Hohner EXACT-PLUS Operating Instructions Manual

Operating Instructions Page 1

Spare parts list E1

EXACT-PLUS

Semiautomatic

booklet wire

stitching machine

Hohner Maschinenbau GmbH

Gänsäcker 19, D-78532 Tuttlingen, Telefon +49 (0) 74 62 / 94 68-0, Telefax +49 (0) 74 62 / 94 68-20

2 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

Customer Details

Inventory no.: ...........................

Location ...........................

Manufacturer's Address

Company name: hohner

Maschinenbau GmbH

Street: Gänsäcker 19

Town: D-78532 Tuttlingen

Telephone: +49 (0) 74 62 / 94 68-0

Fax: +49 (0) 74 62 / 94 68-20

Email: info@hohner-postpress.com

Internet home page: www.hohner-postpress.com

Obtaining Spare Parts / Customer Service

Telephone: +49 (0) 74 62 / 94 68-0

Fax: +49 (0) 74 62 / 94 68-20

Operating Manual

Document: Translation of the german original Operating

Instructions

Document number: EXACT-PLUS, Volume 1/2

Version: 10/2010

Spare Parts Lists

Document number: EXACT-PLUS, Volume 2/2

Hohner Maschinenbau GmbH EXACT-PLUS 10/2010 3

Table of Contents

Table of Contents

1 Basic safety precautions.................................................................................. 5

1.1 Purpose of this document .............................................................................................. 5

1.2 The operator .................................................................................................................. 5

1.3 Safety symbols and the displays in use......................................................................... 5

1.4 Duty and liability............................................................................................................. 6

1.5 Correct use of the machine............................................................................................ 6

1.6 User requirements ......................................................................................................... 6

1.7 Safety and protective systems....................................................................................... 6

1.8 Informal safety measures .............................................................................................. 6

1.9 Personnel training.......................................................................................................... 6

1.10 Parts of the machine that are particularly dangerous .................................................... 7

1.11 Servicing and repair work, elimination of faults ............................................................. 7

1.12 Structural modifications to the machine......................................................................... 7

1.13 Cleaning the machine and the removal of waste products ............................................ 7

1.14 Noise levels produced by the machine .......................................................................... 7

2 Description of the stitching machine EXACT-PLUS ........................................ 8

2.1 Safety-related components............................................................................................ 9

2.1.1 Position of the cut-out switch / emergency switch ..................................................... 9

2.1.2 Stitching aggregate.................................................................................................... 9

2.1.3 Delivery...................................................................................................................... 9

2.1.4 Staggered stitch......................................................................................................... 9

2.1.5 Main switch and emergency switch ........................................................................... 9

2.2 Electrical connections ................................................................................................. 11

2.3 Motor protective relay .................................................................................................. 11

2.4 Block mode for drive motor sliding connecting rods .................................................... 11

2.5 Dimensions .................................................................................................................. 13

2.6 Conformity ................................................................................................................... 13

2.7 Marking and type plate ................................................................................................ 13

2.8 Technical data ............................................................................................................. 13

2.9 Accessories ................................................................................................................. 15

2.9.1 Equipment ............................................................................................................... 15

2.9.2 Tools........................................................................................................................ 15

3 Installation and commissioning of the machine ............................................. 16

3.1 Installation.................................................................................................................... 17

3.2 Mounting - stitching head............................................................................................. 17

3.3 Mounting - clincher box................................................................................................ 19

3.4 Fine adjustment - clincher box..................................................................................... 21

3.5 Pressure adjustment - clincher back press.................................................................. 21

3.6 Mounting and adjustment - guiding brushes / guiding angle ....................................... 23

3.7 Mounting - centering device and guiding cam ............................................................. 23

3.8 Adjustment - stitching thickness at the stitching aggregate ......................................... 25

3.9 Adjustment - stitching thickness on the delivery .......................................................... 25

3.10 Adjustment - paper stop in the delivery ....................................................................... 27

3.11 Adjustment - guiding rollers on the delivery table ........................................................ 29

3.12 Adjust by hand - stitching head actuation .................................................................... 31

3.13 Adjustment - "staggered stitch".................................................................................... 33

3.14 Carbon brushes and switch-off brushes ...................................................................... 35

4 Flow diagrams ............................................................................................... 36

4 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

Basic safety precautions

1 Basic safety precautions

1.1 Purpose of this document

This document is to inform the operator of the Wire Stitching Machine EXACT-PLUS about the

following matters:

• the safety symbols and signs

• the installation and commissioning

• the adjustment and operation

Familiarity with this Operating Manual is a prerequisite for the safe and correct running of the

machine. It must be read carefully by the operator before the machine is commissioned.

