Hohner UNIVERSAL 43/6 S Operating Instructions Manual

Hohner Maschinenbau GmbH

Gänsäcker 19, 78532 Tuttlingen, Telefon 07462/9468-0, Telefax 07462/9468-20

1 :egaP snoitcurtsnI-gnitarepO

Spare parts list E1

UNIVERSAL

43/6 S

Narrow Stitching Head

Edition 01/2008

CPB 9134121

HK 43/6 S Hohner Maschinenbau GmbH

2

Hohner Maschinenbau GmbH HK 43/6 S

3

Customer Entries

Stitching head no: ...........................

Machine manufacturer: ...........................

Type of manufacturer: ...........................

Manufacturer' s Address

Company name: Hohner Maschinenbau GmbH

Street: Gänsäcker 19

Town: D-78532 Tuttlingen

Telephone: +49 7462 / 9468-0

Fax: +49 7462 / 9468-20

Email: info@hohner-gmbh.de

Internet: http://www.hohnerstitching.com

Spare Parts / Customer Service

Service telephone no: +49 7462 / 9468-23

List of Contents

HK 43/6 S Hohner Maschinenbau GmbH

4

List of Contents

1 SAFETY INFORMATION 6

1.1 Purpose of this document ...............................................................................................6

1.2 The operator....................................................................................................................6

1.3 Safety symbols and the displays that have been used...................................................6

1.4 Obligation and liability .....................................................................................................7

1.5 Correct use......................................................................................................................7

1.6 Organisational measures ................................................................................................7

1.7 Safety and protective devices .........................................................................................7

1.8 Non-formal safety measures...........................................................................................7

1.9 Staff training....................................................................................................................7

1.10 Parts of the equipment which are particularly dangerous...............................................8

1.11 Maintenance and repair work, elimination of faults.........................................................8

1.12 Structural modifications to the stitching head .................................................................8

1.13 Cleaning the machine and the disposal of waste products.............................................8

2 DESCRIPTION OF THE STITCHING HEAD 10

2.1 General overview ..........................................................................................................11

2.2 Conformity.....................................................................................................................11

2.3 Marking and type plate..................................................................................................11

2.4 Technical data...............................................................................................................11

2.4.1 Normal stitch ...............................................................................................................12

2.4.2 Loop stitch...................................................................................................................13

2.5 Dimensional sheet.........................................................................................................15

2.6 Outfitting of the stitching head ......................................................................................15

2.6.1 Basic features..............................................................................................................15

3 OPERATION 16

3.1 Installation of the stitching head....................................................................................17

3.1.1 Clamping the stitching head........................................................................................17

3.1.1.1 Lateral adjustment of the stitching head.........................................................17

3.1.1.2 Front adjustment of the stitching head ...........................................................17

3.1.2 Fitting the wire guide ...................................................................................................19

3.1.3 Fitting the clincher box ................................................................................................21

3.1.4 Adjusting the clincher box ...........................................................................................23

3.2 Feeding the stitching wire .............................................................................................25

3.3 Removing the stitching wire ..........................................................................................25

3.4 Removing the wire guide tubes in the event of a wire jam ...........................................25

3.5 Straighten the stitching wire..........................................................................................27

3.6 Setting the stitch length.................................................................................................29

3.6.1 Basic setting of the stitch length..................................................................................29

3.6.2 Fine adjustment of the stitch length ............................................................................29

3.6.3 Setting the leg length of the stitch...............................................................................31

3.7 Setting the former..........................................................................................................33

3.8 Spine centering parts ....................................................................................................35

3.8.1 Fitting the holding down device - “old” model............................................................35

3.8.2 Fitting the slide ............................................................................................................35

3.8.3 Setting the holding down device .................................................................................35

3.8.4 Fitting the holding down device - “new” model..........................................................37

3.8.5 Fitting the slide ............................................................................................................37

3.8.6 Setting the centering prism .........................................................................................37

3.9 Exchangeable parts ......................................................................................................39

3.10 Procedure......................................................................................................................39

3.11 Adapting the stitch and leg length settings ...................................................................39

4 SERVICING 40

4.1 Lubrication.....................................................................................................................41

