Page 1

Forward Optical Receiver

CATV OPTICAL RECEIVER

Operation Manual

Operation Manual

Ver. A1

- 1 -

Page 2

Forward Optical Receiver

Operation Manual

TABLE OF CONTENTS

TABLE OF CONTENTS ....................................................................................................2

Chapter 1 Introduction......................................... .............................................................3

Chapter 2 Installation................................................... .....................................................8

Chapter 3 Operating Instruction.....................................................................................10

Chapter 4 LCD Display and Operation Procedure.........................................................13

Chapter 5 Status Monitoring and communication interface...........................................17

Chapter 6 Maintenance and Repair ................................................ ...............................20

- 2 -

Page 3

Forward Optical Receiver

Operation Manual

Chapter 1 Introduction

Overview

The CATV fiber optic receiver uses a high linear InGaAs PIN diode as light detector, converting the optical

signal from transmitter into RF signals. The RF signals are then distributed to the end users. There are two

front-end opt ical rece ivers in th e units, and s hare the sam e RF signal am plifier, two receiv ers could prov ide

redundancy function in network. The main applications are as follows:

• Head-end broadcasting

• Head-end to head-end program exchange

• Transmission of video and sound through Hybrid Fiber Coaxial (HFC) networks

In order to achieve maximum performance and confidence by the customer, we detail the characteristics,

applications, and operating instructions in the following chapters. We expect to satisfy the needs of the

customer and provide quality service.

