Page 1

®

®

®

®

CONVEYOR

TOASTER

MODEL

QCS1-350-120V

QCS1-500B-120V

Installation and

Operation

Instructions

2M-Z9777 Rev. A 6/22/2010

QCS1-350-120V

1

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business

8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 264-7827 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

2

Page 3

GENERAL INSTALLATION DATA

CAUTION

This equipment is designed and sold for commercial use only by personnel trained and experienced

in its operation and is not sold for consumer use in and around the home nor for use directly by the

general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated with

the unit prior to putting it into operation. Make sure all people associated with its use understand the

units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed. This unit

has been tested and carefully packaged to insure delivery of your unit in perfect condition. If equipment is received in damaged condition, either apparent or concealed, a claim must be made with the

delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a

request for inspection of concealed damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials for inspection. The carrier will make

an inspection and will supply necessary claim forms.

INSPECTION & ASSEMBLY

UNCRATING AND INSPECTING

Unpack the unit and components from the shipping container. Remove all visible packing material

and those from inside the cooking chamber. If damage is discovered, le a claim immediately with

the carrier that handled the shipment. Do not operate the unit if it was damaged during shipping.

ASSEMBLY AND INSTALLATION

The unit was shipped fully assembled and ready to plug into a standard outlet specied for its voltage

and amp draw. If improper electrical supply is determined, contact a qualied electrician prior to using

the unit. Removal and replacement of the power cord and plug will void the warranty. For assistance,

contact your local authorized service agent for service or required maintenance.

Level unit using the adjustable feet under the unit (approximately 1/2" adjustment).

Before using the unit for the rst time, wipe down the exterior with a damp cloth.

CAUTION

Allow enough space around the toaster for adequate ventilation. Do not operate the unit without the

crumb tray properly positioned. Overheating and poor toasting may occur. Read all labels on the unit

and follow their instructions.

ELECTRICAL CONNECTION

WARNING

Before making any electrical connection to this unit, check that the power supply is adequate for the

voltage, amperage and requirements stated on the rating plate.

A wiring diagram is included herewith.

Disconnect the unit from the power source before installing or removing any parts.

Be absolutely sure that the ground connection for the receptacle is properly wired. Do not connect

equipment to power without proper ground connections. Improper grounding may result in personal

injury or fatality.

WARNING

DO NOT CUT OR REMOVE THIS PLUG OR GROUNDING PRONG FROM THE

PLUG.

3

Page 4

WARNING

CLEAN

OPERATE

CONNECT/PLUG UNIT INTO DEDICATED A.C. LINE ONLY SPECIFIED ON THE

DATA PLATE OF THE UNIT.

DAILY OPERATION

ROTARY POWER SAVER SWITCH

For toasters equipped with a Rotary Power Saver Switch, turn clockwise or counterclockwise to get in

the following positions.

FULL POWER

When in this position your equipment is at full power and ready to use.

OFF ROTARY

Two off positions are provided, a single rotation to either direction will shut the unit off.

STANDBY

The standby position reduces the power consumption by 75%. Using this position during the quiet

times will save electricity, and keep the toaster warm. When needed, turn the switch to FULL POWER. Recovery time is about 30 seconds.

CAUTION

CERTAIN SURFACES ARE EXTREMELY HOT DURING OPERATION AND CARE

SHOULD BE TAKEN WHILE USING THIS UNIT.

COOKING PROCEDURES

BREAD TOASTING

Some toasters are equipped with a swinging heat shutter at the toaster entrance. This shutter will

move out of the way as the product passes under it.

1) Turn the power saver to FULL POWER.

2) Set the conveyor speed to 5.

4) Allow warm up time of 5 to 10 minutes.

5) Place a sample product on the conveyor belt to test the settings.

•If toasting is too light, turn conveyor speed control counterclockwise to a slower speed.

•If toasting is too dark, turn conveyor speed control clockwise to a faster speed.

(NOTE: Some products may require adjustment of the speed control in order to

achieve the desired results.)

