Page 1

user manual

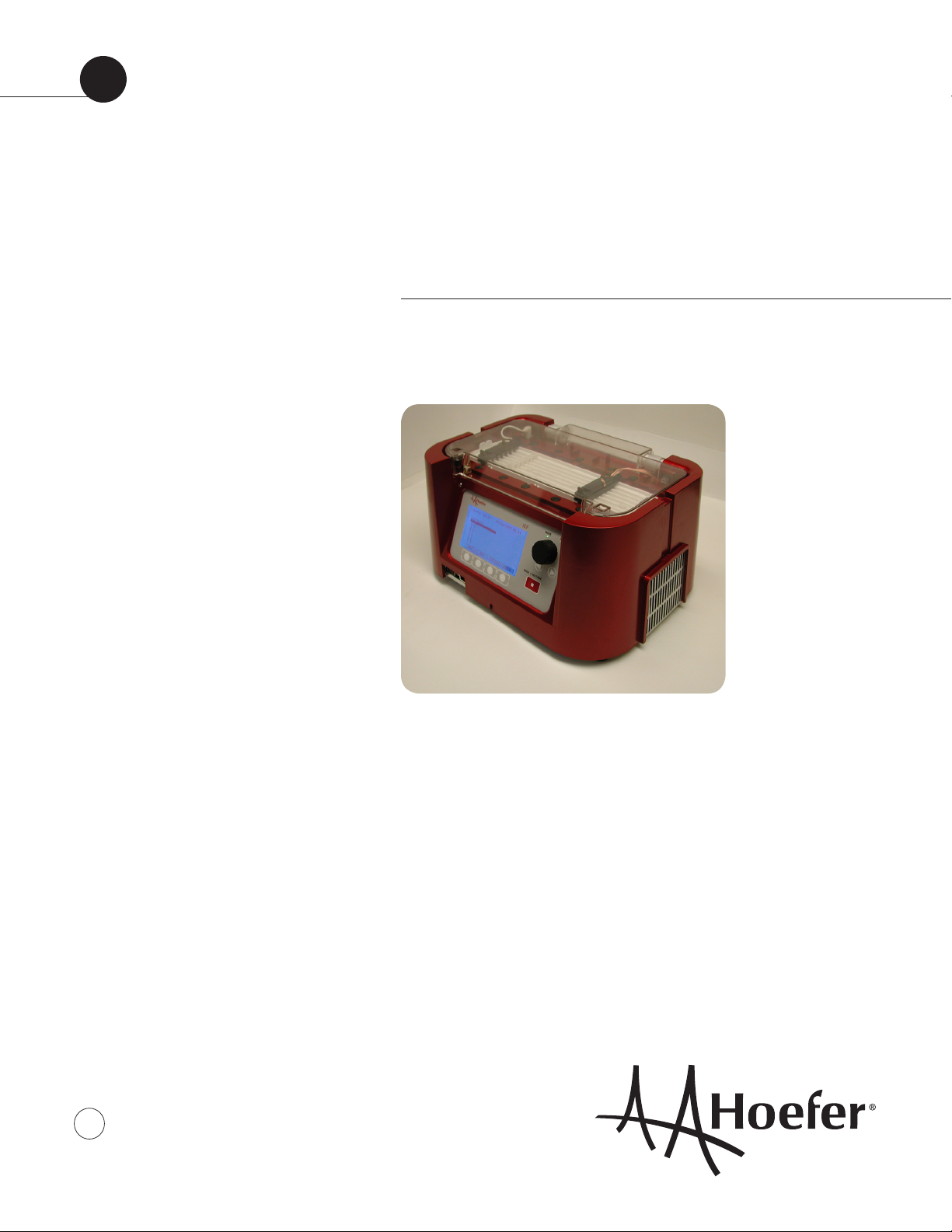

Hoefer IEF100

Isoelectric Focusing Unit

um IEF100-IM/Rev.B0/07-12

Page 2

Page Finder

Important Information ................................................................ii

Waste Electrical And Electronic Equipment (WEEE) .................... vi

Function and Description ...........................................................1

Specifications ...........................................................................2

System Components .................................................................3

Component Descriptions .............................................................5

Programming the IEF100 .........................................................10

IEF100 Operation ....................................................................20

Optional Data Connections .......................................................35

Care and Maintenance ............................................................42

Technical Service and Repair ...................................................42

Troubleshooting .......................................................................43

Ordering Information ...............................................................45

Appendix A: Preprogrammed Protocols ......................................46

Appendix B: Reagents and Solutions .........................................51

Appendix C: References IEF100 ...............................................57

•

pi

Page 3

Important Information – English

• If this equipment is used in a manner not specied by Hoefer, Inc. the

protection provided by the equipment may be impaired.

• This instrument is designed for indoor laboratory use only.

• Only accessories and parts approved or supplied by Hoefer, Inc. may

be used for operating, maintaining, and servicing this product.

• Only use a power supply that is CE marked or safety certied by a

nationally recognized testing laboratory.

• The safety lid must be in place before connecting the power supply

leads to a power supply.

• Turn all power supply controls o and disconnect the power leads

before removing the safety lid.

• Circulate only water or 50/50 water/ethylene glycol through the

heat exchanger if so equipped. Do not connect the heat exchanger

to a water tap or any coolant source where the water pressure is

unregulated.

• Never introduce antifreeze or any organic solvent into any part of the

instrument. Organic solvents will cause irreparable damage to the

unit!

• Do not operate with buer temperatures above the maximum

specied technical specications. Overheating will cause irreparable

damage to the unit!

Duležité Informace – Czech

• Pokud by toto zařízení je použito způsobem, který není podle Hoefer,

Inc. ochrana poskytovaná na základě zařízení může být narušena.

• Tento nástroj je určen pro vnitřní použití v laboratoři pouze.

• Pouze příslušenství a části schválen, nebo poskytnutých Hoefer, Inc.

mohou být použity pro provoz, údržbu, a údržbě tohoto výrobku.

• zdroj napájení používají jen že je opatřen označením CE osvědčena

nebo bezpečnost vnitrostátně uznanými zkušebními laboratoř.

• Bezpečnosti lid musí být zavedena před připojením napájecí zdroj

napájení vede k.

• Turn veškeré napájení kontroly vypnuto a odpojit před odběrem

energie vede bezpečnostní víko.

• Rozeslat pouze voda nebo 50/50 voda/ethylenglykolu

prostřednictvím výměník tepla je li to vybavena. Nemají připojení

výměník tepla s vodními setřepná nebo jakékoli chladicí kapaliny

zdroje, kde tlak vody je neregulo.

• Nikdy zavést prostředek proti zamrznutí nebo jakákoli organická

rozpouštědla do jakékoli části z tohoto nástroje. Rozpustidlům

způsobí nenapravitelné poškození jednotka!

• Nejsou provozována s pufru teplotách nad maximální stanovenou

technickými specikacemi. Přehřátí způsobí nenapravitelné poškození

jednotka!

Vigtig Information – Danish

• Hvis dette udstyr bruges i en måde ikke speciceret ved Hoefer,

Inc. den beskyttelse, som er blevet forsynet af udstyret kan måske

svækkes.

• Dette instrument er designet for indendørs laboratoriumbrug bare.

• Bare tilbehør og del godkendede eller forsynede ved Hoefer, Inc. kan

måske bruges for drive, funktionsfejl, og betjening dette produkt.

• bruger Bare en strømforsyning, der er CE markerede eller sikkerhed,

som er blevet attesteret af en, som nationalt er blevet anerkendt

prøve laboratorium.

• Sikkerhedlåget må være på plads før forbinding strømforsyningsblyet

til en strømforsyning.

• Drejer alle strømforsyningskontroller af og afbryder kraftblyet før

erning sikkerhedlåget.

• Cirkulerer bare vand eller 50/50 vand/ethylene glykol gennem

varmeveksleren i så fald udrustet. Forbind ikke varmeveksleren

til en vandhane eller nogen kølemiddelkilde hvor vandtrykket er

unregulated.

• Introducerer Aldrig antifreeze eller noget organisk opløsningsmiddel

ind i nogen del af instrumentet. Organiske opløsningsmidler vil

forårsage uboelig skade til enheden!

• Driver ikke med stødpudetemperaturer over maksimummet

specicerede tekniske specications. Overheding vil forårsage uboelig

skade til enheden!

Belangrijke Informatie – Dutch

• Indien deze uitrusting in een manier wordt gebruikt die niet door

Hoefer, Inc. is gespeciceerd de bescherming die door de uitrusting is

verzorgd kan worden geschaad.

• Dit instrument is voor binnenlaboratoriumgebruik enkel ontworpen.

• Enkel onderdelen en delen keurden goed of leverden door Hoefer,

Inc. kan voor het bedienen worden gebruikt, handhavend en

onderhouden van dit product.

• gebruik Enkel een netvoeding die CE is markeerde of veiligheid

die door een is gecerticeerd die nationaal is herkend testene

laboratorium.

• Het veiligheidsdeksel moet in plaats voor het verbinden van de

netvoeding leidt tot een netvoeding zijn.

• Doe alle netvoedingscontroles Uit en koppel los de machtleiding voor

het verwijderen van het veiligheidsdeksel.

• Circuleer enkel water of 50/50 water/ethyleenglycol door de

hitte exchanger zo ja uitrust. Verbind de hitte exchanger naar

een waterkraan of koelmiddelbron niet waar de waterdruk niet

geregulariseerd is.

• Stel Nooit antivriesmiddel of organische oplosmiddelen in deel van

het instrument voor. Organische oplosmiddelen zullen onherstelbare

schade aan de eenheid veroorzaken!

• Bedien niet met buertemperaturen boven het maximum

speciceerde technische specicaties. Oververhittend zal

onherstelbare schade aan de eenheid veroorzaken!

Tärkeää Tietoa – Finnish

• Jos tätä varusteita käytetään tavassa ei määritetty Hoefer, Inc. suojelu

ehkäisty varusteille saattaa olla avuton.

• Tämä väline suunnitellaan sisälaboratoriokäytölle vain.

• Vain lisävarusteet ja osat hyväksyivät tai toimitti Hoefer, Inc. oheen ää

voi käyttää käyttämiselle, valvoalle, ja servicing tämä tuote.

• Vain käyttää käyttöjännitettä joka on CE merkitsi tai turvallisuus

joka on todistanut aidoksi ohi joka on kansallisesti tunnustettnut

testaaminen laboratoriota.

• Turvallisuuskansi täytyy olla paikallaan ennen yhdistäminen

•

pii

Page 4

käyttöjännitelyijyjä käyttöjännitteeseen.

• Kiertää kaikki käyttöjännitevalvonnat ja irrottaa valtalyijyt ennen

poistaminen turvallisuuskantta.

• Kiertää vain vesi tai 50/50 vesi/ethyleneä glycol siinä tapauksessa

varustetun lämmönvaihtimen läpi. Älä yhdistä lämmönvaihdinta

vesinapautukseen eikä jäähdytysnestelähteeseen, missä vesipaine on

unregulated.

• Pakkasneste eikä orgaaninen liuotin välineen osassa ei esitele

Koskaan. Orgaaniset liuottimet aiheuttavat korvaamattoman

vahingon yksikköön!

• Ei käytä puskuria yllä olevia lämpötiloja enintään määritetyillä

teknisillä täsmennyksillä. Ylikuumeneminen aiheuttaa

korvaamattoman vahingon yksikköön!

Information Importante – French

• Si cet équipement est utilisé dans une manière pas spécié par

Hoefer, Inc. la protection fourni par l’équipement pourrait être

diminuée.

• Cet instrument est conçu pour l’usage de laboratoire intérieur

seulement.

• Seulement les accessoires et les parties ont approuvé ou ont fourni

par Hoefer, Inc. pourrait être utilisé pour fonctionner, maintenir, et

entretenir ce produit.

• utilise Seulement une alimentation qui est CET a marqué ou la

sécurité certié par un nationalement reconnu essayant le laboratoire.

• Le couvercle de sécurité doit être à sa place avant connecter

l’alimentation mene à une alimentation.

• Tourner tous contrôles d’alimentation de et débrancher les avances

de pouvoir avant enlever le couvercle de sécurité.

• Circuler seulement de l’eau ou 50/50 glycol d’eau/éthylène par

l’exchanger de chaleur si si équipé. Ne pas connecter l’exchanger de

chaleur à un robinet d’eau ou à la source d’agent de refroidissement

où la pression d’eau est non régulée.

