Hoist Fitness CL-2601 User Manual

RR

O

FITNESS SYSTEMS

I

SH

CL-2601

T

RECORD SERIAL NUMBER HERE

OWNERS MANUAL

June 2000

Note: Both Serial Number and Model Number are Required when Ordering Parts

Customer Service

(800) 548-5438

(619) 578-7676

Fax

(619) 578-9558

A S S E M B LY

I N S T R U C T I O N S

CONTENTS

INSTRUCTIONS (Step 1) .............................................................

FRAME ASSEMBLY (Step 2) ........................................................

PARTS LISTING ............................................................................

HARDWARE LISTING ..................................................................

BOLT SIZING CHART ..................................................................

WASHER SIZING CHART ............................................................

WEIGHT RATIOS .........................................................................

WEIGHT TRAINING TIPS ...........................................................

WEIGHT TRAINING EXERCISE LOG .......................................

2

4

27

28

29

30

32

33

35

Page 1

DECAL REFERENCE ...................................................................

GENERAL MAINTENANCE .........................................................

LIMITED WARRANTY ..................................................................

RR

O

H I

FITNESS SYSTEMS

S

T

2601 Assembly

37

39

42

A S S E M B LY

I N S T R U C T I O N S

Step 1

I N S T R U C T I O N S

Before beginning assembly please take the time to read the

instructions thoroughly. Please use the catalog in this manual to

make sure that all parts have been included in your shipment.

When ordering use the part number and description from the

catalog.

to do so will void your warranty and could result in personal

injury.

effective exercise motion possible. After assembly, you should

check all functions to ensure correct operation. If you

experience problems, first recheck the assembly instructions to

locate any possible errors made during assembly. If you are

unable to correct the problem, call your authorized Hoist dealer.

Be sure to have your serial number and this catalog when calling.

When all parts have been accounted for, continue on to Step 2.

Use only Hoist replacement parts when servicing. Failure

Hoist equipment is designed to provide the smoothest, most

TOOLS REQUIRED

Standard Allen Wrench Set

(2.5mm 3/32” - 5/16”)

Belt Tensioning Wrench

Crescent Wrench

Belt Tensioning Wrench

(Hoist Tool SM374)

