Page 1

IRRIGA TION CONTROLLER

6 Station Model

INSTRUCTION MANUAL

SUITABLE FOR INDOOR USE ONL Y OTHERWISE

WARRANTY IS VOID

Page 2

T able Of Content s

Features 1

Glossary 2

Programming Instructions

Introduction 3

Programming Example 4

Other Functions 5

General tips for programming 5

Programming

Set Current Time & Correct Day 6

Set Calendar (Optional) 6

Step 1. Set Start T imes 7

Step 2. Set Watering Days 8

Interval Day Selection 8

Individual Day Selection 8

Odd / Even Day Selection 9

Step 3. Set S tation Run T imes 9-10

Manual Operations

System test facility 1 1

Run A Single S tation 1 1

Run A Program 12

Other Features

Stop 12

Stacking S tart Times 12

Automatic BackUp Program 12

Rain Sensor Ready 13-15

Rain Off Mode 16

Water Budgeting 16

Installation Instructions

Mounting The Controller 17

Electrical Hook-Up 17

Field Wiring Connections 18

T erminal Block Layout 18

Power Supply Connections 19

Connection Of V alves 19

Pump Hook-Up Connections 20

Electrical Characteristics 21

Servicing The Controller 22

Fault Finding Guide 23

Spare Watering Planners 24-25

Features

This unit is available as a 6 station configuration.

Designed for residential and light commercial

applications, this controller has four separate programs

with up to sixteen possible start times a day. This

ensures efficient watering of different garden or turf

areas.

These different areas may require individual watering

programs and often use different types of sprinklers.

Examples: Turf areas generally use pop-up sprinklers

and require less frequent but heavier watering. However,

flower beds use micro sprays and require more frequent

watering. The valves (stations) which water similar

garden areas are often grouped together and put into the

same program as they need to be watered on the same

days.

These stations (valves) will water in sequential order

from the lowest number at the start time (or times)

nominated and on the days selected. Maximum watering

duration for a station (valve) is 12 hours and 59 minutes.

This controller has three types of watering day options.

Either, interval watering from everyday to every 15th day,

individual day selection per program, or a 365 day

calendar for ODD/EVEN day watering.

An innovative feature of this controller is the Rain Sensor

Ready (RSR) technology. This allows

to be controlled by a rain sensor. In this way, garden

areas that are subject to rain, can have their irrigation

suspended during wet periods, while areas under cover

can continue to be watered.

