHEN

HEAT LIMIT SWITCH HAS BEEN ACTIVATED:

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Check to see if air intake area in the bottom center of the control box

cover is free of dust, grease or other obstructions.

Troubleshooting guide continued on page 6

REVISED 9/10/2008

PAGE 6

OPERATOR'S MANUAL

Page 8

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

TROUBLESHOOTING GUIDE CONT.

3. Check if crumb tray is in place. NEVER OPERATE UNIT WITHOUT

CRUMB TRAY IN PLACE AS THIS CAUSES OVERHEATING IN THE

CONTROL BOX.

4. If no obstructions to the airflow can be found and if the crumb tray is in

place, call Holman Factory Service Department at 1-800-225-3958 for

assistance.

D. CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY.

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove right hand side panel (from operator's position). Loosen screws

holding drive motor in place and slide motor toward the rear of unit.

Remove drive chain and manually move conveyor belt to check for

mechanical binding. If conveyor moves freely, call Holman Factory

Service Department at 1-800-225-3958 as drive motor and/or speed

control may need replacement.

CONTROL KNOBS

SHAFT BEARINGS

RIGHT SIDE SHOWN WITHOUT SIDE PANEL

DRIVE SHAFT SPROCKET

DRIVE CHAIN

DRIVE MOTOR ADJUSTMENT SLOTS

RESET BUTTON

CONVEYOR

SPEED CONTROL

HEAT CONTROLS

TERMINAL STRIP

DRIVE MOTOR

E. CONVEYOR TURNS AT ONE SPEED REGARDLESS OF SPEED

CONTROL SETTING.

1. Call Holman Factory Service Department at 1-800-225-3958 as speed

control should be replaced.

REVISED 9/10/2008

PAGE 7

OPERATOR'S MANUAL

Page 9

HOLMAN CONVEYOR TOASTERS

MAINTENANCE PROCEDURES

A. REPLACING HEATER TUBES (as below)

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove right and left side panels.

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

3. Remove heater tube wire from terminal block connection, keeping

top and bottom wires separate.

4. Remove heater tube retainers by removing retaining screws with washer.

5. Gently,

6. Gently,

pull defective heater tube out of unit.

put new heater tube into unit.

7. Replace heater tube retainers, reconnect heater tube wires to terminal

block and install side panels.

HEATER TUBE RETAINER

HEATER TUBE TERMINAL BLOCK (4 POS.)

(2 POS. ON OPOSITE SIDE)

SIDE PANEL

HEATER TUBE RETAINER

HEATER TUBE

Maintenance procedures continued on page 8

OPERATOR'S MANUAL

AIR INTAKE

REVISED 9/10/2008

PAGE 8

Page 10

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

MAINTENANCE PROCEDURES (CONT.)

B. REPLACING FAN MOTOR

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove control box cover with fan motor.

3. Unplug power supply cord from fan motor.

4. Remove(4)screws that hold fan motor and grill to cover.

5. Put replacement motor and grill in place and secure to the control box

cover with screws.

6. Reconnect power supply cord to fan motor.

7. Replace control box cover.

CONTROL BOX COVER

AIR INTAKE

FAN MOTOR

SECURED BY 4 SCREWS

AIR INTAKE SCOOP

Maintenance procedures continued on page 9

REVISED 9/10/2008

Page 11

PAGE 9

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

MAINTENANCE PROCEDURES (CONT.)

C. REPLACING BELT DRIVE MOTOR

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove right side panel and control box covers.

3. Remove sprocket from motor shaft.

4. Remove the wire from terminal block connecting the drive motor to internal

wiring. On units rated 208 or 240 volts, note which color leads are being used for

these connections and which lead is capped with white tape. The new motor

should use the same arrangement.

5. Remove screws holding motor in place.

6. Put new motor in place and attach loosely with mounting screws.

7. Replace sprocket on motor shaft.

8. Slide motor until the drive chain has about 1/8" slack when lightly pushed

at the center of its top open run.

