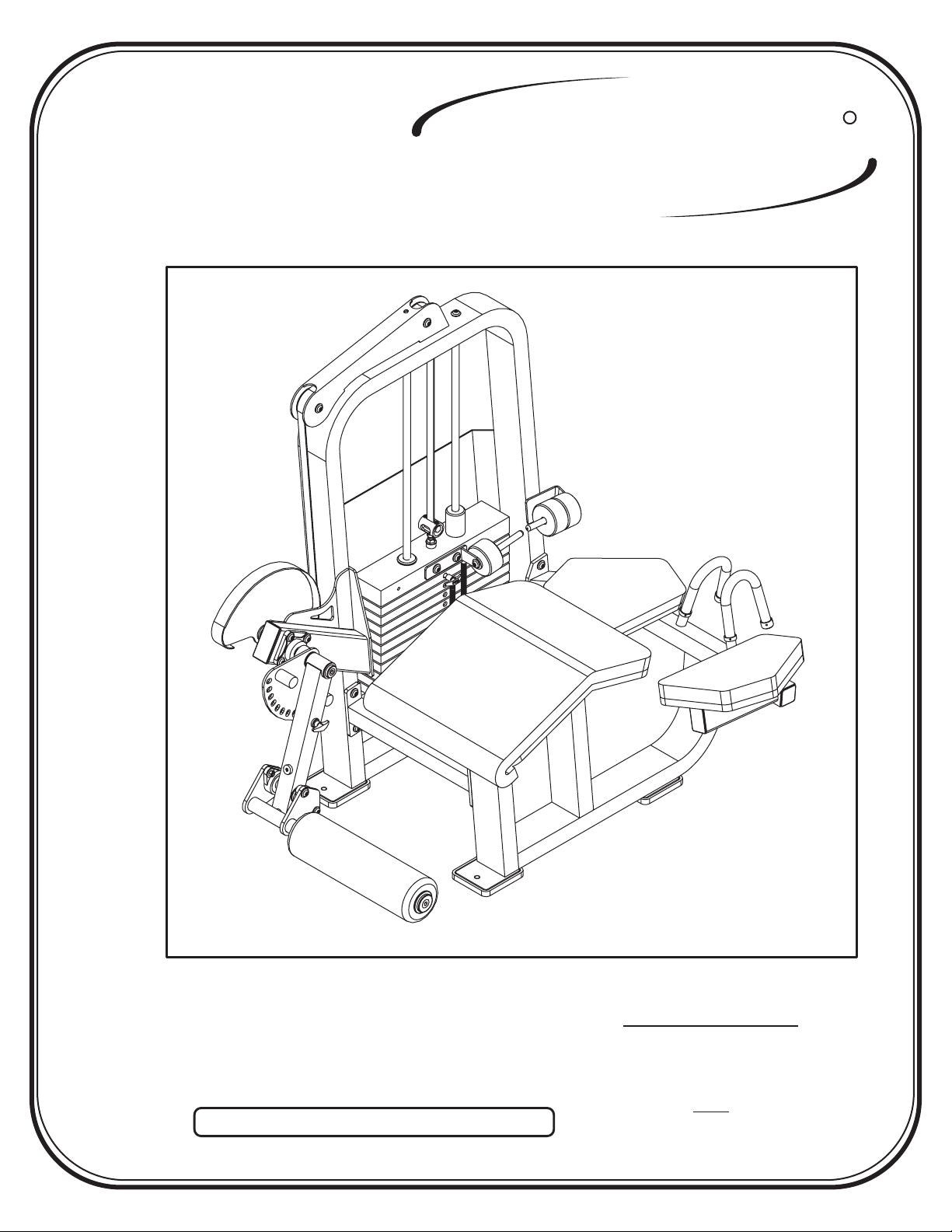

Hoist Fitness CL-2408 User Manual

HOIST

FITNESS SYSTEMS

CL-2408

R

Note: Both Serial Number and Model Number are Required when Ordering Parts

RECORD SERIAL NUMBER HERE

OWNERS MANUAL

August 2000

Customer Service

(800) 548-5438

(619) 578-7676

Fa x

(619) 578-9558

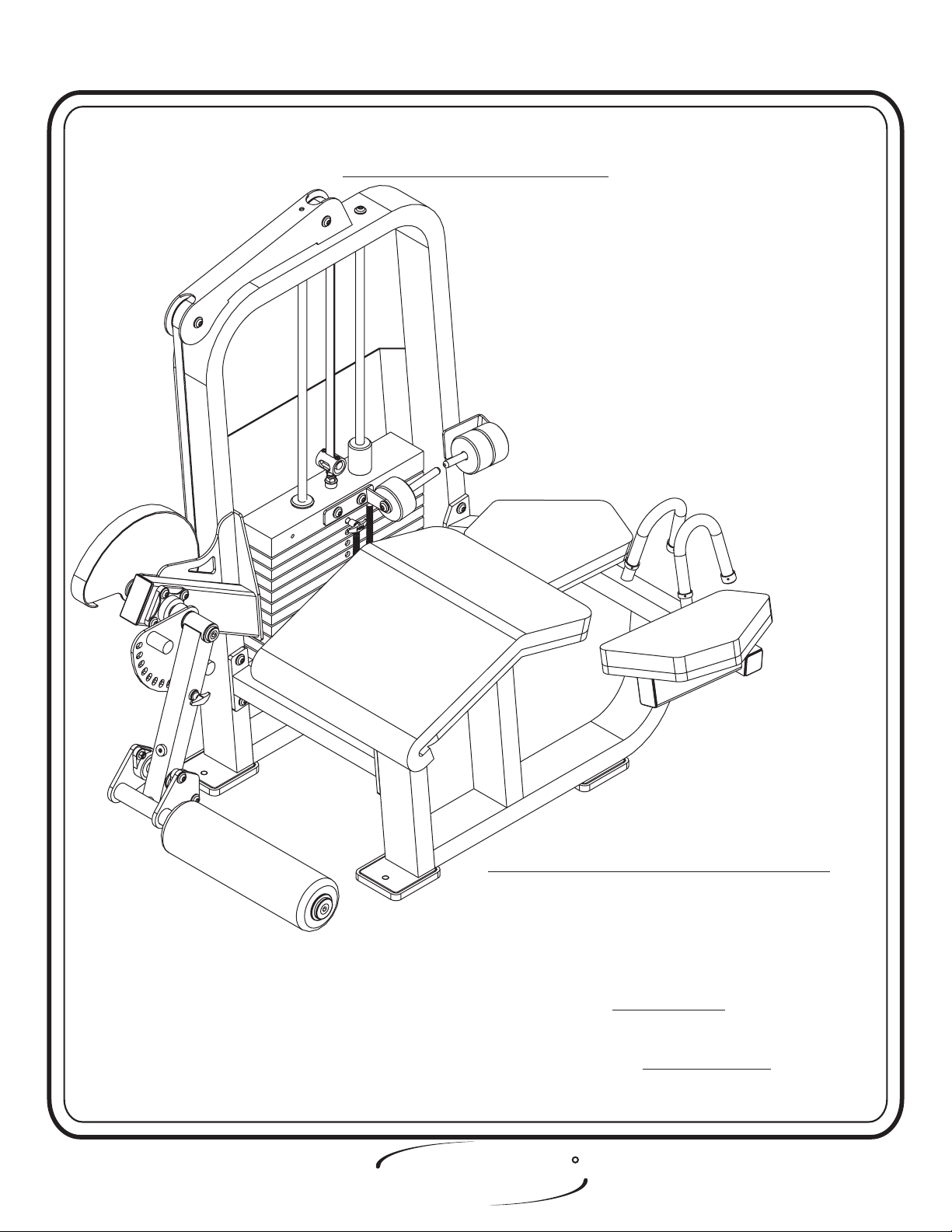

ASSEMBLY

INSTRUCTIONS

CONTENTS

INSTRUCTIONS (Step 1) .............................................................

FRAME ASSEMBLY (Step 2) ........................................................

PARTS LISTING ............................................................................

HARDWARE LISTING ..................................................................

BOLT SIZING CHART ..................................................................

WASHER SIZING CHART ............................................................

WEIGHT RATIOS .........................................................................

WEIGHT TRAINING TIPS ...........................................................

WEIGHT TRAINING EXERCISE LOG ......................................

2

4

21

22

24

25

26

28

30

DECAL PLACEMENTS .................................................................

GENERAL MAINTENANCE INFORMATION............................

LIMITED WARRANTY ..................................................................

