Page 1

10 SUNNEN DRIVE, ST. LOUIS MO 63143

PHONE 314-781-2777, FAX 314-781-3636

U. S. AND CANADA CALL: TOLL FREE 1-800-225-3958

UNCRATING AND INSPECTION PAGE 1

ASSEMBLY AND INSTALLATION PAGE 1, 2, 3

STACKING INSTRUCTIONS PAGE 3

OPERATION PAGE 4

CLEANING PROCEDURES PAGE 4, 5

TROUBLESHOOTING GUIDE PAGE 5, 6, 7

MAINTENANCE PROCEDURES PAGE 8, 9, 10

PARTS LIST/EXPLODED VIEW PAGE 11

LOAD AND UNLOAD TRAYS PAGE 2

REMOVING THE CONVEYOR BELT PAGE 4

HEAT REFLECTOR/CRUMB TRAYS PAGE 6

HEATER TUBE & FAN MOTOR INSTALLATION PAGE 8

DRIVE SYSTEM PAGE 9

COMPONENT ARRANGEMENT PAGE 10

WIRING DIAGRAM PAGE 12

HEATER TUBE CHART PAGE 13

U:\HOLMAN MANUALS\CURRENT MODELS\QUIZNO'S

HG0341

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

FOR SERVICE INFORMATION

TABLE OF CONTENTS

DRAWINGS

REVISED 06/18/04

Page 2

PAGE 1

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

UNCRATING AND INSPECTION

Unpack unit and components from container. Remove all visible packing material, inspect unit for damage.

If damage is discovered, file a claim immediately with the carrier that handled the shipment.

The following should be included in the container:

A. 1ea. Baking oven with heaters, tunnel extender, power supply lead and conveyor belt in place.

(NOTE): Remove heating element shipping supports.

