Page 1

user manual

Hoefer Multiple

Gel Casters

SE215, SE235, and SE275

um SE215-IM/Rev.L0/08-12

Page 2

Contents

1. Multiple Gel Caster function ...............................1

2. Unpacking ........................................................ 2

3. Assembly ..........................................................2

Prepare the gel caster ........................................2

Construct the gel sandwich stack and

load into caster .................................................3

Prepare the monomer solution ............................6

Stacking gel preparation .................................... 8

Linear gradient gels ...........................................9

After Gel Polymerization ...................................12

4. Care and maintenance .....................................13

5. Troubleshooting ...............................................14

6. Ordering information ........................................ 16

pi

•

Page 3

1. Multiple Gel Caster function

Multiple gel casters prepare gels that are for

use in a Hoefer® miniVE, SE250 or SE260 gel

electrophoresis unit. The caster model selected

depends on the electrophoresis unit used and the

number of gels to be prepared:

Table 1: Multiple Gel Caster/electrophoresis

unit compatibility guide

for use with

Hoefer gel

gel plate electrophoresis

Gel caster no. of gels size (cm) unit:

SE215 4–10 10 × 8 SE250

SE235 2–4 10 × 10.5 SE260, miniVE

SE275 2–4 10 × 8 SE250

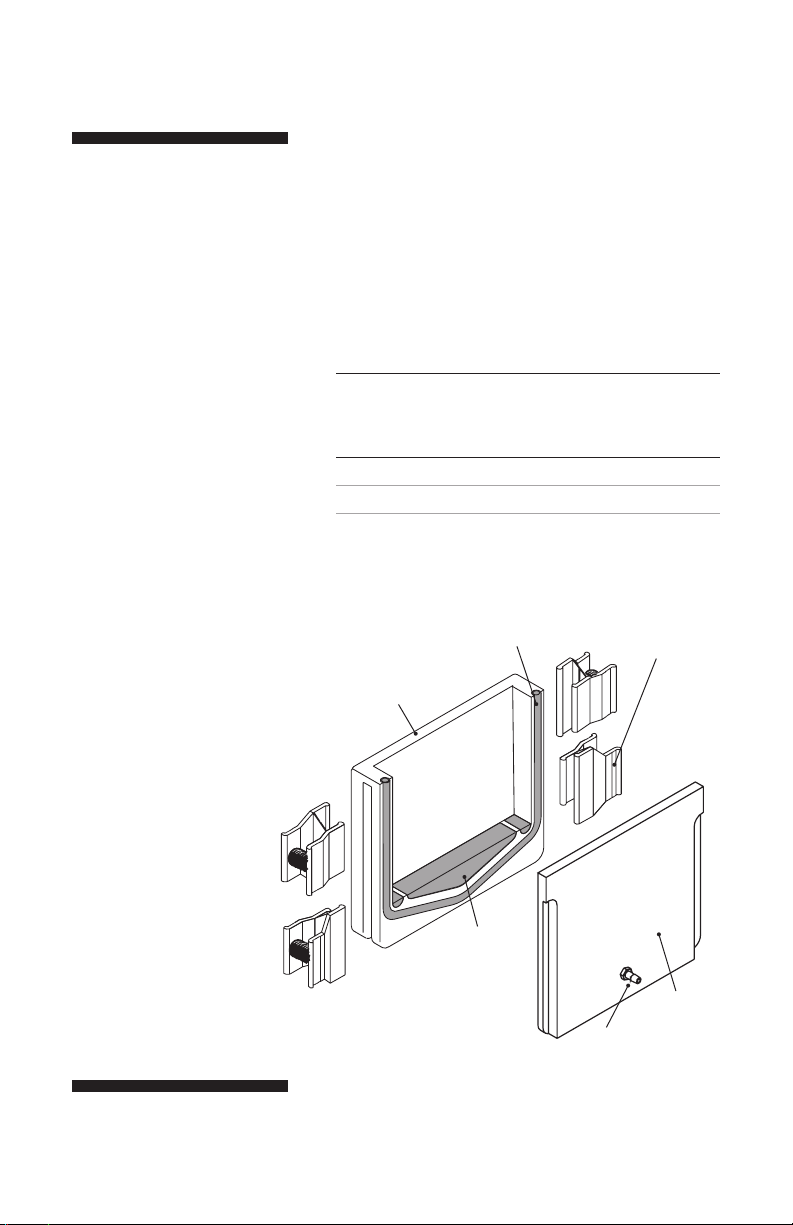

Fig 1. Multiple Gel Caster.