Features

19” 1U height standard enclosure, front LCD display

45 ~750/860 MHz bandwidth

Redundancy A/B switch receiver

Automatic Gain Control / Manual Gain Control

Microprocessor control & Monitoring

RS232/RS485 control interface

High performance value

+1dB ~-3dB Range Adjustable Slope

- 3 -

Page 4

r

Forward Optical Receiver

Operation Manual

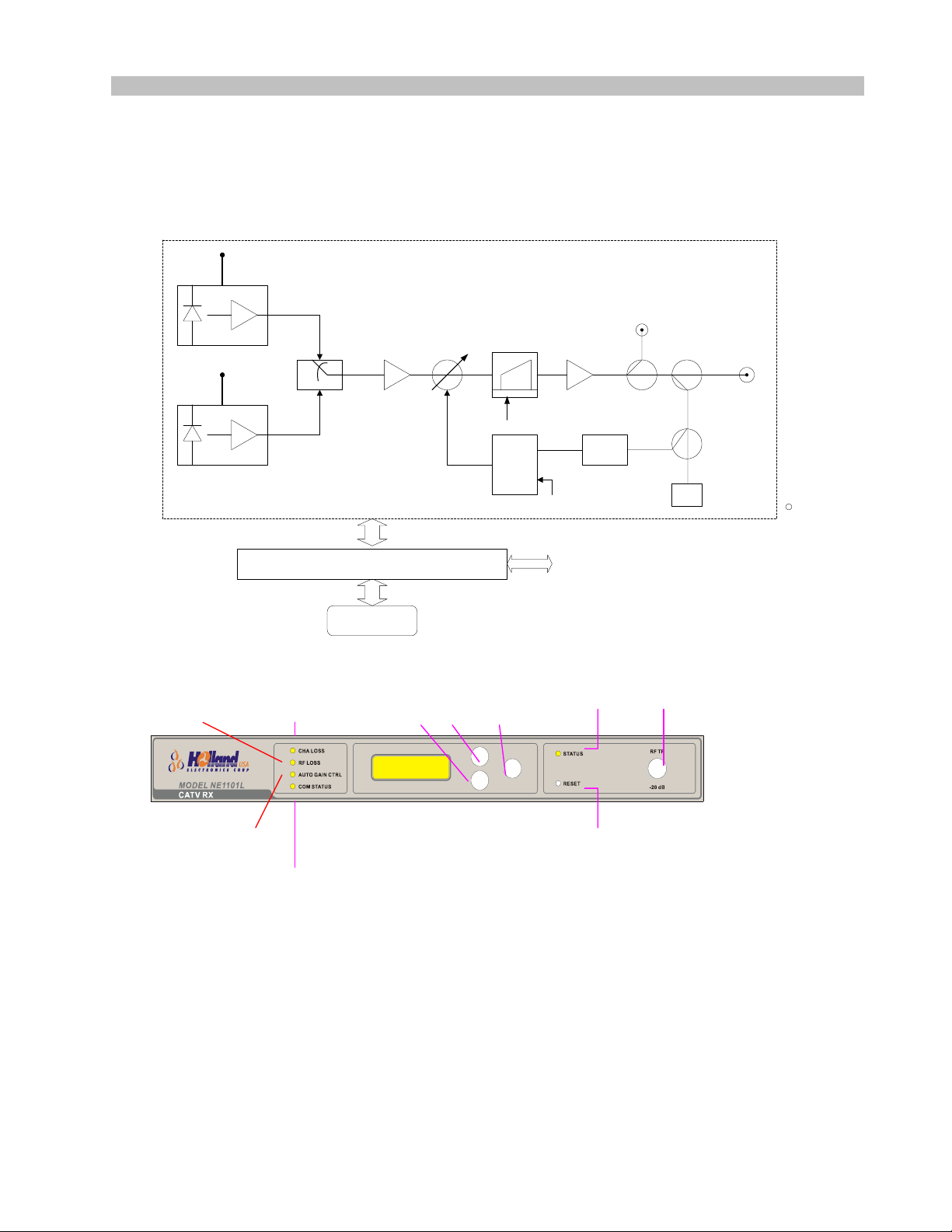

Product Description

FRx Block Diagram

FRx Function Block Diagram

PD_A

monitor

Rx_A

Rx_B

Front Panel

RF loss

PD_B

monitor

Ch A Loss

RF

Amp

u-controller

LCD

Button Button Button

Attenuator Slope

Slope

CTL

S

RF

Amp

Pilot Tone Detect

AGC

Communication

TP -20dB

RS485

Powe

RF

Output

RF Level

RF MONITOR

Auto Gain Ctrl

Reset

Com Status

- 4 -

Page 5

p

A

Forward Optical Receiver

Indicator/Control Description

Power

Ch A Loss

RF Loss RF signal power less than RF power threshold.

Auto Gain Ctrl

Com Status

Button Rest Reset System, Note: it will restart all system.

Button UP Scroll up

Button DN Scroll up

Button ENT Select highl ighted item on LCD display

RF MONITOR

–20dB

Operation Manual

Main power indicator

Green – AC Power On

OFF -- AC Power OFF

Ch A Optical Power

OFF – Optical input power > Channel A optical power low

threshold

RED Flashing – A port Optical input < Ch annel A optical power low

threshold

Displays status of the gain control mode

GREEN – AGC mode

OFF – MGC mode

Displays status of RS485 or RS232 connection

GREEN – Data transmit or received

F-type female connector, Monitoring output port signal, Measured

value is 20 dB below actual value. Accuracy to ±1 dB.

