Hoist Fitness HF4357 Owner's Manual

HF4357

LEG PRESS HACK COMBO

Note: Both Serial Number and Model Number are Required when Ordering Parts

RECORD SERIAL NUMBER HERE

OWNERS MANUAL

CATALOG NUMBER

CATALOG NUMBER

Customer Service

(800) 548-5438

(619) 578-7676

Fa x

(619) 578-9558

1205-000

OWNERS

INSTRUCTIONS

CONTENTS

INSTRUCTIONS (Step 1) .............................................................

FRAME ASSEMBLY (Step 2) ........................................................

PRE-ASSEMBLY .....................

PARTS LISTING ............................................................................

HARDWARE LISTING ..................................................................

BOLT SIZING CHART

WASHER SIZING CHART ............................................................

DECAL PLACEMENTS .................................................................

WEIGHT TRAINING TIPS ...........................................................

..................................................................

........................................................

2

4

17

20

21

22

23

25

31

WEIGHT TRAINING EXERCISE LOG ......................................

GENERAL MAINTENANCE .........................................................

MAINTENANCE SCHEDULE........................................................

LIMITED WARRANTY ..................................................................

Page - 1

32

34

36

37

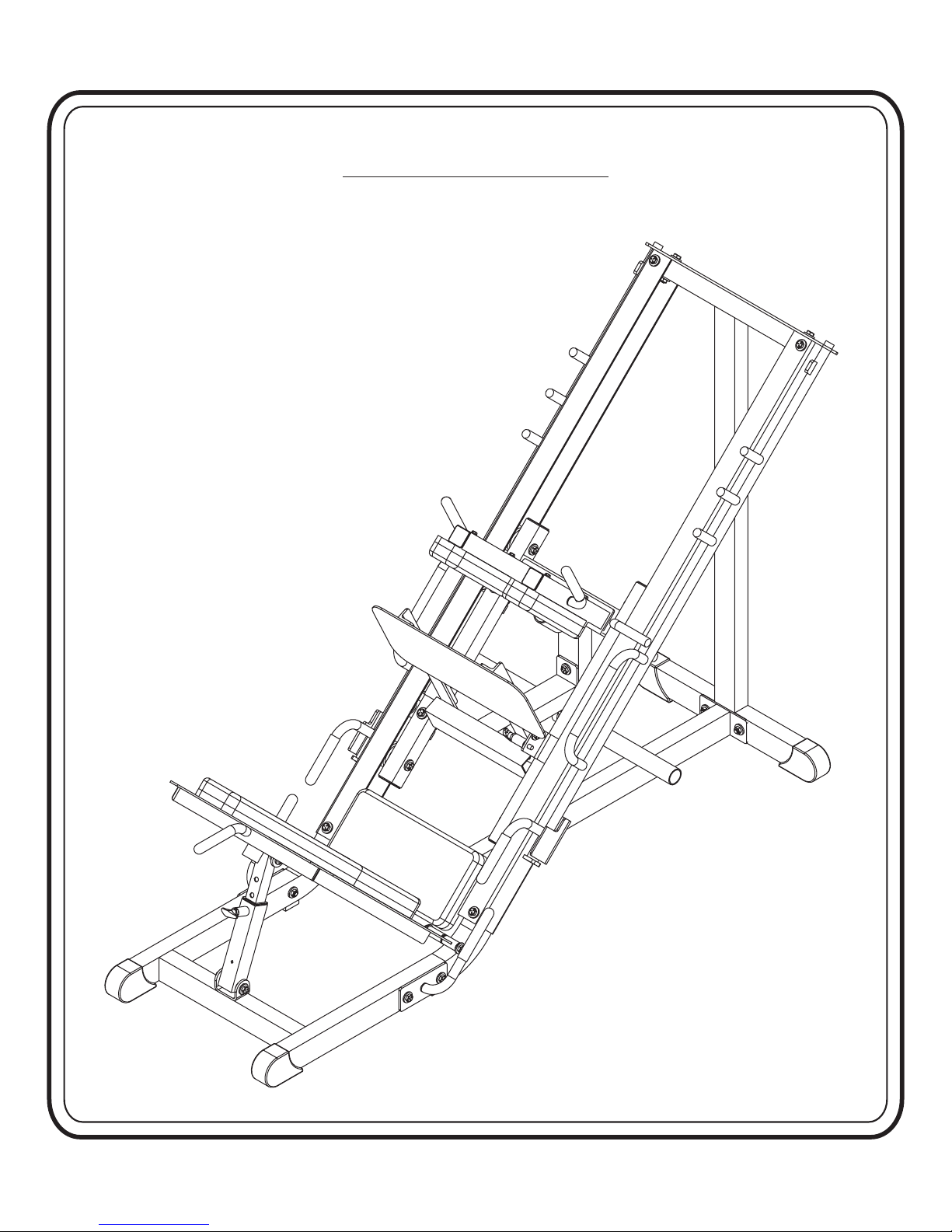

HF4357 Assembly

OWNERS

INSTRUCTIONS

Step 1

INSTRUCTIONS

Before beginning assembly please take the time to read the

instructions thoroughly. Please use the catalog in this manual to

make sure that all parts have been included in your shipment.

When ordering use the part number and description from the

catalog.

to do so will void your warranty and could result in personal

injury.

effective exercise motion possible. After assembly, you should

check all functions to ensure correct operation. If you

experience problems, first recheck the assembly instructions to

locate any possible errors made during assembly. If you are

unable to correct the problem, call your authorized Hoist dealer.

Be sure to have your serial number and this catalog when calling.

When all parts have been accounted for, continue on to Step 2.