The faceplate seals against the

cylindrical silicone rubber gasket.

Included but not shown:

• Acrylic block

• Black vinyl cap for inlet port

• Polycarbonate filler sheets

• Glass and alumina plates

Accessories that may be

ordered separately:

• Combs

• Spacers

• Additional plates

Acrylic casting

chamber

Silicone rubber

gasket

Filler plugs

(1 large,

2 small)

Spring clamps

(2 or 4, depending

on model)

Inlet port

Faceplate

p1

•

Page 4

Note: Wear gloves to keep

the caster and plates free of

finger marks.

2. Unpacking

Unwrap all packages carefully and compare

contents with the packing list, making sure all

items arrived. If any part is missing, contact

Hoefer, Inc. Inspect all components for damage

that may have occurred while the unit was in

transit. If any part appears damaged, contact the

carrier immediately. Be sure to keep all packing material for damage claims or for repacking

should it become necessary to return the unit.

3. Assembly

All casters are assembled and used in the manner

described below. Both single concentration gel

and gradient gel instructions are included.

Prepare the gel caster

1

Prepare gel caster, plates and spacers by washing

with a mild detergent and rinsing thoroughly with

deionized water.

2

Periodically remove the U-shaped silicone rubber

gasket and inspect for nicks. If the gasket appears to

be intact, apply a light film of Gel seal lubricant to it

and replace: avoid stretching the gasket by laying it

onto the groove and pressing it into place. (Gel seal

is supplied with the SE250 and SE260 units.)

p2

•

Page 5

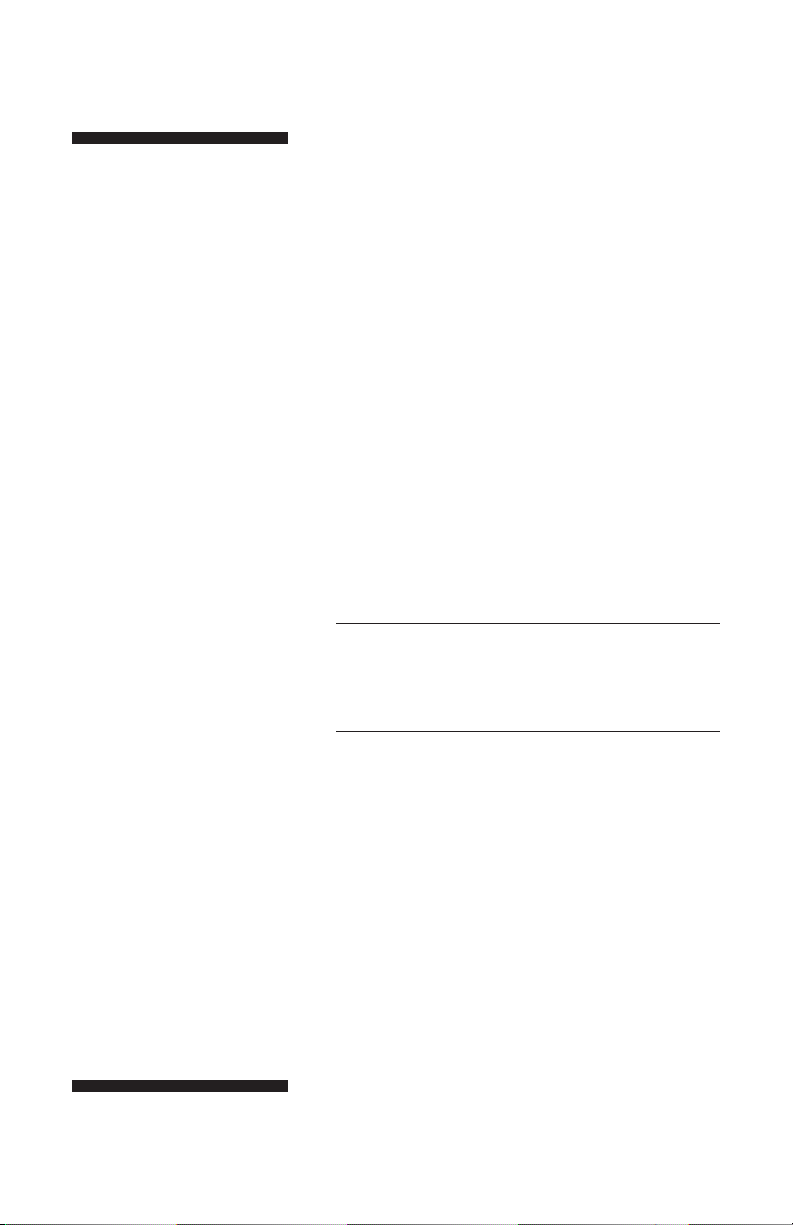

Fig 2. Location of T-shaped

spacers on notched plate.