List of Contents

Hohner Maschinenbau GmbH HK 43/6 S

5

4.1.1 Lubricants....................................................................................................................41

4.1.2 Lubrication plan...........................................................................................................41

4.2 Installation and replacement of parts............................................................................ 42

4.2.1 Replacing the former...................................................................................................43

4.2.2 Removing the bender stop.......................................................................................... 45

4.2.3 Replacing the bender..................................................................................................47

4.2.3.1 Bender lock ....................................................................................................47

4.2.3.2 Removing the bender lock.............................................................................. 47

4.2.4 Replacing the knife .....................................................................................................49

4.2.4.1 Rotating/Changing the flat knife..................................................................... 49

4.2.4.2 Replacing the circular knife ............................................................................49

4.2.4.3 Adjusting the circular knife .............................................................................49

4.2.5 Replacing the driver (normal stitch)............................................................................51

4.2.6 Replacing the driver (loop stitch) ................................................................................51

4.2.7 Replacing the clincher.................................................................................................53

5 FAULTS 54

5.1 Causes and elimination of faults................................................................................... 54

7 LIST OF SPARE PARTS E1

Safety Information

HK 43/6 S Hohner Maschinenbau GmbH

6

1 Safety Information

1.1 Purpose of this document

This document will inform the operator of the Stitching Head M 43/6 S of the following:

• The safety symbols and signs

• The packing of the machine and its transportation

• The function and operation of the machine

• Commissioning the machine

• The elimination of faults which arise

• Servicing

Familiarity with this Operating Manual is thus a prerequisite for the safe and correct operation of

the stitching head. It must be read carefully by the operator before the machine is commissioned.

Keep the manual safely in a place where it is readily available and which is close to hand for

persons working on the machine.

1.2 The operator

The Stitching Head M 43/6 S must only be operated by trained personnel.

Training will be undertaken by the manufacturer or by persons who have been authorised by the

manufacturer to undertake such training.

1.3 Safety symbols and the displays that have been used

This symbol indicates immediate danger to the life or health of

persons in the immediate vicinity of the machine.

Non-observance of dangers which are so indicated can have grave

consequences and can cause serious damage to health, or may even to

lead to deaths.

This symbol indicates that a potentially dangerous situation has

arisen.

Non-observance of dangers which are so indicated can lead to slight injuries

to persons or damage to equipment.

This symbol indicates that tips on how to use the machine or

particularly useful information are available.

These will help you to use all of the functions of the machine in an optimal

manner.

-

This symbol requires you to take action.

•

This sign serves as a symbol for listing items.

Safety Information

Hohner Maschinenbau GmbH HK 43/6 S

7

1.4 Obligation and liability

The 43/6 S Stitching Head has been built according to state-of-the art technology under

observance of all the recognised safety regulations. However, dangers to life and limb of the user

or third parties and damage to the system or other material assets can still occur during use.

The stitching head should only be used,

• for the purpose for which it was designed

• when it is in a perfect technical condition.

Faults which could reduce levels of safety when using the machine must be eliminated

immediately.

Warranties and liability on the part of the manufacturer are fundamentally covered by the

regulations laid down in our ”General sales and delivery conditions”.

Warranty claims will only be valid if the number label is affixed

(number label on stitching head housing).

1.5 Correct use

The Stitching Head 43/6 S is designed exclusively for binding brochures and leaflets or similar

items.

Any use of the machine contrary to that described above is forbidden, since incorrect use of the

machine can present a danger.

1.6 Organisational measures

The user of machine is required to provide the required personal safety equipment. All existing

safety devices should be checked regularly.

1.7 Safety and protective devices

All safety and protective devices must be correctly attached to the machine and should be in full

working order before every start-up of the machine and Stitching Head 43/6 S.

Safety and protective devices may only be removed:

• After the machine has come to a standstill and

• As security against the machine starting up again.

1.8 Non-formal safety measures

The Operating Manual must be kept so that it is permanently at hand at the machine with

Stitching Head 43/6 S. There are also generally valid local regulations concerning accident

prevention and environmental protection measures which should be made available and observed

in addition to those described in the Operating Instructions.