R

HOIST

Page - 1 2408 Assembly

FITNESS SYSTEMS

32

37

40

ASSEMBLY

INSTRUCTIONS

Step 1

INSTRUCTIONS

Before beginning assembly please take the time to read the

instructions thoroughly. Please use the catalog in this manual to

make sure that all parts have been included in your shipment.

When ordering use the part number and description from the

catalog.

Use only Hoist replacement parts when servicing. Failure

to do so will void your warranty and could result in personal

injury.

Hoist equipment is designed to provide the smoothest, most

effective exercise motion possible. After assembly, you should

check all functions to ensure correct operation. If you

experience problems, first recheck the assembly instructions to

locate any possible errors made during assembly. If you are

unable to correct the problem, call your authorized Hoist dealer.

Be sure to have your serial number and this catalog when calling.

When all parts have been accounted for, continue on to Step 2.

TOOLS REQUIRED

Standard Allen Wrench Set

(2.5mm, 3/32” - 5/16”)

Crescent Wrench

Belt Tensioning Wrench

(Hoist Tool SM374)

Rubber Mallet

Tape Measure

R

HOIST

FITNESS SYSTEMS

Page - 22408 Assembly

ASSEMBLY

INSTRUCTIONS

R

HOIST

Page - 3 2408 Assembly

FITNESS SYSTEMS

ASSEMBLY

INSTRUCTIONS

Step 2

FRAME ASSEMBLY

FACTORY INSTALLATION INSTRUCTION ONLY

1. ALL THREADED HOLES SHOULD BE TAPPED,

EXCEPT INSERTS.

2. ALL CALLED OUT INSERTS MUST BE INSTALLED BEFORE

ANY ASSEMBLY.

3. PUT A DROP OF ON BOLTS IF

NECESSARY.

4. IF NECESSARY APPLY TO ALL

BEARINGS.

