Page 1

A Star Manufacturing Company

10 SUNNEN DRIVE, ST. LOUIS, MO/U.S.A. 63143

PHONE (314) 781-2777 FAX (314) 781-3636

HOLMAN CONVEYOR SANDWICH WARMER MANUAL

MODEL QT14

FOR SERVICE INFORMATION U. S. AND CANADA CALL:

TOLL FREE 1-800-807-9054

SUBJECT

TABLE OF CONTENTS PAGE

UNCRATING AND INSPECTION 1

ASSEMBLY AND INSTALLATION 1 & 2

OPERATION 3

BASIC CLEANING PROCEDURES 3 & 4

TROUGLESHOOTING 5 & 6

PREVENTATIVE MAINTENANCE & SCHEDULED CLEANING

DAILY CLEANING 7 & 8

•

• WEEKLY BELT CLEANING 9

• MONTHLY CLEANING 10 & 11

LONG TERM CLEANING 12

•

•

REPLACING HEATER TUBES 13 & 14

• REPLACING COOLING FANS 15

REPLACING BELT DRIVE MOTOR 16 & 17

•

WARRANTY PAGE 18

PARTS LIST AND HEATER TUBE LISTING 19 - 21

WIRING DIAGRAMS 22 - 24

Certain Models

Electric Cooking Equipment for the Food Service Industry

Conveyor Toasters & Ovens Cheese Melters Broilers Pretzel Bakers

2M-HG0500 Rev C 2/22/06

Page 2

Common Questions, Myths, and Misconceptions

of Holman Conveyor Ovens

Misconception: High Voltage (208v typical) is always the same.

Reality: An oven designed for 208v should operate from 208-215v. This range is

typical of local power grids and daily fluctuations. Some municipalities

operate at 220 and 240v which would require design variations. Improper

voltage can result in reduced control, performance, and reliability. Voltage

Misconception: The under-carriage of your oven is a safe haven for paper wraps and utensils.

Reality: The high-speed fan is the lungs of your oven. The oven has under-clearance

Misconception: Vent hoods can be hard-wired into the oven or to the same wall circuit.

Reality: Your conveyor oven can not support the current draw of the oven and a hood.

Misconception: My conveyor oven is maintenance-free.

Reality: Proactive or preventive maintenance (PM) is the best way to protect against a

Misconception: My heater-tubes will last forever.

Reality: Your infra-red radiant style heating elements use a quartz sheath. They are

“It’s what you learn after you know it all that counts.” -John Wooden

mismatches or daily fluctuations can be monitored for corrective action.

to maximize fan performance, cooling, safety, and reliability. Please

maximize the air-circulation to your fan and clean the debris on fan-grill

often. Note: Beware of paper and plastic wraps being drawn into fan-grill.

This practice will decrease performance and reliability as well as jeopardize

the Underwriter Laboratory’s safety certification. Please have a qualified

electrician wire your vent hood to a separate circuit.

catastrophic failure (Murphy’s Law states: components will fail at peak

sandwich time). Maintenance provisions include heater-tubes, fan, chain,

belt, incoming power, lubrication, working and aesthetic surfaces, overall

cleanliness, and ventilation. Refer to weekly, monthly, and long-term

maintenance manuals for step-by-step instruction. Owning an emergency

repair kit is also recommended.

extremely effective and efficient in the bake, as well as producing quick risetime from cold start to full bake. However, just like a light bulb, quartz is

brittle and can break from jarring or careless maintenance. Long term

degradation of quartz also occurs from air borne sugars, salts, and debris

settling on the sheath. For consistent performance replace your tubes at

prescribed intervals.

Page 3

UNCRATING AND INSPECTION

Unpack unit and components from container. Remove all visible packing material, inspect

unit for damage. If damage is discovered, file a claim immediately with the carrier that

handled the shipment.

The following should be included in the container:

• 1ea. baking oven with heaters, and conveyor belt in place.

(NOTE): Remove heating element-shipping supports.

• 1ea. stainless steel unload tray, 1ea. stainless “Bake Aid” bracket

1ea. “Bake Aid” magnet label, 2ea. crumb trays & 4ea. metal legs.

ASSEMBLY AND INSTALLATION

1. Attach legs by screwing into weld nuts.

2. Anti Skid pads are available at no charge and may be adhered to the foot section of

each leg to prevent sliding. Call 1-800-807-9054 for details.

ADJUSTABLE LEGS SCREW

INTO BOTTOM OF UNIT

CAUTION: The National Sanitation Foundation does not approve use of these pads.

3. Install unit in its operating position. The load & unload ends must be at least 6" from

any vertical combustible surfaces. Allow sufficient space for operating personnel.

Have an electrician connect input power to the unit in accordance with local electrical

codes.

WARNING:

INSTALLING/REMOVING ANY PARTS.

WARNING:

LOCAL POWER COMPANY TO DETERMINE ACTUAL VOLTAGE AT JOB SITE.

WARNING:

PROPERLY WIRED. NEVER CONNECT UNIT TO POWER WITHOUT PROPER

GROUND CONNECTIONS. IMPROPER GROUND MAY RESULT IN SEVERE INJURY

OR FATALITY.

4. Before applying input power to the unit check heating elements for breakage. Do not

apply power to the unit if a broken tube is found. If no broken tubes are found apply

input power by switching the master On/Off toggle to the ON position. Turn conveyor

belt speed control to the maximum setting and check all heater tubes and conveyor for

proper operation.

MAKE SURE ALL INPUT POWER IS OFF BEFORE

BEFORE INSTALLING UNIT, HAVE YOUR ELECTRICIAN CHECK WITH

BE ABSOLUTELY SURE THE GROUND (EARTH) CONNECTION IS

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

1

Page 4

5. Allow approximately 5 to 8 minutes for the twin-fan cooling system to come on. Check

the air intake fan area as noted below and be sure that there is a sufficient flow of air

into the control box.

Air intake areas are

located on each side

of the control panel.

6. If all heaters and conveyor system are operating properly, turn the master On/Off switch

to the OFF position and allow unit to cool. The fans will continue to circulate cool air

throughout the unit until the internal temperatures have been decreased.

7. If a problem is discovered during start up procedures, immediately turn the Master

On/Off switch to the OFF position and call the Holman Cooking Equipment Factory

Service Team at 1-800-807-9054.