B. 1ea. Stainless Steel Unload Tray and 1ea. Stainless Steel Load Up Tray.

ASSEMBLY AND INSTALLATION

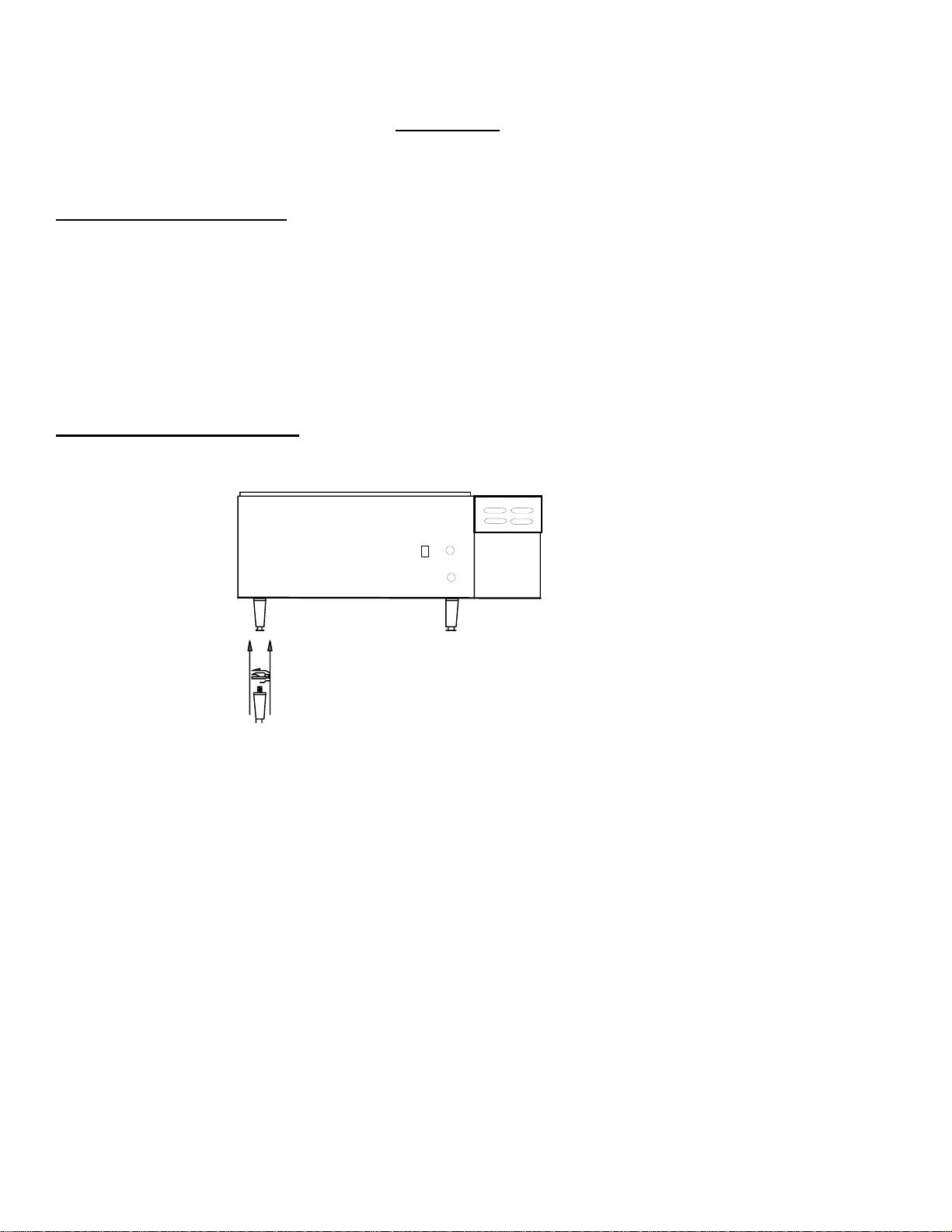

A. Attach legs by screwing into weld nuts, as shown

ADJUSTABLE LEGS SCREWS INTO

WELD NUT ON BOTTOM OF UNIT.

B. Anti Skid pads are available at no charge and may be adhered to the foot

section of each leg to prevent sliding. Call 1-800-225-3958 for details.

CAUTION: Use of these pads are not approved by the National Sanitation Foundation.

C. Install unit in its operating position. The load & unload ends must be at least 6" from any vertical

combustible surfaces. Allow sufficient space for operating personnel.

1. Your model MM14 conveyor oven is suppiled with a six foot power supply lead. Have an

electrician connect input power to the unit in accordance with local electrical codes.

ASSEMBLY AND INSTALLATION CONT. ON PAGE 2 REVISED 7/9/01 MJC

Page 3

PAGE 2

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

ASSEMBLY AND INSTALLATION (CONT)

WARNING:

MAKE SURE ALL INPUT POWER IS OFF BEFORE INSTALLING/REMOVING ANY PARTS.

WARNING:

BEFORE INSTALLING UNIT(S), HAVE YOUR ELECTRICIAN CHECK WITH LOCAL POWER

COMPANY TO DETERMINE ACTUAL VOLTAGE AT JOB SITE.

WARNING:

BE ABSOLUTELY SURE THE GROUND (EARTH) CONNECTION FOR THE RECEPTACLE IS

PROPERLY WIRED. NEVER CONNECT UNIT TO POWER WITHOUT PROPER GROUND CONNECTIONS.

IMPROPER GROUND MAY RESULT IN SEVERE INJURY OR FATALITY.

E. Before applying input power to the unit(s) check heating elements for breakage, do not apply power to

the unit(s) if a broken tube is found. If no broken tubes are found apply input power by switching the

master On/Off toggle to the ON position. Turn conveyor belt speed control to the maximum setting and

check all heater tubes and conveyor for proper operation.