Rubber Mallet

Tape Measure

RR

O

H I

FITNESS SYSTEMS

S

T

Page - 22601 Assembly

A S S E M B LY

I N S T R U C T I O N S

Page 3

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

A S S E M B LY

I N S T R U C T I O N S

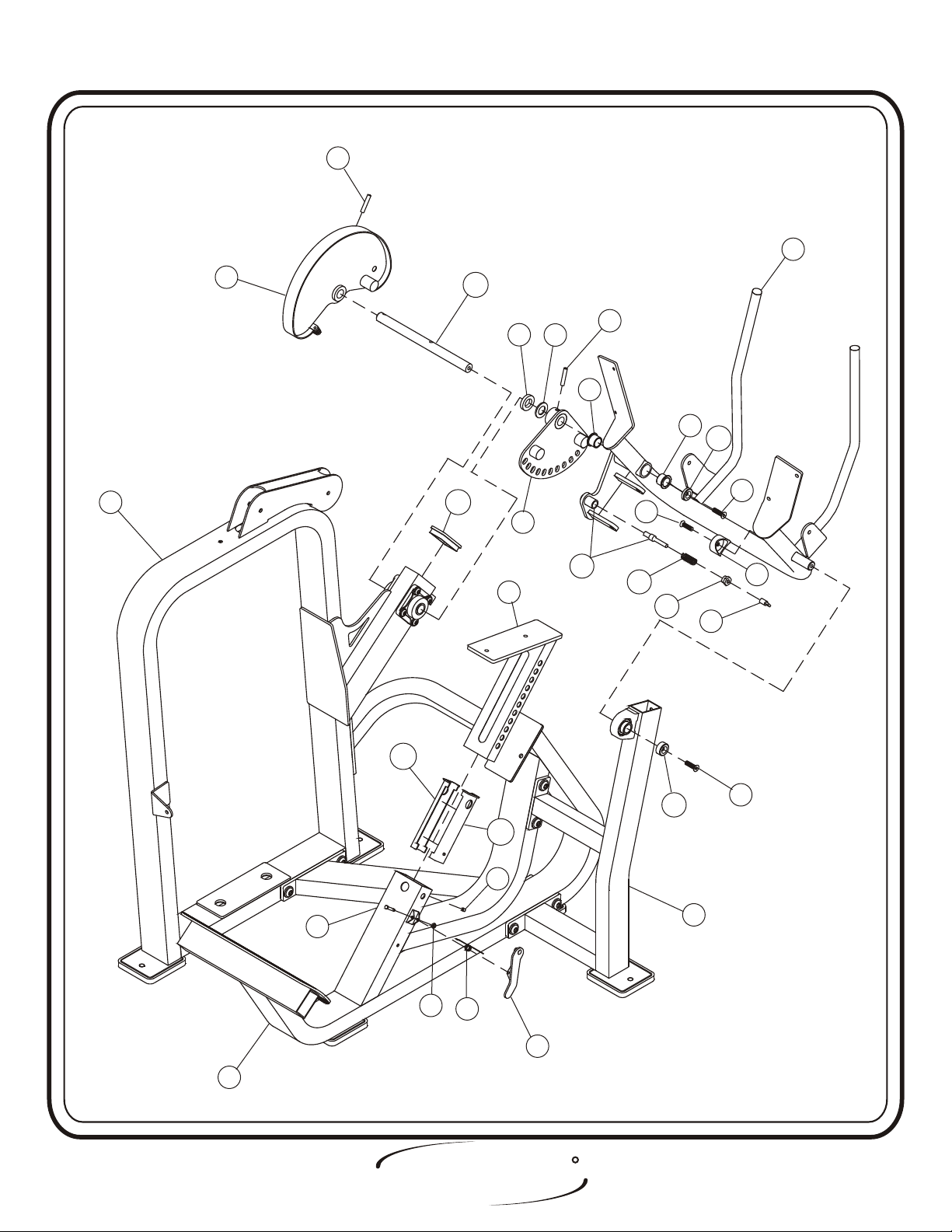

Step 2

F R A M E A S S E M B L Y

FACTORY INSTALLATION INSTRUCTION ONLY

1. ALL THREADED HOLES SHOULD BE TAPPED,

EXCEPT INSERTS.

2. ALL CALLED INSERTS MUST BE INSTALLED BEFORE ANY

ASSEMBLY.

