Page 1

FireNET 4127

Analog Addressable Fire Alarm System

Installation and Operation Manual

Hochiki America Corporation

7051 Village Drive, Suite 100

Buena Park, CA 90621-2268

714.522.2246 Corporate Headquarters

800.845.6692 Technical Support

http://www.hochiki.com

FireNET 4127 I & O Manual 1 v1.90 UL

Version 1.90 - UL

Created: 08/15/05

Updated: 08/24/2010

PN# 1700-09948

Page 2

Table of Contents

Table of Contents ........................................................................................................................... 2

Prefix – Programming Compliance with UL864 9

Section 1 – Introduction

......................................................................................................................................................... 8

th

Edition ........................................................ 7

1.1 Basic Features .................................................................................................... 8

1.2 System Devices and Equipment ......................................................................... 9

1.2A System Devices BOSCH ................................................................................ 11

1.2B System Devices Silent Knight ........................................................................ 12

1.2.1 System Replacement Parts ......................................................................... 13

1.3 Limitations of Fire Alarm Systems .................................................................... 14

1.4 Agency Listings, Approvals, Requirements ...................................................... 17

1.4.1 Federal Communications Commission (FCC) .............................................. 17

1.4.2 Underwriters Laboratories (UL) .................................................................... 17

1.4.3 National Fire Protection Association (NFPA) ............................................... 17

Section 2 – Control Panel Installation

....................................................................................................................................................... 18