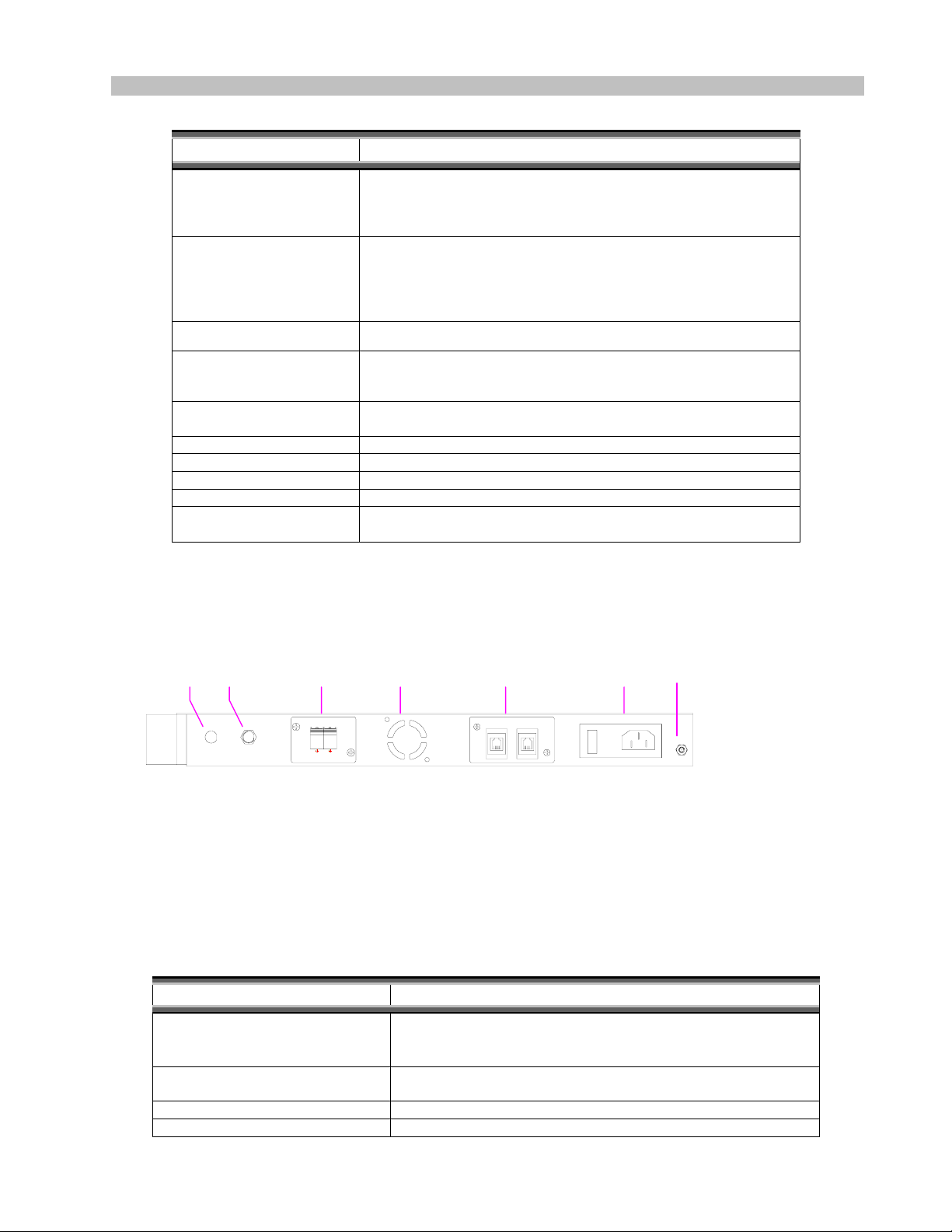

Rear Panel

Dummy

Hole

AC Power In(ON/OFF Switch,

Plug, Fuse)

RS-485 Interface

Dummy FAN Hole

A/B Port Optical Input

Dummy

FAN

Hole

RS485

Interfac

RS-485

AC

Power In

90V~220V 50/60Hz

FUSE 3.15A

ON

OFF

Groundin

g spacer

RF

Output

/B

Port

Optical

OPTICAL

BA

Connector/Control Description

AC power plug and main power switch. Fuse is rated 250V、

3.15A. For inspection or replacement, press down on the fuse

cap and turn to loosen.

Provides connection to an external computer through RS-485 for

monitoring and configuration setup purposes

Dummy: Not used in this type

tical Input connectors are SC/APC type. For connection, use

O

- 5 -

Page 6

Forward Optical Receiver

RF Output

Dummy Hole

Operation Manual

same type of connector.