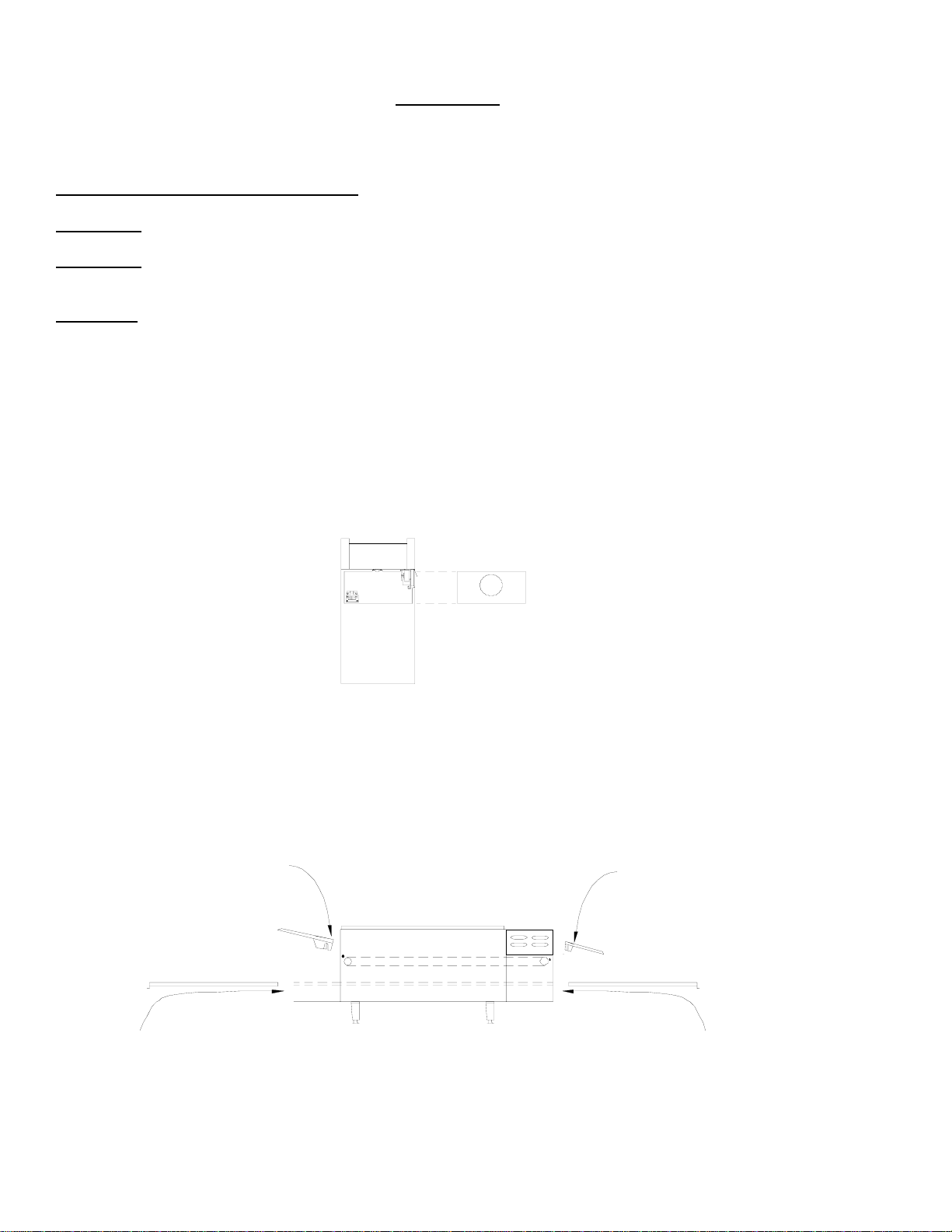

F. Allow approximately 5 to 8 minutes for the fan cooling system to come on, check the air intake area as

noted below and be sure that there is a sufficient flow of air into the control box.

AIR INTAKE LOCATED

ON BOTTOM CONTROL

BOX COVER.

G. If all heaters and conveyor system are operating properly, switch the master on/off switch to the OFF

position and allow unit to cool. The fan will continue to circulate cool air through out the unit until the

internal temperatures have been decreased.

H. If a problem is discovered during start up procedures, immediately switch the Master On/Off switch to

the OFF position and notify a service agent in your area. Install load and unload trays as shown.

UNLOAD TRAY

LOAD UP

TRAY

CRUMB TRAYCRUMB TRAY

ASSEMBLY AND INSTALLATION CONT. ON PAGE 3

REVISED 7/9/01 MJC

Page 4

PAGE 3

A

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

ASSEMBLY AND INSTALLATION (CONT.)