HOIST

FITNESS SYSTEMS

BLUE LOCTITE 242

GREEN LOCTITE 680

R

Page - 42408 Assembly

ASSEMBLY

INSTRUCTIONS

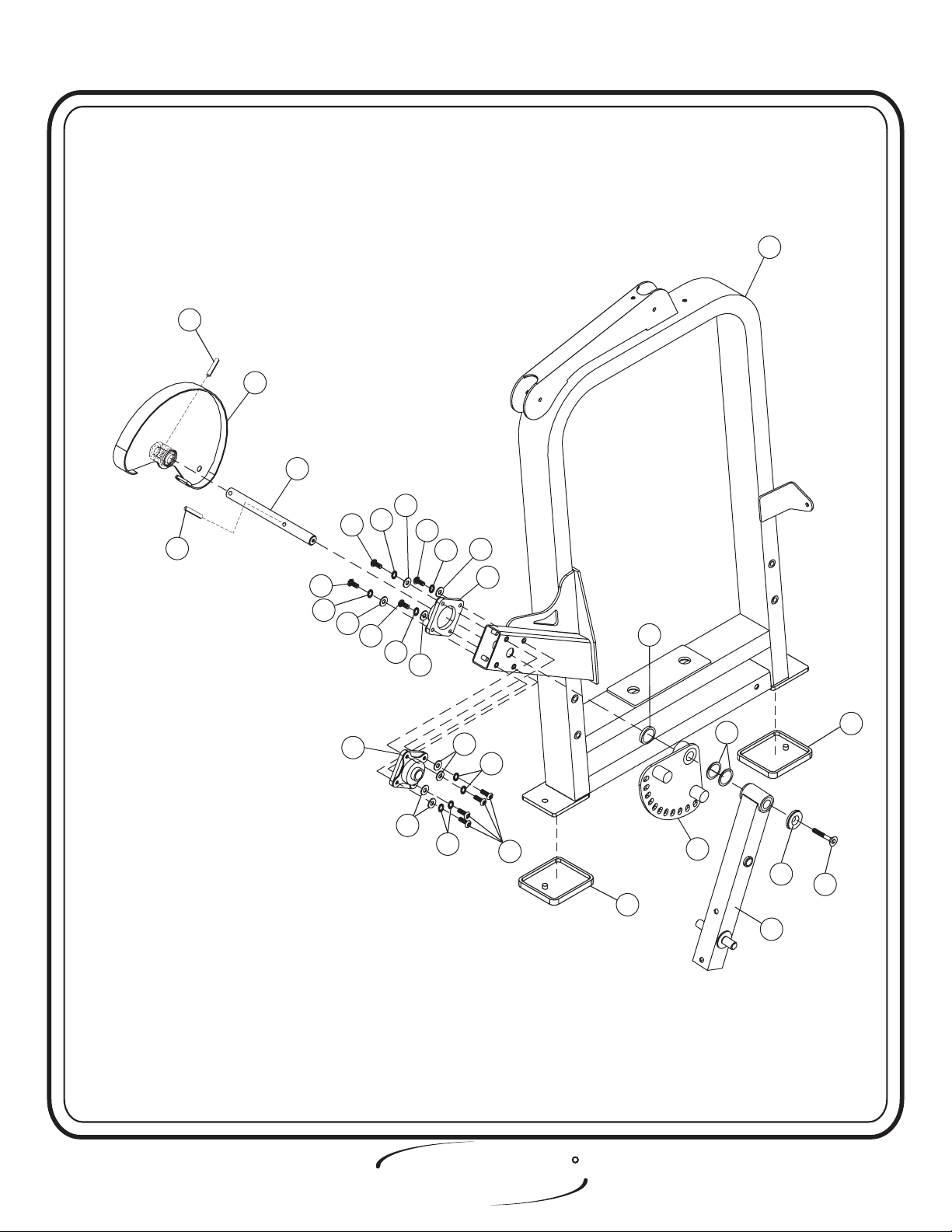

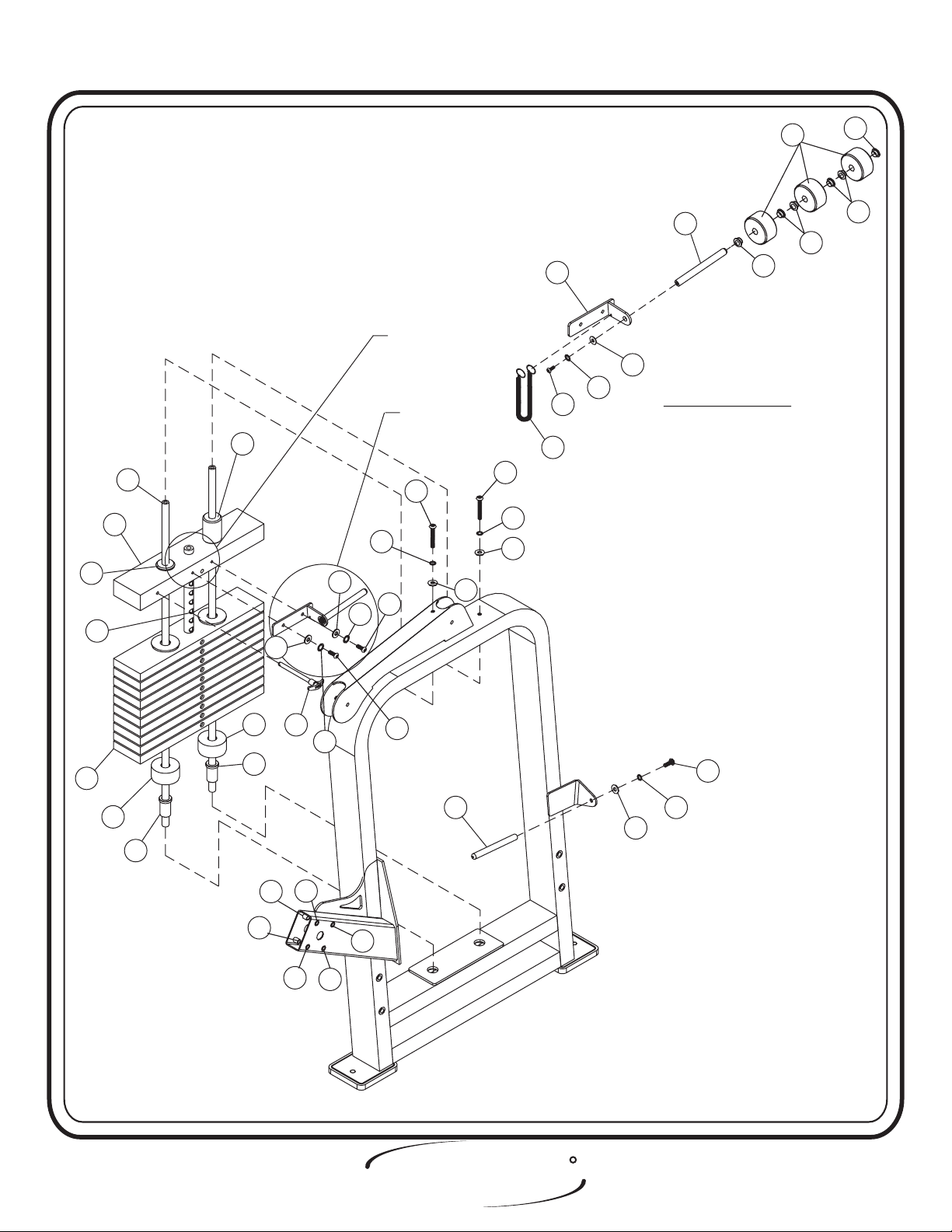

Step 2a

FRAME ASSEMBLY

In this step attach two Flange Bearings to the Weight Cage. Make sure to

put zerk fitting facing down on Flange Bearings. Next attach the 1” Dia.

CRS to the Cam Assembly (Large). Slide the other side of the 1” Dia. CRS

through the Flange Bearings and the Weight Cage. Attach the Range of

Motion, Extension Tube Assembly, and a Red Iodized Aluminum Cap to

the 1” Dia. CRS. bolts only, they will be tightened later.

Hand Tighten

Lift Machine to position Rubber Feet.

Part Descriptions

2 - Range of Motion

4 - Extension Tube Assembly

6 - Cam Assembly (Large)

7 - Weight Cage

12 - 1” Dia. CRS

23 - Rubber Feet

34 - Red Iodized Aluminum Cap

36 - Black Plastic Ring

Hardware Descriptions

D - 3/8” x 1 1/4” Flat Head Screw

E - 3/8” x 1 1/4” Button Head Screw

T - 3/8” Lock Washer (black)

W - 3/8” x 2 Open Roll Pin

X - 1” Dia. X .8mm Shims

AH - Flange Bearing

BE - 3/8” Flat Washer

R

HOIST

Page - 5 2408 Assembly

FITNESS SYSTEMS

ASSEMBLY

INSTRUCTIONS

7

W

6

12

BE

T

E

W

E

BE

T

E

T

BE

E

T

BE

AH

BE

AH

36

BE

T

T

E

23

X

2

34

4

23

D

SEE PRE-ASSEMBLED PARTS ON PAGE 20

BEFORE ASSEMBLED MACHINE.