Keep the manual safely in a place where it is readily available and which is close to hand for persons working on the machine.

1.2 The operator

The Wire Stitching Machine EXACT-PLUS must only be operated by trained personnel.

Training will be undertaken by the manufacturer or by persons who have been authorised by the

manufacturer to undertake such training.

1.3 Safety symbols and the displays in use

This symbol displays immediate danger to the life or health of persons

in the immediate vicinity of the machine.

Non-observance of the warnings indicated can have immediate, grave con-

sequences and can cause extensive damage to health or may even lead to

death.

This symbol displays possible danger to the life or health of persons

in the immediate vicinity of the machine.

Non-observance of the warnings indicated can have grave consequences,

and can cause extensive damage to health, or may even lead to death.

This symbol displays the existence of a potentially dangerous

situation.

Non-observance of the warnings indicated can lead to minor injuries to persons.

This symbol displays the existence of the risk of damage to

equipment.

Non-observance of the warnings indicated can lead to slight damage to

equipment.

This symbol indicates the availability of tips on how to use the

machine or particularly useful information.

TIP

These tips will help you to use all of the functions of the machine to best

advantage.

- This sign requires you to take action.

• This sign serves as a symbol for listing items.

Hohner Maschinenbau GmbH EXACT-PLUS 10/2010 5

Basic safety precautions

1.4 Duty and liability

The Wire Stitching Machine EXACT-PLUS has been built according to state-of-the-art technology

under the observance of all the recognised safety regulations. It is, nevertheless, still possible when

using this machine to cause danger to life and limb of the user or a third party or to cause damage

to the machine or other property.

The machine should only be used,

• for the purpose for which it was designed

• when it is in a perfect technical condition

Faults that could reduce the levels of safety in using the machine must be removed immediately.

Warranties and liability on the part of the manufacturer are fundamentally covered by the regulations laid down in our ”General sales and delivery conditions”.

1.5 Correct use of the machine

The Wire Stitching Machine EXACT-PLUS is designed exclusively stitching of brochures and

leaflets or similar items. Any use of the machine contrary to that described above is forbidden since

incorrect use of the machine can present a danger.

1.6 User requirements

The user of the machine is required to provide the required personal safety equipment. All existing

safety systems should be checked regularly.

1.7 Safety and protective systems

All safety and protective systems must be attached to the machine and should be in full working

order before every start-up of the machine.

Safety and protective systems may only be removed:

• when the machine is stationary and

• after it has been secured against being started up again.

1.8 Informal safety measures

The Operating Manual should be stored in such a way as to be permanently to hand at the

machine. There are also generally valid local regulations concerning accident prevention and environmental protection measures that should be made available and observed, in addition to those

described in the Operating Instructions.

All safety and danger signs on the machine should be maintained in a legible condition and should

be renewed where necessary.

1.9 Personnel training

Only skilled and trained personnel are allowed to work on the machine.