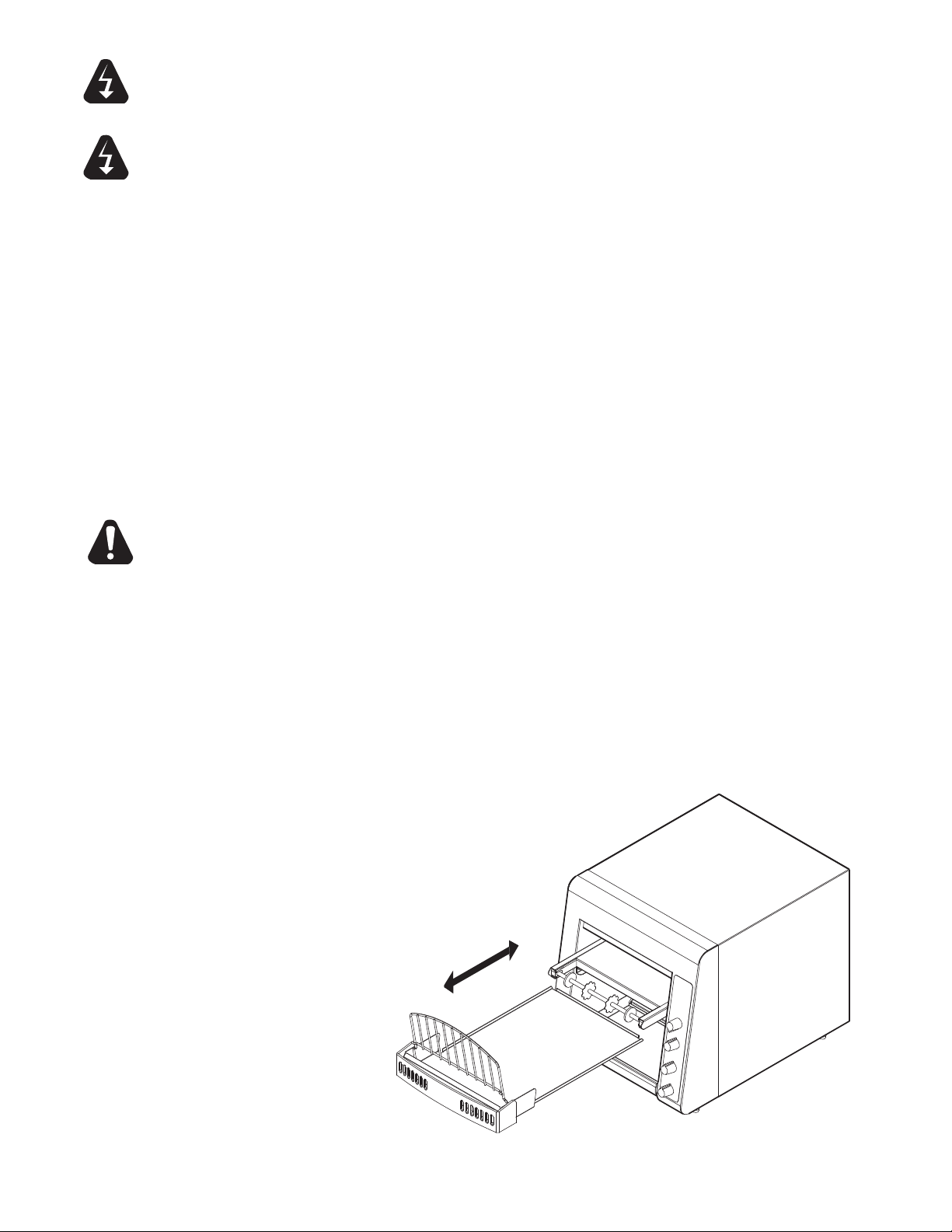

Crumb Tray Removal

4

Page 5

TOASTER COMPONENTS

LOAD UP

CRUMB TRAY

POWER SAVER SWITCH

SPEED CONTROL

FRONT

BOTTOM VIEW

AIR INTAKE FAN

POWER CORD

IL1555

IL1555

DAILY OPERATION

Check the power cord to insure that it is plugged into a proper outlet.

Set the Rotary Power Saver Switch & speed control knob to desired settings.

Always allow 10 minutes of preheat time before loading the unit with product. Failure to allow

sufcient preheat time will result in unsatisfactory cooking until the unit reaches operating

temperature.

OPERATING HINTS AND SAFETY

Disconnect power to the unit with the switch at the end of each day of operation.

Do not leave the unit in operation without an attendant.

Turn Power Saver Switch to Standby during idle periods. It will take only a few minutes to regain

operating temperature.

Do not leave the unit at high temperature when not in use or during idle periods. This will cause food

particles and grease lm to carbonize.

