Page 1

HOLLYWOOD Deluxe Trailer Hitch Rack

R A C K S

www.hollywoodracks.com

Assembly and Installation instructions for model numbers:

Road Runner 3 Series

HR300 - 3-bike model for 2” receiver, class 2 or higher

HR310 - 3 bike model for 1 ¼” receiver, class 2 (maximum weight of bikes 150 lbs.)

HR320 - 3-bike model extended for 2” receiver, class 3 or higher

Road Runner 4 Series

HR400 – 4-bike model for 2” receiver, class 2 or higher

HR410 – 4 bike model for 1 ¼” receiver, class 2 (maximum weight of bikes 150 lbs.)

HR420 – 4-bike model extended for 2” receiver, class 3 or higher

Destination 5

HR520 – 5-bike model 2” receiver, class 3 or higher

WARNING! THIS PRODUCT IS NOTTO BE USED ON ANY TRAILER

PLEASE FOLLOW THESE IMPORTANT POINTS:

DRIVE SLOWLY WHEN USING THE RACK ON BUMPY OR DIRT ROADS.

CHECK THE RACK, BIKES AND STRAPS REGULARLY DURING USE.

IF YOU HAVE ANY QUESTIONS OR INSTALLATION PROBLEMS, PLEASE SEE YOUR

RETAILER OR CONTACT US AT 800 – 747- 4085.