2.1 What’s in the Box? ............................................................................................ 18

2.2 Environmental Specifications ............................................................................ 18

2.3 Control Panel Layout ........................................................................................ 19

2.3.1 Front Panel Layout, Standard Build ............................................................. 19

2.3.2 Front Panel Layout, Denver Door Build ....................................................... 20

2.3.3 Control Panel Annunciator, Control Unit and Power Supply Layout ............ 21

2.4 Mounting the Control Panel .............................................................................. 22

2.5 Wiring Specifications ........................................................................................ 22

2.5.1 Suggested Routing of AC Power ................................................................. 23

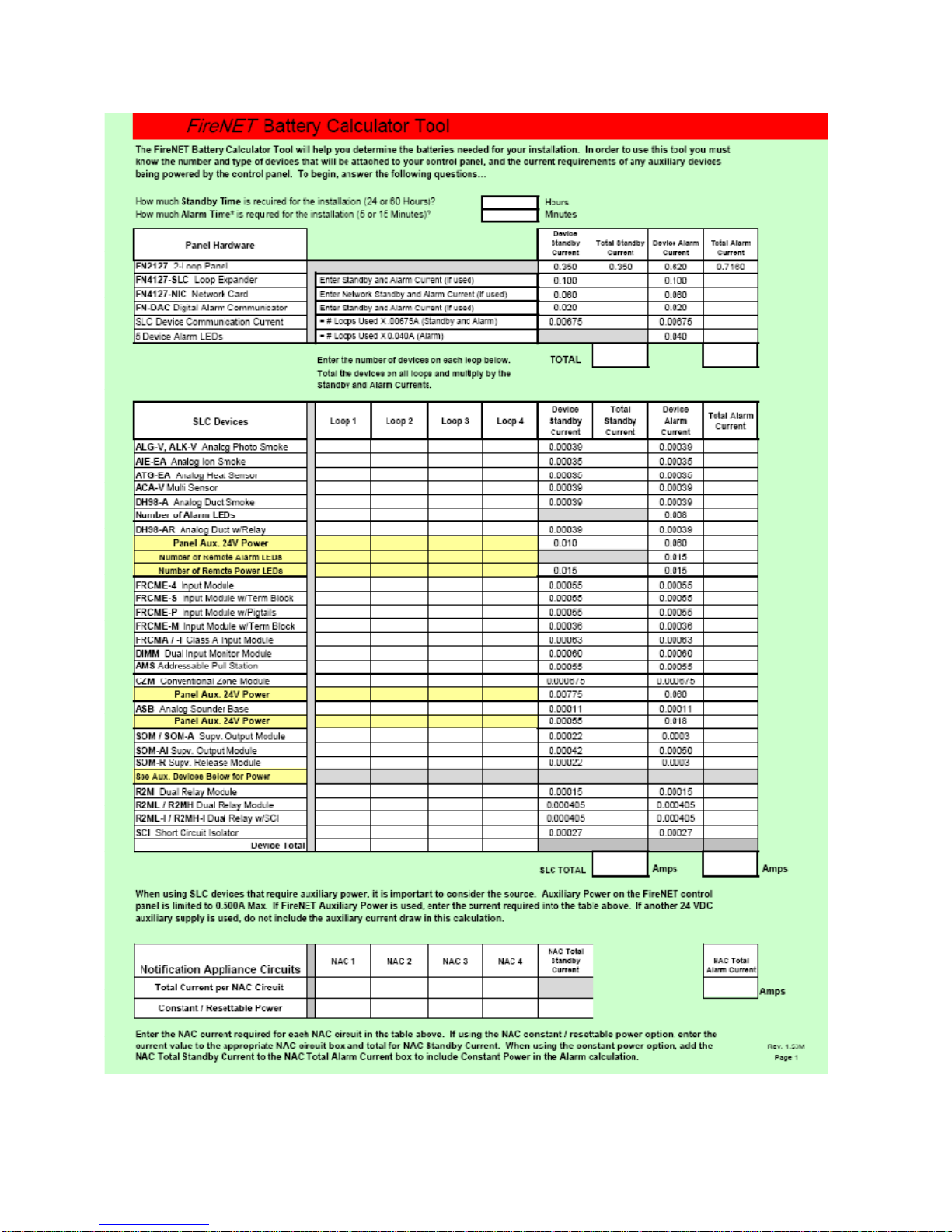

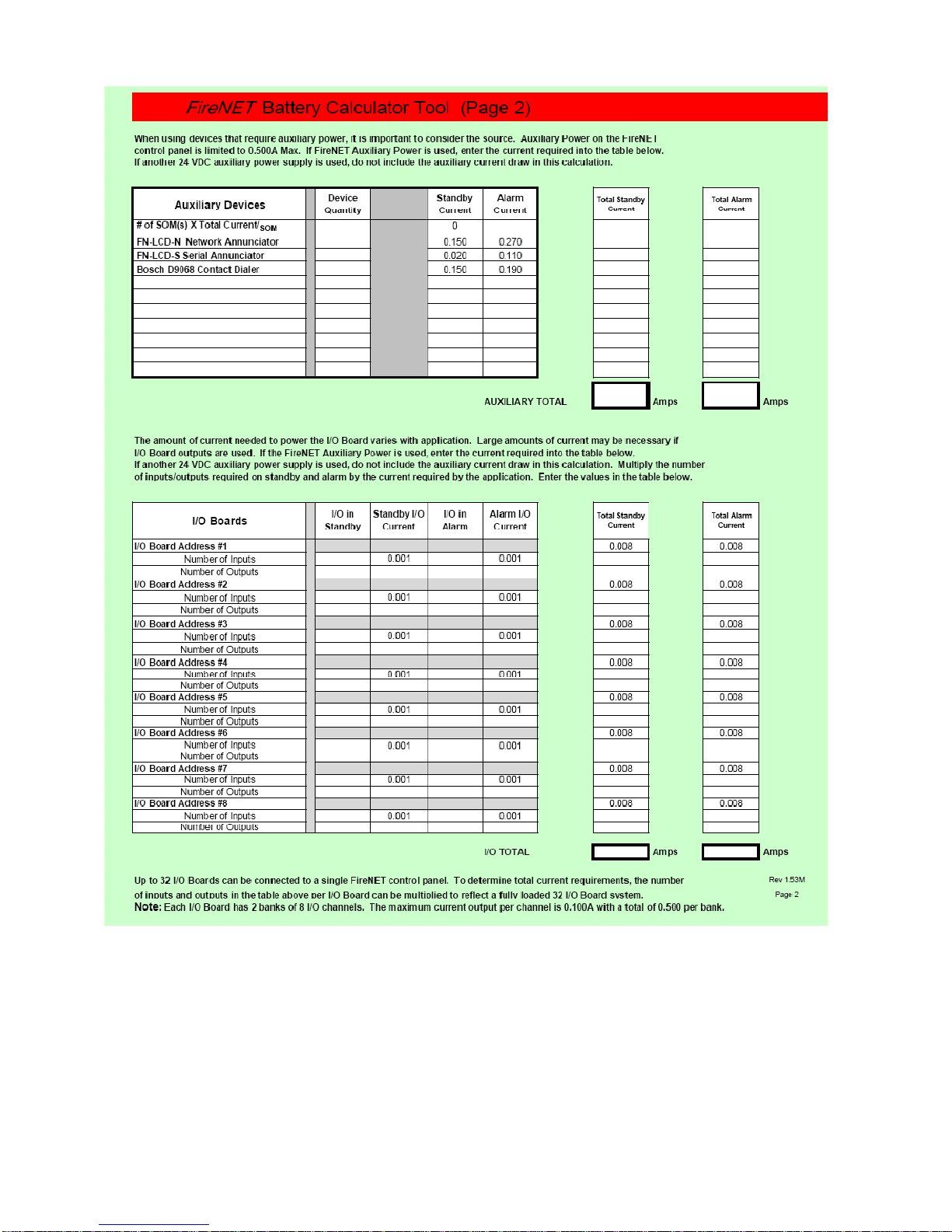

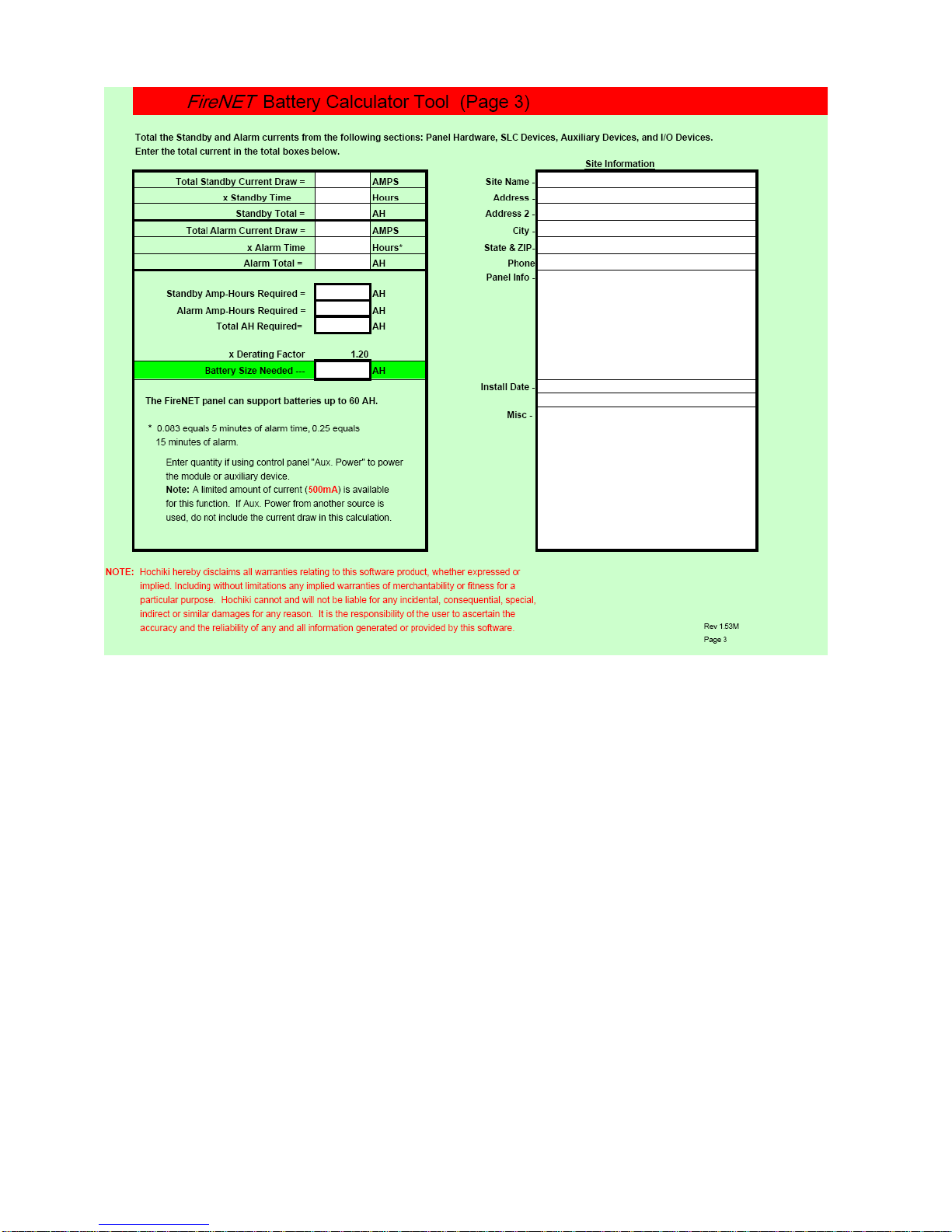

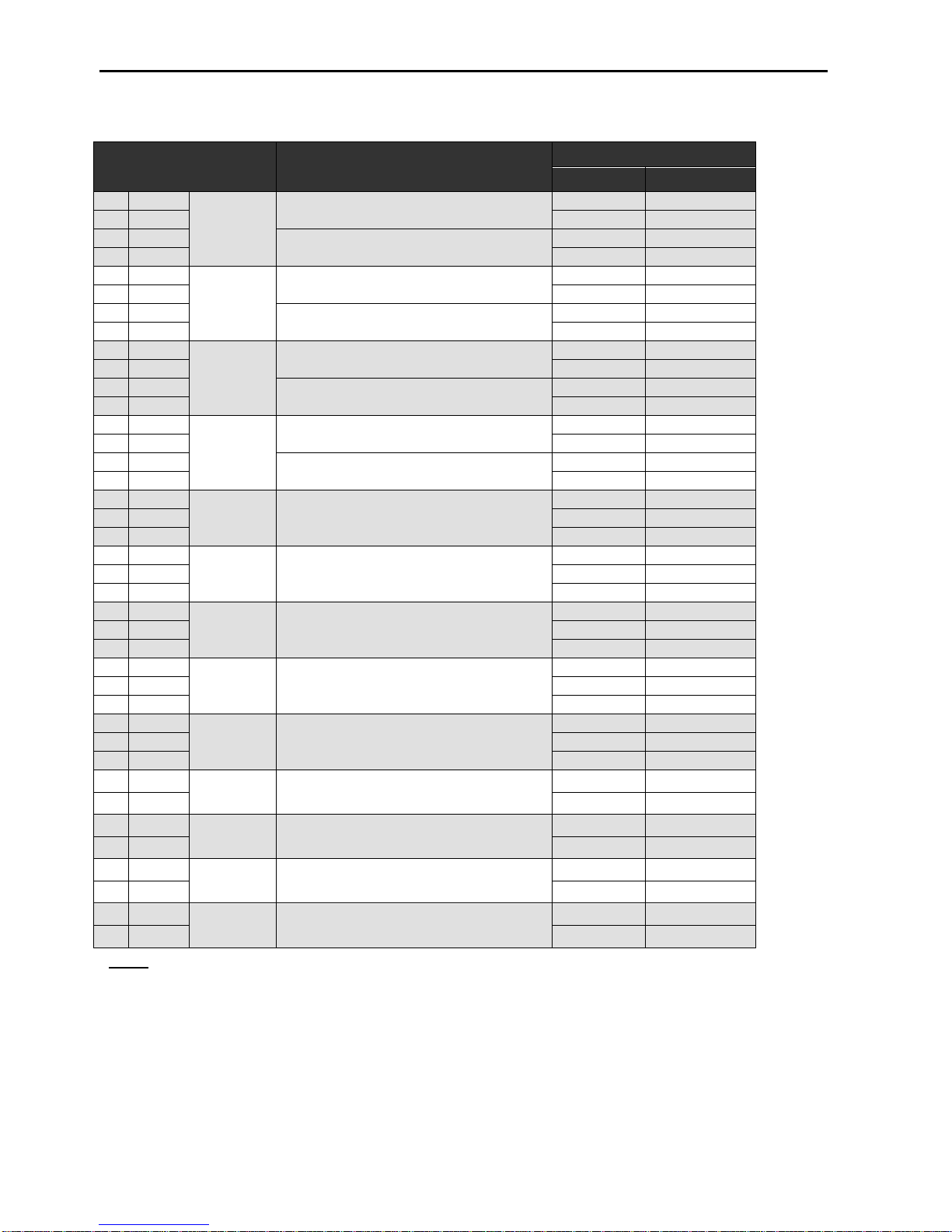

2.6 Battery Calculations .......................................................................................... 24

2.7 Electrical Ratings .............................................................................................. 27

2.8 Specifications ................................................................................................... 30

Section 3 - Power Supply and Main Control Unit Connections

....................................................................................................................................................... 31

3.1 AC Power Connection ...................................................................................... 31

3.2 Battery Connection ........................................................................................... 31

3.3 Auxiliary Power Connection .............................................................................. 32

3.4 Notification Appliance Circuit Connection ......................................................... 34

3.5 Voltage Routing and Relay Output Connection ................................................ 35

3.5.1 Voltage Routing Outputs .............................................................................. 35

3.5.2 Relay Outputs .............................................................................................. 36

3.6 Digital Input Connection .................................................................................... 37

3.7 Using a Printer .................................................................................................. 38

Section 4 – Expander Board Installation

....................................................................................................................................................... 39

2

FireNET 4127 I & O Manual v1.90 UL

Page 3

4.1 Compatible Expander Boards ........................................................................... 39

4.2 General Installation of RS-485 Bus Devices ..................................................... 40

4.2.1 Wiring Distance and Mounting Locations ..................................................... 40

4.2.2 Addressing ................................................................................................... 41

4.2.3 Terminating .................................................................................................. 41

4.2.4 Power Connections ...................................................................................... 42

4.2.5 COMMS Connection .................................................................................... 42

4.3 FN-4127-IO - Input / Output Board ................................................................... 43

4.3.1 Configuring Inputs ........................................................................................ 43

4.3.2 Configuring Outputs ..................................................................................... 44

4.3.3 LED Indicators ............................................................................................. 45

4.4 Reserved for Future Use .................................................................................. 45

4.5 Reserved for Future Use .................................................................................. 45

4.6 FN-4127-SLC – Dual SLC Loop Expander ....................................................... 46

4.6.1 Installation of the FN-4127-SLC ................................................................... 46

4.7 FN-LCD-S Serial Liquid Crystal Display Annunciator ...................................... 47

4.7.1 Installation of the FN-LCD-S ........................................................................ 47

Section 5 – SLC Device Installation

....................................................................................................................................................... 50

5.1 Compatible SLC Devices .................................................................................. 50

5.2 Number of Devices ........................................................................................... 52

5.3 SLC Loop Wiring .............................................................................................. 52

5.3.1 Class B SLC Loop Wiring Distance ............................................................. 53

5.3.2 Class A SLC Loop Wiring Distance ............................................................. 54

5.4 Addressing Devices .......................................................................................... 55

5.4.1 Detector Addressing .................................................................................... 57

5.4.2 4-S Module and AMS Addressing ............................................................... 57

5.4.3 Mini Module Addressing .............................................................................. 58

5.5 Smoke and Heat Detector Wiring ..................................................................... 59

5.6 Analog Duct Detector Wiring ............................................................................ 60

5.6.1 DH98-A Analog Duct Detector ..................................................................... 61

5.6.2 DH98-AR Analog Duct Detector with Relay ................................................. 62

5.7 FRCME-4 Input Module Wiring ......................................................................... 63

5.8 FRCME-S Mini Input Module (w/ Terminal Blocks) ........................................... 64

5.9 FRCME-P Mini Input Module (w/ Pigtails) ......................................................... 65

5.10 FRCME-M Mini Input Module (w/ Terminal Blocks) ........................................ 66

5.11 FRCMA / FRCMA-I Input Module ................................................................... 67

5.12 R2M Dual Relay Module Wiring ...................................................................... 69

5.13 SOM Supervised Output Module .................................................................... 70

5.14 SOM-A / SOM-AI Supervised Class A Output Module .................................... 71

5.15 SOM-R Supervised Output Module (Preaction Sprinkler Systems) ................ 72

5.15 CZM Conventional Zone Module .................................................................... 76

5.16 DIMM Dual Input Monitor Module ................................................................... 77

5.17 SCI Short Circuit Isolator Module .................................................................... 78

5.17.1 Class A Operation ...................................................................................... 79

5.17.2 Class B Operation ...................................................................................... 80

5.18 ASB Analog Sounder Base ............................................................................. 81

5.19 AMS Addressable Manual Pull-Station ........................................................... 82

3

FireNET 4127 I & O Manual v1.90 UL

Page 4

Section 6 - Network Connections

....................................................................................................................................................... 83

6.1 Compatible Network Devices ............................................................................ 83

6.1.1 FN-4127-NIC Network Interface Card .......................................................... 84

6.1.2 FN-LCD-N Network Liquid Crystal Display Annunciator .............................. 89

Section 7 - Basic Front Panel Operations and Programming .................................................. 91

(Access Level 1, 2, and Real-Time Operation)

....................................................................................................................................................... 91

7.1 Operating Modes .............................................................................................. 92

7.1.1 Access Level 1 ............................................................................................. 92

7.1.2 Access Level 2 ............................................................................................. 92

7.1.3 Access Level 3 ............................................................................................. 92

7.2 Access Level 1 Operations ............................................................................... 92

7.2.1 Performing a Lamp Test .............................................................................. 92

7.2.2 More Fire Events ......................................................................................... 93

7.2.3 More Events ................................................................................................. 93

7.2.4 Menu Navigation (Up, Down, Left, Right Arrows, Enter / Exit Buttons) ........ 93

7.2.5 Help (?) ........................................................................................................ 93

7.3 Access Level 2 Operations ............................................................................... 94

7.3.1 Entering Access Level 2 .............................................................................. 94

7.3.2 Silencing an Alarm ....................................................................................... 94

7.3.3 Resounding an Alarm .................................................................................. 94

7.3.4 Resetting an Alarm ...................................................................................... 95

7.3.5 Initiating a Fire Drill ...................................................................................... 95

7.3.6 Silence the Panel Sounder .......................................................................... 95

7.4 Advanced Access Level 2 Operations .............................................................. 96

7.4.1 Access Level 2 Main Menu .......................................................................... 96

7.4.2 Disablements ............................................................................................... 96

7.4.3 View Devices ............................................................................................... 98

7.4.4 Test Zones ................................................................................................... 98

7.4.5 Set System Time ......................................................................................... 99

7.5 Panel Operation ................................................................................................ 99

7.5.1 Fire Condition .............................................................................................. 99

7.5.2 Trouble Condition ...................................................................................... 100

7.5.3 Supervisory Condition ................................................................................ 101

7.5.4 Pre-Alarm Condition .................................................................................. 102

Section 8 - Advanced Front Panel Operations and Programming (Access Level 3)

..................................................................................................................................................... 103

8.1 Access Level Overview ................................................................................... 103

8.1.1 Entering Access Level 3 ............................................................................ 103

8.2 Access Level 3 Menu ...................................................................................... 104

8.2.1 Edit Configuration ...................................................................................... 104

8.2.2 Set Times................................................................................................... 112

8.2.3 View Print Event Log ................................................................................. 113

8.2.4 Print Configuration ..................................................................................... 114

8.2.5 System Disablements ................................................................................ 114

8.2.6 Loop Data Test .......................................................................................... 115

4

FireNET 4127 I & O Manual v1.90 UL

Page 5

Section 9 - Loop Explorer Software Programming

..................................................................................................................................................... 116

9.1 PC Requirements ........................................................................................... 116

9.2 Installing Loop Explorer .................................................................................. 116

9.3 Launching Loop Explorer ................................................................................ 117

9.4 Connecting Your PC to the FireNET 4127 ...................................................... 117

9.4.1 Using PC Connect ..................................................................................... 117

9.4.2 Setting a COM Port .................................................................................... 122

9.5 Getting Familiar with Loop Explorer ................................................................ 122

9.5.1 User Interface ............................................................................................ 123

9.5.2 Menu and Toolbar Overview ...................................................................... 125

9.5.3 Main Tool Bar Icons ................................................................................... 132

9.5.4 Items Pane Icons ....................................................................................... 134

9.6 Developing a Site............................................................................................ 138

9.6.1 Creating a New Site ................................................................................... 138

9.6.2 Editing an Existing Site .............................................................................. 139

9.6.3 Saving a Site .............................................................................................. 140

9.7 Configuring Panels to a Network .................................................................... 141

9.7.1 Adding a Panel .......................................................................................... 141

9.7.2 Configuring and Editing a Panel ................................................................ 142

9.7.3 Editing a FN-LCD-N Network LCD Annunciator ......................................... 147

9.7.4 Reserved for Future Use ........................................................................... 147

9.7.5 Editing a Local Panel I/O ........................................................................... 148

9.7.6 Removing a Panel ..................................................................................... 148

9.8 Configuring Option Boards/Serial LCD Annunciators on a Panel ................... 149

9.8.1 Adding an Option Board/Serial LCD Annunciator ...................................... 149

9.8.2 Editing an Option Board/Serial LCD Annunciator ...................................... 149

9.8.3 Removing an Option Board/Serial LCD Annunciator ................................. 150

9.9 Configuring Panel I/O and Devices on a Loop ................................................ 151

9.9.1 Adding a Device on a Loop ........................................................................ 151

9.9.2 Editing Panel I/O and Devices on a Loop .................................................. 151

9.9.3 Changing a Device on a Loop .................................................................... 157

9.9.4 Deleting a Device on a Loop ...................................................................... 157

9.10 Loop Explorer Abilities .................................................................................. 158

9.10.1 Reserved for Future Use.......................................................................... 158

9.10.2 Cause & Effect Summary......................................................................... 158

9.10.3 Reserved for Future Use.......................................................................... 158

9.10.4 Zone Manager ......................................................................................... 158

9.10.5 Reserved for Future Use.......................................................................... 158

9.11 Loop Explorer Networking ............................................................................ 159

9.11.1 Getting it working ..................................................................................... 159

9.11.2 Using the Loop Explorer PC configuration ............................................... 159

9.11.3 Fire action ................................................................................................ 160

9.11.4 Auxiliary action ......................................................................................... 160

9.11.5 Pre-alarm action ...................................................................................... 160

9.11.6 Trouble action .......................................................................................... 160

9.11.7 Disablement action .................................................................................. 161

9.11.8 Supervisory Alarm action ......................................................................... 161

9.11.9 Test action ............................................................................................... 161

9.11.10 Status .................................................................................................... 161

5

FireNET 4127 I & O Manual v1.90 UL

Page 6

9.12 Loop Explorer Networking - Keeping a record .............................................. 164

9.13 Loop Explorer Networking - Using zones ...................................................... 171

9.14 Loop Explorer Options .................................................................................. 172

9.14.1 COM Port ................................................................................................. 172

9.14.2 Default Project Folder/ Memory Management ......................................... 172

9.14.3 Splash Screen ......................................................................................... 172

9.14.4 Other ........................................................................................................ 173

9.15 Cause and Effect Programming .................................................................... 174

9.15.1 Cause & Effect Types .............................................................................. 174

9.15.2 Cause & Effect Examples ........................................................................ 176

Section 10 - Testing and Troubleshooting

..................................................................................................................................................... 178

10.1 One Man Walk Test - TEST ZONES ............................................................ 178

10.2 View / Print Event Log .................................................................................. 179

10.2.1 View Event Log ........................................................................................ 179

10.2.2 Print Event Log ........................................................................................ 180

10.2.3 Clear Event Log ....................................................................................... 181

10.3 Loop Data Test ............................................................................................. 182

10.4 Troubleshooting ............................................................................................ 184

Section 11 - Installation Records

..................................................................................................................................................... 186