H T

OIS

FITNESS SYSTEMS

RR

Page - 42601 Assembly

A S S E M B LY

I N S T R U C T I O N S

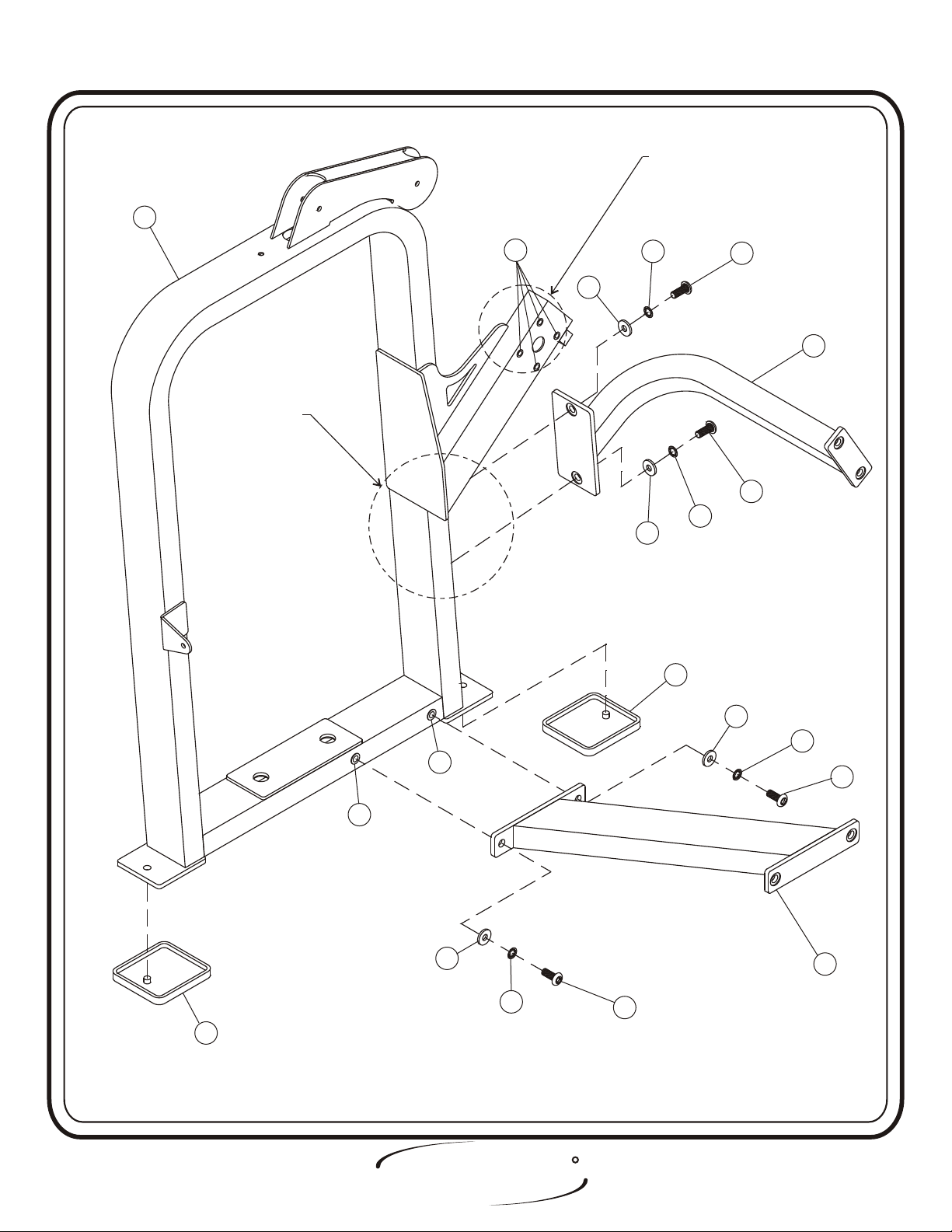

Step 2a

F R A M E A S S E M B L Y

(Factory Installation) Insert (CA) and (CB) into (1). Attach (1) to

(2). Then (3) to (1). Hand tighten bolts only, they will be tightened later.

Lift machine to position (4).

Part Descriptions

1 - Weight Cage

2 - Mount Assembly

3 - Bottom Mount Assembly

4 - Rubber Foot Pad

Hardware Descriptions

A - 1/2”-13 x 1 1/2” Button Head Screw (White Zinc)

AA - 1/2” Lock Washer (White Zinc)

AB - 1/2” Flat Washer (White Zinc)

CA - Insert 1/2”

CB - Insert 3/8”

Page 5

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

A S S E M B LY

I N S T R U C T I O N S

Factory install 4

Factory install 4

threaded inserts

threaded inserts

(CB) to weight cage.

(CB) to weight cage.

11

Factory install 2

Factory install 2

threaded inserts

threaded inserts

(CA) to weight cage.

(CA) to weight cage.