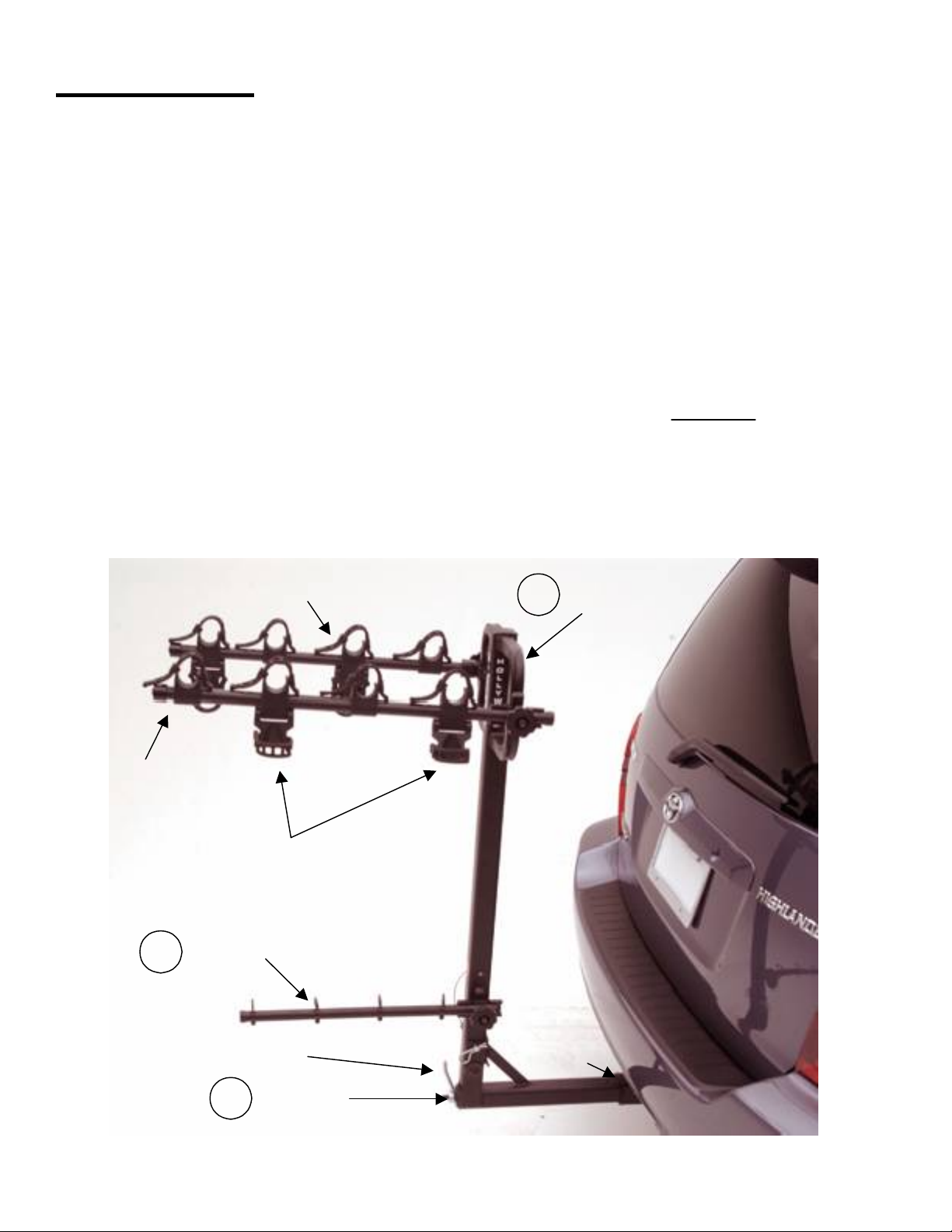

Bike Cradle with strap

Support Arm

Anti-sway Block

3 Lower brace

1 Upright Beam

No Wobble lever

2 Insert tube

Receiver

1

Page 2

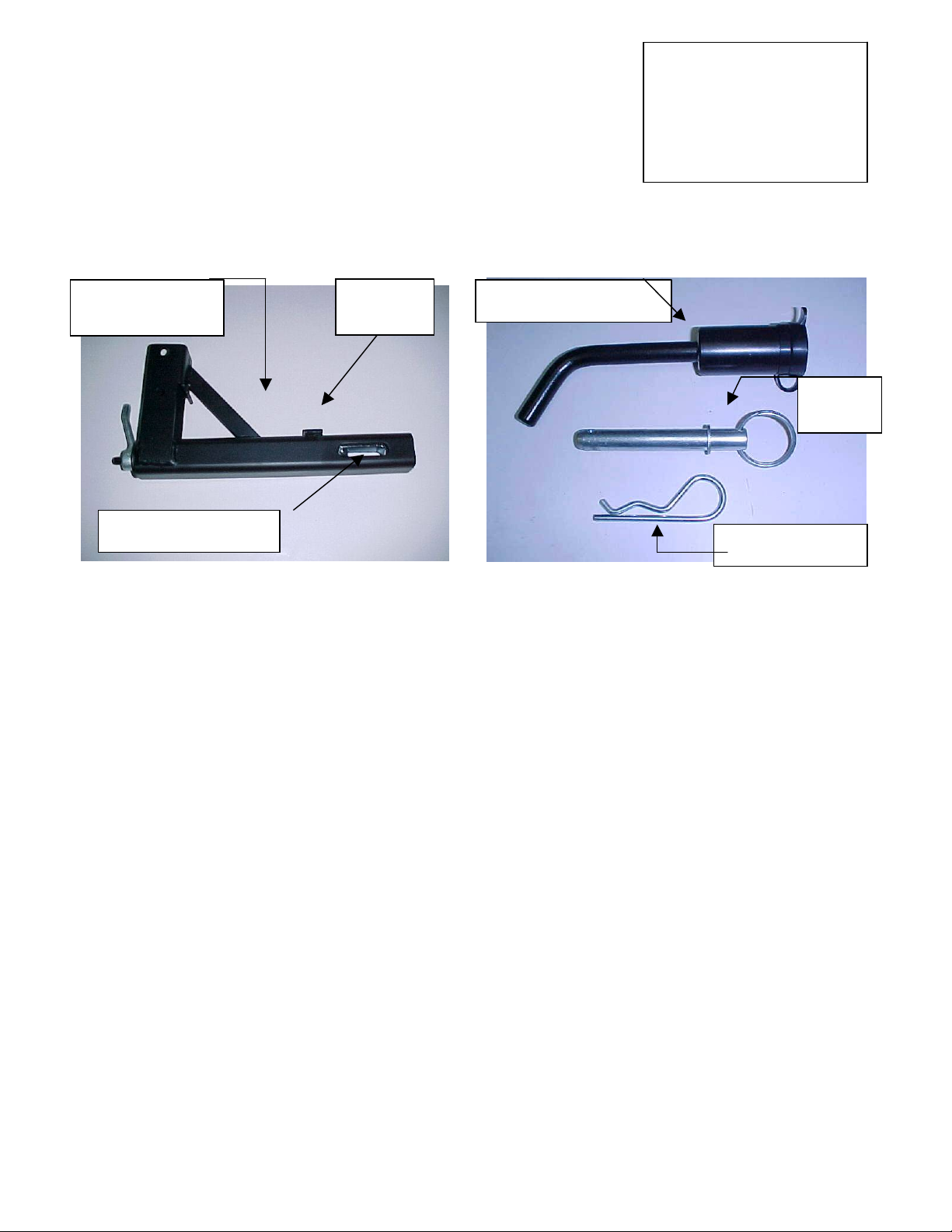

Lynch

Lynch Pin Clip

Insert tube

Welded

Strap Qty:

After opening the box, you should have the following parts:

1. Upright beam assembly with upper support arms installed.

2. Insert tube assembly with “no wobble” system and handle lever.

3. Lower (wheel) brace (straight bar with eyelets).

4. Parts bag including through bolt, washers and nut, lynch pin and clip.

5. Strap bag including, tie down straps (rubber straps and woven fabric straps).

6. Security cable with integrated lock, and Locking Hitch Pin.

Locking Hitch Pin

2” Size shown

No Wobble Loop

on stop

3 Bike: 9 Rubber, 4 nylon

4 bike: 12 Rubber, 5 nylon

5 bike: 15 rubber, 5 nylon

Pin

ASSEMBLY

Tools required for assembly: 6” adjustable wrench or equivalent.

1. The Road Runner rack is easily assembled on your workbench or any flat surface. To assemble the rack, lay

the upright beam face down on the bench (Hollywood decal facing down). Place the insert tube’s bracket on to

the end of the upright beam so that the insert tube is pointing up.

2. Place a washer on the end of the through bolt, then insert the bolt through the lower hole of this

bracket and pass it through the lower hole of the upright tube. We keep our hole tolerances fairly

tight, so you may have to wiggle it through. Once the bolt is protruding through the other side of the

bracket, install the other washer and nut. Tighten the nut securely on the bolt and use an adjustable wrench or