3

Single-concentration gels — Plug the red inlet port

near the bottom of the faceplate with the black vinyl

cap included with the unit. Check that the two small

semi-circular and one large triangular rubber filler

plugs, which reduce the amount of solution needed

to fill the chamber, are properly seated in the bottom.

The crosswise groove in the plug distributes the monomer solution to all gel sandwiches so that they fill to

the same level simultaneously.

Gradient gels — Remove the large triangular plug.

Check that the two smaller rubber filler plugs are

properly seated in the bottom of the chamber. Refer

to page 9 for gradient casting instructions.

Construct the gel sandwich stack and load into caster

1

Construct each gel sandwich: For each sandwich,

choose one notched alumina plate, one rectangular

glass plate and two spacers. Use the same size spacers for each sandwich.

Lay the notched plate on a flat surface, place one

spacer along each edge so that it aligns with the

notch. Fit a glass plate onto the spacers as shown.

The stem of the T-shaped spacers fits between both

plates. The top of the T forms the edge of the gel

sandwich, (Fig 2).

(Alternatively, assemble the sandwich while it is in

a standing position.)

Fig 3. Align bottom edges of plates

and spacers carefully.

2

Pick up each sandwich and align both sides with the

spacers and also the bottom on a flat surface, (Fig 3).

•

p3

Page 6

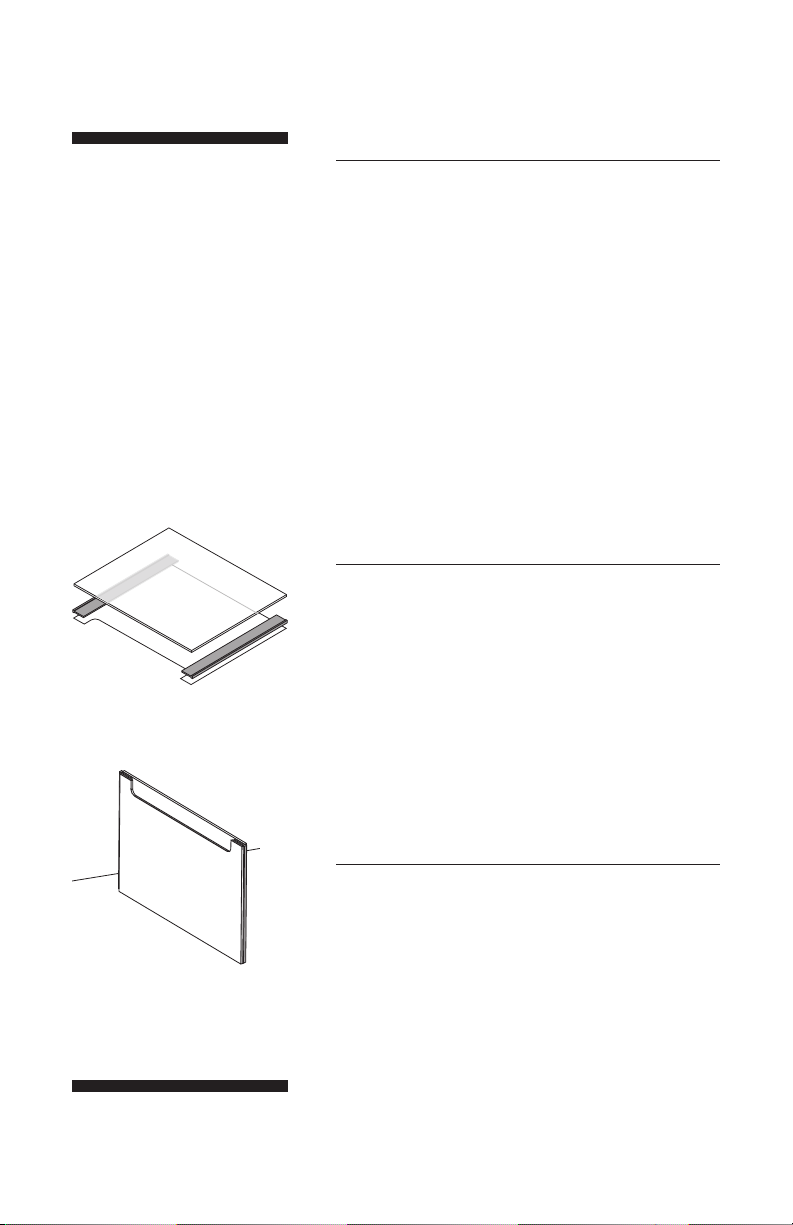

Face plate

Polycarbonate

sheet

Fig 4. Stack components

(Load from bottom up; Fillers are

added after sandwiches are in

place to adjust stack height)

• Polycarbonate sheet. (Acts as

lever for adding fillers below

the stack. Aids in inserting filler

blocks and disassembling the

stack.)

• Sheet of wax paper (not visible

on drawing). Repeat as needed

to fill the caster.

• Gel sandwich

• Face plate

Gel

sandwich

3

Build the stack in the caster.

(All components fit flush against the bottom and one

side.) Place a polycarbonate sheet in the caster so that

2/3 of the sheet lays within the caster and the rest

extends out of the top. (This will act as a lever when

inserting filler sheets once all sandwiches are in place.)

Place a sheet of wax paper onto the polycarbonate

sheet. (The wax paper makes it easier to disassemble

the stack.) Slide the first sandwich into the caster

along one side, notched plate side down and notched

side pointing toward the open end of the caster (top

when filled). Repeat with all sandwiches, building

the stack by layering sheets of wax paper and gel

sandwiches, all oriented the same way. Over the final

sandwich, lay a sheet of polycarbonate instead of wax

paper so that you can observe the liquid level when

pouring the gel solution, (Fig 4).

Notes:

• Inspect glass for nicks. Use only unchipped plates.

• Work on a flat surface for best results.

• Clean off the acrylamide film from both sides of

each polycarbonate sheet.

p4

•

Page 7

gel number

caster of clamps

SE215, SE275 2

SE235 4

4

If pouring fewer gels than the capacity of the caster,

lift up the polycarbonate sheet at the bottom of the

stack and slide in fillers such as the acrylic block,

polycarbonate sheets, or extra glass plates until the

stack is approximately 1 mm higher than the chamber

sides. (Once fillers are in place, slide the polycarbonate sheet in so that it is level with all other stack

components.)

(The stack must be slightly thicker than the space so

that the stack compresses slightly when the faceplate

is clamped in place. If the stack is too tall, a glass

plate may break or the caster won’t seal properly, but

if the stack is too short, the spacers may fall out of

alignment or the stack will not stay vertical.)

5

Lay the faceplate on the casting chamber, aligning it

so that is flush with all sides. Pick up the assembled

unit and check that the gasket compresses slightly.

6

Secure the stack with either 2 or 4 clamps (see

adjacent table). Open the jaws of the spring clamp,

then position the longer side jaws on the faceplate.

When the clamp is released, the short jaw seats in the

groove on the casting chamber side and the long jaw

seats in the groove on the faceplate.

2 clamps — position each clamp in the middle of

the faceplate.

4 clamps — Slide the top clamp upward to fit

against the end of the groove on the front panel.

7

Stand the assembled caster upright and inspect.

Check that the gasket forms a tight seal and is not

unduly deformed. Check that the stack fits snugly and

that the plates and spacers are still aligned; adjust

if necessary.

p5

•

Page 8

Prepare the monomer solution

1

Prepare enough monomer solution to fill all sandwiches to the level of the notched plate (or lower

if a stacking gel or first dimension IPG strip will be

added — see step 2). The formula below allows extra

solution to fill the space between the sandwich and

the chamber.

Table 2: Variables for calculating monomer volume

gel caster area X cm2 extra vol. required (Y ml)

SE215 60 11

SE235 80 8

SE275 60 5

Monomer = area X × spacer × total gel + extra chamber

vol (ml) (cm2) thickness (cm) sandwiches vol (Y ml)

An example volume calculation for the SE215 for 10 sandwiches, each with a thickness of

1.5 mm follows: From Table 2, the area variable for the SE215 is 60 and the extra volume

variable is 11 ml.

(60 cm2) (0.15 cm) (10 sandwiches) + 11 ml extra volume required = 101 ml

p6

•

Page 9

Note: Avoid repeated and

prolonged contact of

n-butanol with the acrylic

casting chamber to prevent the

acrylic from becoming opaque.