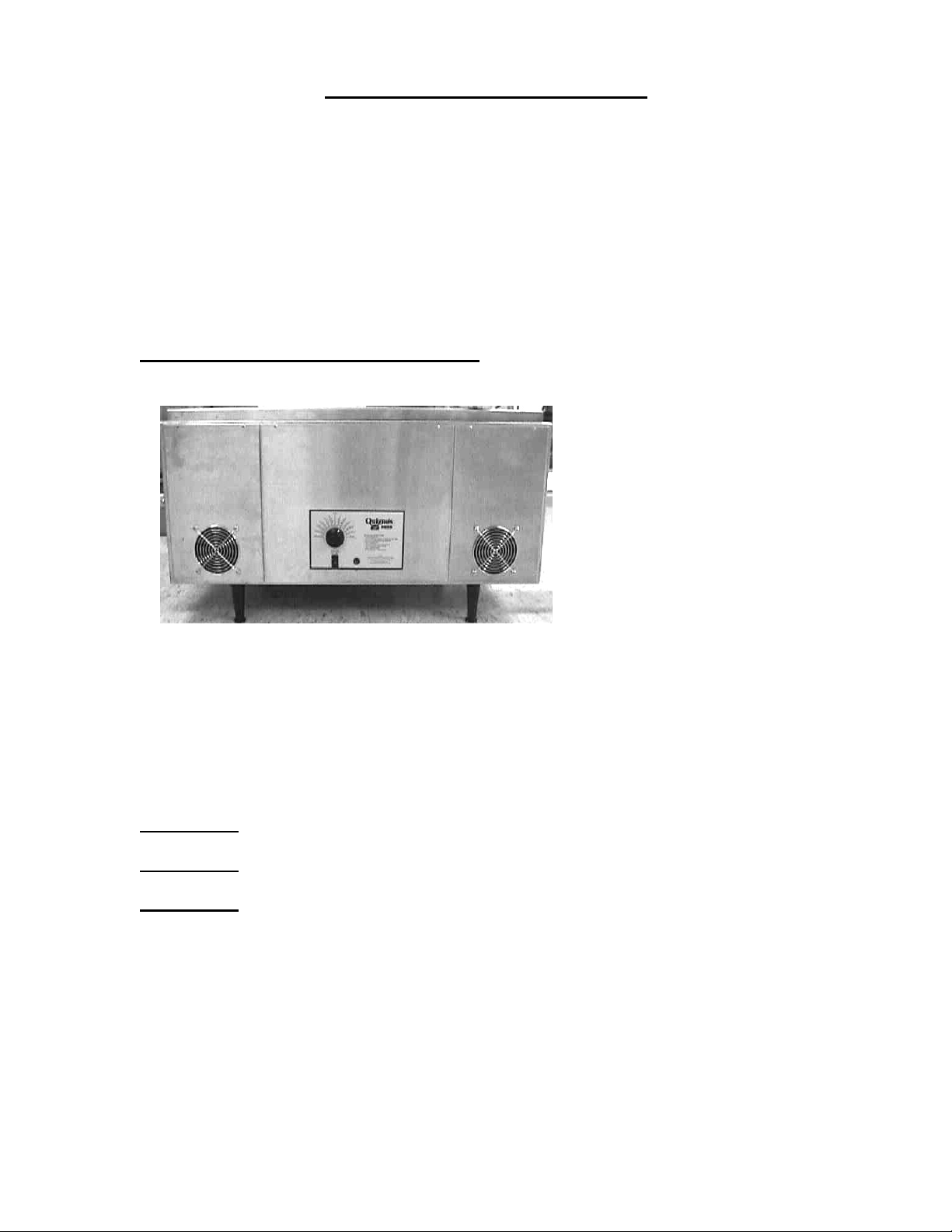

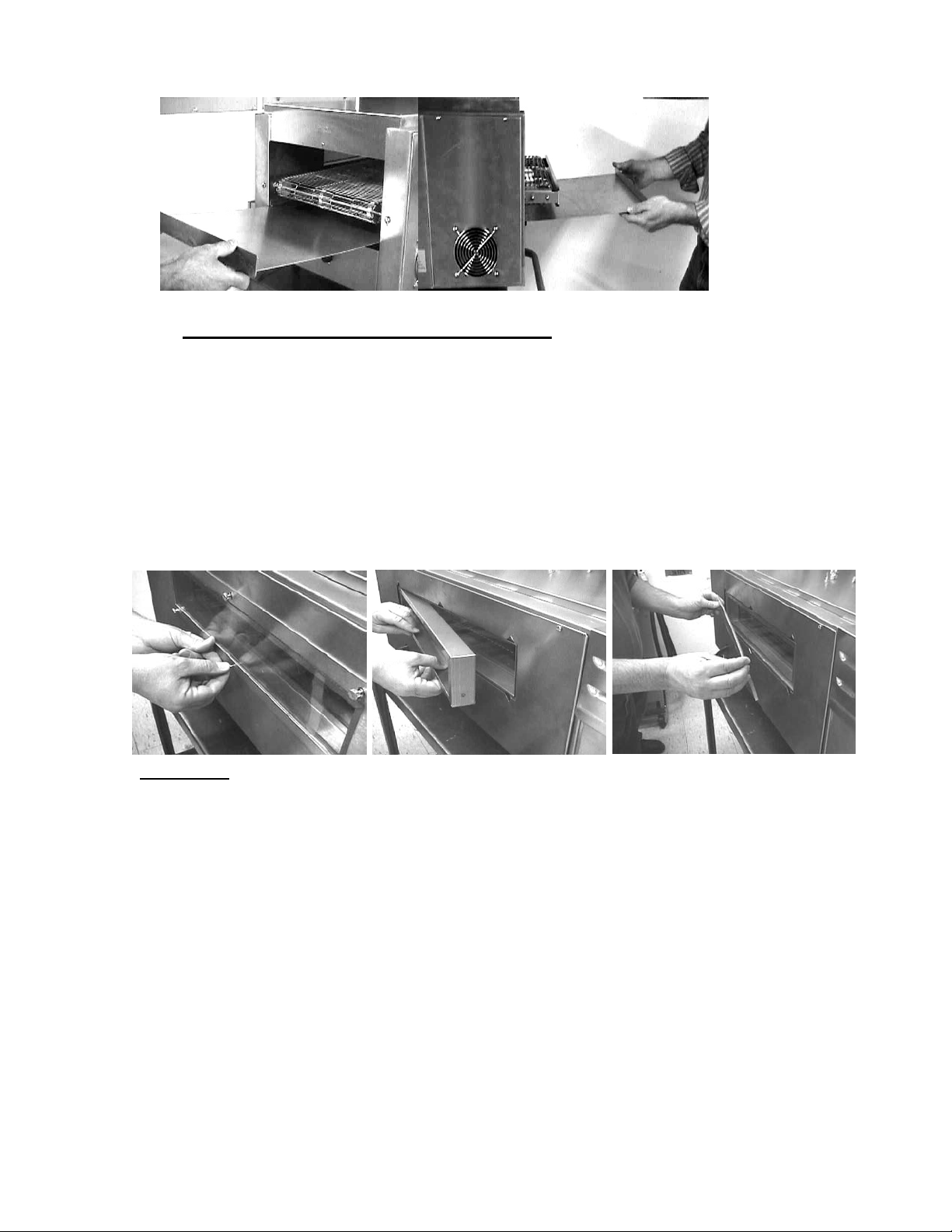

8. The unload tray has a key-hole slot on the end of the tray that will slide over the two

screw heads on the end of the oven as shown below;

9. The crumb trays slide into each end of the warmer under the conveyor. A slot is formed

by two pieces of metal on each side of the area for the tray to slide into. The crumb

trays are important by keeping the interior of the machine clean and reflecting heat

away from the controls inside the bottom of the machine back up to the sandwiches. A

layer of aluminum foil on the tray (check that it will not interfere with the conveyor) will

make the tray more reflective and make cleanup quicker.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

2

Page 5

OPERATION

1. Turn Master On/Off switch to the ON position and variable speed control to fastest

time setting. Allow 1 hour for complete machine warm up.

