Page 1

user manual

Hoefer SE615

and SE675

Multiple gel casters

um SE615-IM/Rev.C0/08-12

Page 2

Page finder

Safety warnings and precautions ...........................viii

Introduction .......................................................... 1

Setting up the caster ............................................. 5

Casting with divider plates .....................................7

Pouring standard homogeneous gels ........................9

Pouring standard gradient gels ..............................11

Pouring stacking gels ...........................................15

Removing polymerized gels ...................................17

Troubleshooting ...................................................18

Care and maintenance .........................................20

Appendix A: Gel identification numbers ................. 21

Appendix B: References .......................................21

Ordering information ............................................ 22

pi

•

Page 3

Important! Most organic solvents

including methanol, isobutanol,

isopropanol, and even n-butanol

will craze or cloud the acrylic

plastic with prolonged exposure.

Only use small amounts to

overlay the gels.

Safety warnings and precautions

• Acrylamide is a neurotoxin.

• Wear gloves when handling acrylamide or

polyacrylamide.

• Wear a dust mask when weighing acrylamide

or preparing acrylamide solutions.

Protecting your equipment

To keep your instrument in excellent condition,

please take the following important steps:

• Use water-saturated n-butanol for overlayering

resolution gels during polymerization.

• Avoid using small metal spatulas to separate

the plates. Spatulas may chip the edges of glass

plates and prevent them from sealing.

• After casting, you may need to use a wedge

to separate one glass-and-gel sandwich from

another. Slip a Wonder Wedge in between

adjacent sandwiches to separate them.

pii

•

Page 4

Introduction

Gel sizes

The Hoefer® SE615 and SE675 Multiple Gel

Casters are designed for casting vertical slab

acrylamide gels of homogenous or gradient

concentration.

Use the casters with 16 × 18 cm glass plates and

2 cm-wide spacers to cast 16 × 14 cm gels. Use

1-cm wide spacers to cast 16 × 16 cm gels for

two-dimensional electrophoresis. The resulting

gels are compatible with Hoefer SE400, SE600

and SE600 Chroma Vertical Slab Gel Electrophoresis Units.

Homogeneous and gradient gels

The SE615 and SE675 can be used for casting

both homogeneous and gradient gels. Gradient

gels are cast through the port at the bottom of

the caster. When casting homogeneous gels, the

results are most consistent when the gels are cast

from the bottom. The V-shaped region at the

bottom of the casting unit allows the gel solution to rise evenly, producing identical gels.

p1

•

Page 5

Standard casting

In the standard casting procedure, a gel is cast

between two glass plates held apart by a pair of

spacers. (See Fig 2 on page 5.) The result can be

pictured as a “sandwich,” with the gel between

two glass plates. When you set up a vertical slab

gel electrophoresis unit, you place the glass and

gel sandwich in the electrophoresis unit.

The maximum number of gels you can cast

simultaneously using the standard casting procedure is shown in Table 1.

Table 1. Maximum number of

standard gels cast

0.75-mm 1.0-mm 1.5-mm

spacers spacers spacers

SE615 11 10 10

SE675 4 4 4

p2

•

Page 6

Casting with divider plates

You may find it useful to double the number of

gels run simultaneously in one electrophoresis

unit. This can be accomplished by casting a

“club sandwich.” A club sandwich contains a

notched glass divider plate and a second pair

of spacers between the standard plates, and

thus forms two layers of gel between three glass

plates (see Fig 3 on page 8.) Divider plates are

available for the SE400 and SE600.

The maximum number of gels you can cast

simultaneously, using divider plates (two gels

per sandwich), is shown in Table 2.

Table 2. Maximum number of gels

cast with divider plates

0.75-mm 1.0-mm 1.5-mm

spacers spacers spacers

SE615 14 14 12

SE675 6 6 4

See Fig 1 on page 4 to identify the components

of the multiple gel casters. For information on

parts, accessories and related equipment, see

page 22.

Pouring second-dimension slab gels

When preparing second-dimension slab gels in

the multiple casters, it is important to pour the

slabs to the correct height.

If you are using IPG strips, you do not need a

stacking gel. Pour the second-dimension gel to

0.5–1.0 cm below the top of the sandwich for

standard casting, or 1 cm below the notch if

you are casting with divider plates. This allows

ample room to hold the IPG strips between the

two glass plates. Use 1.0- or 1.5-mm spacers

with IPG strips.

