Page 1

10 SUNNEN DRIVE P.O. BOX 430129 ST. LOUIS, MISSOURI 63143

(314) 781-2777 y (800) 807-9054 y FAX (800) 264-6666

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

FOR SERVICE INFORMATION

U.S. AND CANADA CALL: 1-800-807-9054

24 HOURS/DAY 7 DAYS/WEEK

TABLE OF CONTENTS

UNCRATING AND INSPECTION PAGE 2

ASSEMBLY AND INSTALLATION PAGE 2

ROTARY POWER SAVER PAGE 3

SPRING LOADED FRONT BEARING PAGE 4

COOKING PROCEDURES PAGE 5

CLEANING PROCEDURES PAGE 5

TROUBLESHOOTING GUIDE PAGE 6, 7

MAINTENANCE PROCEDURES PAGE 7, 8

PARTS LIST PAGE 9

WIRING DIAGRAM PAGE 10

Conveyor Toasters & Ovens Cheese Melters Broilers Pretzel Bakers

2M-HG0652 Rev. A 7/22/04

Electric Cooking Equipment for the Food Service Industry

Page 2

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

PAGE 2

UNCRATING AND INSPECTION

Unpack the unit and components from the shipping container.

Remove all visible packing material and those from inside the cooking chamber.

If damage is discovered, file a claim immediately with the carrier that handled the shipment.

ASSEMBLY AND INSTALLATION

The QCS3-950HB was shipped fully assembled and ready to plug into a standard outlet specified for its

voltage and amp draw. Removal or replacement of the power cord and plug will

VOID the warranty. For

assistance contact the Holman Cooking Equipment Factory Service Team at 1-800-807-9054. Check Page

8 for the wiring diagram. Consult with a licensed electrician prior to installation.

FIGURE 1 – PLUG CONFIGURATION

NEMA 6-20 PLUG

208/240V / 20 AMPS

G

W

CAUTION

Allow enough space around the toaster for adequate ventilation.

Do not operate the unit without the crumb tray properly positioned. Overheating and poor toasting may occur.

Read all the labels on the outside of the unit and follow their instructions.

WARNING

DISCONNECT THE UNIT FROM THE POWER SOURCE BEFORE REMOVING OR INSTALLING ANY PARTS.

WARNING

Before installing unit(s), check with your local power company or your electrician to determine the actual

voltage coming into the equipment. For units rated 208 or 240 volts; never plug a 208-volt unit into 240 volts or

a 240-volt unit into 208 volts.

WARNING

Be absolutely sure that the ground connection for the receptacle is properly wired. Do not connect equipment

to power without proper ground connections. Improper grounding may result in personal injury or fatality.