2. Adjust speed control to desired speed.

3. Adjust speed as required during operation to achieve a good bake.

4. When done for the day, turn Master On/Off switch to the OFF position. The conveyor

will stop and the elements will go off. The two fans should continue to run. They are

controlled by a thermostat that will allow the fans to cool the machine. Do not begin

to service or clean the machine until the fans have stopped. CAUTION: Some parts

of the machine will still be warm.

Refer to the Troubleshooting section if the machine is not performing as expected.

BASIC CLEANING PROCEDURES

Preventive maintenance for your Holman oven consists of the following recommended

cleaning procedures. To keep your oven in its top operating condition, these steps should

be performed daily or weekly as indicated. Also refer to the Preventative Maintenance

section for more complete cleaning activities that should be performed on a less frequent

basis.

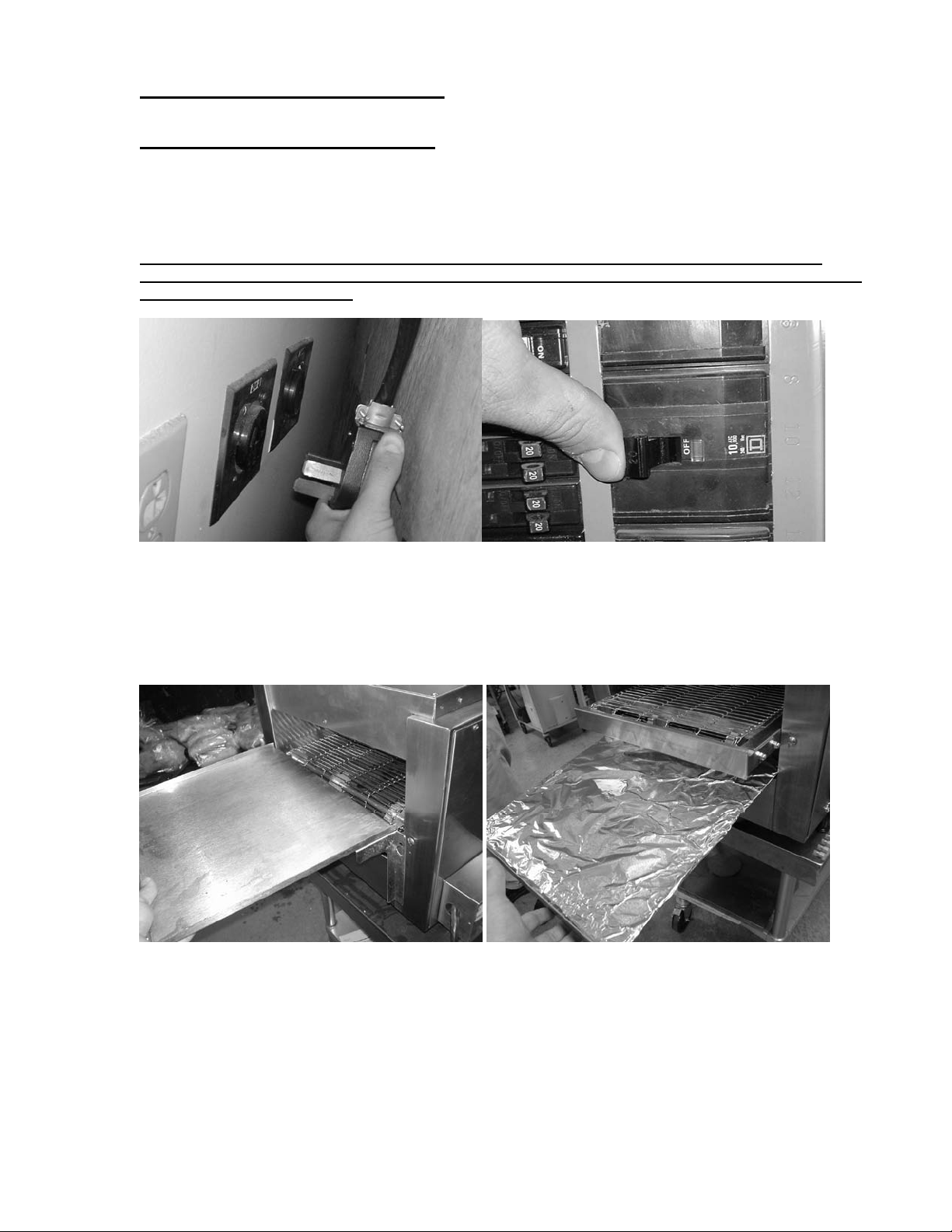

Turn power off and allow cooling fans to run until the control box is cooled off. The fans are

controlled by a thermostat in the control box.

