Holding Cabinets HC-900 Service Manual

Henny Penny

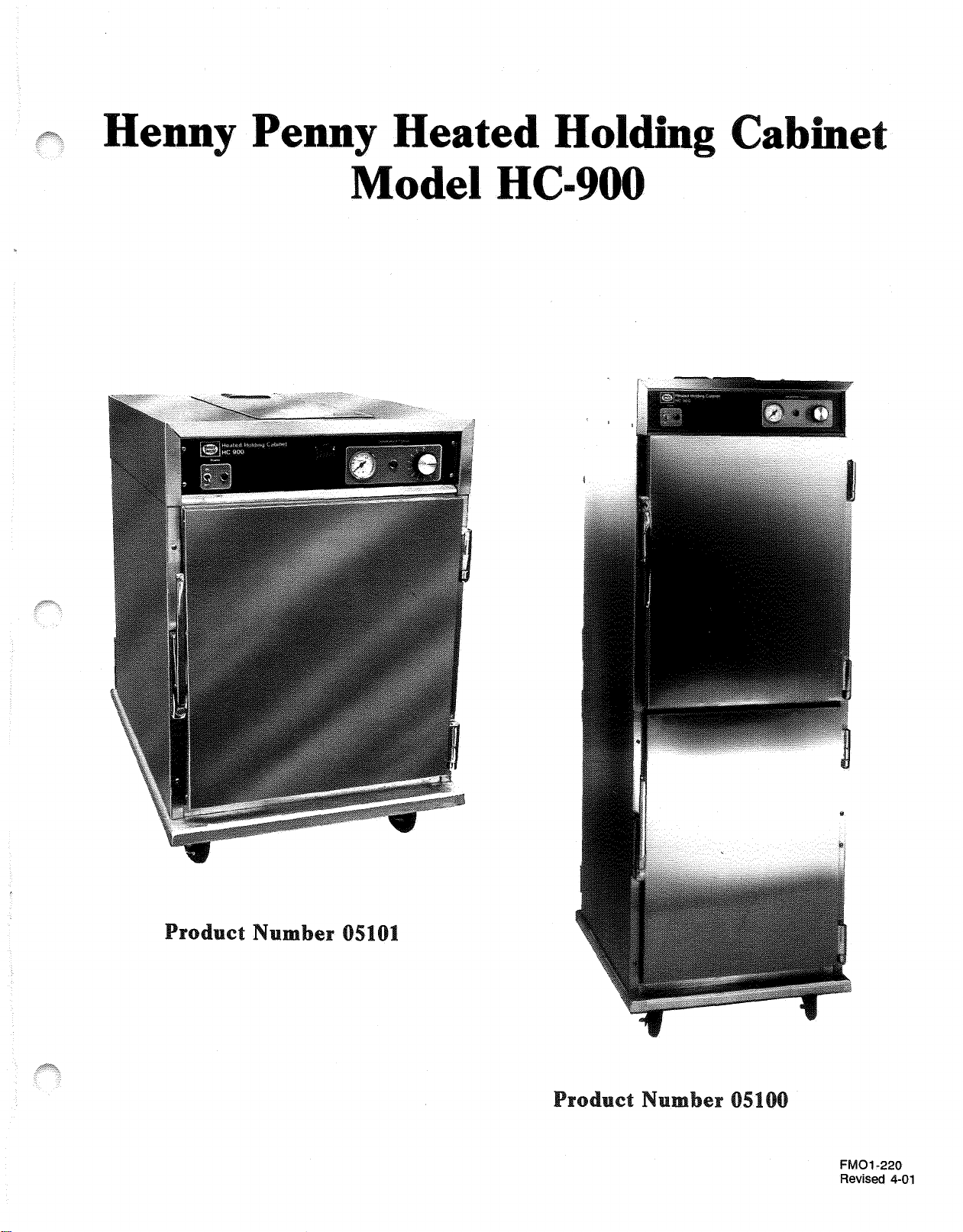

Heated Holding Cabinet

Model HC 900

SERVICE MANUAL

enn

FMO1-220

Revised 4-01

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

Henny Penny Model HC-900

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION

1-1. Heated Holding Cabinet .................................................................................. 1-1