Page 3

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

PAGE 3

OPERATION

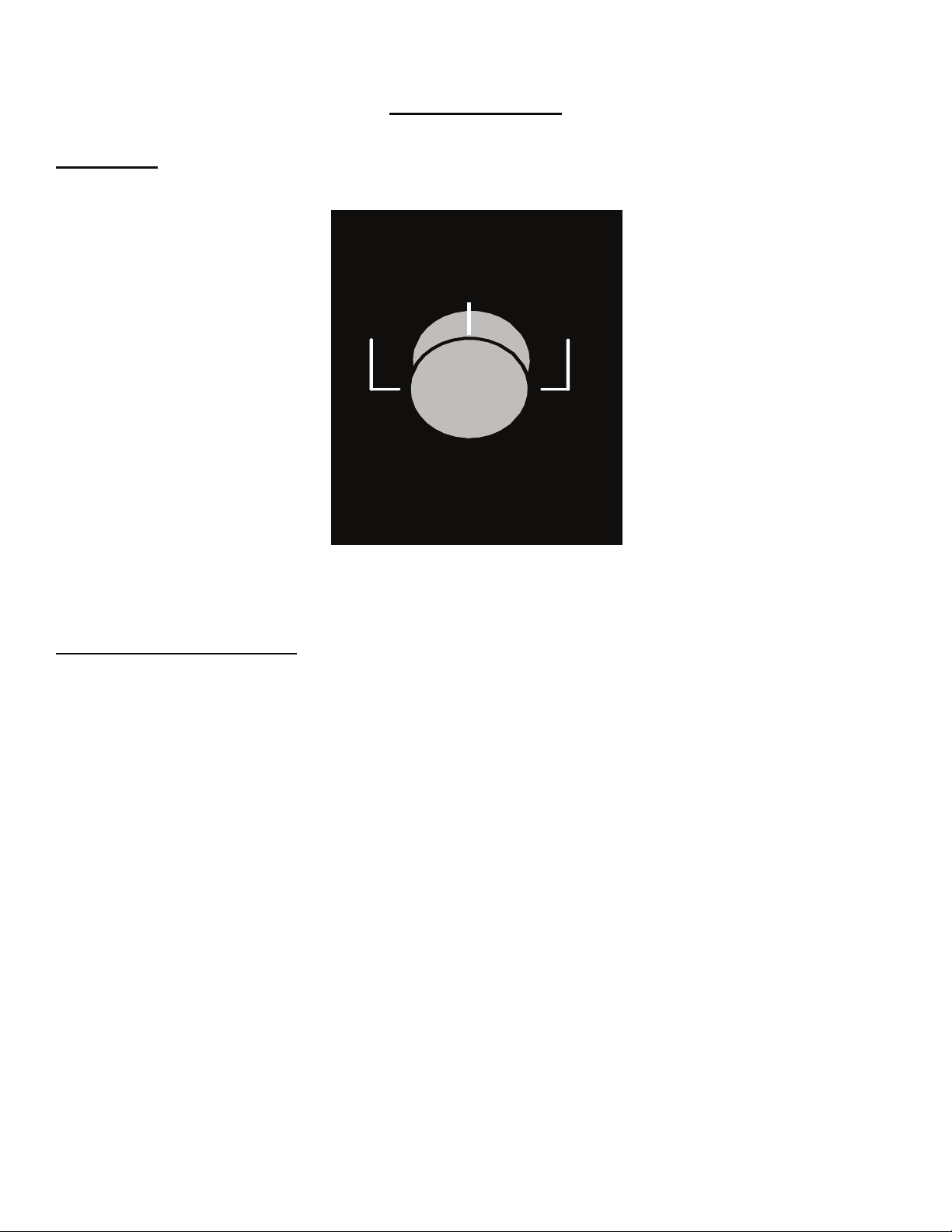

Your BLIMPIE toaster is equipped with a Rotary Power Saver Switch, details are as follow:

STANDBY FULL HEAT

POWER/STANDBY

OFF

OFF

PATENTED

ROTARY POWER SAVER SWITCH

USING YOUR POWER SAVER

For toasters equipped with a Rotary Power Saver Switch, turn clockwise or counterclockwise to get in the

following positions:

FULL POWER

When in this position your equipment is at full power and ready to use.

OFF ROTARY

STANDBY

Two off positions are provided so that a single rotation to either direction will shut the unit off.

The standby position reduces the power consumption by 75%. Using this position during the

quiet times will save electricity, and keep the toaster warm. When needed, turn the switch to

FULL POWER. Recovery time is about 30 seconds.

Page 4

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

PAGE 4

SPRING LOADED FRONT BEARING ASSEMBLY

Your BLIMPIE Conveyor Toaster is equipped with a spring-loaded front bearing assembly as shown below in

(Figure 2). The spring-loaded bearing assembly keeps the conveyor belt at a constant tension as the unit heats

up and cools down. The conveyor belt is set to the proper tension when the white Teflon bushing is flush with

or 1/8’’ inside of the extension as shown in (Figure 3).

FIGURE 2

FIGURE 3

Page 5

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

PAGE 5

COOKING PROCEDURES

A. BREAD TOASTING

The QCS3-950HB comes with a swinging heat shutter at the product entrance. This shutter will move

out of the way as product passes beneath it.

