Page 1

Certain actions can cause permanent damage to the detect or. If the detector is subjected t o any of the following it should not

be used:

Dis-assembly and re-assembly, apart f r om chamber r epl ac em ent in the case of photoelectric smoke detectors (the

detectors cannot be r epaired and must be replaced in their entirety).

Impact or shock.

Suspected damage following a fire.

In the case of heat detec tors, touching the thermistor element.

These detectors m ust be subj ec t to periodic maintenance during regular service visits. This period should be outlined i n the

appropriate standar ds or rec om mendations. If there are no such standards existing, Hochik i r ec ommend that the minimum

period of maintenance should be 1 year and that the following should be taken into account:

A regular oper ation test should be perform ed using suitabl e test equipment (cert ain types of test equipment should not be

used in flammabl e/com bustible atmospheres).

A visual check for staining and mechanical dam age shoul d be m ade.

A magnetic test facility is incorporated int o both detectors which can be operated using a sui table magnet.

HOCHIKI INTRINSI CALLY SAFE SMOKE AND HEAT DETECTORS (AND

MOUNTING BASE) INSTRUCTIONS

Products Covered: SLR-E-IS Photoelectric Smoke Detector, DCD- 1E-IS Combined Rate of Rise

Heat Detector, YBN-R/4(IS) Electronics-Free Mounting Base

Introduction

These Detectors are certified by BASEEFA as suitable for use in hazardous atmospheres as detailed below. It is essential t hat

the detector s and base are installed and operated in conformance with the certific ation in order to remain safe. It is the

responsibility of the installer to ensure t hat the detectors and base are installed according to the certifi c ation requirements, and

it is recommended that the installation only be car ri ed out by qualified personnel.

The YBN-R/4(IS ) Base m ay onl y be used with Hochiki Intrinsically S afe specified detector heads. The use of other det ec tor

heads is expressly forbidden and may cause fire or explosi on.

A dust cover is included wit h these detectors to prevent cont ami nation during installation and prior to commissioning. The dust

cover must be removed for the detectors to operate.

