Hochiki SLR--24C, SLR--24VC, SLR--24H, SLR--24HC, SLV-24V Installation Instructions Manual

...Page 1

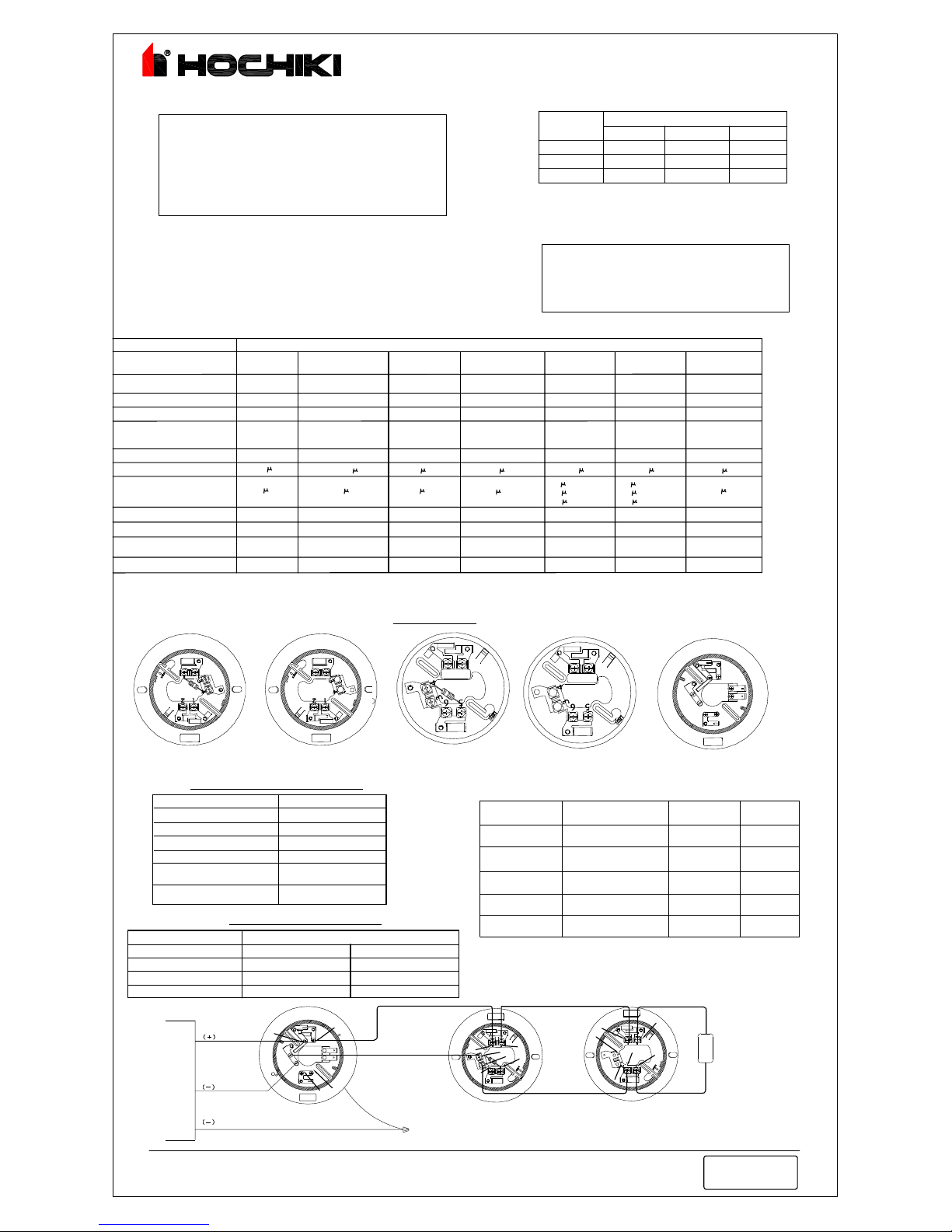

Connect wiring to the bases as shown in the wiring diagrams that

follow. Detectors and bases may be mixed on the same initiating

loop as long as the number of two-wire powered detectors does not

exceed the specifications of the control panel (see Figure 2 below)

SMOKE DETECTOR DATA

BUILT-IN

TEST FEATURE

135°F(SLR-24H only)

30/ZONE

17.7-30.0 VDC

HD3

FIG. 2

BREAK WIRE RUN TO PROVIDE SUPERVISION

DO NOT LOOP WIRE UNDER TERMINALS.

CONNECT WIRING TO TERMINALS AS SHOWN.

