Holland Hitch XL-FW232-02, XA-71-DA, Hitch XA-71, XA-71-DA-03705, XA-71-OA-03713 Troubleshooting Manual

XL-FW232-02

GO THE DISTANCE.

FIFTH

WHEELS

HITCH

XA-71 Series

Fifth Wheel Top Plates

TROUBLESHOOTING

AND REBUILD

PROCEDURES

XA-71-DA

2” SAE Kingpin (Rebuild Kit RK-65014)

XA-71-DA-03705

2” SAE Kingpin for FW2570-7103 SERIES or

FW2570-7113 SERIES - RK-65014-1

XA-71-OA-03713

31⁄2” SAE Kingpin for FW2570-7103 SERIES or

FW2570-7113 SERIES - RK-65015-1

XA-71-OA

31⁄2” SAE Kingpin (Rebuild Kit RK-65015)

2 XL-FW232-02

TROUBLESHOOTING HINTS

Fifth Wheel is Hard to Hook Up to Trailer:

✔ POSSIBLE CAUSE REMEDY

■■

The trailer may be too high; the kingpin Lower the trailer landing gear.

is not entering the locks properly.

■■

Locks are closed. Pull the secondary and primary release handles to the unlocked position and force the

hinged lock open.

■■

The locks are adjusted too tightly. Check lock adjustments in accordance with the procedure in this manual.

■■

Accumulated rust or grime Spray a light lubricant or diesel fuel on all moving parts, including the release

interfering with the lock operation. handle, and operate several times.

■■

Bent release handle or kingpin or Check and repair/replace as required. The kingpin can be inspected in accordance

damaged bolster plate may be with SAE J2228.

interfering with lock movement.

■■

The locks may be damaged. Inspect and replace, if required, following the procedures in this manual.

■■

The fifth wheel may need rebuilding. Follow the procedures contained in this manual using the appropriate rebuilding kit.

■■

Using lube plate with wrong kingpin See Holland Service Bulletin XL-SB004.

length.

Fifth Wheel is Hard to Unhook from Trailer:

✔ POSSIBLE CAUSE REMEDY

■■

The secondary lock is not released. Pull the secondary lock release handle and lift up to engage the handle lug with the

top plate casting.

■■

The tractor may be putting pressure Back the tractor into the trailer to relieve the pressure and lock the tractor brakes

against locks. before pulling the release handle.

■■

Rust or grime on the locking Spray a light lubricant or diesel fuel on all moving parts, including the release handle,

mechanism. and operate several times.

■■

Bent kingpin or damaged bolster Check the kingpin with a Holland TF-0110 Kingpin Gage and bolster plate with a 48”

plate. straightedge. Repair/replace as required. The kingpin can be inspected in accordance

with SAE J2228.

■■

Fifth wheel locks may be adjusted Check the lock adjustment in accordance with procedures in this manual.

too tightly.

■■

The release handle will not stay out. Pull the release handle out and up, then release.

■■

The release handle will not stay out; Replace release handle.

pops off lug.

■■

The release handle must be held out. Build up release handle lug to hold out further or replace XA-1005-FH, XA-1117-H or

XA-03715 release handles.

■■

Long plunger. Pull the release handle to the fully extended position and hold it while someone else

attempts to uncouple. If the locks do not open under this condition, close the swinging lock

partially and grind 1/16” of the tip of the swinging lock. Round off after grinding.

■■

Using lube plate with wrong See Holland Service Bulletin XL-SB004.

kingpin length.

NOTE: After the fifth wheel is unlocked and moves freely from the kingpin, it is normal for the release handle to return to the “in” position.