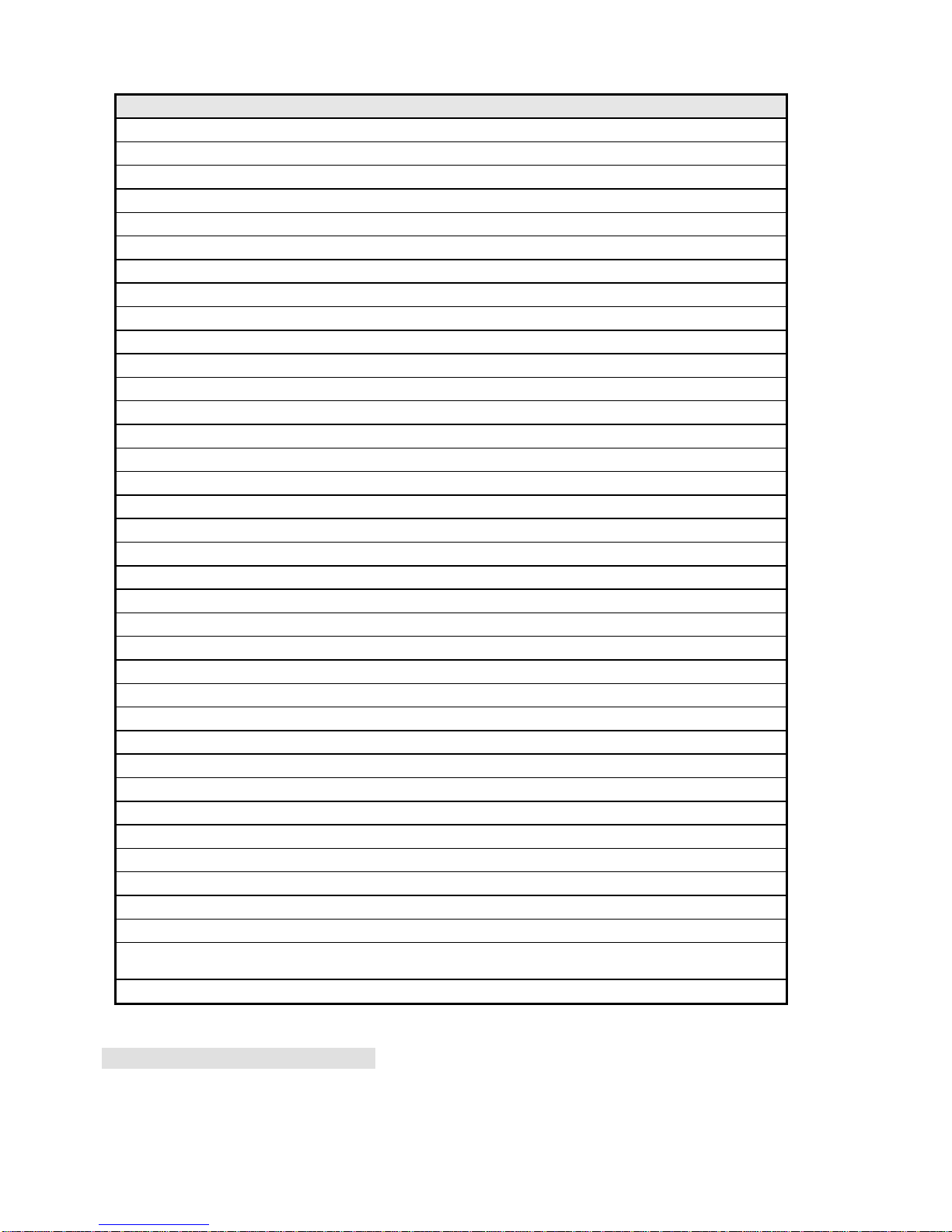

11.1 SLC Loop Point Record ................................................................................ 186

11.2 RS485 Bus Device Record ........................................................................... 186

11.3 Network Node Device Record ...................................................................... 186

Appendix A - Compatible Devices

..................................................................................................................................................... 199

A.1 Two-Wire Smoke Detectors ........................................................................... 199

A.1.1 Two-Wire Smoke Detectors BOSCH ........................................................... 200

A.2 Reserved for Future Use ................................................................................ 200

A.3 Compatible Notification Appliances ................................................................ 201

A.4 Compatible 24VDC Devices ........................................................................... 206

A.4.1 Compatible 24VDC Devices BOSCH .......................................................... 207

A.5 Using the Bosch D9068 Dialer with FireNET .................................................. 208

A.5.1 Using the Bosch D9068 Contact Dialer with FireNET (Diagram) ............... 208

A.5.2 Programming FireNET for use with the Bosch D9068 Dialer..................... 209

A.5.3 Installation notes when using the Bosch D9068 Dialer with FireNET ........ 212

A.6 Using the FN-CTM City Tie module with FireNET .......................................... 213

A.7 Using the FNV-MP with FireNET .................................................................... 214

A.8 Changing the FN-PS402 Power Supply to 240VAC operation ....................... 215

Appendix B – Panel Door Label Drawing ................................................................................. 216

Appendix C - WARRANTY ......................................................................................................... 217

6

FireNET 4127 I & O Manual v1.90 UL

Page 7

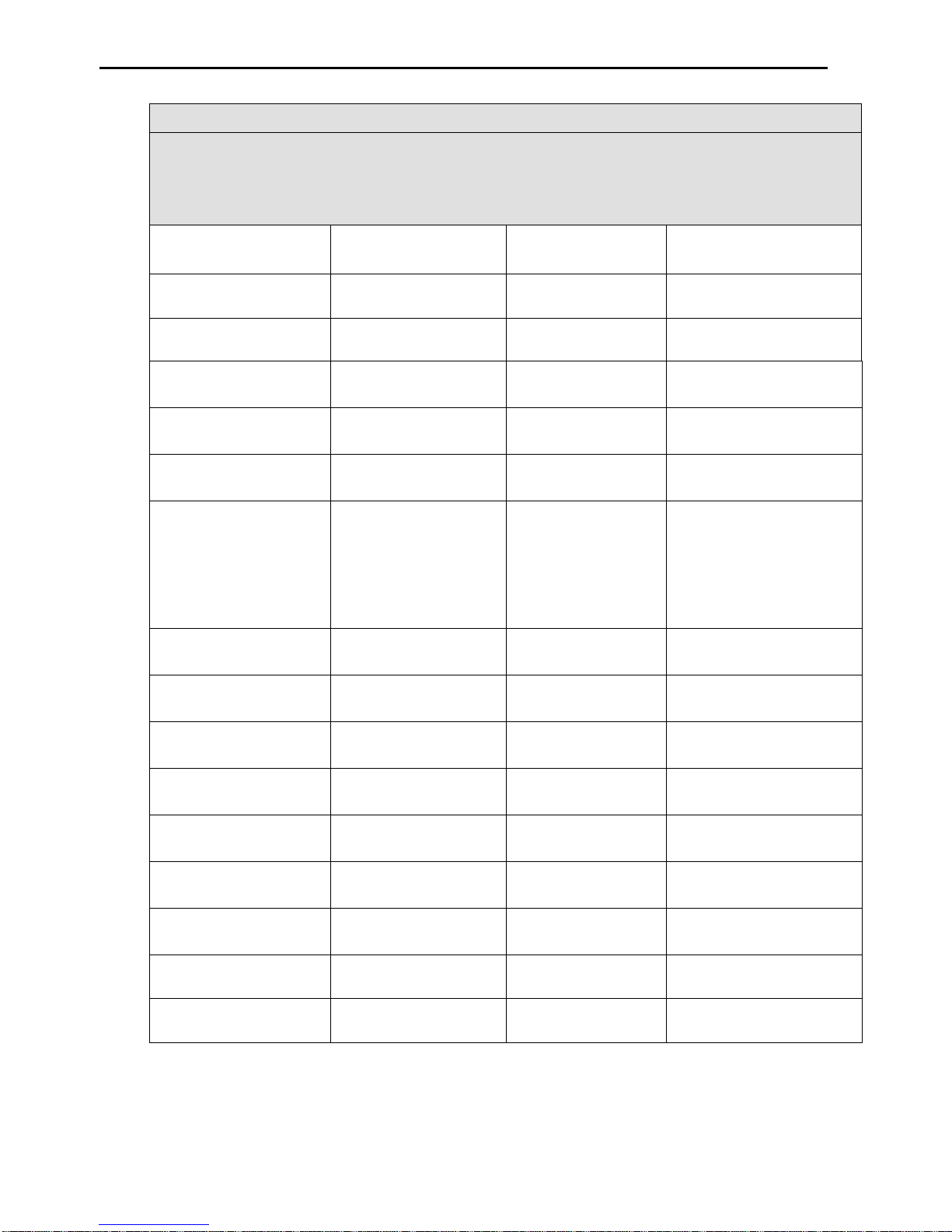

Prefix – Programming Compliance with UL864 9th Edition

Notice to Users, Installers, Authorities Having Jurisdiction, and other involved parties

This product incorporates field-programmable software. In order for the product to comply with the

requirements in the Standard for Control Units and Accessories for Fi re Alarm Systems, UL 864 9th

Edition, certain programming features or options must be limited to specific values or not used at all

as indicated below.

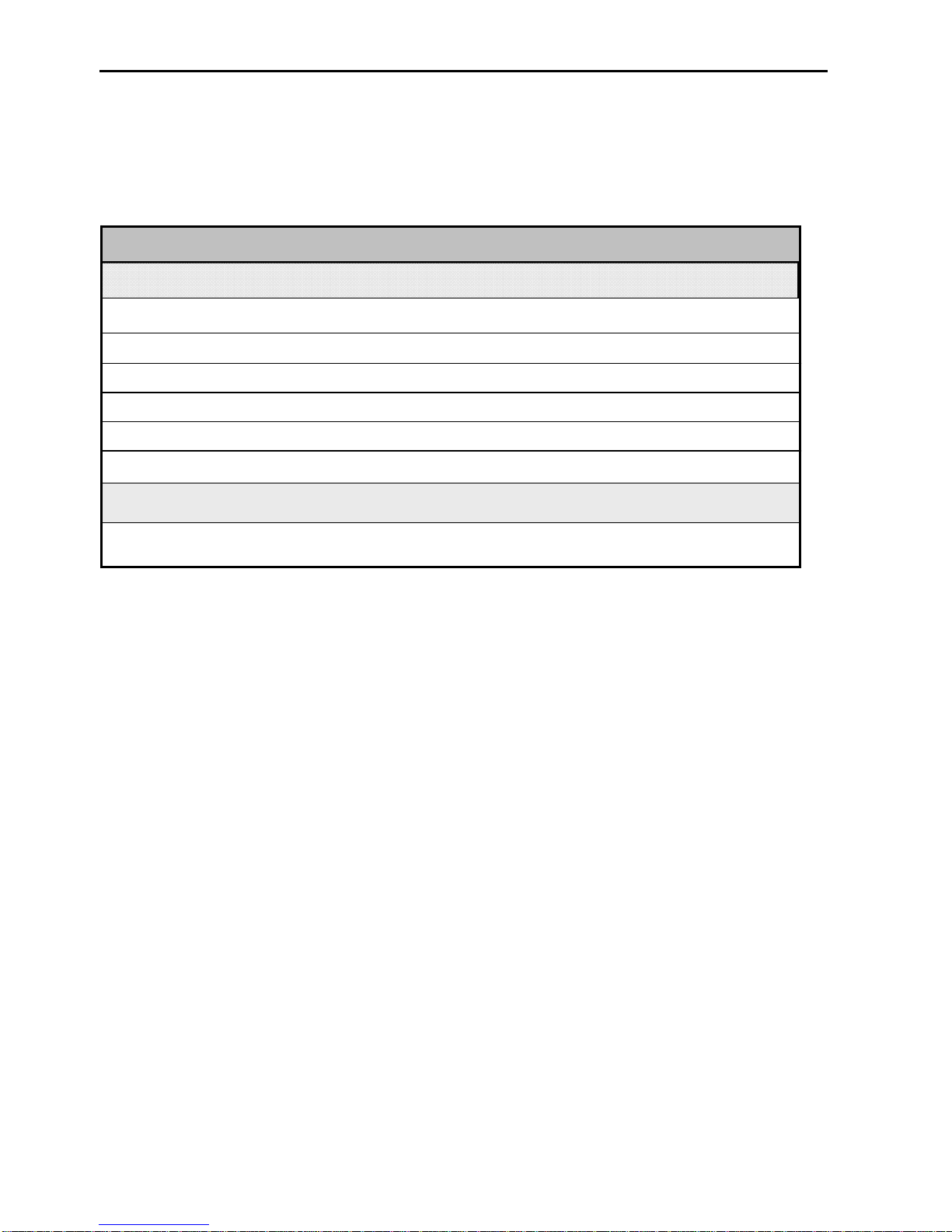

Program Feature or

Option

AC Fail Delay Yes 0 – 24 hours 1 – 3 hours

Alarm Verification Yes 5 – 60 seconds 60 second setting

Disable Buzzer Yes Enable/Disable Enable

Disable Ground Trouble Yes Enable/Disable Enable

Permitted in UL 864?

(Y/N)

Possible settings

Settings permitted in

UL864

Set Buzzer Silence

Access Level

“Waterflow Alarm” and

“General Purpose” Device

Type

Disable SOM-R No Enable/Disable None

Yes 1 or 2 2

No 0 – 120 seconds 0 seconds

7

FireNET 4127 I & O Manual v1.90 UL

Page 8

Section 1 – Introduction

The FireNET 4127 is an analog addressable fire alarm system that meets the

requirements of UL 864 9th Edition.