•

p3

Page 7

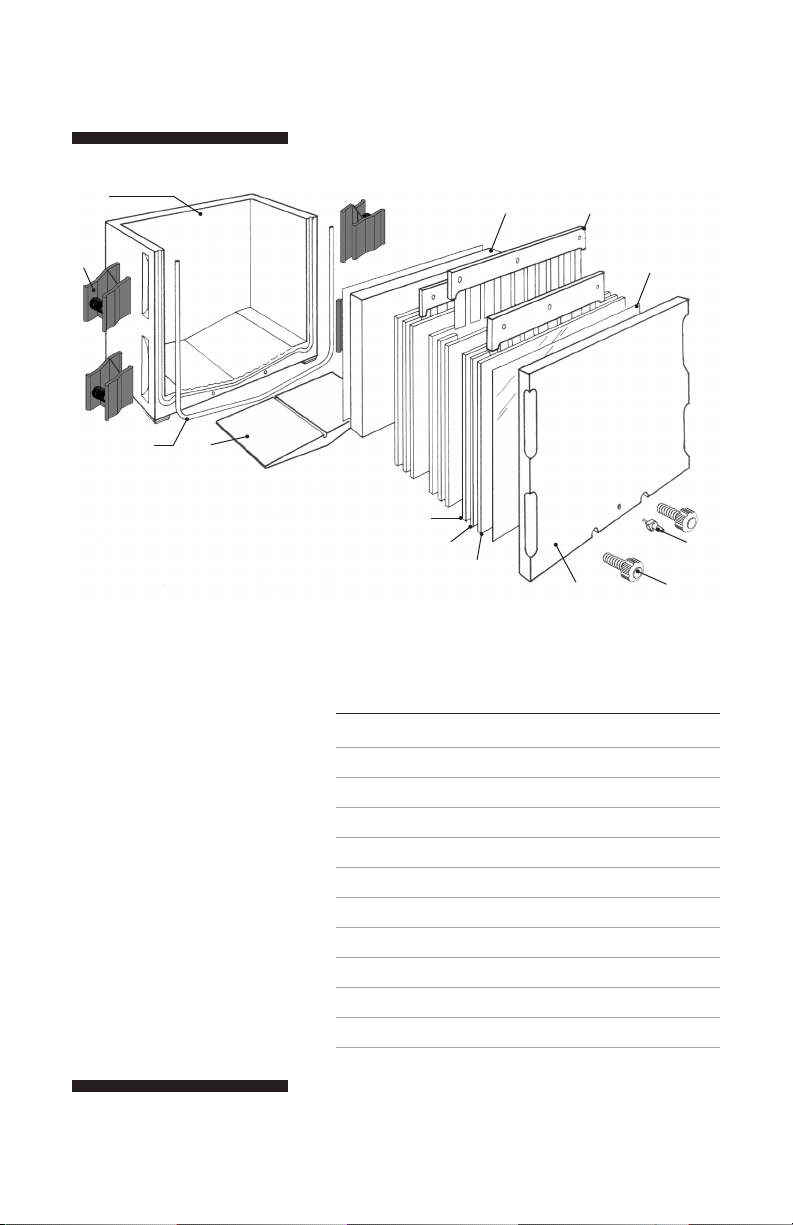

1

5 6

2

3 4

Fig 1. Components of the SE615

and SE675 Multiple Gel Casters.

7

8

9

0

8

1

!

SE615 and SE675 components

no. description

1 Caster body, includes faceplate

2 Spring clamp (4)

3 Foam cord gasket

4 Silicone displacement block*

5 Acrylic spacer block

6 Comb

7 Polycarbonate filler sheet

8 Glass plate

9 Spacer

10 Inlet port

11 Nylon thumb screw

* A small silicone displacement block is also available for the SE675.