• Ne Jamais introduire d’antigel ou du dissolvant organique dans

n’importe quelle partie de l’instrument. Les dissolvants organiques

causeront des dommages irréparables à l’unité!

• Ne pas fonctionner avec les températures de tampon au-dessus du

maximum a spécié des spécications techniques. La surchaue

causera des dommages irréparables à l’unité !

Wichtige Informationen – German

• Wenn diese Ausrüstung gewissermaßen nicht angegeben durch

Hoefer, Inc. verwendet wird, kann der durch die Ausrüstung zur

Verfügung gestellte Schutz verschlechtert werden.

• Dieses Instrument wird für den Innenlaborgebrauch nur dafür

entworfen.

• Nur Zusätze und Teile genehmigten oder lieferten durch Hoefer, Inc.

kann für das Funktionieren, das Aufrechterhalten, und die Wartung

dieses Produktes verwendet werden.

• Verwenden Sie nur eine Energieversorgung, die CE gekennzeichnet

oder durch ein national anerkanntes Probelaboratorium bescheinigte

Sicherheit ist.

• Der Sicherheitsdeckel muss im Platz vor dem Anschließen der

Energieversorgung sein führt zu einer Energieversorgung.

• Alle Energieversorgungssteuerungen abdrehen und die Macht

trennen führt vor dem Entfernen des Sicherheitsdeckels.

• Nur Wasser oder 50/50 Glykol des Wassers/Äthylens durch den

Wärmeaustauscher, wenn so ausgestattet, in Umlauf setzen.

Verbinden Sie den Wärmeaustauscher mit einem Wasserklaps oder

jeder Kühlmittel-Quelle nicht, wo der Wasserdruck ungeregelt wird.

• Führen Sie nie Frostschutzmittel oder jedes organische Lösungsmittel

in jeden Teil des Instrumentes ein. Organische Lösungsmittel werden

nicht wiedergutzumachenden Schaden der Einheit verursachen!

• Mit Puertemperaturen über angegebenen technischen

Spezizierungen des Maximums nicht funktionieren. Die Überhitzung

wird nicht wiedergutzumachenden Schaden der Einheit verursachen!

Informazioni Importanti – Italian

• Se quest’apparecchiatura è usata in un modo specicato da Hoefer,

Inc. la protezione fornito dall’apparecchiatura potrebbe essere

indebolita.

• Questo strumento è disegnato per l’uso di laboratorio interno solo.

• Solo gli accessori e le parti hanno approvato o hanno fornito da

Hoefer, Inc. potrebbe essere usato per operare, per mantenere, e per

revisionare questo prodotto.

• usa Solo un alimentatore che è CE ha marcato o la sicurezza certicato

da un nazionalmente riconosciuto testando il laboratorio.

• Il coperchio di sicurezza deve essere nel luogo prima di collegare i

piombi di alimentatore a un alimentatore.

• Spegne tutto i controlli di alimentatore e disinserisce i piombi di

potere prima di togliere il coperchio di sicurezza.

• Circola solo l’acqua o 50/50 glicole di acqua/etilene attraverso

lo scambiatore di calore se così equipaggiato. Non collegare lo

scambiatore di calore a un rubinetto di acqua o qualunque fonte di

refrigerante dove la pressione di acqua è sregolata.

• Non introduce mai l’antigelo o qualunque solvente organico in

qualunque parte dello strumento. I solventi organici causeranno il

danno irreparabile all’unità!

• Non opera con le temperature di tampone al di sopra del massimo

ha specicato le descrizioni tecniche. Il surriscaldamento causerà il

danno irreparabile all’unità!

Viktig Informasjon – Norwegian

• Hvis dette utstyret blir brukt i en måte ikke spesisert ved Hoefer, Inc.

beskyttelsen som ha blitt git av utstyret kan bli svekket.

• Dette instrumentet er utformet for innendørs laboratoriumbruk bare.

• Bare tilbehør og deler godkjente eller forsynte ved Hoefer, Inc. kan bli

brukt for drive, vedlikeholde, og betjene dette produktet.

• bruker Bare en kraftforsyning som er CE merket eller sikkerhet

som ha blitt sertisert av et som nasjonalt ha blitt anerkjent prøver

laboratorium.

• Sikkerheten lokket må være på plass før forbinding kraftforsyningene

blyene til en kraftforsyning.

• Vender all kraftforsyningsstyring av og frakopler kreftene blyene før

erning sikkerheten lokket.

• Sirkulerer bare vann eller 50/50 vann/ethylene glykol gjennom

oppvarmingen veksleren i så fall utstyrer. Ikke forbind oppvarmingen

veksleren til en vanntapp eller noe kjølemiddelkilde hvor vannet

•

piii

Page 5

trykket er unregulated.

• Introduserer Aldri antifreeze eller noe organisk løsemiddel inn i noe

del av instrumentet. Organiske løsemiddler vil forårsake irreparabel

skade på enheten !

• Driver med buertemperaturer over maksimum ikke spesiserte

teknisk spesikasjoner. Å overoppheting vil forårsake irreparabel

skade på enheten !

Wazne Informacje – Polish

• Jeżeli ten sprzęt jest wykorzystywany w sposób nie określone przez

Hoefer, Inc. do ochrony przewidzianej przez urządzenie może zostać

obniżony.

• Instrument ten jest przeznaczony do użytku w laboratoriach kryty

tylko.

• Tylko akcesoriów i części zatwierdzone lub dostarczone przez Hoefer,

Inc. mogą być wykorzystane do eksploatacji, utrzymania i obsługi

tego produktu.

• korzystać jedynie zasilacza że jest noszące oznakowanie CE lub

bezpieczeństwa uwierzytelnione przez uznane na poziomie krajowym

laboratorium badawcze.

• Bezpieczeństwo lid musi być w miejsce przed podłączeniem zasilania

prowadzi do zasilania.

• Zaś wszystkie źródła zasilania urządzenia sterujące o i odłączyć moc

prowadzi przed odbiorem bezpieczeństwa lid.

• Krążą tylko wody lub wody 50/50/ethylene glycol wymiennik ciepła

poprzez jeśli tak wyposażone. Nie należy połączyć wymiennik ciepła

woda z kranu lub jakimkolwiek chłodziwo źródła, jeżeli ciśnienie wody

jest nieuregulowanych.

• Nigdy nie wprowadzać rozpuszczalnika organicznego przeciw

zamarzaniu lub jakichkolwiek na dowolną część dokumentu.

Rozpuszczalniki organiczne spowoduje nieodwracalne szkody dla

jednostki!

• Nie działają w buforze temperatury powyżej maksymalnego

określone specykacje techniczne. Przegrzania spowoduje

nieodwracalne szkody dla jednostki!

Informações Importantes – Portuguese

• Se este equipamento é usado numa maneira não especicada por

Hoefer, Inc. que a protecção fornecida pelo equipamento pode ser

comprometida.

• Este instrumento é projectado para uso de interior de laboratório só.

• Só acessórios e partes aprovaram ou forneceu por Hoefer, Inc. pode

ser usada para operar, manter, e servicing este produto.

• Só usa um estoque de poder que é CE marcou ou segurança

registrada por um nacionalmente reconhecido testando laboratório.

• A tampa de segurança deve estar em lugar antes de ligar o estoque

de poder leva a um estoque de poder.

• Desliga todos controlos de estoque de poder e desconecta os

chumbos de poder antes de retirar a tampa de segurança.

• Circulam só água ou 50/50 glicol de água/ethylene pelo exchanger de

calor se for assim equiparam. Não ligue o exchanger de calor a uma

torneira de água nem qualquer fonte de refrigerante onde a pressão

de água é não regulado.

• Nunca introduz anticongelante nem qualquer orgânico solvente em

qualquer parte do instrumento. Orgânico solvente causará agressão

irreparável à unidade!

• Não opera com temperaturas de buer acima do máximo especicou

especicações técnicas. Superaquecer causará agressão irreparável à

unidade!

Información Importante – Spanish

• Si este equipo es utilizado en una manera no especicado por Hoefer,

Inc. la protección proporcionado por el equipo puede ser dañada.

• Este instrumento es diseñado para el uso interior del laboratorio sólo.

• Sólo accesorios y partes aprobaron o suministraron por Hoefer, Inc.

puede ser utilizado para operar, para mantener, y para atender a este

producto.

• Sólo utiliza una alimentación que es CE marcó o la seguridad

certicada por un nacionalmente reconocido probando el laboratorio.

• La tapa de la seguridad debe estar en el lugar antes de conectar la

alimentación lleva a una alimentación.

• Apaga todos controles de alimentación y desconecta los plomos del

poder antes de quitar la tapa de la seguridad.

• Circula sólo agua o 50/50 glicol de agua/etileno por el intercambiador

de calor si ése es el caso equiparon. No conecte el intercambiador

de calor a un toque de la agua ni cualquier fuente del líquido

refrigerante donde la presión del agua está libre.

• Nunca introduce anticongelante ni algún solvente orgánico en

cualquier parte del instrumento. Los solventes orgánicos causarán

daño irreparable a la unidad!

• No opera con temperaturas de búfer encima del máximo especicó

especicaciones técnicas. Recalentar causará daño irreparable a la

unidad!

Viktig Information – Swedish

• om denna utrustning används i ett sätt som inte har speciceras av

Hoefer, Inc. skyddet tillhandahöll vid utrustningen kan skadas.

• Detta instrument formges för inomhuslaboratorium användning bara.

• Bara medhjälpare och delar godkände eller levererade vid Hoefer, Inc.

kan användas för fungera, underhålla, och servicing denna produkt.

• använder bara en kraft tillgång som är CE markerade eller säkerhet

intygade vid en nationellt erkänd testande laboratorium.

• Säkerheten locket måste vara på platsen före koppla kraften

tillgången blyen till en kraft tillgång.

• Vänder sig alla kraft tillgång kontroller av och kopplar bort kraften

blyen före ytta säkerheten locket.

• Cirkulerar bara vatten eller 50/50 vatten/ethylene glycol genom

värmen exchanger i så utrustad fall. Inte kopplar värmen exchanger

till en vatten kran eller något kylmedel källa där vattnet trycket är

unregulated.

• Inför aldrig kylvätska eller något organiska lösningsmedel in i någon

del av instrumentet. Organiskt lösningsmedel ska orsaka irreparable

skada till enheten!

• Använd inte med buert temperaturer över det högsta angivna

tekniska specikationerna. Överhettning skulle orsaka irreparabla

skador på enheten!

•

piv

Page 6

English

Waste Electrical And Electronic Equipment (WEEE)

This symbol indicates that the waste of electrical and electronic

equipment must not be disposed as unsorted municipal waste

and must be collected separately. Please contact an authorized

representative of the manufacturer for information concerning the

decommissioning of your equipment.

French

German

Italian

Ce symbole indique que les déchets relatifs à l’équipement

électrique et électronique ne doivent pas être jetés comme les

ordures ménagères non-triées et doivent être collectés séparément.

Contactez un représentant agréé du fabricant pour obtenir des

informations sur la mise au rebut de votre équipement.

Dieses Symbol kennzeichnet elektrische und elektronische Geräte,

die nicht mit dem gewöhnlichen, unsortierten Hausmüll entsorgt

werden dürfen, sondern separat behandelt werden müssen. Bitte

nehmen Sie Kontakt mit einem autorisierten Beauftragten des

Herstellers auf, um Informationen hinsichtlich der Entsorgung Ihres

Gerätes zu erhalten.

Questo simbolo indica che i rifiuti derivanti da apparecchiature

elettriche ed elettroniche non devono essere smaltiti come

rifiuti municipali indifferenziati e devono invece essere raccolti

separatamente. Per informazioni relative alle modalità di

smantellamento delle apparecchiature fuori uso, contattare un

rappresentante autorizzato del fabbricante.

Spanish

Swedish

Este símbolo indica que el equipo eléctrico y electrónico no debe

tirarse con los desechos domésticos y debe tratarse por separado.

Contacte con el representante local del fabricante para obtener más

información sobre la forma de desechar el equipo.

Denna symbol anger att elektriska och elektroniska utrustningar

inte får avyttras som osorterat hushållsavfall och måste samlas in

separat. Var god kontakta en auktoriserad tillverkarrepresentant för

information angående avyttring av utrustningen.