Use only Hoist replacement parts when servicing. Failure

Hoist equipment is designed to provide the smoothest, most

SUGGESTED TOOLS

Socket Wrench

1/2”, 9/16” & 3/4” Sockets

Crescent Wrench

Rubber Mallet

Tape Measure

Page - 2HF4357 Assembly

OWNERS

INSTRUCTIONS

Page - 3

HF4357 Assembly

OWNERS

INSTRUCTIONS

Step 2

FRAME ASSEMBLY

Page - 4HF4357 Assembly

OWNERS

INSTRUCTIONS

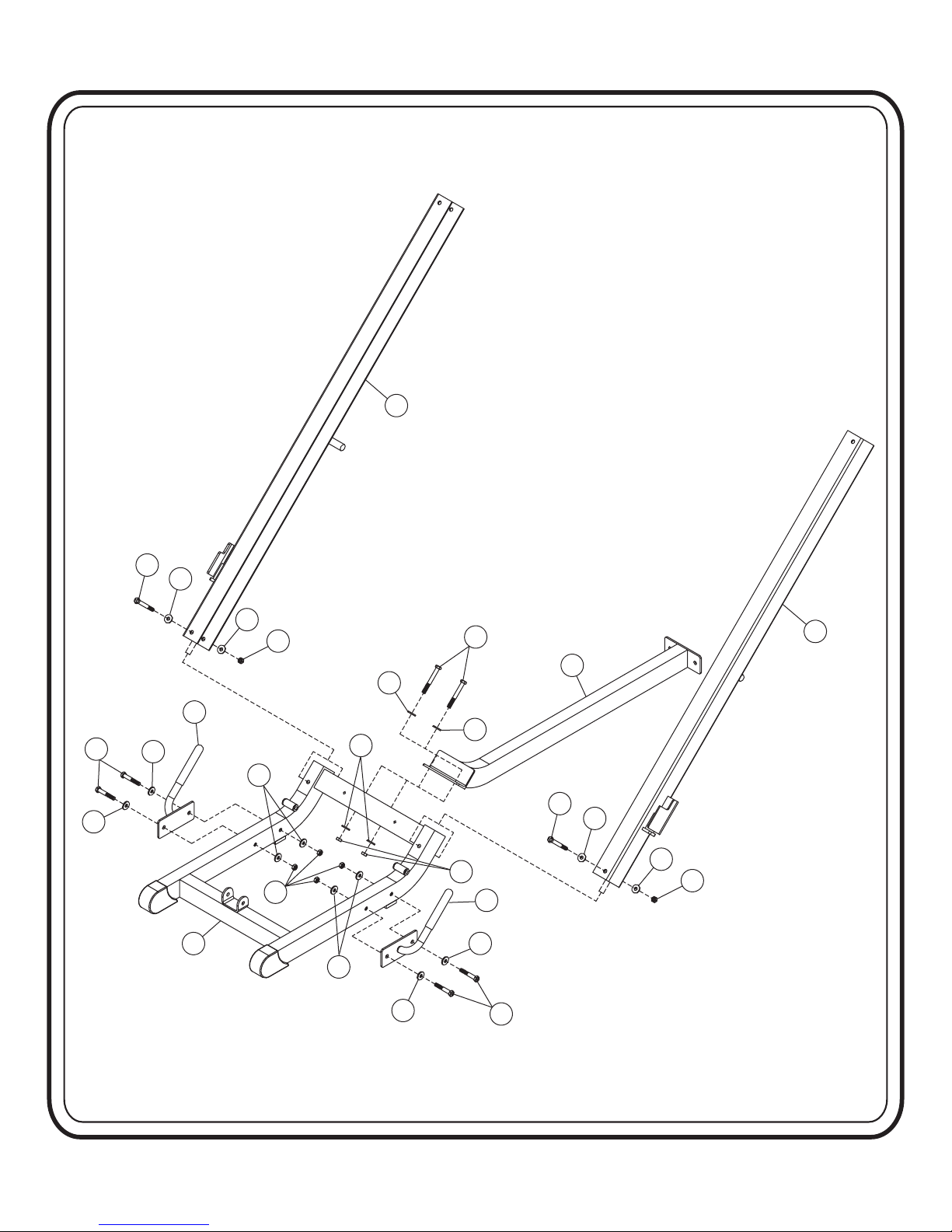

Step 2a

FRAME ASSEMBLY

Start this assembly by attaching (2) to (1). Then you will attach (4)

and (5) to (1). Finish by attaching (8)

Just Snug these bolts at this point.

and (9) to (1). .Wrench Tighten these bolts

Part Descriptions

1 - Base Front

2 - Base Runner

4 - Left Rail

5 - Right Rail

8 - Right Handle

Hardware Descriptions

A - 1/2”-13 x 3” Hex Head Screw

B - 1/2”-13 x 4” Hex Head Screw

E - 1/2”-13 x 4 1/4” Hex Head Screw

AA - 1/2” Flat Washer

BA - 1/2” Nylok Nut

9 - Left Handle

Page - 5

HF4357 Assembly

OWNERS

INSTRUCTIONS

4

AA

E

AA

AA

BA

B

2

AA

E

AA

AA

BA

8

AA

A

BA

AA

9

A

AA

AA

BA

1

AA

AA

AA

5

Page - 6HF4357 Assembly

OWNERS

INSTRUCTIONS

Step 2b

FRAME ASSEMBLY

In this step you will attach (15) to (1). Now insert (18) into (10).

Then attach (10) to (1) and (18) to (15). Wrench Tighten bolts. Then

back off 1/2” turn or enough so these parts can adjust easily.