9. Tighten screws to secure motor.

10. Rewire leads same as removed in step 4.

11. Replace side panel and control box cover.

IF ASSISTANCE IS REQUIRED FOR THIS OR ANY OTHER PROCEDURE IN THIS

MANUAL CALL HOLMAN FACTORY SERVICE DEPARTMENT AT 1-800-807-9054, 24

HOURS/DAY 7 DAYS/WEEK.

DRIVE SPROCKET WITH SET SCREW

SHAFT BEARINGS

RIGHT SIDE SHOWN WITHOUT SIDE PANEL

DRIVE SHAFT SPROCKET

DRIVE CHAIN

DRIVE MOTOR ADJUSTMENT SLOTS

(BOTTOM VIEW)

DRIVE MOTOR

DRIVE MOTOR

MOUNTING SCREW

REVISED 9/10/2008

Page 12

PAGE 10

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

PARTS LIST /EXPLODED VIEW MODEL T710(H), 120, 208, 240 VOLT

28.

..

3

2.

1.

1.

4.

5.

27.

17.

16.

18.

26.

21.

11.

22.

19.

23.

20.

13.

14.

15.

12.

24.

11.

10.

9.

8.

7.

25.

6.

Model: T710 (H) 120, 208, 240V

PART No.

QTY DESCRIPTION

1) HO-400821 1 Cover, Top 16) HO-100901 1 Idler Shaft

2) GH-197848 4 Heater Tube, 120 Volt 17) HO-100541 1 Crumb Tray

2a) HO-197841 4 Heater Tube, 208 Volt 18) 2J-200538 2 Infinite Switch, 208/240 Volt

2b) HO-197844 4 Heater Tube, 220 Volt 18a) 2J-200539 2 Infinite Switch, 120 Volt

2c) HO-197842 4 Heater Tube, 240 Volt 19) SP-118000 1 Speed Control, 120 Volt

3) NLA 4 Retainer, Heater TubeHH 19a) SP-118042 1 Speed control, 208/240 Volt

4) HO-160000 1 Conveyor Belt, T710(H) 20) 2E-200566 1 Reset/High Limit

5) HO-400827 1 Back Panel, Low 21) 2R-200702 2 Knob, Infinite Switch

5a) HO-400925 1 Back Panel, High 22) 2R-200703 1 Knob, Speed Cont'l/ Power Saver

6) HO-401486 2 Side Panel, Low 23) 2E-200551 1 Power Saver Switch

6a) NLA 2 Side Panel, High (H) 24) 2R-Y5092 4 Leg, 4" Plastic

7) 2P-200662 1 Drive Chain T710(H) 2E-200376 Power Supply Cord, 208V

8) 2P-Z8779 1 Drive Sprocket

9) 2P-200645 1 Driven Sprocket 26) HO-400825 1 Toast Chute

10) HO-100900 1 Drive Shaft 27) 2B-200753 1 Load up Tray

11) HA-112261 4 Bearings 28) GA-400891 1 Heat Shutter (H Model Only)

12) 2U-Z13803 1 Drive Motor, 120 Volt *29) SP-115603 4 Security Leg , S710(H) (not shown)

12a) 2U-200509 1 Drive Motor, 208/240 Volt

13) 2U-200558 1 Fan Motor, 120 Volt

2U-200560 Fan Motor, 208/240 Volt

13a)

HO-115103

1

Retro Kit,Motor, T710h

14) NLA 1 Control Box Cover

15) 2R-200562 1 Fan Grill

PART No. QTY DESCRIPTION

25)

HA-140026

2M-200839 1 LABEL, POWER SAVER

NI

2M-200801 1 LABEL, CONTROLS

NI

HC-115381 1 TERM, BLOCK-4 POS.

NI

HA-115383 1 TERM, BLOCK-3 POS.

NI

HA-115386 1 TERM, BLOCK-9 POS.