individual stations

PAGE 1

Page 3

Glossary

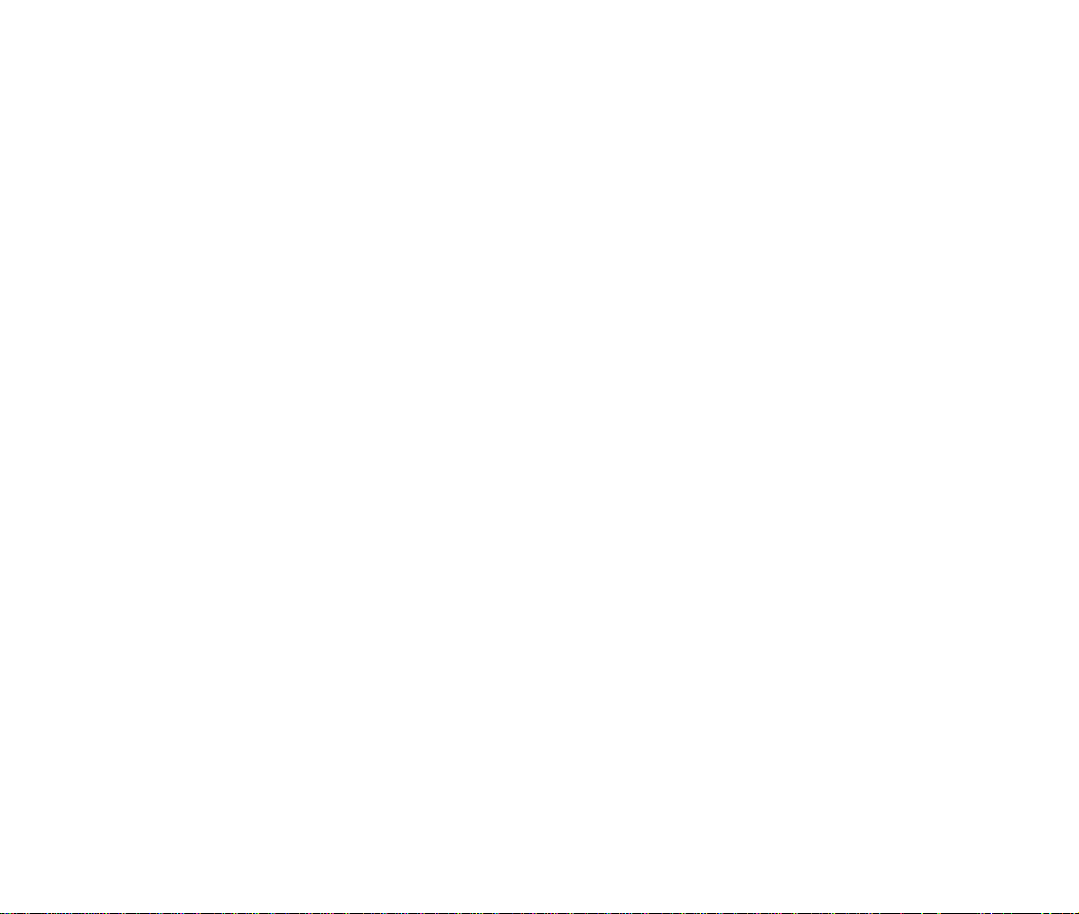

Battery Cover

Remove cover

to fit 9V block

battery.

Fuse

Location

Remove

cover to

access.

Socket & Rubber Plug (RSR)

Rain Sensor Cable Socket.

Simple push in, pull out, plug

& socket configuration.

Compatible with HOLMAN

Rain Sensor

PAGE 2

Selection Dial

Used for

operations &

programming.

(CRS1000BC)

LCD Display

Easy to read

display.

Programming

Buttons

Used for

adjusting the

programmed

information.

Terminal Cover

Remove to access

terminals for

solenoid / valve

wires.

Programming Instructions

Introduction

This controller has been designed with four separate

programs, to allow different garden areas to have their

own individual watering requirements.

A program is basically a method of grouping stations

(valves) with similar watering requirements to water on

the same days. These stations will water in sequential

order from the lowest number at the start time (or times)

nominated and on the days selected.

The key elements when programming

your controller are:

l Grouping the stations. (valves)

Group together garden areas which have similiar

watering requirements. Examples are: Turf Areas,

Flower Beds, Pergola/Undercover Areas, or Vegetables.

These different groups require individual settings.

l Planning out your watering program.

Complete your individual watering planner, supplied at

the back of this book.

l Setting the current time and correct day of the week.

l Setting an automatic program.

Use the following 3 steps to program each group.

1. Set Start(s).

This sets the time of the day when the watering

program will commence.

2. Set Watering Days.

These are the nominated days when the

automatic system will be active.

3. Set Station Run Times.

This sets the watering duration required for each

station (valve).