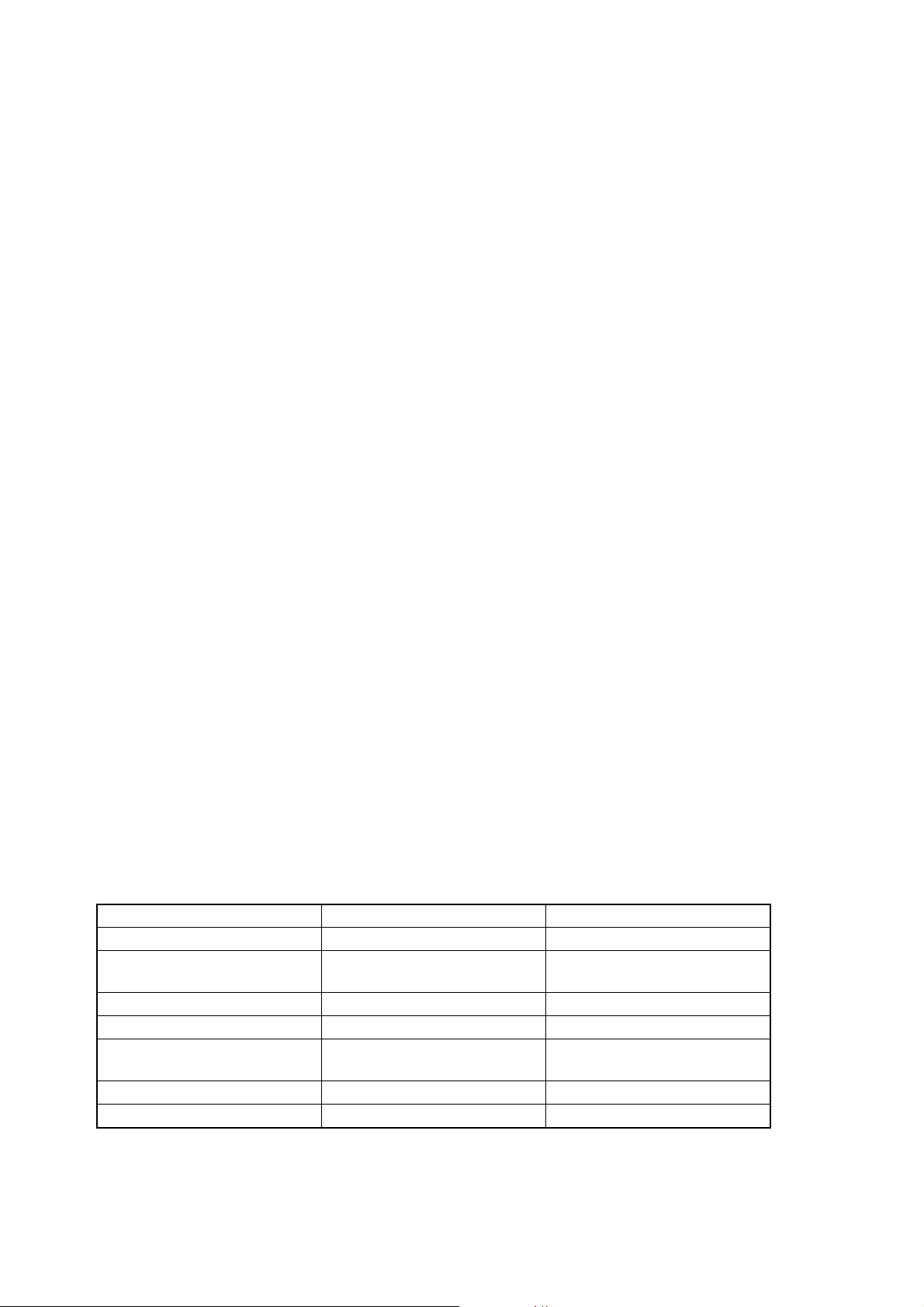

The responsibility of the various parties involved is laid out in the following table:

Trained persons Specialists

Transportation A haulage company

Installation and commissioning

Operation x

Locating faults x

Removing the fault The Hohner company,

Setting up, equipping x

Servicing x

The Hohner company,

Customer Service

Customer Service

6 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

1.10 Parts of the machine that are particularly dangerous

Quick stroke movements of the stitching heads!

Danger of crushing!

¾Before carrying out maintenance or repairs, take care that the power supply is switched off

and prevented from being switched on again accidentally.

¾Never operate the system without properly mounted finger guard.

1.11 Servicing and repair work, elimination of faults

Quick stroke movements of the stitching heads!

Danger of crushing!

¾Before carrying out maintenance or repairs, take care that the power supply is switched off

and prevented from being switched on again accidentally.

¾Never operate the system without properly mounted finger guard.

Basic safety precautions

Mount the finger guard again after adjustment-, maintenance- and inspection work.

1.12 Structural modifications to the machine

Changes to the machine, additions or modifications may only be undertaken with the permission of

the manufacturer.

1.13 Cleaning the machine and the removal of waste products

The functionality of the machine and clean processing of the products can only be guaranteed over

a prolonged period of time, if the machine is regularly cleaned in accordance with the normal methods used in mechanical engineering.

Clean with mild, non-abrasive and non-scratch cleaners. Never use aggressive cleaning agents

such as e.g. solvents.

While doing this, it is particularly important to remove trimmed paper remnants

and paper dust regularly, as these can result in jamming of the machine and in

increased wear of its parts.