HSC-BASE

NS4-BASE

NS6-BASE

BASE

PHOTOELECTRIC

5V RIPPLE MAX.

FILTERED DC

160 A

45 A

150 mA

15-33.0 VDC

NSTT-A100

30/ZONE

HCP-1008E CONTROL PANEL

HEAT ELEMENT RATING

TYPE OF DETECTOR

SENSITIVITY TEST DEVICES

COMPATIBILITY IDENTIFIER

AVERAGE STANDBY CURRENT

MAX. SURGE CURRENT

MAX. ALARM CURRENT

VOLTAGE WAVEFORM

RATED VOLTAGE (4-WIRE)

WORKING VOLTAGE (2-WIRE)

DETECTORS

NOTE:

HD3

N/A

IONIZATION

200 A

5V RIPPLE MAX.

FILTERED DC

40 A

150 mA

17.7-30.0 VDC

15-33.0 VDC

SPECIFICATIONS

BUENA PARK, CA 90621-2268

7051 VILLAGE DRIVE SUITE 100

HOCHIKI AMERICA CORPORATION

CAUTION

INSTALLATION INSTRUCTIONS

BUILT-IN

TEST FEATURE

SLR-835/-835W/

PHOTOELECTRIC

8.0~35.0 VDC

8.0~35.0 VDC

*FILTERED DC

15% RIPPLE MAX.

150 mA

200 A

55 A @ 24VDC

38 A @ 12 VDC

70 A @ 35VDC

HD5

30/ZONE 30/ZONE

135/190°F

DCD-135/-135W/-135C

OF RISE HEAT

FIXED TEMP/RATE-

35 A

HD3

160 A

*

5V RIPPLE MAX.

FILTERED DC

TTA-1H

150 mA

17.7-30.0VDC

15.0-33.0VDC

DWG. # HA-06-060

*

CAUTION

BOX MOUNTING

NO

YES

NO

3" OCT

YES

YES

NO

4" OCT

YES

NO

YES

4" SQR

FIG. 1

(Pg.1 of 2, 06/16)

PART# 1700-09987

*

DETECTOR MODEL

DFE-190/-190W/DFE-190C

NON-CURRENT

NON-CURRENT

(57mA MAX)

37~45 mA @ 24V

(88.5mA @ 26.5VDC MAX)

(54 mA MAX.)

ALARM CURRENT

67~80 mA @ 24V

35~42 mA @ 24V

NOTE: BASES/DETECTORS WITH THE "W" SUFFIX ARE WHITE IN COLOR.

HSC-221L/-221LW

NS6-100,100W

NS4-100,100W

BASE MODEL

HSC-220L/-220LW

HSC-224L/-224LW

TEMPERATURE RATING

MAX. ALARM CURRENT

DETECTOR TYPE

Pig Tail Lead

NS6-100

LISTED

DEVICE

END OF LINE

190°F.

100 mA

FIXED TEMPERATURE

HB-63

FIXED TEMPERATURE

100 mA

135°F.

COMPATIBILITY

IDENTIFIER

HB-64

HB-62

LATCHING

INDICATION

YES

DFE HEAT DETECTORS

BASE STYLES

SPECIFICATIONS

NS6 SERIES

S1

HEAT DETECTOR DATA

(4 INCH BASE)

NS4 SERIES

HSC SERIES

S2

L2

L1

H1

H2

YES

YES

LIMITED

N/A

NO

LIMITED

N/A

NO

COMPATIBLE

CONTROL

PANEL

UL LISTED

SUPPLY

NEGATIVE

PANEL

POWER

HSC-220L

6

SIJ-24/-24C SLR-24/-24C/-24V/-24VC

OF CONNECTIONS.

-24VN/-24H/-24HC

-190/-190W/-190C -835C

55 A @ 24VDC

70 A @ 35VDC

38 A @ 12 VDC

200 A

150 mA

15% RIPPLE MAX.

FILTERED DC *

8.0~35.0 VDC

8.0~35.0 VDC

PHOTOELECTRIC

SLR-835H/-835HW

HD5

BUILT-IN

TEST FEATURE

30/ZONE

135°F

N/A

DFE-135/-135W/DFE-135C

15°F./MIN.