1.1 Basic Features

The basic FireNET 4127 control panel includes two SLC (Signaling Line Circuit)

loops. Each loop is capable of supporting 127 analog addressable points (can be

any combination of sensors and modules) for a total of 254 analog addressable

points on the basic panel. Two additional SLC loops can be added to the panel

increasing the analog addressable point capacity to 508. When analog sounder

bases are used, the upper addresses 128 – 254 are allocated to increase loop

capacity to 254 analog addressable points. This doubles the analog addressable

point capacity of the panel. The combination of analog addressable points

derived from sensors, modules, and sounder bases cannot exceed 800

addresses and sub-addresses maximum.

Up to 4.0 amps of power is available to drive the system, SLC loops, notification

appliances, and auxiliary equipment.

Four Class B notification appliance circuits rated at 2.5 amps each (see Section

2.7 and 2.8 for additional details regarding NAC circuit ratings).

Five programmable Form C relays are built-in to the control panel.

500 network-wide zones for device and circuit grouping.

Analog Smoke Detector Features:

Automatic Drift Compensation

Maintenance Alert

Adjustable Day/Night Sensitivity

Calibration checking meets sensitivity test requirements of NFPA 72.

Auto-Learn utility identifies system devices, which makes initial system start-up

easier.

8 line by 40 character graphic display provides the most intuitive operator

interface in the industry (320 characters total).

Help screens are available from the front panel and annunciator user interface to

assist in programming and operation.

512 additional points can be added to the system using the FN4127-IO 16

channel input/output boards. Each of these points can be programmed

individually to be an input or low current output. These points are for secondary

use only.

8

FireNET 4127 I & O Manual v1.90 UL

Page 9

1.2 System Devices and Equipment

The following boards, expanders and devices are available from Hochiki America

Corp. to be used with the FireNET 4127 analog addressable fire alarm system. For

a complete description and installation instructions of each product, please see the

appropriate section of this manual and the literature supplied with the device itself.

Model Description

Control Panels

FN-4127

NOTE: There are several ordering models (i.e. 2 loop, 4 loop, network options,

120/240VAC, colors, etc.). Hochiki America’s order entry department will establish

exact model and configuration at time of order. Different ordering models are also

reflected on the FireNET product datasheets.

FN-4127-NIC Network Interface Card

FN-4127-SLC Dual SLC Loop Expander Card

FN-4127-IO 16 Channel Input Output Board

FN-CTM City-Tie Module

FN-DAC Digital Alarm Communicator/Transmitter

FN-LCD-N Network LCD Annunciator

FN-LCD-S Serial LCD Annunciator

ALK-V Analog Photoelectric Smoke Sensor

ALK-V2 Analog Photoelectric Smoke Sensor

ALG-V Analog Photoelectric Smoke Sensor

AIE-EA Analog Ionization Smoke Sensor

ATG-EA Analog Heat Sensor

ACA-V Analog Photoelectric and Heat Multi Sensor

YBN-NSA-4 4” Base for Analog Sensors

HSB-NSA-6 6” Base for Analog Sensors

DH98-A Analog Duct Smoke Detector

DH98-AR Analog Duct Smoke Detector w/Relay

MS-RA, MS-RA/R, MSKA/R

FRCME-4 Input Module 4” Box Mount

FRCME-S Mini Input Module w/ Terminal Block

FRCME-P Mini Input Module w/Pigtail Leads

FRCME-M Mini Input Module w/ Terminal Block

FRCMA, FRCMA-I Class A Input Module 4” Box Mount (FRCMA-I has built-in SCI)

SOM, SOM-A, SOM-AI Supervised Output Module

SOM-R Supervised Output Module (Preaction Sprinkler Systems)

R2M Dual Relay Module

R2ML, R2ML-I Dual Relay Module, 2 amp @ 30VDC (R2ML-I has built-in SCI)

Analog/Addressable Fire Alarm Control Panel

(2 SLC Loop, expandable to 4 SLC Loop)

Control Panel Expanders

Annunciators

SLC Loop Devices

Remote Test Station for DH98A & DH98AR

9

FireNET 4127 I & O Manual v1.90 UL

Page 10

R2MH, R2MH-I Dual Relay M odule, 8 amp @ 30VDC (R2MH-I has built-in SCI)

SCI Short Circuit Isolator Module

DIMM Dual Input Monitor Module

CZM Conventional Zone Module

ASB Analog Sounder Base

AMS/KL/LP Addressable Manual Pull-Station

Accessories

TCH-B100-NS Hand-held Programmer

FN-ACC Battery/Accessory Enclosure (houses up to 33AH size batteries)

FN-ETR Enclosure Trim Ring for Panel Flush Mount

10

FireNET 4127 I & O Manual v1.90 UL

Page 11

1.2A System Devices BOSCH

The following boards, expanders and devices are available from BOSCH to be used

with the FireNET 4127 analog addressable fire alarm system. For a complete

description and installation instructions of each product, please see the appropriate

section of this manual and the literature supplied with the device itself.

Model Description

FN-4127 Analog/Addressable Fire Alarm Control Panel

D323A Analog Photoelectric Smoke Sensor

NOTE: There are several ordering models (i.e. 2 loop, 4 loop, network

options, 120/240VAC, colors, etc.). Bosch’s order entry department will

establish exact model and configuration at time of order. Different ordering

models are also reflected on the FireNET product datasheets.

(2 SLC Loop, expandable to 4 SLC Loop)

D324A Analog Ionization Smoke Sensor

D322A Analog Heat Sensor

D336A 4” Base for Analog Sensors

D321A 6” Base for Analog Sensors

D331A Analog Duct Smoke Detector

D332A Analog Duct Smoke Detector w/Relay

D326A Input Module 4” Box Mount

D339A Mini Input Module w/ Terminal Block

D327A Supervised Output Module

D335A Dual Relay Module

D333A Short Circuit Isolator Module

D5070 Hand-held Programmer

Control Panels

SLC Loop Devices

Accessories

11

FireNET 4127 I & O Manual v1.90 UL

Page 12

1.2B System Devices Silent Knight

The following boards, expanders and devices are available from Silent Knight to be

used with the FireNET 4127 analog addressable fire alarm system. For a complete

description and installation instructions of each product, please see the appropriate

section of this manual and the literature supplied with the device itself.

Model Description

SD505-APS Analog Photoelectric Smoke Sensor

SD505-AIS Analog Ionization Smoke Sensor

SD505-AHS Analog Heat Sensor

SD505-4AB 4” Base for Analog Sensors

SD505-6AB 6” Base for Analog Sensors

SD505-DUCT Analog Duct Smoke Detector

Accessories

SD505-DTS-K Remote Test Switch

SLC Loop Devices

12

FireNET 4127 I & O Manual v1.90 UL

Page 13

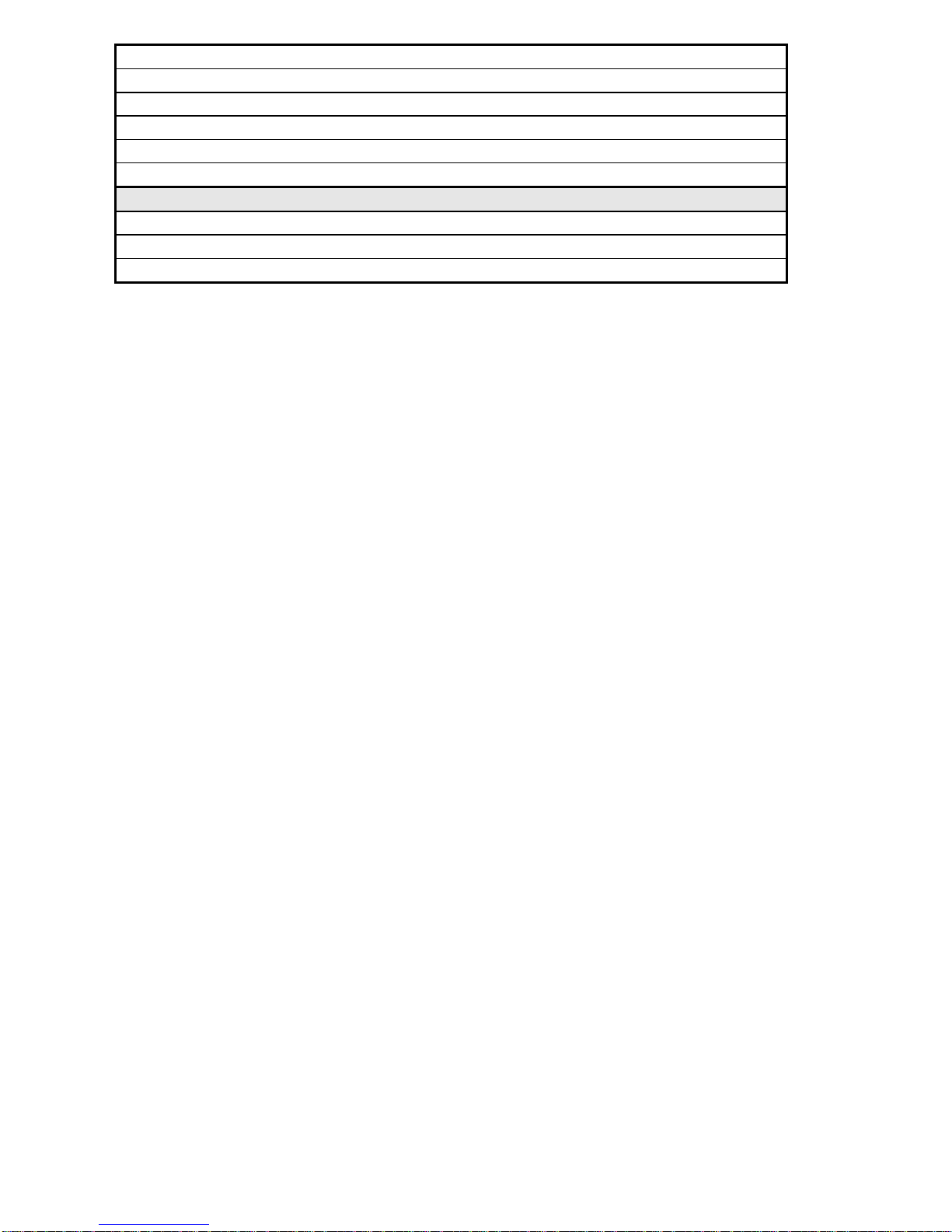

1.2.1 System Replacement Parts

Control Panel Repair / Replacement Parts

FN-4127-BO FireNET 4127 Control Unit Board Only (K6002)

FN-4127-CPA-BO FireNET 4127 Panel Annunciator Board Only (K6001)

FN-PS4 FireNET 4 Amp Power Supply (UL864 8th Edition Compliant)

FN-PS402* FireNET 4 Amp Power Supply (UL864 9th Edition Compliant)

FN-ENC FireNET Enclosure Complete

FN-ENC-DO FireNET Enclosure Door Only

FN-ENC-BC FireNET Enclosure Back-Can Only

FN-PMP FireNET Panel Mounting Plate

FN-PBS FireNET Panel Bonding Strap

FN-PGB FireNET Panel Grounding Block

FN-EOL FireNET Panel EOLR (package)

FN-STO FireNET Panel Standoffs (for panel covers)

FN-PRC FireNET Panel Ribbon Cables (package)

FN-FUS FireNET Main AC Input Fuse

FN-FUS-BATT FireNET Battery Input Fuse

FN-BLJ FireNET Battery Leads & Jumper

FN-MAN FireNET Installation Manual

FN-PDL FireNET Panel Door Label

FN-LSW Loop Explorer Software CD

FN-X187 Programming Cable (Standard)

FN-S187 Programming Cable (Jacketed)

FN-SKDK Spare Keys for Door Keyswitch

FN-SKCK Spare Keys for Controls Keyswitch

FN-ECK Enable Controls Keyswitch

FN-BLE Battery Leads for Accessory Enclosure (extended length 3.28ft)

FN-LCD-N-ETR Enclosure Trim Ring for Network Annunciator Flush Mount

FN-LCD-N-BB Network Annunciator Back-box

FN-LCD-N-CPA-BO Network Annunciator Annunciator Board Only (K6001 R version)

FN-LCD-N-BO Network Annunciator Control Unit Board Only (K6007)

FN-LCD-S-BO Serial Annunciator Control Unit Board Only (K6017)

FN-LCD-S-BB Serial Annunciator Back-box

FN-EBS Expansion Boards Standoffs (SLC board & I/O board stacking)

FN-ENC-DD Denver Do or Enclosure Front Door, including clear window

FN-CB-DD Denver Door Circuit Board Mounting Plate

FN-ENC-BC-DD Denver Door Enclosure Back-Can Only

FN-KEY-DD

FN-S-DD Access Level 2 Switch for Denver Door Build

*NOTE: 240VAC option available

CAT-30 Enclosure Key and Lock for FireNET and FireNET

Denver Door version

13

FireNET 4127 I & O Manual v1.90 UL

Page 14

1.3 Limitations of Fire Alarm Systems

Follow Recommended Installation Guidelines: To achieve early fire detection, fire

detection sensors should be installed in all rooms and areas of a house, apartment,

or building in accordance with the recommendations of the National Fire Protection

Association Standard 72 (NFPA 72), manufacturer’s recommendations, state and

local codes, and the recommendations contained in Guide for the Proper Use of

System Smoke Detectors, which is made available at no charge to all installing

dealers. Generally, the standards and recommendations include the following (but

installers should refer to the specific guidelines above before installing):

• Sleeping Rooms:

room.

• Hallways: More than one smoke detector should be installed in a hallway if it

is more than 30 feet long.

• At least Two Smoke Detectors: There should never be less then two smoke

detectors per apartment or residence.

• Smoke Detectors in Alarm, Electrical, or Phone Locations: Smoke detectors

should be located in any room where an alarm control is located or an alarm

control connects to an electrical source or phone line. If detectors are not so

located, a fire within the room could prevent the alarm control from reporting

a fire.