The machine contains bare metal parts. These should be cleaned regularly with a protective cleaning agent, especially when using the machine in rooms of high air humidity.

All substances and materials used (e.g. solvents and lubricants) must be handled appropriately and

removed in an environmentally friendly way.

1.14 Noise levels produced by the machine

The noise emitted by the machine when it is running does not exceed a value of 81 dB(A) as measured in accordance with DIN 45635, Part 27.

Hohner Maschinenbau GmbH EXACT-PLUS 10/2010 7

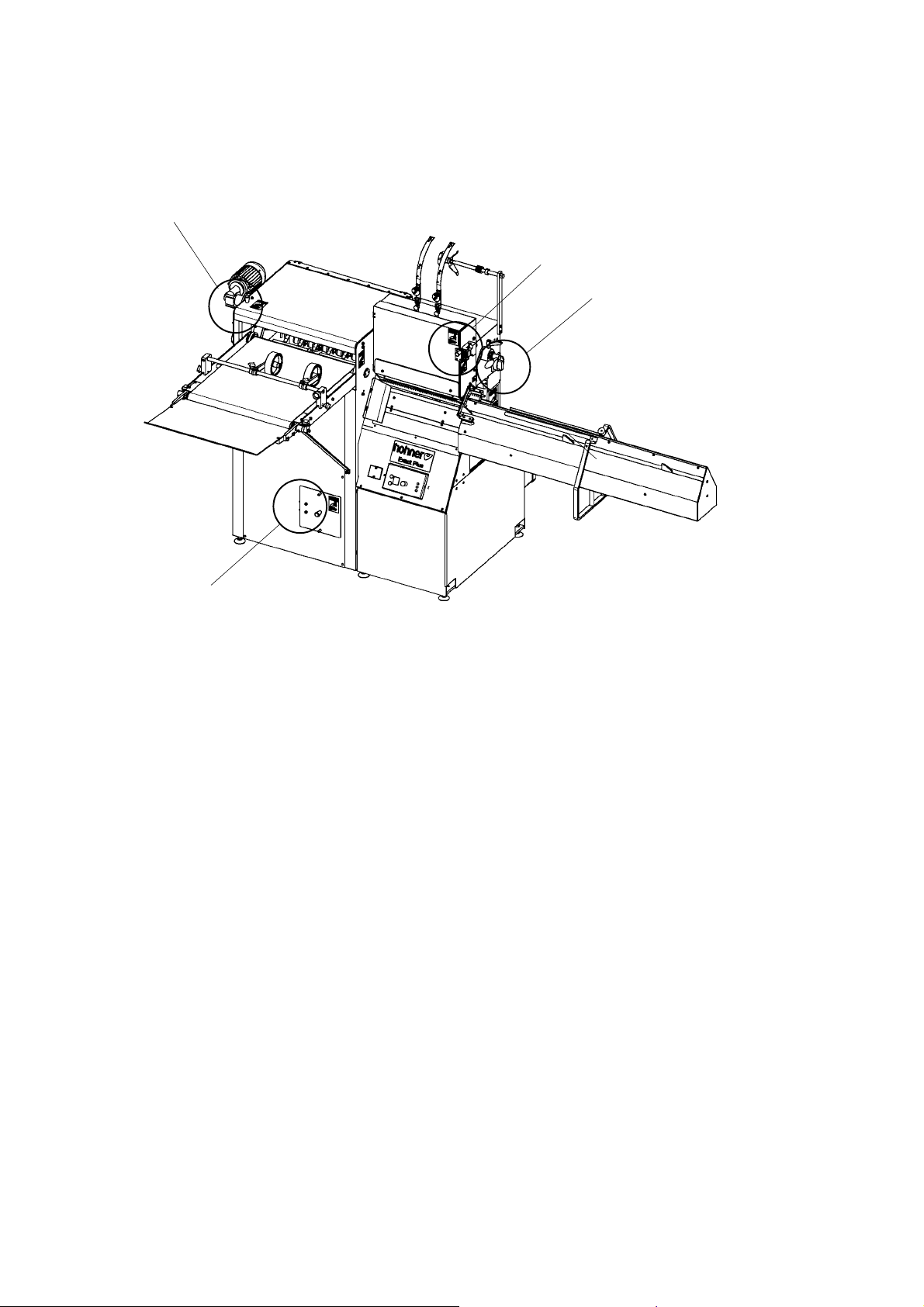

Description of the stitching machine EXACT-PLUS

2 Description of the stitching machine EXACT-PLUS

2

1

4

1

Fig. 2.1

3

8 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

Description of the stitching machine EXACT-PLUS

2.1 Safety-related components

- Fig. 2.4 -

2.1.1 Position of the cut-out switch / emergency switch

The operator of the machine EXACT-PLUS is extensively protected by covers and shells from any

danger. The main danger sources are additionally guarded against by special danger signs and

appliances (cut-out switches).