p4

•

Page 8

Setting up the caster

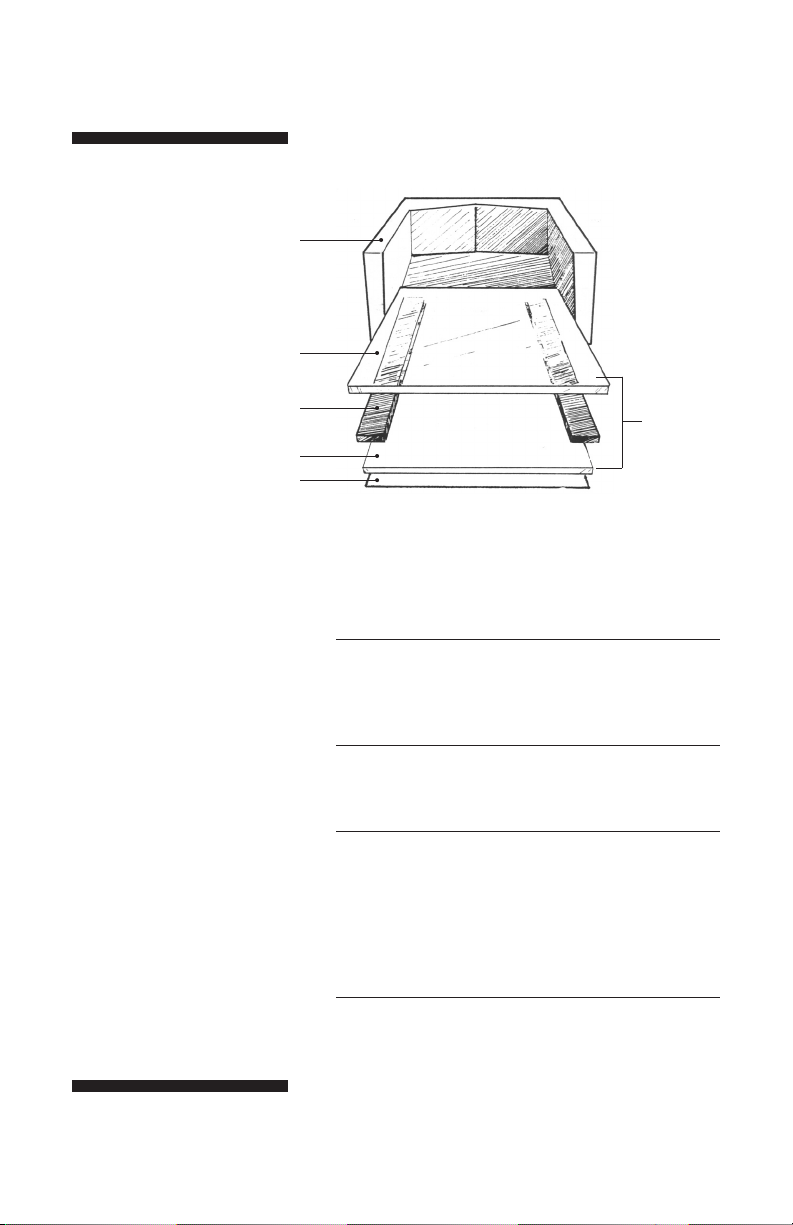

Fig 2. Building a

glass sandwich for

standard casting.

glass plate

glass plate

wax paper or

polycarbonate sheet

Note: Do not block the red

inlet port at the bottom of

the faceplate.

caster

spacer

one sandwich

Preparing the caster

1

If the faceplate is attached to the caster, remove it.

Remove the four side clamps, loosen the two thumb

screws, and slide off the faceplate.

2

Remove the foam cord gasket. Apply a light coat of

Gel Seal lubricant and replace the gasket.

3

When casting gradient gels, attach the tubing from the

gradient maker to the inlet port at the bottom of the

faceplate. Homogeneous gels may also be cast through

this port. If casting homogeneous gels from the top,

insert the appropriate displacement block in the open,

V-shaped region at the bottom of the chamber.

4

Place the open caster in a horizontal position with its

back on the bench top.

p5

•

Page 9

Building the stack

Note: To make separation of

polymerized gel sandwiches

easier, place wax paper sheets

in the caster between each set

of glass sandwiches.

Note: When analyzing a large

number of gels, you may

find it useful to include gel

identification numbers into the

polymerized gel.

See the appendix on page 21

for directions on making gel

identification tags. Lightly wet

and place the tags in the lower

corner of the gel sandwich

during stack assembly.

Note: If you use polycarbonate

sheets instead of wax paper

between each sandwich, the

caster holds fewer sandwiches.

1

Place a polycarbonate sheet in the caster so that 1/3

of the sheet extends out of the top.

You can use this sheet as a lever when inserting filler

sheets after all sandwiches are in place. All remaining

components fit flush against the bottom and sides.

2

Place a sheet of wax paper on the polycarbonate

sheet. Build the first sandwich into the caster.