PAGE 3

Page 4

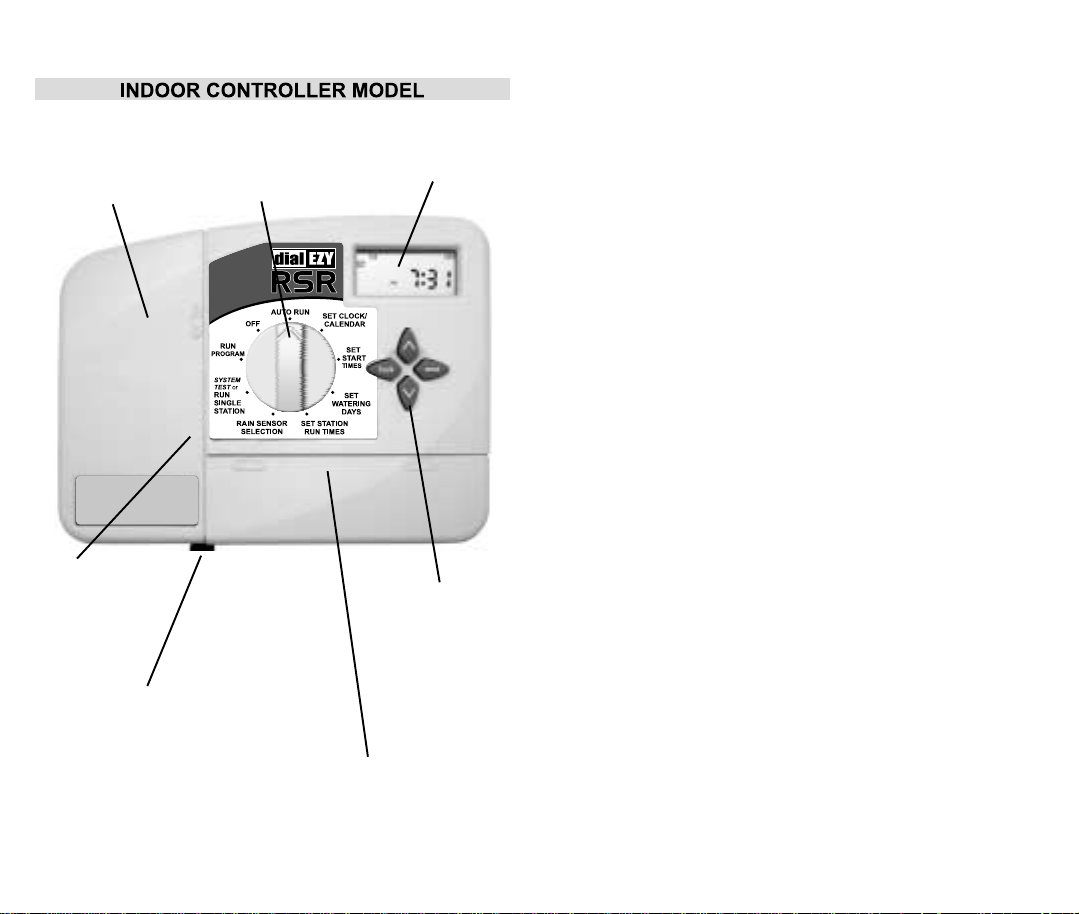

Programming Example

In this example, the lawn areas , Program 1 (Group 1), are

using pop-up sprinklers & require less frequent watering.

The vegetables are being watered using drippers on a

longer run time, with the flower beds, pots, hanging

baskets and pergola areas being watered using micro

sprays. Two stations are not affected by rainfall, these are

individually set to OFF. During rain, these stations are still

watered, whilst the rest of the system is suspended.

Programming InstructionsProgramming Instructions

Other Functions

This controller can also manually run a selected program

once, or an individual station can be set to run once from

1 minute up to 12 hours and 59 minutes. During winter

the automatic programs can be suspended to prevent

watering while it is raining. A test facility for checking the

valves and sprinklers is also provided.

General tips for easy programming

Tips to help eliminate programming confusion.

l Complete the spare watering planner.

l When setting, one push of the button will increment

one unit.

l Holding one button down will fast scroll through units.

l During programming, only the flashing values are able

PAGE 4

to be set, use the

l Pressing

in an orderly sequence.

l Pressing

settings can be changed.

next

back

or buttons.

will scroll forward through the settings

will scroll back to previous settings and

PAGE 5

Page 5

Set Current Time & Correct Day

Turn the dial to Set Clock/Calendar position.

The hour will be flashing. Use

or to adjust.

Note: AM / PM must be set correctly.

Press the

Use

or to adjust.

Press

next

button and the “minutes” will flash.

next

and the “day of the week” will flash.

Use or to set correct day.

Set Calendar (Optional)

Note: The calendar only needs to be set when selecting

ODD/EVEN day watering in areas where water

restrictions may require this feature.

Press

shown. The “year” will be flashing.

Use

Press

Use

Press

adjust. Tip: To return to the clock, press

to another position.

Note: When in the “Auto” position “ODD” or “EVEN” will be

shown.

PAGE 6

button until the year, month and day are

back

or to adjust, if required.

button and the “month” will flash.

back

or to adjust.

and the “day” will flash. Use or to

back

, or turn dial

next

ProgrammingProgramming

Before proceeding, ensure your watering planner has

been completed. From this, you should be aware of

which stations are allocated to each program.

Note: Set one program at a time -This will ensure that

all the values are entered correctly.

SETTING PROGRAM 1 - The program number

can only be set/changed in the Set Start Times position.

