Page 1

IFD-E(IS)

Intrinsically Safe Flame Detector

User Manual

Page 2

2 Hochiki Europe ( UK ) Ltd

General

Description

This Install ation Guide gives information on the intrinsically safe (I.S.) version of t he flame detectors that

have been approv ed by BASEEFA (British Approvals Service for Electrical Equipment in Flammable

Atmospheres). The requirements of the European Community Directive 94/ 9/EC, t he ATmosphere

EXplosives AT E X Directive have been met. The approval have been accessed to European Standards

EN 50014, EN 50020 and EN 50284.

The detector s are cer tif ied

The range comprises single infra-red (IR), dual infra-red (IR²) and tri ple infra-red (IR³ ) flam e detectors.

The detector housings are available in zi nc met al alloy or stainless steel and also stai nless steel

(antistati c ) glass fi lled polycarbonate.

The guide also provi des i nformation on intri nsi c safety, the applicati on, maintenance, installation and

adjustments of the detectors. Reference to ot her indiv i dual detector publi c ations can be made for more

information on none intrinsically safety issues. These public ations are available on request.

II 1 G EEx ia IIC T4 and can be used with all listed gase s.

Introduction to Intrinsic Safety

There are many places where an explosive mixture of air and gas or vapour is or may be pr esent

continuously , intermittentl y or as a result of an ac ci dent. These are defined as hazardous areas by BS

EN 50014:1998, El ect ri c al appar atus for potentially explosiv e atmospheres – General requirem ents.

Hazardous areas are common in petroleum and chemical engineering plants and in f act ori es proces si ng

and storing gases, solvents, paints and other v olatile substances.

Electri c al equipm ent for use in these areas needs to be designed so that it cannot ignite an explosive

mixture, not only in normal operation but also in fault conditions. There ar e a number of met hods

available to achieve this – oil immersion, pressuri se d appar atus and powder fill ing, for example, but the

two most common used are flam epr oof enclosures and intrinsic safety.

Flameproof equipment is contained i n a box so strong that an i nter nal explosion will neither damage the

box nor be transmitt ed outside the box. The surface must remain cool enough not to ignit e the explosive

mixture.

When flameproof equipment is interconnected, flameproof wiri ng must be used. This method is most

valuable when high power l evels are unavoidable but it is not acceptable for areas in which an ex plosive

gas/air mixt ur e m ay be conti nuousl y present or present for long per iods.

For this reason these flame detectors are made int rinsically safe rather than fl am epr oof. Intrinsic ally safe

equipment operates at such low power and with such small amounts of stored energy t hat it i s incapable

of causing ignition:

In normal conditions

With a single fault (for ib type of protection c ode)

With any combination of two faults (for ia type of protection code)

In any of these conditi ons every component must remain cool enough not to ignite gases for which it is

approved. See Table 2

Classification of Hazardous Areas

EN 50014 states that el ec trical apparatus for potentially explosive atm ospheres is divided into:

Group I: Electrical appar atus for mines susceptible to fire damp;

Group II: Electri c al appar atus for places with a pot entially explosive atm osphere, other than

mines susceptible to fire damp.

2-3-0-809/ISS2/JUL07

Page 3

Hochiki Europe ( UK ) Ltd 3

These flame det ector s are designed to meet the requirements of Group II apparat us. For the type of

protection “i” intrinsi c ally safe, Group II is subdivided into Equi pm ent Cat egories, Type of Expl osive

Atmosphere (Table 1), Type of Protection Code (Table 2), Temperature Class (Table 3) and Gas Group

(Table 4).