WARNING

CLEANING

Preventive maintenance for your Holman toaster consists of the following recommended cleaning

procedures. To keep your toaster in its top operating condition, these steps should be performed on a

daily or weekly as indicated.

A.

Turn main power saver switch to the OFF position. Disconnect unit from power source.

B. After the unit cools, remove interior crumb tray (as shown on page 4) and clean.

Slide crumb tray back into position.

C.

Wipe exterior surface of unit.

D. Areas inside the toaster, be sure to unplug the unit and allow to cool prior to wiping clean

with a damp cloth.

E. Clean air intake on bottom of unit.

F. For lightly soiled conveyor belts, turn conveyor speed control to fastest setting and

wipe with a damp cloth (daily) For heavily soiled conveyors, turn conveyor speed control

to fastest setting, with crumb tray installed and wipe with a light abrasive pad

(as needed).

DO NOT IMMERSE OR LET THE UNIT STAND IN WATER.

DO NOT HOSE DOWN THE UNIT OR THE TABLE/COUNTER IF THE UNIT IS

ON THE TABLE/COUNTER.

KEEP AWAY FROM RUNNING WATER.

5

Page 6

MAINTENANCE PROCEDURES

1/4”

A. REPLACING HEATER TUBES

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the enclosure, by removing the screws on both the back and bottom of the unit and

lifting the enclosure's back up rst and pulling away from the unit.

3) Remove heater tube wires from terminal block connection, keeping top and

bottom wires separate.

4) Lift heater tube retainers by loosening retaining screws and sliding the retainer plate.

Hand tighten the plate to hold it up so the heater tubes will slide out freely.

5) Gently, pull defective heater tube out of unit.

6) Gently, put new heater tube into unit.

7) Loosen retainer screws and slide the retainer back into place. Tighten the screw to secure the

retainer in place over the ends of the heater tubes.

8) Install the heater tube wires to the terminal block, and reinstall the enclosure.

9) Connect unit to power source and test by toasting some bread after unit has properly reached

operating temperature.

B. REPLACING FAN MOTOR

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the enclosure, by removing the screws on both the back and bottom of the unit and

lifting the enclosure's back up rst and pulling away from the unit.

3) Remove the enclosure and the back panel.

4) Unplug power supply cord from fan motor.

5) Remove (4) screws, which hold fan motor and grill to bottom of unit and remove fan.

6) Put replacement motor and grill in place and secure to the bottom of unit with screws.

7) Reconnect power supply cord to fan motor.

8) Replace back panel and enclosure. Fasten with screws removed in step 2.

C. REPLACING BELT DRIVE MOTOR

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the enclosure, by removing the screws on both the back and bottom of the unit and

lifting the enclosure's back up rst and pulling away from the unit.

3) Remove sprocket from motor shaft, using an Allen wrench and loosening the set-screw.

4) Remove the wire from terminal block connecting the drive motor to internal wiring.

On units rated 208 or 240 volts, note which color leads are being used for these connections

and which lead is capped with white tape. The new motor should use the same arrangement.

5) Remove screws holding motor in place and remove motor from unit.

6) Put new motor in place and attach loosely with mounting screws.

7) Replace sprocket on motor shaft.

NOTE: The two sprockets should line up FLUSH with each other,

so the chain does not twist any during operation.

Also the hub gets installed closets to the motor.

8) Slide motor until the drive chain has about 1/4” slack when

lightly pushed at the center of its top open run.

See chain tensioning illustration.

9) Tighten screws to secure motor.

10) Rewire leads same as removed in step 4.

11) Replace side panel and control box cover.

D. CLEANING AIR INTAKE ONCE A WEEK.

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Place unit on its backside.

3) Use a vacuum cleaner and or a damp cloth to clean

the air intake. This procedure should be done at least once a week.

QCS/RCS Chain Tension

6

Page 7

MAINTENANCE PROCEDURES continued

E. LUBRICATE THE CHAIN & SPROCKETS EVERY 6 MONTHS

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove enclosure exposing chain drive.

3) Using an extreme pressure, synthetic chain lubricant with a

temperature range up to 400°F. Apply liberally onto chain

and sprockets. This grease is available as part no. 1P-Z8914.

4) Replace enclosure, Reconnect power source and test unit.

TROUBLESHOOTING GUIDE

A. UNIT WILL NOT HEAT, CONVEYOR BELT WILL NOT MOVE.

1) Be sure the main circuit breaker is switched to the ON position.