1) Turn the power saver to FULL power and the conveyor speed control to 50.

2) Allow warm up time of 5 to 10 minutes.

3) Test with a sample roll or other intended product:

♦ If toasting is too light, turn conveyor speed control counterclockwise to a slower speed.

♦ If toasting is too dark, turn conveyor speed control clockwise to a faster speed.

CLEANING PROCEDURES

Preventive maintenance for your BLIMPIE toaster consists of the following recommended cleaning procedures.

To keep your toaster in its top operating condition, these steps should be performed daily.

A. Clean air intake on bottom of unit.

B. For lightly soiled conveyor belts, turn conveyor speed control to fastest setting (100) and wipe with a

damp cloth (daily) For heavily soiled conveyors, turn conveyor speed control to fastest setting and wipe

with a light abrasive pad. (as needed)

C. Turn main power saver switch to the OFF position. DISCONNECT UNIT FROM POWER SOURCE.

D. After the unit cools, remove interior crumb tray and clean. Slide crumb tray back into position.

E. Wipe exterior surface of unit.

CAUTION

DO NOT OPERATE UNIT WITHOUT CRUMB TRAY IN PLACE. THE UNIT WILL OVERHEAT AND

ACTIVATE THE HEAT LIMIT SWITCH.

Page 6

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

TROUBLESHOOTING GUIDE

A. UNIT WILL NOT HEAT, CONVEYOR BELT WILL NOT MOVE.

1) Be sure the main circuit breaker is switched to the ON position.

2) Check to see if the toaster is plugged in and all controls are turned to the ON position.

B. UNIT HAS HEAT ONLY ON ONE SIDE, CONVEYOR BELT TURNS FREELY.

1) Call the Holman Cooking Equipment Factory Service Team at 1-800-807-9054, as heating

element may need replacing.

C. CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY. To check for mechanical binding:

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove 2 screws holding enclosure to the bottom of the unit.

3) Set unit on the legs and remove 4 screws on the back of the toaster.

4) Slide the enclosure off the unit and remove the back panel.

5) Loosen the four screws which hold the drive motor in place.

6) Slide the motor up allowing the drive chain to be removed from the sprockets.

7) Move the conveyor belt by hand to check for mechanical binding. If conveyor moves freely, call the

Holman Cooking Equipment Factory Service Team at 1-800-807-9054 as the drive motor and/or

speed control may need replacing.

8) Replace the enclosure by sliding it forward towards the front of the unit. The front edge of the

enclosure will slide beneath the toaster front.

PAGE 6

Page 7

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

TROUBLE SHOOTING GUIDE CONT.

D. HEAT LIMIT SWITCH (RESET)

Your BLIMPIE conveyor toaster is equipped with an automatically activated heat limit switch that

interrupts the heater tube connections if the ambient temperature in the control box exceeds 190°F

(88C). This switch can be reset manually by pushing the red button under the toaster as shown above.

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Check to see if air intake area in the bottom center of the control box cover is free of dust, grease or

other obstructions.

3) Check if crumb tray is in place. NEVER OPERATE UNIT WITHOUT CRUMB TRAY IN PLACE AS

THIS CAUSES OVERHEATING IN THE CONTROL BOX.

4) If no obstructions to the air flow can be found and if the crumb tray is in place, call the Holman

Cooking Equipment Factory Service Team at 1-800-807-9054 for assistance.

F. CONVEYOR TURNS AT ONE SPEED REGARDLESS OF SPEED CONTROL SETTING.

1) Call the Holman Cooking Equipment Factory Service Team at 1-800-807-9054, as speed control

should be replaced.

MAINTENANCE PROCEDURES

A. REPLACING HEATER TUBES

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the enclosure.

3) Remove heater tube wire from terminal block connection, keeping top and bottom wires separate.

4) Lift heater tube retainers by loosening retaining screws and sliding the retainer plate up. Hand

tighten the plate to hold it up so the heater tubes will slide out freely.