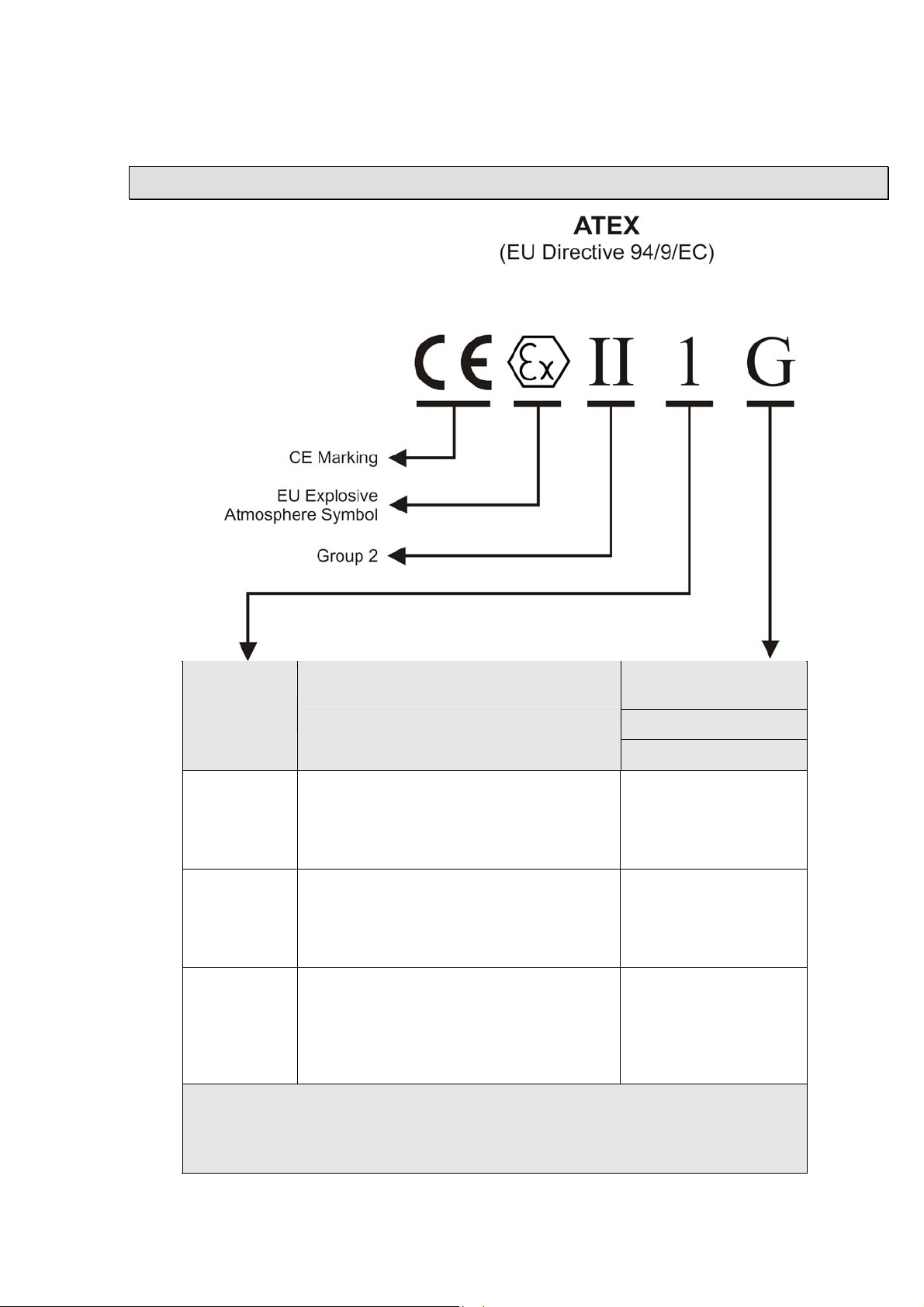

Equipment Markings

Type of Explosive

Equipment

Category

Definition

Atmosphere Group II

G - gas vapour mist

Zone

1 - very high level of pr otection

in which explosive atmosphere mixtures of

0

air gases, vapours or mist are present

continuously, for long periods

2 - high level of protec tion

in which explosive atmosphere mixture of

1

air and gases, vapours or mist are likely to

occur

3 - normal level of protection

in which explosive atmosphere mixtures of

air and gases, vapours or mist are unlikely

2

to occur and if it occurs it will exist only for a

short period

These Flame Det ector s are suitable for all the above equipment categories.