3

Place a sheet of wax paper on top of the sandwich

and build the next sandwich.

4

Repeat step 3, alternating wax paper and gel sandwiches. Over the final sandwich, lay a polycarbonate

sheet instead of wax paper so that the gel solution

level is visible through the faceplate.

5

Place the faceplate on the caster and make sure the

stack fits snugly, about 0.5 mm above the edge of the

caster. If necessary, adjust the number of extra polycarbonate sheets, acrylic spacer blocks, glass plates

and sandwiches to obtain a snug fit.

6

Make sure the spacers are straight and along the

edges of the glass plates. Use the Spacer Mate to

correct the alignment if necessary.

If necessary, take the faceplate off and make sure all

edges of the stack components are flush. Press on

those that are sticking out until all edges are flush

and replace the faceplate on the caster.

7

Secure the faceplate with the four spring clamps and

tighten the bottom thumb screws.

p6

•

Page 10

Casting with divider plates

To double the number of gels run simultaneously

on the SE600 and related units, place a notched

glass divider plate and another pair of spacers

between the standard glass plates. The result is a

“club sandwich,” with two layers of gel formed

by the three glass plates.

To use divider plates, follow the directions in

“Pouring standard homogeneous gels” on

page 9 or “Pouring standard gradient gels”

on page 11. When calculating solution volumes,

use the formula on page 9. When stacking glass

sandwiches, use the following procedure.

1

Stack glass sandwiches in the caster, using one club

sandwich for each two gels you will cast. Fill extra

space with acrylic blocks, glass plates and polycarbonate sheets.

2

Slide in one polycarbonate sheet against the back.

3

Slide in a glass club sandwich. (See Fig 3.)

To construct a club sandwich, slide in one rectangular

glass plate and place spacers along each of the two

side edges. Slide in a notched divider glass plate and

place spacers along each of the side edges. Finally,

slide in a second rectangular glass plate.

p7

•

Page 11

Note: For optimum visibility,

place a polycarbonate sheet

against the faceplate.

Fig 3. Constructing a “club

sandwich” for casting with

divider plates.

glass plate

spacer

notched divider plate

spacer

glass plate

wax paper or

polycarbonate sheet

4

Place a polycarbonate sheet or wax paper on top of

the club sandwich.

Repeat step 3, alternating wax paper and club

sandwiches.

5

After the last club sandwich, add acrylic spacer blocks

and extra polycarbonate sheets until the entire stack is

approximately 0.5 mm above the rim of the box.

one club

sandwich

additional club

sandwiches

p8

•

Page 12

Warning! Acrylamide is a

neurotoxin. Wear gloves

when handling acrylamide or

polyacrylamide. Wear a dust

mask when weighing acrylamide

or preparing acrylamide stocks.

Pouring standard homogeneous gels

Table 3. Gel casters and volume required

gel caster required volume gradient maker

(ml) size*

SE615 190 –500 SG500

SE675 60 –150 SG100 or

SG500

*Actual size depends on calculated volume.

1

Prepare and degas enough monomer solution to fill all

sandwiches to the level of the notched plate.

The following formula allows extra solution to fill the

space between the sandwich and the chamber:

Note: The 1.1 multiplier in this

formula assures enough solution

to fill dead volume.

Monomer vol. = height × width × spacer × total number of × 1.1

(ml) (cm) (cm) thickness (cm) gel sandwiches

No stacking gel. Fill solution to just below the top of

the notched plate. If air pockets form, remove with a

pipette or syringe. Introduce a comb, at a slight angle,

into each sandwich, taking care not to trap air under

the teeth.

Stacking gel. Fill solution to 4 cm below the top of the

rectangular glass plate. This height allows 1 cm of

stacking gel below the wells. Pour the gel and apply

an overlay. After the gel is set, prepare the stacking

gel as described on page 15.

2-D electrophoresis. Fill solution to about 1.0 cm

below the top of the rectangular glass plate. This

height allows 4 to 5 mm of space for the IPG strip

and an agarose seal. Overlay the separating gel as

described in step 3.

p9

•

Page 13

Caution! Isobutanol crazes

or clouds the acrylic caster

walls, making it difficult to see

the gels.

2

Add initiator and catalyst, and pour the solution into

the glass sandwiches from the top.