2) Check to see if the toaster is plugged in and all controls are turned to the ON position.

3) Call the Star Service Help Desk at 1-800-807-9054.

B. UNIT HAS HEAT ONLY ON ONE SIDE, CONVEYOR BELT TURNS FREELY.

1) Call the Star Service Help Desk at 1-800-807-9054, as heating element may need replacing.

C. CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY.

To check for mechanical binding:

1) DISCONNECT UNIT FROM POWER SOURCE.

2) Remove 2 screws holding enclosure to the bottom of the unit.

3) Set unit on the legs and remove 4 screws on the back of the toaster.

4) Slide the enclosure off the unit and remove the back panel.

5) Loosen the four screws that hold the drive motor in place.

6) Slide the motor up allowing the drive chain to be removed from the sprockets.

7) Move the conveyor belt by hand to check for mechanical binding.

If conveyor moves freely, call the Star Service Help Desk at 1-800-807-9054, as the drive

motor and/or speed control may need replacing.

8) Replace the enclosure by sliding it forward towards the front of the unit.

The front edge of the enclosure will slide beneath the toaster front.

D. CONVEYOR TURNS AT ONE SPEED REGARDLESS OF SPEED

CONTROL SETTING.

1) Call the Star Service Help Desk at 1-800-807-9054, as speed control MAY need replacing.

E. PRODUCT STICKING TO CONVEYOR OR SLIDE

Your Holman conveyor toaster is designed to toast product that is a current room temperature.

DO NOT attempt to put frozen, refrigerated, or any butter or a butter substitute material in the

toaster. Doing so may cause it to come out doughy or very moist, as well as possibly sticking to

parts of the unit.

1) Follow the cleaning procedures listed on page 5.

7

Page 8

2M-4497-2 12/06

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

LIMITED EQUIPMENT WARRANTY

PARTS WARRANTY

SERVICES NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

8

Page 9

1

3

2

4

GREEN

BLACK (BROWN 230V)

FOR 120V

NEMA 5-15P

C

D

FOR 230V

CEE7-7

TOP HEAT

BOTTOM HEAT

WHITE (BLUE 230V)

2

1

4

3

A

B

E

F

LETTER DESCRIPTION

A SWITCH - POWER SAVER

B SPEED CONTROL

C MOTOR - CONVYEOR

D COOLING FAN

E TOP HEATING ELEMENTS

F BOTTOM HEATING ELEMENTS

MODEL:

QCS1-350-120V, CUL15, CUL20, 230V

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

SK2206 Rev -

6/09/2006

9

Page 10

LETTER DESCRIPTION

A SWITCH - POWER SAVER

B SPEED CONTROL

C MOTOR - CONVYEOR

D COOLING FAN

E TOP HEATING ELEMENTS

1

3

2

4

GREEN

BLACK (BROWN 230V)

FOR 120V

NEMA 5-15P

C

D

FOR 230V

CEE7-7

TOP HEAT

WHITE (BLUE 230V)

4

3

A

B

E

NEMA 5-20P

1

5

6

MODEL:

QCS1-500B-120V, CUL20, 230V

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

SK2207 Rev -

6/09/2006

10

Page 11

27

24

1

2

3

4

5

6

7

8

10

7

25

12

13

14

15

16

17

19

21

22

23

29

28

30

36

20

9

Nameplate

18

26

31

32

33

3435

37

38

34

35

39 40 41 42

OPTIONAL ACCESSORY PARTS

39

40

42

41

44

43

MODEL:

QCS1-350/500B-120V CONVEYOR TOASTER

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

SK2212 Rev. - 8/14/2007

11

11

Page 12

Description

Per

Quantity

Part

Number

Fig

No.