XL-FW232-02 3

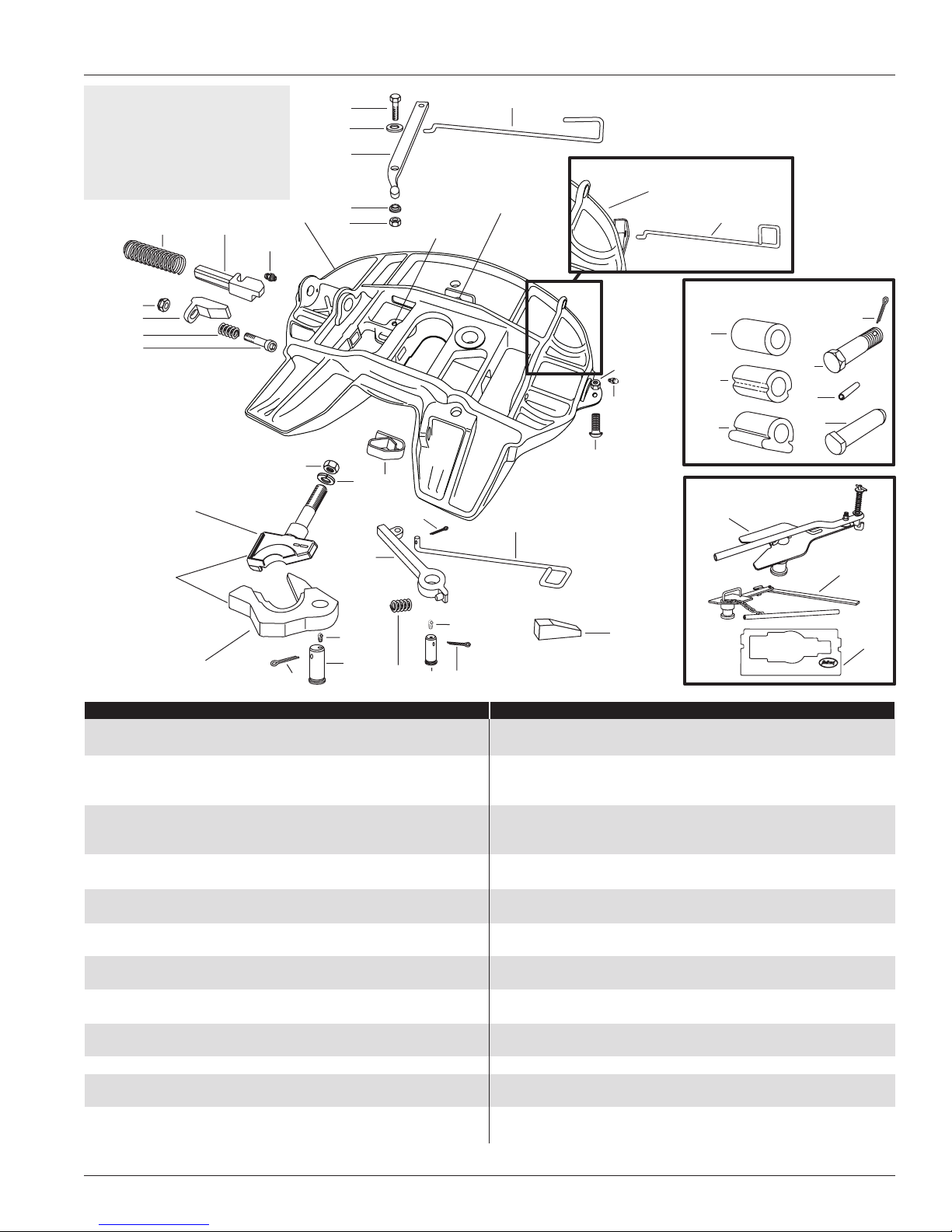

1 XA-71-D 1 Fifth wheel top plate for 2˝ kingpin

1A XA-71-O 1 Fifth wheel top plate for 3.5˝ kingpin

1B XA-71-03706 1 Fifth wheel top plate - 2˝ kingpin for

FW2570-7103 series or

FW2570-7113 series only

1C XA-03711 1 Fifth whl. top plate - 3.5˝ kingpin

for FW2570-7103 or

FW2570-7113 series only

2 XB-5 1 Cotter pin 1/4˝ x 2˝

3 XA-1016-C 1 Lock pin

4 XB-T-60 1 Cotter pin 1/4˝ x2.5˝

5 XA-FW-108-D 1 Lock pin

6 XA-FW-104-D 1 Lock set for 2˝ kingpin

6A XA-FW-104-03 1 Lock set for 3.5˝ kingpin

7 XA-FW-128 1 Spring

8 XB-16 1 Cotter pin 1/8” x 1”

9 XA-FW-78 1 Secondary lock release handle

10 XA-FW-137-2 1 Secondary lock arm

11 XB-1028-2 1 Spring

12 XB-2083 1 Hex hd. bolt 1/2” - 20 x 1.75”

13 XB-T-49 1 Plain washer

14 XB-T-69-A 1 Hex lock nut

15 XA-1005-FH 1 Release lever

16 XA-1117-H 1 Release handle

16A XA-03715 1 Release handle

17 XA-1104 1 Plunger

18 XB-1007 1 Compression spring (red)

19 XB-04473 1 Jam nut 1” - 14

20 XB-09407 1 Socket head cap screw

21 XB-HNH-58-C 1 Lock nut 5/8” - 11

22 XD-3123-1 1 Adjusting wedge

23 XB-403 1 Compression spring

24 XB-02949 1 Nylon bushing

25 XB-0769 2 Lube fitting (90˚)