The solution flows from one sandwich to another

through the groove at the bottom of the caster and

rises to the same level in all sandwiches. Pour slowly

to avoid overfilling.

3

After reaching the final level, overlay each gel

sandwich with 300 µl of water-saturated n-butanol

or buffer.

Use the same amount of overlay on each gel sandwich

to assure that all the gels polymerize to the same

heights. Pour the liquid gently, taking care not to

disrupt the gel surface.

After polymerization is complete, remove the

n-butanol and replace it with buffer or add stacking

gel. Water-saturated n-butanol will cloud acrylic parts

if used in large amounts or for long periods.

4

Allow the gels to polymerize for at least an hour. To

remove the polymerized gels, see “Removing polymerized gels” on page 17. To add a stacking gel, see

“Pouring stacking gels” on page 15.

•

p10

Page 14

Pouring standard gradient gels

See Fig 1 on page 4 for a diagram of the caster

components. See “Setting up the caster” on

page 5 for recommended solution volumes.

Setting up the gradient maker

1

Prepare a 50% glycerol displacement solution

containing a small amount of bromophenol blue:

approximately 75 ml for the SE615 and 35 ml for the

SE675.

2

Calculate the amount of gradient solution you will

need by referring to the formula on page 9.

For one-dimensional gels: Use a 12-cm separation

gel with a 4-cm stacking gel.

For two-dimensional gels using IPG strips: Calculate

the amount of solution needed to fill the sandwiches

to approximately 0.5 –1.0 cm below the top of

the plates.

3

Set up the peristaltic pump. Using a graduated

cylinder and water, adjust the flow rate so that the

volume of the gradient separation solution plus the

volume of the glycerol solution will be completely

delivered in 10 –15 minutes.

4

Choose a gradient maker that holds no more than

four times the total volume of gradient solution to

be poured. Check that the gradient maker is clean

and that the outlet and mixing port are free of

polymerized acrylamide.

•

p11

Page 15

Fig 5. Gradient making system

connections.

5

Assemble the gradient components. (See Fig 5.)

a. Close all gradient maker valves and place a stir

bar in the mixing chamber, the one with the tube

connector port.

b. Attach one end of a piece of tubing to the outlet of

the gradient maker.

c. Run the other end of the tubing through the peri-

staltic pump and attach it to a tubing connector.

d. Use a second piece of tubing to attach the tubing

connector to the red inlet port at the bottom of

the caster.

mixing

chamber

multiple gel

caster

reservoir chamber

gradient maker

peristaltic pump magnetic stirrer

•

p12

Page 16

Pouring gradient separation gels

Warning! Acrylamide is a

neurotoxin. Wear gloves

when handling acrylamide or

polyacrylamide. Wear a dust

mask when weighing acrylamide

or preparing acrylamide stocks.

1

Prepare and degas the two monomer solutions for the

gradient maker.

Add glycerol or sucrose to the solution of higher

acrylamide concentration to stabilize the gradient as

the solution is pumped in. Decrease the concentration

of initiator so that polymerization occurs from top to

bottom. This minimizes convective mixing due to the

heat generated by polymerization.

2

Close both the mixing port and outlet port, if

appropriate, on the gradient maker. Clamp the tubing

from the outlet when using the SG500.

3

Add initiator and catalyst, and immediately pour the

light (low concentration) acrylamide solution into the

mixing chamber—the chamber with the outlet port.

Open the mixing valve slightly to allow the connecting

channel to fill and force out air bubbles.

Close the valve again and pour the heavy (high concentration) acrylamide solution into the reservoir chamber.

4

Start the magnetic stirrer and unclamp or open the

outlet valve. Start the pump and open the mixing valve.

•

p13

Page 17

5

When almost all the acrylamide solution is drained

from the gradient maker, stop the pump and close

the mixing valve. Tilt the gradient maker towards the

outlet side and remove the last few milliliters of mix.

Do not allow any air bubbles to enter the tubing.

6

Add the glycerol displacement solution to the mixing

chamber and start the pump. Make sure no bubbles

are introduced. Pump until the bottom of the caster

is filled with displacement solution to just below the

glass plates, then turn off the pump. Clamp off the

tubing to the red inlet port of the caster.

Note: Isobutanol clouds the

acrylic, making it difficult to see

the gels.

7

Overlay each separate sandwich with 300 µl of watersaturated n-butanol or buffer.

Use the same amount of overlay on each gel to

assure that all the gels polymerize to the same height.