1-2. Model Variations .............................................................................................. 1-1

1-3. Features............................................................................................................ 1-1

1-4. Proper Care ...................................................................................................... 1-2

1-4. Assistance ........................................................................................................ 1-2

1-5. Safety ............................................................................................................... 1-2

Section 2. INSTALLATION

2-1. Introduction ..................................................................................................... 2-1

2-2. Unpacking........................................................................................................ 2-1

2-3. Location ........................................................................................................... 2-2

2-4. Electrical Connection ...................................................................................... 2-2

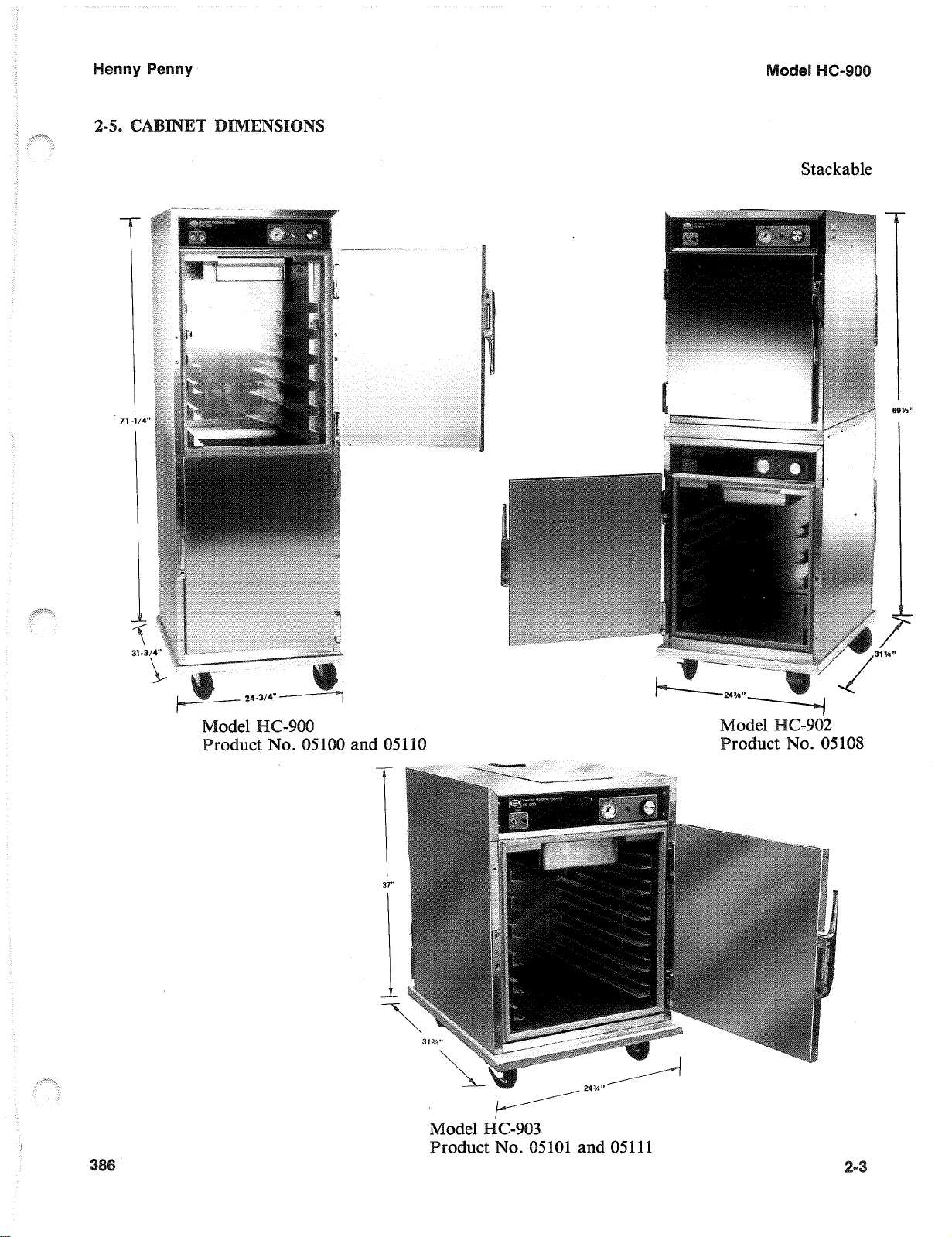

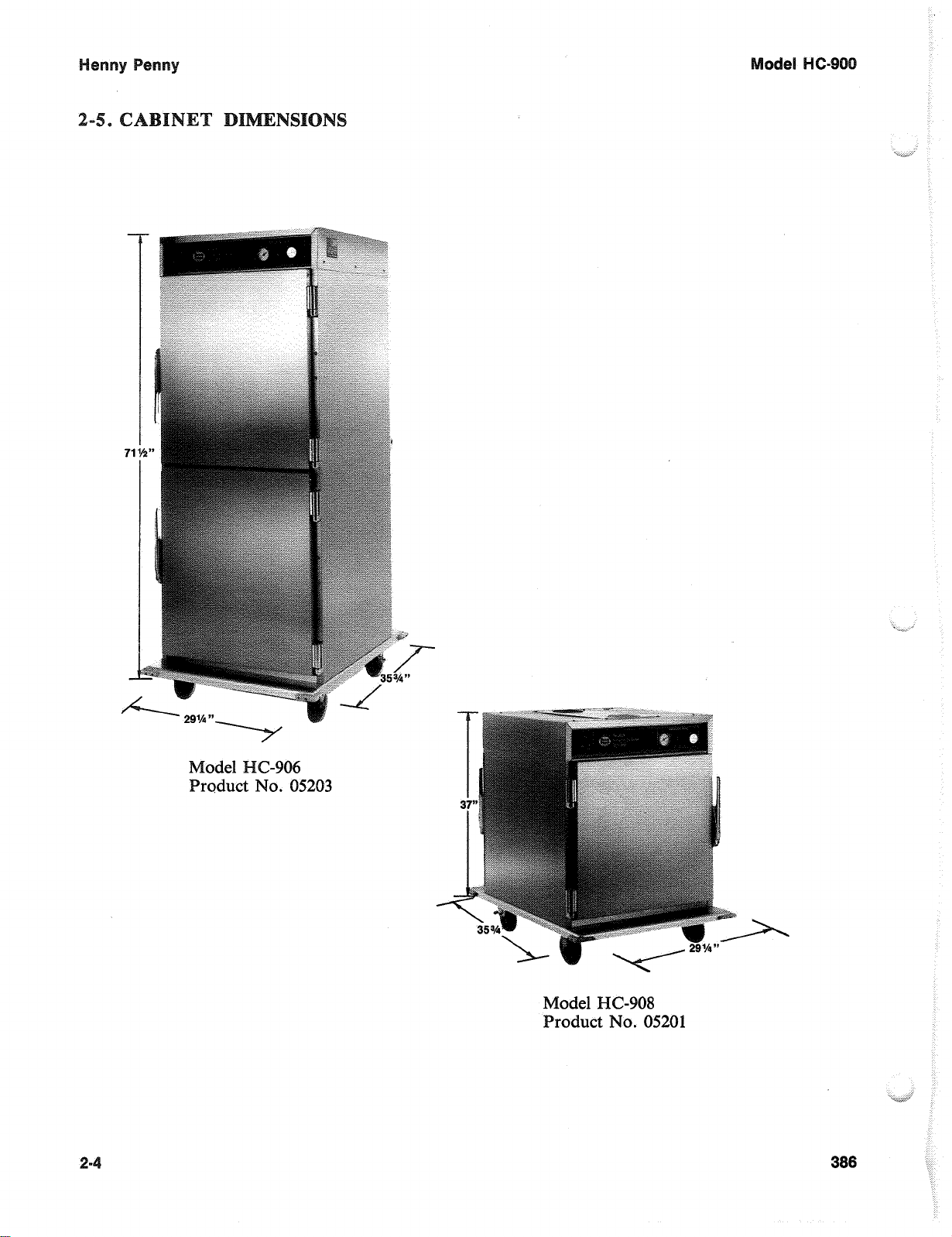

2-5. Cabinet Dimensions......................................................................................... 2-3