¾” wrench to tighten the nut and bolt. Insert the lynch pin through the upper hole, and install lynch pin clip in

hole at the end of the lynch pin.

3. To install the lower bike brace, place the carriage bolt through the main upright such that the threaded section

protrudes through the welded-on lower locator bracket. Slide the lower brace onto the carriage bolt and add the

small square channel section locator. Complete the installation by threading on the black knob and the low

profile nyloc-retaining nut. When the rack is in use, the lower brace should be a horizontal position, and set in

place by tightening the black knob. When the rack is not in use, the lower brace can be folded up, into the

vertical position, by loosening the knob, rotating the lower brace up (to a vertical position, parallel with the

main upright), and then retightening the knob.

2

Page 3

INSTALLING THE RACK ON YOUR VEHICLE:

careful not to

Anti

-

Anchor

Bicycle

Bike

1. Within the parts bag, please locate the Locking Hitch Pin. See Photo above.

2. When inserting the rack into the trailer hitch, try to get the insert tube as parallel to the receiver hitch as

possible, then slide the rack in a couple of inches until the welded on stop on the top of the insert tube meets the

outer flange (face) of your vehicle’s receiver.

3. Unlock the Locking Hitch Pin and insert the long end through the trailer hitch (receiver) and insert tube. Be

sure to install the lock onto the end of the Locking Hitch Pin. Failure to do so will result in an accident. Be

certain that the hitch pin goes through the “loop” at the end of the “no wobble” internal threaded rod. Failure to

do so will render the “No Wobble” system inoperable.