Carefully and gently pipette the liquid, taking care not

to disrupt the gel surface.

After polymerization, remove the n-butanol. Replace

it with buffer or add a stacking gel.

8

Allow the gels to polymerize for at least an hour.

To remove the polymerized gels, see “Removing

polymerized gels” on page 17. To add a stacking gel,

see “Pouring stacking gels” on page 15.

•

p14

Page 18

Pouring stacking gels

You may add stacking gels to the entire set of

polymerized gels —homogeneous or gradient—

while the sandwiches are still in the casting box,

or you may add stacking gel to individual gels

immediately prior to use.

For optimal resolution, add the stacking gel at

the last minute to prevent diffusion of buffers

between the two gel layers.

1

If you are pouring stacking gels later, skip to step 1

under “Removing polymerized gels” on page 17.

If you are pouring stacking gels now, calculate the

volume of stacking gel monomer solution needed by

referring to the following formula:

Monomer vol. = height × width × thickness × total number of

(ml) (cm) (cm) (cm) stacking gels

Where:

• Height is the distance between the separating gel

and the top of the plates.

• Width is the distance between the spacers.

2

Rinse off the water-saturated n-butanol overlay with

distilled water or Tris buffer and invert the caster to

drain it. Repeat this 2–3 times.

3

Degas the stacking gel monomer solution and add

catalyst and initiator.

•

p15

Page 19

Note: Oxygen inhibits gel

polymerization. Do not trap

air bubbles underneath the

comb teeth.

Note: Use gels with stacking

gels immediately. Do not store.

4

Replace the caster in a vertical position. Make sure

the surface of the separating gel is free of liquid.

Use a pipette to fill each sandwich individually with

stacking-gel monomer solution.

5

Hold a comb, attached to a comb back, at a 45°

angle and centered within the sandwich. Insert one

end into the gel so that the end tooth is almost

completely inserted. Slowly lower the remaining comb

teeth in one by one, rotating the comb gradually

downward until it is in a horizontal position.

Refer to Fig 1 on page 4 for the final position of the

comb. Repeat this for each sandwich.

6

Allow the stacking gels to polymerize for at least one

hour. To remove the polymerized gels, see “Removing

polymerized gels” on page 17.

•

p16

Page 20

Note: The SDS buffer makes

the glass plates slippery.

Note: Do not use metal

spatulas to separate the

sandwiches. Narrow metal

spatulas often chip the edges of

glass plates, making the plate

ineffective for sealing into the

electrophoresis tank.

Note: Separate the sandwiches

from one another before placing

the gels in the refrigerator.

Removing polymerized gels

1

After the gels have polymerized, place the caster in a

horizontal position. If you poured stacking gels, leave

the combs in place. Remove the faceplate.

2

Tip the caster to pour off the glycerol solution.

3

Slide the stack of sandwiches, acrylic blocks, and

polycarbonate sheets out of the caster. Remove the

acrylic blocks and polycarbonate sheets from the top

of the stack.

4

Carefully remove individual glass and gel sandwiches

from the stack. If necessary, insert a Wonder Wedge

between adjacent sandwiches to separate them.

Work slowly and cautiously when prying apart adjacent

sandwiches after polymerization.

5

Rinse the caster and polycarbonate sheets, as

described in “Care and maintenance” on page 20.

To store gels for future use

Rinse the individual sandwiches with distilled water.

Fill cassettes with gel storage buffer. Wrap gel sandwiches you are not using at this time in plastic wrap

and store them in the refrigerator.

To use gels immediately

1

Gently remove the combs by pulling them upward and

out of the gel sandwich.

2

Fill the wells with SDS Electrophoresis buffer.

3

Load samples and complete assembly. Refer to the

user manuals that come with SE600 or SE400 Series

electrophoresis systems.

p17

•

Page 21

Troubleshooting

symptom possible cause recommended action

1. Gels adhere to glass plates Dirt, grease or Soak plates in a strong laboratory detergent;

when opening sandwich. fingerprints on plates. rinse well in distilled water. Handle with

2. Gels cast simultaneously Different amounts of Use the same amount of overlay on all

are different sizes. overlay were used on separation gels. Add the overlay as rapidly

the separation gels as possible.

before polymerization.

3. Caster leaks. Gasket leaks. Apply a light film of Gel Seal to the gasket

each time the unit is used.