•

pv

Page 7

Note: Ohm’s law states that the

10 mA of output is available at

1000 V and less.

Function and Description

The Hoefer IEF100 Isoelectric Focusing instrument is designed to

perform isoelectric focusing of proteins in Immobilized pH Gradient

(IPG) strips. It is an integrated system with a built-in Peltier cooled

temperature platform, and a 12,000 V, 10 W power supply capable

of delivering up to 10 mA. There are 30 fully editable protocols, nine

of which are pre-programmed with recommended IEF protocols. One

running tray will hold all currently available IPG strips, 3.0 – 3.5 mm

wide. The IPG strips are run gel side up, using electrode wicks to

help remove impurities that collect at the end of the pH gradients.

Samples can be loaded into the IPG strips during rehydration, or

with sample cups.

The IEF100 is fully tested and certified to all applicable international

standards.

Features of the IEF100 are:

• One 6 channel tray that focuses:

Up to 6, 7 – 24 cm IPG strips using the single electrode set.

Up to 12, 7 cm IPG strips using the dual electrode accessory

(included).

Fig. 1. The Hoefer IEF100.

• Sample loading during rehydration or with sample cup.

• Monitors current in each IPG strip.

• Integrated 12,000 volt DC power supply, with 10 mA capability,

the most voltage and current capability available.

• A large blue/white LCD display for easy viewing that supports a

graphical display of voltage and current.

• The ability to program, edit and store up to 30 protocols, each

with 9 steps.

• Constant power mode.

• A real time clock, settable to local time zones.

• Temperature controlled platform.

• Ethernet and RS232 ports to report data or load protocols.

•

p1

Page 8

This declaration of conformity is only

valid for the instrument when it is:

• used in laboratory locations,

• used as delivered from Hoefer, Inc.

except for alterations described in the

user manual, and

• connected to other CE-labeled instruments or products recommended or

approved by Hoefer, Inc.

Specifications

Capacity using

Single Electrode set 1– 6 IPG strips 7 to 24 cm long

Capacity using

Dual Electrode accessory 2– 12 IPG strips 7 cm long

Output Volt 12,000 V

Current 10 mA

Power 10 W

Power in 100 – 240 V

50 – 60 Hz

100 W

User interface Large blue/white graphical display

Knob

7 button keypad

Platform temperature 15 – 25 °C

Protocol capacity 30 programs with 9 steps each

Input/output ports Ethernet, RS232

Dimension (w × d × h) 38 cm × 27 cm × 19 cm

Weight 8 kg

Environmental Indoor use 4 – 40 °C

operating conditions Humidity up to 80%

Altitude up to 2000 m

Installation category II

Pollution degree 2

Product certifications EN61010-1:2001,

EN61326:1998, CE, WEEE, RoHS

•

p2

Page 9

Fig. 2. The IEF100 unit.

System Components

Unpacking

Unwrap all packages carefully and compare the contents with the

packing list, making sure all items arrived. If any part is missing,

contact your local Hoefer, Inc. sales office. Inspect all components

for damage that may have occurred while the unit was in transit. If

any part appears damaged, contact the carrier immediately. Be sure

to keep all packing material for damage claims or to use should it

become necessary to return the unit.

Required but not supplied:

• Immobilized pH Gradient (IPG strips).

• Reagents required for sample preparation and strip rehydration.

• Mineral oil.

•

p3

Page 10

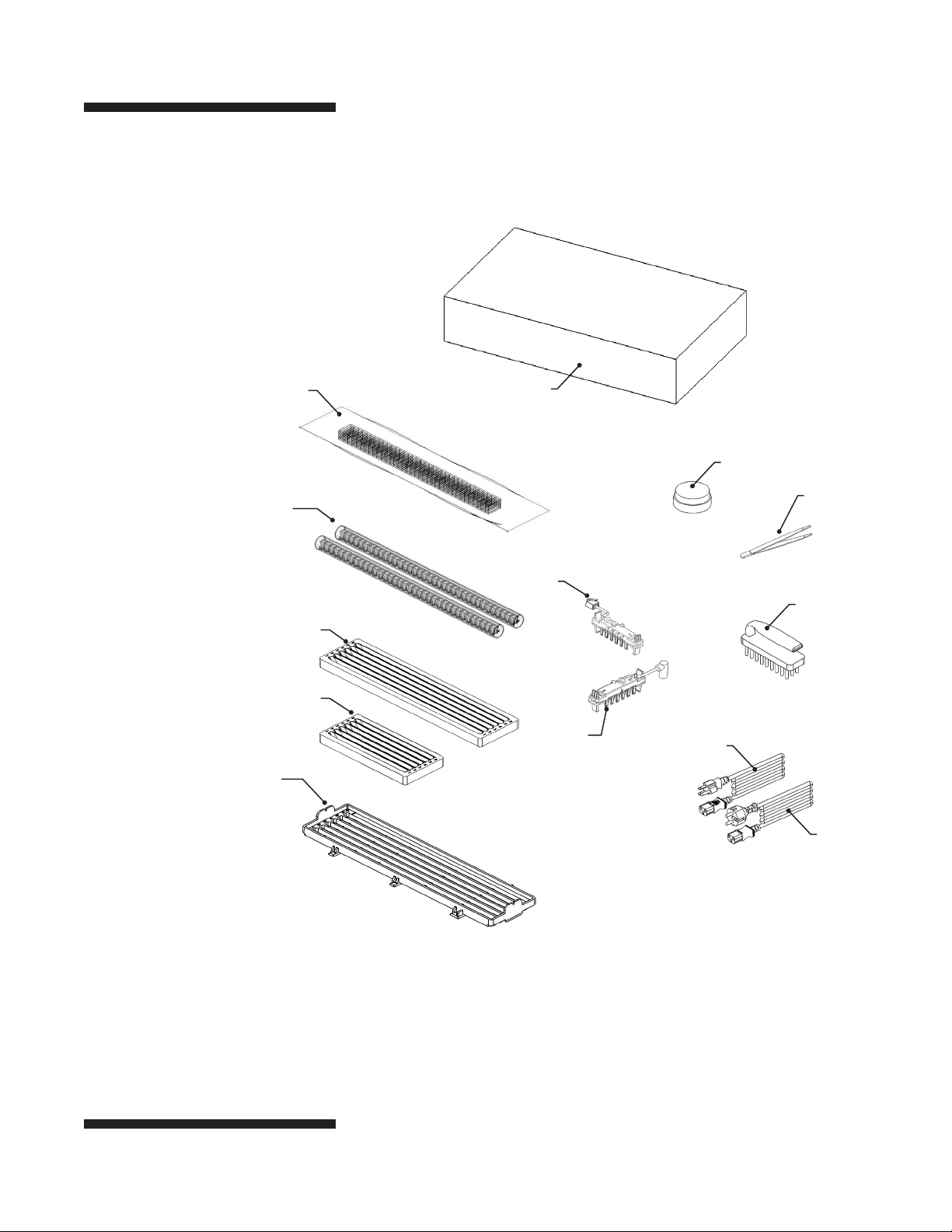

Fig. 3. Instrument components.

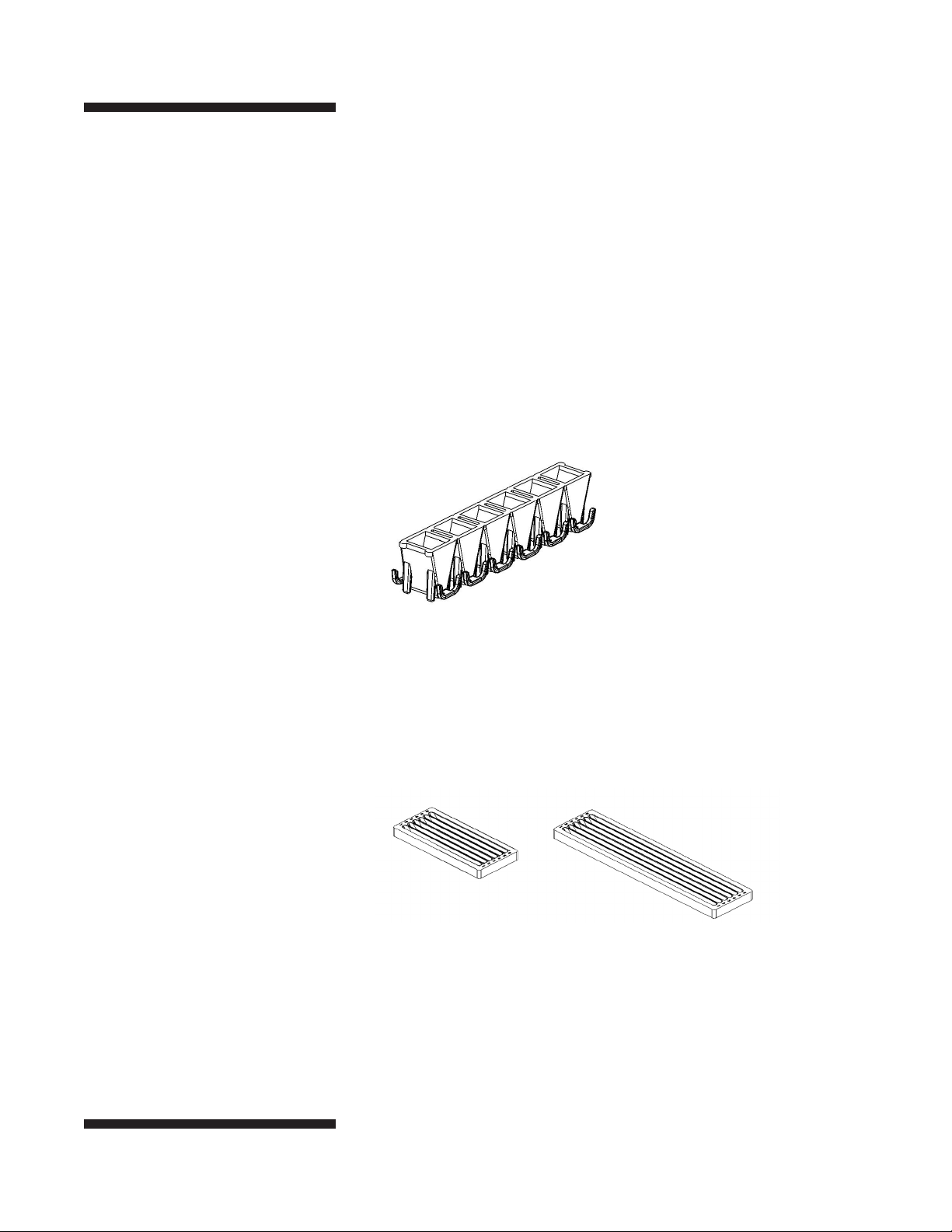

Electrode Wicks

IEF106

Sample Cups

IEF108

Large Rehydration/

Equilibration Tray

IEF110

Small Rehydration/

Equilibration Tray

IEF109

Focus Tray

IEF105

Accessory Box

Level

Forceps

(–) Electrode

Brush

115 V Power Cord

(+) Electrode

Not pictured:

Dual Electrode

Accessory IEF212.

•

230 V Power Cords

(EU and UK)

p4

Page 11

Note: Turn the knob slowly to get

desired movement on the screen.

Turning the knob too fast causes the

cursor to blink, and stay in place. If this

happens, turn the knob slower until the

proper behavior is observed.

Note: The click action of the knob is to

quickly push and release, like a mouse

click. Do not hold the knob in.

Component Descriptions

Safety Lid

The transparent safety lid must be closed in order for voltage to

be applied to the electrodes. Interlocks are used to stop the voltage

output should the lid be opened during electrophoresis.

Knob

The knob moves the cursor or changes the values of a given field.

Pressing the knob inwards to “click” switches between these two

functions. A LED indicates which function is active, MOVE or SET.

Horizontal Arrow Keys

The horizontal arrows are used when setting protocol names, and the

date and time fields.

High Volt Indicator LED

This LED is lit when voltage is being applied to the electrodes.

Fig. 4. Front of the instrument.

RS232 port

Safety lid

Knob

Horizontal

Arrow Keys

High Voltage LED

STOP Button

LCD Display

Function Keys

Ethernet

Port

•

p5

Page 12

STOP Button

Immediately stops the IEF, and terminates the protocol.

LCD Display

The large blue/white display simplifies the interface, and displays

graphical IEF results.

Function Keys

The function of these keys is shown on the display directly above the

key. The function varies depending on what screen is active.

Ethernet Port/RS232 Port

These two ports can be used to download IEF data from the

instrument and transfer protocols.

