Holland KINGPIN Specifications And Installation Instruction

KINGPIN

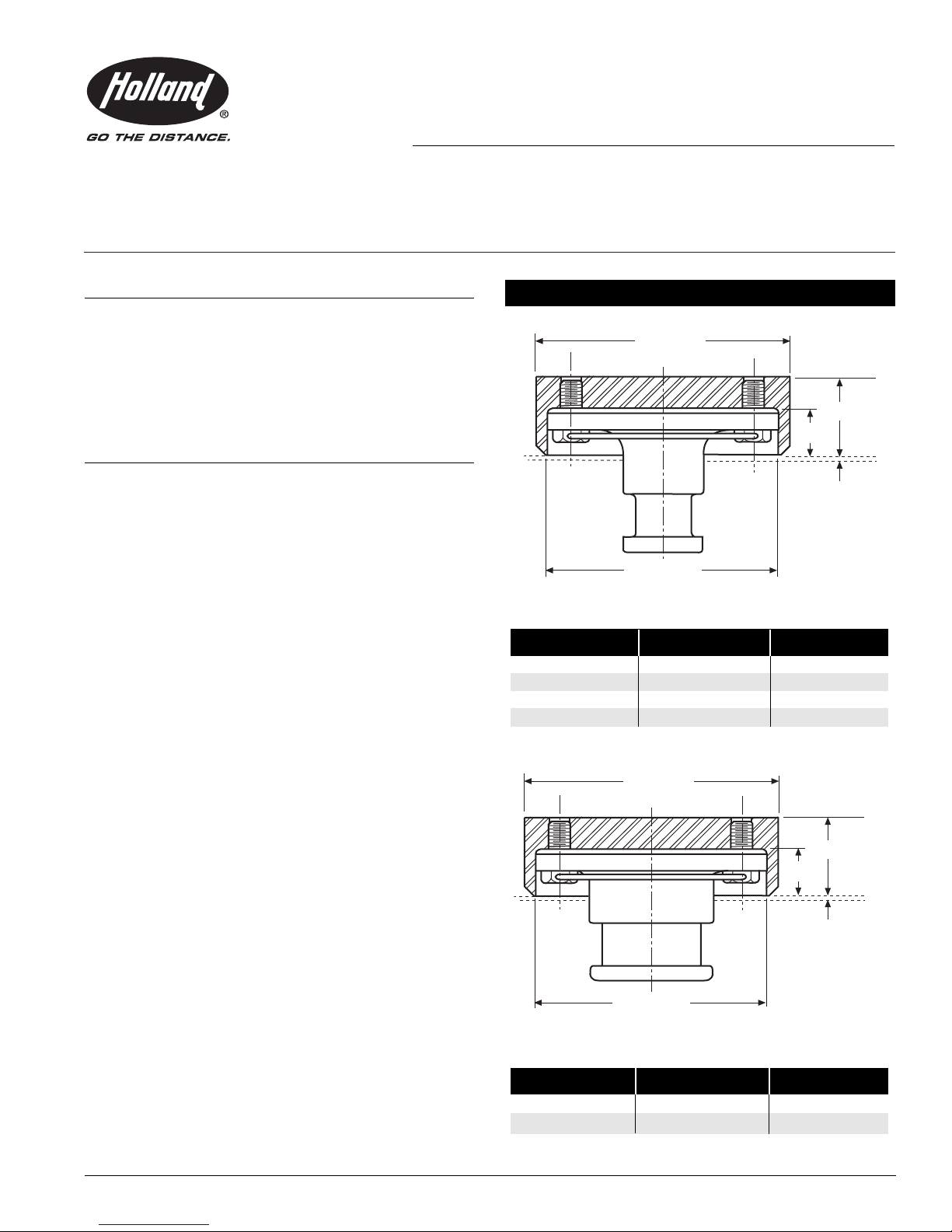

SAE 2.00˝ KING PIN

9.00˝ SQ.

8.25˝ DIA.

2.75˝

A

B

BOLSTER PLATE

2.75˝

A

B

BOLSTER PLATE

SAE 3.50˝ KING PIN

9.00˝ SQ.

8.25˝ DIA.

REPLACEABLE KINGPIN

SPECIFICATIONS and

INSTALLATION INSTRUCTIONS

HOLLAND REPLACEABLE KINGPINS PROVIDE:

Secure installation.

•

• Ease and economy of replacement should wear or

damage occur to the kingpin.

This series of kingpins is designed specifically for van

and enclosed trailers, but can be used on other types of

trailers as well. The kingpin design permits economical

replacement of the kingpin since it is bolted in place —

no expensive rework of the trailer upper coupler.