CBCB

ABAB

ABAB

AAAA

AA

2

2

AA

AAAA

44

ABAB

AAAA

CACA

CA CA

ABAB

AAAA

44

RR

H T

OIS

FITNESS SYSTEMS

AA

AA

33

Page - 62601 Assembly

A S S E M B LY

I N S T R U C T I O N S

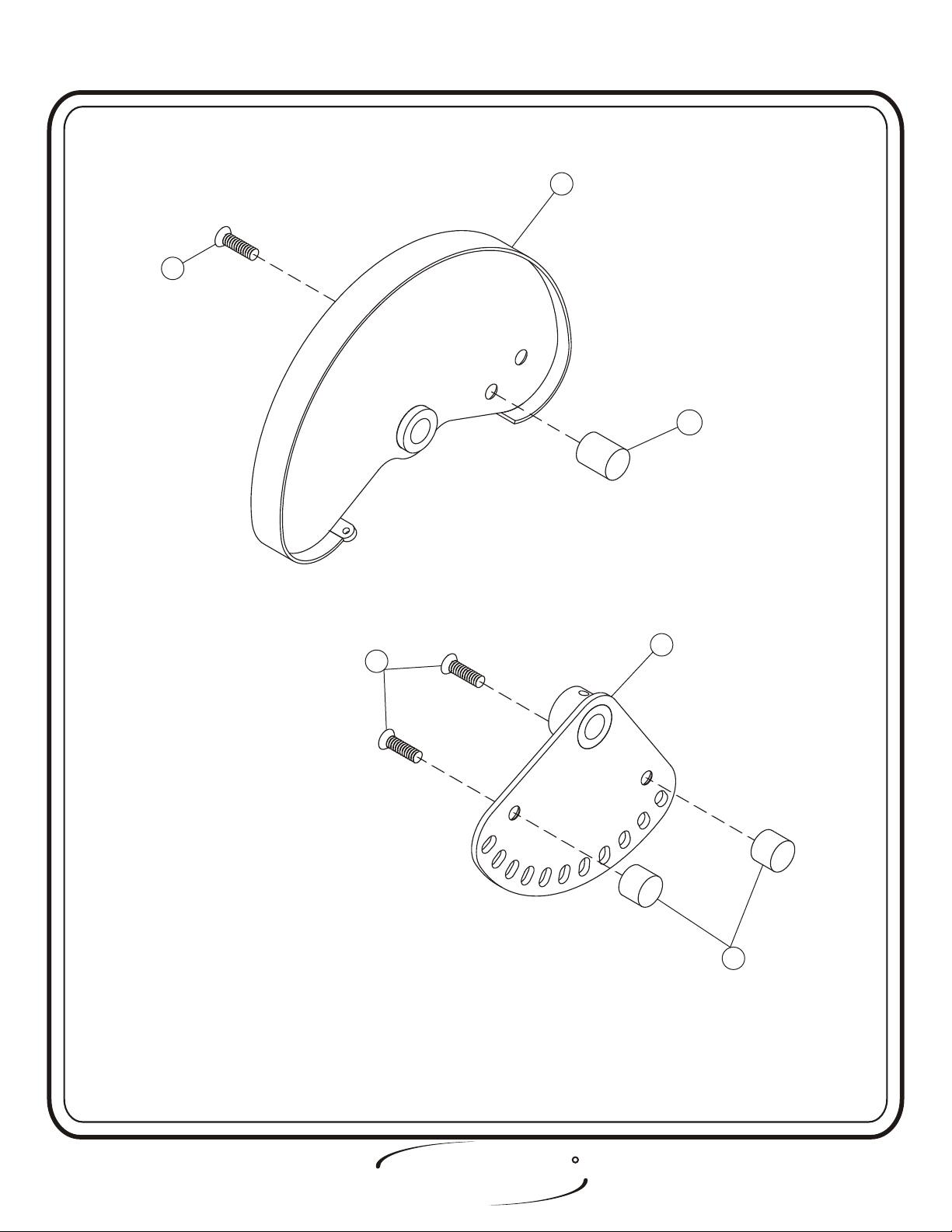

Step 2c

F R A M E A S S E M B L Y

Attach one (DW) to (10), and two (DX)’s to (9) Wrench tighten

bolts.