• Notification Systems: All fire alarm systems require notification devices,

including sirens, bells, horns, and/or strobes. In residential applications, each

automatic alarm initiating device when activated should cause the operation

of alarm notification device that should be clearly audible in all bedrooms

over ambient or background noise levels (at least 15dB above noise) with all

intervening doors closed.

• Alarm in Every Bedroom and Level of Residence: A smoke detector with an

integral sounder (smoke alarm) should be located in every bedroom and an

additional notification device should be located on each level of a residence.

• Maintenance: A maintenance agreement should be arranged through the

local manufacturer’s representative and maintenance should be performed

annually by authorized personnel only. To keep a fire alarm system in

excellent working order, ongoing maintenance is required per the

manufacturer’s recommendations and UL and NFPA standards. At a

minimum the requirements of Chapter 7 of NFPA 72 (1999) shall be followed.

• Test Weekly:

sensors and transmitters are working properly. The most common cause of

an alarm system not functioning when a fire occurs is inadequate

maintenance.

Alarms Cannot Guarantee Warning or Protection: Fire alarm system cannot

guarantee warning or protection against fire in every potential situation. A study by

the Federal Emergency Management Agency (an agency of the United States

government) indicated that smoke detectors may not go off or give early warning in

as many as 35% of all fires.

Smoke detectors should be installed in every sleeping

The alarm system should be tested weekly to make sure all

14

FireNET 4127 I & O Manual v1.90 UL

Page 15

Limitation on Fire Alarm Effectiveness: A fire alarm system may not provide timely

or adequate warning, or simply may not function, for a variety of reasons. For

example:

• No Detection: Particles of combustion or smoke from a developing fire may

not reach the sensing chambers of smoke detectors because:

1. Barriers (such as closed or partially closed doors, walls, or chimneys)

may inhibit particle or smoke flow.

2. Smoke particles may become cold, stratify, or not reach the ceiling

or upper walls where detectors are located.

3. Smoke particles may be blown away from detectors by air outlets.

4. Smoke particles may be drawn into air returns before reaching the

detector.

• No Multi-Floor Detection: In general, smoke detectors on one level of a

structure cannot be expected to sense fires developing on another level.

• Insufficient Smoke: The amount of smoke present may be insufficient to

alarm smoke detectors. Smoke detectors are designed to alarm, at various

levels of smoke density. If such density levels are not created by a

developing fire at the location of the detector, the detector will not go into

alarm.

• Smoldering vs. Flaming Fires: Smoke detectors, even when working

properly, have sensing limitations. Detectors that have photoelectric sensing

chambers tend to detect smoldering fires better than flaming fires, which

have little visible smoke. Detectors that have ionizing-type sensing chambers

tend to detect fast flaming fires better than smoldering fires. Because fires

develop in different ways and are often unpredictable in their growth, neither

type of detector is necessarily best and a given type of detector may not

provide adequate warning of a fire.

• False Alarms and Pre-Fire Disconnection: Smoke detectors are subject to

false alarms and nuisance alarms and may have been disconnected by

users. For example, a smoke detector located in or near a kitchen may go

into nuisance alarm during normal operation of kitchen appliances. In

addition, dusty or steamy environments may cause a smoke detector to

falsely alarm. If the location of a smoke detector causes an abundance of

false alarms or nuisance alarms, do not disconnect the smoke detector, call a

professional to analyze the situation and recommend a solution.

• Fast Fires and Explosions: Smoke detectors cannot be expected to provide

adequate warning of fires caused by arson and children playing with matches

(especially within bedrooms), smoking in bed, violent explosions (caused by

escaping gas, improper storage of flammable materials, etc.).

• Heat Detectors:

Heat detectors do not sense particles of combustion and are

designed to alarm only when heat on their sensors increases at a

predetermined rate or reaches a predetermined level. Heat detectors are

designed to protect property, not life.

15

FireNET 4127 I & O Manual v1.90 UL

Page 16

• Unheeded Warning: Warning devices (including horns, sirens, and bells)

may not alert people or wake up sleepers who are located on the other side

of closed or partially open doors. A warning device that activates on a

different floor or level of a dwelling or structure is less likely to awaken or alert

people. Even persons who are aware may not notice the warning if the alarm

is muffled by noise from a stereo, radio, air conditioner or other appliance, or

by passing traffic. Audible warning devices may not alert the hearing

impaired (strobes or other devices should be provided to warn these people).

Any warning device may fail to alert people with a disability, deep sleepers,

people who have recently used alcohol or drugs, or people on medication or

sleeping pills.

• Strobes: Strobes can under certain circumstances, cause

seizures in people with conditions such as epilepsy.

• Drills: Studies have shown that certain people, even when they

hear a fire alarm signal, do not respond or comprehend the

meaning of the signal. It is the property owner’s responsibility to

conduct fire drills and other training exercises to make people

aware of fire alarm signals and instruct on the proper reaction to

alarm signals.

• Hearing Loss: In rare instances, the sounding of a warning

device can cause temporary or permanent hearing loss.

• Telephone Transmissions Problems: Telephone lines needed to transmit

alarm signals from a premises to a central station may be out of service or

temporarily out of service. For added protection against telephone line failure,

backup radio transmission systems are recommended.

• System Failure With Age or Lack of Maintenance: System components,

though designed to last many years, can fail at any time. As a precautionary

measure, it is recommended that smoke detectors be checked, maintained,

and replaced per manufacturer’s recommendations.

• Electrical Power Problems: System components will not work without

electrical power. If system batteries are not serviced or replaced regularly,

they may not provide battery backup when AC power fails.

• High Air Velocity or Dusty or Dirty Environments: Environments with high air

velocity or that are dusty or dirty require more frequent maintenance.

Importance of Maintenance: In general, fire alarm systems and devices will not

work without power and will not function property unless they are maintained and

tested regularly.

Alarm is Not Substitute for Insurance: While installing a fire alarm system may

make the owner eligible for a lower insurance rate, an alarm system is not a

substitute for insurance. Property owners should continue to act prudently in

protecting the premises and the people in their premises and should properly insure

life and property and buy sufficient amounts of liability insurance to meet their

needs.

16

FireNET 4127 I & O Manual v1.90 UL

Page 17

1.4 Agency Listings, Approvals, Requirements

1.4.1 Federal Communications Commission (FCC)

The FireNET 4127 has been verified to comply with FCC Rules Part 15, Class A

Operation is subject to the following conditions:

1. This device may not cause radio interference.

2. This device must accept any interference received, including any that may cause

undesired operation.

1.4.2 Underwriters Laboratories (UL)

The FireNET 4127 is UL864 9th Edition listed and is suitable for use as a commercial

protected premises control unit as follows:

-Local signaling unit

-Types of signaling services are automatic, manual, waterflow, & sprinkler

supervisory.

-Style 4, 6, or 7 for Signaling Line Circuits

-Style Y for Notification Appliance Circuits

-Non-coded signaling

-Central Station Service – DACT type (protected premise)

-Remote Station Service – DACT type (protected premise)

-Proprietary Service – DACT type (protected premise)*

-Auxiliary Service – local energy type (protected premise)

*When used with the Bosch D6600 Digital Alarm Communicator Receiver.

1.4.3 National Fire Protection Association (NFPA)

Install and configure the FireNET system in accordance with NFPA 72 and 13.

All field wiring must be installed in accordance with NFPA 70 National Electric Code

(Article 760).

17

FireNET 4127 I & O Manual v1.90 UL

Page 18

Section 2 – Control Panel Installation

2.1 What’s in the Box?

The FireNET 4127 control panel includes the following components and hardware:

Control panel cabinet with hinged door.

Power supply module pre-mounted in cabinet

Control panel annunciator & RS232 interface pre-mounted in cabinet

Main control unit pre-mounted in cabinet.

Two keys for the cabinet lock and two keys for the Enable Controls keyswitch.

Note that the Denver Door build does not include keys for the Enable Controls

keyswitch.

(2) 10k ohm EOL resistors PN# 0400-01046, (4 or 8) zero ohm jumpers PN#

0400-01025, (1) 1N4004S diode PN# 0400-01024, and (4) EOLD devices PN#

0400-1023.

Battery jumper for series connection of 2 – 12 volt batteries.

Installation Manual (PN# 1700-09948)

2.2 Environmental Specifications

The FireNET 4127 main control panel should be installed in locations where it will NOT

be exposed to temperatures outside the range of 32

range of 10%-85% non-condensing.

The FireNET 4127 control panel must be installed so that it is not subjected to damage

by water and condensation. AVOID mounting the control panel cabinet directly on

exterior masonry walls, in areas subject to plumbing leaks, in areas subject to splash

from sprinkler test valves, or in high humidity areas.

The FireNET control panel is intended for installation in indoor environments in a dry

location.

18

FireNET 4127 I & O Manual v1.90 UL

o

F – 120oF or humidity outside the

Page 19

2.3 Control Panel Layout

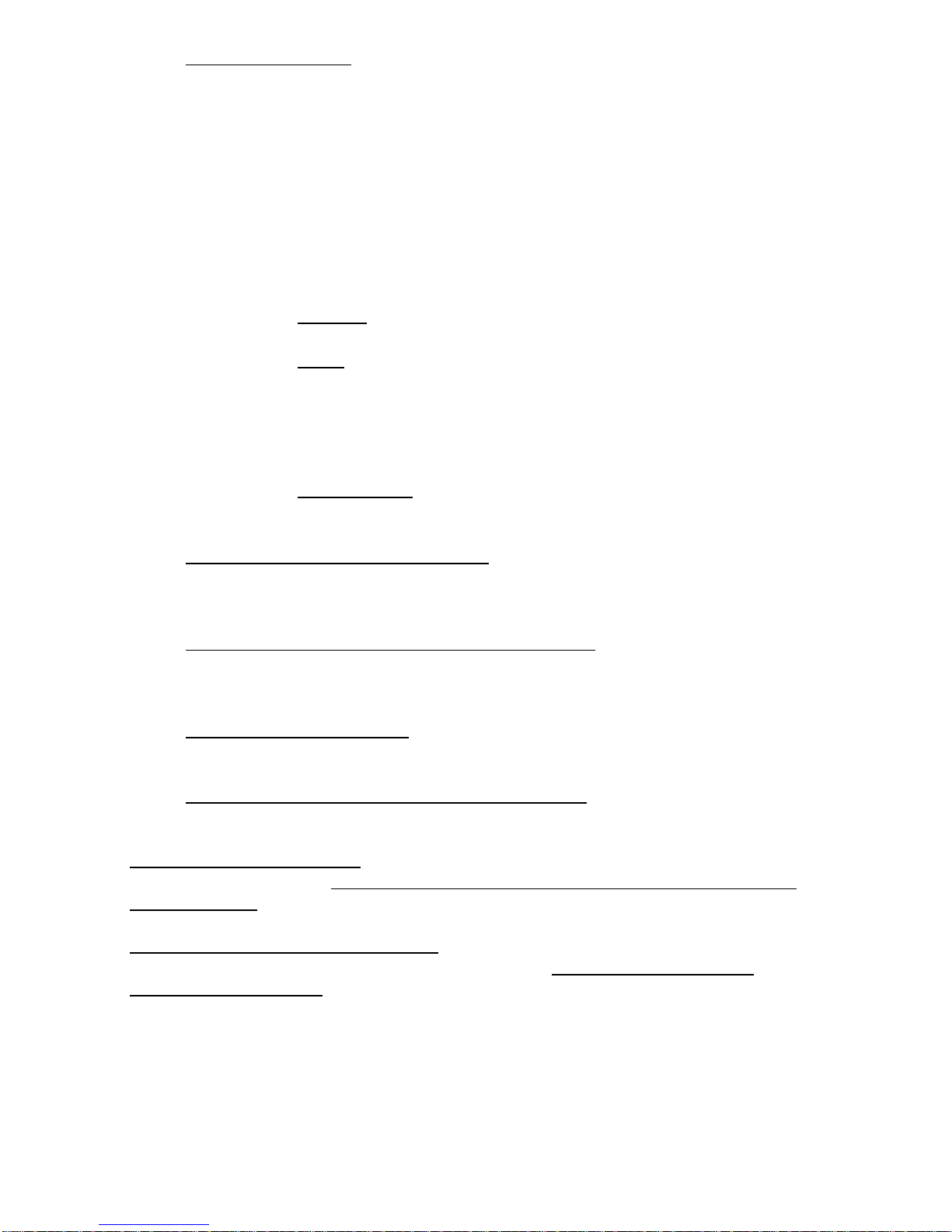

2.3.1 Front Panel Layout, Standard Build

Front Panel Controls

8-Line x 40

character LCD

Front Panel

Indicators

Enable Controls Key-switch

(Access Level 2)