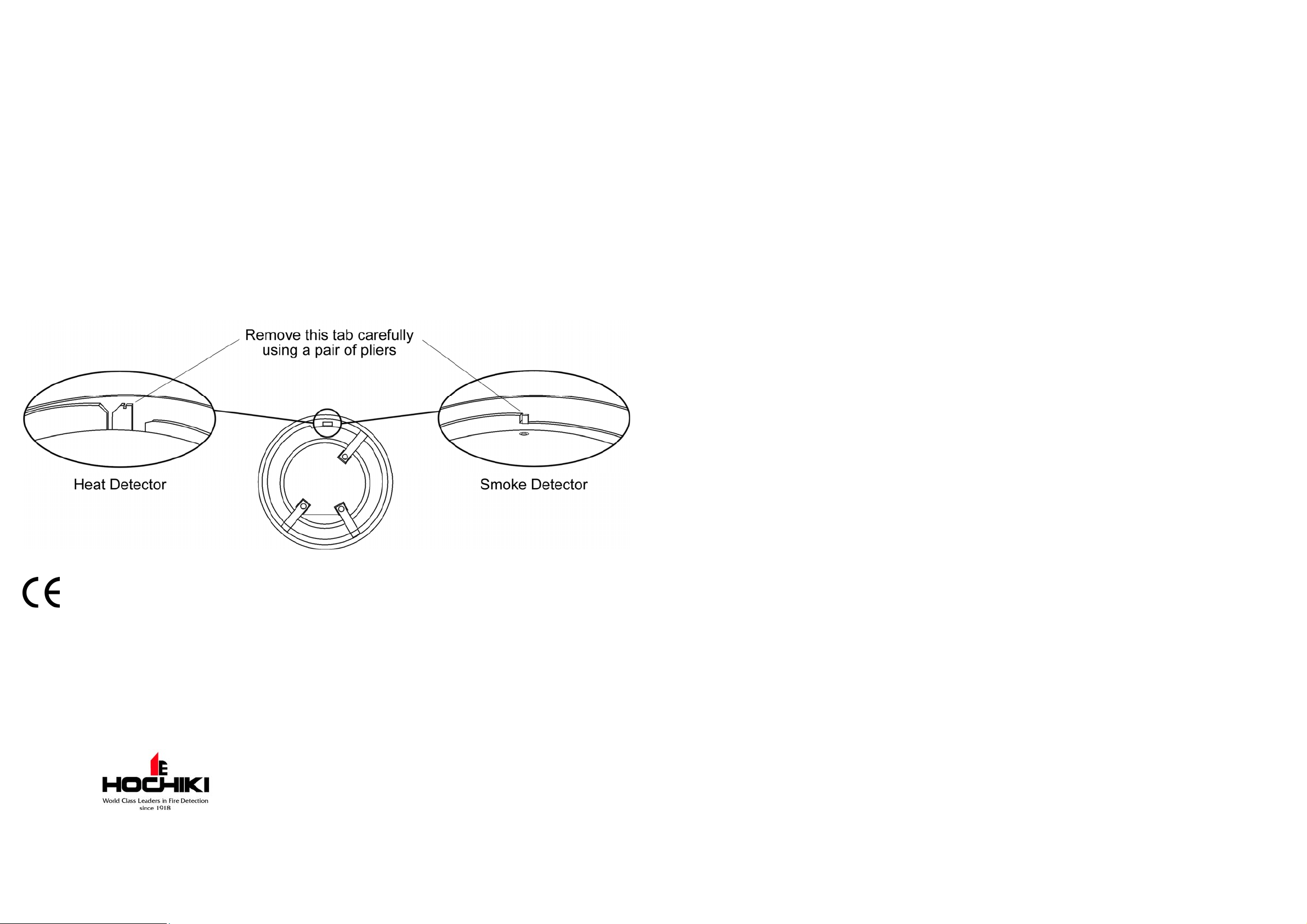

The detector s can be lock ed on to t he base by rem oving a plastic lug on the underside, please refer to the diagram below. The

locked detector c an then only be removed by using a special removal tool whic h is available from Hochiki Europe (UK) Ltd

(part number TSC-A 100/ALG).

DCD-1E-IS 0832-CPD-0121 05 EN54-5 Point type heat detectors

SLR-E-IS 0832-CPD-0113 05 EN54-5 Point type heat detectors

Classification - SLR-E-IS

This Detector has BASEEFA certification classificati on according to EN 60079-11:2007 and an ATEX Classification of

II 1 G Ex ia IIC T5 -20°C<Ta<55° C. Areas suitable for installati on: Category 1, 2 or 3 hazardous atmospheres, wit h a

maximum ambient temper ature of up to 55°C.

Classification - DCD-1E-IS

This Detector has BASEEFA certification classificati on according to EN 60079-11:2007 and an ATEX Classification of

II 1 G Ex ia IIC T5 -20°C<Ta<55° C. Areas suitable for installati on: Category 1, 2 or 3 hazardous atmospheres, wit h a

maximum ambient temper ature of up to 55°C.

Refer to the system dr awing ov er leaf for important inf ormati on concer ning installati on/wiring requirements which must be

strictly observed in order to comply with BASEEFA certification. These detectors and base MUST be used with eit her a Zener

Diode Barrier or a Galvanic Isolator, using suitable models as detailed in the system drawing overleaf. The Zener Diode

Barrier or Galv anic Isolator should be install ed ac c or ding to t he manufac turer's instructi ons.

Note

These products have been designed to

Avoid physi c al injury or harm by direct or indirect contact

Not produce surface temperatures of accessible parts or radiation which could cause danger

Eliminat e any non- elec trical dangers

Not give ri se to dangerous conditions in the event of overload

Precautions

Hochiki smok e and heat det ec tors cannot be used to prevent a fire itself , t hey ar e intended only to detect certain charact er istics

of fire. When installing the detectors, check that t he location of each one has been planned according to appropriate fire

regulati ons and rec ommendations.

Hochiki detec tors are suitable for indoor use only. A detector shoul d not be installed in the following env ir onmental conditions:

Excessive am bient temperature.

Where excessive condensation or moisture is present.

Where corrosive gas or any other harmful agent is present .

Where flamm able dust or st eam is present.

Where obstruct ions are present which could impede the flow of air to the detector.

Where mechanical stresses could affect the det ec tor when fitted in accordanc e to these instructions.

Hoch iki Europe (UK) Ltd

Grosvenor Road, Gillingham Business Park,

Gillingham, Kent, ME8 0SA, England

Tele phone: +44(0)1634 260133 Facsimile: +44(0)1634 260132

Email: sales@hochikieurope.com

Web: www.hochikieurope.com

Hochiki Europe (UK) Limited 2-3-0-345/ISS7/OCT10 Hochiki Europe (UK) Limited 2-3-0-345/ISS7/OCT10

Hochiki Europe (UK) Ltd. reserves the right to alter the specification of its products from

time to time without notice. Although every effort has been made to ensure the accuracy of

the information contained within this document it is not warranted or represented by

Hochiki Europe (UK) Ltd. to be a complete and up-to-date description. Please check our

web site for the latest version of this document.