2

Deaerate the monomer solution and add the initiator

and catalyst just prior to pouring the gel. Fill the solution into only one sandwich, allowing the groove in the

bottom plug to distribute the solution evenly between

all sandwiches. (Pouring into more than one sandwich

could introduce air pockets.) Watch the solution level

through the faceplate. See below for the appropriate

solution level according to the application.

No stacking gel

Fill with solution to just below the top of the notched

plate. If air pockets form, remove them with a pipette or

syringe. Introduce a comb (at a slight angle) into each

sandwich, taking care not to trap air under the teeth.

Stacking gel

Fill with solution to 3 cm below the top of the rectangular glass plate. This height allows 1 cm of stacking

gel below the wells. Pour the gel and apply an overlay.

(See step 3.) After the gel is set, prepare the stacking

gel as described below.

2-D electrophoresis

Fill with solution to about 1 cm below the top of the

rectangular glass plate. This height allows 4 to 5 mm

of space for the IPG Strip and an agarose seal). Overlay the separating gel as described in step 3.

3

If casting polyacrylamide gels, overlay each gel with

a thin layer of water-saturated n-butanol, water, or

diluted gel buffer to prevent gel exposure to oxygen.

Apply the same amount to each gel to keep the gel

levels the same. Deliver the overlay solution slowly

near the spacer at the side of the sandwich. Allow the

solution to flow across the surface unaided.

4

Allow the gel to polymerize for a minimum of 1 hour.

See page 12 for stack disassembly.

•

p7

Page 10

Important! For optimal gel

performance, cast stacking gels

just prior to use.

Stacking gel preparation

Add a stacking gel to as many gels as required

either individually to each gel after it is transferred to the electrophoresis unit (see instructions with unit), or to the whole stack of gels

while it is still in the caster. To pour stacking

gels in a multiple gel caster:

1

Rinse off the overlay with distilled water. Invert the

casting chamber to drain.

2

Calculate the stacking gel monomer solution volume

(ml): measure the distance, in cm, from the top of

the resolving gel to the notch in the notched plate.

Multiply this distance by the gel width (8 cm), the gel

thickness (cm), and the number of gel sandwiches.

Add the extra volume required for the caster model

used. (Variable Y in Table 2.)

3

Prepare the stacking gel monomer solution, deaerate

it, and add catalyst and initiator. Gauge the amount of

volume required to fill the sandwich to the notch by

adding the stacking gel with a Pasteur pipette to the

first sandwich, which is visible through the faceplate.

Then add the same amount of monomer solution to

each sandwich, working fairly rapidly.

4

Once all stacking gels are poured, insert a comb (at

a slight angle to prevent trapping air) into the front

sandwich, allowing the comb sides to rest on the

spacers. Insert the remaining combs from front to

back in the same manner. Allow a minimum of one

hour for the gels to polymerize. See page 12 for

stack disassembly.