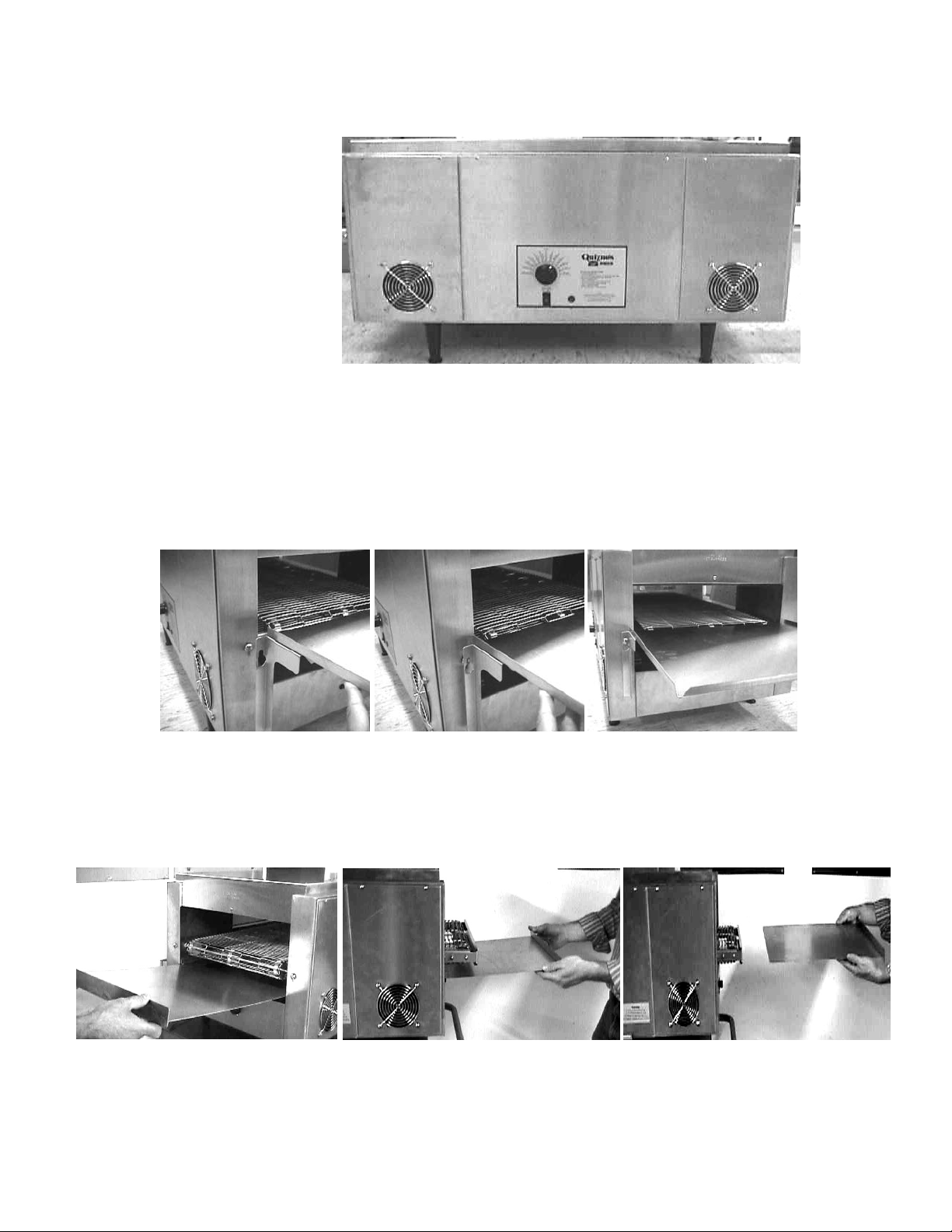

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER. BE

SURE THE SANDWICH WARMER IS COMPLETELY COOLED BEFORE PERFORMING ANY OF THE

FOLLOWING PROCEDURES.

1. Remove Unload Tray (daily) as shown and wash with hot, soapy water.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

3

Page 6

2. Remove the Crumb Trays from both sides of the oven (daily) as shown below

(DO NOT CLEAN WITH CAUSTIC CLEANERS)

.

3. For lightly soiled conveyor surfaces a damp cloth or scotch pad can be used without

removing the conveyor belt. (daily) For heavily soiled conveyor surfaces refer to the

Preventative Maintenance section for more detailed instruction to remove the

conveyor belt. The belt will need removed for more thorough cleaning.

4. Check air intake area for dust and grease. To clean, vacuum and wipe with a dry

cloth. (daily) Do not spray cleaning fluids into the air intake. This may result in

component failure.

5. Carefully remove and clean the Neo-ceram window. (daily) Remove the

thumbscrews securing the window ring. Remove the window ring, the glass retainer,

and the piece of glass. Wash with hot, soapy water.

WARNING:

THE GLASS THAT IS SUPPLIED WITH THIS OVEN IS SPECIFICALLY

DESIGNED FOR IT. DO NOT SUBSTITUTE ANY OTHER GLASS PRODUCTS IN ITS

PLACE. NEVER OPERATE THE OVEN WITHOUT THE GLASS. NEVER ATTEMPT TO

TOUCH OR REMOVE THE GLASS WHILE THE OVEN IS HOT. ALLOW THE OVEN TO

COOL FOR SEVERAL HOURS BEFORE STARTING THE CLEANING PROCEDURE.

6. Re-assemble unit and check to be sure it is operating properly. If assistance is

required contact the Star/Holman Factory Service Team at 1-800-807-9054 (24

hours/day 7days a week).

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

4

Page 7

eat

TROUBLESHOOTING GUIDE

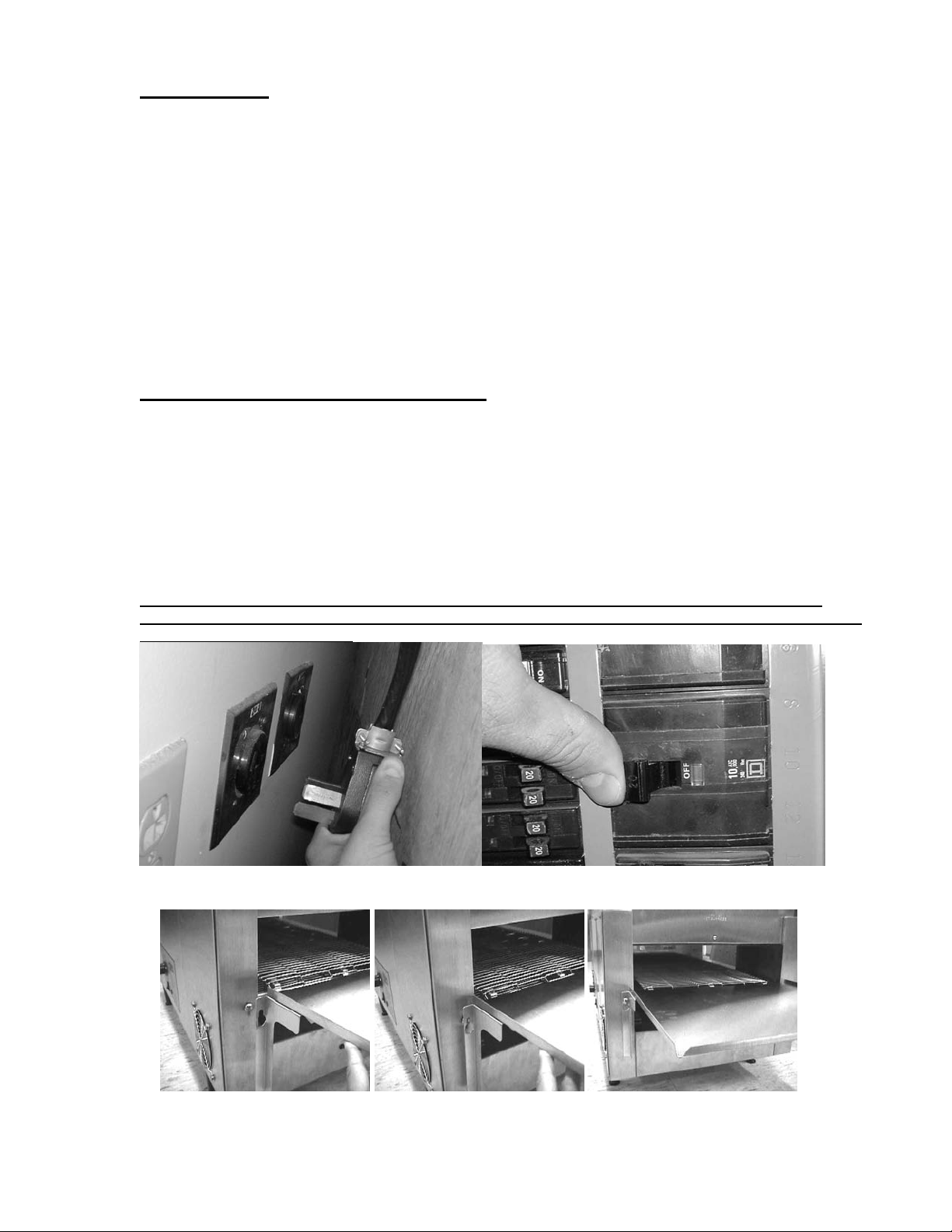

# UNIT WILL NOT HEAT, CONVEYOR BELT WILL NOT TURN.

o Be sure main circuit breaker is switched to the ON position.

o Check that the unit is connected to power and Master On/Off switch is ON.