Note: The detectors are not certified for explosive dust atmospheres.

Table 1Equipment Categories and Type of Explosive Atmosphere (Group II )

2-3-0-809/ISS2/JUL07

Page 4

4 Hochiki Europe ( UK ) Ltd

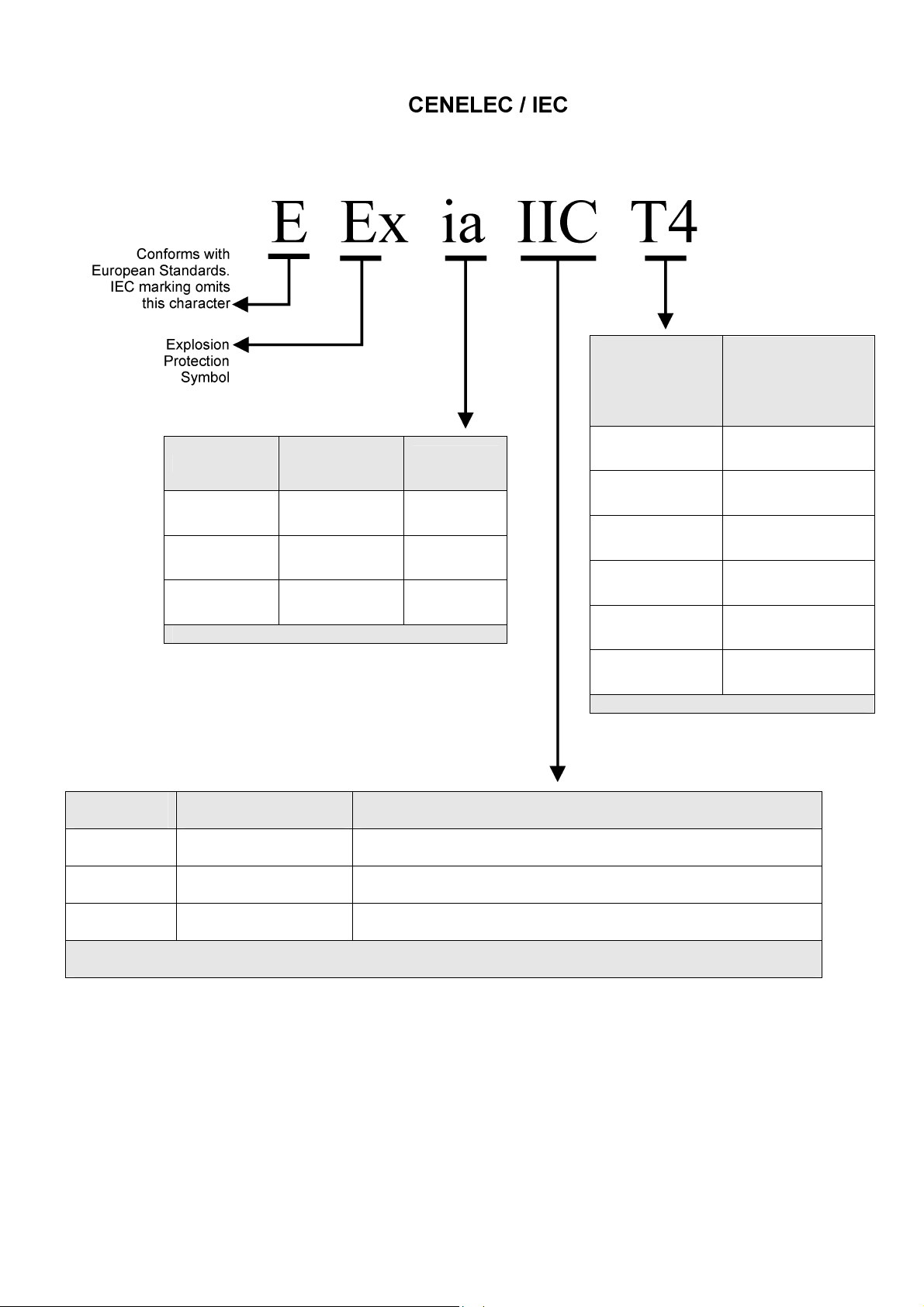

Temperature

Code

Type of

Protection

Code

Equipment

Category

Class

Referred to

ambient of

-20°C to +40°C

T6 85°C

T5 100°C

Maximum Surface

Temperature

ia Intrinsic safety 1

ib Intrinsic safety 2

d Flameproof 3

These Flame Detectors are approved ia.

Table 2 – Type of Protecti on Codes

Gas Group Representative Gas Other Gases, Liquids & Vapours

IIC

IIB

IIA

Hydrogen Acetylene, Car bon Disulphide

Ethylene Diethyl ether, Tetrafluroethylene

Methane Butane, Met hanol, Petroleum, Propane, Styrene

These Flame Detectors are approved IIC for listed gases in EN 50014.

T4 135°C

T3 200°C

T2 300°C

T1 450°C

Detectors approved to T4 at 40°C

Table 3 – Temperat ur e Classif ic ations

2-3-0-809/ISS2/JUL07

Table 4 – Subdivisions of Group II Gases

Page 5

Hochiki Europe ( UK ) Ltd 5

y

Intrinsically Safe Product

Technical Data

Mechanical

Fig. 1

Intrinsically Safe Flame Detector

(Alloy Housing)

The flame detector s respond to light

emitted from flames during combustion.

The detectors discriminate between fl am es

and other light sourc es by respondi ng only

to low frequency flickering produced by

flames (ty pic ally 1 to 15Hz) . The detectors

ignore fixed light sources and rapidly

flickering illumination predominantly

produced by lighting.

The flame flicker techniques have the

advantage of still allowing the detection of