RF signal Output Port; 75Ω F type female connector

Dummy: Not used in this type

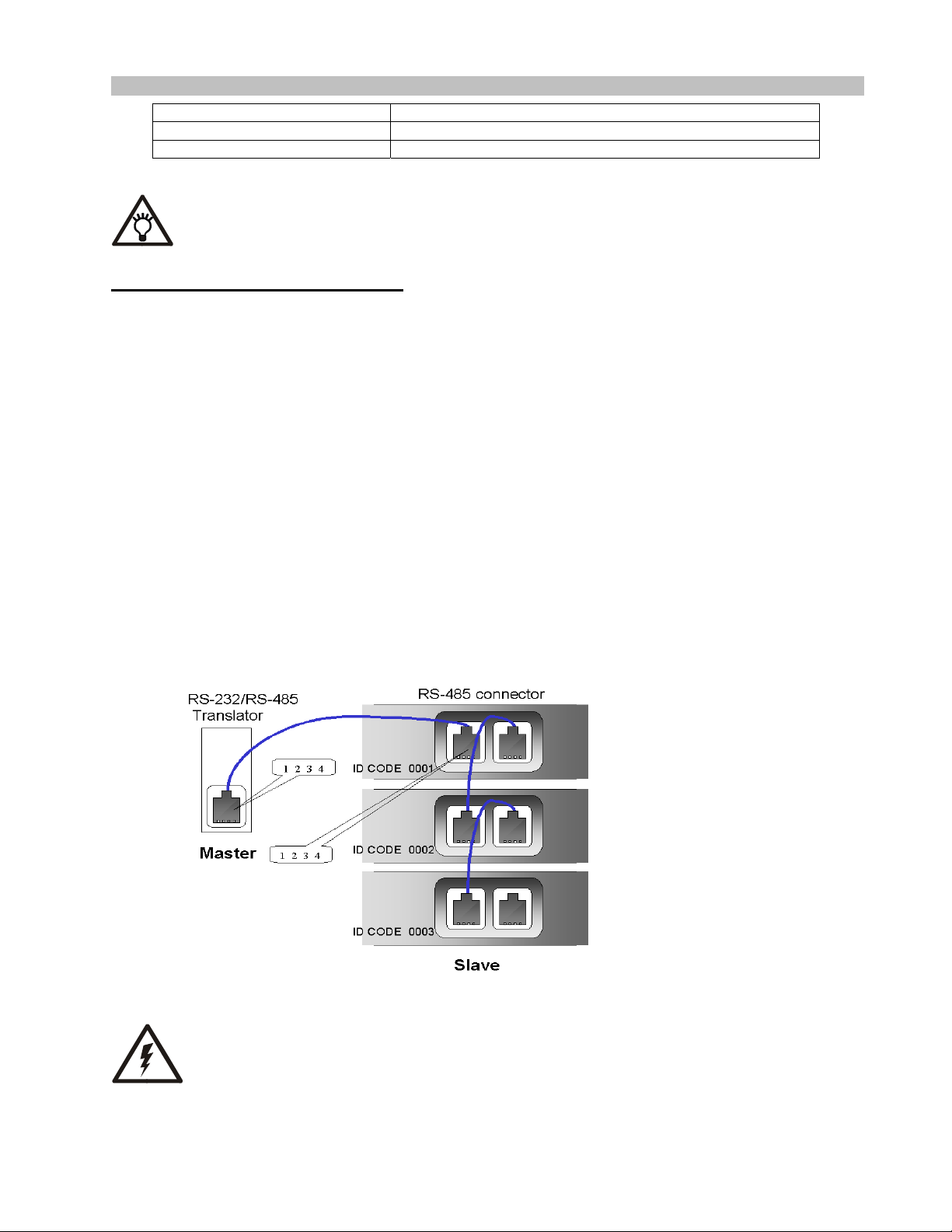

RS-485Interface Pin Definition

This RS-485 is full duplex type, so master and slave pin assignment is not the sa me. The connector definition

should be as following.

Master:(PC side)

1、 Receive+

2、 Receive3、 Transmit4、 Transmit+

Slave:(TX side)

1、 Transmit+

2、 Transmit3、 Receive4、 Receive+

Please make sure AC power is off when replacing new fuse.

- 6 -

Page 7

Forward Optical Receiver

Operation Manual

Mechanical Information

OPTICAL

BA

RS-485

90V~220V 50/60Hz

FUSE 3.15A

ON

OFF

- 7 -

Page 8

Forward Optical Receiver

Operation Manual

Chapter 2 Installation Procedure

Checklist

Parts Qty

Hanger 1 set

AC power cord 1

Installation

The following are procedures to be followed in the installation of Rack Mount Forward Receiver(called as FRx in the

following description):

1. Before installing the FRx, check to make sure that enough space is provided for air circulation especially in the

Heat Sink portion of th e FRx.

2. Check the power plug of the supply and proper grounding to avoid damage to the FRx.

3. Conn ect the AC power cord.

4. Connect the 「RF Output」 coaxial cable.

5. Lift the eye-safety shutter from the rear panel 「Optical Input」 fiber connector, and connect the jumper optical fiber.

Before connection, clean the connector and make sure that the connector type is SC/APC.

6. Ch A Port of Optical input port is recommended as the Main loop. And use the Ch B Port as Backup loop.

Caution: Direct eye exposure to laser beam may cause physical damage,

- 8 -

Page 9

Forward Optical Receiver

Operation Manual

Cleaning Fiber Connectors

1. Use a lint-free cloth (3 cm x 3 cm)

2. Moisten one-half of the lint-free cloth with >90% pure ethyl or alcohol, and gently wipe the connector end face

3. Use the other half of the lint-free cloth to gently wipe the connector end face, then rapidly shake the connector

4. Wait until dry to insert connector into the adapter

5. Caution: do not use any compressed air to directly blow onto the connector end face to avoid damage by dust

particles

Caution: Direct eye exposure to laser beam may cause physical damag e.