All safety and danger signs on the machine should be maintained in a legible condition and should

be renewed where necessary.

1.9 Staff training

Only trained and instructed personnel may install, operate, set and maintain the stitching head.

Safety Information

HK 43/6 S Hohner Maschinenbau GmbH

8

1.10 Parts of the equipment which are particularly dangerous

There is a risk of injury in the area of moving parts of the stitching head.

1.11 Maintenance and repair work, elimination of faults

Undertake the required setting, servicing and inspection work on schedule.

The machine may only be operated in cycle mode during all servicing, inspection and repair work

on the Stitching Head 43/6 S.

Always make absolutely sure that the machine is only being operated by one person in order

to avoid any influence to the machine by any other persons.

1.12 Structural modifications to the stitching head

Changes to the stitching head, additions or modifications may only be undertaken with the

manufacturer's permission.

1.13 Cleaning the machine and the disposal of waste products

The functionality of the stitching head and perfect processing of the product can only be

guaranteed over a prolonged period of time if the stitching head is regularly cleaned and

maintained in accordance with the standard methods of mechanical engineering.

In this regard, particular attention should be paid to the regular removal of trimmed paper

residue and paper dust, as these can result in jamming of the stitching head or increased

wear.

Substances and materials used (e.g. solvents and lubricants) must be handled correctly and

disposed of in an environmentally friendly manner.