NI

1

Cord Set, VA T710 120V

Parts continued on page 11

REVISED 1/28/2011 RMS

Page 13

PAGE 11

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

PARTS LIST /EXPLODED VIEW MODEL TX710(H) 120, 208, 240 VOLT

..

3

28.

2.

1.

4.

5.

16.

17.

27.

29.

18.

20.

21.

22.

19.

23.

26.

13.

14.

15.

11.

6.

9.

10.

12.

8.

25.

24.

7.

Model: TX710 (H) 120, 208, 240V

PART No.

QTY. DESCRIPTION

1) HO-400821 1 Cover, Top 13a) 2U-200560 1 Fan Motor, 208/240 Volt

2) GH-197848 4 Heater Tube, 120 Volt 14) NLA 1 Control Box Cover

2a) HO-197841 4 Heater Tube, 208 Volt 15) 2R-200562 1 Fan Guard

2b) H0-197844 4 Heater Tube, 220 Volt 16) HO-100901 1 Idler Shaft

2c) HO-197842 4 Heater Tube, 240 Volt 17) HO-100541 1 Crumb Tray

3) NLA 4 Retainer, Heater TubeHH 18) 2J-200538 2 Infinite Switch, 208/240 Volt

4) HO-160003 1 Conveyor Belt, T710(H) 18a) 2J-200539 2 Infinite Switch, 120 Volt

5) HO-400827 1 Back Panel, Low 19) SP-118000 1 Speed Control, 120 Volt

5a) HO-400925 1 Back Panel, High 19a) SP-118042 1 Speed control, 208/240 Volt

6) HO-401486 2 Side Panel, Low 20) 2E-200566 1 Reset/High Limit

6a) NLA 2 Side Panel, High (H) 21) 2R-200702 2 Knob, Infinite Switch

7) 2P-200662 1 Drive Chain 22) 2R-200703 1 Knob, Speed Cont'l/ Power Saver

8) 2P-Z8779 1 Drive Sprocket 23) 2E-200551 1 Power Saver Switch

9) 2P-200645 1 Driven Sprocket 24) 2R-200715 4 Leg, 4" Plastic

10) HO-100900 1 Drive Shaft 25) 2E-200376 1 Power Supply Cord, 208/240 Volt

11) HA-112261 2 Bearings, Rear 25a) 2E-200375 1 Power Supply Cord, 120 Volt

12) 2U-Z13803 1 Drive Motor, 120 Volt 26) HO-400825 1 Toast Chute

12a) 2U-200509 1 Drive Motor, 208/240 Volt 27) GA-401131 1 Extension Guard

13) 2U-200558 1 Fan Motor, 120 Volt 28) GA-400891 1 Heat Shutter (H Model Only)

29) 2P-200693 2 Idler Bushing

PART No. QTY. DESCRIPTION

Parts continued on page 12

REVISED 9/10/2008 RMS

Page 14

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

PARTS LIST /EXPLODED VIEW MODEL T714(H)

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

28.

..

3

2.

1.

1.

PAGE 12

4.

5.

27.

17.

16.

18.

26.

21.

11.

22.

19.

23.

20.

13.

14.

15.

12.

24.

11.

10.

9.

8.

7.

6.

25.

Model: T714 (H)