2.1.2 Stitching aggregate

When installing or adjusting stitching heads the front cover has to be open. The front cover is electrically locked with the cut-out switch -1-, i.e. the machine cannot be operated with open front

cover.

2.1.3 Delivery

Adjustment of paper stop (see 3.10) or installation at the delivery has to be done when plastic cover

is open. The plastic cover is electrically locked with the cut-out switch -2-, i.e. the machine cannot

be operated with open plastic cover.

2.1.4 Staggered stitch

To change-over from standard to "staggered stitching" remove the protecting cover. The protecting

cover is electrically locked with the cut-out switch -3-, i.e. the machine cannot be operated with

open protecting cover.

2.1.5 Main switch and emergency switch

Before all repairs and adjustments on the machine cut out the main switch -4-.

Hohner Maschinenbau GmbH EXACT-PLUS 10/2010 9

Description of the stitching machine EXACT-PLUS

1

2

Fig. 2.2

Fig. 2.3

3

4

5

10 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

Description of the stitching machine EXACT-PLUS

2.2 Electrical connections

Voltage

Danger of electrical shock!

¾ Only qualified skilled workers may carry out work in the vicinity of the mains

power supply.

- Employ a specialist to connect the machine to the mains supply. The local connection regulations

must be adhered to. The cable should not lie loosely on the ground after it has been laid.

Specifically observe the direction of rotation of the motor shaft (visible at the vane

marked by the red arrow, see Fig. 3.9). Direction can be reversed by exchanging

2 phases in the mains supply cable.