Figure 2-3-1

19

FireNET 4127 I & O Manual v1.90 UL

Page 20

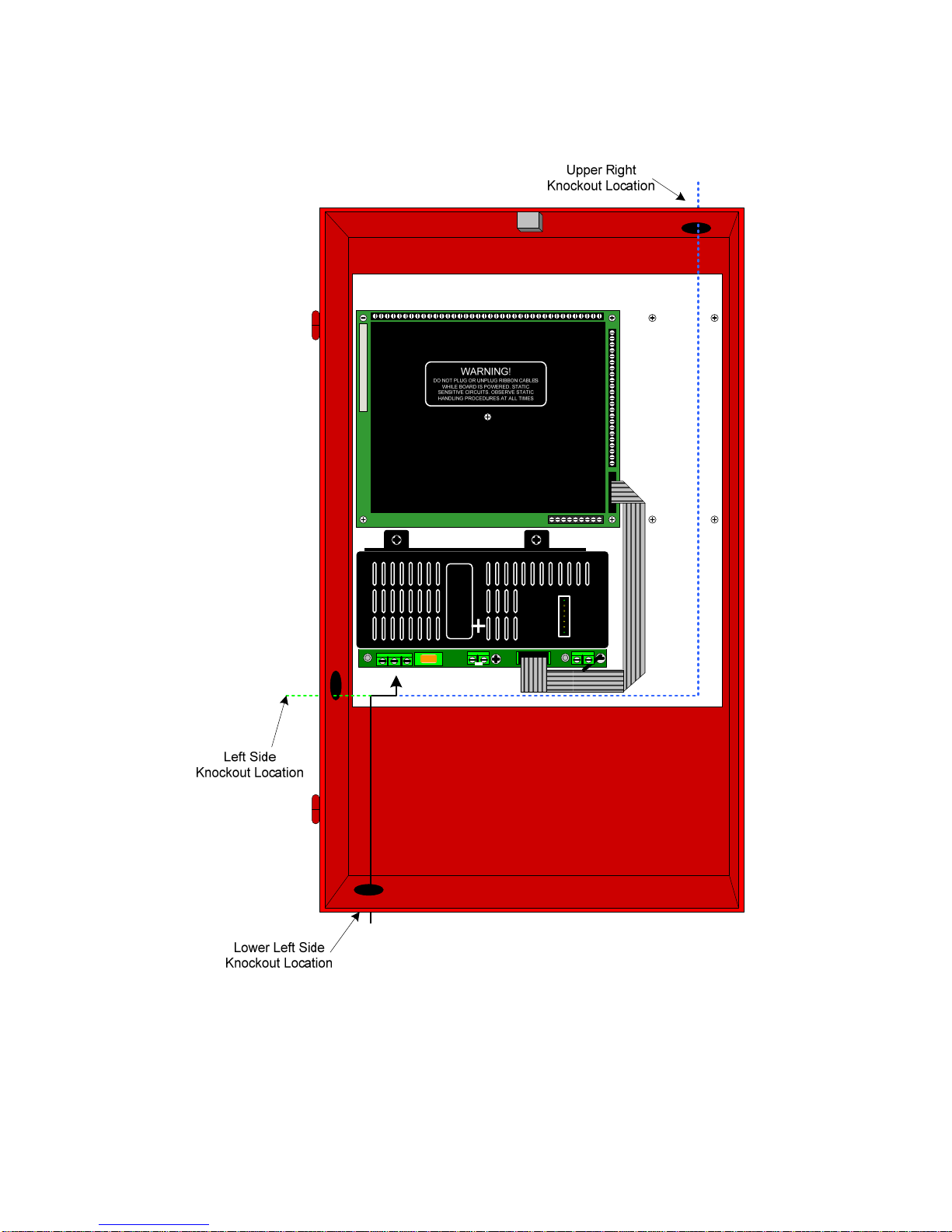

2.3.2 Front Panel Layout, Denver Door Build

Figure 2-3-2

Figure 2-3-2a

20

FireNET 4127 I & O Manual v1.90 UL

Page 21

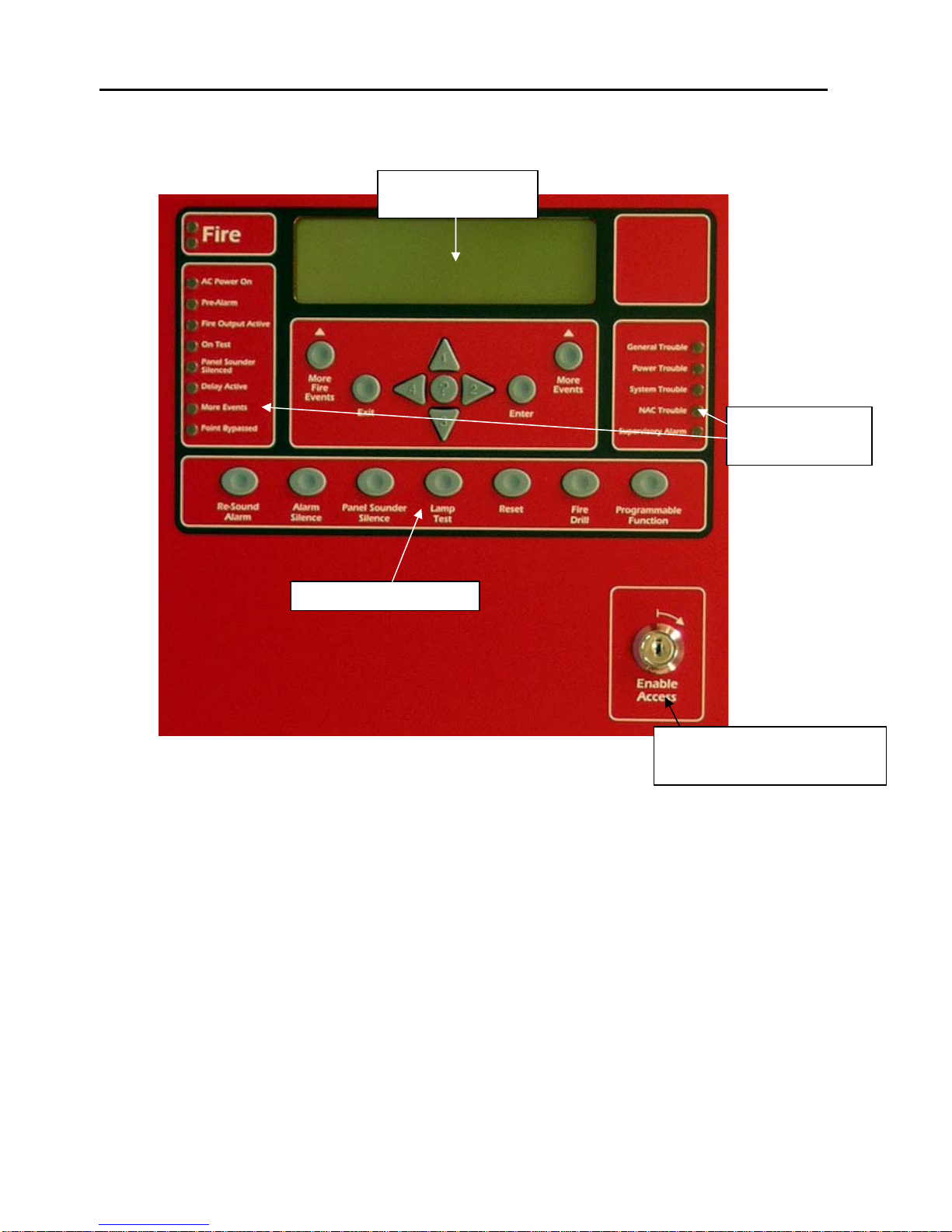

2.3.3 Control Panel Annunciator, Control Unit and Power Supply Layout

WARNING!

DO NOT PLUG OR UNPLUG RIBBON CABLES

WHILE BOARD IS POWERED. STATIC

SENSITIVE CIRCUITS. OBSERVE STATIC

HANDLING PROCEDURES AT ALL TIMES

WARNING!

DO NOT PLUG OR UNPLUG RIBBON CABLES

WHILE BOARD IS POWERED. STATIC

SENSITIVE CIRCUITS. OBSERVE STATIC

HANDLING PROCEDURES AT ALL TIMES

+

-

Control Panel Annunciator &

RS 232 Interface

Printer Connection

PC Connection

Front Panel Controls

Figure 2-3-3

Main Control Unit

SLC Loops

Programmable Relays

Notification Appliance

Circuits

Programmable Outputs

Remote Control and Aux

Inputs

Expansion Board

Connections

Network Connections

Aux Power Output

Power Supply Module

AC Power Connection

Battery Connection

21

FireNET 4127 I & O Manual v1.90 UL

Page 22

2.4 Mounting the Control Panel

Consult the environmental specifications listed in Section 2.2 to determine a suitable

location to mount the FireNET 4127 main control panel.

The panel should be mounted so that it is accessible to service personnel and located

in a secure area.

Do not mount directly to a concrete wall. Use a suitable standoff material such as

plywood to keep condensation away from the control panel.

2.5 Wiring Specifications

Care should be taken when wiring the system to avoid situations that would contribute

to inducing electrical noise from one wire to another. Induced noise can interfere with

telephone communications or cause erratic system operation. Follow these guidelines

to plan your system wiring prior to installation.

• Route high and low voltage wiring separately. Maintain a minimum 2” separation

between high and low voltage wiring throughout the building.

• Route control panel wiring around the perimeter of the enclosure. A minimum

.25” separation is required between high and low voltage wiring.

• Identify which group each wire or cable is associated with from the list below.

Isolate each groups wiring as much as possible. Avoid running a single multiconductor cable for multiple groups of conductors.

• AC Power - Main Power Supply

• Notification Appliances

• SLC Circuits

• Relay Outputs

• Voltage Outputs

• Remote Control and Auxiliary Inputs

• Network Wiring (Shielded wire required)

• RS485 Bus Wiring (Shielded wire required)

• Keep wiring from different groups separated as much as possible. If you must

share the same conduit with different conductor groups consider using shielded

cable.

• If shielded cable is used terminate the shield to the earth ground terminal block

in the main control panel and leave open at field side of cable. Do not ground at

both ends of cable.

• All terminals on the FireNET control can accept wire gauges from 22AWG and

14AWG.

22

FireNET 4127 I & O Manual v1.90 UL

Page 23

2.5.1 Suggested Routing of AC Power

Route the AC input power wiring as outlined below. Follow recommendations outlined

in section 2.5 regarding the separation of high and low voltage wiring.

The preferred entry location for AC input power is via the left side knock-out (see green

dotted line above). DO NOT route AC input power across the main control board

(K6002), the ribbon cable interconnects, or directly across or adjacent to the lowvoltage connections made on terminal strips X1 (top) or X2 (side).

23

FireNET 4127 I & O Manual v1.90 UL

Page 24

2.6 Battery Calculations

24

FireNET 4127 I & O Manual v1.90 UL

Page 25

25

FireNET 4127 I & O Manual v1.90 UL

Page 26

26

FireNET 4127 I & O Manual v1.90 UL

Page 27

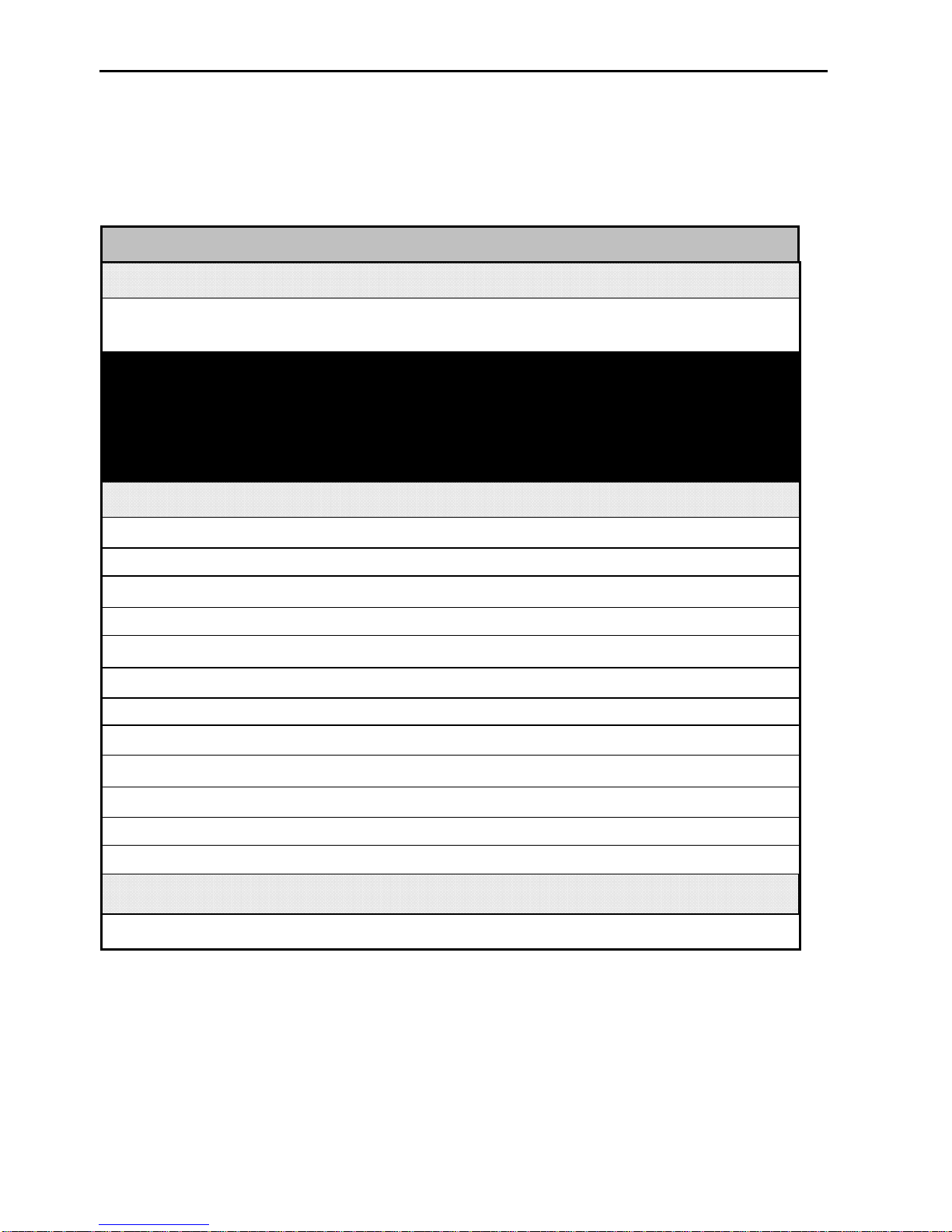

2.7 Electrical Ratings

Table 2.7.1 (X1) Top Terminal Strip Electrical Ratings for Main Control Unit

Terminal # and Label Description

1 - OUT

2 + OUT

3 - IN

4 + IN

5 - OUT

6 + OUT

7 - IN

8 + IN

9 - OUT

10 + OUT

11 - IN

12 + IN

13 - OUT

14 + OUT

15 - IN

16 + IN

17 NC

18 C

19 NO

20 NC

21 C

22 NO

23 NC

24 C

25 NO

26 NC

27 C

28 NO

29 NC

30 C

31 NO

32

+

33

-

34

+

35

-

36

+

37

-

38

+

39

-

SLC 1

SLC 2

SLC 3

SLC 4

Fire 1 Fire condition relay contacts #1.