TEMPERATURE RATING

MAX. ALARM CURRENT 100 mA

SPECIFICATIONS

DETECTOR TYPE

DETECTOR MODEL

HEAT DETECTOR DATA

DSC-EA HEAT DETECTORS

RATE OF RISE

DSC-EA/DSC-EAW

UL LISTED TEMPERATURE

6

L4

L3

56

3

4

1

2

S1

S2

H2

H1

L2

L1

L3L4

L2

L1

L3

L4

(EXCEPT NS6-100)

NS6-100

(EXCEPT NS4-100)

NS4-100

(4 INCH BASE)

1

2

6

5

3

4

6

NS6 SERIES

(EXCEPT NS6-100)

For testing and cleaning information, refer to Page 2 of these instructions and

to Technical Bulletin HA-97 Conventional. Also refer to NFPA-72 Chapters 2

and 7 for Automatic Fire Detector installation guidelines, testing, and

maintenance.

Use "3M" Weatherban # 606 non-flammable sealing compound to seal

field wiring conduit openings in the mounting back box. Compliance with

this request may reduce the occurrence of the "STACK EFFECT".

These instructions apply to all Hochiki America detector bases that utilize an NS detector with LEDs to

indicate power, and alarm.

Install the bases in this instruction in accordance with applicable

NFPA standards, local codes, and the authorities having

jurisdiction. Failure to follow these instructions may result in

failure of the detector to initiate an alarm condition. Hochiki

America is not responsible for detectors that have been

improperly installed, tested, or maintained.

* When using a four-wire

base full wave rectified

AC can be used.

When mounting detector on

a wall, it must be between 4"

and 12" from the ceiling.

PHOTOELECTRIC

SLV-24V/-24N

BUILT-IN

TEST FEATURE

30/ZONE

17.7-30.0 VDC

HD3

5V RIPPLE MAX.

FILTERED DC

45 A

150 mA

15-33.0 VDC

*

N/A

160 A

-24NW/SLV-24

Note: The SLR-24V, SLV-24V and SOC-24V are suitable for installation in air velocities up to 4000ft./min.

0°C ~ 37.8°C

(32°F ~ 100°F)

OPERATING TEMPERATURE

(14°F ~ 122°F)

-10°C ~ 50°C

NOTE: BASES/DETECTORS WITH THE "C" SUFFIX ARE CANADIAN.

PHOTOELECTRIC

SOC-24V/-24VN

30/ZONE

HD3

FILTERED DC

59 A

150 mA

*

N/A

160 A

8.0~35.0 VDC

8.0~35.0 VDC

15% RIPPLE MAX.

SOC-24VW

5

6

5

1 2

1 2

BUILT-IN

TEST FEATURE

Page 2

the factory for servicing. Refer to Technical Bulletin HA-97 for cleaning information.

4) When the condition exists as stated in 2) the device needs to be cleaned or returned to

3) In the alarm state both LEDs are on Red continuously.

2) When the sensitivity drifts outside of its sensitivity limits, both LEDs flash Red

SLR -24/-835/SLV-24 AND SOC-24V SERIES SENSITIVITY TEST FEATURE

1) In normal condition both LEDs flash Green.

For go/no-go testing, a magnet will be required.

1. Hold the magnet just UNDER the word "TEST" as shown on Diagram A.

2. The detector should alarm within 10 seconds (If control panel is programmed for Fire Alarm

Verification, it may take up to 30 seconds).

3. The detector's LEDs should be on Red continuously and any control panel indicating appliances should activate.

4. Silence the system and activate the control panel reset to reset smoke detector.

5. The smoke detector LEDs should flash Green.

TESTING THE SLR-835/SLR-24 AND THE SLV-24 SERIES INSTALLATION

FIG. 1

DWG. # HA-06-060

(Pg.2 of 2, 06/16)

DIAGRAM A

FIG. 2

Hold Magnet

Here

TEST

Testing is performed with the Hochiki America Alarm Test Magnet

SIJ-24/-24C SENSITIVITY TEST PROCEDURE

POWER CONDITIONS MAY AFFECT SENSITIVITY. ALWAYS RESET POWER PRIOR TO

within specified sensitivity limits and may require service. See Tech Bulletin

3). Place magnet on detector as shown in Figure 2 (opposite side).

source and with normal applied power, place magnet as shown in Figure 1.

1). With detector wired to appropriate initiating circuit or current limited power

CONDUCT TESTING ONLY UNDER NORMAL STANDBY CONDITIONS. ABNORMAL OR LOW

produce an alarm when magnet is positioned as in Figure 2, detector is not

5). If detector does alarm when magnet is positioned as in Figure 1 or does not

2). Wait at least six seconds. Detector SHOULD not alarm and LED should not light.

TESTING OF NEXT UNIT.

4). Wait at least six seconds. Detector SHOULD alarm.

HA-97 for more information and for additional sensitivity test devices.

NOTE:

SIJ-24/-24C DETECTOR

TOP VIEW OF

(Part Number 0700-01110) shown below.