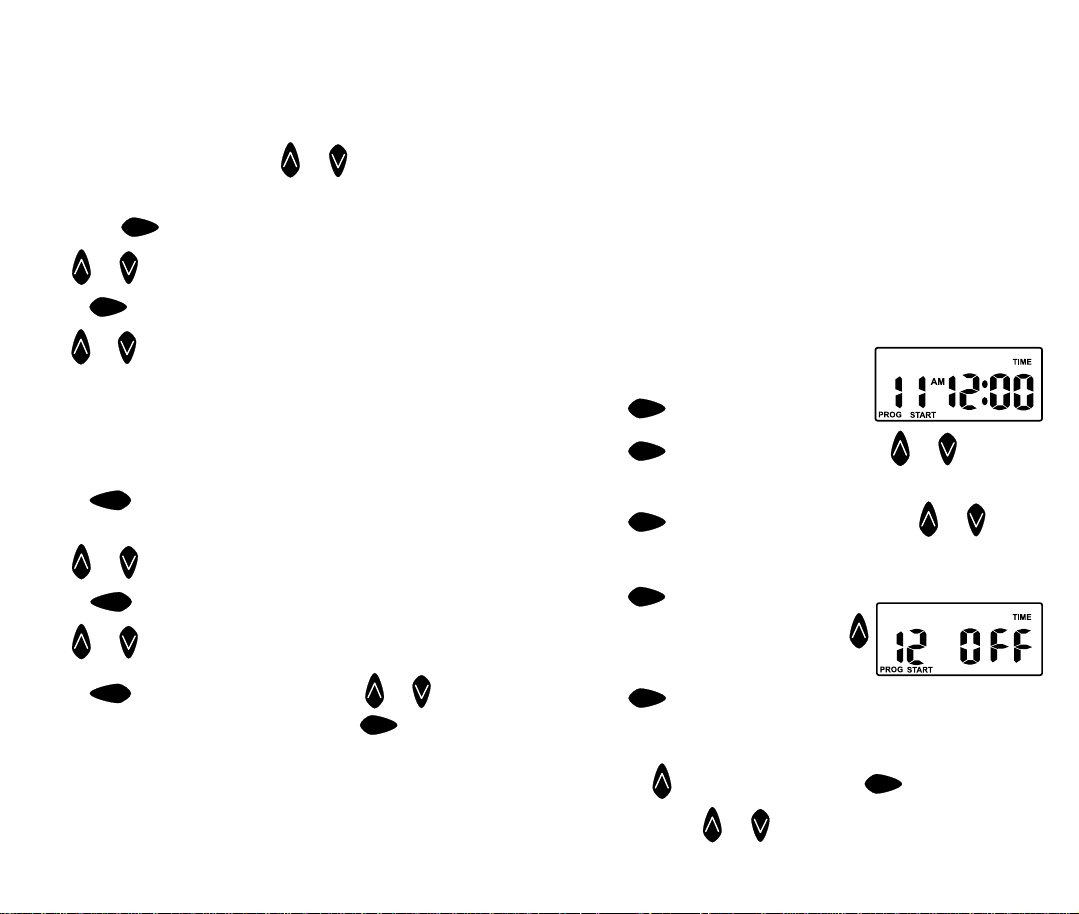

Step 1. Set Start Times

All valves will activate in sequential order for each start

time. Turn the dial to Set Start Times and ensure that

“Prog 1” is flashing.

The display will show:

Press

Press

Note: AM / PM is set correctly .

Press

adjust, if required. Each program has up to four start

times and should you require a second start time,

Press

Advance to start 2 by pressing

The display will show.

Press

Tip: To turn an active start time off, turn the dial to the Set

Start times position, Select the start number required

using the button and then press

is flashing. Use

Tip: “OFF” position is between 12 and 1pm.

& “Start 1” willl flash.

next

& the “hour” will flash. Use or to adjust.

next

& the “minutes” will flash. Use or to

next

twice & “Start 1” will flash.

next

.

and proceed as per setting Start 1.

next

until the “hour”

next

or until “OFF” is shown.

PAGE 7

Page 6

Programming

Step 2. Set W atering Days

This unit has interval watering or individual day selection

from everyday to every 15th day or a 365 day calendar

with odd/even day selection in areas where water

restrictions require this feature.

Turn the dial to Set Watering Days.