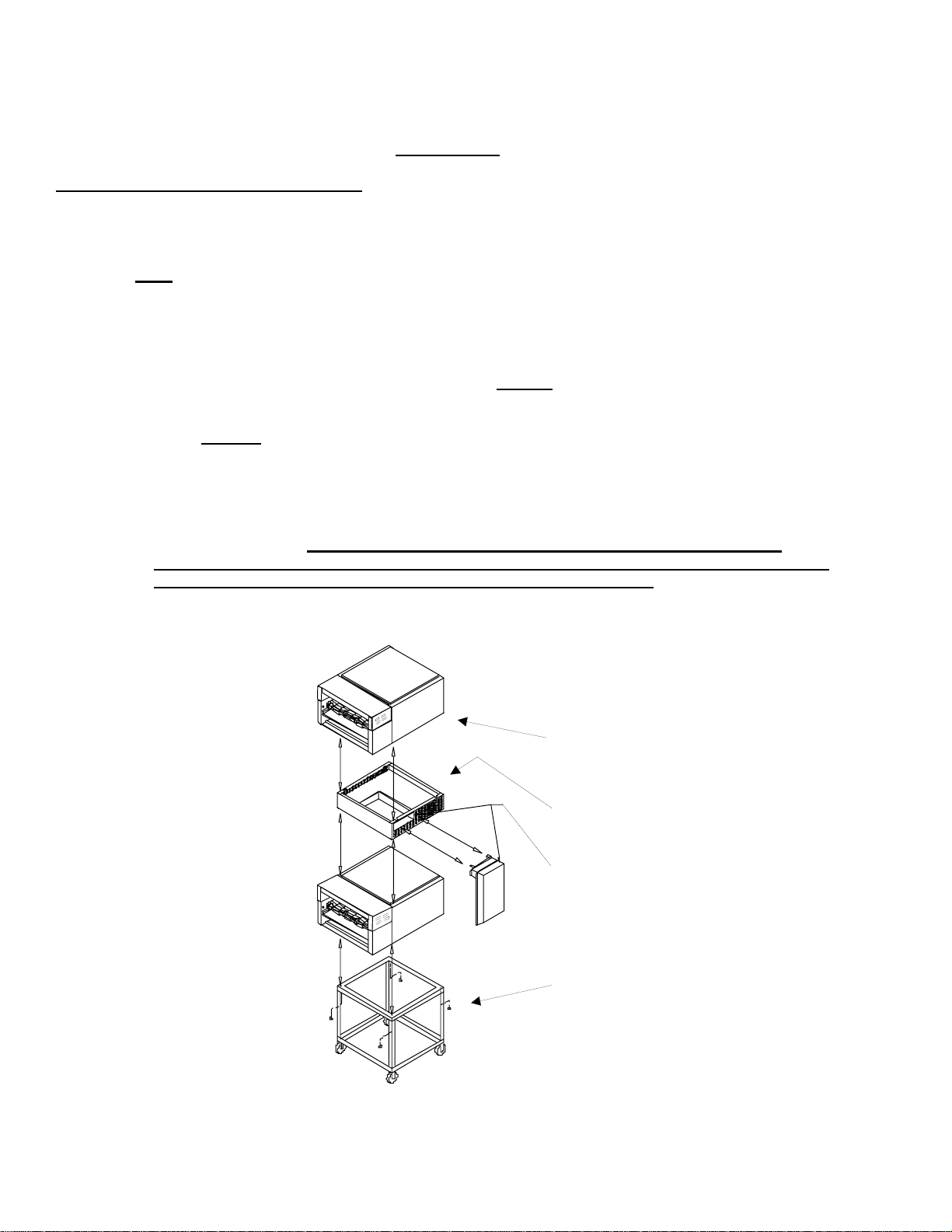

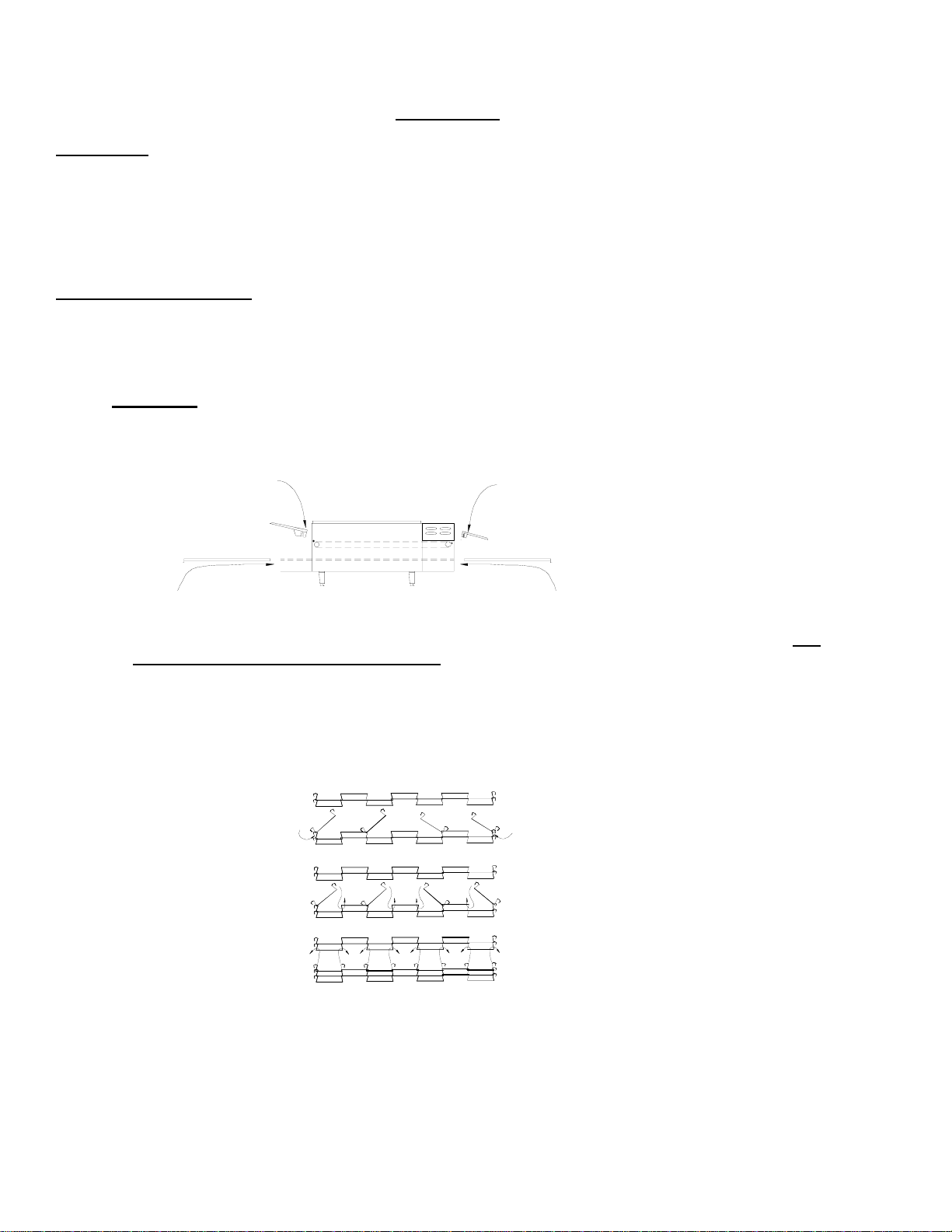

F. Stacking Instructions

When stacking two Holman Proveyor ovens a stacking spacer with external air

duct must

be used to prevent overheating of the control box in the top oven.

1). If cart is to be used with units, place bottom unit on cart and align leg holes of unit

to holes in top portion of cart. Insert 3/8" bolts through cart and into leg holes to secure bottom unit

to cart as shown below.

2). Place stacking spacer on top of bottom oven with internal

air duct facing up and toward the rear of

the oven.

3). Mount external

air duct on stacking spacer as shown below. External air duct must be installed for

cooling system of top unit to function properly.

4). Screw cap screws (4ea.) into leg holes on top oven.

5). Place top oven on stacking spacer. Cap screws will set into cut outs in top of stacking spacer to

lock unit into position. (NOTE) Air intake of top unit must fit over the internal air duct of

stacking spacer to allow airflow into the control box of the top oven. For stacking spacer to

work properly, both ovens must have the same belt travel direction.

BOTTOM UNIT - CAN

BE COUNTER MOUNTED

OR PLACED ON A CART

S SHOWN.

TOP UNIT - LEGS ARE

REPLACED WITH CAP SCREWS.

UNIT SITS ON TOP OF SPACER

STACKING SPACER (REQUIRED)

MOUNTS ON TOP OF LOWER OVEN

EXTERNAL AIR DUCT

MOUNTS ON SPACER

MOUNTING BOLTS FOR LOWER

UNIT SCREW INTO LEG HOLES

THROUGH CART

REVISED 7/9/01MJC

Page 5

PAGE 4

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

OPERATION

A. Switch Master On/Off switch to the ON position and turn Variable Speed Control to fastest time setting.

B. Allow 10 to 15 minutes for unit(s) to warm up.

C. Adjust conveyor belt speed to the desired pass time and place product on conveyor belt.

CLEANING PROCEDURES