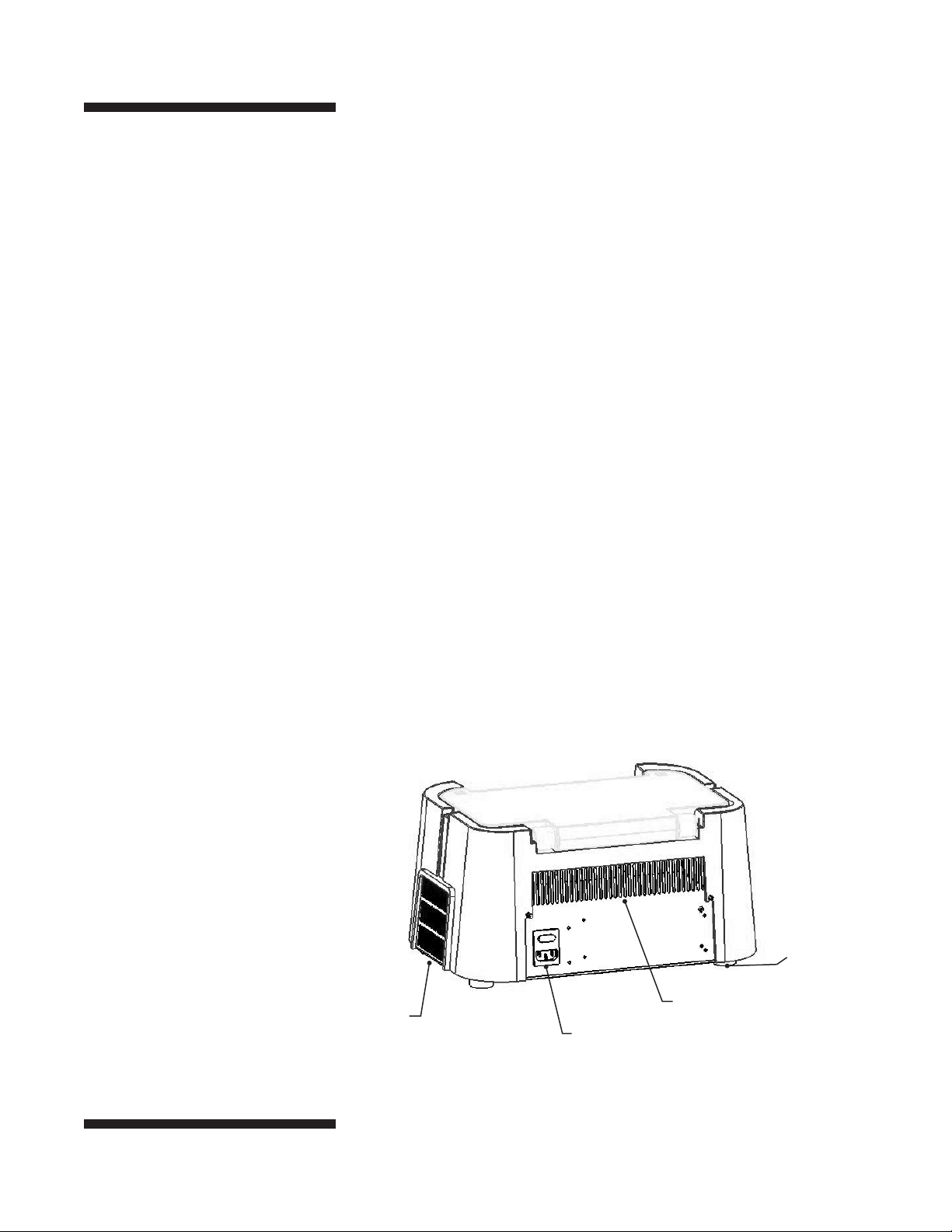

Air Flow

Fans pull air in through the side vents, and blow air out the rear

vents. The air cools the electronic components, and helps the Peltier

modules maintain constant temperature.

Mains Power

The power entry module operates at all volts and frequencies.

Fig. 5. Rear panel.

Note: The vents should not be blocked.

Leveling Feet/Bubble Level

The leveling feet and the bubble level can be used to level the IEF

platform. A level instrument will help ensure oil completely covers

the IPG strips.

Leveling Feet

Air Out Vents

Air In Vents

(2X)

Power Entry

Module ON/OFF

Switch

•

p6

Page 13

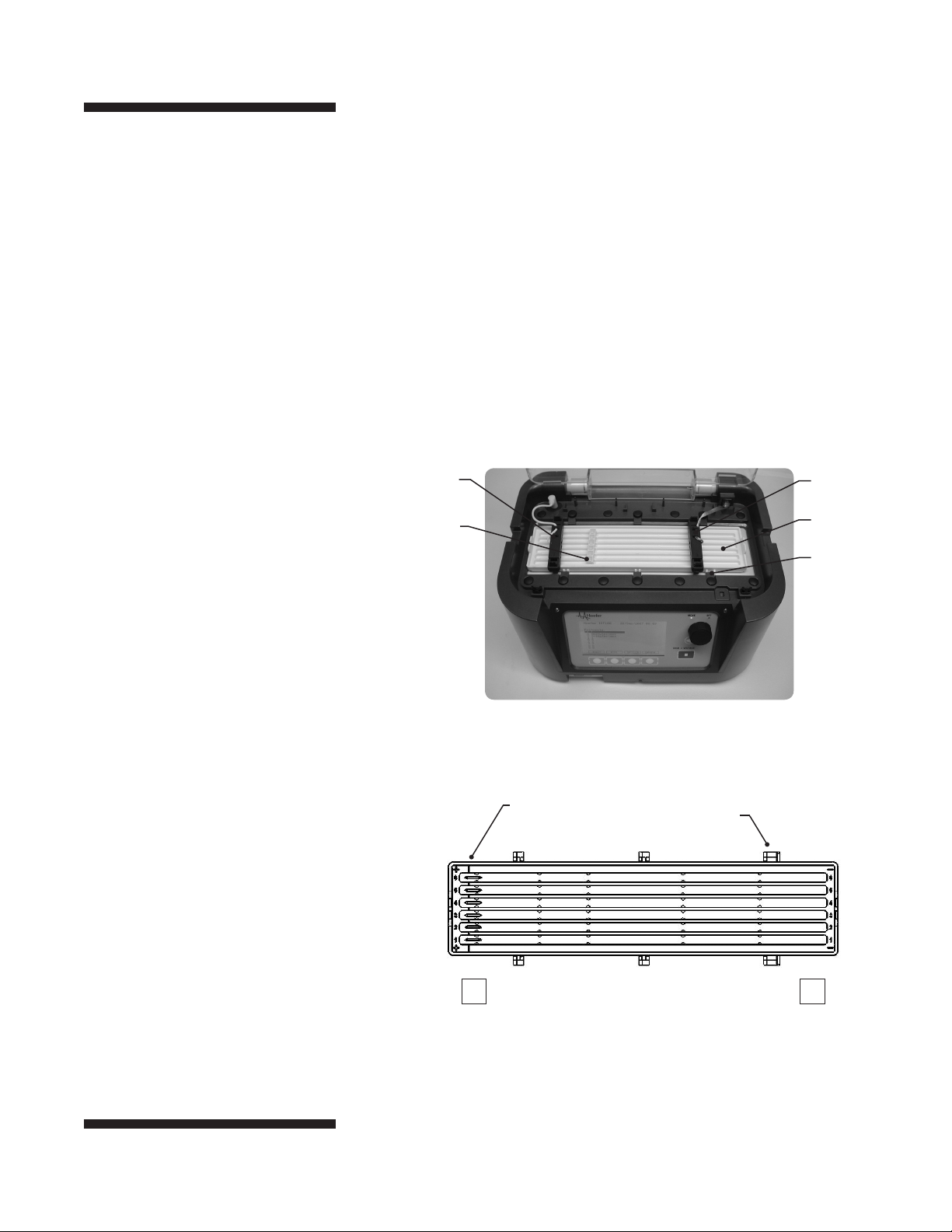

Focusing Tray

The 6 channel focusing tray accommodates IPG strips up to 24 cm in

length. Small grooves in the tray allow for easier removal of the IPG

strip after focusing. Detail of these features can be seen on page 24.

The channels in the tray are numbered 1– 6, from front to back of the

IEF100.

The tray fits in the instrument in only one orientation. It is set in

place on the right side of the platform, and moved sidewise to the

left, clamping the tray down against the cold plate. The clamping

mechanism improves the heat transfer for the plastic trays.

There are (+) and (–) marks on the tray and the instrument to help

with proper orientation.

Fig. 6. Top of the instrument.

(+) Electrode

Sample Cups

Align IEF Strips with this Line

(–) Electrode

Focusing Tray

Clamps

Clamping Tabs (6X)

+ –

Front of Instrument

•

p7

Page 14

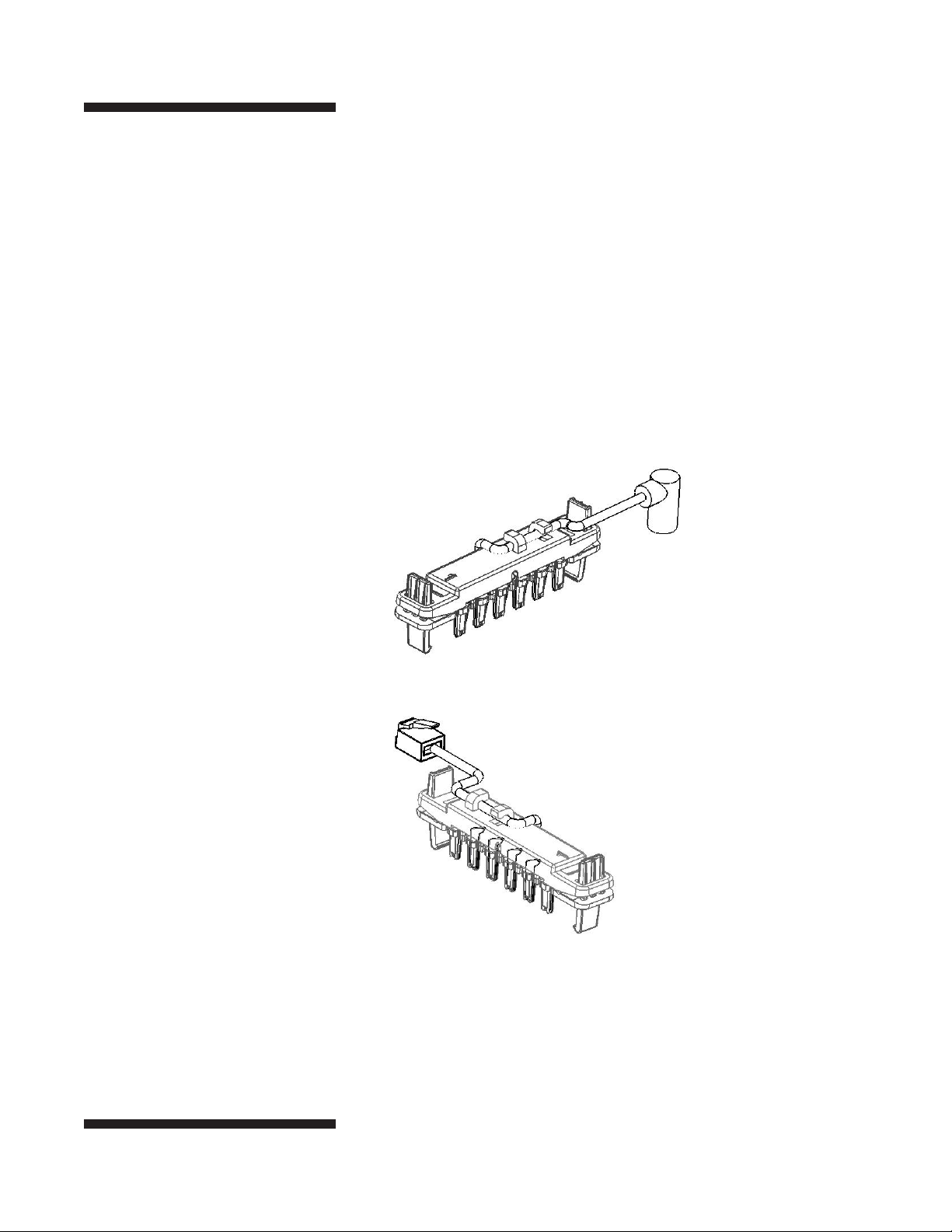

Fig. 7. Positive electrode (top), and

negative electrode (bottom).

Electrodes

Positive Electrode (Anode)

A high volt connector attaches the positive (+) electrode(s) to the high

volt terminal. The anode has a single white wire and connector, and

locates on the left side of the tray.