flames through a thin layer of oil, water

vapour, ice or dust. This makes these

detectors particularly usef ul in industr ial

applications.

Full details of the princ iples of operation,

electric al description, and other det ailed

technical data are published in the products

individual dat a sheet .

Housing Materi al:

See Fig 1

Housing Colour: Blue (typical)

Housing

Dimension:

(Excluding M ount)

Cable Gland

Entries:

Die Cast Zinc Alloy

Height = 142mm

Width = 108mm

Depth = 82mm

2 X 20mm

Electrical

Supply In:

Voltage

Current

Polarity sensitive

Optional Input:

Voltage

Current

Polarity sensitive

Optional Output:

Voltage

Current

Optional Relays

Contact Ratings:

Voltage

Current

Resistive Loads Onl

Terminals 1(+ ) & 2( -)

14 to 30Vdc

2 to 30mA See datasheet for detail

Terminals 3(+ ) & 4( -)

14 to 30Vdc

40µA typ. @ 24V IN

Terminals 3(+ ) & 4( -)

0V to Supply In (O/C)

2.4mA typ. Inter nally Limi ted

Terminals 3 to 8

30Vdc. Max.

1 Amp. Max.

Environmental

Operating Ambient

Temperature:

Check detector

limits

ATEX

Approval Category

CENELEC / IEC

Marking

Apparatus

Certific ate Number BAS02ATEX1001

-20°C to +40°C(T 4)

-20°C to +85°C(T 3)

II 1 G

EEx ia IIC T4

2-3-0-809/ISS2/JUL07

Page 6

6 Hochiki Europe ( UK ) Ltd

System Design

Engineers f amili ar with codes of practice for hazardous area systems should only under take the design of

an intrinsic ally safe fire detecti on system. In Europe the standard is EN 50014, El ectri c al appar atus for

potentially explosive atmospheres – General requirements.