HOIST

FITNESS SYSTEMS

R

Page - 62408 Assembly

ASSEMBLY

INSTRUCTIONS

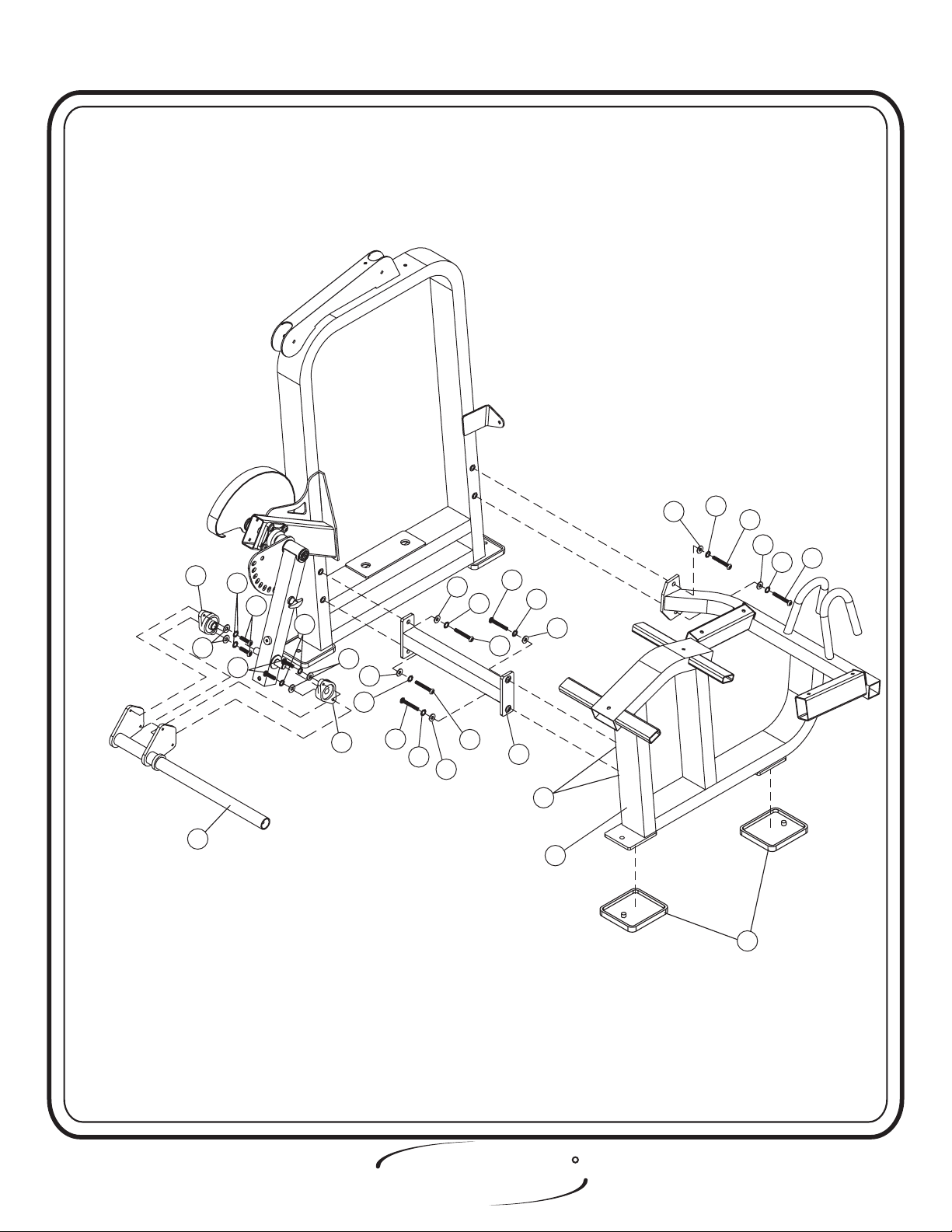

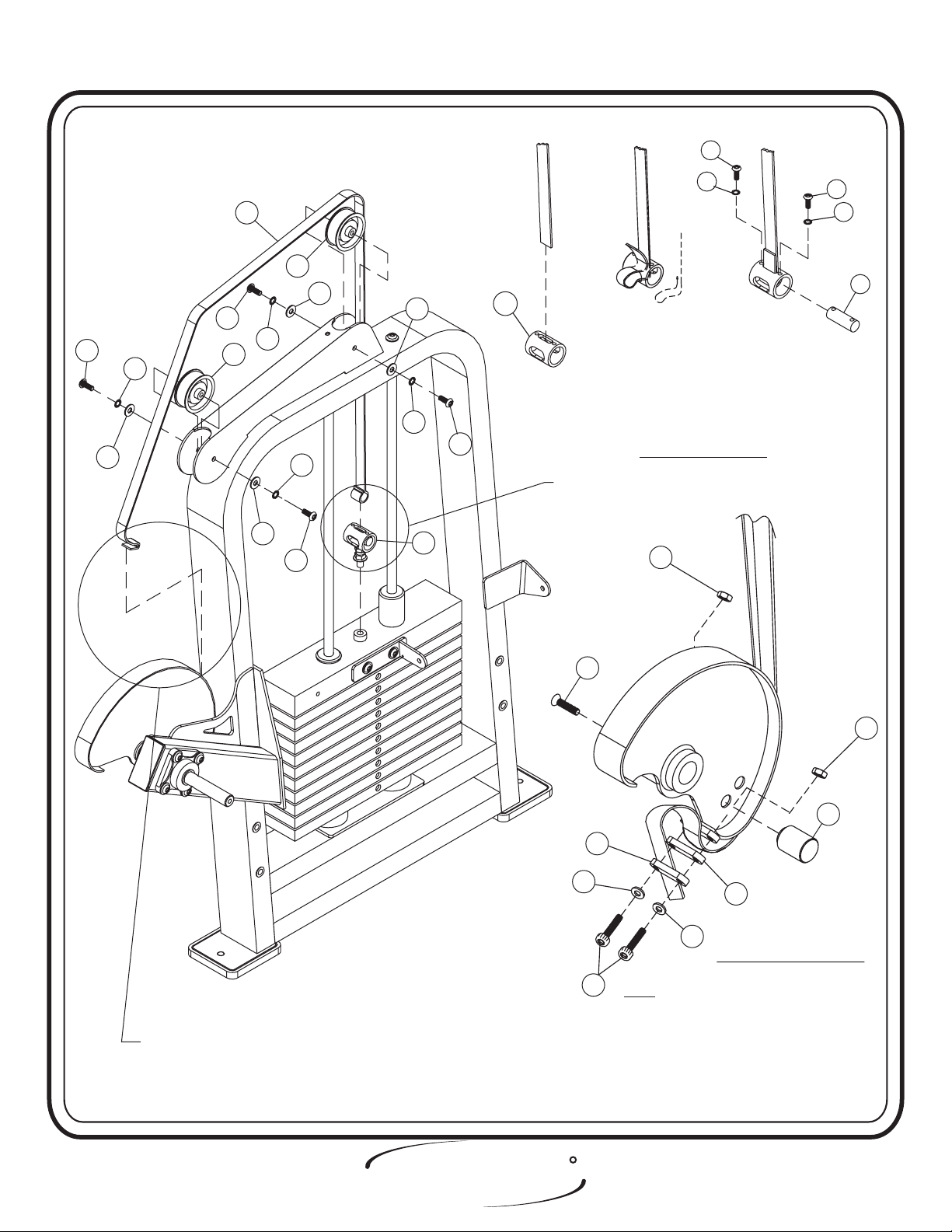

Step 2b

FRAME ASSEMBLY

In this step, start by attaching the Cross Tube Assembly to the Weight Cage,

then attach the Seated frame to the Cross Tube Assembly and the Weight Cage.

Next insert the Bearings (BF) in the Extension Tube Assembly then align the Shin

bar Assembly to the Bearings and secure. Make sure to put zerk fitting facing

down. bolts only, they will be tightened later.Hand Tighten

position Rubber Feet.

Part Descriptions

5 - Shin Bar Assembly

8 - Seated Frame Assembly

9 - Cross Tube Assembly

13 - Shaft

23 - Rubber Foot Pad

Lift Machine to

Hardware Descriptions

A - 1/2” x 1 1/2” Button Head Screw

H - 3/8-16” x 1” Button Head Screw

N - 1/2” Lock Washer

P - 1/2” Flat Washer

T - 3/8” Internal Lock Washer

AJ - 1/2” Insert

AR - Flange Bearing (014-0008004)

BE - 3/8” Flat Washer

R

HOIST

Page - 7 2408 Assembly

FITNESS SYSTEMS

AR

BE

AR

ASSEMBLY

INSTRUCTIONS

N

P

T

H

T

BE

P

N

P

A

N

N