Section 3. OPERATION

3-1. Introduction ..................................................................................................... 3-1

3-2. Operating Controls and Components .............................................................. 3-1

3-3. Start-Up ........................................................................................................... 3-4

3-4. Operation with Product .................................................................................... 3-5

3-5. Vent Adjustments ............................................................................................. 3-5

3-6. Cleaning Procedures ........................................................................................ 3-5

3-7. Operating Controls 900 and 903 CDT (if applicable) ..................................... 3-7

3-8. Error Codes (CDT Controls) ........................................................................... 3-12

Section 4. TROUBLESHOOTING

4-1. Introduction ..................................................................................................... 4-1

4-2. Troubleshooting ............................................................................................... 4-1

Section 5. MAINTENANCE

5-1. Introduction ..................................................................................................... 5-1

5-2. Test Instruments ............................................................................................... 5-1

5-3. Removal of Module Access Panel ................................................................... 5-1

5-4. Module Removal ............................................................................................. 5-1

5-5. Module Housing Removal............................................................................... 5-2

5-6. Fuse.................................................................................................................. 5-2

5-7. Power Switch ................................................................................................... 5-3

5-8. Thermostat ....................................................................................................... 5-4

5-9. Indicating Lights .............................................................................................. 5-5

5-10. Thermometer ................................................................................................... 5-5

902 i

Y

ontinue

e

6.2

6.3

6.4

6.5

6.6

6.7

6.8

imit

.

Genuine Parts

.

How

to

.

.

.............................................................

.

.

.

..................................

........................................................

..........................................

.........................................

W

...............................

0

OOW

...............................

TION

60

60

HZ,

HZ,

150012000

3000 W

Z,

1612

3086W

2000 W

12

2086

W

.......................

............................

W

........................

............................

............................

w

............................

W

.............................

.......................................................

......................................................

Find Parts

Order

..................................................

......................................................

...........................................................

..........................................................

.........................................................

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

5-17

5-18

6-1

6-1

6-1

6-1

6-2

6-2

6-2

6-4

enny Penny Distributor ist (Domestic and International)

991

Henny Penny Model HC-900

SECTION 1. INTRODUCTION

1-1 HEATED HOLDING The Henny Penny Heated Holding Cabinet is a basic unit

CABINET (HC-900) of food processing equipment designed to hold hot foods at

proper temperature in commercial food operations. This

cabinet will keep hot foods humid while maintaining

temperature.

1-2 MODEL VARIATIONS This manual covers the following variations of the HC-900:

Product No. 05100 or 05110 Product No. 05101 or 05111

-Full Size Unit -HC-903

-4 Doors -120V/1500 Watt

-120V/2000 Watt -Vented Module

-Right (05100) or -Right (05101) or

Left Hand (05110) Left Hand (05111)

Hinged Doors Hinged Doors

Product No. 05102 Product No. 05103

-Full Size Unit -HC-903

-Features & Options -Features & Options

Product No. 05203 Product No. 05201

-HC-906 -HC-908

-Full Size 2 door -Single Door

-Vented Module -Vented Module

Some of the instructions and procedures in this manual will not

apply to all units.

1-3 FEATURES • Easily Cleaned

• Adjustable, Thermostatically Controlled Heat

• Lift-off Doors

• Easy Access to Electrical Components

• Moist Heat

• Removable Control Module

• Stainless Steel Construction

• Full Perimeter Magnetic Door Seals

• Lift Out Tray Racks

• UL & NSF Listed

• Venting System to Limit Humidity Levels in Cabinet (Units

with vent adjustment).

• Optional Adjustable Legs.

• 200 lbs. (91 kgs) Product Capacity

-Vented Module

299 1-1

Henny Penny Model HC-900

1-4 PROPER CARE As in any unit of food service equipment, the Heated Holding

Cabinet does require care and maintenance. Suggestions for the

proper care and maintenance are contained in this manual.