Safety Information

Hohner Maschinenbau GmbH HK 43/6 S

9

Description of the Stitching Head

HK 43/6 S Hohner Maschinenbau GmbH

10

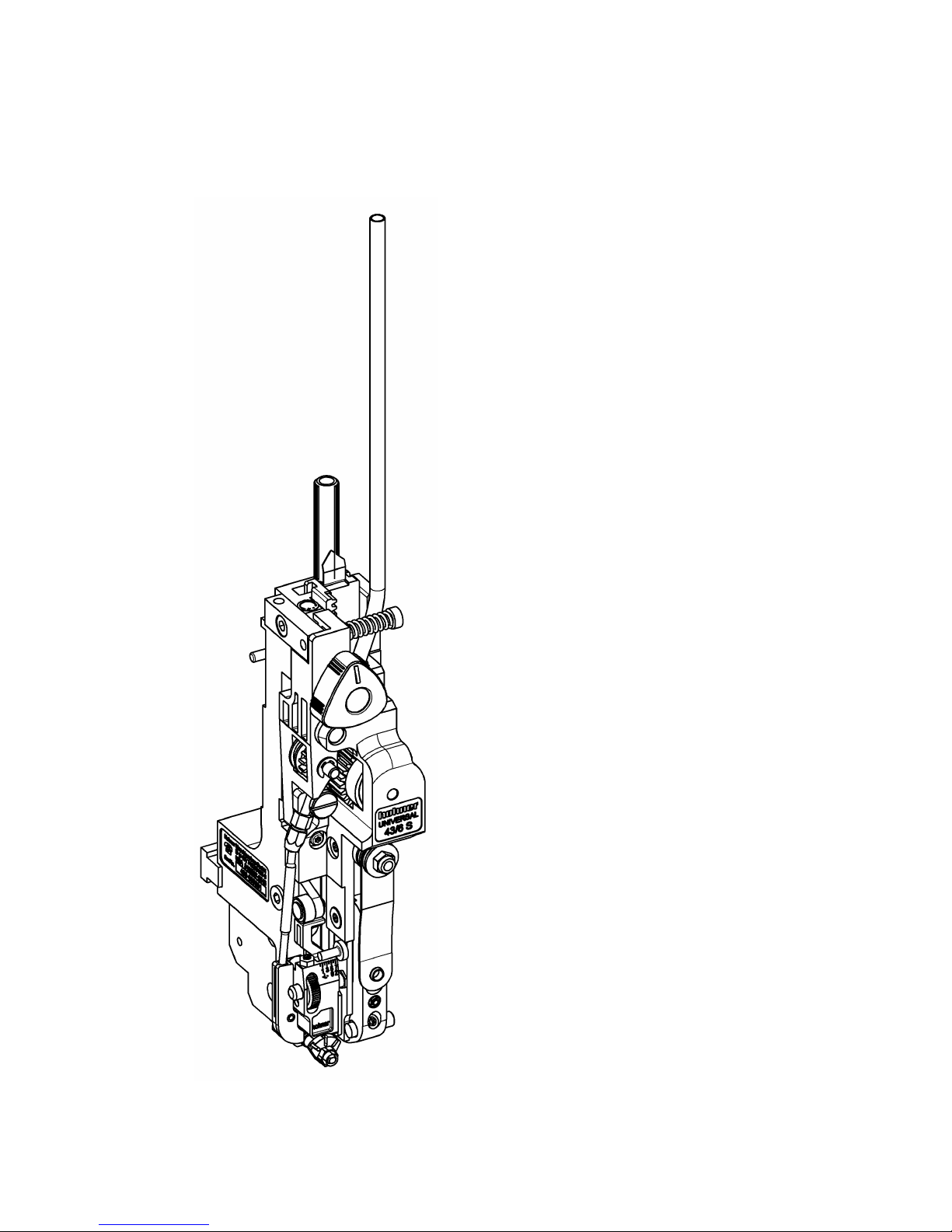

2 Description of the Stitching Head

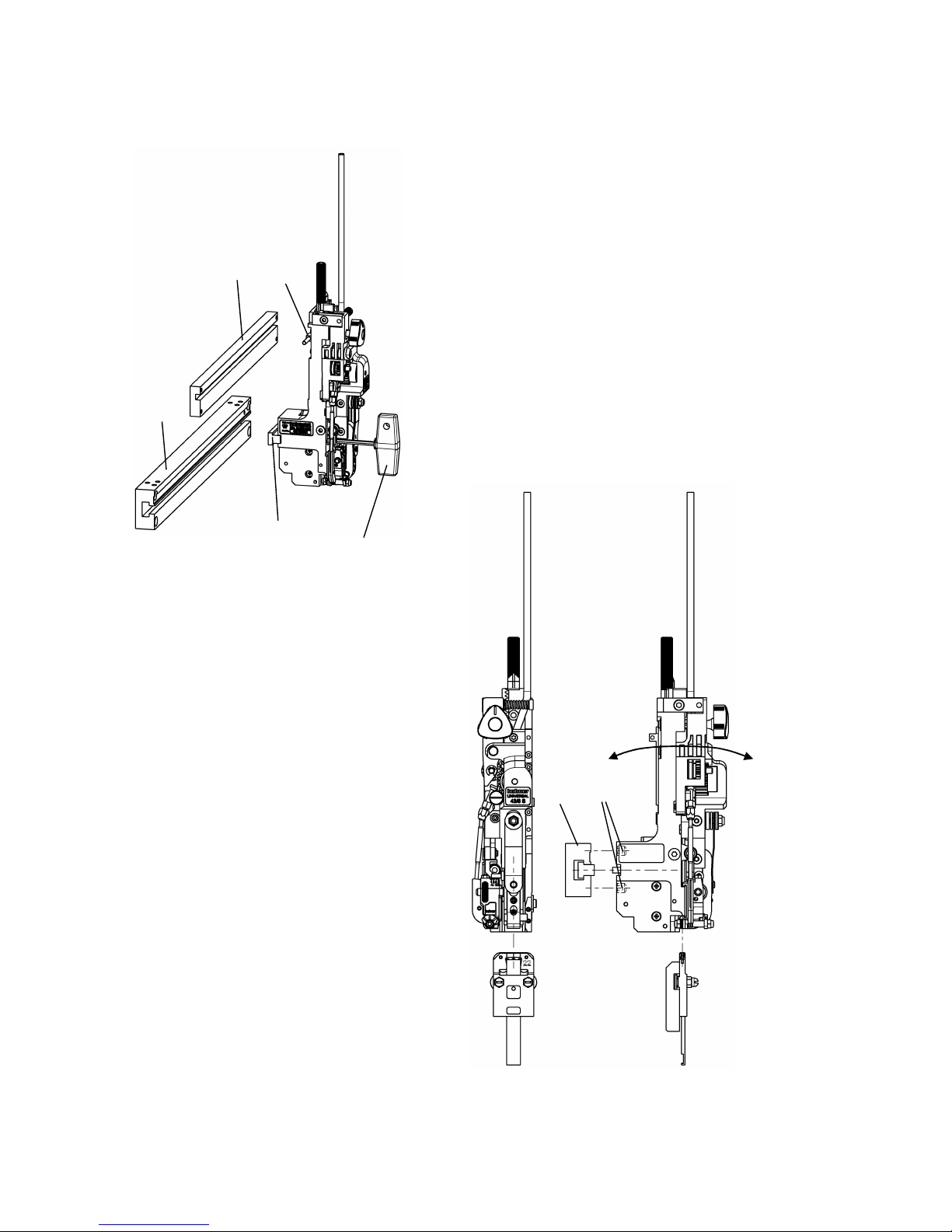

Fig. 1

Description of the Stitching Head

Hohner Maschinenbau GmbH HK 43/6 S

11

2.1 General overview

- Fig. 1 -

2.2 Conformity

The Stitching Head 43/6 S conforms to the following guidelines and standards:

- Machine Guideline (98/37/EEC)

- EN 1010-1:1998 (final draft version) and

EN 1010-4:1997 ”Machine safety – safety requirements in connection with the design and

manufacture of printing and paper processing machines”, ”Part 1: General requirements” and

”Part 4: Bookbinding, paper processing and paper finishing machines”.

- This Operating Manual takes account of DIN EN 292, machine safety, basic terminology, general

principles of design.

2.3 Marking and type plate

The type plate is located at the front of the stitching head.

2.4 Technical data

Net weight of the stitching head 1,5 kg / 3.31 lbs

Quality of the stitching wire Only use perfect quality classes, in normal or

steel strength as required. Pay attention to

abrasion resistance, as heavy abrasion will clog

the wire-guidance parts.