Page 2

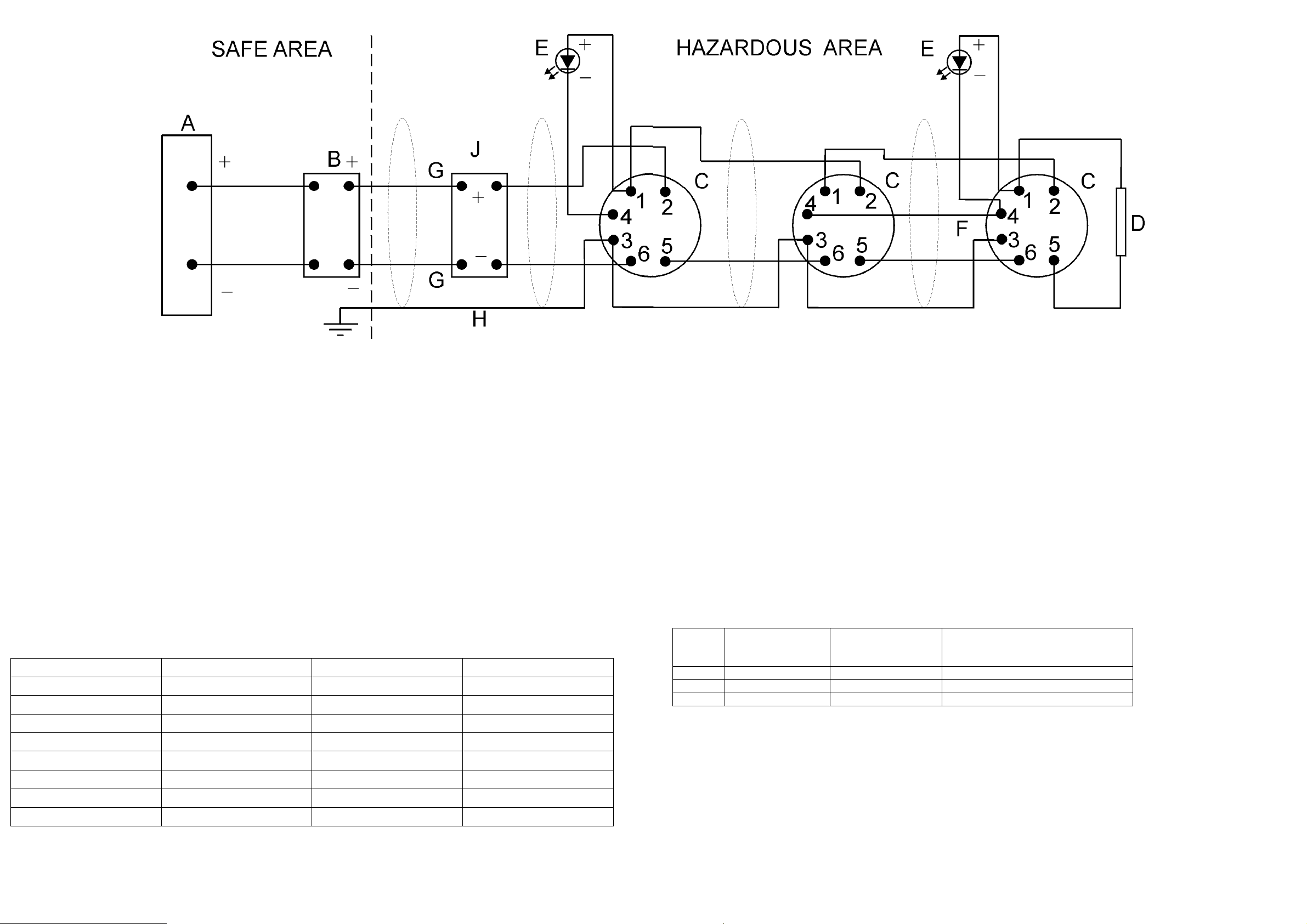

Notes

1. The electrical ci r c uit in the hazardous area must be capable of withstanding an a.c. test voltage of 500 volts to earth or

frame of the equi pm ent, for a peri od of one mi nute without breakdown.