p8

•

Page 11

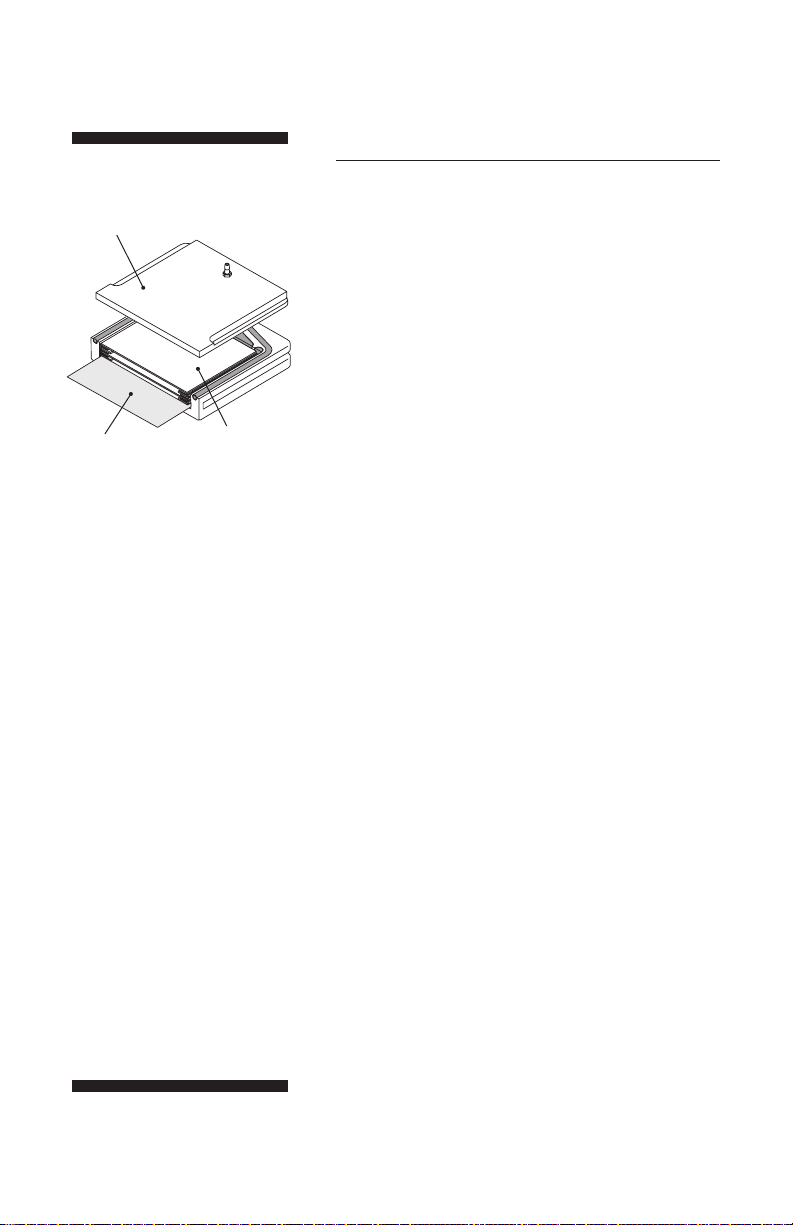

Fig 5. Gradient maker set-up.

Attach tubing to inlet port of the

multiple gel caster, run the tubing

through a peristaltic pump, and

attach to gradient maker.

Linear gradient gels

Gradient gels are prepared by first pumping the

“light” (lower % acrylamide) solutions and then

gradually adding a “heavy” (higher % acrylamide) into the caster by way of the inlet port

on the faceplate.

1

Follow instructions for preparing the gel caster on

page 2. Remove only the triangular rubber plug from

the bottom of the casting chamber, leaving the two

smaller plugs in place.

2

Follow the instructions for constructing the gel sandwich stack and loading it into the caster on page 3.

3

Connect the gradient maker to the gel caster. Run

a length of clear vinyl tubing through a peristaltic

pump and attach one end of the tubing to the gradient maker outlet port and the other end to the casting

chamber inlet port on the faceplate. Adjust the pump

to run a rate of about 5 ml/min for 4-gel casters and

about 10 ml/min for 10-gel casters.

Mixing chamber

Multiple gel caster

Gradient maker

Peristaltic pump Magnetic stirrer

p9

•

Page 12

Note: 15% solid sucrose (w/v)

or 25% glycerol (w/v) in the

“heavy” solution minimizes

mixing and aids gradient

layering.

gel caster required volume gradient maker

range (ml) size*

SE215 55 –100 SG100

SE235 32– 56 SG50 or SG100

SE275 22– 40 SG30 or SG50

*Actual size depends on calculated volume.

4

Prepare solutions

Plug solution

Prepare enough plug solution (50% sucrose or 75%

glycerol in 1X separating gel buffer) to fill the space

below the sandwiches. The SE215 requires about

30 ml and the SE235 or SE275 requires about

15 ml. The plug solution is pumped in after the gradient to displace all of the monomer solution into the

sandwich stack.

Optional: Add bromophenol blue to help track the

plug as it is pumped into the multiple gel caster.

Monomer solution

Follow the instructions on page 6, step 1 for

calculating the total volume of monomer solution

needed. Divide the total volume in half and prepare

this volume of each of the higher and lower %

acrylamide solutions.

•

5

Pour the “heavy” solution into the reservoir chamber

(the chamber furthest from the outlet). Open the stopcock long enough to displace air in the connection

between the chambers and then close. Fill the light

solution into the mixing chamber and place a stirring

bar in this chamber. Place the gradient maker on a

magnetic stirrer and begin stirring at a rate that does

not introduce bubbles into the solution.

p10

Page 13

Note: Avoid repeated and

prolonged contact of

n-butanol with the acrylic

casting chamber to prevent the

acrylic from becoming opaque.

6

Mix the gradient and pump the solution into the caster.