Interval Day Selection

The display will show:

“Interval 1” will be flashing.

This means that watering will occur every day.

To change the interval day, press the

Examples: Interval 2 means watering will take place every

second day, 3 means watering will take place every third

day etc.

Interval watering can be set from everyday to every 15th

day. The Run Day refers to the number of days

next watering program will occur.

Individual Day Selection

Press the

This is the selectable day option.

This refers to Mon being Day 1. To turn Monday off, press

button

next

The display will show:

button.

before the

Programming

Odd / Even Day Selection (Optional)

In some regions, users are only allowed to water their

gardens on, ODD dates if their house number is ODD, or

on EVEN dates when their number is EVEN .

This controller allows this to be done simply by setting

the relevant selection of ODD or EVEN and setting the

current date into the controller. The controller will account

for leap years.

If you require the ODD / EVEN day option, simply press

the

button and “EVEN” will be shown. This feature may be

required in areas where water restrictions are enforced.

Note: Remember to set the 365 day calendar when

setting the clock, or this feature will be out of sequence.

Step 3. Set Station Run Times

This is the length of time that each station (valve) is set to

water on a particular program. Maximum watering time is

12 hours 59 minutes for each station. A station can be

assigned to 1 or 2 programs if required.

Turn the dial to the Set Station Run Times position and

the display will show the following:

button until “ODD” is shown. Press the

next

next

button. To leave Monday active, leave as is and

advance to Tuesday (day 2) by pressing the

Again press the

followed by

days have been set “on”

PAGE 8

button to set the day off if required

next

to advance. Continue until all seven

or “off” .

next

button.

This means station 1 has a default run time of 10

minutes in program 1. “Station 1” will be flashing.

PAGE 9

Page 7

Step 3. Set Station Run Times. (Continued)

To adjust the Run time in minutes press

or . To set the run time in hours, press

will appear and flash. To adjust use

If not required, press

pressing the button.

Continue until all the stations in Program 1 have been set

with a run time, or if a station (or stations) are not

required to be active in this particular program, ensure

that the run time is set to “OFF”.

Note: To set a station to “OFF”.

Use when the “RUN TIME” is flashing.

This completes the setting up procedure for automatic

watering of Program 1.

Should you need a second program.

Turn the dial to “Set Start Times” and “Prog 1” will flash.

Press

the same 3 steps to set an automatic watering program.

Tip: Remember to return the dial to the “Auto Run”

position after completing the set up of an automatic

program.

This will ensure that the automatic cycles will take place.

PAGE 10

and change to program 2 position and follow

1. Set Starts

2. Set Watering Days

3. Set Station Run Times

and advance to station 2 by

next

or .

next

, and use

and “0”

next

Manual OperationsProgramming

System T est Facility

T urn the dial to System Test or Run Single Station.

(This is a dual function position)

The display will show:

Use this feature to go & check that

your valves & sprinklers are working correctly. The unit

will run all stations in sequential order. The factory preset

time of 2 minutes per station can NOT be adjusted.

IMPORTANT TIP: If the water supply is from a pump

system, it is critical to ensure all outputs are connected to

a valve. Any output NOT connected to a valve, should be

linked back with a wire to the nearest output with a valve.

This prevents the pump running against a closed head.

Run A Single S t ation

Turn the dial to System Test or Run Single Station.

(This will be in the system test mode)

To manually run a single station once,

press button to kick the unit into the

other mode. The display will change

from 2 minutes to 10 minutes.

To adjust the run time, use

To advance to the next station press

next

the

button.

or .

PAGE 11

Page 8

Manual Operations (cont.)

Run A Program

To manually run a complete program once for the run

times as set in the automatic schedule. Turn the dial to

the Run Program position. “Prog 1” will be shown in the

display. To run program 1, leave or advance to program 2

by pressing

the display shows “SEN WET”, the stations set to rain

sensor “ON” will not activate. However, individual stations

can be watered by using the Run Single Station facility.

. Note: if a rain switch is connected and

next

Other Features

Stop

To stop an automatic or manual watering schedule, turn

the dial to the Off position. Tip: For automatic watering,

remember to turn the dial back to the Auto Run position.

The Off position will stop any watering from occuring.

Stacking Start Times

Should you accidently set the same watering start time

on more than one program, the controller will stack them

in sequential order from the lowest number. All

programmed start times will be watered, but the start

times will be shunted along.