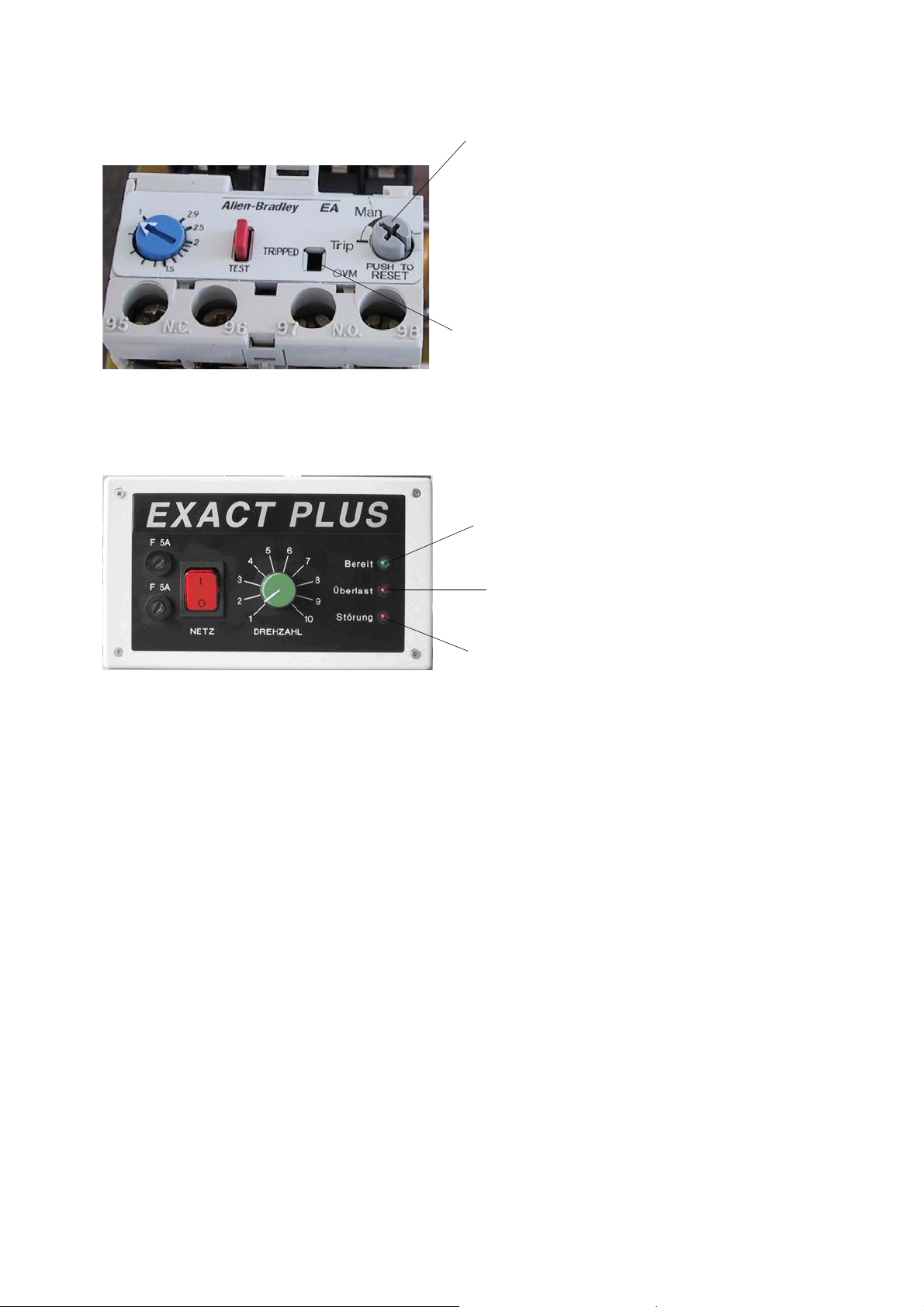

2.3 Motor protective relay

- Fig. 2.2 -

The motor protective relay is triggered upon overload of the motor and switches off the power supply of the motor. This is indicated on the trigger display window -2-.

• Yellow display, invisible: relay not triggered

• Yellow display, visible: relay triggered

- Should the motor protective relay have triggered, the machine must first be switched off with the

ON/EMERGENCY-STOP button. Then determine and eliminate the cause.

Once the cause has been eliminated, the motor protective relay can be reset by

pressing the reset key -1-, - Fig. 2.2 -.

While doing so, ensure that all protective systems are installed on the machine

and all tools have been removed from the machine.

2.4 Block mode for drive motor sliding connecting rods

- Fig. 2.3 -

Disconnection of the three-coil regulation of the DC motor occurs when the motor has been blocked

for 10 sec.

The block mode is set back by switching off the mains voltage.

•-3-, Green

Illuminated when the mains voltage is adjusted and released (ready).

•-4-, Red

Illuminated when the current limit has been reached (overload).

•-5-, Red

Illuminated once the block protection has switched off the controller (fault)