4. Tighten the lever clockwise to engage the patented “No Wobble” system, which will eliminate the

movement of the insert tube in the receiver. The lever should be turned “up” or to the side after tightening

to prevent it from being damaged in the case you have to descend a steep driveway or have some other

close encounter with “Solid Ground.” The rack should now be attached to your vehicle, and locked into place.

INSTALLING BIKES ON THE RACK:

1. Back off the knob on the rack’s support arms, pull out the support arms and rotate them into the

horizontal position. Retighten the knobs securely. Rotate lower brace to its horizontal position,

and retighten lower black knob. All knobs should be snug, but do not over-tighten.

2. For ease of installation, we suggest you put the bigger bikes on the inside (closest to vehicle), smaller frames

or kids bikes on the outside. The first bike loaded should have the handlebars facing towards the driver’s side of

the vehicle. For the five-bike rack, the bike between the vehicle and the rack goes on first. Place the top tube

(or closest appropriate frame tube) onto the bike cradles, install the straps over the bike tube and attach to the

anchor tabs on both sides of the cradle. Use a strap notch-hole that provides a snug fit, but take care not to pull

the strap over-tight. This can put undue stress on the bike’s paint, and may over-stretch the strap, making it

more susceptible to breakage. Be sure to use the Anti-Sway blocks (below the support arms) to strap the bikes

seat tube (or other frame tube as appropriate) to prevent the bikes from swaying on the Road Runner rack.

Note photos below for correct application of the straps on the anti-sway blocks.

Note:

Sway

Block

Use Antisway

blocks to

keep bikes

stable while

vehicle is in

Seat

Tube

motion. Be

over-stress

Tab

the straps!

Strap

3

Page 4

3. Installing “wrap around tie down,” and security cable: After all the bikes have been installed, take

the 86” tie down strap and wrap it around the rack’s upright tube and all of the bikes. There is not a lot of room,

but this is a very important safety step. Tighten this strap securely.

4. Anti – Theft Security

For anti-theft security, the rack comes with a locking hitch pin and a 9-foot cable with an integrated lock.

Wrap the cable around the bike frames, their wheels and through the rack. Secure by inserting end of cable in

the lock.

REMOVING THE BIKES AND RACK

To remove the bikes, simply undo the straps and gently lift the bikes off. If you’re in a parking lot, be sure

to fold down the support arms and fold up the wheel brace so as to minimize the length of the rack when not in

use. To remove the rack from the vehicle, fold the support arms and lower brace, and remove the Locking Hitch

Pin. Unscrew (counter-clockwise) the “no wobble” lever and slide the rack out of the hitch receiver.

BACKING OUT OF DRIVEWAYS AND GOING OVER BUMPS

Please keep in mind that when transporting bikes, you will be carrying more weight on your hitch. This means

the rear of your vehicle will be lower to the ground. When going up driveways or over bumps, drive slowly and

at an angle if possible. If you have a car or minivan where the hitch is low to the ground, the rack may hit the

ground. Go slowly and please be sure the handle lever for the no wobble system is turned up or to the side.

Limited One Year Warranty: This rack is warranted for a period of one year against defects in materials and

workmanship, effective from the date of purchase to the original purchaser. The manufacturer will repair or

replace any defective parts due to materials or workmanship. The manufacturer of this product shall not extend

the warranty to 1) Any failure or malfunction of the product due to any modification to the product; or 2.)

Damages not attributable to a defect in materials or workmanship; or 3.) Damages resulting from improper

installation on the vehicle or attachment of bicycles on rack. Consequential or Incidental Damages: The

manufacturer shall not be liable for any consequential or incidental damages in connection with the purchase,

use or handling of this bike rack. Purchaser’s Rights: Some states do not allow the exclusion or limitation of

consequential or incidental damages and the above limitation may not apply to you. This warranty gives you

specific legal rights and you have other rights, which vary from state to state.

Hollywood Racks

12812 S spring St. Los Angeles, CA 90061

(800) 747-4085 or (310) 516-8600 FAX (310) 516-8955

Made In Taiwan

www.hollywoodracks.com info@hollywoodracks.com

customer service: M-F 8:00AM to 3:00 PM PST

022608 rev c

4

Page 5

5

Loading...

Loading...