Trouble Trouble condition relay contacts.

Fire 2 Fire condition relay contacts #2.

Supervisory Supervisory relay contact.

Auxiliary Programmable auxiliary relay contacts.

NAC 1

NAC 2

NAC 3

NAC 4

Signaling Line Circuit. Out terminals used for

Class B or A wiring.

Signaling Line Circuit. In terminals used for

Return Loop for Class A wiring.

Signaling Line Circuit. Out terminals used for

Class B or A wiring.

Signaling Line Circuit. In terminals used for

Return Loop for Class A wiring.

Signaling Line Circuit. Out terminals used for

Class B or A wiring.

Signaling Line Circuit. In terminals used for

Return Loop for Class A wiring.

Signaling Line Circuit. Out terminals used for

Class B or A wiring.

Signaling Line Circuit. In terminals used for

Return Loop for Class A wiring.

Notification Appliance Circuit #1. 10K EOLR

Required.

Notification Appliance Circuit #2. 10K EOLR

Required.

Notification Appliance Circuit #3. 10K EOLR

Required.

Notification Appliance Circuit #4. 10K EOLR

Required.

Voltage Current

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

32VDC 400mA

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

30VDC 1 A

24VDC 2.5 A*

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

*Note: See Section 2.8 for additional details regarding NAC circuit ratings

Rating

2.5 A*

2.5 A*

2.5 A*

2.5 A*

2.5 A*

2.5 A*

2.5 A*

27

FireNET 4127 I & O Manual v1.90 UL

Page 28

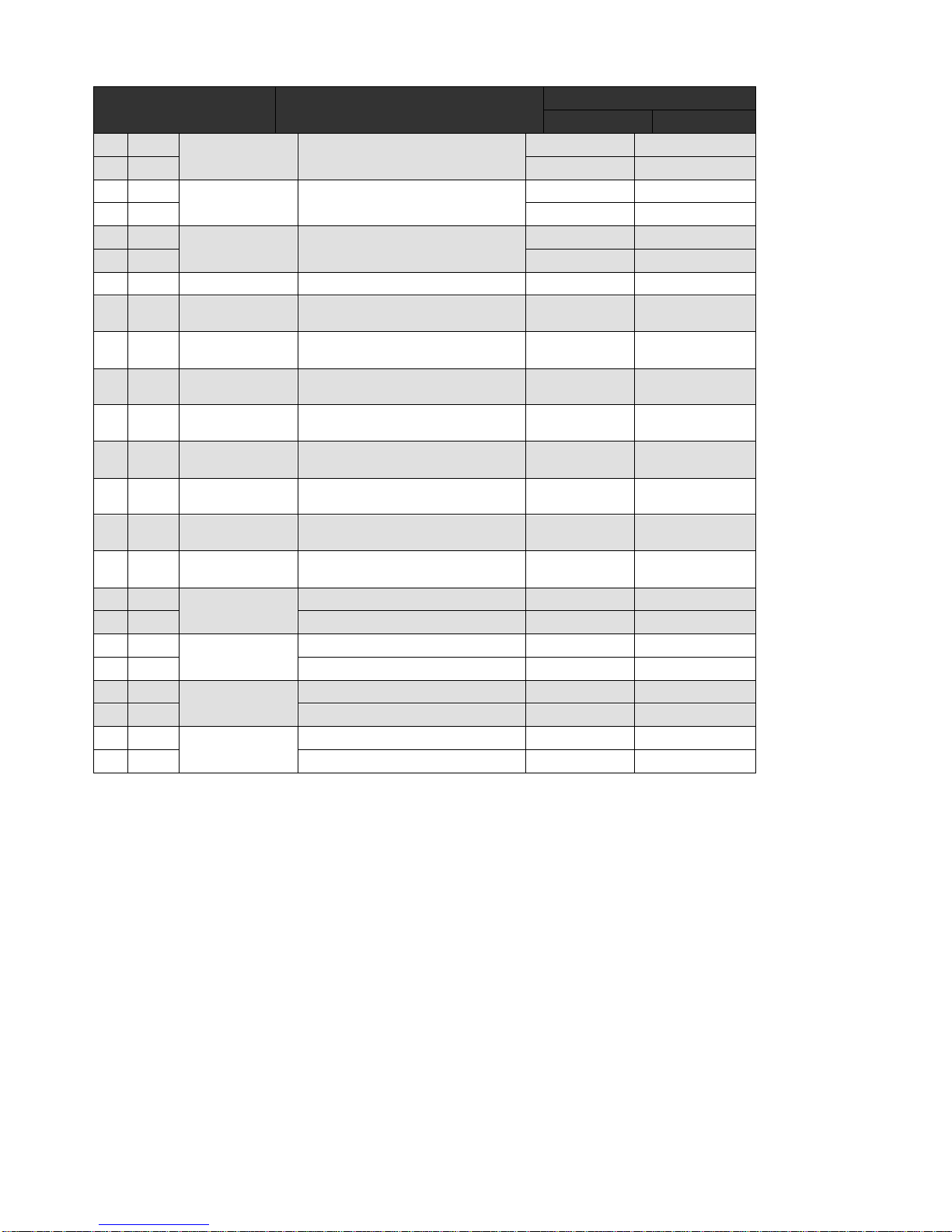

Table 2.7.2 (X2) Side Terminal Strip Electrical Ratings for Main Control Unit

Terminal # and Label Description

1

+

2

3

+

4

5

+

6

7 TBL

8 RES

9 INT

10 CNT

11 SIL

12 0V

13 PR1

14 PR2

15 PR3

16

+

17

18

+

19

20

+

21

22

+

23

Fire Routing

-

Trouble

-

Routing

Programmable

-

Output

Trouble Input Remote control input 0V 30mA

Reset

Input

Intermittent

Input

Continuous

Input

Silence/Ack

Input

DC Ground

Programmable

Input 1

Programmable

Input 2

Programmable

Input 3

COMMS

-

AUX

-

-

-

24V

NETWORK

IN

NETWORK

OUT

Supervised fire signaling

output

Supervised trouble signaling

output

Supervised programmable

output

Remote control input

Remote control input

Remote control input

Remote control input

Signal for activating remote

inputs

Auxiliary input 0V 30mA

Auxiliary input

Auxiliary input

RS485 to I/O boards 12VDC 100mA

RS485 to I/O boards 12VDC 100mA

Auxiliary 24V supply 24VDC 500mA

Auxiliary 24V supply 24VDC 500mA

RS485 to other panels 12VDC 100mA

RS485 to other panels

RS485 to other panels

RS485 to other panels

Voltage Current

24VDC 500mA

24VDC 500mA

24VDC 500mA

24VDC 500mA

24VDC 500mA

24VDC 500mA

0V 30mA

0V 30mA

0V 30mA

0V 30mA

0V 500mA

0V 30mA

0V 30mA

12VDC 100mA

12VDC 100mA

12VDC 100mA

Rating

28

FireNET 4127 I & O Manual v1.90 UL

Page 29

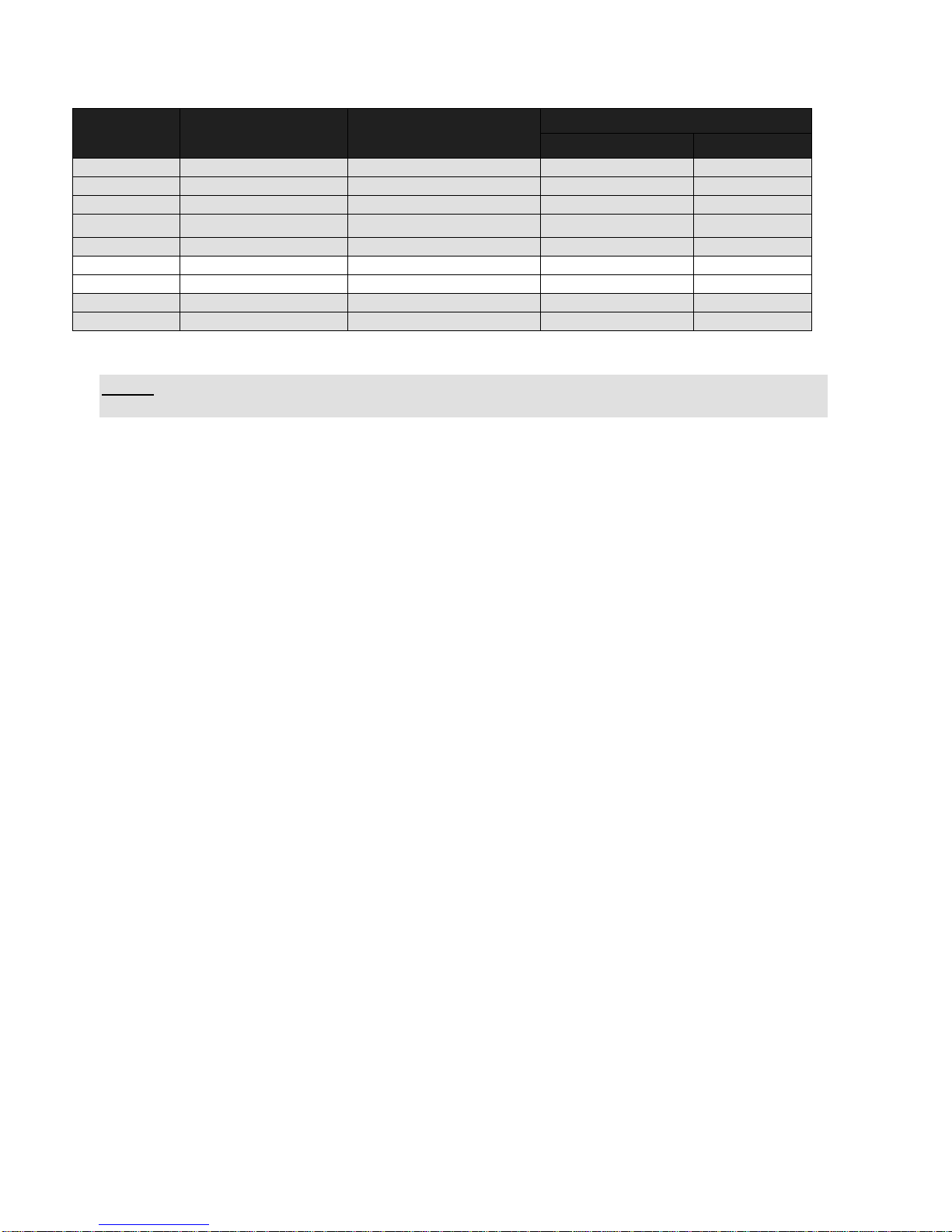

Table 2.7.3 Terminal Strip Electrical ratings for the Power Supply Module

Connector Terminal Description

TB6 G Earth Ground N/A N/A

N AC Neutral 120 VAC, 50/60Hz 2.1A

240 VAC, 50/60Hz 1.1A

L AC Line 120 VAC, 50/60Hz 2.1A

240 VAC, 50/60Hz 1.1A

TB4 +24VDC + DC Output +24 VDC 0 - 4 Amps

DC RTN - DC Output DC Common 0 - 4 Amps

TB3 + Battery +24 VDC 5A

- Battery DC Common 5A

Voltage Current

Rating

NOTE: Earth ground fault detection impedance is approximately 15K ohms between

earth ground and the FireNET internal floating DC supply.

29

FireNET 4127 I & O Manual v1.90 UL

Page 30

2.8 Specifications

Primary AC: 120VAC @ 2.1 amps 50/60hz (or) 240VAC @ 1.1 amp

50/60hz

Output DC: 24VDC @ 4 amps

Power Supply: 4 amp integrated

Max Charger Current: 1.5 amps

Dimensions: 14.5”W x 24” H x 5”D

Weight: 31 lbs (without batteries)

Color: Red (optional charcoal)

Material: ABS/steel enclosure

Display: 8 line x 40 character LCD (320 characters total)

Network: Dual RS485 ports (64 panels max.)

Zones: 500 network wide software zones per system (Output

zones allocated to zones 1 to 253 only for SOM 2.0 and

earlier)

SLC loops: 2 or 4 (class A or B)

Devices per Loop: 127 sensors & modules, plus 127 analog sounder bases,

254 total

Addresses per Panel (800 addresses + sub-addresses max per panel)

NAC Outputs: (4) 2.5 amp@24VDC (class B)*

Relay Outputs: (5) Form C contact 1amp@30VDC

Voltage Outputs: (3) 500mA@24VDC

Aux. Power: 500mA@24VDC

Aux. Inputs: (8) digital pull downs

PC Port: RS232

Printer Port: RS232

*NOTE: FireNET panels dated 1/24/05 or later with s/n 411-00412

or later have NAC circuits rated at 2.5AMPS each. All

FireNET panels dated earlier than 1/24/05 with s/n prior to

411-00412 have NAC circuits rated at 1.6AMPS each.

30

FireNET 4127 I & O Manual v1.90 UL

Page 31

Section 3 - Power Supply and Main Control Unit Connections

3.1 AC Power Connection

The AC power connection terminals are located in the lower left hand corner of the

power supply module. (See Figure 3.3) Observe the wiring polarity and connect as

shown. Local electrical codes may require that a licensed electrician make these

connections.

NFPA 72 requires that the AC connection be made from a dedicated branch circuit that

is mechanically protected. The circuit must be marked in red and identified as a “FIRE

ALARM CIRCUIT”. The location of the circuit and its disconnecting means shall be

permanently noted at the fire alarm control panel. The circuit breaker must be rated at

20 amps maximum.