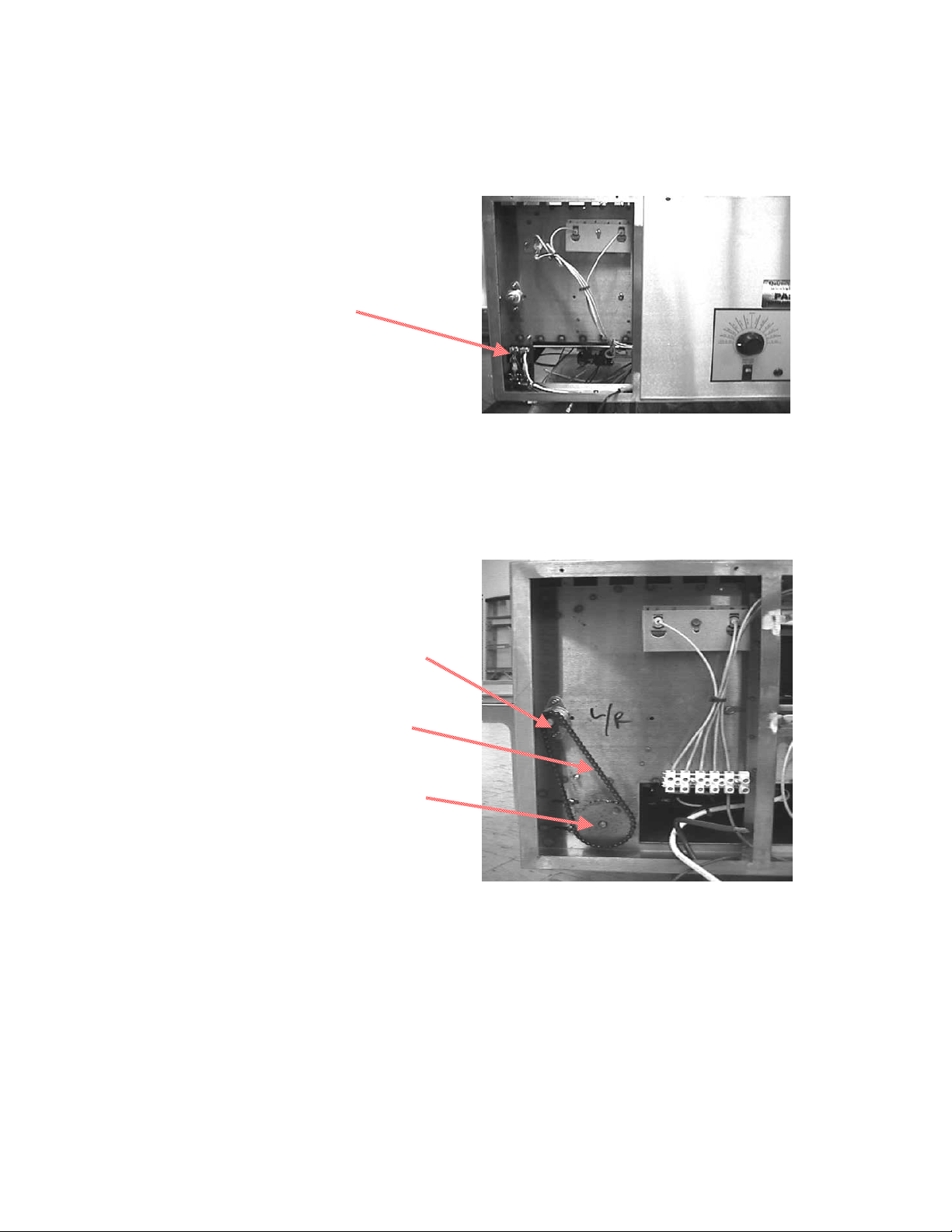

o Be sure HEAT LIMIT SWITCH is pushed in (see below).

Crumb Tray Slots

# UNIT WILL NOT HEAT, CONVEYOR TURNS.

o Check to see if the Master On/Off Switch is in the ON position.

o Press heat limit switch, located beneath the unload tray as shown above

H

Limit Switch

Your Holman Conveyor Oven is equipped with an automatically activated HEAT

LIMIT SWITCH that interrupts the heater tube connections if the air temperature in

the control box exceeds 190°F (88°C). This limit switch can be reset manually by

pushing the button in the center of the switch that is located beneath the unload

tray.

THE HEAT LIMIT SWITCH CAN BE ACTIVATED IF THERE IS NOT A PROPER

AMOUNT OF AIR FLOW BEING GENERATED BY THE COOLING FANS. IF THIS

OCCURS:

• DISCONNECT UNIT FROM POWER SOURCE.

• Make sure the air intakes in the front of the unit are free of dust, grease or other

obstructions.

• Make sure the crumb trays (heat reflectors) are in place (see photos this page

and page 2) NEVER OPERATE UNIT WITHOUT CRUMB TRAYS IN POSITION

AS THIS CAUSES OVERHEATING IN THE CONTROL BOX AND WILL SHUT

DOWN THE MACHINE.

• If the outside of the air intakes is clear and the crumb trays are in place and the

unit continues to shut down because of the Heat Limit Switch, refer to the

cleaning instructions in the more complete Preventative Maintenance section.

A heavy buildup of dust and grease from the kitchen can cover parts inside the

control box area and cause overheating.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

5

Page 8

# CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY

o DISCONNECT UNIT FROM POWER SOURCE

o Check both fuses (replace if necessary)

Twin Fuse Block

o Check for obstructions that may have caused a conveyor jam. Utensils, foil or

large pieces of food could stall the motor. If there are no visible obstructions, try

turning the belt manually. If the belt turns, remove the power supply panel and

check for loose sprockets or chain. Realign any loose sprockets and re-tighten

the setscrews making sure the setscrews seat on the flats of the motor and drive

shafts.

Driven Sprocket

Drive Chain

Driver Sprocket

o If further assistance is required, contact the Star/Holman Factory Service

Team at 1-800-807-9054 (24 hours/day 7days a week).

# COOLING FANS DO NOT START (fans should start after the machine is warmed up)

o DISCONNECT UNIT FROM POWER SOURCE

o Remove panels with fan motors and check fan blades for obstructions/breakage.

o Check motor cords for secure connection

o Call the Star/Holman Factory Service Team, as the fan switches and/or fan

motor(s) may need to be replaced.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

6

Page 9

PREVENTIVE MAINTENANCE

DAILY CLEANING PROCEDURES

TO KEEP YOUR HOLMAN MODEL QT14 CONVEYOR SANDWICH WARMER AT PEAK

OPERATING EFFICIENCY, THE FOLLOWING INSTRUCTIONS ARE RECOMMENDED:

Turn power off and allow cooling fans to run until the control box is cooled off. The fans are

controlled by a thermostat in the control box.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER. BE

SURE THE SANDWICH WARMER IS COMPLETELY COOLED BEFORE PERFORMING ANY OF THE

FOLLOWING PROCEDURES.

1. Remove the unload tray as shown below.

a. For lightly soiled tray, clean with a damp cloth.

b. For heavily soiled tray, use an abrasive pad and mild cleaner.

2. Remove crumb trays from beneath each end of conveyor belt and discard soiled aluminum foil.

If cleaning is necessary, use a wet cloth and mild detergent cleaner. Do not use a caustic

cleaner to clean the crumb tray.

3. Cover crumb tray with clean aluminum foil and return crumb tray to oven.

(NOTE: DO NOT RUN SANDWICH WARMER WITHOUT CRUMB TRAYS INSTALLED)

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

7

Page 10

4. Wipe exterior of unit with a damp cloth.

5. Wipe fan grills/air intakes (located on side of the unit) to remove any dust build up using a damp

cloth. Reassemble unit making sure crumb trays are properly installed. The crumb tray should

slide into the slot on each side of the area under the belt.