Negative Electrode (Cathode)

A six wire (lan) connector attaches the negative (–) electrode(s) to the

ground terminal, monitoring the current in each lane. The cathode

locates on the right side of the tray.

Electrodes should be placed in the tray with the number “1” towards

the front of the tray, and the platinum wire electrodes facing the

middle of the IPG strips.

(–) Negative Electrode

(+) Positive Electrode

•

p8

Page 15

Note: The electrodes will not make

contact with the IPG strips without the

electrode wicks in place.

Electrode Wicks

The electrode wicks are small rectangular filter papers that are placed

over the end of the IPG strips. The electrodes make contact with the

top of the wicks. The electrode wicks help remove impurities that

collect at the end of the IPG strips, and generally improve electrode

contact.

The electrode wicks come in long strips, and must be cut apart into

individual rectangles as they are used. The electrode wicks need to be

moistened by lightly blotting with water prior to use.

Sample Cups

Note: The sample cups can be cut into

individual cups, if desired.

Fig. 8. Sample cups.

Fig. 9. Rehydration/equilibration trays.

The sample cups load protein into the IPG strip. Sample cups can

hold up to 240 μl of sample. The cups can be applied in most places

along the length of the IPG strip, and are normally applied at the

anode (+) end.

Rehydration/Equilibration Trays

The rehydration/equilibration trays can be used for both functions.

The lanes are narrow enough for proper rehydration, but deep

enough to hold the volume of reagent required for equilibration. A

small tray is included for use with 7 cm IPG strips. The large tray can

be used with IPG strips up to 24 cm in length.

Brush

The cleaning brush is used for cleaning the focusing tray.

Forceps

Forceps facilitate handling of IPG strips.

•

p9

Page 16

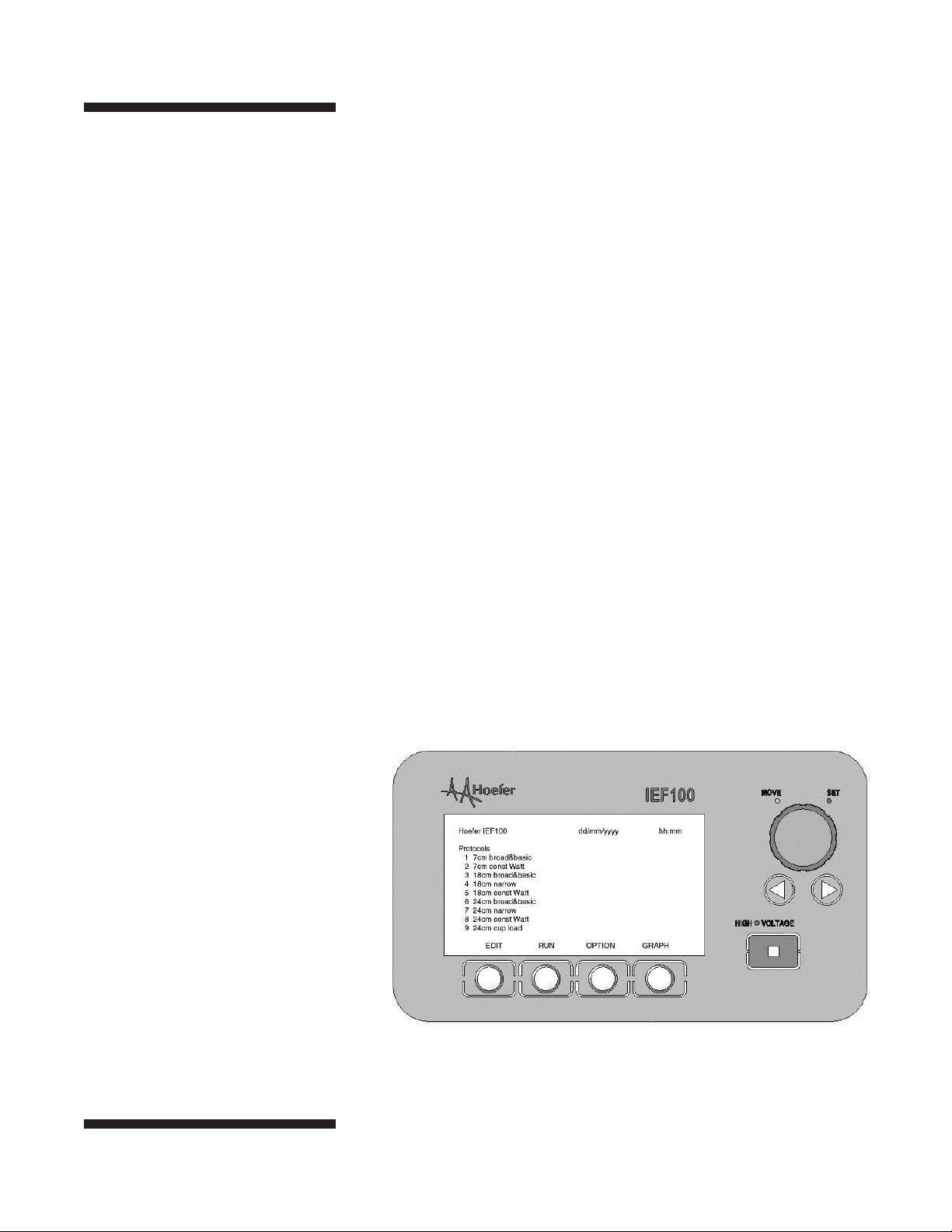

Programming the IEF100

Main Screen

When turned ON, the main screen is displayed (Fig. 10). The main

screen contains the following fields.

Date and Time

The date and time are set up at Pacific Standard Time. Use the

OPTION button to set the date and time for your location. (See

options screen page 17).

List of 30 Protocols

The first nine protocols are shown on the display. One of the protocols is always highlighted. Use the knob to scroll through the other

protocols.

The instrument is preloaded with 9 protocols for focusing 7, 18 or

24 cm IPG’s. These are general guidelines for focusing. IPG strip

manufacturers normally give recommended focusing times in total

volt-hours (volts multiplied by hours). Both under and over focusing

can be problematic. Optimum focusing times should be determined

by the end user considering the IPG strip, the sample type and sample

protein load. All protocols can be overwritten, if desired.

Fig. 10. Main screen.

In addition to these 9 protocols, there are 21 additional unnamed

protocols without preprogrammed steps, allowing the user ample

space to create custom protocols.

•

p10

Page 17

Note: The last run data is retained

in memory until a new run is

started. Once a new run is started,

the last run data is no longer

available.

Note: The volt and current graphs

can not be printed directly from

the IEF100. If data output is sent

to a computer, the data can be

transferred to a program such as

Excel to create the graph.

The Four Buttons: EDIT, RUN, OPTION and GRAPH

EDIT

Edits the highlighted protocol.

RUN

Starts the highlighted protocol.

OPTION

Allows access to port settings and the date and time.

GRAPH

Will display the volt and measured currents graphically. Use the knob

to scroll through the voltage and the μA profiles in channels 1– 6. The

active run will be displayed.

If not actively running a protocol, the graph button will display the

last run data.

•

p11

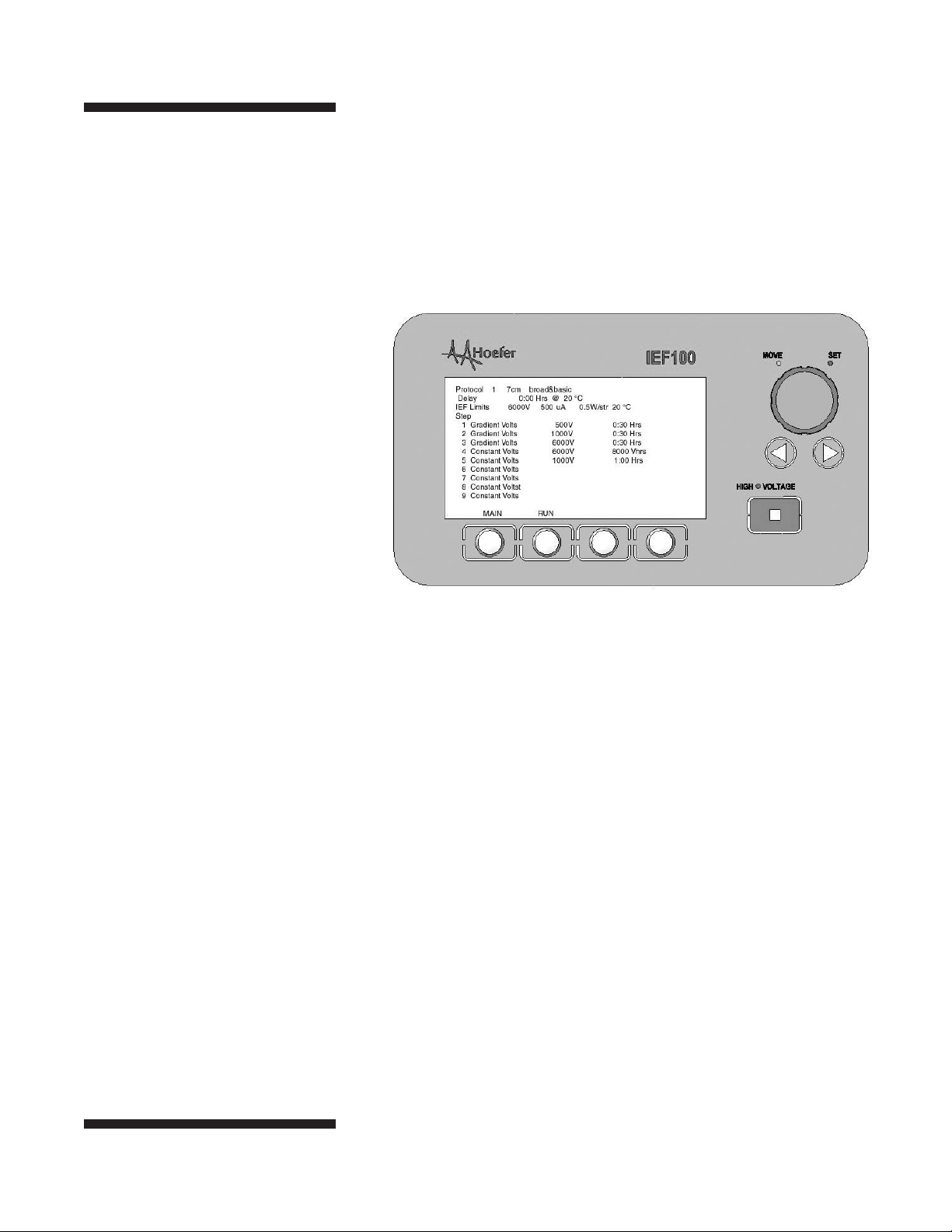

Page 18

Fig. 11. Edit protocol screen. All

parameters for an entire protocol

are viewable on one screen.

Edit Protocol Screen

From the main menu, use the knob to highlight the desired protocol.

Press the button beneath EDIT on the screen. The IEF100 will now

display the edit protocol screen (Fig. 11).

All IEF parameters are displayed on one screen. Each protocol can be

programmed with up to nine steps. The protocol ends with the first

step that has a step time of zero.

Use the knob to move between the following editable fields. Once

highlighted, click the knob to change the value of the field.

Protocol Number

Click the knob. The knob will now cycle through the 30 protocols,

allowing a quick review of each protocol.

Protocol Name

Protocol names can have up to 16 alphanumeric symbols.

The following symbols are available:

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

% . @ / - + m u n 0 1 2 3 4 5 6 7 8 9

Highlight the protocol name field, and click the knob.

A cursor will cause the first character to blink. Turn the knob to scroll

through the above symbols. Once the desired symbol is reached, use

the horizontal arrows (the keys directly beneath the knob) to move the

cursor to the next position. Repeat until the protocol name is correct.

The “blank space” is between the lower case “n” and the “0” symbols.

•

p12

Page 19

The lower case “m”, “u”, and “n” can be used to designate milli,

micro, and nano, if desired.

When the name is correct, click the knob to enter the name, and

move to the next field.

Delay

The delay line is an optional step. Both a time and a temperature

can be entered. Focusing will start after the delay time has elapsed.

This can be helpful for overnight runs where the user may want to

have focusing end at some specific time the next morning. The Peltier

modules will maintain the cold plate at the set temperature.

Note: Times to the nearest minute

increment can be uploaded to protocols

from a computer.

Note: It is recommended not to

exceed 6000 V or more than 0.5 W/

strip for a 7 cm IPG. Please follow the

IPG strip manufacturer’s instructions

for recommended limits.