- 9 -

Page 10

Forward Optical Receiver

Operation Manual

Chapter 3 Operation Procedure

The following are procedures for the normal operation of t he FRx :

1) Switch the AC Power switch located on the rear panel to the ON position; the LED indicator for [POWER] on the

front panel will light up to indicate AC Power is connected.

2) Inspect the front panel [Ch A Loss] LED indicator.

Operation range of optical input power is from –6dBm to +3dBm , when the optical power large than –3dBm ,

the Output RF level could reach the default output level 96dBuV per channel when 77 channel load and

OMI=3.6%.

Under normal conditions, the LED should be off.

A flashing red light indicated abnormal Optical operation that can be caused by:

a) Ch A Optical Input Power lower than optical loss threshold.

b) Receiver module inside of the FRx work abnormally.

3) Inspect the [RF Loss] LED indicator.

Under normal conditions, the LED should be off.

A flashing red light indicates abnormal RF Output conditions, usually low output signal level.

4) Inspect the [Auto Gain Ctrl] LED indicator.

OFF: Operating in MGC Mode

Green: Operating in AGC Mode

Note: 1.There is two modes on AGC operation, one is detect Pilot signal, and

other is composite RF power feedback control. Before operation, please

select the AGC mode on “SETTING” menu.

2.Pilot tone mode used with Pilot Tone 10.7MHz ±100KHz coming from the

Trans mitt er. If there is no this feature in transmitter, please select RF

AGC or MGC control mode.

5) Check Optical Input Power in the LCD panel, 0 dBm is recommended.

6) Adjust the RF output level by using the front panel [SETTING] page. RF power operate in 96dBuV per channel

when 77 channel which have flat frequency response , if Channel number is higher , user could operate

level per channel .Keep the total composite power to maintain the distortion performance .

- 10 -

lower RF

Page 11

Forward Optical Receiver

Operation Manual

Note: RF output adjusting please refer the following page [LCD/LED Display User

Interface].

7) Adjust RF output slope to compensate the network loss in higher frequency.

- 11 -

Page 12

Forward Optical Receiver

Operation Manual

Chapter 4 LCD Display and Operation Procedure

LCD/LED Display User Interface

(LCD: Scrolling M enu)

OPT CHA 0.50 mW

OPT CHB 3.50 mW

RF LVL + 0.02 dB

GAIN CTRL LVL 2.5V

12V CURRENT 1.5 A

24V CURRENT 2.1 A

ENT

OPT CHA 05.0 mW

OPT CHB 05.0 mW

ENT

RECEIVER ST A TUS

RECEIVER SETTINGS

RECEIVER ALARMS

Up

RETURN TO MAIN MENU

RECEIVER STATUS

RECEIVER SETTINGS

RECEIVER ALARMS

RETURN TO MAIN MENU

RECEIVER STATUS

RECEIVER SETTINGS

RECEIVER ALARMS

RETURN TO MAIN MENU

RECEIVER STATUS

RECEIVER SETTINGS

Dn

RECEIVER ALARMS

RETURN TO MAIN MENU

24V DC 23.9 V

12V DC 11.9 V

Forward Rx

Forward Rx

FIBER OPTI C

FIBER OPTI C

RECEIVER

RECEIVER

TURN TO MENU

ENT

Dn

Up

Dn

Up

Dn

Up

ENT

ENT

ENT

ENT

ENT

1. MSG#1 is displayed for no alarm

2. Automatic switch to this screen wh en al arm occurs

3. Table 1 shows messages for various alarm events

5V DC 5.0 V

ID CODE 0A21

FIRMWARE VER 1.01

ENT

RETURN TO PREV. MENU

Dn

Dn

GAIN CONTROL = AGC

AGC MODE = RF

GAIN LV L SET. = 1 68

SLOPE LVL SET. = 66

CHA THRESHOLD = 020

CHB THRESHOLD = 015

SHOW CHB ALARM= NO

OPT LVL UNIT = dBm

SWITCH MODE =MANU

OPT CHANNEL = CHB

FACTORY PRESET

RETURN TO PREV. MENU

ALARM MESSAGE

ENT RETURN TO PREV. MENU

Please note:

due to space constraint of LCD screen, some words are abbreviated.