Description of the Stitching Head

HK 43/6 S Hohner Maschinenbau GmbH

12

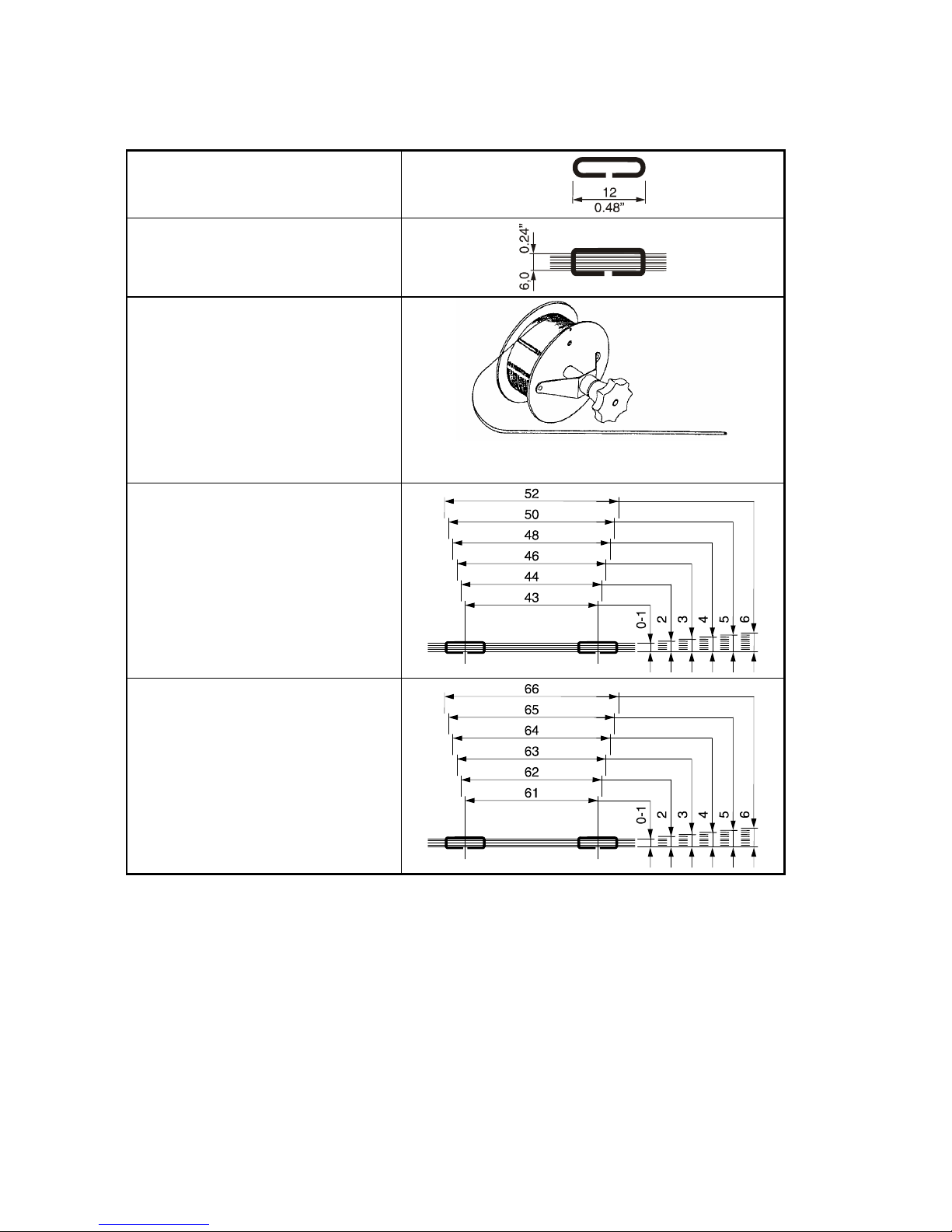

2.4.1 Normal stitch

Wire stitch dimensions

Max. stitch thickness

Stitching wire coil

No. 24 - 26

Ø 0.60 - 0.50 mm

(Ø 0.024 - 0.020 in.)

or:

Stitching wire coil

No. 26 - 28

Ø 0.50 - 0.40 mm

(Ø 0.020 - 0.016 in.)

Possible distances between wire

stitches and stitch thicknesses in mm

With holding down device

Description of the Stitching Head

Hohner Maschinenbau GmbH HK 43/6 S

13

2.4.2 Loop stitch

Standard - L6 - - L8 Wire stitch

dimensions

Max. stitch

thickness

Stitching wire coil:

No. 24 - 26

Ø 0.60 - 0.50 mm

Ø 0.024 - 0.020

in.

