Hoist Fitness HD1700 User Manual

HD1700

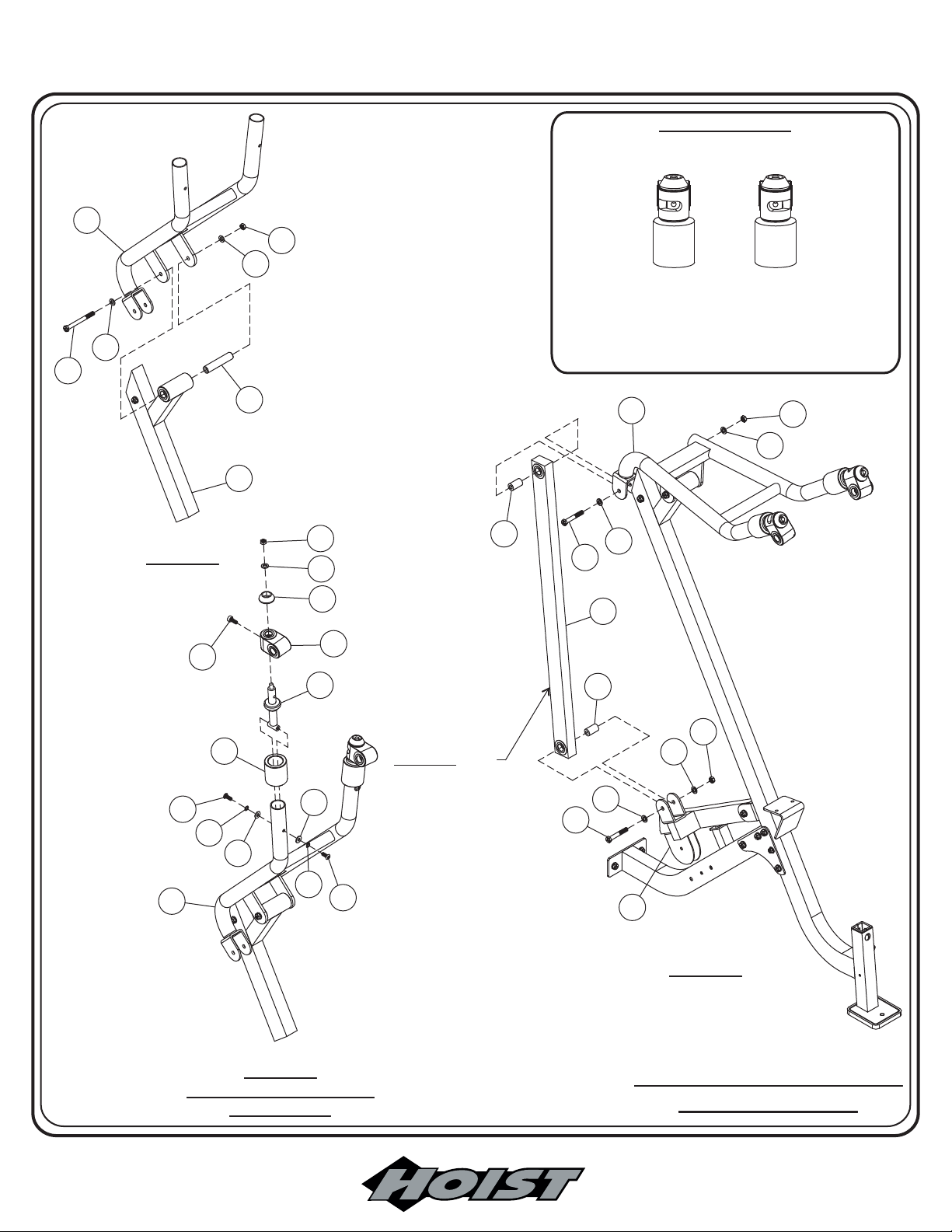

LAT/HIGH ROW

Note: Both Serial Number and Model Number are Required when Ordering Parts

RECORD SERIAL NUMBER HERE

OWNERS MANUAL

CATALOG NUMBER

Customer Service

(800) 548-5438

(858) 578-7676

Fa x

(858) 578-9558

0102-003

OWNERS

MANUAL

CONTENTS

INSTRUCTIONS (Step 1).............................................................