Part Descriptions

9 - Range of Motion

10 - Cam Assembly Large

.

Hardware Descriptions

S - 1/2”-13 x 3/4” Flat Head Screw

T - 1/2”-13 x 1” Flat Head Screw

DW - Dia. 1 1/4” x 1 1/2” Delrin

DX - Dia. 1 1/4” x 1” Delrin

Page 7

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

A S S E M B LY

I N S T R U C T I O N S

1010

T

T

DWDW

99

S

S

DXDX

H T

OIS

FITNESS SYSTEMS

RR

Page - 82601 Assembly

A S S E M B LY

I N S T R U C T I O N S

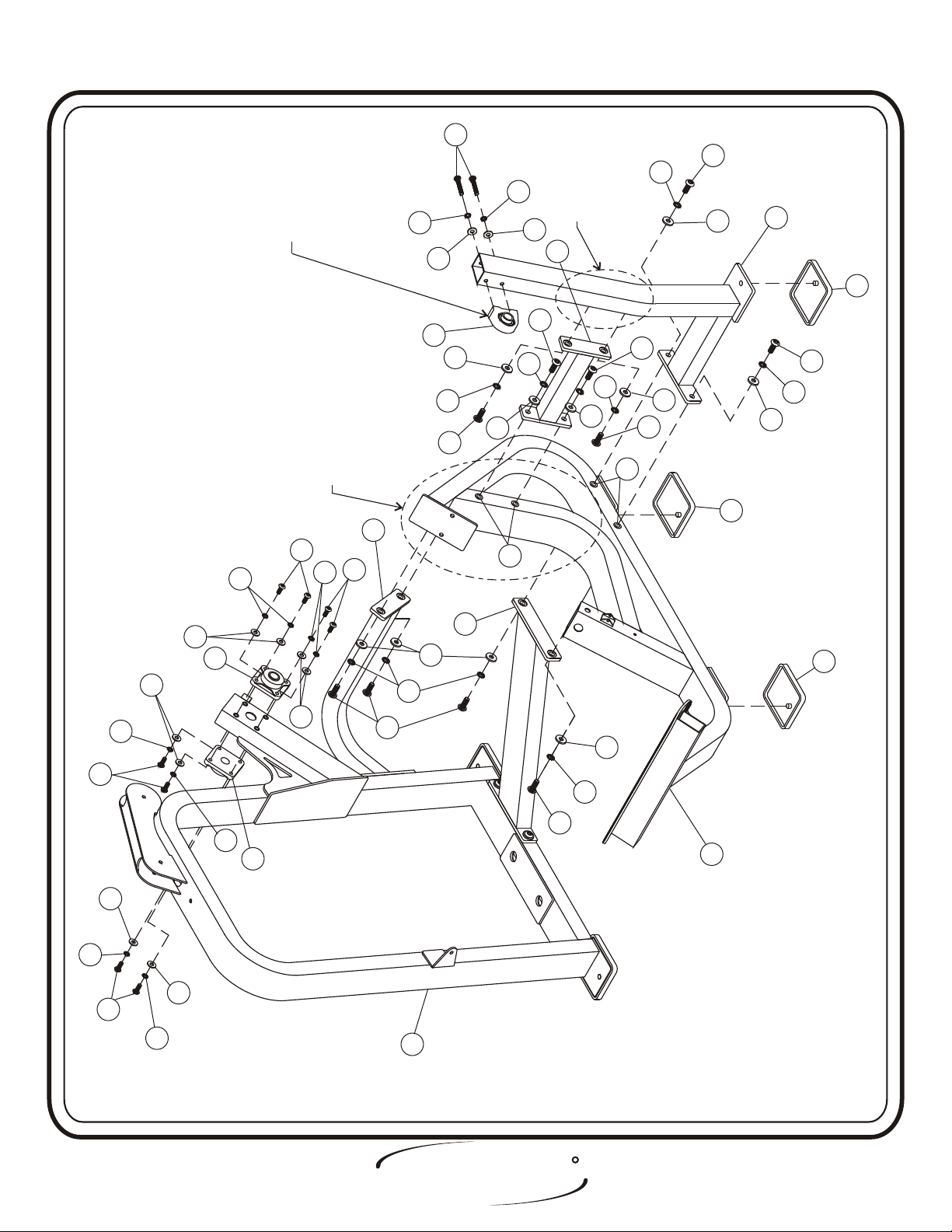

Step 2b

F R A M E A S S E M B L Y

(Factory Installation) Insert (CE) into (1), and (CA) into (5). Attach

(5) to (2) and (3). Next, attach (7) to (5), then (6) to (5) and (7). Now,

attach two (CE)’s to (1); then, (CD) to (6), insuring the set screws are

facing inwards toward (1) . Hand tighten bolts only, they will be

tightened later. Lift machine to position (4).

Part Descriptions

1 - Weight Cage

2 - Mount Assembly

3 - Bottom Mount Assembly

4 - Rubber Foot Pad

5 - Seat Frame Assembly

6 - Seat Support Mount

7 - Seat Mount Support

Hardware Descriptions

A - 1/2”-13 x 1 1/2” Button Head Screw (White Zinc)

B - 3/8”-16 x 1 1/4” Button Head Screw

C - 3/8”-16 x 3 1/2” Button Head Screw (White Zinc)

AA - 1/2” Lock Washer (White Zinc)

AB - 1/2” Flat Washer (White Zinc)

AE - 3/8” Flat Washer

AF - 3/8” Flat Washer (

CA - Insert 1/2”

CD - Pillow Block Bearing