While the solution is stirring, begin pumping from the

mixing chamber and open the stopcock to the reservoir chamber. As the last of the monomer solution is

leaving the mixing chamber, pour the plug solution

into the mixing chamber, leaving no opportunity for

air pockets to form in the tubing. Watch for the plug

solution to approach the bottom of the sandwiches (do

not pump plug solution into the bottom of the sandwiches) then turn off the pump and clamp the tubing

so that no air enters the gel caster.

7

Overlay each gel with a thin layer of water-saturated

n-butanol, water, or diluted gel buffer to prevent

gel exposure to oxygen. Apply the same amount to

each gel to keep the gel levels the same. Deliver the

overlay solution slowly near the spacer at the side of

the sandwich. Allow the solution to flow across the

surface unaided. Apply the same amount to each gel

to keep all gel levels equal.

8

Allow the gels to polymerize for a minimum of one

hour. Open the casting chamber over a sink and

discard the plug solution.

•

p11

Page 14

Note: Do not store gels in the

caster because they will be

difficult to remove.

After Gel Polymerization

1

To remove combs (if necessary): cover each sandwich

with several ml 1X electrophoresis buffer, then work

each comb out slowly by gently rocking it side to side

while pulling it out.

Remove the gel stack from the casting chamber. Take

care to keep the spacers in place while separating

sandwiches: Slip a razor blade between the first two

sandwiches and gently pry the top sandwich loose.

Remove the wax paper between each sandwich.

2

Rinse each sandwich with distilled water to wash off

the overlay and remove any extra gel adhering to the

plates, then blot dry.

3

To use gels — Follow instructions accompanying the

electrophoresis unit.

To store unused gels — Add approx. 5.0 ml of 1X

separating gel buffer to the top of each sandwich,

seal with plastic wrap, and lay flat in refrigerator set

to 4 °C. Or, lay gels flat, submerge in 1X separating

buffer, and store refrigerated. Use within 1 week.

•

p12

Page 15

4. Care and maintenance

Important! Never autoclave any

casting kit component.

Clean the unit with soap and water after each

use and rinse thoroughly with distilled water.

Never use abrasive cleansers. Do not expose

the unit to solutions or vapors of aromatic or

halogenated hydrocarbons, ketones, esters,

alcohols (over 30%), or concentrated acids or

bases (over 25%). All components are resistant

to common electrophoresis buffers.

Clean glass plates with a mild laboratory detergent such as Pierce RBS-35®.

•

p13

Page 16

5. Troubleshooting

problem solution

Plates broken Stack may be too tall. Before clamping, check that

the stack is about 1 mm higher than the top of the

caster edge.

Check that all spacers and plates are aligned before

applying the clamps.

Notched plate ears broken Avoid stressing the ears by only handling the sand-

wiches by the sides and bottom.

Separate sandwiches along the bottom of the stack.

Caster leaks Apply a light film of Gel seal to the gasket each time

the unit is used.

Check the foam gasket for cracks or nicks and replace

if necessary.

If the stack is too tall, the front plate may not seat

firmly against the gasket. Remove filler plates until

the stack seals.

Gel heights uneven Pour the monomer solution into only one sandwich

and allow the groove in the triangular plug to evenly

distribute the solution.

Make sure the groove in the triangular plug is clean

and clear of material.

Wait one minute before overlaying each gel so that

the solution “settles”. Then add the same amount of

overlay solution to each sandwich.

•

p14

Page 17

problem solution

Sample wells damaged or leak Remove air pockets before inserting combs. Slide comb

into solution at an angle. If comb must be removed,

add more monomer solution before reinserting the comb.

Allow the gel to set for a minimum of 1 hour.

Remove the comb at a slight angle and very slowly to

prevent the gel from becoming damaged.

Degas stacking gel solution.

Increase catalysts up to 0.1% v/v TEMED,

0.1% v/v APS.

Gel sandwiches separate Place wax paper between sandwiches in the stack and

in the back of the caster so that sandwiches separate

easily from each other. (This reduces any tendency

for plates to stick to each other instead of to the gel.)

Also, place a polycarbonate sheet on the top of the

stack to prevent a vacuum from forming between the

glass and acrylic face plate.

Gradient gels — uneven layering Add sucrose (15% final concentration) or glycerol

(25% final concentration) to the high percent monomer solution.

Add a small amount of bromophenol blue to the heavy

solution to track the gradient formation.

Decrease the pump rate.