FRAME ASSEMBLY (Step 2)........................................................

CABLE ASSEMBLY (Step 3).........................................................

CABLE ADJUSTMENT/GENERAL MAINTENANCE ...............

PRE-ASSEMBLED PARTS ...........................................................

PARTS LISTING ..........................................................................

HARDWARE LISTING ................................................................

BOLT SIZING CHART ................................................................

WASHER SIZING CHART ..........................................................

2

4

17

18

23

25

26

28

29

WEIGHT RATIOS .......................................................................

DECAL PLACEMENT

WEIGHT TRAINING TIPS

WEIGHT TRAINING EXERCISE LOG ...................................

GENERAL MAINTENANCE INFORMATION ..........................

MAINTENANCE SCHEDULE........................................................

LIMITED WARRANTY ................................................................

.................................................................

........................................................

31

33

39

40

42

44

45

Page - 1

HD1700 Assembly

OWNERS

MANUAL

Step 1

INSTRUCTIONS

Before beginning assembly please take the time to read the

instructions thoroughly. Please use the various lists in this

manual to make sure that all parts have been included in your

shipment.

from the lists.

Failure to do so will void your warranty and could result in

personal injury.

Hoist equipment is designed to provide the smoothest, most

effective exercise motion possible. After assembly, you should

check all functions to ensure correct operation. If you

experience problems, first recheck the assembly instructions to

locate any possible errors made during assembly. If you are

unable to correct the problem, call your authorized Hoist dealer.

Be sure to have your serial number and this manual when

calling. When all parts have been accounted for, continue on .

When ordering use the part number and description

Use only Hoist replacement parts when servicing.