Preventive maintenance for your Holman oven consists of the following recommendecleaning

procedures. To keep your oven in its top operating condition, these steps should be performed daily or

weekly as indicated.

WARNING:

HIGH VOLTAGES ARE PRESENT IN THESE UNITS. DISCONNECT UNIT FROM POWER

SUPPLY BEFORE SERVICING OR CLEANING UNIT.

A. Remove Load and Unload Trays (daily) as shown and wash with hot soapy water.

UNLOAD TRAY

LOAD UP

TRAY

CRUMB TRAYCRUMB TRAY

B. Remove the Crumb Trays from both load and unload ends of the oven (daily) as shown above, (DO

NOT CLEAN WITH CAUSTIC CLEANERS ).

C. For lightly soiled conveyor surfaces a damp cloth or scotch pad can be used without removing the

conveyor belt. (daily)

D. For heavily soiled conveyor surfaces disconnect and remove the conveyor as shown and soak in hot

soapy water overnight (as required).

NOTE: LUBRICATION OF DRIVE CHAIN WITH A GRAPHITE BASED LUBRICANT IS REQUIRED AS

PERIODIC MAINTENANCE. CALL HOLMAN FACTORY SERVICE DEPARTMENT FOR DETAILS.

CLEANING PROCEDURES CONT. PAGE 5

REVISED 7/9/01 MJC

Page 6

PAGE 5

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

CLEANING PROCEDURES CONT.

E. Check Air Intake area for dust and grease. To clean, remove the Control Box Cover and wipe with a

dry cloth. Do not spray cleaning fluids into the Air Intake. This may result in component failure.

F. Re-assemble unit and check to be sure it is operating properly. Contact the Holman Cooking

Equipment Factory Service Team if assistance is required.

TROUBLESHOOTING GUIDE

A. UNIT WILL NOT HEAT, CONVEYOR BELT WILL NOT TURN.

1. Be sure main Circuit Breaker is switched to the ON position and there is power at the outlet.

2. Check to see that the unit is connected to power and Master On/Off is switched to the ON

position.

3. Be sure HEAT LIMIT SWITCH is pushed in (see below).

HEAT LIMIT SWITCH LOCATED ON FRONT OF CONTROL BO

BENEATH FRONT EXTENSION.