Gasket damaged. Check the foam gasket for nicks or wear and

replace if necessary.

Stack too tall. Remove filler plates or gel sandwiches until

4. Gel heights uneven. Bubbles trapped Pour the monomer solution into one sandwich

under gel sandwiches. and allow the groove in the plug to evenly

distribute the solution.

Polymerized gel Make sure the groove in the triangular plug is

in groove. clean and clear of material.

Insufficient time for Wait one minute before overlaying the gels.

gel levels to stabilize. Add the same amount of overlay to each

5. Sample wells damaged Air bubbles under Remove air pockets before inserting combs.

or leak. comb teeth. Slide comb into solution at an angle. If comb

must be removed, add more monomer

solution before reinserting the comb.

Insufficient Allow the gel to set for a minimum of 1 hour.

polymerization.

Comb removed Slowly remove the comb at a slight angle to

too abruptly. prevent damaging the gel.

Poor polymerization. Degas stacking gel solution.

6. Gel sandwiches No wax paper Place wax paper between sandwiches

difficult to separate. between glass plates. in the stack.

7. Uneven gradient gels. Uneven layering. Add sucrose or glycerol to the heavy

Decrease the pump rate.

gloves only.

the stack top is just below the level of the

caster wall.

sandwich.

Increase catalysts up to 0.1% v/v TEMED,

0.1% v/v APS.

monomer solution. Add a small amount of

bromophenol blue to the heavy solution to

track gradient formation.

•

p18

Page 22

symptom possible cause recommended action

8. No polymerization of Insufficient APS Increase both APS and TEMED by 30–50%

SDS gel (or incomplete or TEMED. APS solution is old. Make up fresh APS

polymerization.) each day.

APS stack is wet. APS is hygroscopic. Open a fresh bottle.

02 in gel solution. Degas at least 10 minutes.

Solutions at low Make sure all solutions are at room

temperature. temperature (20–30 °C).

TEMED is old. Use new TEMED.

9. Gel too soft. Not enough crosslinker. Crosslinker should be 2.6% C for standard

10. Gel is brittle. Too much bis. See #9 above.

11. Gel is white. Too much bis. Check concentrations of solutions.

12. Gel contains swirls, Too much catalyst: Reduce both APS and TEMED by 25%.

polymerization artifacts. gel polymerized in

< 10 min.

Not enough catalyst: Increase both APS and TEMED by 50%.

gel polymerized Also see #8.

in > 50 min.

Solutions not mixed. Mix thoroughly after adding TEMED.

13. Bands are diffuse or broad. Sample doesn’t contain Use the same buffer for the sample

same buffer as as for the stacking gel.

stacking gel.

Too much TEMED Reduce concentrations by 25%.

or APS.

SDS or Use fresh solutions.

sample buffer is old.

Poor interface between Remove all liquid from the surface of the

separation gel and separation gel before adding the stacking

stacking gel. gel solutions.

14. Protein mobilities Incomplete See #8.

not consistent. polymerization.

Aged gels or acrylamide. Do not store liquid acrylamide more than

Gas in gel. Degas gel solutions at least 10 minutes.

15. Heavy background Acrylamide or bis Use reagents specified as electrophoresis purity.

during silver staining. contain acrylic acid.

Water is impure. Use only double-distilled water.

SDS gels where

%C =

See #9 above.

3 months. Use gels within 1–2 weeks of

casting. Use gels with stackers immediately.

g bis

(g monomer + g bis)

× 100

•

p19

Page 23

Care and maintenance

• Do not autoclave or heat any part above 45 °C.

• Do not expose the caster or its parts to

organic solvents.

Cleaning

Rinse the caster, faceplate, silicone plugs and

polycarbonate sheets in dilute detergent and

rinse with distilled water. Allow the unit to air

dry completely.

•

p20

Page 24

Appendix A: Gel identification

numbers

For positive identification of gels, label each slab

by incorporating a small label printed on thin

filter paper in the bottom corner of the gel. Use

a carbon typewriter ribbon, photocopier or laser

printer to make these labels, since many liquidbased inks are electrophoresed off paper during

an SDS electrophoresis run.

A variety of numbering schemes are possible.

In our experience the easiest uses three parts

as follows:

• An upper-case letter to identify the investigator

or an extended gel series.

• A two- or three-digit serial number to identify

the slab gel batch.