CE - 4 Hole Flange Bearing

White Zinc)

Page 9

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

A S S E M B LY

I N S T R U C T I O N S

CC

AFAF

TOWARDS (1).

TOWARDS (1).

FACING INWARD

FACING INWARD

FOR SET SCREWS ARE

FOR SET SCREWS ARE

INSURE TAPPED HOLES

INSURE TAPPED HOLES

Factory install 4

Factory install 4

threaded inserts

threaded inserts

(CA) to Seat Frame

(CA) to Seat Frame

AFAF

AEAE

CDCD

ABAB

AAAA

AA

Assembly (5).

Assembly (5).

AEAE

77

AA

AAAA

ABAB

AA

AAAA

Mount (6).

Mount (6).

Factory install 4

Factory install 4

threaded inserts

threaded inserts

(CA) to Seat Support

(CA) to Seat Support

AA

AAAA

ABAB

ABAB

AA

CACA

ABAB

66

44

AA

AAAA

ABAB

44

22

BB

BB

ALAL

AKAK

CECE

AKAK

ALAL

BB

ALAL

CECE

AKAK

ALAL

ALAL

ABAB

AAAA

AKAK

AA

CACA

33

44

ABAB

AAAA

AA

55

BB

AKAK

ALAL

11

H T

OIS

FITNESS SYSTEMS

RR

Page - 102601 Assembly

A S S E M B LY

I N S T R U C T I O N S

Step 2c

F R A M E A S S E M B L Y

ress two (CJ)’s into (8).

P Attach (10) to (CH), then slide (CH)

through (1) and attach to (9). Next, slide one side of (8) onto (CH), then

slide the other side of (8) through (6)

and secure. Attach (13) to (8) and

secure. Attach two (CM)’s to (5), and slide (11) into (5). Attach (12) to

(5). Secure (CN) to (8) and attach (CP) to (CN).

Hand tighten bolts only,

they will be tightened later.