TOOLS REQUIRED

Socket Wrench

1/2”, 9/16" and 3/4" Sockets

3/4” Open End Wrench

Crescent Wrench

Rubber Mallet

Tape Measure

Page - 2HD1700 Assembly

OWNERS

MANUAL

Page - 3

HD1700 Assembly

OWNERS

MANUAL

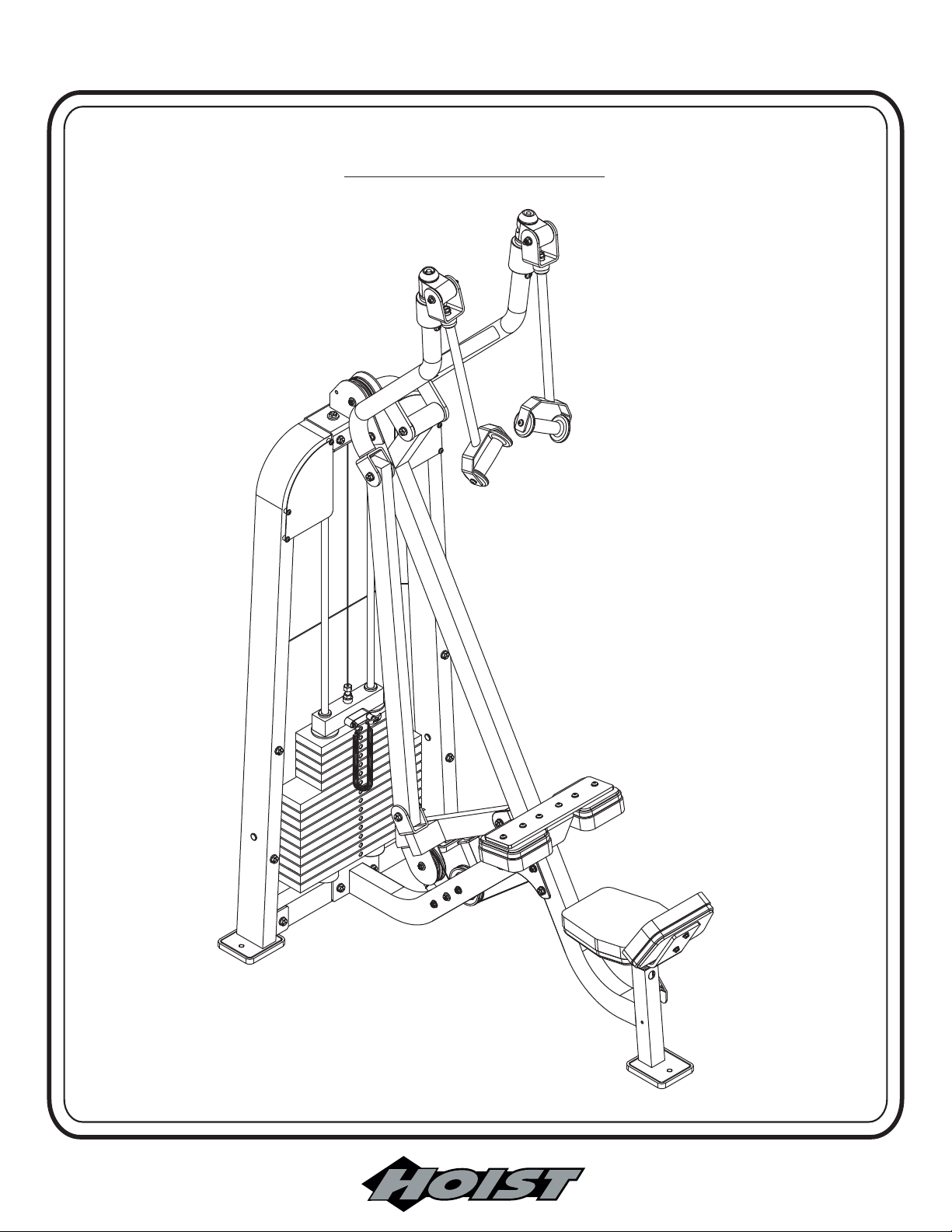

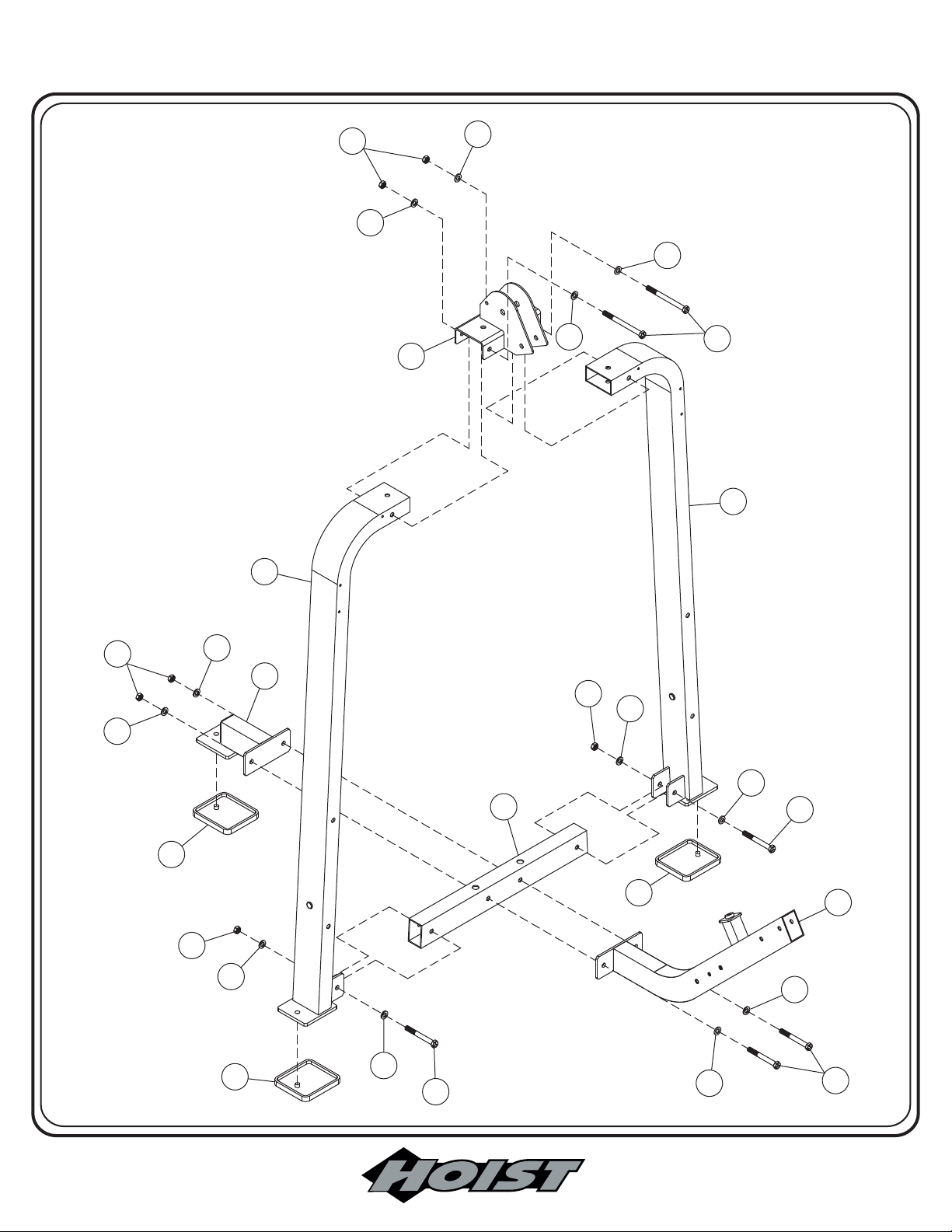

Step 2

FRAME ASSEMBLY

Page - 4HD1700 Assembly

OWNERS

MANUAL

Step 2a

FRAME ASSEMBLY

Start assembly by attaching both (1)’s to (3). Attach (2) to the top of

both (1)’s. Then attach (4) and (5) to (3). bolts. They will

be tighten in a later step.

Part Descriptions

1 - Weight Frame Upright

2 - Top Pulley Mount

3 - Weight Stack Mount

4 - Rear Tie

5 - Front Support

Hardware Descriptions

A - 1/2”-13UNC x 4 3/4” Hex Head Bolt (WZ)

B - 1/2”-13UNC x 3” Hex Head Bolt (WZ)