STANDARD FEATURES INCLUDE:

1. Secure installation with eight .75˝ diameter Grade 8

bolts and safety wire lock.

2. Kingpins are made of AISI 8630H alloy steel and

hardened to 302-363 BHN. When properly installed,

will meet or exceed the performance requirements set

by the Society of Automotive Engineers (SAE) and the

Truck Trailer Manufacturers Association (TTMA).

3. High impact and wear resistance.

4. Housings are made of AISI 4130H alloy steel for

weldability.

5. 100% Brinell hardness tested.

6. 100% magnetic particle tested (to inspect for integrity

below the surface).

7. Ultrasonic tested (MS 105, Tightened, C=0).

8. Bolster plate thicknesses are designed into the

housings as shown. Only one kingpin, either SAE 2˝

or 3.5˝ is required for service parts.

DIMENSIONS

2˝ KINGPIN B A

WITH HOUSING BOLSTER PLATE COUNTER BORE

KP-0880 .25˝ 1.56˝

KP-0881 .31˝ 1.50˝

KP-0882 .38˝ 1.44˝

KP-0883 .50˝ 1.31˝

XL-KP104-01 Rev A

3.50˝ KINGPIN

WITH HOUSING BOLSTER PLATE COUNTER BORE

KP-0884 .38˝ 1.44˝

KP-0885

B

.50˝

A

1.31˝

1

H

XA-0676

XA-0677

.25˝ XA-0765

.31˝ XA-0766

.38˝ XA-0767

.50˝ XA-0768

.25˝ XA-0765

.31˝ XA-0766

.38˝ XA-0767

.50˝ XA-0768

XB-0886 (8 REQ.)

XA-01516

WIRE LOCK

OUSING INSTALLATION

RECOMMENDATIONS:

. The housing is designed for welded installation into the

1

pper coupler assembly. The design of the upper coupler

u

s the responsibility of the installer and must be consistent

i

with the type and capacity of trailer and design loads for

the upper coupler.

2. The housing is manufactured from AISI 4130 steel and is

eldable by most processes; a low-hydrogen process is

w

equired. The “square” external shape of the housing will

r

aid the attachment of required bracing or cross members.

3. Since the inner portion of the housing is accurately

machined, a welding procedure which alternates

from side to side and which minimizes heat buildup is

recommended to avoid distortion. The threaded holes and

nner surfaces should also be protected from weld spatter

i

uring upper coupler construction.

