Holland XL-FW208-06 User Manual

STATIONARY

KOMPENSATOR

®

XL-FW208-06 1

MAINTENANCE PROCEDURES

NOTE:

The maintenance procedures contained in this manual apply mainly to the Kompensator®base subassembly portion of

the fifth wheel assembly. Additional procedures beyond those discussed in this manual are required for the fifth wheel

top plate. Contact your nearest Holland distributor for the appropriate additional information.

Failure to read, understand and follow the important information contained herein may

result in a hazardous condition or cause a hazardous condition to develop.

All maintenance must be performed by a qualified person using proper tools and safe

procedures.

All maintenance must be performed while the tractor is uncoupled from the trailer.

MAINTENANCE

INSTRUCTIONS

Stationary Kompensator®for

FW8-77XX Series

FW35-77XX Series

FW7040-77XX Series

FW2040-77XX Series (obsolete)

FW3540-77XX Series (obsolete)

All of the following must be performed after the

initial 5,000 miles of service and then every 60,000

miles or 6 months, whichever comes first.

Perform all inspections and adjustments

after a thorough steam cleaning.

NOTE: Severe service applications may require

more frequent intervals.

1. Inspection – General

A. Inspect the fifth wheel mounting. Check

bolt torque and replace any loose,

missing, or damaged bolts. Check for

broken, distorted, or cracked components.

Repair or replace as needed.

B. Inspect fifth wheel top plate and

Kompensator assembly for bent, worn,

cracked, or broken parts. Replace with

HOLLAND parts only. (See Figure 2.)

2. Fifth Wheel Locking Mechanism: Measure

Fore-Aft Movement.

A. Test the operation of the fifth wheel locking

mechanism using a Holland TF-TLN-5001,

2˝ Kingpin or TF-TLN-1500, 31/2˝ Kingpin

Lock Tester. Inspect for proper locking.

AS-NEEDED LUBRICATION

The following should be performed before putting into

use and then at least once per week or more

frequently as required by operating conditions.

Perform the following steps while in the uncoupled

condition to allow correct application of lubricant.

While lifting up on the fifth wheel top plate, apply

grease to the:

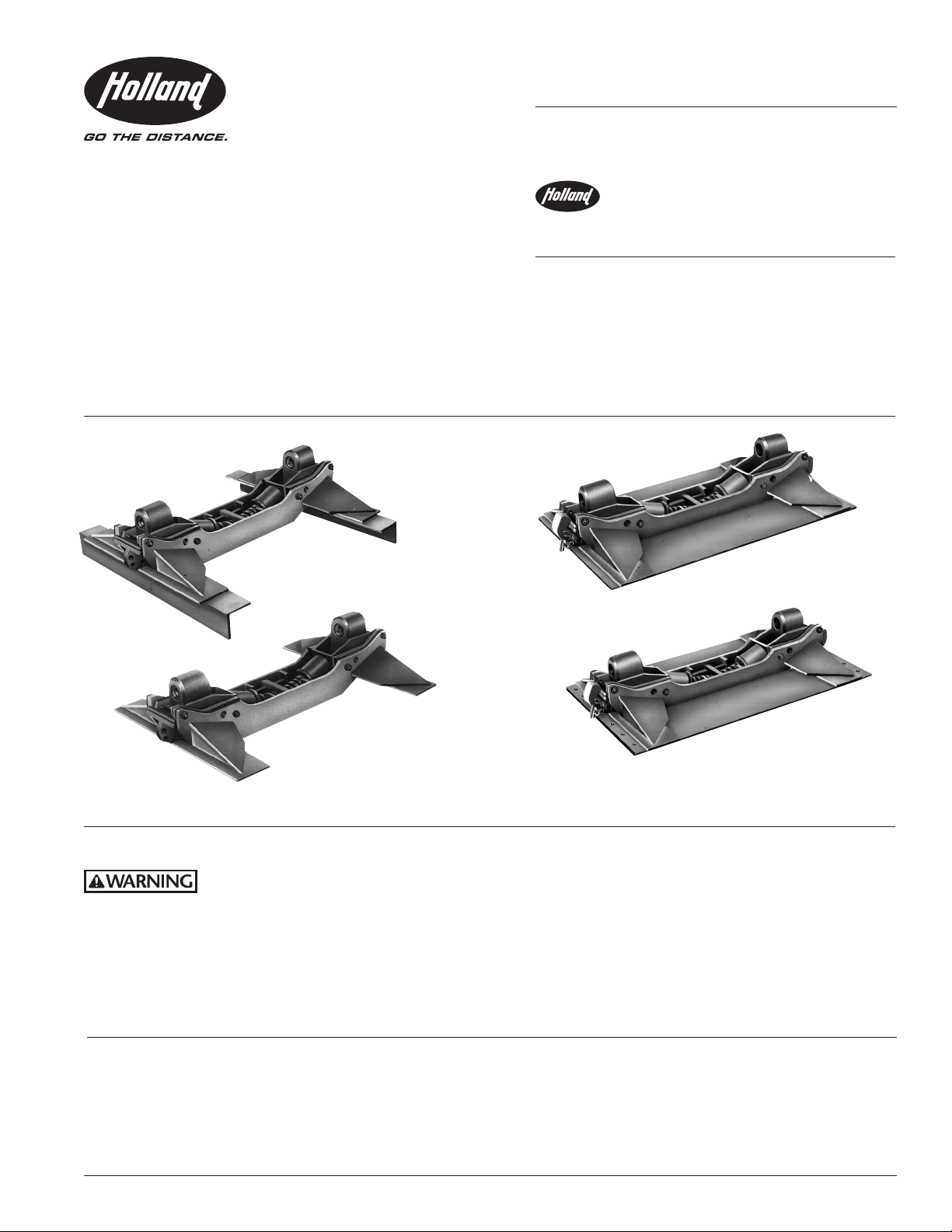

1. ...fittings on the fifth wheel top plate (see

FIGURE 1, ❶) that supply grease to lubricate

the bracket shoe cap and top plate pocket.

(NOTE: LowLube or NoLube top plates do not

have these fittings.)

2. ...fittings ➋ on the side of the shoes (Item 3)

that fill a reservoir that requires approximately

2 pounds of grease.

3. ...fittings ➌ on the base (ends) of the cradle

(Item 14).

4. ...fittings ➍ on the front and back of the cradle

(Item 15).

B. Check the adjustment of the fifth wheel

locks by moving the lock tester fore and

aft when locked in the locking mechanism.

Fore and aft play should be adjusted to less

than 0.06˝ (

1

/16˝). Adjust the fifth wheel

locks as described in Holland Publications

“Fifth Wheel Maintenance Procedures”

XL-FW303-XX, XL-FW308-XX, and

XL-FW354-XX for the particular type of

locking mechanism. If the locks cannot be

properly adjusted due to wear, the fifth

wheel should be repaired or replaced. Your

HOLLAND Distributor has parts, part kits

and fifth wheel top plates available.

C. The trailer kingpin should also be

inspected for wear and damage.

A HOLLAND Kingpin Gauge (TF-0110)

is available to aid this inspection.