QTY

PART #

. DESCRIPTION

PART #

1) GC-400847 1 Top Cover 13) 2U-200560 1 Fan Motor

2) HT-197850 4 Heater Tube, 240 Volt 14) HT-100312 1 Control Box Cover

2a) HT-197846 4 Heater Tube, 220 Volt 15) 2R-200562 1 Fan Guard

2b) HT-197851 4 Heater Tube, 208 Volt 16) 2A-202904 1 Idler Shaft

3) NLA 4 Retainer, Heater Tube 17) HO-100508 1 Crumb Tray

4) HM-160004 1 Conveyor Belt 18) 2J-200538 2 Infinite Switch

5) HT-400853 1 Back Panel, Low 19) SP-118042 1 Speed Control

5a) HT-400926 1 Back Panel, High 20) 2E-200566 1 Reset Switch

6) HO-401486 1 Side Panel, Low 21) 2R-200702 1 Knob, Infinite Switch

6a) NLA 1 Side Panel, High 22) 2R-200703 2 Knob, Speed control/Power Saver

7) 2P-200663 1 Drive Chain 23) SP-115142 1 Power Saver Switch

8) 2P-200645 1 Drive Sprocket 24) 2R-Y5092 4 Leg, 4" Plastic

9) 2P-Z8779 1 Driven Sprocket 25) HJ-140027 4 Cord/Plug Set

10) 2A-202902 1 Drive Shaft 26) HT-400846 1 Toast Chute

11) HA-112261 1 Bearings 27) HM-401089 1 Extension Guard

12) 2U-200509 1 Drive Motor 28) HM-400899 1 Heat Shutter (H model only)

Parts continued on page 13

REVISED 1/31/2011 RMS

QTY

. DESCRIPTION

Page 15

PAGE 13

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

PARTS LIST /EXPLODED VIEW MODEL TX714(H)

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

1.

..

3

2.

28.

4.

5.

17.

27.

16.

18.

26.

21.

29.

22.

19.

23.

20.

13.

14.

15.

12.

24.

11.

25.

10.

9.

8.

7.

6.

Model: T714 (H)

QTY

PART #

. DESCRIPTION

PART #

1) GC-400847 1 Top Cover 13) 2U-200560 1 Fan Motor

2) HT-197850 4 Heater Tube, 240 Volt 14) HT-100312 1 Control Box Cover

2a) HT-197846 4 Heater Tube, 220 Volt 15) 2R-200562 1 Fan Guard

2b) HT-197851 4 Heater Tube, 208 Volt 16) 2A-202904 1 Idler Shaft

3) NLA 4 Retainer, Heater Tube 17) HO-100508 1 Crumb Tray

4) HM-160004 1 Conveyor Belt 18) 2J-200538 2 Infinite Switch

5) HT-400853 1 Back Panel, Low 19) SP-118042 1 Speed Control

5a) HT-400926 1 Back Panel, High 20) 2E-200566 1 Reset Switch

6) HO-401486 1 Side Panel, Low 21) 2R-200702 1 Knob, Infinite Switch

6a) NLA 1 Side Panel, High 22) 2R-200703 2 Knob, Speed control/Power Saver

7) 2P-200663 1 Drive Chain 23) SP-115142 1 Power Saver Switch

8) 2P-200645 1 Drive Sprocket 24) 2R-Y5092 4 Leg, 4" Plastic

9) 2P-Z8779 1 Driven Sprocket 25) HJ-140027 4 Cord/Plug Set

10) 2A-202902 1 Drive Shaft 26) HT-400846 1 Toast Chute

11) HA-112261 1 Bearings 27) HM-401089 1 Extension Guard

12) 2U-200509 1 Drive Motor 28) HM-400899 1 Heat Shutter (H model only)

QTY

. DESCRIPTION

Parts continued on page 14 REVISED 1/31/2011 RMS

Page 16

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

PARTS LIST /EXPLODED VIEW MODEL TX710(H), 208, 240 VOLT

1.

..

3

2.

28.

4.

PAGE 14

5.

17.

27.

16.

18.

26.

21.

29.

22.

19.

23.

20.

13.

12.

14.

15.

24.

11.

25.

10.

9.

8.

7.

6.

Model: TX710 (H) 120, 208, 240V METAL ELEMENTS

PART No.