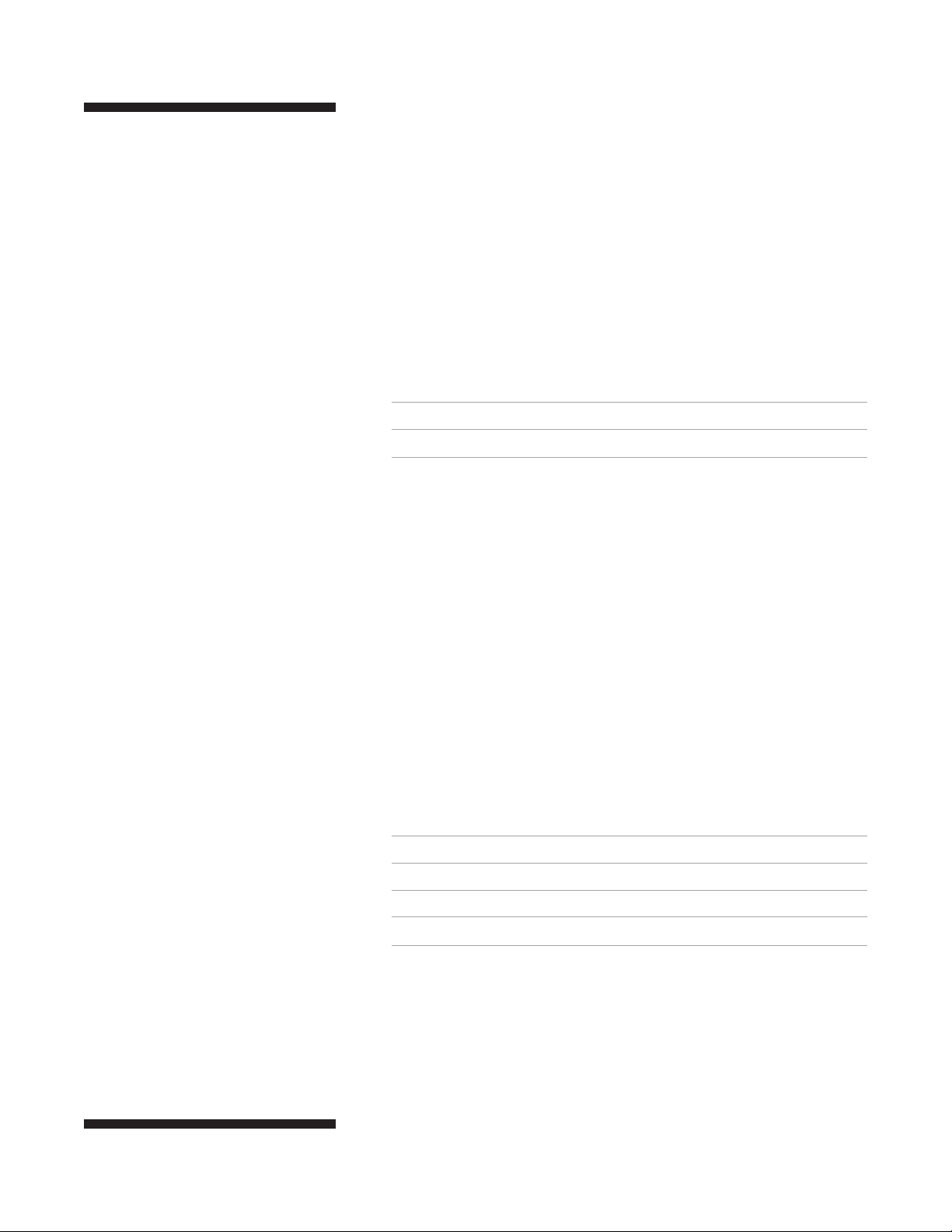

Parameter Units Range Increment

Time (hour:min) 0:00 – 99:59 0:15

Temperature (°C) 15 – 25 1

IEF Limits

Maximum volt, current per strip, and watt per strip are applied to

the protocol. These settings will override the values in the individual

steps. These overall limits can be used to avoid certain focusing

conditions that cause damage or problems with the IPG strips.

The temperature for the focusing is also set. Since the isoelectric

points of proteins are temperature dependent, IEF is typically at

a single temperature, usually 20 °C. It is not recommended to use

temperatures lower than 20 °C as it can cause problems with urea

crystallization in the IPG strip.

Knob Computer

Settable Settable

Parameter Units Range Increments Increments

Volt (V) 0 – 12,000 250 1

Current/strip (μA) 0 – 999 25 1

Watts/strip (W) 0 – 2.0 0.1 0.1

Temperature (°C) 15 – 25 1 1

•

p13

Page 20

Steps

To edit any step parameter, turn the knob to highlight the parameter.

Press the knob, and turn the knob to set the desired value. Press the

knob again to enter the value, and move to the next field.

Each step has four fields that can be edited: the step type, a step value,

a step time, and step units:

Step Type Constant volt, gradient volt, constant watt.

Step Value Sets the maximum value of volt or watt depending

on step type.

Step Time Time in hours or volt-hours.

Step Units Hours (Hrs) or volt-hours (Vhrs).

Step Type and Step Value

Note: It is not recommended to set

a series of discrete volt steps. The

discontinuities between steps cause

spikes in power levels that tend to

increase the chances of burning strips.

Note: In some cases, the volt settings

may never be reached.

Note: If a constant watt step is

followed by a gradient volt step, the

gradient volt step will start from

0, and increase linearly to the set

voltage.

Each step can be programmed in one of three different modes,

constant volt, gradient volt, or constant watt.

• In constant volt, the voltage remains constant thoughout the length

of the step.

• In gradient volt, the voltage will start at the end voltage of the

previous step and increase (or decrease) linearly over time to the

voltage entered in the current step. If the first step of the protocol is

a gradient volt step, the voltage will increase from 0.

• Gradient volt steps gradually increase the power being applied to

the IPG strips, resulting in more even heating of the strip over time.

• Constant watt steps will smooth out the heat generation as much

as possible over the course of the IEF separation. There will still

be localized heating due to different ion concentrations along the

length of the IPG strips.

• When using the constant watt step, the units for the step value

automatically change to watts.

• In constant watt steps, the IEF100 calculates the resistance, and

adjusts the voltage to maintain the constant watt setting.

•

p14

Page 21

Step Time

Note: When switching between time

units, the IEF100 will convert between

hours and Vhrs automatically. It may

help to set the step time units (Hrs or

Vhrs) before the numerical endpoint

is entered.

Steps can be programmed to run for a set amount of time, Hrs (00:00

in hours:minutes), or for a set amount of volt-hours, Vhrs (volts

multiplied by the number of hours). Most IEF strip manufacturers

recommend to run the IPG strips to a specific volt-hours endpoint.

The researcher should determine the endpoint for their specific sample.

The first step with a 0 value entered in the step time is treated as the

end of the protocol.

Step Value

Knob Computer

Settable Settable

Step Type Range Increments Increments

Constant Volt 0 – 12,000 250 1

Gradient Volt 0 – 12,000 250 1

Constant Watt 0.1 – 2.0 0.1 0.1

Step Time

Hrs (hours:minutes) 00:00 – 99:59 0:15 0:01

Vhrs (volt-hours) 0 – 300,000 500 1

•

p15

Page 22

Note: The IEF100 instrument monitors

the current and wattage in each

individual strip. If necessary, conditions

can be adjusted and/or problematic

strips can be removed.

Fig. 12. Run screen.

Note: The IEF100 also beeps

between step changes.

Run Screen

The information on the run screen is described in detail in the IEF

operation section.

The run screen has no editable fields. It does have the following four

soft keys, MAIN, PAUSE, NEXT and GRAPH (Fig. 12).

MAIN

Allows the user to review and edit all protocols while the current IEF

is still running.

PAUSE

The PAUSE button interrupts the high voltage to the IPG strips,

allowing the user to interface safely with the strips.

After a pause, RUN will continue from where it was interrupted, or

ABORT will terminate the run.

NEXT

The NEXT button allows the user to skip the remaining portion of

the active step, and start the next step in the protocol.

GRAPH

The GRAPH button will display the current run results graphically.

Use the knob to scroll through the voltage profile, and the μA profiles

in channels 1– 6.

Press EXIT to return to the run screen.

•

p16

At the end of the run the IEF100 will beep, and turn off the high

voltage power supply. A screen displays the protocol number, the end

date and time, and the final IEF conditions in each IPG strip.

Page 23

Note: When the options screen is

accessed, the IEF100 will first check to

see if there is an ethernet connection.

The IEF100 is inaccessible until the

check is completed (about 10 seconds).

The words “Checking Ethernet” will

flash until the check is completed.

Fig. 13. Options screen.

Options Screen

From the main menu, pressing the OPTION key will allow access to

the following options (Fig. 13).

Serial Port and Intvl

Ethernet

Date/Time

Diagnostics

Clear all protocols

Serial Number

Serial Port

The serial port sets the speed at which data is sent to or received from

an external device. The baud rate can be set to 9600, 38400 or 57600,

with 38400 being the default. The baud rate should match the data

reporting rate of the external device (computer or printer serial port).

Intvl

The time interval between data points sent to an external receiving device. The IEF100 internally records data points every minute.

When downloading the data, the interval between data points can be

changed from 1 to 15 minutes. The default interval is 5 minutes. For

long runs, it may be desirable to have fewer data points, and therefore

use higher values for the interval.

Ethernet

The ethernet connection is determined automatically. “NO

CONNECTION” will be displayed until an ethernet cable is attached

to the port. Once an active LAN connection is established, the local

server will assign an IP address that will be displayed in the XXX.

XXX.XXX.XXX format. This process usually takes about

10 seconds.

•

p17

Page 24

To Set the Date

The date field is three separate fields of DAY/MONTH/YEAR.

1 Use the knob to highlight the date field. Click the knob to set the date.

2 Turn the knob to change the date. Use the horizontal arrows (the

keys directly beneath the knob) to access the MONTH and YEAR

fields, if necessary.

3 When all three fields are correct, press the knob to enter the new date.

To Set the Time

The time field is two separate fields, HOUR:MINUTE. The HOUR field uses

the range 0 – 24 to denote the time of day.

1 Use the knob to highlight the time field. Click the knob to set

the time.

2 Turn the knob to change the HOUR. Use the horizontal arrows

(the keys directly beneath the knob) to access the MINUTE field,

if necessary.

3 When both fields are correct, click the knob to enter the new time.

Diagnostics

1 Highlight diagnostics, and click the knob. The function key RUN

appears on the screen. Press RUN to show a popup screen with

three options:

Run Diags

Manual Vout

Cancel

2 Use the knob to select the option, and press the function OK.

Run Diags

The diagnostics function has the IEF100 go through a series of inter-

nal tests to confirm function. The tests include the voltage and current

output of the internal high voltage power supply, the eprom, and the

clock. If everything tests OK, the message “All OK” is briefly displayed

on the screen.

If one of the tests fail, contact the Hoefer, Inc. representative to

arrange service for the instrument.

Manual Vout

Press OK to show a run screen. Click the knob to SET mode, and the

voltage output is adjustable in 250 V increments. The manual run will

continue until stopped by the user, or up to 4 hours.

Exiting this screen will return to the main menu.

•

p18

Page 25

Note: You cannot recover user

programmed protocols once they

have been reset, or erased.

Clear All Protocols

This option is used to overwrite the existing protocols in memory. A

popup screen shows three options:

Defaults

Erase

Cancel

• Highlight the appropriate option and press OK.

• DEFAULTS resets all 30 protocols to the factory default settings, i.e., the

nine pre-programmed protocols and 21 empty protocols.

• ERASE deletes all the data in all 30 protocols in memory. Empty protocols

have default limits of 12,000 V, 500 μA/strip, 2 W/strip and 20 °C.

Serial Number

Displays the serial number of the IEF100. This is not editable.

•

p19

Page 26

IEF100 Operation

Note: Push the knob inwards, and

release quickly to “click”. There

is tactile and audible feedback. A

successful click changes between MOVE

and SET modes.

Fig. 14. The knob.

Fig. 15. ON/OFF switch.

Using the Knob

The knob has two actions, it turns, and pushes in to “click” (Fig. 14).

Turn: Navigates through fields, adjusts values.

Click: Changes between MOVE and SET modes, as indicated by the LED.

1 In MOVE mode, highlight the field that you want to change.

2 Click the knob to change to SET mode.

3 Turning the knob will now adjust the value of the field. When the

proper value is shown, click the knob again to enter the value, and

change back to MOVE mode. Turning the knob will now move to the

next field.