AA - 1/2” Washer

BA - 1/2” Nylok Nut

Hand Tighten

Page - 5

HD1700 Assembly

OWNERS

MANUAL

BA

AA

2

1

AA

AA

AA

A

1

BA

AA

CA

BA

AA

AA

CA

4

BA

AA

AA

AA

3

CA

B

AA

B

5

AA

B

Page - 6HD1700 Assembly

OWNERS

MANUAL

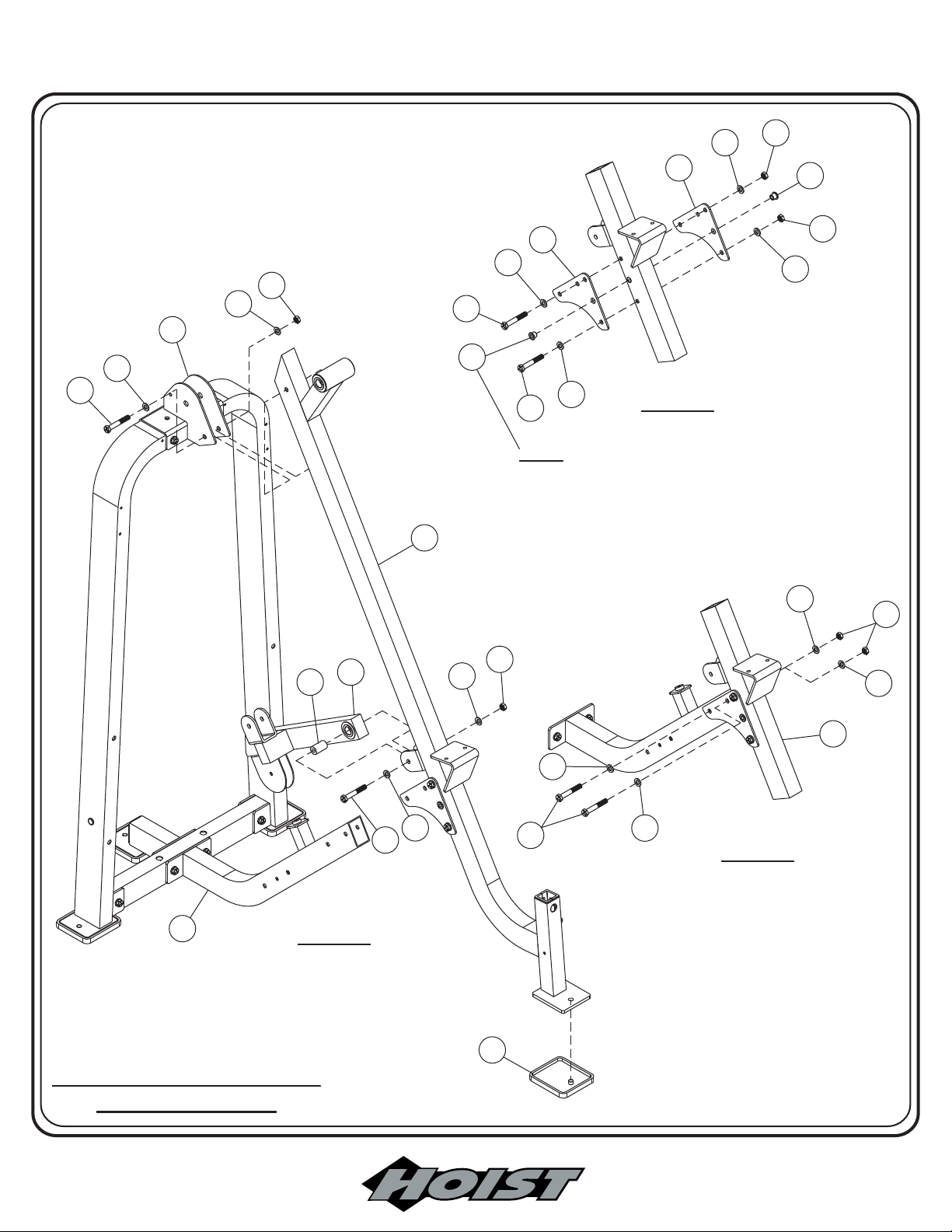

Step 2b

FRAME ASSEMBLY

Continue assembly by attaching both (7)’s to (6); when

NOTE:

securing both (7)’s, and (5) together, slide (CT) into the holes on (7) and

(6) before securing with (B) to ensure proper alignment. (CT) acts as a

spacer for a pulley which is installed in a later step.. Attach (6) to (2) and

(5). Then insert (CS) into (8) and attach (8) to (6). all

bolts. If the Resistance Lever Arm (8) does not swing freely.

NOTE:

Wrench Tighten

Turn back the nut (BA) till the arm swings freely.

Part Descriptions

2 - Top Pulley Mount

5 - Front Support

6 - Front Upright

7 - Gusset Plate

Hardware Descriptions

B - 1/2”-13UNC x 3” Hex Head Bolt (WZ)

C - 1/2”-13UNC x 3 1/4” Hex Head Bolt (WZ)