For your convenience, this manual consists of the following

sections:

! Table of Contents

! Introduction

! Installation

! Operation

! Troubleshooting

! Maintenance

! Wiring Diagrams

! Part List

! Distributor List

The conscientious use of the recommended procedures, coupled with

regular maintenance, will result in few repairs to the equipment.

When such repairs are required, they may be accomplished by following the repair steps contained in this manual.

1-5 ASSISTANCE Should you require outside assistance, just call your local indepen-

dent distributor maintained by Henny Penny Corporation.

In addition, feel free to contact our corporate headquarters in Eaton,

Ohio. Dial 800-417-8405, or 937-456-8405.

1-6 SAFETY The only way to insure safe operation of the Henny Penny Heated

Display Cabinet is to fully understand the proper installation,

operation, and maintenance procedures. The instructions in this

manual have been prepared to aid you in learning the proper

procedures. Where information is of particular importance or is

safety related, the words NOTE, CAUTION or WARNING are

used. Their usage is described below:

NOTE

The word NOTE is used to highlight especially important information.

1-2 299

enny Penny

1-6

SAFETY

(Cont.)

The word CAUTION

is

used to alert you to a procedure that, if

not performed properly, may damage the unit.

The word WARNING

is

used to alert you to a procedure that, if

not performed properly, might cause personal injury.

0682

-3

enn

y

Penny

2-1

~TRODUCTI

SECTION

2.

~ST~LATION

This section provides

Henny Penny Heated

Installation of this unit should be performed only by a qualified

service technician.

Do

not puncture the skin

drills or screws as component damage or electrical shock could

result.

inspected, and expertly packed to insure arrival at its

destination in the best possible condition. The cabinet rests on

cardboard pads that sit on a wooden skid. The racks inside the

cabinet are secured with cardboard packing. The unit

packed inside a heavy cardboard carton with sufficient

padding to withstand normal shipping treatment.

installation instructions for the

of

the olding Cabinet with

olding Cabinet has been tested,

is

then

Any shipping damages should be noted in the presence

delivery agent and signed prior to his or her departure.

To remove the Henny Penny

carton, you should:

1.

Carefully cut banding straps.

2.

Lift the carton off the unit.

3.

Lift the unit off the cardboard padding and skid.

Care should be taken when lifting unit to prevent personal injury.

4.

Open doors and remove packing from behind racks.

5.

Peel off any protective covering from the exterior of the

cabinet.

6.

Your Heated Holding Cabinet is now ready for location and

set up.

Be certain to save any literature that is packed inside the

cabinet.

olding Cabinet from the

of

the

5

Henny Penny Model HC-900

2-3 LOCATION The HC-900 should be placed in an area where the doors can

be opened without interruption and loading and unloading of

product is easy. For proper operation, the cabinet must be level.

Do not set anything on top of the cabinet that might close

the vent holes.

2-4 ELECTRICAL CONNECTION The Heated Holding Cabinet is available from the factory as a

120 VAC or 240 VAC unit for domestic use and as a 240 VAC

unit for foreign use. The data plate, located on the side of the

module, will specify the correct electrical supply. The unit

requires a grounded receptacle with a separate electrical line

protected by a fuse or circuit breaker of the proper rating. For

European markets, verify the electrical plug meets the proper

electrical rating and country type. See local authorities for

proper standards.

The cabinet must be adequately and safely grounded

according to local electrical codes to prevent the possibility

of electrical shock.

Refer to the table below for electrical ratings for the HC-900.

Product Number Volts Watts Amps

05100 or 05110 120 2086 17.5

Full Size (Standard)

05101 or 05111 120 1586 13.0

HC-903 (Standard)

05102 Full Size 240 3086 13.0

05102 Full Size 240 2086 9.0

05103 (HC-903) 240 3086 13.0

05103 (HC-903) 240 2086 9.0

05108 (HC-902) stackable 120 1586 13. 0

05203 (HC-906) 120 2086 17.5

05201 (HC-908) 120 2086 17.5

2-2 1098

-5.

ENS

S

tackable

00

05100

and

05110

-906

0.

05203

Model

Product

HC-908

No.