6. Clean the viewing window by removing the six thumbscrews on the rear of the sandwich

warmer. Remove the window trim ring. Then remove the window spacer. Then carefully remove

the Neo-Ceram glass.

7. Clean the Neo-Ceram glass using the mild soap. DO NOT use any abrasive cleaner or scrub

pad. A scratched glass is more easily broken and will get dirtier faster.

8. Re-assemble the viewing window by carefully placing the Neo-Ceram glass back in. Place the

window spacer with the flanged side against the glass in. Line up the six holes o f the window

trim ring with six holes on the side of the warmer and re-install the thumbscrews.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

8

Page 11

WEEKLY CONVEYOR BELT CLEANING PROCEDURES

TO KEEP YOUR HOLMAN MODEL QT14 CONVEYOR SANDWICH WARMER AT PEAK

OPERATING EFFICIENCY, THE FOLLOWING INSTRUCTIONS ARE RECOMMENDED:

Turn power off and allow cooling fans to run until the control box is cooled off. The fans are

controlled by a thermostat in the control box.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER. BE

SURE THE SANDWICH WARMER IS COMPLETELY COOLED BEFORE PERFORMING ANY OF THE

FOLLOWING PROCEDURES.

1. Remove the unload tray as shown in daily cleaning instructions earlier.

a. For lightly soiled tray, clean with a damp cloth.

b. For heavily soiled tray, use an abrasive pad and mild cleaner.

2. Using a wire grill brush or dry abrasive pad, clean the exposed surface of Conveyor Belt by

passing the brush or pad, back and forth across the surface of the Conveyor Belt.

3. When a section of Conveyor Belt is clean, remove wire brush or abrasive pad from conveyor

surface. Reconnect power or turn power back on.

Allow the Conveyor Belt to advance to expose another section of belt surface. Switch the

ON/OFF Switch to the OFF position. Disconnect or turn power off at wall breaker

4. Repeat steps 2 and 3 until the entire surface of the Conveyor Belt has been cleaned.

5. Remove Crumb Trays from beneath Conveyor Belt and discard the aluminum foil. If cleaning is

necessary, use a wet cloth and mild detergent cleaner. Do not use a caustic cleaner to clean

the crumb tray.

6. Cover Crumb Trays with clean aluminum foil (shiny side facing up) and return Crumb Trays to

Sandwich Warmer. The crumb tray should slide into the slot on each side of the area under the

belt.

Switch the ON/OFF switch to the ON position.

.

(NOTE: DO NOT RUN WARMER WITHOUT CRUMB TRAYS INSTALLED)

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

9

Page 12

MONTHLY CLEANING PROCEDURES

Turn power off and allow cooling fans to run until the control box is cooled off. The fans are

controlled by a thermostat in the control box.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER. BE

SURE THE SANDWICH WARMER IS COMPLETELY COOLED BEFORE PERFORMING ANY OF THE

FOLLOWING PROCEDURES.

1. Working from the power supply side of the oven, locate the electrical box side panel. Remove

two screws holding panel in place and remove panel. Drive chain is now exposed.

2. Check drive chain tension.

a. When properly adjusted, chain will have about 1/8” play but will not sag.

b. To adjust drive chain tension remove power supply side panel and locate drive motor

mounting screws (located behind drive motor sprocket). Loosen screws holding drive

motor in place and slide drive motor forward or backward to adjust chain tension. With

proper chain tension, retighten motor screws.

c. Lubricate drive chain and sprocket teeth

with a high temp synthetic or graphite

based lubricant.

NOTE: WD-40 and similar lubricants are not

recommended. Using an extreme pressure,

synthetic chain lubricant with a temperature

range up to 400°F. Apply liberally onto

chain and sprockets. This grease is

available as part no. 1P-Z8914.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

10

Page 13

3. Clean air intake on the side of Sandwich Warmer by vacuuming any dust and debris built up on fan

grill.

4. Return unit to counter and remove screw holding power supply side panel in place. Carefully lift panel

up and out. Two ground straps hold panel to oven chassis. DO NOT REMOVE GROUND STRAPS

OR DISCONNECT POWER SUPPLY CORD. Vacuum any dust and debris from inside of unit

(repeat for opposite side).

5. Replace all panels when done. CHECK THAT ALL WIRES DO NOT GET PINCHED AS THE

PANELS ARE REPLACED. ALSO CHECK ANY WIRES AROUND THE MOTOR TO MAKE SURE

THEY DO NOT GET PUSHED INTO THE SPROCKETS. Mounting screws for panels should be

started by hand, and then tightened with a screwdriver.

6. For exterior portions of unit that are heavily soiled, an abrasive pad may be used for cleaning. Be

sure to pass the pad in the direction of the grain in the metal to maintain the surface’s finish. Lightly

soiled surfaces may be cleaned with a damp cloth and mild cleaner.

7. Reconnect unit to power supply and test for proper operation.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

11

Page 14

LONG TERM CLEANING PROCEDURES (every 6 months)

Turn power off and allow cooling fans to run until the control box is cooled off. The fans are controlled by a

thermostat in the control box.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER. BE SURE THE

SANDWICH WARMER IS COMPLETELY COOLED BEFORE PERFORMING ANY OF THE FOLLOWING

PROCEDURES.

1. With the power off, allow the unit to cool completely. Place Sandwich Warmer on non-extension end.

Remove screws holding control box covers in place and remove.

NOTE:

TO PREVENT DAMAGE TO CONTROLS

OR ELEMENTS, DO NOT SET THE

MACHINE ON SIDE PANELS.

TO PREVENT DAMAGE TO

ACCESSORIES, REMOVE CRUMB

TRAYS AND UNLOAD TRAY BEFORE

LIFTING OVEN TO UPRIGHT POSITION

2. Remove screws holding control box covers in place and remove.

3. Using a vacuum, clean the inside of control box. Wipe any buildup that cannot be vacuumed with a dry towel.

4. Replace control box covers and fasten with screws. Put the machine back on its feet.

5. Remove side panels and vacuum compartments as performed under monthly cleaning procedures.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

12

Page 15

MAINTENANCE PROCEDURES

REPLACING HEATER TUBES

FOR BEST TOASTING PERFORMANCE, THIS PROCEDURE SHOULD BE DONE EVERY SIX MONTHS

Turn power off and allow cooling fans to run until the control box is cooled off. The fans are controlled by a thermostat in

the control box.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER.

NOTE: PERFORM THIS MAINTENANCE ONLY WHEN THE

CONVEYOR SANDWICH WARMER IS COMPLETELY COOL.

1. Position unit for access to front and rear panels. Also remove the viewing window per instruction in daily cleaning.

2. Remove screws holding front and rear panels. Lift panels up and out to remove.

3. Each heater tube has its own connection to a terminal block at the front and back of the sandwich warmer.

NOTE: MARK WIRE LOCATIONS IN TERMINAL BLOCKS BEFORE DISCONNECTING ANY WIRES. REPLACE

ONLY ONE

HEATER TUBE AT A TIME TO AVOID INCORRECT REWIRING.

4. The heater tubes are held in place by key slot heater tube retainers that are accessible on the control side of the

machine.