•

p15

Page 18

6. Ordering information

product quantity code number

Gel Casters

For 10 × 8 cm gels

SE275 4-Gel Caster, complete (10 × 8 cm), 2– 4 gels. SE275

Includes 4 notched alumina plates, 10 rectangular glass plates,

2 red clamps, 100 sheets wax paper, space-saver plate,

5 filler sheets, set of filler plugs and Spacer-Mate assembly

template. (Order combs and spacers separately.)

SE215 Multiple Gel Caster, complete (10 × 8 cm), up to 10 gels. SE215

Includes 10 notched alumina plates, 20 rectangular glass plates,

2 red clamps, 100 sheets wax paper, space-saver plate,

5 filler sheets, set of filler plugs and Spacer-Mate assembly

template. (Order combs and spacers separately.)

For 10 × 10.5 cm gels

SE235 4-Gel Caster, complete (10 × 10.5 cm), 2– 4 gels. SE235

Includes 4 notched alumina plates, 5 rectangular glass plates,

4 red clamps, 100 sheets wax paper, space-saver plate,

5 filler sheets, set of filler plugs and Spacer-Mate assembly

template. (Order combs and spacers separately.)

Accessories and replacement parts

Wax paper, precut sheets, for SE275 and SE215 100/pk SE201

Wax paper, precut sheets, for SE235 100/pk SE231

Silicone rubber filler plug set for SE215 3/pk SE209

Filler plug set for SE235 and SE275 SE279

Filler sheets, for SE275 and SE215 5/pk SE213

Filler sheets, for SE235 5/pk SE233

Space-saver plate, for SE215 and SE275 1 SE217

Space-saver plate, for SE235 1 SE237

•

p16

Page 19

product quantity code number

Clamps

Red clamps with springs, 4/pk SE252

for use on SE250, SE260 and on gel casters.

Spacers

thickness width

(mm) (cm) quantity code number

For SE250 0.75 8 2 SE2119T-2-.75

1.00 8 2 SE2119T-2-1.0

1.50 8 2 SE2119T-2-1.5

For SE260 and miniVE 0.75 10.5 2 SE2619T-2-.75

1.00 10.5 2 SE2619T-2-1.0

1.50 10.5 2 SE2619T-2-1.5

Glass and alumina plates

For SE250 (10 × 8 cm)

Notched glass plates 5/pk SE202GN-5

Notched alumina plates 10/pk SE202N-10

Rectangular glass plates 10/pk SE202P-10

For SE260 and miniVE (10 × 10.5 cm)

Notched glass plates 5/pk SE262GN-5

Notched alumina plates 5/pk SE262N-5

Rectangular glass plates 5/pk SE262P-5

•

p17

Page 20

Combs

no. of wells thickness (mm) width (mm) quantity code number

5 0.75 13.0 1 SE211A-5-.75

5 1.00 13.0 1 SE211A-5-1.0

5 1.50 13.0 1 SE211A-5-1.5

*9* 1.00 5.8 1 SE211A-9-1.0

10 0.75 4.8 1 SE211A-10-.75

10 1.00 4.8 1 SE211A-10-1.0

10 1.50 4.8 1 SE211A-10-1.5

12 1.00 4.75 1 SE211A-12-1.0

15 0.75 2.9 1 SE211A-15-.75

15 1.00 2.9 1 SE211A-15-1.0

15 1.50 2.9 1 SE211A-15-1.5

18* 1.00 2.9 1 SE211A-18-1.0

1/1† 0.75 68/5 1 SE211A-R-.75

1/1† 1.00 68/5 1 SE211A-R-1.0

1/1† 1.50 68/5 1 SE211A-R-1.5

*Microtiter spacing

†

Preparative/reference well

Gradient makers

volume (ml) chamber ID (cm) quantity code number

SG15 15 1.27 1 SG15

SG30 30 1.58 1 SG30

SG50 50 1.91 1 SG50

SG100 100 2.54 1 SG100

p18

•

Page 21

Hoefer, Inc.

84 October Hill Road

Holliston, MA 01746

Toll Free: 1-800-227-4750

Phone: 1-508-893-8999

Fax: 1-508-893-0176

E-mail: support@hoeferinc.com

Web: www.hoeferinc.com

Hoefer is a registered trademark

of Hoefer, Inc.

RBS-35 is a trademark of Pierce

Chemical Co.

© 2012 Hoefer, Inc. —

All rights reserved.

Printed in the USA.

Loading...

Loading...