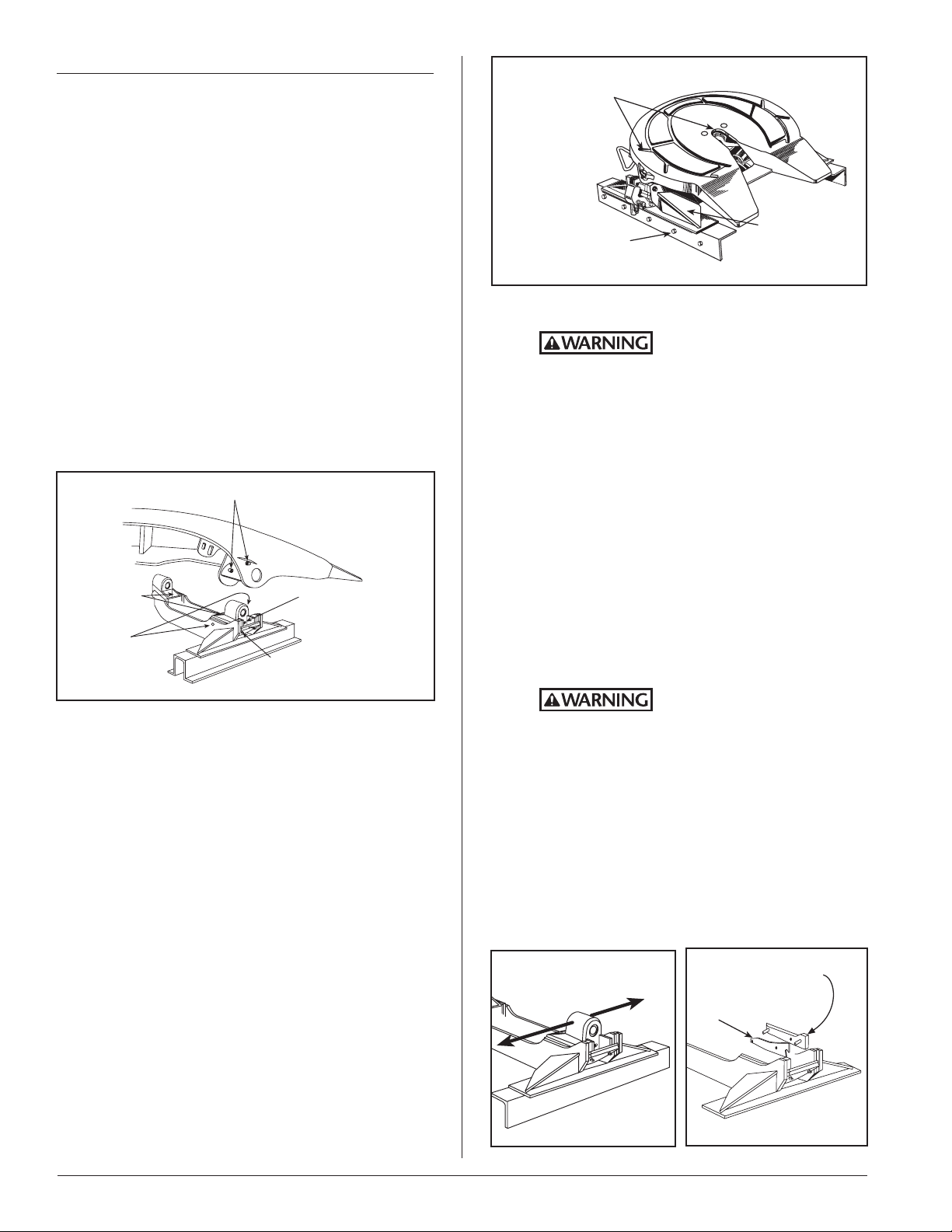

3. Kompensator Base Sub-Assembly:

Measure Fore-Aft Movement.

A. Measure the fore and aft movement of the

shoe sub-assembly in the Kompensator

bracket. (See Figure 3.)

Improper adjustment can

cause improper locking of

the mechanism.

2 XL-FW208-06

Do not use any fifth

wheel which does not

operate properly

FIGURE 1

FIGURE 2

FIGURE 3 FIGURE 4

Grease

resevoir

➍

Grease front

cradle zerks.

➊

Grease top plate contact

surfaces. The grease fitting is

on the side or under the front

of the top plate.

Fill reservoirs

➋

with grease,

then apply

grease to shoes

using zerks.

➌

Grease cradle zerks.

Check for warn,

bent, or broken

parts. Replace with

Holland parts only.

Check for

cracked,

Check bolt torque.

Replace missing

or damaged bolts.

broken, or

distorted

components.

Check fore/aft

movement of shoe.

Shim if greater

than .060".

Bearing plate

ITEM 12, ITEM 13

Shim ITEM 11

Loading...

Loading...