1) HO-400821 1 Cover, Top

2) 2N-209197 4 Heater Tube, 208V TX710

2a) HO-199106 4 Heater Tube, 240V TX710 17) HO-100511 1 Crumb Tray

2) 2N-209197 4 Heater Tube, 208V TX710H 18) 2J-200538 2 Infinite Switch, 208/240 Volt

2a) 2N-209193 4 Heater Tube, 240V TX710H 19) SP-118040 1 Speed control, 208/240 Volt

3) HO-401276 4 Retainer, Heater Tube 20) 2E-200566 1 Reset/High Limit

4) HM-160004 1 Conveyor Belt 21) 2R-200702 2 Knob, Infinite Switch

5) HO-400925 1 Back Panel, High 22) 2R-200703 1 Knob, Speed Cont'l/ Pwr Saver

6) NLA 2 Side Panel, High (H) 24) 2R-Y5092 4 Leg, 4" Plastic

7) 2P-200662 1 Drive Chain 25) 2E-200376 1 Power Supply Cord, 208/240V

8) 2P-200645 1 Drive Sprocket 26) HO-400825 1 Toast Chute

9) 2P-Z8779 2 Driven Sprocket 27) GA-401131 1 Extension Guard

10) 2A-202900 1 Drive Shaft 28) GA-400891 1 Heat Shutter (H Model Only)

11) HA-112261 2 Bearings, Rear

12) 2U-200509 1 Drive Motor, 208/240 Volt

13a) 2U-200560 1 Fan Motor, 208/240 Volt

14)

HO-401462 1 Control Box Cover

QTY DESCRIPTION

PART No. QTY. DESCRIPTION

15) 2R-200562

16) 2A-202904

29) 2P-200693 2 Idler Bushing

1 Fan Guard

1 Idler Shaft

Page 17

PAGE 15

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

WIRING DIAGRAM FOR MODEL T710(H & TW) 120 VOLT

TX710(H) 120 VOLT

WIRE DIAGRAM

FOR MODEL T710(H), TX710(H) - 120 VOLT

PLUG CONFIGURATION

NEMA 5-15P

120 VOLT

REV. 9/15/98 MJC

H:\TOASTERS\T710\

120VAC/WIRDIAG\

T710SCM.DS4

REVISED 9/10/2008

Page 18

PAGE 16

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

WIRING DIAGRAM FOR MODEL T710(H & TW) 208, 240 VOLT

TX710(H) 208, 240 VOLT

T714(H) 208, 240 VOLT (3.2 KW)

BLUE

220/240

VAC

WHITE

208 VAC

BLACK

COMMON

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

PLUG CONFIGURATION

NEMA 6-20P

208/240 VOLT

REV. 9/15/98 MJC

H:\TOASTERS\T710\

208VAC\WIRDIAG\

T710SCM.DS4

REVISED 9/10/2008

PAGE 17

Page 19

WIRING DIAGRAM FOR MODEL T714(H & TW) TX714, 3.6 kW 208, 240 VOLTS, WIRED

PARELLEL

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

PLUG CONFIGURATION

NEMA 6-30P

REVISED 9/10/2008

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

PAGE 18

Page 20

WIRING DIAGRAM FOR MODEL B710(H), 120 VOLT

Top Heat

Bottom Heat

Top

H2

L2

H1

L1

Speed

Speed

Control

Power Saver

Power Saver

Switch

Switch

Heat

1

3

2

4

H2

L2

H1

Bottom

Heat

L1

M

Conveyor

Conveyor

Motor

Motor

High Limit

High Limit

Reset

Reset

Cooling

Cooling

Fan

M

L2

L1

WIRING DIAGRAM FOR MODEL S710(H), 120, 208, 240 VOLT

GROUND

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

Fan

Plug Configuration

NEMA 5-20P

120V

OPERATOR'S MANUAL

REVISED 9/10/2008

PAGE 19

Page 21

MODEL TX710 WITH OUT POWER SAVER 120, 208, 240 VOLT

OPERATOR'S MANUAL

HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

WIRING DIAGRAM FOR MODEL S714(H) 208, 240 VOLT

PLUG CONFIGURATION

NEMA 5-15P NEMA 6-20P

120 VOLT 208/240 VOLT

REVISED 9/10/2008

PAGE 20

Page 22

PLUG CONFIGURATION

NEMA 6-30P

REVISED 9/10/2008

Loading...

Loading...