The fire detector performance is the same as the standard none intrinsically safe counterparts.

Performance information given in standard pr oduc t guides is theref or e appl icable to the intrinsi c ally safe

range.

The BASEEFA certification of the intrinsically devices covers their characteristics as components of an

intrinsic ally safe system. This indicates that the flame detector s can be used with a margin of safety in

such syst e ms.

In safe area (standard) applications it is some times desirable t o connect the wiring as a loop, with both

ends terminated at the control panel. In the ev ent of an open-cir c uit fault it is then possible to drive both

ends simult aneousl y . In a hazardous area it is not possible t o use a loop confi gur ation because the

potential t o feed power from each end of the loop would double t he av ailable energy in the hazardous

area and contravene the energy limitations of the intrinsically safe certification. All circuits must therefor e

be connected as spars fr om the safe area or as radial connections from the control panel.

Types of Safety Barrier

The system confi gur ation can for three types of saf ety barrier, each of which has its own advantages and

disadvantages. A bri ef outline of the characteristics is given below.

Single Channel 28V/300Ω Barrier

This is the most basic t y pe of barrier and therefore the lowest cost. B eing passive devices, they also

impose the minimum of restrictions on the operation of the flame detectors. Thus, single channel barrier s

are availabl e either as positive or negativ e polar ity where the polarity r efers to the polarity of the applied

voltage relative to earth. The significance of this is that one side of the barrier must be connected t o a

high-integrity ( s afety) earth. Although this connection has no eff ect on the operation of the flame det ector

and is not needed for t heir correc t operation, it may not be accept able to the operation of the contr ol and

indicating equipment. This is particularly true if the control equipment incorporates earth-leakage

monitoring and ev en without this featur e the earthing of the loop may cause unwanted cross-talk between

loops.

If the earth connec tion is not acceptable then the A.C. or isolating barrier s should be used.

Star-connected A.C. Barrier

A.C. barrier s are also passive devices and must still be connected to a high-int egri ty safety earth.

However, they ar e desi gned to allow either positiv e or negative voltages with respect to ear th and under

normal conditi ons provide a connection t o earth v ia a reverse-diode, rather than dir ec tly.

The disadvantage of this type of barrier is that the end-to- end r esi stanc e is nominally 1200ohms

compared wit h the 300 ohms of the single channel type. This high resi stanc e r esul ts in an extra voltage

drop in the circuit . Thi s ty pe of barrier is not recommended f or general use

Galvanically Isolated Barrier

Galvanically isolated barri er s (also know as transformer isolat ed bar ri er s) dif fer from conventi onal shunt

zener barrier s i n that they pr ov ide electrical isolat ion between the input (safe area) and the output

(hazardous area). This is achieved by the use of a D.C./D.C. converter on the input si de, which is

connected to t he haz ar dous area t hr ough a v oltage and power limiti ng r esistor/zener com bination similar

to a conventional barrier.

The galvanic isolation technique means that the circuit does not need a high integrity (safety) earth and

that the intrinsically safe circuit is fully floating. Earth leakage problems for control and indicating

equipment are therefore eliminated if this type of interface is used.

2-3-0-809/ISS2/JUL07

Page 7

Hochiki Europe ( UK ) Ltd 7

Galvanically isolated barri er s are widely used with conventional flame detector system s. If the system is

of an addressable ty pe with signal pulses on the supply li nes then the response time of most standard

barriers will be too slow to allow their use. In these applications special galv anic ally isolated barri ers are

required that can freely transmit the requir ed pr otocol pulses without introducing sever e voltage dr ops.

These interf ac es are available as single or dual channel versions and are recomm ended for any

application in which direct earth connec tions are not acceptable.

The galvanically isolated barri er i s a two-wire device which does not need an exter nal power supply.