CUTAWAY VIEW OF CONTROL BOX WITHOUT

CONTROL BOX COVER.

B. UNIT WILL NOT HEAT, CONVEYOR TURNS.

1. Check to see if the Master On/Off Switch is in the on position.

2. Press Heat Limit Switch, located on the front section of the control box as shown above. If this

reactivates the Heater Tubes, see section C page 6.

3. Contact the Holman Cooking Equipment Factory Service Team if assistance is required.

TROUBLESHOOTING GUIDE CONT. ON PAGE 6

REVISED 7/9/01 MJC

Page 7

PAGE 6

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

TROUBLESHOOTING GUIDE CONT.

C. HEAT LIMIT SWITCH

Your Holman Conveyor Oven is equipped with an automatically activated HEAT LIMIT SWITCH which

interrupts the heater tube connections if the air temperature in the control box exceeds 190F (88C). This

Limit Switch can be reset manually by pushing the button in the center of the switch which is located as

shown.

HEAT LIMIT SWITCH

THE HEAT LIMIT SWITCH CAN BE ACTIVATED IF THERE IS NOT A PROPER AMOUNT OF AIR

FLOW BEING GENERATED BY THE COOLING FAN. IF THIS OCCURS:

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Check to see if air intake area (openings in bottom center of Control Box) is free of dust, grease

or other obstructions.

3. Check to see if Crumb Trays (heat reflectors) are in place.

NEVER OPERATE UNIT WITHOUT CRUMB TRAYS IN POSITION AS THIS CAUSES

OVERHEATING IN THE CONTROL BOX.

CRUMB TRAYCRUMB TRAY

TROUBLESHOOTING GUIDE CONT. ON PAGE 7

REVISED 7/9/01 MJC

Page 8

PAGE 7

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

TROUBLESHOOTING GUIDE CONT.

D. CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY.

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Check to see if there are obstructions in the conveyor system that may cause a jam.

3. Remove Air Intake Cover as shown on page 9 and spin the Drive Motor Shaft as shown on page

10. Recheck to see if the Conveyor now works.

IF CONVEYOR STILL DOES NOT TURN;

4. Remove power supply Side Panel and Drive Motor Sprocket (see below). Manually move

Conveyor Belt to check for mechanical binding. If Conveyor moves freely, call Holman Service

Department (1-800-225-3958) as Drive Motor and/or Variable Speed Control may have to be

replaced (refer to page 9 for instructions on replacing drive motor).

DRIVEN SPROCKET

DRIVE CHAIN

DRIVE SPROCKET

E. CONVEYOR TURNS AT ONE SPEED REGARDLESS OF SPEED

CONTROL SETTING.

1. Call Holman Service Department (1-800-225-3958) as Variable Speed Control may have to be

replaced. (refer to page 10 for instructions on replacing the Variable Speed Control).

F. COOLING FAN DOES NOT START.

1. Remove Control Box Cover and check Fan Blade for obstructions.

2. Check Fan Motor Cord for secure connection.

3. Call Holman Factory Service Team as the Fan Switch and/or Fan Motor may have to be

replaced.

REVISED 7/9/01 MJC

Page 9

PAGE 8

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

MAINTENANCE PROCEDURES

A. REPLACING HEATER TUBES (see below)

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove left and right side panels by removing the philips head screws in each panel. Pull the top

3. Disconnect heater tube wires which require replacement from terminal block connections.

of each panel out slightly and lift up.

4. Remove Heater Tube Retainer by removing retainer screw with washer (retainers are located on

5. GENTLY

6. GENTLY

7. Replace heater tube retainers.

8. Reconnect heater wires to terminal block connections.

power supply side of unit).

, pull defective Heater Tube out of unit.

, place new Heater Tube into unit.

9. Replace side panels and test unit for proper operation

HEATER TUBE

HEATER

TUBE RETAINERS

SIDE PANEL

B. REPLACING FAN MOTOR

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove control box cover with Fan Motor.

3. Unplug power supply cord from Fan Motor.

4. Remove(4)screws which hold Fan Motor and grill to cover.

5. Put replacement motor and grill in place and secure to the control box cover with screws.

6. Reconnect power supply cord to Fan Motor.

7. Replace control box cover.

CONTROL BOX COVER

AIR INTAKE

FAN MOTOR

SECURED BY 4 SCREWS

MAINTENANCE PROCEDURES CONT. PAGE 9

REVISED 7/9/01MJC

Page 10

PAGE 9

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

MAINTENANCE PROCEDURES CONT.

C. REPLACING BELT DRIVE MOTOR

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove power supply side panel and control box cover as described in section B

in previous procedure.

3. Remove sprocket from motor shaft by loosening the

allen screw on the sprocket collar.