2. The installation must comply with National requirements.

3. The system must be marked wit h a durable label which should appear on or adjacent to the principal item of electrical

apparatus in the system or at the interface between the i ntrinsically safe and non-i ntrinsically safe circuits. This

marking shall include the word SYST or SYSTEM, for example “System No. BAS Ex 98D2264” or “BAS No. Ex

98D2264 SYST”.

A. Unspecified equipment except that no voltage shall exceed 250V with respect to earth.

B. EITHER:

Any BASEEFA Certified shunt safety Zener Diode Barrier with the following parameters:

30V or less

200mA or less

1W or less

2

The barrier eart h m ust be connect ed v ia a high integrity connecti on, using an insulated conductor equivalent to a 4mm

conductor, such t hat the impedance from the point of connection to the main power system earth is less than 1 ohm.

OR:

Any one channel from the f ollowing BASEEFA Certified Galvanic Isolators:

Type Number Um=250V I.S. Output Certificate No.

MTL 3043 2-3 5/6-7/8 Ex86B2285

MTL 40612Channel 9-8 or 12-11 1/2-3 or 4/5-6 Ex94C2040

MTL 5061 2Channel 9-8 or 12-11 1/2-3 or 4/5-6 Ex96D2426

MTL5561 2 Channel 9-8 or 12-11 1/2-3 or 4/5-6 BASEEFA09ATEX0027

P&F KFD0-CS-Ex1.51 11-12 1-2 Ex96D2152

P&F KFD0-CS-Ex2. 51 11-12 or 9-8/ 10 1-2 or 4-5 Ex96D2152

P&F KFD0-CS-Ex1.51P 11-12 1-2 Ex96D2152

P&F KFD0-CS-Ex2. 51P 11-12 or 9-8/10 1-2 or 4-5 Ex96D2152

Note: Earthing requirements as described above for Zener Diode Barriers, is not requi r ed with Galvanic Isolators.

copper

C. Up to 20 SLR-E-IS Intrinsically Safe Photoelectric Smoke Detectors complete with YBN-R/4 IS Bases, BASEEFA Certificate

BAS01ATEX1281

OR:

Up to 20 DCD-1E-IS Intrinsically Safe Heat Detectors complete with YBN-R/4 IS Bases, BASEEFA Certificate No

BAS01ATEX1021

OR:

A combinati on of each type to a maximum of 20 units.

2

D. End-of-line r esi stor . The end-of-line resistor must have a body surface area of 230mm

E. Optional Rem ote I ndic ator consisting of Light Emitting Diode (LED) only. The LED must have a surfac e ar ea of 230mm

or more.

2

or

more. The interconnec ting cable to any Remote Indicator( s) is to be considered as part of the inter c onnec ting cable described

at G below.

F. Optional i nterc onnec tion for sharing a single Remot e Indicator between any number of SLR-E-I S or

DCD-1E-IS/ YBN-R4/IS Detector/Base combi nations as shown above. The terminal 4 in each base may be interconnect ed as

shown at F above and a single Rem ote I ndic ator connected to any one such base. The interconnec ting cable between any

terminals 4 and the wiri ng to any Remote Indicator is to be considered as part of the interconnecting cable described at G

below.

G. Interconnecting cable having the following maximum parameters:

Group

Capacitance

C

µF

Inductance

L

mH

Inductan ce to Resistance ratio

L/R

µH/ohm

IIC 0.07 0.62 36

IIB 0.56 1.86 146

IIA 1.82 4.96 286

H. Optional cable screen. If used, this must only be connected to earth within the safe area and must be isolated f r om the

electric al ci r c uit and must be capable of withstanding an a.c. test v oltage of 500 volts for a period of one minute without

breakdown.

J. Up to 20 optional dev ic es, for example switches such as manual call points having appropriate BASEEFA Certification for

use in the intended hazardous environment (Hochi ki part no. CCP-IS) or otherwise cl assif ied as simple apparatus according to

BS EN 60079-11:2007. Such devic es may be fitted with a resistor in seri es wit h the switc h and /or an end-of-line resistor as

per D above. Where such a resistor is used it must have a body surface area of 230mm

2

or more (typical resistanc e 470 - 680

ohm).

Hochiki Europe (UK) Limited 2-3-0-345/ISS7/OCT10 Hochiki Europe (UK) Limited 2-3-0-345/ISS7/OCT10

Loading...

Loading...