P

A

A

P

A

N

AR

5

A

N

HOIST

FITNESS SYSTEMS

A

9

P

AJ

1/2” INSERTS ARE BEHIND

8

23

R

Page - 82408 Assembly

ASSEMBLY

INSTRUCTIONS

Step 2c

FRAME ASSEMBLY

In this step start by pressing two Guide Rod Bushings into the

Weight Cage. Take the two 3” x 1” I.D. Bumpers and place them over the

two holes in the bottom of the Now slide the Guide Rods into

Weight Cage.

the holes. Make sure to lube the Guide Rods with Spindle Oil. Next slide

on ten(10) 20 LBS Intermediate Weight Plates and one(1) 15 LBS

Aluminum Top Plate onto the Guide Rods, and bolt into place. Make sure

the Weight Stack and its Guide Rods are sitting level. Next, attach the

5/8” Dia. x 6 13/32” Rod to the Center RH BRK ( Add-On). Secure the

Center RH BRK (Add-On) to the . Slide on

15 LBS Aluminum Top Plate

three 5 LBS. Add-On Weights and attach the 5/8” Dia. x 6 13/32” Rod to

the . Attach bigger end of the Selector Pin Lanyard to the

Weight Cage

Center RH BRK ( Add-On)

, and the other end to the Weight Selector Pin.

Then bolts including all previously hand tightened boltsWrench tighten .