26 XB-H-38 2 Lube fitting

*27 XB-1604-9 2 Bushing (prior to 5/82)

* 27A XB-0012-1 2 Bushing (5/82 - 9/87)

* 27B XB-0012-3 2 Bushing (after 9/87)

*28 XA-2632 2 Pivot bolt (prior to 11/86)

* 28A XE-02759 2 Pivot pin (after 11/86)

*29 XB-T-9N-2 2 Nut (prior to 11/86) (not shown)

*30 XB-T-60 2 Cotter pin (prior to 11/86)

*31 XB-21-S-375-1750 2 Roll pin

*32 XB-T-69-A 2 Hex lock nut

*33 XB-08002 2 Socket button head cap screw

*34 TF-0110 1 Kingpin gage

*35 TF-TLN-5001 1 2˝ kingpin lock tester

* 35A TF-TLN-1500 1 3.5˝ kingpin lock tester

36 XA-05768-1 1 Adjusting block

37 XB-10327 1 Lock washer, 1˝

ITEM PART NO. NO. PART NAME ITEM PART NO. NO. PART NAME

*

Not included in Rebuild Kits

16

1 or 1A

26

18 17

20

21

22

23

Lockset

6 or 6A

(6 shown)

19

7

8

9

25

2

3

33

26

32

5

10

4

11

25

37

15

12

13

14

24

16A

ACCESSORIES

35

34

27

27A

27B

28

31

28A

NOT INCLUDED IN

REBUILD KIT

30

35A

Stationary lock

Swinging lock

Hole A

36

Hole B

Fifth Wheel Top Plate

1B or 1C

XA-71 SERIES PARTS EXPLOSION

Part numbers indicated

throughout the instructions

in bold numbers—for

instance “fifth wheel top

plate (

1)”—refer back to

this drawing.