AA - 1/2” Washer

BA - 1/2” Nylok Nut

CA - Rubber Foot Pad

CS - 19mm dia. x 57.5mm lg. Axle

CT - 11/16” Flanged Spacer

Page - 7

HD1700 Assembly

OWNERS

MANUAL

AA

7

7

AA

BA

AA

2

AA

B

B

CT

AA

B

NOTE: WHEN SECURING BOTH (7)’S, (6),

NOTE: WHEN SECURING BOTH (7)’S, (6),

(5) TOGETHER, SLIDE (CT) INTO HOLES

AND (5) TOGETHER, SLIDE (CT) INTO HOLES

AND

(7) AND (6) BEFORE SECURING WITH (B) TO

ON

ON (7) AND (6) BEFORE SECURING WITH (B) TO

ENSURE

ENSURE PROPER ALIGNMENT. (CT) ACTS AS A

SPACER

6

SPACER FOR A PULLEY WHICH IS INSTALLED IN

PROPER ALIGNMENT. (CT) ACTS AS A

FOR A PULLEY WHICH IS INSTALLED IN

STEP -1-STEP -1-

LATER STEP.

A

A LATER STEP.

BA

CT

BA

AA

AA

BA

CS

8

AA

C

AA

BA

AA

6

AA

B

AA

STEP -3-STEP -3-

5

STEP -2-STEP -2-

*ASSEMBLY SHOWN IN THREE

*ASSEMBLY SHOWN IN THREE

STEPS FOR CLARITY.

STEPS

FOR CLARITY.

HD1700 Assembly

CA

Page - 8

OWNERS

MANUAL

Step 2c

FRAME ASSEMBLY

Continue assembly by inserting (CE) into (6), then attach (10) to (CE).

Wrench Tighten NOTE:

freely. If not, turn back the nut on the bolt for the axle just enough so that the

Arm Assembly rotates freely. Slide a (CF) onto each tube end of (10). Then

install an (11) to each side capturing (CF) between (11) and Button Head Bolt

(F). bolts. Slide a (12) onto each (11).

for the correct rear slot positioning of (12). Install the range limiting bolt (F)

through the slots in each (12). bolts. Attach (CG) to the top

of each (12). the retaining nuts then turn the nuts back just

enough so that each (12) rotates freely. Now insert both (CS)’s into (9), then

attach to (10) at the top and to (8) at the bottom. when attaching

(9) to (10), take special precaution when handling the arm. If released, the

front of (10) will swing up with a considerable amount of force, and could

cause bodily injury. bolts.

Assembly and the Weighted Connector rotates freely. If not, turn back the nut

on the bolt for the axle just enough so that the Arm Assembly and Weighted

Connector rotates freely.

Wrench Tighten See the Assembly Note

bolts. Check to see that the Arm Assembly rotates

Wrench Tighten

Wrench Tighten

WARNING:

Wrench Tighten NOTE: Check to see that the Arm

Part Descriptions

6 - Front Upright

8 - Resistance Lever Arm

9 - Weighted Connector

10 - Arm

11 - Handle Assembly

12 - Bearing Housing

Hardware Descriptions

C - 1/2”-13UNC x 3 1/4” Hex Head Bolt (WZ)

E - 1/2”-13UNC x 6” Hex Head Bolt (WZ)

F - 3/8”-16UNC x 3/4” Button Head Bolt (WZ)

R - 3/8”-16UNC x 1” Socket Head cap Screw

AA - 1/2” Washer

AB - 3/8” Washer

AE - 3/8” Lock Washer

BA - 1/2” Nylok Nut

CS - 19mm dia. x 57.5mm lg. Axle

CE - 25.4mm dia. x 120mm lg. Axle

CF - Rubber Sleeve

CG - Aluminum Bolt on Cap

Page - 9

HD1700 Assembly

OWNERS

MANUAL

ASSEMBLY NOTE:ASSEMBLY NOTE:

This view is shown from the rear for clarityThis view is shown from the rear for clarity

10

BA

AA

This view shows the proper positioning of assembly

This view shows the proper positioning of assembly

Notice how the slots in these assemblies are not

12. Notice how the slots in these assemblies are not

12.

centered

centered with the part but have been rotated more

to

AA

to one side instead. The sides of the parts which

contain

contain more of the slot are positioned to the inside.