Part Descriptions

1 - Base Front

10 - Outer Footrest Adjuster

15 - Hack Footrest

18 - Inner Footrest Adjuster

Hardware Descriptions

B - 1/2”-13 x 4” Hex Head Screw

G - 1/2”-13 x 5 1/2” Hex Head Screw

AA - 1/2” Flat Washer

BA - 1/2” Nylok Nut

Page - 7

HF4357 Assembly

OWNERS

INSTRUCTIONS

15

AA

B

AA

AA

BA

BA

BA

AA

AA

18

G

10

B

AA

G

1

BA

AA

Page - 8HF4357 Assembly

OWNERS

INSTRUCTIONS

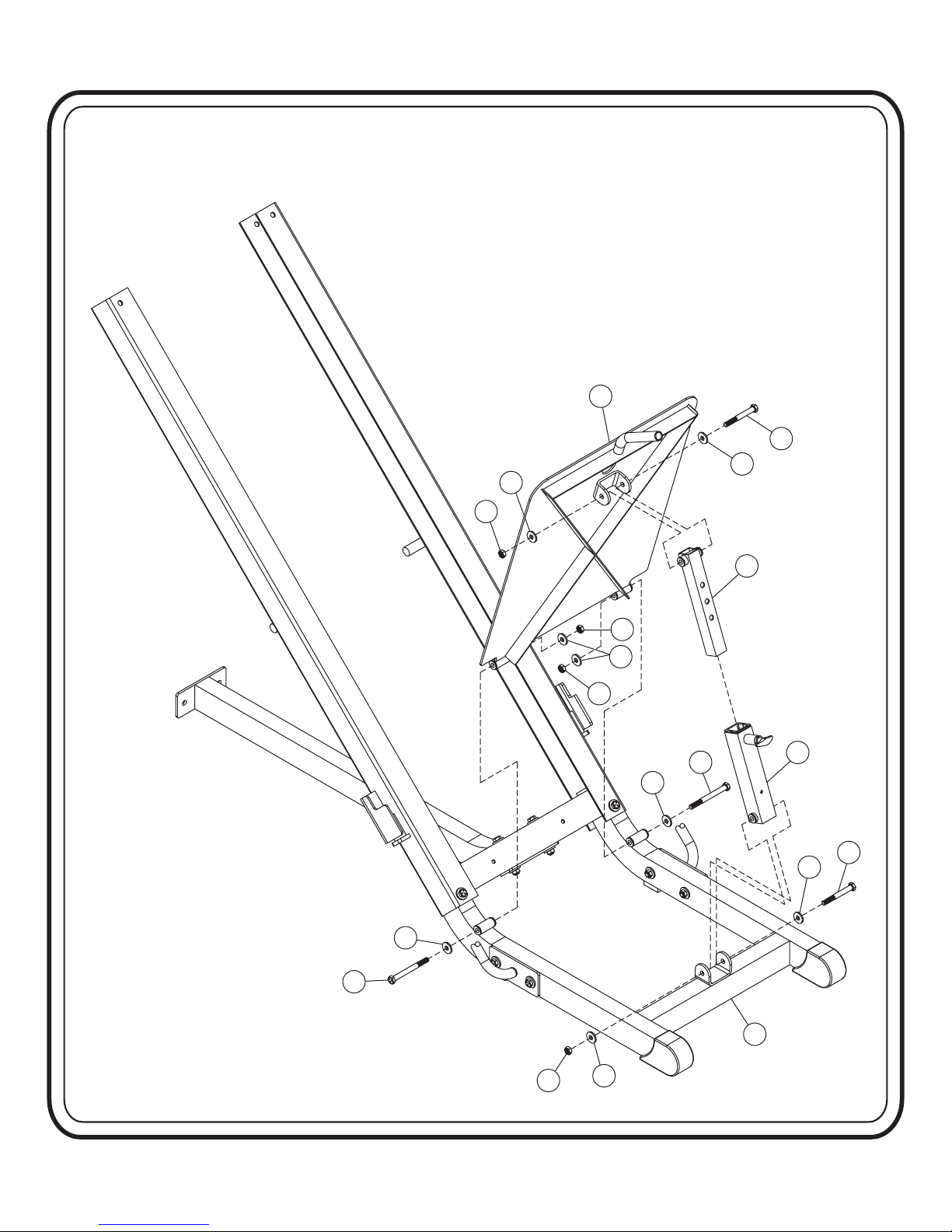

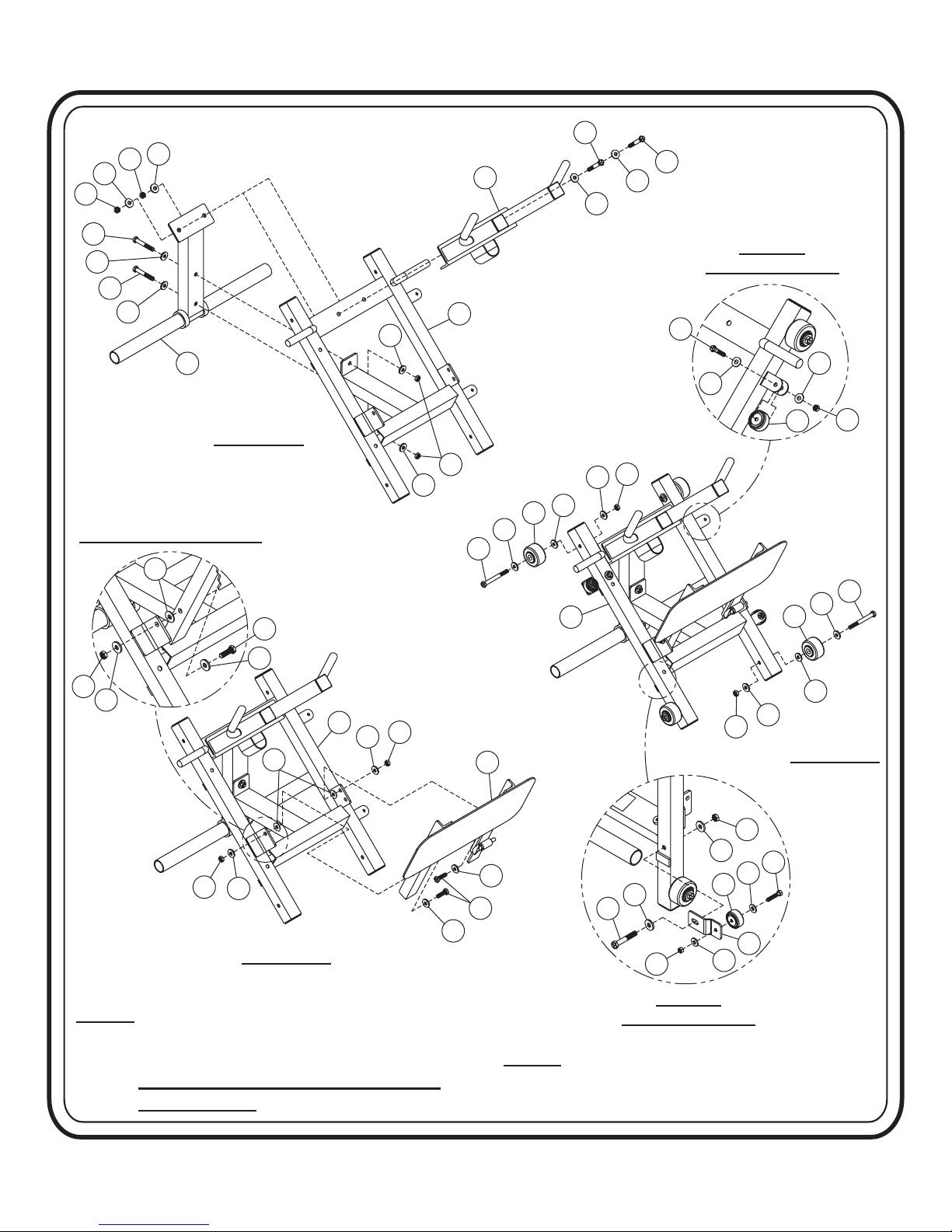

Step 2c

FRAME ASSEMBLY

Start by attaching (14) and (7) to (6). . Attach

(16) to (6).

these parts can adjust easily

Wrench Tighten bolts. Then back off 1/2” turn or enough so

. Attach (CK) to the both sides of (6). And a

(CJ) in each bracket on the right side of (6). .