5. Using a screwdriver, loosen the screws holding the retainer in place.

6. Slide the retainer to line up the round part of the keyhole with the tube. Re-tighten one or two of the screws to hold the

retainer up.

7. Select the first heater tube to be replaced and remove the wires from terminal block connections (both sides).

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

13

Page 16

8. Gently slide one heater tube out of hole in warmer wall.

9. Select new heater tube to be installed. To ease installation, a short piece of tubing such as an automotive brake line

or sipping straws may be used. Insert heater tube wire into one end of tubing. Slide the tubing over the wire and use

the tube to guide the wire and heater tube through the body of the machine.

NOTE: Top and bottom tubes are of

different wattage ratings. Make sure that

the correct tubes are being replaced or

toasting will be dramatically affected.

10. When the heater tube is installed correctly the ceramic end of the heater tube will stick out of the tube

retainers. (Fig.7)

11. Reconnect wires to terminal block and check connections.

12. Tug lightly on wire to ensure a good connection.

13. Repeat above steps for each heater tube.

14. Loosen the screw(s) holding the retainer secure and slide the retainer back to secure the heater

tubes.

15. Secure all loose heater tube wires with high temperature wire ties.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

14

Page 17

REPLACING FAN MOTORS

Turn power off and allow cooling fans to run until the control box is cooled off.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER.

NOTE: PERFORM THIS MAINTENANCE ONLY WHEN THE

CONVEYOR SANDWICH WARMER IS COMPLETELY COOL.

1. Remove the panel with the fan that needs replaced.

2. Unplug the power supply cord. Remove any wire ties holding the cord to the fan. Disconnect the

ground wire if present.

3. Remove the four screws attaching the fan and grill to the panel.

4. Place the new fan on the panel in the same orientation and re-attach using the grill and screws.

5. Reconnect the power cord to the fan and secure it to the fan with wire ties in the original location.

6. Replace the air intake panel and turn on the machine.

7. Check that both fans come on after the oven has heated up.

FAN MOTOR

SECURED BY 4 SCREWS

AIR INTAKE COVER

AIR INTAKE

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

15

Page 18

REPLACING BELT DRIVE MOTOR

Turn power off and allow cooling fans to run until the control box is cooled off.

DISCONNECT UNIT FROM POWER SUPPLY OR TURN POWER OFF AT WALL BREAKER.

NOTE: PERFORM THIS MAINTENANCE ONLY WHEN THE

CONVEYOR SANDWICH WARMER IS COMPLETELY COOL.

1. Remove the unload tray and crumb trays.

2. Lift the machine to stand on the unload end. The machine can then be rotated again to rest it on the

top. This will give the most stable access to the bottom control box area.

DRIVEN SPROCKET

DRIVE CHAIN

DRIVE SPROCKET

3. Remove the panel with the power input box and bottom control box cover.

4. Loosen the screws holding the motor in place. Slide the motor to loosen the chain. Remove the

chain. Remove the sprocket on the motor by loosening the setscrew and sliding the sprocket off.

5. Disconnect the drive motor leads to the internal wiring. The motor can be used in 208 or 240 volt

ovens. Note how the old motor is wired for replacement. For reference, use the black and white

wires for 208 volt ovens and the black and blue wires for 240 volt ovens. The unused wire should be

taped on the end and bundled with the existing wires so it will not get tangled in any moving parts.

6. Remove the screws holding the motor in place and remove the drive motor.

Install the new motor in place and loosely re-attach using the screws removed earlier.

7.

Replace the sprocket onto the motor shaft and replace the chain onto the sprockets.

8.

Slide the motor until the drive chain has about 1/8” slack when lightly pushed at the ce nter of the

9.

upper section. Tighten the drive motor screws. Align driver and driven sprockets and tighten the

setscrews onto the flat areas on the motor and drive shafts.

10.

Rewire the new motor as noted in the disconnect instructions above.

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

16

Page 19

Note: During factory assembly, a 1/8” side-to-side

play is adjusted into the driveshaft to allow for

chassis expansion.

1. Unit must be cool

2. Do not adjust the sprocket on the driveshaft.

3. Insert a 1/16” spacer (drill bit etc) between the

driveshaft sprocket and the washer that is

outside the bearing.

4. Measure the distance “A” while holding the

sprocket against the spacer.

5. Adjust the sprocket on the drive motor so that

dimension “B” is equal to “A”

1

+

/

/16”.

-

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

17

Page 20

Visit our Website at:

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty

status of the unit.

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is

limited to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited

to the repair of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below)

should be taken to the closest Star service agency, transportation prepaid.

www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

LIMITED EQUIPMENT WARRANTY

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar series six (6) ounce popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is five (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teflon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teflon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is

chargeable to the customer.

SERVICES NOT COVERED BY WARRANTY

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

* The Model 510FD Fryer.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPDE, & SPDE Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16 . Replacement of bulbs

17. Replacement of fuses

18 . Repair of damage created during transit, delivery, &

installation OR created by acts of God

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

* Heat Lamps

* Pumps

Part# 2M-4497-2 10/05 RB

Page 21

Page 22

20

35

36

26

25

49

24

44

18

14

47

7

37

19

15

S

L

O

O

S

C

G

T

I

IN

T

N

S

T

U

D

E

R

G

S

L

A

I

N

I

T

D

E

T

N

N

T

S

I

U

A

E

V

T

T

S

E

A

S

S

E

R

E

D

H

T

S

,

E

E

A

O

S

R

I

R

R

N

E

S

E

P

Z

H

I

E

P

C

U

D

O

I

N

:

I

Q

S

W

G

O

N

R

D

S

E

T

O

N

U

N

B

T

FA

A

O

D

IO

S

H

E

E

O

T

T

:

E

C

N

S

AK

G

P

F

U

O

S

S

N

F

B

R

IN

E

O

O

T

N

E

N

R

A

S

I

E

K

O

R

R

S

N

P

A

I

:

Y

E

E

E

U

O

E

B

V

E

W

W

B

S

G

V

E

I

O

O

O

O

N

N

I

P

H

P

T

L

G

VE

O

T

C

N

C

R

A

I

C

N

A

R

N

E

R

R

R

R

T

O

S

E

I

T

U

A

U

O

U

B

P

E

R

D

T

T

T

S

O

O

P

4

34

31

32

33

29

46

22

23

2

51

6

30

27

28

STAR MANUFACTURING INTERNATIONAL INC.

SK2093 11-02-04

50

48

17

10

3

11

39

8

43

42

40

45

5

1

9

38

16

21

12

41

TYPICAL QT14 EXPLODED PARTS VIEW

13

REFER TO THE PARTS LIST SPECIFIC TO YOUR MODEL FOR MORE DETAIL INFORMATION.