Possible

distances

between wire

stitches and stitch

thicknesses in

mm

With holding

down device

Description of the Stitching Head

HK 43/6 S Hohner Maschinenbau GmbH

14

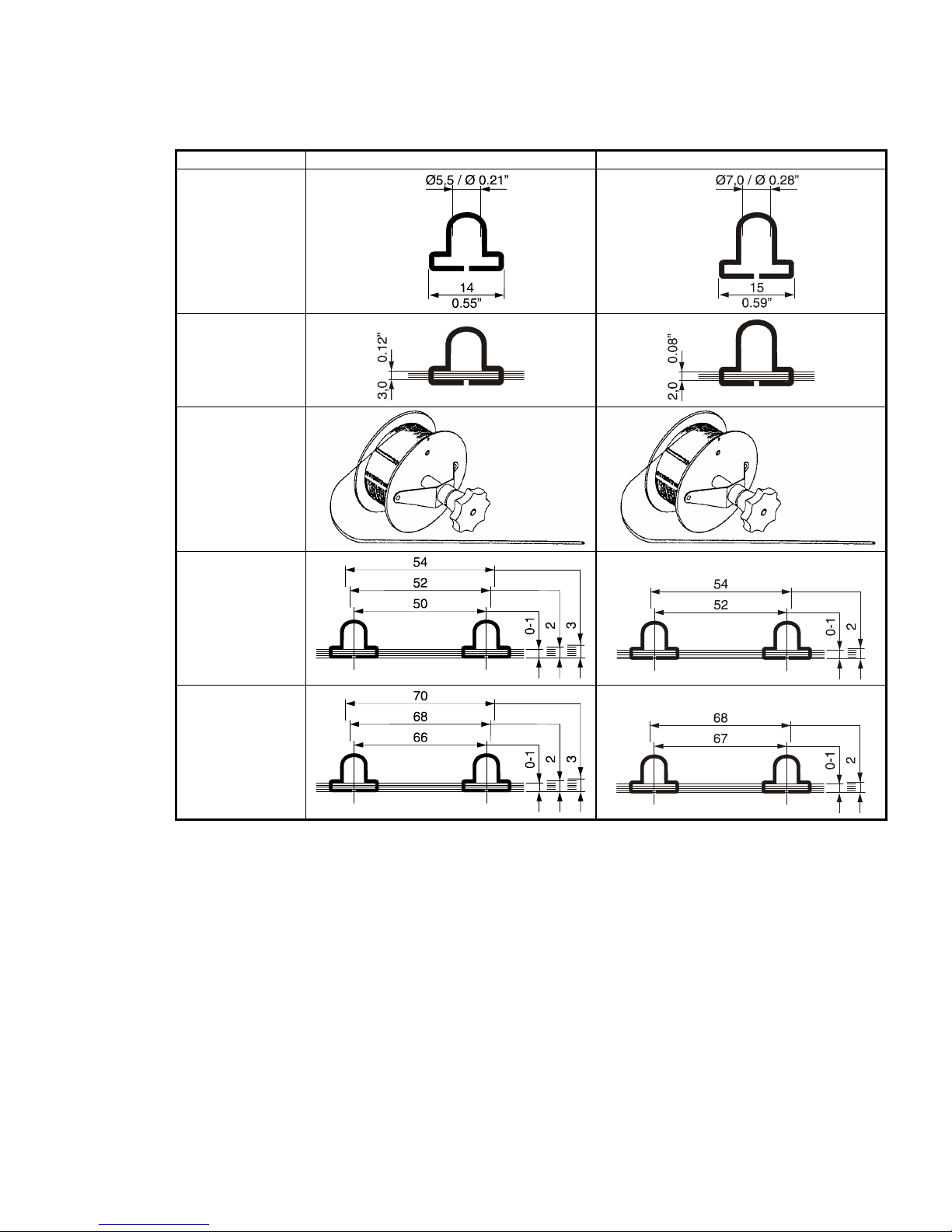

Fig. 2

Stroke

Description of the Stitching Head

Hohner Maschinenbau GmbH HK 43/6 S

15

Fig. 3

2.5 Dimensional sheet

- Fig. 2 , Fig. 3-

2.6 Outfitting of the stitching head

2.6.1 Basic features

The stitching head is delivered with the following accessories:

DESIGNATION ORDER NUMBER

Clincher box setting gauge 31 64 448

Torx screwdriver T10 46 00 044

Torx screwdriver T20 46 00 045

Allen key with T-handle SW4 x 70 / SW4-150 46 64 098 / 46 00 033

Adjusting handle 94 64 115

Wire guide, complete according to machine manufacturer

Clincher box, complete according to machine manufacturer

Stroke

Middle of Staple

Stroke

Operation

HK 43/6 S Hohner Maschinenbau GmbH

16

3 Operation

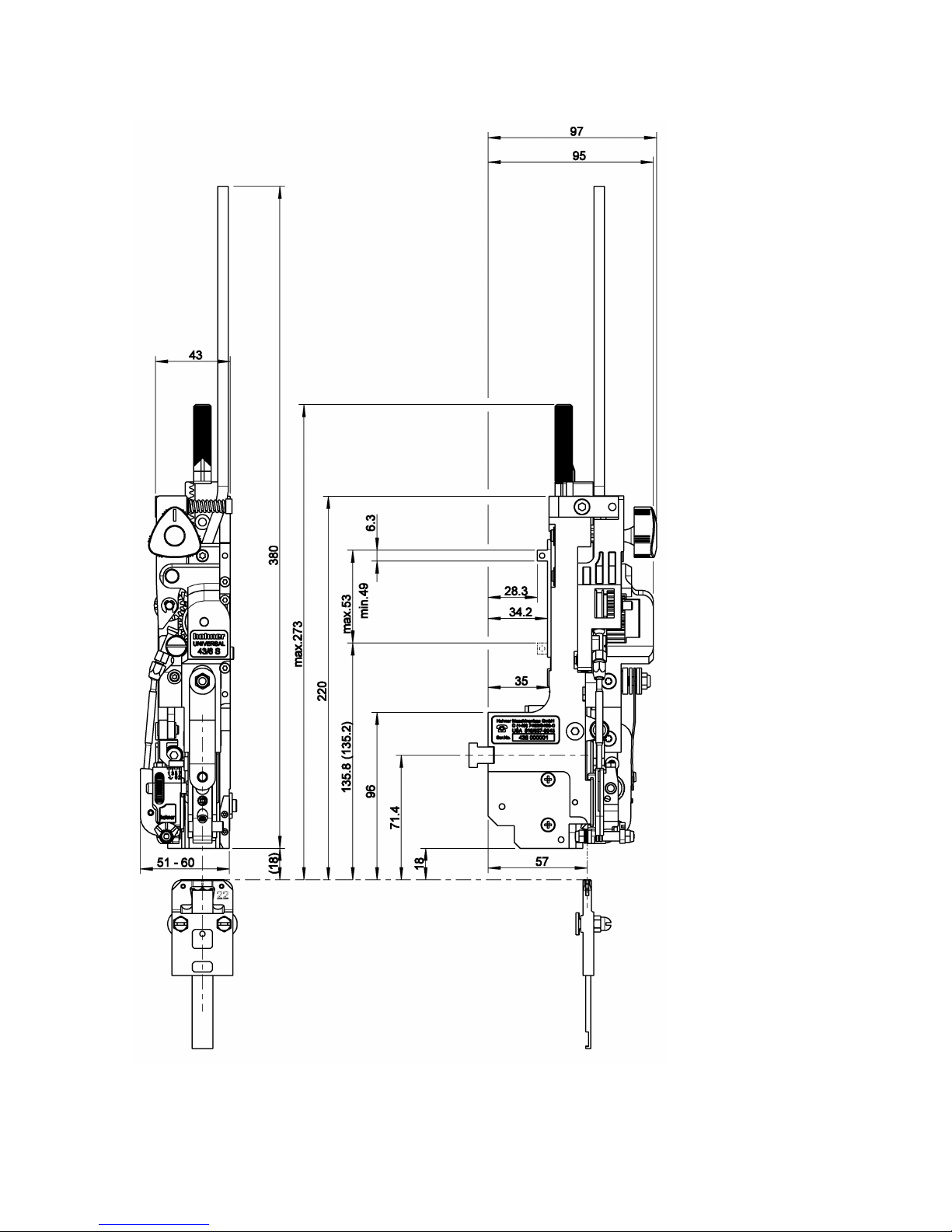

Fig. 4

Fig. 5

a

e

d

c

b

f

b

Middle of staple

Operation

Hohner Maschinenbau GmbH HK 43/6 S

17

3.1 Installation of the stitching head

3.1.1 Clamping the stitching head

- Fig. 4 -

The stitching head is held by a tenon block which is inserted into the stitching head mounting on

the machine.

- Unscrew tenon block from the stitching head with Allen key SW4 e.

- Introduce tenon block laterally into the stitching head mounting b.

- Insert stitching head into stitching head mounting, so that the driver lug c can be inserted into

the stroke bar d and the tenon block fits into the stitching head.

- Fix the stitching head by tightening the tenon block in the stitching head mounting using the Allen

key e.

3.1.1.1 Lateral adjustment of the stitching head

- Fig. 4, Fig. 5 -

The center of the wire formed parts within the stitching head must be set to the desired stitching

position for the wire stitch by lateral adjustment.

- Loosen the tenon block a with the Allen key e.

- Move the stitching head sideways, until the desired position is reached.

- Fix the tenon block in the stitching head mounting b with the Allen key.

3.1.1.2 Front adjustment of the stitching head

- Fig. 5 -

The lifting movement of the wire formed parts must drive the stitch accurately into the clincher box

forming gap. (Cf. Chap. 3.1.4). If the center of the wire stitch is located too far in front of or behind

the clincher box, or if the lifting movement is not precisely aligned with the clincher box, this can be

corrected by adjusting the set screws f on the stitching head.

- Remove stitching head.

- Adjust set screws f.

- Fit stitching head.

Loading...

Loading...