Detail -A-)

(See Detail -B-)

. Attach two (CJ)’s to the two (11)’s. .

. Then attach both (11)’s to the left side of (6). Note that

Wrench Tighten bolts

Wrench Tighten bolts

Wrench Tighten bolts

(See

there is a slotted hole in (11) at this connection point which allows for

adjustment of these wheels. At this point, position the (11)’s all the way

in. . They will be adjusted out in Step 2e.

Just Snug bolts

Part Descriptions

Hardware Descriptions

6 - Carriage

7 - Shoulder Pad Mount

11 - Wheel Mount

14 - Weight Carriage

16 - Leg Press Footrest

A - 1/2”-13 x 3” Hex Head Screw

C - 1/2”-13 x 3 1/4” Hex Head Screw

D - 1/2”-13 x 1 1/2” Hex Head Screw

F - 1/2”-13 x 4 1/2” Hex Head Screw

H - 3/8”-16 x2” Hex Head Screw

AA - 1/2” Flat Washer

AB - 3/8” Flat Washer

AD - 1/2” Nylon Flat Washer

BA - 1/2” Nylok Nut

BB - 3/8” Nylok Nut

BC - 1/2” Nylok Nut

CJ - 2” Dia. Wheel

CK - 3” Dia. Wheel

(Thin)

Page - 9

HF4357 Assembly

BA

AA

BA

AA

OWNERS

INSTRUCTIONS

C

7

AA

AA

C

A

AA

A

AA

14

ASSEMBLY -1-ASSEMBLY -1-

AREA ENLARGED FOR CLARITYAREA ENLARGED FOR CLARITY

AD

AA

DETAIL -A-DETAIL -A-

ROTATED FOR CLARITYROTATED FOR CLARITY

6

AA

BA

AA

AA

CK

AA

F

D

6

AA

BC

H

AB

AB

AA

BB

F

CJ

CK

BA

AA

NOTE:

NOTE:

6

AD

BA

AA

ASSEMBLY -2-ASSEMBLY -2-

Make sure to place Nylon Washer (AD)

Make

between the Leg Press Footrest (16) and

between

Carriage (6) when assembling.

Carriage

Nylon Washer is placed in this area to

Nylon

reduce friction

reduce

sure to place Nylon Washer (AD)

the Leg Press Footrest (16) and

(6) when assembling.

Washer is placed in this area to

friction

.

.

AA

BA

AA

AA

BC

16

BA

AA

AA

AA

D

NOTE: Wheel assemblies are only shown once

NOTE: Wheel assemblies are only shown once

A

BB

DETAIL -B-DETAIL -B-

ROTATED FOR CLARITYROTATED FOR CLARITY

for clarity. Repeat assembly where

for

clarity. Repeat assembly where

applicable.

applicable.

CJ

AB

AB

11

ASSEMBLY -3-ASSEMBLY -3-

J

AA

Page - 10HF4357 Assembly

OWNERS

INSTRUCTIONS

Step 2d

FRAME ASSEMBLY

Start this assembly by sliding (6) into (4) and (5). Then attach (3) to

both (4), (5) and (2). Wrench Tighten these bolts and the bolts that were

Snug Tightened in Step 2a.

Part Descriptions

2 - Base Runner

3 - Rear Upright

4 - Left Rail

5 - Right Rail

6 - Carriage

Hardware Descriptions

A - 1/2”-13 x 3” Hex Head Screw

E - 1/2”-13 x 4 1/4” Hex Head Screw

AA - 1/2” Flat Washer

BA - 1/2” Nylok Nut

Page - 11

HF4357 Assembly

Loading...

Loading...