Automatic BackUp Program

When the battery is not fitted or is flat, there is a backup

default program in program 1 watering every day at

12:00am for 10 minutes per station.

A standard 9 volt alkaline block battery should be fitted to

the battery snap supplied to maintain the clock accuracy

and hold the automatic programs during power outs.

Tip: The display has a warning indicator to let you know

when the battery is low or not fitted. The word BAT is

displayed under the AM / PM indicator in the clock mode.

PAGE 12

Other Features

Rain Sensor Ready

This feature should only be used when a rain sensor has

been connected. The controller comes pre-fitted with a

socket, ready to take the “HOLMAN” Rain Sensor (P/N

CRS1000BC, not included) which has also been prefitted with a plug. Simply push the plug into the socket

and mount the rain switch, exposing it to direct weather.

Turn the dial to Rain Sensor Selection to enable

individual stations to be rain sensor “ON” or “OFF”

The display will show:

Note: all stations are set to “OFF” at first power up.

The stations set to “OFF” will water automatically at all

times and the stations set to “ON” will be controlled by

the rain sensor. Eg: The stations set to “ON” will not water

automatically with the rain sensor in the “WET” mode. To

set individual stations to “ON” press

advance by pressing

are set “ON” for rain sensor control or “OFF”.

In the “Auto” position, the display

will show:

TIP: If the display is showing “

SENS WET” and you need to

override the rain switch, pull the

plug connected to the “HOLMAN”

Rain sensor.

Note: Both the “System Test” and

“Run Single Station” will work on

all stations regardless of wether

the sensor is wet or dry.

. Continue until all stations

next

button and

PAGE 13

Page 9

Other Features

Rain Sensor Ready (cont.)

DELA Y FEA TURE - When using the Rain Sensor Ready

feature, in conjunction with the rain sensor. It is possible

to set a delay in the controller to stop the automatic

programs from activating too quickly.

This feature is applicable to the stations nominated to be

controlled by the sensor. EG: Set to rain sensor “ON”, and

will only occur when the rain sensor is “WET”.

The reason for this feature is that the rain sensor itself

can dry out due to strong winds or warm temperatures.

Often the sensor will dry out in 24 hours or less and the

automatic watering cycles will start. The soil may still be

too wet in clay or loam situations and it may be desirable

to increase the delay time. This can be set at the

controller.

The delay can be set from 24 hours up to 96 hours and

will prevent any automatic starts from occurring for the

nominated delay period. At the end of the nominated

delay time, the controller will check the rain sensor again

and if it is still reading “SENS WET”, the delay time will

override the automatic watering programs and prevent

any start time from ocurring. This will continue until the

rain sensor is “DRY” and then the automatic programs

will start at the next available start time.

This delay is locked in the controller memory and will

activate any time the Rain Sensor is in the “WET” mode.

NOTE: Stations set at rain sensor “OFF” will continue to

water automatically, and any station can be watered

manually in “system test” or “rain single station” mode.

Other Features

Rain Sensor Ready (cont.)

DELA Y FEA TURE - SETTING RAIN SENSOR DELA Y .

Turn the dial to Rain Sensor Selection.

Press the

The display will show OFF.

This means there is NO delay set for the rain sensor.

The sensor delay will increment in 24 hr blocks, so to set

the required delay, press button & 24 “Sensor Delay

Hrs” will be shown in the display:

If a 48 hr sensor delay is required, press again, a

maximum of 96 hours, (4 days), can be set.

To cancel or clear a rain sensor delay:

Turn the dial to Rain Sensor Selection, press the

button, followed by the button.

The display will show OFF Sensor Delay Hrs.

If a delay period has been set & the rain switch is WET,

the controller display will show

“SEN WET” and will show

the remaining delay time in hours.

This will continue to override the rain sensor until the

delay time has finished counting down, or unless you

clear the delay feature.

back

button.

back

PAGE 14

PAGE 15

Page 10

Other Features

Rain Off Mode

To stop the automatic watering cycles during winter, turn

the dial to the Off position. The word “Off” will appear in

the display. This means the automatic programs will not

come on, but the programmed information is still

retained in the memory. To reactivate the automatic

schedule, turn the dial back to the Auto Run position.