5) Gently,

pull defective heater tube out of unit.

6) Gently,

put new heater tube into unit.

7) Loosen retainer screws and slide the retainer back into place. Tighten the screw to secure the

retainer in place over the ends of the heater tubes.

PAGE 7

Page 8

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

PAGE 8

MAINTENANCE PROCEDURES CONT.

B. REPLACING FAN MOTOR

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove screws from the enclosure and the back panel at rear of unit.

3) Remove the enclosure and the back panel.

4) Unplug power supply cord from fan motor.

5) Remove (4) screws, which hold fan motor and grill to bottom of unit.

6) Put replacement motor and grill in place and secure to the bottom of unit with screws.

7) Reconnect power supply cord to fan motor.

8) Replace back panel and enclosure. Fasten with screws removed in step 2.

C. REPLACING BELT DRIVE MOTOR

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove enclosure and back panel.

3) Remove sprocket from motor shaft.

4) Remove the wire from terminal block connecting the drive motor to internal wiring. On units rated

208 or 240 volts, note which color leads are being used for these connections and which lead is

capped with white tape. The new motor should use the same arrangement.

5) Remove screws holding motor in place.

6) Put new motor in place and attach loosely with mounting screws.

7) Replace sprocket on motor shaft.

8) Slide motor until the drive chain has about 1/8" slack when lightly pushed at the center of its top

open run.

9) Tighten screws to secure motor.

10) Rewire leads same as removed in step 4.

11) Replace side panel and control box cover.

IF ASSISTANCE IS REQUIRED FOR THIS OR ANY OTHER PROCEDURE IN THIS MANUAL CALL THE

HOLMAN COOKING EQUIPMENT FACTORY SERVICE TEAM at 1-800-807-9054 24 HOURS/DAY 7

DAYS/WEEK

Page 9

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

PARTS LIST MODEL QCS3-950HB

PART #

HC-402499 1

2P-200643 1

2P-200646 1

HX-150016 1

2U-200509 1

2A-200902 1

HA-112261 2

2A-202905 1

2P-200700 2

2P-200736 2

2E-200551 1

SP-118042 1

2R-200768 1

2R-200769 1

2E-200566 1

QTY DESCRIPTION PART # QTY DESCRIPTION

HEATER TUBE RETAINER

DRIVEN SPROCKET

DRIVE SPROCKET

DRIVE CHAIN

DRIVE MOTOR

DRIVE SHAFT

TEFLON BEARING

IDLER SHAFT

BUSHING, IDLER SHAFT

SPRING

ROTARY POWER SAVER

SWITCH

SPEED CONTROL

KNOB, SPEED CONTROL

KNOB, POWER SAVER

RESET

HEATER TUBE PART NUMBER

HS-198017 HEATER TUBE QUARTZ 208V 3

HU-198020 HEATER TUBE QUARTZ 240V 3

MODEL QCS3-950HB

HH-100561 1

HH-402465 1

HH-402466 1

2B-200764 1

HM-101114 1

HS-160024 1

2U-200561 1

2R-200562 1

2E-200574 1

2E-200387 1

HG-140024 1

HH-101371 1

HH-402470 1

2R-200709 4

SEE HEATER

TUBE CHART

PULL OUT TRAY

CRUMB TRAY

CRUMB TRAY GUARD

LOAD UP TRAY

COMPLETE CRUMB TRAY ASSEMBLY

CONVEYOR BELT

FAN MOTOR

FAN GRILL

FAN SWITCH

FAN MOTOR CORD SET

CORD SET

ENCLOSURE

BACK PANEL

LEG

HEATER TUBE

DESCRIPTION QTY.

PAGE 9

Page 10

GENERAL OPERATOR’S MANUAL

BLIMPIE CONVEYOR TOASTERS

MODEL QCS3-950HB

WIRING DIAGRAM MODEL QCS3-950HB 208, 240

PAGE 10

Loading...

Loading...