Page 23

PARTS LIST February 22, 2006, Rev C

HOLMAN CONVEYOR SANDWICH WARMER

QT14

MODEL

Number

Key

Number

1 GE-100715 1 BELT SUPPORT

2 GE-100991 1 TOP COVER

3 GE-101390 1 WINDOW SPACER

4 GE-402340 2 PANEL - FAN MOUNT

5 GE-402356 1 PANEL - PLAIN SIDE

6 GE-402705 1 PANEL - POWER INPUT

7 GE-402609 1 PANEL - CONTROL SIDE

8 GE-402689 1 PANEL - UPPER BACK

9 GE-101028 1 PANEL - LOWER BACK

10 GE-402709 1 ELECTRICAL BOX (POWER INPUT)

11 GE-402710 1 ELECTRICAL BOX COVER

12 GE-402729 1 BAKE AID BRACKET

13 2M-200816 1 BAKE AID MAGNET

14 GE-402651 2 HEATER TUBE RETAINER - SMALL

15 GE-402359 1 HEATER TUBE RETAINER - LARGE

16 GE-402631 1 WINDOW RETAINER - OUTSIDE

17 GE-402344 2 CONTROL BOX COVER

18 GE101029 2 CRUMB TRAY

19 GE-402654 1 CRUMB TRAY - LOWER

20 GE-100944 1 UNLOAD TRAY

21 GE-402610 1 CONVEYOR END GUARD

22 2P-115362 1 SPROCKET DRIVEN - 25B11x3/8

23 2P-200650 1 SPROCKET DRIVEN - 25B24x5/16

24 2P-150000 1 CHAIN, DRIVE - #25x16”

25 2J-200427 1 PILOT LIGHT - RED

26 2E-200552 1 SWITCH, MAIN ON/OFF

27 2E-200566 1 SWITCH, OVERTEMP (RESET)

28 2E-200574 1 SWITCH, FAN (COOLDOWN)

29 2E-200596 2 FUSE - 15A TYPE G

30 2E-200597 1 FUSEHOLDER - 2 POSITION, TYPE G

31 2E-Z8966 1 CONTRACTOR/RELAY - 1 PHASE OVENS

31b 2E-200573 1 CONTRACTOR/RELAY - 3 PHASE OVENS QT14R-V12

32 2U-200577 2 COOLING FAN - 240V HIGH OUTPUT

33a 2U-200504 1 CONVEYOR MOTOR LEFT TO RIGHT QT14

33b 2U-200509 1 CONVEYOR MOTOR RIGHT TO LEFT QT14R

34 2R-200721 1 FAN BLADE - CONVEYOR MOTOR

35 2R-200562 1 FAN GUARD - COOLING FAN

36 2R-200761 1 KNOB, SPEED CONTROL

37 GE-118067 1 SPEED CONTROL POTENETIOMETER

Part

Number

Per

Unit

Description and Model Designation

IMPORTANT: WHEN ORDERING, INCLUDE MODEL AND SERIAL NUMBER

Some items are included for illustrative purposes only and in certain instances may not be available.

Page 24

PARTS LIST February 22, 2006, Rev C

HOLMAN CONVEYOR SANDWICH WARMER

QT14

MODEL

Number

Key

Number

38 2Q-200588 1 WINDOW - NEO SARAMA

39 2A-Z0314 4 LEG - 4”

40 GE-160031 1 CONVEYOR BELT W/ 3 LINKS - 82.5” LONG

41 2B-200620 3 CONVEYOR BELT SINGLE SPACE CLIP

42 2P-200785 2 BEARING, SPRING LOADED

43 2P-200766 2 SPRING, BEARING

44 GE-101254 1 DRIVE SHAFT ASSY (W/SPROCKETS)

45 GE-101255 1 IDLER SHAFT ASSY (W/SPROCKETS)

46 2A-101257 1 RETURN SHAFT ASSY (W/SPROCKETS)

47 GB-112262 4 BEARING ASSY. 3/8” FLANGED

48 2A-200672 3 SHAFT COLLAR - 3/8”

49 2M-201822 1 LABEL, MAIN CONTROL

50 2E-200387 2 FAN CORD

51 2E-200554 6 TERMINAL BLOCK - 12 TRIMMABLE, “WHITE”

NI 2E-200487 1 TERMINAL BLOCK - 6 POSITION, “BLACK”

NI SP-115402 1 TERMIINAL BLOCK - MAIN POWER, “BLACK”

NI 2M-HG0300 1 VIDEO MAINTENANCE

NI 1P-Z8914 1 EXTREME PRESSURE MULTIPURPOSE SYNTHETIC GREASE

(80°F TO 400°F) , TUBE 8 oz.

GE-198077 6 675W 208V BOTTOM

GE-198078 10 375W 208V TOP

GE-198080 6 675W 240V BOTTOM

GE-198081 10 375W 240V TOP

GE-198082 6 700W 220V BOTTOM

GE-198083 10 375W 220V TOP

GE-198087 9 417W 208V TOP 3PHASE

GE-198077 6 675W 208V BOTTOM

Part

Number

Per

Unit

HEATER TUBE LISTING

Description and Model Designation

IMPORTANT: WHEN ORDERING, INCLUDE MODEL AND SERIAL NUMBER

Some items are included for illustrative purposes only and in certain instances may not be available.

Page 25

WIRING DIAGRAM #020514A

QT14 W/ POT SPEED CONTROL

THREE PHASE DELTA SOURCE

RED

WHT

BLK

RED

RED

BLK

WHT

WHT

RED

BLK

WHT

RED

WHT

BLK

BLKBLK

WHT

BLK

RED

YEL

BLK

BLU

BLK

YEL

ORN

WHT

BLK

DETAIL OF

RESISTOR/DIODE

TERMINAL BLOCK

DIODE

WHT

YEL

BLK

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

250 OHM POT

(PART OF GE-135702)

47 OHM

20

Page 26

WIRIN G DI AG RA M #020513A

QT14 W/ P OT SP EED CONTROL

SI N G LE PHASE - 208/220/240

WHT

DIODE

47 OHM

DETAIL OF

RESISTOR/DIODE

TERMINAL BLOCK

MOLDED

FAN CORDS

ORN

WHT

WHT

YEL

YEL

BLU

BLK

PUR

BLU

WHT

BLK

ORN

ORN

WHT

BLU

PUR

YEL

BLK

WHT

BLK

WHT

BLK

BLK

WHT

BLK

WHT

WHT

BLK

250 OHM PO T

(PART OF 135702)

BLK

RED

BLK

IF FURTHER ASSISTANCE IS REQUIRED:

CONTACT STAR/HOLMAN FACTORY SERVICE TEAM AT 1-800-807-9054

YEL

21

Page 27

WINDOW SIDE

TOP HEATERS

BOTTOM HEATERS

RED

BLK

YEL

N

L1

L2

L3

Gnd

WHT

BLU

RED

WHT

BLK

GRN

WHT

BLK

BLK

BLU

BLU

RED

DRIVE MOTOR:

USE BLK/WHT FOR 208V

USE BLK/BLU FOR 240V

FUSE

WHT

BLK

YEL

FUSE

BLK

BLK

BLK

WHT

FAN

SWITCH

PILOT LIGHT

WHT

WHT

ORG

250 OHM POT

(PART OF GE-135702)

BLU

RED

BLU

BLU

BLU

WHT

RESET SWITCH

BLK

YEL

CONTROL SIDE

ON/OFF

THIS DRAWING CONTAINS INFORMATION

CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE

OF ITS CONTENTS IS PERMITTED.

MODEL:

QT14 380/220/60 3 phase, 15 TUBE - SERIES

BLK

¸

STAR MANUFACTURING INTERNATIONAL INC.

020525 Rev -

2/06/2006

Page 28

STAR MANUFACTURING

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...