NOTE: If a rain sensor has been connected, the stations

set to rain sensor control, will be turned OFF

automatically, when the sensor is wet.

Water Budgeting

The automatic station run times can be adjusted by

percentage as the seasons change. This will save time

and money as the run times can be adjusted quickly in

spring, winter and autumn to reduce the amount of water

used.

Ensure that the dial is in the Auto Run position and then

press the

The display will show:

Displayed is the word “Budget” and “100%”.

This represents the current automatic watering run times

as being 100%. The percentage budget can be set in

25% increments from 25% up to 150%.

Example: 50% reduces watering by half.

back

and

buttons simultaneously.

next

Installation Instructions

Mounting The Controller

This controller unit is an INDOOR MODEL and MUST not

be exposed to rain or water ingress.

(If the controller needs to be outdoors, you can purchase

a HOLMAN outdoor weatherproof box, P/N COBOX, to

mount the controller inside.This box is available from

your irrigation supplier.)

Install the controller near a 240V AC mains outlet,

preferably located in a house, garage or other covered

area. For ease of operation, eye level placement is

recommended.

Drive one #8 screw into the wall, leaving about 4mm of

the screw exposed. If necessary, use a toggle bolt or

masonary shield.

Hang the controller from the key slot located in the back

of the case. Make sure the head is properly seated inside

the controller case. Additional screws may be inserted

through the holes in the lower corners of the controller

case.

Electrical Hook-Up

WARNING

1 All electrical work must be carried out in

accordance with these instructions following all

applicable Local, State and Federal codes, or

warranty will be void.

To adjust in 25% increments, use

To return to the clock press the

simultaneously. The display will show the word Budget to

indicate that the water budgeting feature is in use.

or buttons.

and

back

next

buttons

2 Disconnect mains power supply before

maintenance work to controller or valves and when

connecting and disconnecting field wiring and

pump or master valve hook-ups.

PAGE 17PAGE 16

Page 11

Installation Instructions

Field Wiring Connections

PREP ARA TION

1 Prepare wires for hook-up by cutting the wires to the

correct length and stripping approximately 6.0mm

(¼ inch) of insulation from the end to be connected to

the controller.

2 Ensure terminal block screws are loosened

sufficiently to permit easy access for wire ends. Insert

stripped wire ends into the clamp aperture and

tighten screws. Do not over tighten as this may

damage the terminal block.

3 A maximum of 0.5 Amps may be supplied by any

output. Check the inrush current of your solenoid coils

before connecting more than two valves to any one

station.

Terminal Block Layout

The terminal block is laid out as follows:

Installation Instructions

Power Supply Connections

The controller itself can run off a 240V AC to 24V AC

external transformer..

It is recommended that the transformer is not connected

to a 240V AC supply which is also servicing or supplying

motors (i.e. Air conditioners, pool pumps, refrigerators,

etc.) Lighting circuits are suitable as a power source.

Connections to the unit are as follows:

Fuse located under battery cover.

GLOSSARY

AC 24VAC Power Supply

COM Common valve wire input

PUMP Master valve or pump start active wire

ST1 to ST6 Station (Valve) active wire connection

Connection Of V alves

Up to two 24VAC Solenoid Valves can be connected to

each station output and wired back to the common (COM)

thus:

Valve wires enter the controller

through the rear

PAGE 19PAGE 18

Page 12

Installation Instructions

Pump Hook-Up Connections

Do not attempt to drive a pump starter directly from the

controller. Pump start is provided by connecting one side

of the coil of a suitable relay to the Master Valve/Pump

Start output of the controller and the other side to the

controller common.

For systems supplied with water from a pump, unused

stations must be connected back to the last used station

to eliminate the possibilty of the pump running against a

closed head. Failure to do so could lead to pump

damage.

The diagram shows an 6 station controller with

stations (valves):

4 active

Unused

stations must

be linked back

to the last

used station.

Electrical Characteristics

Power Supply

MAINS SUPPL Y

This unit can run off a 50Hz external transformer,

(plugpack), with an output of 24VAC 50Hz @ 1 Amp.

Plug Pack Model

The correct wiring installation for the 24VAC plug pack is

shown on page 19. The plug pack model is only suitable

for indoor installation.