4. Disconnect the Drive Motor leads to the internal wiring. Motors are rated 208

Volts or 240 Volts, note which color leads are being used for these

connections and which lead is capped with white tape. The new Drive Motor

should use the same arrangement.

5. Remove the four screws that hold the Drive Motor in place.

6. Put the new motor in place and loosely attach with the four screws

removed from step 5.

7. Replace the Sprocket onto the motor shaft, then replace the Drive Chain onto the sprockets.

DRIVE SPROCKET WITH SET SCREW

CUT AWAY VIEW OF DRIVE MOTOR

IN CONTROL BOX.

DRIVE MOTOR

DRIVE MOTOR

MOUNTING SCREW

8. Slide the Drive Motor until the Drive Chain has about 1/8" slack when

lightly pushed at the center of its top open run. Tighten the Drive Motor

screws.

9. Rewire the Drive Motor as described in step 4 above. Replace the panels and test

for proper operation.

MAINTENANCE PROCEDURES CONT. PAGE 10

REVISED 7/9/01 MJC

Page 11

PAGE 10

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

MAINTENANCE PROCEDURES CONT.

D. REPLACING THE VARIABLE SPEED CONTROL (see below)

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove two philips head screws holding control side panel in place and remove side panel.

3. Remove the Variable Speed Control knob and the lock nut holding the Variable

Speed Control in place.

4. Wires from Variable Speed Control go in to terminal block located on side of

chassis. Remove wires for old Variable Speed Control and insert wires for new

Variable Speed Control in same positions as shown on wiring diagram on page 12.

5. When replacing the Variable Speed Control in the side panel be sure to reposition

the anti-rotation pin in the anti-rotation slot on the panel.

6. Replace lock nut and control knob

FAN SWITCH

SWITCH

WASHER

NUT

NUT

KNOB

E. REPLACING HEAT CONTROLS

1. DISCONNECT UNIT FROM POWER SOURCE.

2. Remove two philips head screws holding control side pane in place and remove side panel.

3. Remove the Control Box Cover by removing the two screws and pulling

down and out to the front.

4. Remove the lock washers and nuts holding the mounting brackets in

place.

5. Place the new control into position and replace mounting nut and washer, exchange wires one

terminal at a time from the defective control to the replacement control.

6. Replace control box cover.

1). Contactor/Relay 2). Heat Limit Switch 3). Drive Motor 4). Terminal Strip

2

3

4

1

REVISED 7/9/01 MJC

Page 12

WIRE DIAGRAM

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14-3

BOTTOM HEATERS

TOP HEATERS

PAGE 13

HEATER TUBE PART LIST

PART NUMBER DESCRIPTION QTY.

198010 HEATER TUBE QUARTZ, TOP, 208V 6

209195 HEATER TUBE METAL, BOTTOM, 208V 6

198011 HEATER TUBE QUARTZ, TOP, 240V 6

209196 HEATER TUBE METAL, BOTTOM, 240V 6

MOTOR CONTROL

FAN MOTOR

G

01/14/02 MJC

Page 13

H:\Y2KWDIAG\020259.dwg, 12/16/2003 02:50:40 PM

Y

E

L

L

O

W

Page 14

WIRE DIAGRAM

OPERATOR'S MANUAL

HOLMAN CONVEYOR BAKERS

MODEL MM14

PAGE 12

REVISED 7/9/01 MJC

Page 15

Page 16

MM14 & MM14-3 Parts

KEY

Serial Number Range

0801 to 0102 0999 to 0701

DESCRIPTION PART # QTY PART # QTY PART # QTY

0998 to 0899

1 COVER, TOP GE-402163 1 GE-402163 1 GE-402224 1

3 RETAINER, HEATER TUBE GE-402629 1 GE-402161 1 GE-402303 1

4 CONVEYOR BELT GD-160008 1 GD-160008 1 GD-160008 1

NS LINK, CONVEYOR BELT 2B-200624 EA 2B-200624 EA 2B-200624 EA

NS LINK, MASTER, CONVEYOR BELT 2B-200626 3 2B-200626 3 2B-200626 3

5 TUNNEL EXTENDER GE-100982 1 GE-100982 1 GE-100956 1

6 SHAFT, IDLER GE-101257 1 GE-101257 1 GE-101257 1

7 SHAFT, DRIVE GD-101252 1 GD-101252 1 GD-101252 1

BUSHING, REAR, FIXED

8

BUSHING, FRONT, NON-SPRING LOAD

8a

MOTOR, DRIVE (L-R)

9

MOTOR, DRIVE (R-L)