Current drawn fr om the detector supply connecti ons by t he bar ri er itself is less than 500µA

Approved Safety Barriers

For systems a generi c specification for the barriers is as follows:

Any shunt zener diode safety barrier certif ied and approved to meet the ATEX Dir ectiv es or CENE LE C /

IEC standards.

ATEX group and category

CENELEC / IEC marking [EEx ia] II C (associated apparatus)

Having the followi ng or lower output parameters:

Max. output volts U

Max. output curr ent I

Max. output power P

A number of barrier s meet this speci fication and ex am ples are given below:

: = 30V

o

: = 100mA

o

: = 0.65W

o

II (1) G

Supplier Type Polarity Mounting Technique

Pepperl & Fuchs Ltd

77 Ripponden Road

Oldham

Lancashire O L2 8PF

United Kingdom

www.pepperl-fuchs.com

MTL

Power Court

Luton

Bedfordshi r e LU1 3J J

United Lingdom

www.mtl-inst.com

Z728

Z779

Z828

KFD0-CS-Ex1.51

KFD0-CS-Ex2.51

MTL7028+

MTL7728+

MTL7779+

MTL7706+

+

+

-

+

+

+

+

DIN rail

DIN rail

DIN rail

DIN rail

DIN rail

DIN rail

DIN rail

DIN rail

DIN rail

Shunt 300Ω

Shunt 300Ω X 2

Shunt 300Ω

Galvanic X 1

Galvanic X 2

Shunt 300Ω

Shunt 300Ω

Shunt 300Ω X 2

Active 300Ω,

4-20mA output

Safety Earth

Single channel and st ar c onnec ted A.C. safety barriers must be connected to a high integrity earth by at

least one and preferably two copper cables, each of cross sectional area of 4mm² or greater. The

connection m ust be such t hat t he im pedanc e from the connection point to the main power system earth is

less than one ohm.

Intrinsically safe circuit s in the haz ar dous area shoul d be insulated fr om eart h and must be capable of

withstanding a 500V RMS A.C. test voltage for at least one minut e.

When using armoured or c opper sheathed c ables, the armour or sheath is normally isolat ed from the safe

area busbar.

2-3-0-809/ISS2/JUL07

Page 8

8 Hochiki Europe ( UK ) Ltd

Wiring and Cable Types

It is not permitted to connect more than one barrier ci r cui t in the hazardous area to any other ci r cuit.

Both separate and twin cables may be used. A pair contained in a type ‘A’ or ‘B’ m ulticor e cable (as

defined in clause 5.3 of E N50 039) m ay also be used, provided that the peak volt age of any ci r c uit

contained wit hin the multicore does not exc eed 60V.

The capacitance and either inductance or the inductance to resistance ( L/R) ratio of the hazardous area

cable must not exceed t he par am eters specified in Table 6. The reason for this is that energy can stored

in a cable and it is necessary to use cable in which energy stored is i nsufficient to ignit e an expl osive

atmosphere.

To calculate t he tot al c apaci tance or inductance for the length of cable in the hazardous area, refer to

Table 7, which gives typical per kilometre capacitance and inductance for commonly used cables.

Note: The fl ame detector s have zero equivalent inductance (Li = 0) and a 0.03μF capacitance ( Ci =

0.03μF).

Gas group IIA IIB IIC

Capacitance μF

Inductance mH

L/R ratio μH/ohm

Table 6 – 28V Barrier, Maximum Permissible Stored Energy in Cables

Cable Type Core

MICC Pyrtenax

light duty

MICC Pyrotenex

heavy duty

Pirelli FP200

PVC sheathed and

Insulated to B S 6004

Table 7 Examples of el ectri c al c har acteristic s of cabl es comm only used in fire protection system s