d

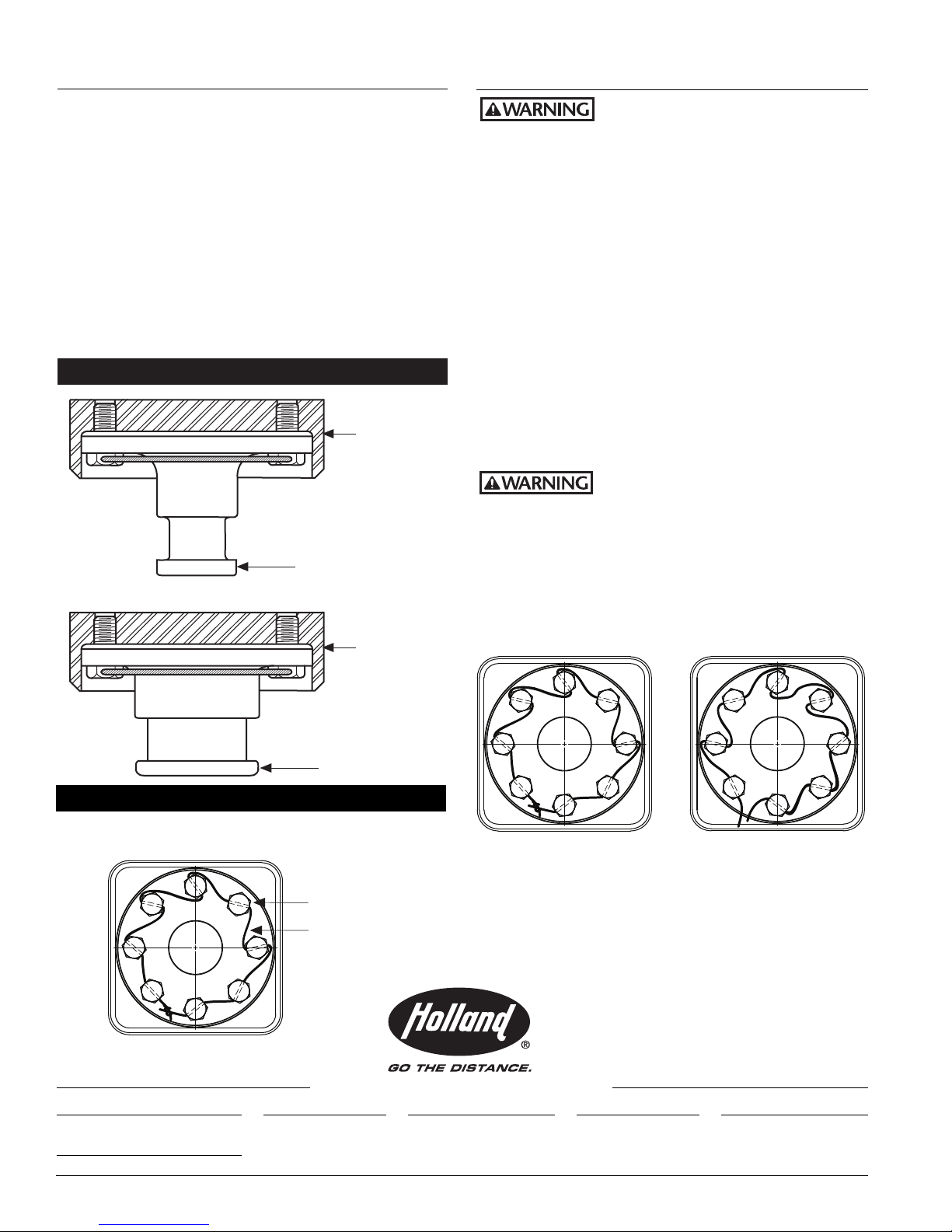

PARTS BREAKDOWN

K

INGPIN INSTALLATION

I

NSTRUCTIONS:

Before starting installation work, verify

that the trailer is securely chocked and

supported to prevent the trailer from moving or falling.

Failure to do so may result in property damage, personal

injury or death.

1. Clean all foreign material from the housing and the

kingpin. The application of a VERY THIN coating of

rust preventative lubricant to the kingpin prior to

installation will aid subsequent removal.

2. Insert the kingpin fully into the housing, taking care to

keep it in line to prevent binding. Rotate the kingpin to

lign bolt holes and install all bolts until hand tight.

a

Continue tightening, alternating across the bolt pattern

to insure uniform fit. Tighten all bolts to 180-200 foot

pounds. Recheck torque on all bolts a second time.

3. After bolts have been properly torqued, wind wire

through holes in bolt heads as shown in

Figure 1. Feed

the wire through the bolt from the center of the kingpin

out, moving clockwise from bolt to bolt. Wire should be

pulled tight with no slack between bolts. When finished

winding, end of wire should be adequately wound with

the beginning, so as not to come loose.

Lock wire must be installed for a secure

installation. Do not use without lock

wire installed correctly. Failure to correctly install lock wire

may allow bolts to loosen during operation causing kingpin

failure, resulting in separation of the towed vehicle and

subsequent property damage, personal injury or death.

IMPORTANT: Lock wire integrity must be checked every

6 months. Replace if damaged, broken or missing, using

parts from RK-0882 kit and the preceding instructions.

Correct Wrong

REPLACEMENT P

ARTS

RK-0882............Bolt and wire lock kit

Includes one wire lock and 8 bolts

Holland USA, Inc. Facilities:

Dumas, AR Muskegon, MI

Holland, MI Warrenton, MO

Monroe, NC Wylie, TX

Ph: 888-396-6501 Fax: 800-356-3929

2 XL-KP104-01 Rev A

Holland International, Inc.

Holland, MI

Phone:

Fax:

Copyright © August 2006 • The Holland Group, Inc.

Holland Hitch of Canada, Ltd.

616-396-6501

616-396-1511

Woodstock, Ontario • Canada

Phone:

Fax:

• Wire is tight • Wire is loose

• Wire ends are tied • Wire ends are not tied

Wire is wound in • Wire is wound

•

correct direction in wrong direction

These products are covered by Holland's Commercial

Products Warranty. Holland reserves the right, without

giving prior notice, to change specifications and

dimensions as designs are altered or improved.

Holland Equipment, Ltd.

519-537-3494

800-565-7753

Norwich, Ontario • Canada

Phone:

Fax:

Figure 1 Lock Wire Installation

Holland Hitch of Canada, Ltd.

519-863-3414

519-863-2398

Surrey, British Columbia • Canada

Phone:

Fax:

www.thehollandgroupinc.com

604-574-7491

604-574-0244

Loading...

Loading...