E

with the part but have been rotated more

one side instead. The sides of the parts which

more of the slot are positioned to the inside.

STEP -1-STEP -1-

R

F

AE

10

CF

AB

6

CE

AB

AE

BA

AA

CG

11

12

10

BA

AA

CS

AA

C

9

CS

BA

WARNING: when

WARNING: when

attaching (9) to (10),

attaching

take

take special precaution

when

when handling the

arm.

arm. If released, the

front

front of (10) will swing

up

up with a considerable

amount

amount of force and

could

F

could cause bodily

injury,

injury, or damage the

machine.

machine.

(9) to (10),

special precaution

handling the

If released, the

of (10) will swing

with a considerable

of force and

cause bodily

or damage the

AA

C

AA

8

STEP -2-

STEP -2-

NOTE: REPEAT ASSEMBLY ON

NOTE: REPEAT ASSEMBLY ON

OPPOSITE SIDE.

OPPOSITE

SIDE.

STEP -3-STEP -3-

*ASSEMBLY SHOWN IN THREE

*ASSEMBLY SHOWN IN THREE

STEPS FOR CLARITY.

STEPS

FOR CLARITY.

Page - 10HD1700 Assembly

OWNERS

MANUAL

Step 2d

WEIGHT STACK ASSEMBLY

Continue assembly by attaching (14) and (CK) to (6). Now slide (15)

through (CH) and slide them both into (3). Tilt both (15)’s forward

enough to allow room to slide the Weight Plates on. Slide all 10 (22)’s and

all 5 (23)’s onto both (15)’s. Now slide (24) onto both (15)’s. Slide (13)

over both (15)’s. Angle both (15)’s vertical and secure (13) to both (1) and

(2). Secure both (15)’s to (13) using set screw (U). bolts.Wrench Tighten

Part Descriptions

1 - Weight frame Upright

2 - Top Pulley Mount

3 - Weight Stack Mount

6 - Front Upright

13 - Guide Rod Top Mount

14 - Latch Assembly

15 - Guide Rod

22 - 20 lb. Intermediate Weight

23 - 12 1/2 lb. Intermediate Weight

24 - 8 1/4 lb. Top Plate

Hardware Descriptions

C - 1/2”-13UNC x 3 1/4” Hex Head Bolt (WZ)

G - 3/8”-16UNC x 3/4” Square Head Set Screw

U - 5/16”-18UNC x 5/16”-Scocket Set Screw

AA - 1/2” Washer

BA - 1/2” Nylok Nut

CH - Weight Stack Bumper

CK - Latch Spring

CL - Latch Pin

CM - C-Clip

Page - 11

HD1700 Assembly

OWNERS

MANUAL

C

AA

2

1

U

14

CK

CL

G

CM

6

U

24

1

3

15

13

AA

BA

23

22

15

CH

Page - 12HD1700 Assembly

OWNERS

MANUAL

Step 2e

FRAME ASSEMBLY

Continue assembly by inserting (CP) into (CN). Then attach both to

(27). Now attach (27) to (16). Insert (CB) into (12) and attach (16) to

(12). bolts. Check to see that the Handle

Wrench Tighten NOTE:

Weldment and U-Bracket rotates freely. If not, turn back the nut on the

bolt for the axle just enough so that the Handle Weldment and U-Bracket

rotates freely.

Part Descriptions

12 - Bearing Housing

16 - U-Bracket

27 - Handle Weldment

Hardware Descriptions

H - 1/2”-13UNC x 3 1/2” Hex Head Bolt (WZ)

J - 5/16”-18UNC x 1” Button Head Bolt (WZ)

AA - 1/2” Washer

AC - 5/16” Washer

AF - 5/16” Lock Washer

BA - 1/2” Nylok Nut

Page - 13

CB - 25.4mm dia. x 63mm lg. Axle

CN - Handle

CP - 25.4mm dia. x 148mm lg. Axle

CQ - 3/4” Thrust Washer

CR - 3/4” Thrust Bearing

HD1700 Assembly

Loading...

Loading...