Such as: LVL – LEVEL , VER – VERS ION , PREV. – PREVIOUS ,SET. – SETTING

OPT – OPTICAL , CHA - CHANNEL A , CHB - CHANNEL B

Up

Up

UpDn

TX ALARMS (M9)

ENT

ENT

AGC

MGC

SELECT ENTRETURN

(AGC MODE)

GAIN LVL SET. = 168

ADJUST ENT RETURN

SLOPE LVL SET.= 66

ADJUST ENT RETURN

CHA THRESHOLD = 01 5

ADJUST ENT RETU R N

CHB THRESHOLD = 015

ADJUST ENT RETURN

YES

NO

SELECT ENT RETURN

mW

dBm

SELECT ENT RETURN

AUTO

MANUAL

SELECT ENT RETURN

CHA

CHB

SELECT EN T RETURN

ALL SETTINGS TO

FACTORY PRESET

YES

NO

SELECT EN T RETURN

GAIN CONTRO L

GAIN LEVEL SET TING

(AGC MODE OR MGC MODE )

SLOPE LEVEL SETT ING

(AGC MODE OR MGC MODE )

CHA THRESHOLD SETTING

CHB THRESHOLD SETTING

CONTROL CHB ALARM SETTING

SETTING OPTICAL POWER UNIT

SWITCHING MOD E

OPTICAL CHANNEL SELECT

(APP E AR ONL Y IF A/B SW. MODE IS IN ‘MANU AL’ MODE’)

FACTORY PRE S ET

Forward Rx

BUTTONS

ENT

AGC MODE

RF LEVEL

PILOT LEVEL

SELECT ENTR ETURN

(RANGE= 0 ~ 255)

(RANGE= 0 ~ 255)

(RANGE= 0 ~ 255)

(RANGE= 0 ~ 255)

▲ ▼

LCD Display Contents & Operation

1、Main Screen

When the Receiver Power on, it will be on th e main screen. Dur ing system operation, the displayed information w ill be

renewed continuously, to get more detailed information press ENT to access the MAIN MENU.

Display Item Description

Optical Ch A xxmW Receiver A input optical power

Optical Ch B xxmW Receiver B input optical power

- 12 -

Page 13

Forward Optical Receiver

Operation Manual

2

Main Selection Screen

、

At the main screen press the ENT key to ent er into the [MAIN MENU], then use the UP/DOWN keys to select the

following options:

Option Description

STATUS Present status of the Receiver

SETTINGS Settings screen

ALARMS Alarms screen

Return to Main Menu Return to main screen

3. STATUS selecti on screen

Selection Description

Optical A Receiver A input optical power

Optical B Receiver B input optical power

RF level Displays RF output level that relative to reference level.

Gain control level

Power Supply

Operating

Information

Displays Voltage control attenuator voltage, the upper bond would be 9.5V. The

Voltage higher means attenuation loss is lower.

Displays 12VDC supply, +5VDC current supply and -5VDC current supply

Displays software version and other reference information

4. SETTINGS selection screen

Selection Function Description

- 13 -

Page 14

Forward Optical Receiver

Gain Control Gain Control Select AGC or MGC

AGC mode Select RF AGC or Pilot tone AGC

AGC Level Automatic Gain Control Level Adjust AGC reference level

MGC Level Manual Gain Control Adjust MGC reference level

Slope level RF response slope control Adjust Slope from –1dB to +3dB.

CH A threshold

CH B threshold

Show CH B alarm CH B optical power alarm active

LD PWR UNIT OPTICAL POWER UNIT SELECT mW or dBm

Switch mode A/B switch mode

Operation Manual

There are two AGC mode could be

selected, one is pilot tone AGC, it could

detect the 10.7MHz pilot signal from

transmitter, and feedback control

attenuator, other is RF AGC, it detect

composite power of output RF signal

feedback control.

Adjust CH A optical power threshold. If

CH A optical power low threshold

setting

CH B optical power low threshold

setting

optical power lower than setting value, it

would trigger alarm and A/B switch select

B channel, if A/B switch active.

Adjust CH B optical power threshold. If

optical power lower than setting value, it

would trigger alarm.

Enable CH B optical power alarm trigger

active. If there is no optical Connect to

Channel B, select “No”.

Select A/B switch is automatic switch or

manual switch, if Automatic switch, it

would detect Channel A optical power, if

the power lower than threshold, the switch

would be selected to Channel B.

FACTORY

PRESET

SETTING TO FACTORY PRESET YES or NO

Note:

Factory preset will recall all original setting value, like AGC /MGC, in memory.