IEF100 Setup

1 Plug the IEF100 into a grounded mains outlet using the appropriate

power cord. An adapter may be necessary in some countries. The

power entry module is on the rear panel. The ON/OFF switch is located

on the power entry module (Fig. 15).

2 Allow for clearance around instrument and enough clearance above

to allow for opening the lid. The vents should not be blocked. Do not

allow fluids to enter the side intakes.

3 Wash the electrode tray, rinse well with deionized water and allow to

air dry.

4 Gently clean electrode platinum wire contact points and allow to

air dry.

5 When the unit is inactive for a period of time a screensaver will be

displayed to prolong the life of the display. Push any button to exit

the screensaver.

Fig. 16. Ethernet connection.

•

p20

Printer and Computer Connections

Attach and configure a printer or a computer before focusing, and

the IEF100 automatically sends output data in real time (Fig. 16).

See Optional Data Connections, page 35.

Page 27

Preparing IPG Strips

Immobilized pH Gels (IPG) are ultra thin polyacrylamide gels on

plastic support films. The gels are made with a pH gradient covalently

bonded into the gel matrix. The gels are stable and reproducible. The

gels are supplied dehydrated and should be stored at temperatures

-20 °C or below.

The IPG strips have an acidic (+) end and a basic (–) end. 2D gel

images are typically shown with the acidic side on the left, and that is

the orientation of the IPG strips in the IEF100. The proper electrode

must be applied to each end: anodic (+) electrode to the acidic end

(left) and the cathodic (–) electrode to the basic end (right).

The dried strips require rehydration before the run. Typically, several

different reagents are included in the rehydration solution to help

solubilize the proteins, and enable successful isoelectric focusing. Rehydration is typically done at room temperature, or 20 °C, and needs a

minimum of 8 hours for good absorption of the reswelling solution. It

is frequently more convenient to allow rehydration to occur overnight.

During rehydration, the IPG strips are covered in mineral oil to prevent

loss of moisture, and prevent urea crystallization.

The IPG strips are rehydrated using one of the rehydration/equilibration trays supplied with the IEF100. Protein sample can be added to

the IPG strip in this step. The IPG strips are transferred to the IEF100

for focusing.

•

p21

Page 28

Note: The IEF100 is a convenient place

to rehydrate strips. The cold plate will

maintain a constant temperature, and

the cover will help protect the IPG strips

from dust.

Note: Using more than the

recommended volumes may contribute

to loss of protein or blurry IEF results.

Rehydration of IPG Strips

A brief discussion of rehydration ingredients and their function is

included in Appendix B, along with some recommended solutions.

The reagents can be customized for specific samples.

The volume of solution is dependent on the length of the strip to be

used. Hoefer recommends following the IPG strip manufacturer’s

recommendations.

A table of typical volumes is included below.

Strip Length (cm) Volume per Strip (μl)

7 130

18 340

24 450

Note: Rehydration solutions typically

contain high concentrations of urea

that tend to crystallize at lower

temperatures. For this reason,

rehydration should not be done in cold

rooms or in environments significantly

colder than 20 °C.

Note: Sliding the strips in the

rehydration buffer will wet the entire

length of the strip, and helps prevent

sticking. Strips placed directly against

the plastic bottom of the rehydration

tray may stick, and not rehydrate

properly.

Apply rehydration solution in a channel of the appropriately sized

rehydration tray in a line slightly shorter in length than the strip to

be rehydrated.

Many IPG strip manufacturer’s cover the strips with a protective

cover. If present, peel off protective layer.

Place the strip, gel side down, onto the liquid in the channel. Gently

slide the strip back and forth to wet the entire length of the IPG gel

with rehydration solution. Sometimes, lifting and lowering the IPG

strip can aid in getting the proper contact of the solution over the

entire length of the IPG gel strip.

Cover the strips with mineral oil, Hoefer order number GR138-1.

Allow to rehydrate a minimum of 8 hours. Better rehydration occurs

if allowing strips to rehydrate overnight.

•

p22

Page 29

Fig. 17. Open the safety lid.

Fig. 18. Slide the focusing tray.

Isoelectric Focusing

(using the Single Electrode Set)

1

Open the safety lid by pressing down on the white push label in the middle

of the front of the lid (Fig. 17).

2

Insert the IEF105 focusing tray on the far right side of the cold plate. The

tray has only one orientation. There are (+) and (–) marks on the tray that

align with corresponding marks on the IEF100.

The tray will not fit properly in the IEF100 in any other orientation.

3

Slide the focusing tray to the left under the clamping tabs (Fig. 18). These

tabs improve the contact, and the heat transfer, between the tray and the

cold plate.

4

Use forceps to load the rehydrated IPG strips into the focusing tray gel side

up. The anodic (+) end of the strips should be on the left, matching the (+)

on the tray and the IEF100 (Fig. 19).

The strip channels are numbered so that channel 1 is closest to the front

and channel 6 is at the back of the IEF100.

Fig. 19. Load the IPG strips.

Note: In any one run, all the IPG strips

should be the same length for the

electrodes to make good contact.

•

p23

Page 30

Fig. 20. Align strips.

Note: The electrode wicks absorb ions

collecting at the ends of the IPG strips,

and generally improve the IEF results.

Fig. 21. Focusing tray enlarged.

5

Align the (+) end of the strips with the alignment mark in the tray (Fig. 20).

This will help in two ways. First, the clamping tabs will not interfere with the

positioning of the electrodes. Secondly, there are small grooves in the bottom

of the channels for forceps to remove IPG strips after IEF.

6

Apply electrode wicks on top of each end of the IPG strips, overlapping the

gel by 2– 3 mm, and extending off the end of the IPG strip.

• The electrode wicks are supplied in long perforated strips. Use scissors to

cut off the desired number of wicks.

• Moisten the IEF wicks with water and gently blot off any excess water.

Grooves for Forceps

to Remove IPG Strips

Fig. 22. Wick placement.

•

p24

IPG Strip

Alignment Line

Platinum Wire

Electrode Wick

Clamping

Tabs

IPG strip alignment features.

Do not use sample cup over

these features.

IPG Strip

Page 31

Note: The electrodes will not make

contact with the IPG strips without the

electrode wick in place.

Fig. 23. Connect (+) electrode.

7

Connect the (+) electrode to the (+) terminal (Fig. 23).

8

Place the (+) electrode on top of the electrode wicks so that the platinum

wire is centered in the area of overlap between the wicks and the IPG strip

(Fig. 24).

The electrode should lightly lock into place.

Fig. 24. Lock (+) electrode in place.

•

p25

Page 32

Fig. 25. Connect (–) electrode.

9

Connect the (–) electrode to the (–) terminal (Fig. 25).

0

Place the (–) electrode on top of the electrode wicks so that the platinum

wire is centered in the area of overlap between the wicks and the IPG strip

(Fig. 26).

The electrode should lightly lock into place.

!

Cover the strips and any empty channels with 60 ml mineral oil. Using less

oil will risk that IPG strips will not be completely covered and may dry out

during the run (Fig. 27).

Fig. 26. Lock (–) electrode in place.

Fig. 27. Cover with mineral oil.

•

p26

Page 33

Fig. 28. IEF100 set up using the Dual

Electrode Accessory.

Isoelectric Focusing

(using the Dual Electrode Accessory)

The Dual Electrode Accessory increases the Hoefer IEF100 capacity,

enabling up to twelve, 7 cm IPG strips to be run simultaneously. This

is accomplished by running up to six pairs IPG strips in parallel. Each

of the six channels will report the sum of the current and wattage of

the paired strips, therefore, the current and wattage limits should be

set at twice the usual value used when running single strips and, as

always, the IPG strips being run simultaneously must be of the same

pH and conductivity.

1

Open the safety lid by pressing down on the push label in the middle of the

front of the lid.

2

Insert the IEF105 focusing tray on the far right side of the cold plate. The

tray has only one orientation. There are (+) and (–) marks on the tray that

align with the corresponding marks on the IEF100.

The tray will not fit properly in the IEF100 in any other orientation.

3

Slide the focusing tray to the left under the clamping tabs. These tabs

improve the contact, and the heat transfer, between the tray and the

cold plate.

4

Use forceps to load the rehydrated 7 cm IPG strips into the focusing tray

with the gel side of the strips facing up.

5

The first set of IPG strips should be loaded on the left side of the tray with

the anodic (+) end of the strips on the left matching the (+) on the tray and

the IEF100.

•

p27

Page 34

6

The second set of IPG strips are loaded to the right of the first set in the

opposite orientation — with the anodic end (+) of the strips matching the (–)

on the tray and the IEF100. The cathodic end (–) of the each set of strips

should be facing each other in the center of the focusing tray, approximately

4 cm apart (Fig. 29).

7

Parallel IPG strips should be aligned as closely as possible using the (+) or

(–) imprinted on the strip to guide alignment.

8

Apply electrode wicks on top of each end of the IPG strips, overlapping the

gel by 2–3 mm, and extending off the end of the IPG strip.

• The electrode wicks are supplied in long perforated strips. Use scissors to

cut off the desired number of wicks.

• Moisten the IEF wicks with water and gently blot off any excess water.

9

Connect the anode electrodes (+) to the positive (+) terminal on the left side

of the IEF100.

0

The anode electrodes are placed on either end of the focusing tray — the left

side of the first set of IPG strips and the right side of the second set of IPG

strips. The electrodes should be centered on top of the area where the wick

overlaps the gel of the IPG strip.

Fig. 29. IPG Strip Placement.

!

Connect the cathode electrodes (–) to the negative (–) terminal on the right

side of the IEF100.

@

The cathode electrodes are placed in the center of the focusing tray — on the

right side of the first set of IPG strips and the left side of the second set of

IPG strips. The electrodes should be centered on top of the area where the

wick overlaps the gel of the IPG strip.

•

p28

Page 35

Sample Cups

Note: There are small semicircular

features in the bottom of the tray

channels that help align the IPG strip

in the middle of the lane. The legs

of the sample cup must not hit these

features or else the sample cup will

leak. See Fig. 21 on page 24.

Fig. 30. Place sample cups.

Sample cups can be used to apply protein sample to IPG strips

if it was not included in the rehydration buffer. The sample cups

are supplied in strips of six cups. The sample cups can be used all

together, or cut apart and used separately.

1

Press the sample cups down on top of the IPG strips. The sample cups

should stop on the bottom of the channel and seal on the IPG strips

(Fig. 30).

In general, most cup loading is done on the anodic end of the IPG strip.

Each sample is different. In some situations, samples may focus better

loaded elsewhere on a strip. This can only be determined experimentally for

different sample types.

2

Up to 240 μl sample can be applied to the sample cups (Fig. 31).

3

Once loaded, confirm the protocol settings.

4

Close the lid (Fig. 32).

Fig. 31. Apply sample.

Fig. 32. Close safety lid.

•

p29

Page 36

Note: The protocol’s overall limits of

current/strip and watt/strip will not

operate correctly without entering the

proper number of channels containing

strips.

Start IEF

1

Highlight the desired protocol, and press RUN.

2

Confirm the number of focusing tray channels containing IPG strips. Use the

knob to change the value.

3

Press RUN again to start the IEF.

Note: The IEF100 monitors the

current and watt in each channel. If

necessary, conditions can be adjusted

and/or problematic strips can be

removed from the run.

4

The IEF100 will beep to indicate the start of a run. The high voltage

LED will light, and “RUNNING” will be flashing in the top right corner

of the display.

The run screen will display the current run conditions.

•

p30

Page 37

Run Screen

The run screen displays all the information on the current run

(Fig. 33). There are no editable fields. The information on the run

screen is described below.

Note: The IEF100 can only control

the conditions of one focusing tray

channel at a time. The IEF100 limits

the channel with the highest current,

or watts. IPG strips prepared under

identical conditions will show variations

due to geometrical differences in the

IPG gel and contact differences under

the electrodes. IPG strips with different

samples can show large differences in

current and wattage due to different

conductivities of the samples.

Line 1

The protocol number and name are shown. The top right corner indicates the

run status as either running (flashing), paused or finished.

Line 2

Displays the number of IPG strips being focused (or number of channels if

using the Dual Electrode Accessory).

Line 3

Describes the active step; the step number, the step value (volt or watt/strip)

and the step end point (Hrs or Vhrs).

Line 4

Displays the total elapsed time and the total volt-hours of focusing up to

the moment.

Line 5

Displays the total elapsed time and total volt-hours of the active step.

Line 6

Displays the real time output conditions of all the strips, including the

current volts, the total current, the total watts and the platform temperature.