Hardware Descriptions

H - 3/8” x 1 Button Head Screw

Part Descriptions

3 - Center RH BRK (Add-On)

10 - Guide Rod

15 - 5/8” Dia. x 6 13/32” (Add-On)

Rod

19 - 15 lbs Aluminum Top Plate

32 - 11 Plate Selector Stem

33 - 20 lbs Intermediate Weight

37 - Add On Weight Bushing

G - 5/16” x 1” Button Head Cap Screw

J - 3/8” x 2 3/4” Button Head Cap Screw

Q - 3/8” Flat Washer

R - 3/8” Lock Washer

V - 5/16” Flat Washer

T - 3/8” Internal Lock Washer

AK - Guide Rod Bushing

AL - 3” x 1” I.D. x 1 1/2” THK Bumper

AM - Guide Bearing

AN - Guide Bearing

AP - Selector Pin Lanyard

AT - Weight Selector Pin

AU - 5 lbs Add-On Weight

AW - Insert

BB - 3/8” x 1” Button Head Screw (white zinc)

BC - 3/8” Split Washer

BE - 3/8” Flat Washer

BJ - 5/16” Internal Lock Washer

R

HOIST

Page - 9 2408 Assembly

FITNESS SYSTEMS

ASSEMBLY

INSTRUCTIONS

AN

32

19

10

AM

AU

15

3

FOR ASSEMBLY INSTRUCTION

FOR ASSEMBLY INSTRUCTION

PAGE 18

SEE PAGE 18

SEE

BE

T

FOR CLARITY SEE A-1FOR CLARITY SEE A-1

J

J

BC

BC

V

G

BJ

V

Q

Q

H

AP

A-1

37

37

37

37

AL

AT

BJ

33

AL

AK

AK

AW

AW

AW

AW

AW

2408 Assembly Page - 10

G

AW

HOIST

FITNESS SYSTEMS

15

BB

R

Q

R

ASSEMBLY

INSTRUCTIONS

Step 2d

FRAME ASSEMBLY

In this step start by attaching the Belt Assembly to the Weight

Assembly(prior to attaching the Cam Belt). Next slide the Cam Belt

through the Roller Bracket on the top of the Weight Cage. Then use a

Seat Clamp On tool to secure the two 3 1/4” Pulleys to the

under the Cam Belt.

Slide the Cam Belt into the top slot of 1 5/8” Dia. x 2

Weight Cage

1/16” Lg. Dom. (Fig. 1) Loop the end of the Cam Belt and feed it back up

through the slot, keeping the loop open. (Fig 2) Next, slide the 3/4” x 2

1/16 CRS through the Cam belt and line up the holes, then secure to the 1

5/8” Dia. X 2 1/16” Lg. Dom.(Fig. 3). ttaching the Cam Stopper to the

A

Cam Assembly. Next, attach the belt by bringing it around the Cam and in

between the Belt Clamps. Then wrap the cam belt down and around the

Belt Clamps and above another Belt clamp and secure all the Clamps

together.

Part Descriptions

1 - Belt Assembly

14 - 3/4” x 2 1/16” CRS

16 - Clamp

20 - Cam Belt 74” x 15/16” x 1/8”

22 - 1 1/2” Dia. Delrin Stop

35 - 1 5/8” x 2 1/16” lg DOM

bolts.Wrench tighten

Hardware Descriptions

C - 1/2” x 1” Flat Head Cap Screw

F - 1/4” x 1” Button Head Screw

M - 3/8” x 3/4” Button Head Screw

Q - 3/8” Flat Washer

R - 3/8” Lock Washer

S - 1/4” Lock Washer

Z - 1/4-20 x 1 1/2” Socket Head Screw

AS - 3 1/4” Pulley

AY - 1/4” Lock Nut

R

HOIST

Page - 11 2408 Assembly

FITNESS SYSTEMS

ASSEMBLY

INSTRUCTIONS

FIGURE 1FIGURE 1 FIGURE 3FIGURE 3FIGURE 2FIGURE 2

F

S

20

AS

Q

M

M

R

Q

R

AS

R

Q

M

Q

R

1

35

M

FOR BELT ASSEMBLY SEE SX145 B-1FOR BELT ASSEMBLY SEE SX145 B-1

B-1

AY

F

S

14

FOR BELT ASSEMBLY SEE B-2FOR BELT ASSEMBLY SEE B-2

C

16

S

Z

NOTE: 1. BELT SMOOTH SIDE DOWN, ALWAYS

FOR TWO TOP PULLEYS AND CAM.

SMOOTH SIDE TO WRAP AROUND

BELT RETAINER SHAFT

2. WHEN TIGHTENING THE CLAMPS

(44) TO THE BELT DO NOT EXCEED

60 IN. LBS.

3. INSURE DELRIN STOP IS SECURED IN

HOLE CLOSEST TO BELT CLAMP

16

S

B-2

AY

22

R

HOIST

2408 Assembly Page - 12

FITNESS SYSTEMS

Loading...

Loading...