5. ALARMS selection screen

Selection Description

ALARM

MESSAGE

When there is an alarm, the LCD display will automatically display this selection.

If there is no alarm, the display will show the message “NO ALARM”

- 14 -

Page 15

Forward Optical Receiver

Operation Manual

TABLE 1

MSG# ALARM MESSAGE

MSG# ALARM MESSAGE

1 NO ALARM

1 NO ALARM

2 CHA LOSS OF OPTICAL POWER

2 CHA LOSS OF OPTICAL POWER

3 CHB LOSS OF OPTICAL POWE R

3 CHB LOSS OF OPTICAL POWE R

4 LOSS OF RF SIGNAL

4 LOSS OF RF SIGNAL

5 LOSS OF PILOT TONE

5 LOSS OF PILOT TONE

6 24VDC VOLTAGE ALARM

6 24VDC VOLTAGE ALARM

7 12VDC VOLTAGE ALARM

7 12VDC VOLTAGE ALARM

8 5VDC VOLTAGE ALARM

8 5VDC VOLTAGE ALARM

TABLE 3

TABLE 2

LED# COLOR FUNCTION LED ON WHEN...

1

OFF/RED_FLASH

2

OFF/RED_FLASH

3

GREEN/RED

4

GREEN/OFF

5

GREEN/RED

RF IN ALARM

CHA LOSS

AUTO GAIN CTRL

COM PORT

STATUS

See TABLE 3

See TABLE 3

AGC – GREEN , MGC – RED

Transmitting Data via RS232/RS485 Port

See TABLE 3

When any of the following alarm event occurs, the LCD display switch immediately to the M9 screen

Event Condition MSG# LED#

NO ALARM 1

CHA LOSS OF OPTICAL POWER X< MIN_OPTICAL_LEVEL 2 2

CHB LOSS OF OPTICAL POWER X< MIN_ OPTICAL _LEVEL 3 5

LOSS OF RF SIGNAL X<MIN_ RF _LEVEL 4 1

LOSS OF PILOT TONE X<MIN_ PILOT _LEVEL 5 5

24VDC VOLTAGE ALARM X< MIN_24VDC OR X>MAX_24VDC 6 5

12VDC VOLTAGE ALARM X< MIN_12VDC OR X>MAX_12VDC 7 5

5VDC VOLTAGE ALARM X< MIN_5VDC OR X>MAX_5VDC 8 5

- 15 -

Page 16

Forward Optical Receiver

Operation Manual

Chapter 5 Status monitoring and communication interface

RS-485/RS-232 Commands

Table 1 below summarizes the commands available through the serial interface, and specifies the command

message formats. The responses to different commands from the unit are given in the tables 2 through 5.

Please note that commands must be issued in CAPITAL LETTERS.

Command

Type

S Return Status in LCD display format AT: xxxx0S

A Return Alarm Information

In LCD display format

B Return Status in binary format

C Return Alarm Information

In binary format

Note: The notation “xxxx” is the unit’s ID expressed in four hexadecimal characters. The MSB comes first and

LSB follows last. In case when the ID is not known, “FFFF” can be used in its place. Since any unit would

respond to this kind of “address-all” message, it is necessary to limit the reach of this address-all command to

one and only one unit. The “xxxx” is followed by a zero and command type character.

The whole command string should be terminated with a Carry-Return code (0x0D in hexadecimal).

Command Description

(See note)

AT: xxxx0A See Table 3

AT: xxxx0B See Table 4

AT: xxxx0C See Table 5

To unit

See Table 2

From unit

TABLE 1: Command List

The following table defines the response S format.

Each line is ended with one set of <Carriage Return> and <Line Feed>. The whole message block is

terminated with TWO sets of <CR> and <LF> characters.

- 16 -

Page 17

Forward Optical Receiver

Operation Manual

Line

#

(Column 1 – 16)

1 OPT CHA dd.d mW and dBm

2 OPT CHB dd.d mW and dBm

3 RF LVL +dd.d dB

4 GAIN CTRL LVL dd.d V

5 12V CURRENT dd.d A

6 24V CURRENT dd.d A

7 24V DC dd.d V

8 12V DC dd.d V

9 5V DC dd.d V

10 ID CODE FFFF

11 FIRMWARE VER d.dd

12 <CR><LF><CR><LF>

Note1: In normal conditi on, the alarm indicator field should remain blank.

Any “A” in the field indicates the associated value is in alarm condition.