34 2R-200752 1 KEYLOCK SPEC KEYED ALIKE_KEY LOCKING ACCESSORY

35 HF-Z9835 1 SECURITY LOCKING COVER_kEY LOCKING ACCESSORY

36 HA-Z9744 1 ELEMENT RETAINER

37 HA-120231 2 HEATER ASSY 350W 60V - TOP 350-120V, CUL20

HA-120233 2 HEATER ASSY 300W 60V-TOP CUL15

HA-120235 2 HEATER ASSY 350W 115V-TOP 230V

QCS1-350-120V, QCS1-500B-120V

Description

Per

Quantity

HA-120237 2 HEATER ASSY 800W 120V-TOP 500B-120V

HA-120238 2 HEATER ASSY 800W 115V-TOP 500B-230V

38 HA-120232 2 HEATER ASSY 450W 60V - BTM 350-120V, CUL20

HA-120234 2 HEATER ASSY 400W 60V -BTM CUL15

HA-120236 2 HEATER ASSY 450W 115V-BTM 230V

500B-120V

NI HA-120242 1 CORDSET ASSY CUL20

NI HA-120244 1 CORDSET ASSY QCS1-230CE

NI HA-120245 1 CORDSET ASSY NEMA 6-20P 230V

39 HF-102215 1 ASSEMBLY BRACKET LEFT_WALL MOUNTING ACCESSORY

40 HF-102214 1 ASSEMBLY BRACKET RIGHT_WALL MOUNTING ACCESSORY

41 HF-100211 1 PLATE ASSY. _WALL MOUNTING ACCESSORY

42 2C-200041 8 SCREW, 1/4-20 X 1/2 SLOT_WALL MOUNTING ACCESSORY

NI HA-120241 1 CORD SET ASSEMBLY QCS-1 350-120V, CUL15,

NI 1P-Z8914 1 EXTREME PRESSURE MULTIPURPOSE SYNTHETIC

GREASE (80°F TO 400°F), TUBE 8oz.

NI 2K-200464 1 BUSHING, WIRE RING 7/8”

ACCESSORIES (Not necessarily sold with unit)

43 WMK-QCS KIT-QCS WALL MOUNT

NI 2K-Y3240 1 BUSHING HEYCO SR 17-2, CORD

44 KLK-QCS1 QCS-1 LOCKING KIT

NI = NOT ILLUSTRATED

Part

Number

Fig

No.

1 HA-Z9786 1 BODY COVER

2 HA-Z9745 1 BACK PANEL

3 2U-200558 1 MOTOR, FAN 120V 15BTL 120V

2U-200560 1 FAN 240V 230V

4 2R-Z8879 1 2-5/8” DIA FAN BLACK CW

5 HA-120240 1 MOTOR ASSEMBLY 120V, CUL20, 350-CUL15

HA-120243 1 MOTOR W/QC ASSY 230V

6 2A-202900 1 SHAFT, DRIVE

7 HA-112261 2 BEARING ASSY, 5/16 TEFLON

8 2P-200645 1 SPROCKET, 25B17 X 5/16”, DRIVEN

9 2P-200646 1 SPROCKET, 25B20 X 5/16”, DRIVE

10 2P-200665 1 CHAIN, 17 1/2” QCS1-350

11 2E-Z9736 2 TERMINAL BLOCK - POWER

12 2R-200562 1 FAN GUARD (OLDER MODELS)

13 2R-200709 4 LEG 1 INCH CHROME PLASTIC

14 HA-Z9743 2 SPRING RETAINER

15 2R-200736 2 2” INCH BEARING SPRING

16 2P-200700 2 BEARING-PTFE SPRING LOADED

17 2A-202904 1 SHAFT, IDLER

18 HN-160020 1 CONVEYOR BELT (10” X 27”)

2B-200601 1 LINK CONVEYOR BELT (10” WIDE)

19 HA-100560 1 TRAY, PULL OUT, QCS 10”

20 HF-101115 1 CRUMB TRAY ASSEMBLY

21 HA-Z9746 1 CRUMB TRAY

22 2R-200787 1 CRUMB TRAY GUARD

23 2B-200763 1 LOADUP, 10 EURO, WIRE

24 2E-Z9737 1 TERMINAL BLOCK - ELEMENTS

25 2C-200149 1 FLAT WASHER 5/16 ID 31NWX H8Z ZINC

26 2A-200284 1 E-CLIP, 5/16”

27 HA-Z9751 1 TOP LINER QCS-1

28 HA-120239 1 SPEED CONTROL ASSEMBLY

29 2E-200551 1 SWITCH ROTARY

30 2M-Z9715 1 FRONT PANEL LABEL

2M-Z9759 1 LABEL - CONTROL QCS1-500B

31 2C-200231 1 PALNUT, HEX, 3/8-24

32 2R-200768 1 KNOB, CONTROL SERIES

2R-200769 1 KNOB, POWERSAVER SERIES

33 2P-200708 2 CAP, KNOB CONTROL

Rev. A 9/30/2010

12

Loading...

Loading...