9

GB-112262 2 GB-112262 2 GB-112262 2

N/A N/A GB-112262 2 GB-112262 2

2U-200504 1 2U-200504 1 2U-200504 1

2U-200509 1 2U-200509 1 2U-200509 1

10 CHAIN, DRIVE (27") GD-150023 1 GD-150023 1 GD-150023 1

11 SPROCKET, DRIVE (25B24 X 5/16") 2P-200650 1 2P-200650 1 2P-200650 1

12 SPROCKET, DRIVEN (25B11 X 3/8") 2P-115362 1 2P-115362 1 2P-115362 1

13 SWITCH, FAN MOTOR 2E-200574 2 2E-200574 2 2E-200574 2

14 SWITCH, HIGH LIMIT RESET 2E-200566 1 2E-200566 1 2E-200566 1

15 MOTOR, FAN 2U-200561 1 2U-200561 1 2U-200561 1

16 COVER, CONTROL BOX GE-402635 1 GD-401636 1 GD-401636 1

17 GUARD, FAN MOTOR 2R-200562 1 2R-200562 1 2R-200562 1

18 SWITCH, SPEED CONTROL * GE-118064 1 GD-118060 1 GD-118060 1

19 LIGHT, PILOT 2J-200427 1 2J-200427 1 2J-200427 1

20 SWITCH, MASTER ON/OFF 2E-200552 1 2E-200552 1 2E-200552 1

21 KNOB, SPEED CONTROL 2R-200761 1 SP-115360 1 SP-115360 1

PANEL, CONTROL SIDE (L-R)

22

PANEL, CONTROL SIDE (R-L)

22a

PANEL, CORD SIDE (L-R)

23

PANEL, CORD SIDE (R-L)

23a

GE-402638 1 GE-402231 1 GE-402231 1

GE-402639 1 GE-402230 1 GE-402230 1

GE-402156 1 GE-402156 1 GE-402156 1

GE-402155 1 GE-402155 1 GE-402155 1

24 TRAY, CRUMB GE-100955 2 GE-100955 2 GE-100955 2

25 TRAY, LOAD-UP GE-402640 1 GE-100957 1 GE-100957 1

26 TRAY, UNLOAD GE-100944 1 GE-100978 1 GE-100978 1

27 LEG, 2 1/2" METAL 2R-200716 4 2R-200716 4 2R-200716 4

28 CONTACTOR, 40 AMP 2E-200573 1 2E-200573 1 2E-200573 1

29 PANEL, CONVEYOR EXTENSION GD-401206 2 GD-401206 2 GD-401206 2

30 * CONTROL, MOTOR BOARD ANACON * 2U-200579 1 N/A N/A N/A N/A

31 * BUSHING, FRONT, SPRING LOADED * 2P-200765 2 N/A N/A N/A N/A

32 * SPRING, CONVEYOR BUSHING * 2P-200766 2 N/A N/A N/A N/A

33 BLADE, FAN 3" 2R-200721 1 2R-200721 1 2R-200721 1

34 CORD, FAN MOTOR 2E-200387 1 2E-200387 1 2E-200387 1

35 LABEL, CONTROL PANEL 2M-200890 1 2M-200890 1 2M-200890 1

CORD, 10/3, NO PLUG

NS

GE-140062 1 GE-140062 1 GE-140062 1

NS TERMINAL BLOCK, 12 POS., LARGE 2E-200554 4 2E-200554 4 2E-200554 3

NS JUMPER, 12 POSITION, LARGE 2B-200557 3 2B-200557 3 2B-200557 3

NS TERMINAL BLOCK, MAIN POWER SP-115402 1 SP-115402 1 SP-115402 1

NS MAGNET, BAKE AID 2M-200816 1 2M-200816 1 2M-200816 1

NS BRACKET, BAKE AID MAGNET GE-402525 1 GE-402525 1 GE-402525 1

NS RACK, BELT SUPPORT GE-100713 1 GE-100713 1 GE-100713 1

KEY

208V Top Quartz (

2

208V Bottom Quartz (500W, 208V, 81.3 ohm)

2a

DESCRIPTION PART # QTY PART # QTY PART # QTY

198010=450W, 104V, 22.5 ohm)

Serial Number Range

HEATER TUBES

0998 to 0899 0999 to 0701 0801 to 0102

GE-198010 6 GE-198010 6 GE-198002 6

GE-198002 6 GE-198002 6 GE-198002 6

2b 208V Bottom Metal (cal-rod) 2N-209195 6 2N-209195 6 2N-209195 6

240V Top Quartz (

2c

240V Bottom Quartz (500W, 240V, 108.3 ohm)

2d

198011=450W, 120V, 30.10 ohm)

GE-198011 6 GE-198011 6 GE-198005 6

GE-198005 6 GE-198005 6 GE-198005 6

2e 240V Bottom Metal (cal-rod) 2N-209196 6 2N-209196 6 2N-209196 6

2c 220V Top Quartz ZZ-197884 6

2d 220V Bottom Metal (cal-rod) 2N-209196 6

* PART SECIFIC TO MM14-3

4/24/2006 RB

Loading...

Loading...