2.15

33.6

440

2

2

all

all

Size

mm²

1.5

1.5

1.5

1.5

0.65

12.6

165

Conductor

resistance

ohm/km/core

12.1

12.1

12.1

12.1

0.083

4.2

55

Inductance

mH/km

0.534

0.643

0.77

Capacitance µF/km

core

to

core

0.19

0.13

0.08

0.09

core

to

sheath

0.21

0.17

0.15

Sheath

Resistance

ohm/km

2.77

1.58

Maximum Loading of IS Circuit

Because of the finite resistance of the safety bar ri er, there will be a limit to the current drain which can be

tolerated before the voltage on the circuit falls outside the specified limits for the IS detector . The standing

current for the detectors can be calculat ed by the sum of t he indiv idual selected det ector c ur r ents as

given in the detect or data sheet. This may limit the maxim um number of detectors per barri er t o two or

three.

2-3-0-809/ISS2/JUL07

Page 9

Hochiki Europe ( UK ) Ltd 9

Installation

It is important that the I S detec tors are installed in such a way that all t erminals and connections are

protected t o at least I P 20 with the detector cover fitted. The earth bonding terminals are provided for

convenienc e where continuity of a cable sheath or similar is required

Service & Repairs

Servicing of I S flam e detectors may be carried out onl y by a BASEEFA or equivalent authorised body. In

practic al term s this means that IS flame detector m ay be servi c ed only at the manufactures factory.

Servicing of t he fire pr otection system should be car ri ed out as recommended by the local r egulation in

force.

2-3-0-809/ISS2/JUL07

Page 10

10 Hochiki Europe ( UK ) Ltd

IS System Drawing

NOTE 1

Each Barrier fed circuit must be a separate circui t and must not

be conn ect ed w it h an y ot h er electrical circu it .

NOTE 2

The electrical circuit in the hazardous area must be capable of

withst an di ng an AC t est voltag e of 50 0 vol t s RMS to ear t h or

frame of th e ap p aratus for on e min ute.

NOTE 3

Detector Input P ar am eters

Terminal 1 with res p ect to te rminal 2

Terminal 3 with res p ect to te rminal 4

Ui = 30V

Ii = 100mA

Pi = 0.65W

Ci = 0.03µF

Li = 0

Terminal 5 with res p ect to te rminal 6

Terminal 7 with res p ect to te rminal 8

Ui = 30V

Ii = 100mA

The inst all at i on m us t c omply with n at i on al ins tallat i on

requirem ents (f or ex am pl e t o EN 600 7 9- 1 4)

NOTE 4

The capac it ance and either the ind uc tanc e or the ind uc tanc e to

resist ance (L/R) r atio of the haz ard ous area cabl es mus t n ot

exceed the maximum permissible parameters for the required

groups IIA , IIB an d IIC .

NOTE 5

The cable may be separate cables or a twin pair contained in a

type ‘A’ or a t yp e ‘B’ mul t icore cabl e (as def i n ed in cl ause 5.3 of

EN50 039). Provided that the peak voltage of any circuit

contain ed wi thi n t h e mut icore do es n ot exceed 60 vol ts .

NOTE 6

If requir ed a l oad in g r es is t or of n ot les s th an 3k 0.5 w att an d

having a surface area between 20cm² and 10cm² may be

connected betw e en th e t er mi nals of any ci rc uit, but not b et we en

circuits.

2-3-0-809/ISS2/JUL07

Page 11

Hochiki Europe ( UK ) Ltd 11

Hochiki Europe (UK) Ltd

Grosvenor Road, Gillingham Bus ine ss Park,

Gillingham, Kent, ME8 0SA, England

Telephone: +44(0)1634 260133 Facsimile: +44(0)1634 260132

Email: sales@hochikieurope.co m

Web: www.hochiki europe.com

Hochiki Europe (UK) Ltd. reserves the right to alter the specification of its products from time to time without notice. Although eve ry effo r t

has been made to ensure the accuracy of the information contained within this document it is not warranted or represented by Hochiki

Europe (UK) Ltd. to be a complete and up-to-date description. Please check our web site for the latest version of this document.

2-3-0-809/ISS2/JUL07

Loading...

Loading...