Holland FW3510, FW3410, FW3110 User Manual

FW3510/FW3410 &

FW3510

FW3110

FIFTH WHEEL

OPERATING MANUAL

You must read and understand

the instructions in this

manual before operating

your

WARNING

fifth wheel.

ailure to follow all of the

F

important operating procedures

contained in these instructions

may result in a hazardous

condition or cause a hazardous

condition to develop.

These instructions apply to the

proper operation of your fifth

wheel only. There are other

important checks, inspections,

and procedures not listed here

that are necessary, prudent,

and/or required by law.

Table of Contents

1. Component Part Identification and Specifications

1.1

Identification of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Important specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2

Operating Instructions

2.

Pre-service inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1

2.2

Trailer coupling procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Trailer uncoupling procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.3

3. Routine Inspection and Maintenance

As Needed Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1

Required Inspections and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

3.2

3.2.1

General fifth wheel inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.2

Inspection of locking mechanism

Lock adjustment procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

XL-FW1114-01 1

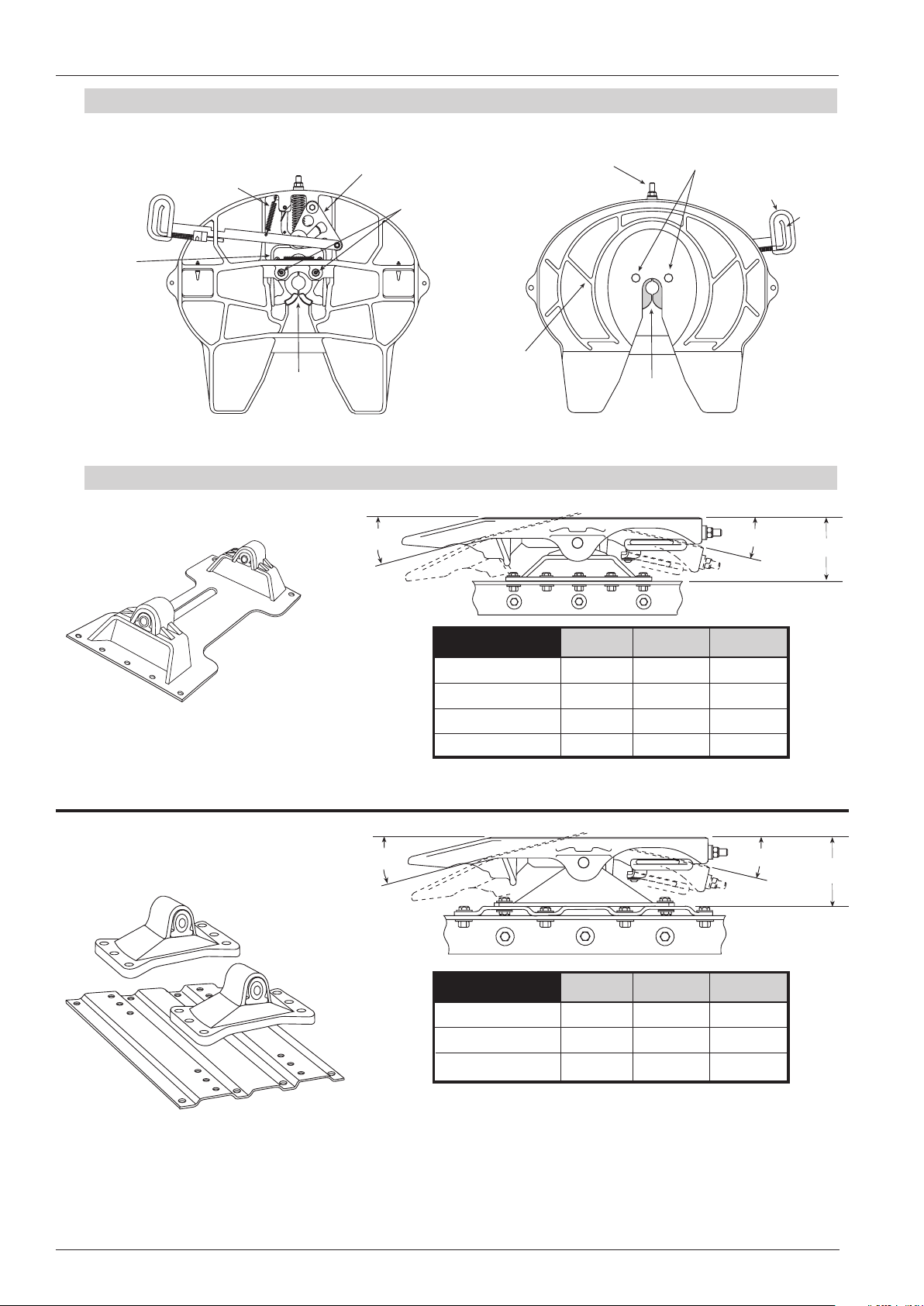

1. Component Part Identification and Specifications

Release

Handle

Spring

Yoke

Lock Jaws

Lock Pin

Grease Fittings

Cam Plate

Adjustment

Bolt and Nut

Grease

Grooves

Lock Pins

Lock Jaws

Release

Handle

Lock

Bar

Release

Handle

“Weightsaver”

Mounting Bracket

"H"

Fifth Wheel Model

No. **

12° min.

12° min.

“ISO/DIN”

Mounting Bracket

"H"

Fifth Wheel Model

No. **

FW3510-150 150 kN 20 tonne 150 mm

FW3510-180 150 kN 20 tonne 180 mm

FW3510-200 150 kN 20 tonne 200 mm

15° min.

15° min.