• A lower-case letter to identify a gel in the

batch. Since a maximum of 14 gels can be

made in a batch, use the letters a–n.

The resulting numbers, in the format A63a,

A63b...., etc., provide a useful system for keep-

ing track of and cross-indexing experiments and

gel production.

Appendix B: References

Laemmli, U.K. 1979. Nature (London) 227:

680–685.

SDS-PAGE and IEF Handbook.

•

p21

Page 25

Ordering information

product quantity code number

SE615 Multiple Gel Caster Kit, 10 gels 1 SE615

Includes 20 glass plates, space-saver plate, 5 filler sheets,

100 sheets of wax paper, and Spacer-Mate alignment

template. (Order combs and spacers separately.)

SE675 Multiple Gel Caster Kit, 4 gels 1 SE675

Includes 8 glass plates, 3 space-saver plates, 5 filler sheets,

100 sheets of wax paper, and Spacer-Mate alignment

template and filler plugs. (Order combs and spacers separately.)

Foam cord gasket, 61 cm × 4.5 mm OD 1 SE208

Red inlet port 4 XP010

Red spring clamps 4 SE253

Glass plates, 18 × 16 cm 2 SE6102

Notched divider glass plates, 18 × 16 cm 1 SE6102D

Acrylic block, 11 mm thick, 18 × 16 cm 1 SE612

Polycarbonate filler sheets 5 SE613

Wax paper, precut sheets, 18 × 16 cm 100 SE614

Spacer-Mate template for aligning spacers 3 SE6119SM

Nylon thumb screws 12 SE6003U-2

Silicone filler plug, SE615 1 SE618

Silicone filler plug set, SE675. Includes 1 large and 1 small plug. 1 SE678

Gel Seal, ¼ oz. tube 1 SE6070

Related products

SE100 PlateMate, plate washer and storage unit 1 SE100

SG100 Gradient Maker, 100 ml total volume 1 SG100

SG500 Gradient maker, 500 ml total volume 1 SG500

Wonder Wedge 1 SE1514

Spacers

length (cm) thickness (mm) width (cm)

16 0.75 2 2 SE6119-2-.75

16 1.0 2 2 SE6119-2-1.0

16 1.5 2 2 SE6119-2-1.5

16 1.0 1 2 SE6118-2-1.0

16 1.5 1 2 SE6118-2-1.5

p22

•

Page 26

Combs

number thickness width

of wells (mm) (mm) quantity code number

10 0.75 8.3 1 SE511-10-.75

10 1.00 8.3 1 SE511-10-1.0

10 1.50 8.3 1 SE511-10-1.5

12 0.75 7.6 1 SE511-12-.75

12 1.00 7.6 1 SE511-12-1.0

12 1.50 7.6 1 SE511-12-1.5

15 0.75 5.7 1 SE511-15-.75

15 1.00 5.7 1 SE511-15-1.0

15 1.50 5.7 1 SE511-15-1.5

20 0.75 4.1 1 SE511-20-.75

20 1.00 4.1 1 SE511-20-1.0

20 1.50 4.1 1 SE511-20-1.5

28a 0.75 2.7 1 SE511-28-.75

28a 1.00 2.7 1 SE511-28-1.0

28a 1.50 2.7 1 SE511-28-1.5

a

Comb depth 15 mm; all others 25 mm.

Preparative combs

These combs are 25 mm deep, adjustable to 10 or 15 mm.

no. of wells thickness width (mm)

prep/ref (mm) prep/ref quantity code number

1/1 0.75 121/6 1 SE511-R-.75

1/1 1.00 121/6 1 SE511-R-1.0

1/1 1.50 121/6 1 SE511-R-1.5

1/2 0.75 113/6 1 SE511-DR-.75

1/2 1.00 113/6 1 SE511-DR-1.0

1/2 1.50 113/6 1 SE511-DR-1.5

Adjustable comb back 1 SE511-BKA

Required to convert any 25-mm deep comb to 10 or 15 mm depth.

•

p23

Page 27

Hoefer, Inc.

84 October Hill Road

Holliston, MA 01746

Toll Free: 1-800-227-4750

Phone: 1-508-893-8999

Fax: 1-508-893-0176

E-mail: support@hoeferinc.com

Web: www.hoeferinc.com

Hoefer is a registered trademark

of Hoefer, Inc.

© 2012 Hoefer, Inc. —

All rights reserved.

Printed in the USA.

Loading...

Loading...