Line 8 –13

Display the individual strip current and watts.

Fig. 33. Run screen.

•

p31

Page 38

Fig. 34. Run screen.

In the example below 6 IPG strips are being focused according

to protocol 7, a maximum of 0.5 W/strip and 100,000 volt-hour

endpoint (Fig. 34).

The protocol is in the third step. The protocol has been running for

4 hours and 24 minutes, or 19,108 volt-hours. Currently, the protocol

is 1 hour and 2 minutes and 12,088 volt-hours, into step 3.

The internal power supply is delivering 11,574 volts, a total of

156 μA and 1.8 watts across six IPG strips.

During a run different strips may control the overall voltage as the

resistance of the strips changes during the run.

•

p32

Page 39

Note: Extra salt in the sample tends to

flatten the graphs (horizontally) and take

longer for the sample to focus.

Note: If there are problems with burning

IPG strips, set the current limit to

50 μA/strip to ensure safe focusing

conditions for the entire separation.

Typical Isoelectric Focusing

The first step is typically set to low voltage to limit the current and

let the ions move to the end of the IPG strips without excessive

currents. If loading sample with a sample cup, an additional slow

step may be added to allow the sample to enter the IPG strip under

gentle conditions.

In the middle steps, the voltage ramps upwards to a plateau, and this

is where most of the focusing occurs. The current decreases down to a

minimum value. The graphs below show typical volt and μA profiles

(Fig. 35).

Note: The volt and μA are scaled and

graphed automatically.

Fig. 35. Typical volts and μA profiles.

A final step has been added to the pre-programmed protocols to

hold the volt at 1000 V for an hour. This will keep the bands focused

in the IEF100 until the next step. Extend the length of this step

as necessary.

•

p33

Page 40

Fig. 36. End run screen.

When focusing is complete, the IEF100 will beep, and an end run

screen will be displayed (Fig. 36).

Line 1

The protocol number and name. The word finished is displayed in the

upper right corner.

Line 2

The number of strips run (or number of channels if using the Dual Electrode

Accessory).

Line 3

The date and time that focusing terminated.

Line 4

The total time and volt-hours of focusing.

Line 5

The last step time and volt-hours.

Line 6

The volts, and the total current and watts of all IPG strips at the end

of the run.

Line 8–13

The conditions in each strip at the end of the run.

Note: Whenever a new IEF is

started, the previous IEF data is

permanently lost.

Note: Do not equilibrate the IPG

strips before storing at -20 °C.

•

p34

The results can be viewed graphically by pushing the function GRAPH.

The data will be retained in memory until a new run is started.

At this point, the IPG strips can be stored at -20 °C.

Or, if the second dimension is to proceed immediately, the buffer

needs to be exchanged in a two step equilibration process before

second dimension PAGE.

Page 41

Optional Data Connections

Serial Printer Connection

Use the RS232 port to connect directly to a serial printer. The printer

and cable are not supplied. The serial printer should have the

following settings.

Baud Rate 9600, 38400 or 57600

(must match IEF100 baud rate setting)

Data Bits 8

Parity None

Stop Bit 1

Flow Control None

The following section describes the serial computer connection or a

ethernet connection to the IEF100.

Fig. 37. Assign name to the new

connection.

HyperTerminal Connection

HyperTerminal is a Windows™ program that can communicate with

external devices. By setting up a connection between a computer and

the IEF100, the user can:

• Import and export protocols from the IEF100.

• Capture data output from the IEF100.

• Control the IEF100.

The description and screens below are HyperTerminal screens. Other

terminal emulator programs will also work using the same settings.

Configuring the Communications Port

1 Start HyperTerminal in Windows.

2 Click Windows “Start” command.

3 Launch All Programs-Accessories-Communications-HyperTerminal.

4 Assign a name to the new connection (Fig. 37).

•

p35

Page 42

Fig. 38. Select a Com Port.

Serial Port Configuration

1 Select a Com Port (Fig. 38). This is the computer port to communicate

directly with the IEF100. Choose TCP/IP if connecting via the

ethernet connection.

Fig. 39. Set the baud rate.

2 Set the baud rate to the same as the IEF100, 9600, 38400 or 57600

and 8 data bits, no parity, 1 stop bit, hardware flow control (Fig. 39).

•

p36

Page 43

TCP/IP Connection Using the Ethernet Port

Use the IEF100 ethernet port to connect to a local area network (LAN).

Plug a live ethernet cable into the port. The LAN will automatically

assign an internet address to the IEF100. The internet address is

shown on the IEF100 options screen.

Ethernet Port Configuration

1 From the HyperTerminal properties screen, select the TCP/IP

(Winsock) option at the communication port properties windows

(Fig. 40).

2 Press OPTION from the main screen of the IEF100. The local

server should automatically assign an internet address in the

XXX.XXX.XXX.XXX format.

Enter the IP address to the IEF100 in the host address line in

XXX.XXX.XXX.XXX format (Fig. 41).

3 Set the port number to 10001 (Fig. 41).

Fig. 40. Select the TCP/IP option. Fig. 41. Enter IP address and

port number.

•

p37

Page 44

Fig. 42.

4 Click on the “SETTINGS” tab and the “ASCII Setup” button (Fig. 42).

5 In the ASCII setup section, check the boxes

“Send line ends with line feeds”

“Echo typed characters locally” (Fig. 43).

6 Set the line delay to 30 milliseconds.

7 Set the character delay to 0 milliseconds

8 In the ASCII receiving section, check the box

“Wrap lines that exceed terminal width”

Fig. 43.

•

p38

Page 45

Note: The data from the IEF100 is

a series of text fields separated by

commas. One method to transfer

data to other programs is to use the

Windows clipboard to copy and paste

the data.

Fig. 44.

Capturing IEF100 Data

1 Make sure a good connection exists between HyperTerminal and

the IEF100.

2 Open HyperTerminal. Type “AT” and press ENTER. “OK” should

appear in the HyperTerminal window.

3 There are two ways to download data from the IEF100. The data can

be collected in real time, or sent as a data log file after focusing.

Collect in Real Time

1 With HyperTerminal program open, use the HyperTerminal menus to

access Transfer/Capture text (Fig. 44).

2 Name the file and directory that will collect the data. Use the browse

button, if necessary (Fig. 45).

The data from the IEF100 is sent automatically to the output ports

every 5 minutes. Once a run is started, data will automatically start

appearing in the HyperTerminal window.

3 After focusing, to stop the data capture, use the menus Transfer/

Capture Text/Stop or Pause (Fig. 46).

4 The data is stored in the named file.

Fig. 45.

Fig. 46.

Note: Copying and pasting the data will,

by default, put all the data into one

column in an Excel spreadsheet. Use

the Excel menu Data/Text to columns

command, set the delimiter as commas,

and the data will sort into columns for

graphing.

Transfer Data Log After IEF

1 Type “XDATALOG” in an active HyperTerminal window.

2 The data from the last run will be transferred to the

HyperTerminal window.

•

p39

Page 46

HyperTerminal Commands

The HyperTerminal program communicates with the IEF100 by transmitting one line of data at a time.

Multiple lines can be typed and sent together. Type each line perfectly

the first time, and press enter, for the command to be successfully

loaded into the IEF100. All commands are case sensitive. Correcting

typographical errors in a line of data using the backspace and delete

keys will not result in successful communication.

The first command to type in HyperTerminal should be “AT” and

enter. A good connection is verified with the word OK returning in

the HyperTerminal window.

Examples of protocols are given at the end of Appendix A. These can

be cut and pasted to help with the line formatting.

A subset of useful HyperTerminal commands are given on the following page.

•

p40

Page 47

Subset of HyperTerminal Commands

Format of

Command Command Description Expand Description Result of Command Command

AT Check connection Check to see if the connection “OK” comes back AT

between HyperTerminal and the with a good connection.

IEF100 is good and configured

properly.

XDATALOG Transfer data Transfer data from the IEF100 Data log shows up in XDATALOG

memory to HyperTerminal. HyperTerminal.

Output Data Format

Line 1 Header prot#,protname,startdate,starttime,#datapoints

Line 2 datapoints minute,volt,μAC1,μAC2,μAC3,μAC4,μAC5,μAC6,temp

End Line END,enddate,endtime

Where µAC1 is the current in microamps in channel 1.

IPROT Import protocol Import and overwrites one of the 30 Uploads protocol into 2 line formats

protocol slots: transfers protocol from IEF100 memory. depending on

computer to IEF100. step type

Input Data format

Delay step – IPROT,prot#,protname,step#,delaytime,delaytemp,runtemp,maxμA,maxA,maxVolt,maxWatt

IPROT,5,18cm const Watt,D,0:00,20,20,500,12000,1.5

Step – IPROT,prot#,protname,step#,steptype,stepvalue,timeunits,timeunits,time

IPROT,5,18cm const Watt,2,W,1.5,V,25000

EPROT,# Export protocol Copies protocol number # from Protocol appears in EPROT,#

IEF100 to HyperTerminal. HyperTerminal window. (# is 1–30)

EPROT, Export all protocols Copies all 30 protocols from Protocol appears in EPROT,

IEF100 to HyperTerminal. HyperTerminal window.

PrnRate,# Data interval setting Changes interval between data points INTVL in IEF100 PrnRate,#

(1–15 minutes). will update. (# is 1–15)

Start,#1,#2 Start protocol Starts protocol #1 with #2 IPG strips. IEF100 will start focusing. Start,#1,#2

(#1 is 1–30)

(#2 is 1–6)

Start Resumes protocol Restarts a protocol in a paused state. IEF100 will resume focusing. Start

Stop Stop protocol Stops a protocol in progress. IEF100 will terminate focusing. Stop

Pause Pause protocol Pauses a protocol in progress. IEF100 will pause focusing. Pause

Report Sends current status. Sends current run data, Report

if actively focusing, sends

current run data, if paused,

sends a paused message,

if not running, prints “idle”.

ID? Sends serial number. Transfers IEF100 serial ID?

number to the computer.

•

p41

Page 48

Care and Maintenance

Turn the mains power switch off and unplug the power cord

before cleaning.

Instrument and Lid

• Use a soft cloth dampened with water or a mild cleaning solution to

clean the cabinet and display.

• If spilled liquids contact the circuit boards, unplug the IEF100 and

allow to dry completely. Call Hoefer, Inc. for advice before using.

Cleaning the Tray and Electrodes

• A detergent designed to remove oil is recommended, followed by

mild, nonionic laboratory cleaning reagents. Rinse tray well with

deionized water and dry completely before use.

• The platinum wire on the electrodes is fragile and should be cleaned

very gently. The electrodes should not be soaked in solution.

Technical Service and Repair

Hoefer, Inc. offers complete technical support for all of our

products. If you have any questions about how to use this product,

or would like to arrange to repair it, please call or fax your local

Hoefer, Inc. representative.

•

p42

Page 49

Troubleshooting

Problem Solution

Instrument does not turn on Check power cord is plugged into grounded outlet and ON/OFF switch is

turned to the on (l) position.

Lid is open Unit will not operate unless the safety lid is fully closed. Press down on both

sides to engage latches.

Unit reads 0 μA, 0 W for all strips Ensure the electrode wicks are in contact with the IPG strips.

The electrodes should be contacting the electrode wicks, and centered in the

area of overlap between the wick and the IPG strips.

Check that the IPG strips have been fully hydrated prior to use.

Ensure the electrodes are connected to the corresponding receptacles.

Low starting voltage of gradient steps may not produce enough current to

register at the beginning of the step. Check the current in the strips again in

a few minutes.

Run diagnostics to check the internal power supply.

Unit reads 0 μA, 0 W for only one strip Poor IPG strip rehydration: inspect the thickness (height) of the IPG strip

over its entire length.

Check for arcing or burning that could break the electrical circuit.

Broken wire in the (–) electrode. Replace electrode.

No voltage output Run diagnostics from the options menu.

Contact your local Hoefer, Inc. representative.

Blank display Turn unit off and on.

Contact your local Hoefer, Inc. representative.

Screen frozen Turn unit off and on.

Contact your local Hoefer, Inc. representative.

Fails diagnostics The diagnostics program will check the volt and current output of the

internal power supply, the eprom and the system clock. Contact your local

Hoefer, Inc. representative if any of these tests come up negative.

•

p43

Page 50

Problem Solution

Set voltage not reached Continue with the IEF.

IPG strip is being limited by μA or W.

Conductivity of the strip is too high.

One IPG strip will focus at its max μA or W, and limit the voltage to all