Max. Fifth Wheel

D

-Value Vertical Load Height* "H"

FW3510-140 150 kN 20 tonne 140 mm

FW3510-160 150 kN 20 tonne 160 mm

FW3510-190 150 kN 20 tonne 190 mm

FW3510-230 150 kN 20 tonne 230 mm

* Fifth Wheel Height "H" Does Not Include Mounting Plate Thickness.

** For the low lube version replace the "35" with "34" (i.e. FW3410-150);

for the no lube version replace the "35" with "31" (i.e. FW3110-150).

Max. Fifth Wheel

D-Value Vertical Load Height*

* Fifth Wheel Height "H" Does Not Include Mounting Plate Thickness.

** For the low lube version replace the "35" with "34" (i.e. FW3410-150);

for the no lube version replace the "35" with "31" (i.e. FW3110-150).

"H"

1.1 Identification of Component Parts (Standard Greased FW3510 Shown)

Important Specifications

1.2

2 XL-FW1114-01 Rev. A

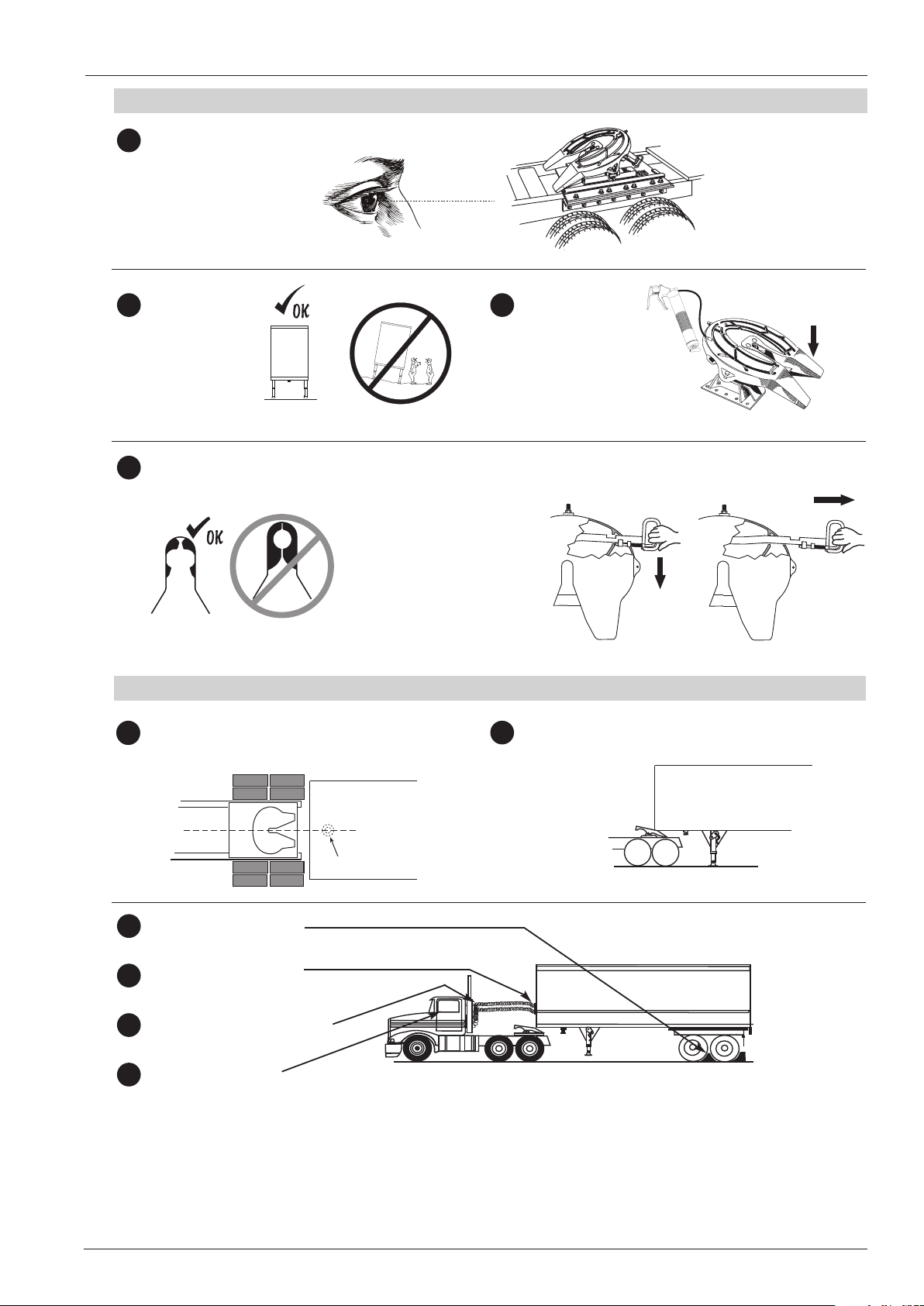

2. Operating Instructions

TILT

DOWN

1

2

4

3

1

1

3

4

5

6

2

2.1 Pre-service Inspection

nspect the fifth wheel mounting.

I

Make sure the

coupling area

is flat, level

and clear of

obstacles

and persons

Make sure the

locks ar

e open.

If the locks are closed:

• Grip handle;

•

• Slide back/left (to

• Pull handle out.

Pull “trigger”;

disengage the lock);

Lubricate the

fifth wheel-to-trailer

contact surface

with grease (not

required for the

FW3310 & FW3110).

Tilt the ramps down.

• Tighten loose

fasteners

• Replace missing

fasteners

Repair/replace

•

racked

c

omponents

c

2.2 Trailer Coupling Procedure

Center the kingpin with the

fifth wheel center.

Top view

of trailer

KINGPIN

Chock trailer wheels

Connect brake and

electrical lines

Support slack in lines to

prevent interference

Set trailer brakes

Back the tractor close to the trailer and

STOP.

XL-FW1114-01 Rev. A 3

Loading...

Loading...