Part Descriptions

1 - Weight Cage

5 - Seat Frame Assembly

6 - Seat Support Mount

8 - Arm Support Assembly

9 - Range of Motion

10 - Cam Assembly Large

11 - Seat Adjuster

12 - Latch Assembly

13 - Aluminum Cap (Red Anodized)

Hardware Descriptions

D - 3/8”-16 x 1 1/4” Flat Head

R - Set Screw

CF - 3/8” x 2” Open Roll Pin

CG - Aluminum Cap

CH - 1.00 Dia. 13.609 Shaft

CJ - 1” OD Oilite Bushing

CK - Adjustment Spring

CL - 1/4” OD Pivot Shaft

CM - EZ-Glide Sleeve

CN - 1/2” Short Pull Pin

CP - Pull-Pin to Chain Link Connector

CQ - 2 x 4 End Cap

CR - 1/4” C-Clip

DR

- 3/8” Flat Head Cap (Red Anodized)

Page 11

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

A S S E M B LY

I N S T R U C T I O N S

CFCF

88

1010

11

CQCQ

CHCH

1111

DSDS

CNCN

CJCJ

CFCF

FBFB

CJCJ

DRDR

DD

DD

1313

CNCN

CPCP

DTDT

99

CMCM

CGCG

CMCM

RR

CLCL

CRCR

CKCK

1212

55

RR

H T

OIS

FITNESS SYSTEMS

DD

6

6

Page - 122601 Assembly

A S S E M B LY

I N S T R U C T I O N S

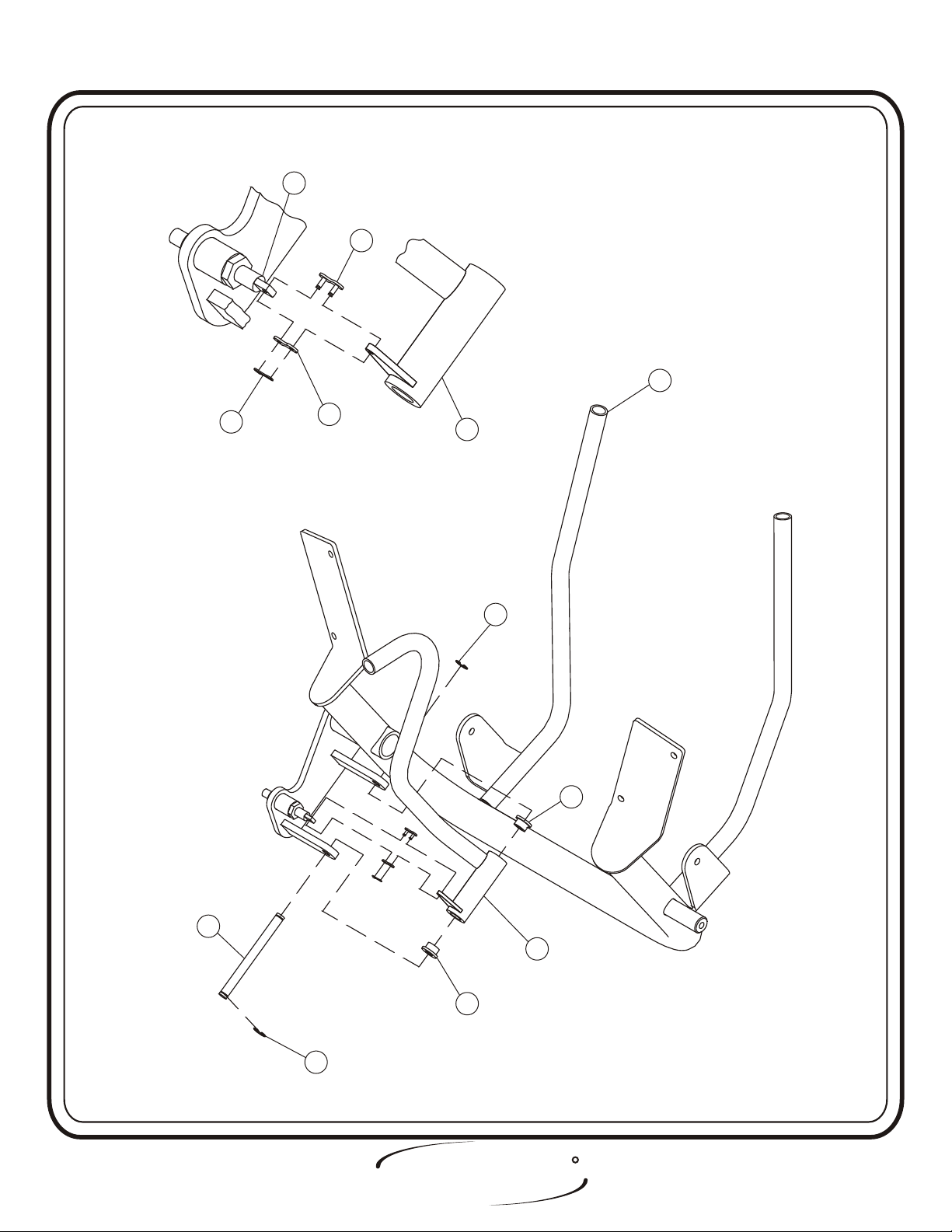

Step 2d

F R A M E A S S E M B L Y

ress two (CX)’s into (23).

P Attach (23) to (8), then (DA) to both (CP)

and (23). Hand tighten bolts only, they will be tightened later.

Part Descriptions

8 - Arm Support Assembly

23 - Handle Assembly

24 - .5 Dia Shaft

Hardware Descriptions

CP - Pull-Pin to Chain Link Connecter

CX - 1/2” Oilite Bearing

CZ - 1/2” C-Clip

DA - Master Chain Link

Page 13

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

A S S E M B LY

I N S T R U C T I O N S

CPCP

DADA

88

DADA