Hohner Maschinenbau GmbH EXACT-PLUS 10/2010 11

Description of the stitching machine EXACT-PLUS

1

Fig. 2.4

12 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

Description of the stitching machine EXACT-PLUS

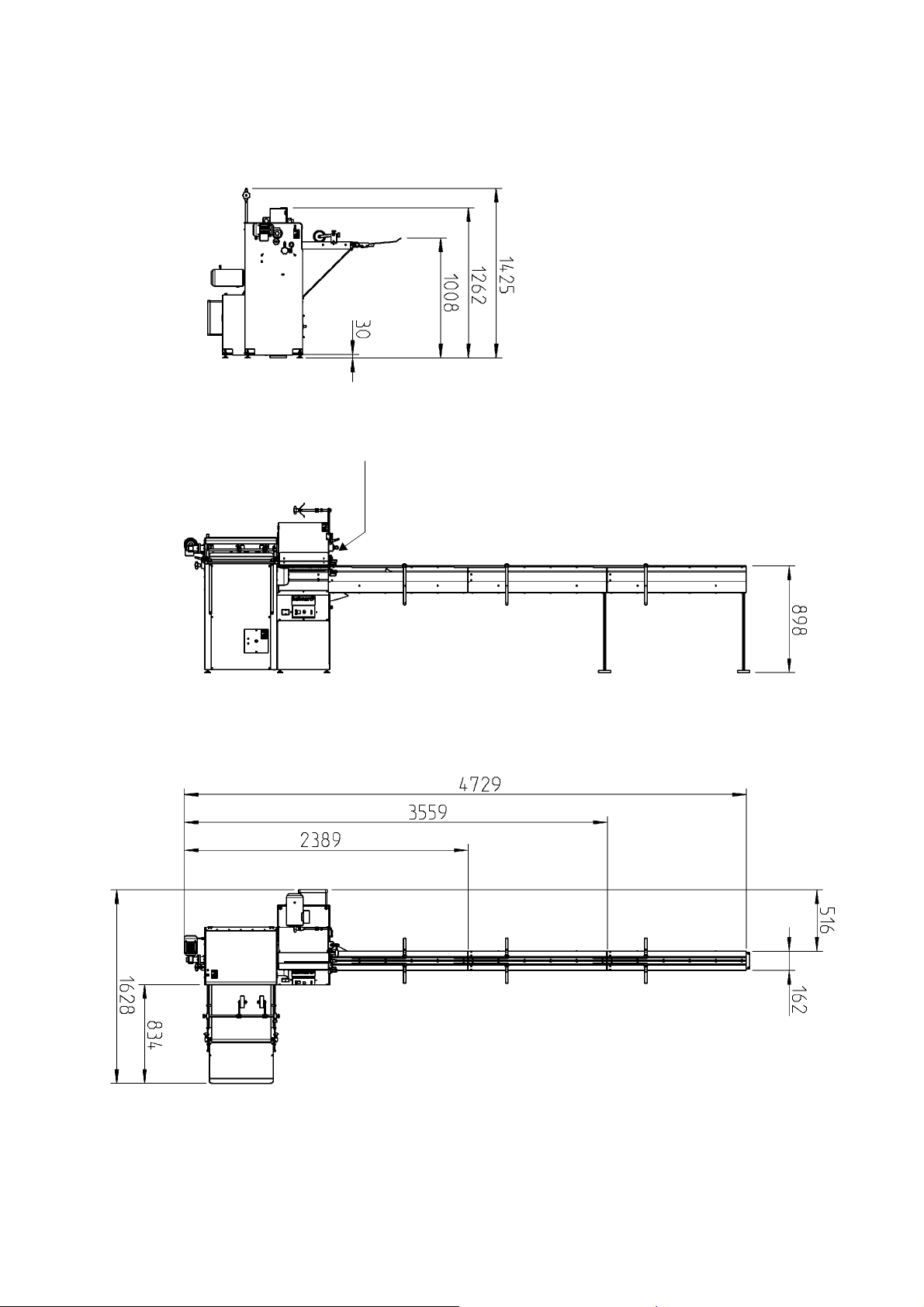

2.5 Dimensions

- Fig. 2.4 -

2.6 Conformity

Please observe the document attached:

„EC Declaration of Conformity according to the EC Machinery Directive 2006 / 42 / EC“

2.7 Marking and type plate

The type plate and the CE labelling are fitted below the main switch - Fig. 2.4 -, Pos. 1.

2.8 Technical data

Smallest brochure size 110 x 80 mm*

Largest brochure size 430 x 340 mm*

Max. setting dimension for narrow stitching heads, approx 330 mm

Stitching capacity, staples per hour, approx: 4,000*,

continuously variable

Staple displacement by "staggered stitch",

from staple middle to staple middle:

crown width of a staple See stitching head operating

Gross weight, machine with 2-station 511 kg

Net weight, machine with 2-station 315 kg

Kind of current, motor standard execution Geared motor

Total wattage of the motor, approx 1 kW

Noise emission under 81 dB(A)

18 mm

instructions

Three-phase A.C.

230/400 V

50-60 Hz

STITCHING AGGREGATE

Max. 4 hohner - narrow stitching heads can be mounted for standard stitching,

for loop-stitching or mixed

Stroke-Narrow Stitching Head: 50 mm

Stroke-clincher back pressure: 5,5 mm

Stitching thickness-standard stitching, max See stitching head

operating instructions

Stitching thickness-loop stitching, max See stitching head

operating instructions

Stitching wire for standard stitching See stitching head

operating instructions

Stitching wire for loop-stitching See stitching head

operating instructions

* depending on nature and quality of the paper

Hohner Maschinenbau GmbH EXACT-PLUS 10/2010 13

Description of the stitching machine EXACT-PLUS

14 EXACT-PLUS 10/2010 Hohner Maschinenbau GmbH

Loading...

Loading...