05201

enny Penny

N

__

TRODUCTION

-2

CONTROL§

NENTS

This section provides operating procedures for the

Sections 1,2 and

3

should be read, and all instructions should

be followed before operating the cabinet.

This section contains an explanation of all controls and

components and information on operating procedures and

daily maintenance.

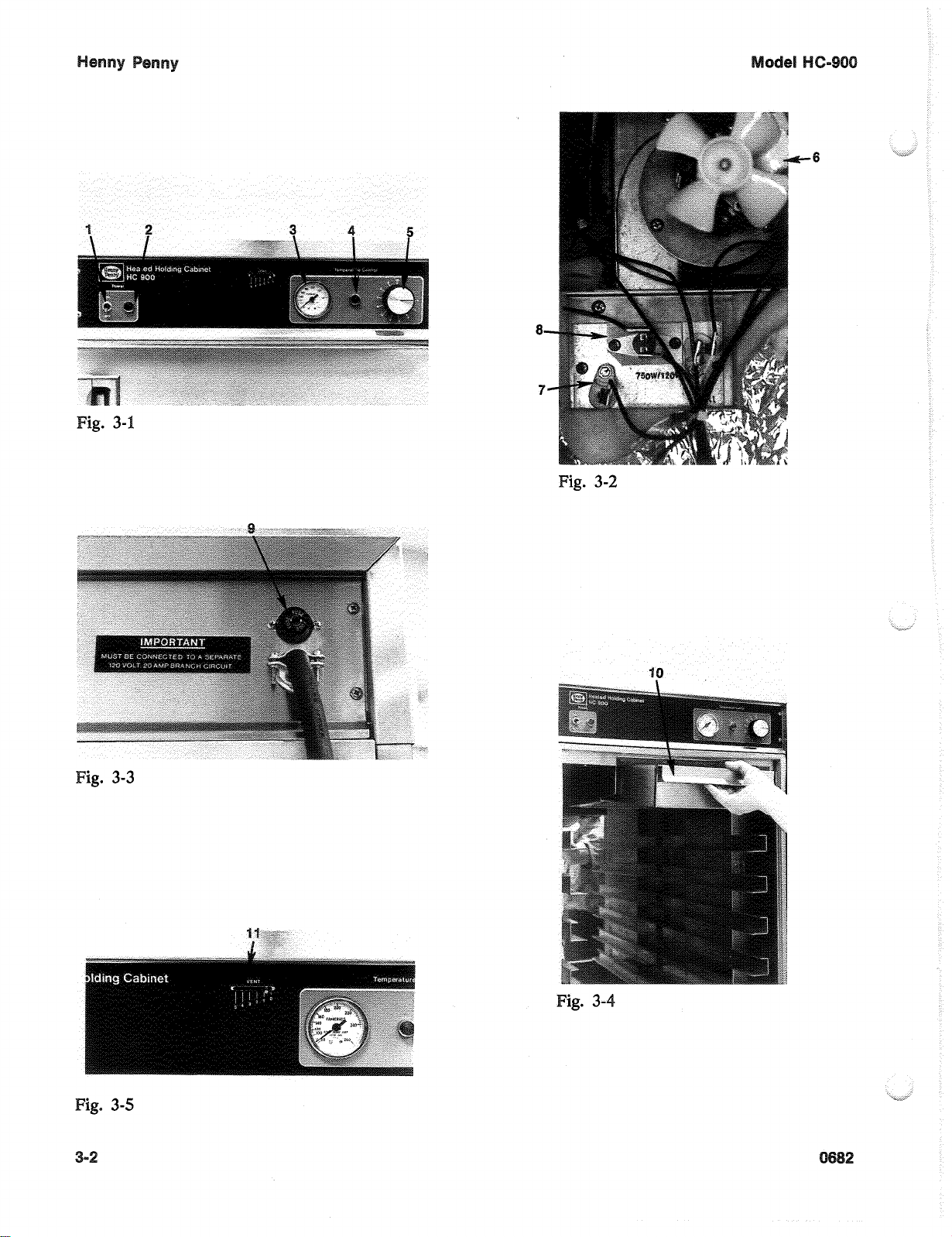

Figures

3-1

through

3-5

identify and describe the functio? of all

the operating controls and the major components of the

cabinet.