Electrical Outputs

ELECTRICAL POWER SUPPL Y

l Input: 24Volts AC 50Hz.

l Electrical Outputs: Maximum of 1.0 AMP

To Solenoid Valves: 24 VAC 50/60 Hz 0.5 AMPs max.

To the Master Valve/Pump S tart: 24VAC 0.25 AMPs

maximum.

Note:

Transformer and fuse capacity must be compatible with

output requirements.

l Overload protection: Standard 20mm 1 Amp fuse.

l Power failure: 9 Volt block type battery maintains

clock and programs for up to 4 weeks.

l The output circuits should be installed and protected

in accordance with wiring rules.

PAGE 21PAGE 20

Page 13

Servicing The Controller

The controller should always be serviced by an

authorized agent.

Follow these steps:

1. Turn mains power off to the controller.

2. Disconnect 24 Volt power leads from the plug pack

at the controller 24VAC terminals.

3. Clearly mark or identify all valve wires according to the

terminals they are connected to, (1 to 6). This allows

you to easily wire them back to the controller,

maintaining your valve watering sequence.

4. Disconnect valve wires from the terminal block.

5. Remove the complete unit from the wall.

6. Carefully wrap the complete unit in protective

wrapping and pack in a suitable box. Return to your

service agent or the manufacturer.

Note: Tampering with the unit will cancel the

Guarantee

7. Replace your controller by reversing this procedure.

Fault Finding Guide

Symptom

No display.

Single Station

not working.

Fuse blows.

No automatic

start.

Buttons on

keypad not

responding.

System

coming on at

random.

More than 1

station coming

on at once.

Pump start

chattering.

Display

cracked or

missing

segments.

Possible Cause

Faulty transformer.

Fuse blown.

Faulty solenoid coil.

Incorrect wiring or bad

wiring joint.

Incorrect

programming or blown

fuse.

Short on keypad or

Programming not

correct.

Short on keypad or

too many start times

entered on automatic

programs.

Damaged main output

driver chip.

Faulty relay or pump

contactor.

Display damaged

during transportation.

Suggestion

Check fuse. Check field wiring.

Check transformer.

Swap faulty station wire on

controller terminal block with

known working station wire. If

the faulty valve still does not

work on the known working

connection then the solenoid coil

is faulty. The panel may need to

be repaired.

Check wiring and joints.

If unit works manually check

programming. Check fuse and

field wiring.

Check instruction book to ensure

programming correct. If keypad

still not responding return panel to

supplier or manufacturer.

Check number of start times

entered on each program. If

programming is correct return

panel to supplier or manufacturer.

Check wiring and swap faulty

station wire(s) on controller

terminal block with known working

station wire. If the same outputs

are still locked on, return panel to

supplier or manufacturer.

Electrician to check voltage on

pump relay or contactor.

Return panel to supplier or

manufacturer.

PAGE 23PAGE 22

Page 14

Sp are W atering Planner

Sp are W atering Planner

PAGE 25PAGE 24

Page 15

Y our Guarantee

The manufacturer Guarantee to the original purchaser that any

product supplied by the manufacturer will be free from defects

in materials and workmanship for a period of three years from

the date of purchase. Any product found to have defects in

material or workmanship within the period of this Guarantee shall

be repaired or replaced by the manufacturer FREE OF CHARGE.

The guarantor does not guarantee the fitness for a particular

purpose of its products and does not make any guarantee,

expressed or implied, other than the guarantee contained herein.

The guarantor shall not be liable for any loss from use of the

product or incidental or consequential damages including

damages to other parts of any installation of which this product

is part.

The guarantee shall not apply to any equipment which is found

to have been improperly installed, set up or used in any way not

in accordance with the instructions supplied with this equipment,

or to have been modified, repaired or altered in any way without

the express written consent of the company. This guarantee

shall not apply to any batteries or accessories used in the

equipment covered under this guarantee or to any damage

which may be caused by such batteries.

If the Controller develops a fault, the product or panel must be

returned in adequate packing with:

1 A copy of your original invoice.

2 A description of any fault.

It is the purchasers responsibility to return the Controller to the

manufacturer or their agent by pre-paid freight.

www.holmanindustries.com.au

463 Scarborough Beach Rd. Osborne Park, 6017, WA.

Ph: +61 8 9204 1011 Fax:+61 8 9204 1013

Email: sales@holmanindustries.com.au

Loading...

Loading...