DADA

2323

CZCZ

CXCX

2424

CZCZ

2323

CXCX

H T

OIS

FITNESS SYSTEMS

RR

Page - 142601 Assembly

A S S E M B LY

I N S T R U C T I O N S

Step 2e

F R A M E A S S E M B L Y

In this step start by pressing

(17) in (1), then place (18) over (17)

and insure holes are lined up. Next slide in two (16)’s in (1). Slide fifteen

(19)’s and one (20) onto both (16)’s. Make sure the weight stack and its

guide rods are sitting level and bolt the tops of (16) to (1). Attach (14) to

(21) and secure (21) to (20),then press two (31)’s in each of the three

(22)’s and slide on three (22)’s on to (21). Next attach (14) to (1). Attach

the bigger end of (CT) to (21) and the other end to (15).

Wrench tighten

bolts including all previously hand tightened bolts.

Part Descriptions

1 - Weight Cage

14 - Add on Rods

15 - Weight Selector Pin

16 - Guide Rod

Hardware Descriptions

E - 5/16”-18 x 1” Button Head

F - 3/8”-16 x 1” Button Head

G - 3/8”-16 x 1” Button Head (White Zinc)

H - 3/8”-16 x 2 3/4” Button Head (White Zinc)

17 - Guide Rod Bushing

18 - Weight Bumpers

19 - 20 LB Intermediate Weight

20 - 15 LB Aluminum Top Plate

21 - Center LH BRK (Add on)

22 - 5 LB Add on Weight

31 - Bushing for Cast Add on Weight

AA - 1/2” Lock Washer

AE - 3/8” Flat Washer

AF - 3/8” Lock Washer

AG - 5/16” Flat Washer

AH - 5/16” Lock Washer

AJ - 3/8” Lock Washer

AK - 3/8” Flat Washer

CT - Selector Pin Lanyard

CV - Guide Bearing (Tall)

CW - Guide Bearing (Short)

Page 15

O

H I

FITNESS SYSTEMS

S

T

RR

2601 Assembly

Loading...

Loading...