2

1

9"

'8

d

e-90

3-

1

3-1 2

3-1

1

3-

3-

3-2

3

4

5

6

eserip

Power Switch The power switch

Thermometer

eat Light

hermostat

i

electrical current to the unit.

When illuminated, the pow light indicates that the

power switch is in the

components are energized.

The thermometer indicates the air tempeiature

inside the cabinet.

When illuminated, the heat light indicates that the

thermostat has turned the heaters on.

The thermostat is an electromechanical device that

controls the temperature inside the cabinet.

I

I

re are two blower motor assemblies in the

-900.

The blower motors are used to recirculate

the hot humid air throughout the cabinet.

is

a toggle switch that switches

‘

N”

position and the

3-2

7

3-2 8

3-3

3-4

9

10

3-5 1

eater

igh Limit he high limit is a safety device mounted next to the

use

Venting System

(Units with vent

adjustment only)

There are

of open-resistance wire typ

sized

rated at

purchased, each heater will be rated at

heaters, each rated at

heater which protects the unit from overheating.

he fuse is a protective device that breaks the circuit

when current exceeds the rated value.

provides an overload protection for the

units.)

The water pan holds the water that, when heated,

creates humidity in the cabinet.

The vent system has been installed into the unit to

limit humidity levels in the cabinet.

two

heaters in the

120

VAC unit is purchased, each heater will be

1000

Watts. If a full sized

240

VAC unit is

1500

C-903

cabinet will be supplied with two

750

Watts.

o

remove the fuse, twist and pull the

is used only on the

120V/2000

Watts.

3-

6-

Stet,

1

efore using the

olding Cabinet, the unit should be

thoroughly cleaned as described in the “Cleaning

section of this manual.

1.

the

HC-900

N”

position. The power light should now be illumi-

into operation, move the power switch to

nated and the blowers should be in operation.

1”

emove the water pan and put approximately

of

water in the pan. Return the pan to its location.

e sure to push the water pan in as far as it will go

so

that it does

not block air from the thermometer and thermostat capillary

his will assure proper operation of these components.

3.

Set the thermostat at

#7

or approximately 180”

heat light goes out, the unit is ready for operation.

25-35

he unit should take appro

temperature during start up

ately

sure that the temperature light

minutes to heat to

goes out before loading with product.

Step

2

roper location of water pan.

3-

2

I

Y Y

1.

Place the hot product on bun pans and insert between the

cabinet racks.

2.

Serve the product first that has been in the cabinet the

longest.

3.

Open the doors only

as

necessary to load and unload product. This will help temperature stay constant and will save

energy.

Step

1

3-2

-5

As mentioned in

of this section, the vent system limits the

humidity level of the cabinet. he vent adjustments are very

easy to follow.

The vent setting corresponds to the number of trays of product.

No.

1.

With one tray of product, set the vent at

No.

2

and

product, set the vent at

so

With two

on.

trays

of

Step

3

urn all controls to the

2.

Disconnect the electrical supply to the cabinet.

" "

position.

Allow the unit to cool before cleaning, as the interior of the

cabinet may be hot enough to burn.

pen the doors and remove all trays from the cabinet.

4.

Take the trays to a sink and clean them thoroughly.

Most surfaces of the

soap, and water.

5.

Remove the water pan. Clean the pan with a soft cloth, soap,

D

and water.

Y

Henny Penny Model HC-900

3-6 CLEANING PROCEDURES 6. Wipe the control panel with a damp cloth. Do not splash

(Cont.) water around the controls.

7. Clean the exterior of the cabinet with a damp cloth.

DO NOT use a spray hose to clean the unit. Failure to

follow these instructions could cause component damage.

8. Open the doors and remove side racks. Clean the racks

with soap and water.

Step 6 9. Clean the interior of the cabinet thoroughly with a cloth

and soap water.

10. Put the side racks and water pan back into the cabinet.

Step 8

11. Leave at least one door open over night to allow the unit to

thoroughly dry out.

3-6 1298

Loading...

Loading...