4 XL-FW232-02

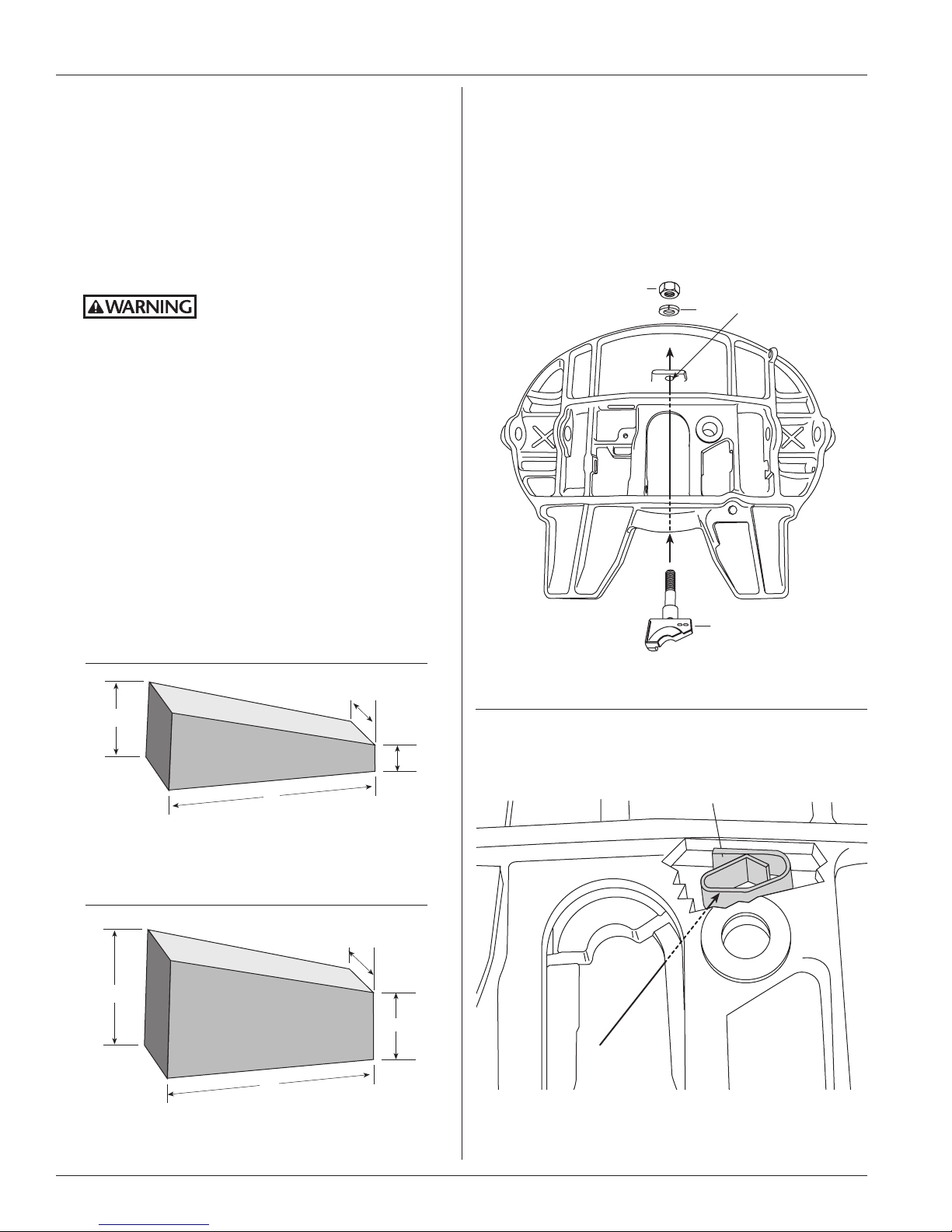

REBUILDING PROCEDURES

1. Before attempting to rebuild, review each troubleshooting hint on page 2 of this manual. You may

find that rebuilding is not necessary.

2. If rebuilding is required, check the front page of this

manual to be sure you have the correct kit for the fifth

wheel you are about to rebuild.

3. Totally disassemble and clean the top plate.

4. Inspect the top plate for cracks and a loose lock pin

hole. If the plate is cracked, or if the lock pin hole is

elongated, the top plate must be discarded.

Do not attempt to repair or

rebuild if the top plate is cracked

or distorted, or the lock pin does not fit tightly, as

the top plate may fail or the locks may malfunction.

Failure to properly install, operate, or maintain this

fifth wheel could result in tractor and trailer

separation causing death or serious injury to others.

NOTE: When rebuilding, use only Holland rebuilding

kits and replace all roll pins, cotter pins, springs, bolts,

nuts, and washers. Also, check the rebuild kit and

verify that all parts are present (refer to page 3).

Fifth Wheel Reassembly

Before starting to reassemble the fifth wheel, it will be

helpful to fabricate a helper block. It can be made from

hardwood or steel. Refer to

FIGURE 1 for proper dimensions.

Primary Lock Installation

1. Install the stationary lock (6) in HOLE A in the casting,

with the large counterbore facing down (see

FIGURE 2).

Install the lock washer (

37) and lock nut (19) onto the

threaded end of the stationary lock. Tighten until

tight, but still allow the lock to rotate slightly, in order

to ensure alignment with the kingpin. The lock nut will

be tightened fully when adjusting the fifth wheel locks

later in this procedure.

8˝

1˝

1.5˝– 2˝

3˝

8˝

2.5˝

4.5˝

1.5˝– 2˝

FIGURE 1

XA-71-DA

XA-71-OA

FIGURE 2

7

FIGURE 3

2. Apply grease to the spring (7) and install it into the

casting. Position it as shown in

FIGURE 3.

continued

19

HOLE A

37

6

Loading...

Loading...