TEST DEVICE:

TEST PROCEDURE

TOP VIEW

SIDE VIEW

NS6-100

DEVICE

END OF LINE

LISTED

EXCEPT NS6-100

(EXCEPT NS4-100)

N/A47mA (75mA @ 18.0V MAX.)

HSC-4R12

LISTED

DEVICE

END OF LINE

2

1

2-WIRE AUXILIARY RELAY BASE

4-WIRE 24V BASE

* - Requires External Current

Limiting To 150mA Max.

2

1

1

ID

HB-5

ALARM CURRENT

43mA (70mA @ 33.0V MAX.)

HB-4

HB-55

HB-4

HB-5

HB-3

HB-55

HB-73

HB-71

N/A

HB-72

1

49mA (62mA @ 30.0V MAX.)

46mA (77mA @ 33.0V MAX.)

150mA @ 15.0~33.0V MAX.

88mA (98mA @ 26.5V MAX.)

43mA (58mA @ 30.0V MAX.)

150mA @ 15.0~33.0V MAX.

46mA (77mA @ 33.0V MAX.)

93mA (136mA @ 33.0V MAX.)

43mA (70mA @ 33.0V MAX.)

43mA (58mA @ 30.0V MAX.)

93mA (136mA @ 33.0V MAX.)

HB-3

AND NS6 ARE IDENTICAL

- BASES WITH THE "W" SUFFIX

ARE WHITE IN COLOR

NS6 SERIES

NOTE: - WIRING TERMINALS FOR THE NS4

BASE

NS6-224, 224W, 224C

HSC-221R/221RW/221RC

HSC-4R/-4RC

HSC-220R/220RW/220RC

NS6-221, 221W, 221C

*NS6-100, 100W, 100C

HSC-224R/224RW/224RC/RA/RST

*NS4-100, 100W, 100C

NS4-221, 221W, 221C

NS4-220, 220W, 220C

NS4-224, 224W, 224C

NS6-220, 220W, 220C

Resistor shown is for example

only. Not all annunciators

have in line resistance.

NS4 SERIES

UL LISTED

CONTROL

PANEL

PANEL

POWER

SUPPLY

NEGATIVE

UL LISTED

2-WIRE OPERATION

2-WIRE RELAY OPERATION

Annunciation device must be current limited to 20 mA @

24VDC Maximum. Not limiting current could result in

damage to the detector or cause a no alarm condition.

6

5

COM

N/C

4

3

N/O

N/O

HSC-(XXX)R (2-WIRE)

BLU

GRN

GRY

YEL

PUR

ORN

HSC-224RA/RST VERSION ONLY

TERMINAL BLOCK USED ON

LISTED

DEVICE

H1

ORN

YEL

H2

2

1

N/C

COM

END OF LINE

2 AND 4 WIRE BASE

RELAYS SHOWN WITH

HSC-4R

POWER OFF.

CONTACTS

HSC-RELAY SERIES

LISTED

RELAY

END OF LINE

HA-EOLR-12 OR HA-EOLR-24

HSC-4R

PUR

CONTROL

PANEL

INITIATING

CIRCUIT

HSC-4R

UL LISTED

POWER

SUPPLY

12VDC OR 24VDC

4-WIRE OPERATION

NOTE: The SLR-24/-24C/-24V/-24VC/-24VN/-24H/-24HC/-835/-835W/-835C/-835H/-835HW,

SLV-24/-24V/-24N/-24NW and SOC-24V/-24VN/-24VW have a built-in automatic sensitivity test feature.

LED

LED

LED

Test tool (back side)

Test tool

SOC-24V/-24VN

Magnet

LED marking

DIAGRAM B

For go/no-go testing, original test tool will be required.

1. Hold the test tool on the detector like Diagram B.

2. The detector should alarm within 10 seconds (If control panel is programmed for Fire Alarm

Verification, it may take up to 30 seconds).

3. The detector's LED should be on Red continuously and control panel indicating

appliances should activate.

4. Silence the system and activate the control panel reset to reset smoke detector.

5. The smoke detector LED should flash Green.

TESTING THE SOC-24V/-24VN/-24VW

NOTE: In case of SOC-24V/-24VN/-24VW, only 1 LED

1

2

3

6

4

5

1

2

3

6

4

5

1

2

3

6

4

5

S1

S2

L2

L1

H1

H2

L4

L3

S1

S2

L2

L1

H1

H2

L4

L3

S1

S2

L2

L1

H1

H2

L4

L3

S1

S2

L2

L1

H1

H2

L4

L3

Loading...

Loading...