In shutdown mode, the data in line 1 through 9 are invalid.

Note2:

And for a single pump model, all pump2 entries are skipped.

Note3: ID CODE display FFFF for Hexadecimal.

The following table defines all types of alarm message used in the response A. One line of alarm text

will be returned for each type of existing alarm(s) in the unit. Each line is ended with one set of

<Carriage Return> and <Line Feed>, and the whole message block is terminated with TWO set of

<CR><LF>.

Alarm

#

1 NO ALARM

2 CHA LOSS OF OPTICAL POWER

3 CHB LOSS OF OPTICAL POWER

4 LOSS OF RF SIGNAL

5 LOSS OF PILOT TONE

6 24VDC VOLTAGE ALARM

7 12VDC VOLTAGE ALARM

8 5VDC VOLTAGE ALARM

9 24VDC CURRENT ALARM

10 12VDC CURRENT ALARM

Heading

TABLE 2: Response to Command S

Alarm Text

(column 1-50)

TABLE 3: Response to Command A

Alarm

Indicator

(note*)

(column

17-19)

Value

Display

Format

(column

20-30)

Remark

Unit

(column

31-33

The following table defines the response B format.

Byte

#

0 <C0> Leading marker

1 OPT CHA 1 = 0.02 mW Range: 0 – 255

2 OPT CHB 1 = 0.02 mW Range: 0 – 255

3 RF LVL Scalar 1=0.1dB Range: (nagtive99) to 99

4 GAIN CTRL LVL 128 = 10 V Range: 0 – 255

Content

Translation

formula

(C0 in hexadecimal)

- 17 -

Remark

Page 18

Forward Optical Receiver

5 12V CURRENT 255 = 10A Range: 0 – 255

6 24V CURRENT 255 = 10A Range: 0 – 255

7 24V DC 102 = 24V Range: 0 – 255

8 12V DC 102 = 12 V Range: 0 – 255

9 5V DC 102 = 5 V Range: 0 – 255

10 Firmware version, major Binary (0-255) Major revision number

11 Firmware version, minor Binary (0-255) Minor revision number

12–

(reserved)

17

18 <C1> Trailing Marker

Operation Manual

(equivalent to the first digit in

display format)

(equivalent to the last two digits in

display format)

(C1 in Hexadecimal)

TABLE 4: Response to Command B

The following table defines the response D format.

Byte

#

0 <C0> Leading

1 Channel A Optical Level status B0: Loss channel A optical level alarm

2 Channel B Optical Level status B0: Loss channel A optical level alarm

3 RF level Status B 0: Loss RF signal alarm

4 Pilot Tone Status B0: Loss Pilot alarm

5 24V DC Supply Status B0: 24V DC Voltage alarm

6 12V DC Supply Status B0:12V DC Voltage alarm

7 5V DC Supply Status B0: 5V DC Voltage alarm

8 CURRENT (24V) B0: 24V Current alarm

9 CURRENT (12V) B0: 12V Current alarm

10-17 (reserved)

18 <C1> Trailing Marker,

Note: 1. B0 = bit 0 (the LSB), B1 = bit 1, B2 = bit 2

2. Bit set = alarm, bit clear = no alarm

Description

TABLE 5: Response for Command C

Bit Definition

(note)

Remark

Marker, in

hexadecimal

in hexadecimal

- 18 -

Page 19

4

Forward Optical Receiver

Operation Manual

Chapter 6 Maintenance and Repair

Problem Repair Procedure

POWER LED does not light,

and the receiver does not

work

Output power level too low 1) Inspect the connector; be sure to use the same type of connector (SC/APC or

1) Inspect the rear panel AC POWER switch, make sure the switch is set to the [ON]

position.

2) Inspect the physical condition of the AC POWER socket

3) Inspect the AC power cord, replace with new cord if damaged.

4) Inspect the AC fuse, if necessary replace with a new fuse with rating of 250V/3.15A.

Do not use fuse with any other rating.

SC/PC).

2) Clean carefully the end face of the connector.

3) Check the AC supply voltage. If below 90 VAC, then the output power level will be

below preset value

) Open the connector panel; remove the internal connector, carefully clean the end

face, then reinstall into the connector panel.

Displayed video signal

deteriorates, excessive noise

present

AGC function not work 1) Check the Pilot tone level, if the pilot is lower than normal, select MGC or RF AGC

As above, handle fibers with care.

mode

- 19 -

Loading...

Loading...