Fuse Replacement: To replace the power supply fuse F2, power down the fire system

by removing the AC power first, then disconnect the backup batteries to the fire alarm

control panel. Remove the blown fuse and replace with a 3A 250VAC, slow blow,

5X20mm fuse. When the fuse replacement is completed, restore AC power to the

control panel and connect the back up batteries observing polarity of connections.

3.2 Battery Connection

The FireNET 4127 fire alarm control panel can charge up to 60AH batteries. Up to 17

AH will fit in the control panel enclosure, as well as larger sizes that have the same size

footprint as 17AH batteries. Batteries larger than 17AH may be mounted remotely in the

FN-ACC accessory cabinet. Use the current draw and battery calculation worksheet in

section 2.6 to determine the appropriate size battery to use.

Two battery leads come pre-connected to the power supply module. Connect two 12volt batteries in series to the battery leads as shown in Figure 3.3. Both batteries must

be of the same AH rating. Do not try to parallel multiple batteries together to obtain a

higher AH rating. Use only UL Recognized Sealed Lead Acid Batteries.

Fuse Replacement: To replace the in-line battery fuse, remove the battery lead (RED)

from the positive battery terminal and twist the bayonet fuse holder to open. Remove

the blown fuse and replace with a “Bussman AGC-10” (10A) type fuse or equivalent.

Reassemble bayonet fuse holder and attach the battery lead to the + terminal of the

battery.

NOTE: The standby batteries cannot power the system until the main

120VAC power has been established. Once the system has

been initially powered from them 120VAC source the batteries

will operate the system in the event of a power failure.

31

FireNET 4127 I & O Manual v1.90 UL

Page 32

3.3 Auxiliary Power Connection

24 VDC auxiliary power is available on the main control unit X2 terminal strip from

terminals 18 and 19. (See Figure 3.4) This auxiliary power is intended to run expansion

boards or other low current auxiliary devices.

The total output from the Auxiliary Power terminals must not exceed .500 amps.

Any devices powered from the auxiliary power terminals should be entered into Table

2.6 and taken into consideration for standby battery size.

Figure 3.3 Four-Amp Power Supply Detail

32

FireNET 4127 I & O Manual v1.90 UL

Page 33

Top Terminal Strip

X1

X2

Side Terminal Strip

Main

Control

Unit

ADDITIONAL

I/O BOARDS

+ -

PROGRAMMABLE

REMOTE

CONTROL

AND AUX.

INPUTS

ROUTING

TROUBLE

ROUTING

OUTPUT

1. TBL

2. RES

3. INT

4. CNT

5. SIL

6. PR1

7. PR2

8. PR3

COMMS

NETWORK

FIRE

AUX

24V

IN

+ - + -

NAC 1 NAC 2 NAC 3 NAC 4

+ -

+

-

+

-

+

-

0V

l +

AUX 24VDC Power 500mA Max

Used for expansion boards and

l +

l +

low current auxiliary devices

(See Section A.4 for compatible

24VDC Devices)

NETWORK

OUT

l +

Figure 3.4 Auxiliary Power Connection Detail

33

FireNET 4127 I & O Manual v1.90 UL

Page 34

3.4 Notification Appliance Circuit Connection

• NAC output rated @ 2.5 Amp each.

• See Appendix A.3 for compatible NAC Devices.

• See Section 8 and 9 of this manual for programming.

Class B (Style Y) - For Indicating Devices

X1

Main

Control

Unit

Top Terminal Strip

+ - + -

NAC 1 NAC 2 NAC 3 NAC 4

+ -

CONTROL

PROGRAMMABLE

REMOTE

AND AUX.

INPUT S

FIRE

ROUTING

TROUBLE

ROUTING

OUTPUT

1. TBL

2. RES

3. INT

4. CNT

5. SIL

6. PR1

7. PR2

8. PR3

+ -

+

H/S H/S H/S

-

+

-

+

-

+

-

0V

+

+

-

-

Hochiki America

EOL Device

(EOLD )

P/N 0400-01023

(Supervised)

Figure 3.5 Notification Appliance Circuit Connection Detail

34

FireNET 4127 I & O Manual v1.90 UL

ADDITIONAL

I/O BOARDS

COMMS

AUX

l +

24V

l +

Page 35

3.5 Voltage Routing and Relay Output Connection

3.5.1 Voltage Routing Outputs

• Outputs are fully programmable.

• Outputs are rated @ 500mA Max.

• Outputs are polarity reversing.

• See Appendix A.4 for compatible devices.

• See Section 8 and 9 of this manual for programming.

X2

+ -

NAC 1

Main Control

Unit

+ -

NAC 2 NAC 3 NAC 4

+ -

+ -

ROUTING

TROUBLE

ROUTING

PROGRAMMABLE

OUTPUT

REMOTE

CONTROL

AND AUX.

INPU T S

6. PR1

7. PR2

8. PR3

COMMS

FIRE

1. TBL

2. RES

3. INT

4. CNT

5. SIL

EXAMPLE OF FIRE ROUTING, TROUBLE

ROUTING, & PROGRAMMABLE OUTPUT

+

-

+

-

+

-

0V

l +

POLARITY

REVERSING DEVICE

500 mA @24VDC max.

10K OHM END-OF-LINE RESISTOR (EOLR)

P/N 0400-01046 (Supervised)

1N4004S END-OF-LINE DIODE (EOLD )

P/N 0400-01024 (Supervised)

10K OHM

END-OF-LINE

RESISTOR (EOLR)

P/N 0400-01046

(Supervised)

Figure 3.6 Voltage Routing Outputs Detail

35

FireNET 4127 I & O Manual v1.90 UL

Page 36

3.5.2 Relay Outputs

• Relays are fully programmable except for the supervisory relay.

• The auxiliary relay defaults to reset function that can be used to reset

conventional devices requiring power reset. This inherent function is negated

when the auxiliary is assigned a function.

• Relays are dry form “C” contacts.

• Fire 2 Relay can optionally be programmed as an AC Fail relay with a delay

value.

• See section 8 and 9 of this manual for programming.

Conventional Relay Contacts rated for 1A @ 30VDC.

Main Control

Unit

Must be connected to power limited source.

(Not Supervised) (Resistive)

NC C NO NC C NO NC C NO NC C NO NC C NO

FIRE 1 TROUBLE FIRE 2

Figure 3.7 Relay Outputs Detail

SUPERVISORY

AUXILIARY

+ - + -

NAC 1 NAC 2

36

FireNET 4127 I & O Manual v1.90 UL

Page 37

3.6 Digital Input Connection

• Digital Inputs are fully programmable.

• Digital Inputs are for secondary use only.

• Digital Inputs are pull-down type.

• Digital Inputs are not supervised.

• Digital Inputs are not intended for use with primary initiating devices for fire

conditions.

• These inputs are activated via N.O. dry contact or switch by connecting terminal

12 on X2 to the input.

• See Section 8 and 9 of this manual for programming.

X2

+ -

+ -

NAC 1

NAC 2 NAC 3 NAC 4

Main Control Unit

+ -

PROGRAMMABLE

AND AUX. INPUTS

ROUTING

TROUBLE

ROUTING

OUTPUT

REMOTE

CONTROL

+ -

FIRE

COMMS

1. TBL

2. RES

3. INT

4. CNT

5. SIL

6. PR1

7. PR2

8. PR3

+

-

+

-

+

-

DIGITAL INPUTS

USE DRY CONTACTS ONLY

(EXAMPLE FOR INPUTS 1-8)

0V

l +

(Not Supervised)

Figure 3.8 Remote Control Input Connection Detail

37

FireNET 4127 I & O Manual v1.90 UL

Page 38

3.7 Using a Printer

The FireNET panel will support a local serial printer. The printer connects to the J10

RS-232 port (labeled Printer) on the inside of the front door. J10 is located in the

bottom left-hand corner of the circuit board. The printer cable must be no longer than

20 feet in length. The printer can be used for real-time logging of events. It can also be

used to print the panel’s configuration (see section 8.2.4) or to print the panel’s history

log (see section 10.2.2).

Serial Printer Properties:

• 19.2K Baud

• 8 Bits

• No Parity

• 1-Stop Bit

38

FireNET 4127 I & O Manual v1.90 UL

Page 39

Section 4 – Expander Board Installation

4.1 Compatible Expander Boards

The following Hochiki America Corp. expander boards are listed as compatible with the

FireNET 4127 analog addressable fire alarm system.

Expanders

• FN-4127-SLC - Dual SLC Loop Expander (Local FACP Expander)

• FN-4127-IO – 16 Channel Input/Output Board (RS-485 Bus Device)

• FN-LCD-S Serial LCD Annunciator (RS-485 Bus Device)

This section covers the installation of the devices listed above. For proper operation

each of these devices must be programmed from the FireNET front panel, or by using

the Loop Explorer software. Please refer to Sections 8 and 9 of this manual for more

information on programming the functionality of expander boards.

39

FireNET 4127 I & O Manual v1.90 UL

Page 40

4.2 General Installation of RS-485 Bus Devices

4.2.1 Wiring Distance and Mounting Locations

RS485 bus devices can be mounted either in the main control panel on the standoffs

provided to the right of the control unit, or in an accessory cabinet (FN-ACC). When

mounting remotely in an accessory cabinet the distance from the panel to the RS485

bus device must not exceed 4000 feet. A suitable communications cable for RS485

applications must be used for the RS485 bus devices.

Specific wiring connections for each device are included later in this section. For

specific wiring distance, connections, and mounting of the FN-LCD-S serial LCD

Annunciator, see Section 4.7.

40

FireNET 4127 I & O Manual v1.90 UL

Page 41

4.2.2 Addressing

Up to 32 RS485 bus devices can be added to the system. Each RS485 bus device

must be set to a unique address 1-32.

The address for each RS485 bus device is set using a position DIP-switch in binary

fashion. Switches 1-5 represent the values 1, 2, 4, 8, and 16, respectively. Switch 6 is

not used. To set the address, move only the switches whose values when added equal

the address value you wish to set, to the “ON” position. For example moving switches 1

and 3 (whose values are 1 and 4 respectively) to the “ON” position sets the address of

5 into the RS485 bus device. See the other examples below:

ADDRESS 1

Addresses must be set with no power applied to the system.

ADDRESS 5

ADDRESS 21

Switch Number – 1 2 3 4 5 6

Value – 1 2 4 8 16 not used

4.2.3 Terminating

The last board connected to the RS485 bus must have a

terminating jumper installed at position J3 as shown in figure

4.2.3.1

Even if only 1 RS485 bus device is connected to the panel this

jumper must be installed.

Jumper J3

1

L

J1

C3

6

5

4

2

2

2

R

R

R

LED1

3

2

R

1

2

W

LED2

2

S

R

1

LED3

2

R

+

RX TX

X2

COMMS ININ

0V

V

7

4

2

0V

9

2

2

R

R

+

C2

+

C1

U1

9

1

R

0

2

R

J2 J3

0

3

R

4

3

R

1

R

T

X

4

5

TR1

S1

R

6

3

U7

R

7

2

8

3

3

2

R

R

R

U6

1

3

3

3

R

R

1

F

D1

U5

C7

D17

+

Figure 4.2.3.1

0

0V0V

1

C

1

1

C

0V

V

OUTCOMMS OUT I/O

-

SD1

+

J4

8

3

R

0V RX TX 24

C9

C6

+

5

3

R

C8

+

L1

41

FireNET 4127 I & O Manual v1.90 UL

Page 42

4.2.4 Power Connections

All RS485 bus devices require 24 VDC to operate. The AUX 24V terminals of the FN4127 can supply this voltage (500 milliamps maximum) or you may use an external

power supply that provides 24 VDC output.

Connections are provided on each RS485 bus device for both incoming and outgoing

power.

4.2.5 COMMS Connection

In addition to power, each RS485 bus device requires a pair of conductors for data

communication. This wiring is connected to the COMMS + and - terminals on the FN4127 control panel or can be connected to the COMMS OUT + and - terminals of

another RS485 bus device.

ADDITIONAL

I/O BOARDS

+ -

FIRE

ROUTING

TROUBLE

ROUTING

PROGRAMMABLE

OUTPUT

REMOTE

CONTROL

AND AUX.

INPUTS

COMMS

AUX

24X

NETWORK

NETWORK

OUT

1. TBL

2. RES

3. INT

4. CNT

5. SIL

6. PR1

7. PR2

8. PR3

IN

+ -

+

-

+

-

+

-

0V

l +

l +

l +

l +

J1

C3

6

5

4

2

2

2

R

R

R

LED

3

1

2

R

LED

W

1

2

S

2

2

R

LED

1

2

3

R

+

RX

X2

COMMS ININ

0V

V

7

4

9

2

2

2

R

R

0V

+

C2

+

C

1

U1

9

1

R

0

2

R

J2 J3

0

3

R

4

3

R

1

R

0

0V0V

1

C

1

L

T

X

1

1

C

4

5

TR1

S1

R

6

3

SD1

U7

R

J4

8

8

7

2

3

2

3

3

R

R

R

R

U6

1

3

5

3

3

3

R

R

R

1

F

D1

U5

C7

L1

D17

+

TO NEXT I/O

BOARD

OUTCOMMS OUT I/O

24V 0V

T

X

-

+

0V RX

C9

C6

+

C8

+

+ - + -

NAC 1 NAC 2 NAC 3 NAC 4

42

FireNET 4127 I & O Manual v1.90 UL

Page 43

4.3 FN-4127-IO - Input / Output Board

In addition to the basic 508 points that the FireNET 4127 can accommodate on the SLC

loops additional input and output points can be added by using FN-4127-IO

Input/Output boards on the RS485 bus.

The FN-4127-IO has 16 channels. Each channel can be individually configured as

either an input or an output. Up to 32 FN-4127-IO boards can be connected to the

system via the RS485 bus giving the system an additional 512 inputs/outputs.

4.3.1 Configuring Inputs

Inputs to the FN-4127-IO are optically

isolated and connected to the board by

installing a normally open contact with a

resistance no greater than 500 ohms to

any input and a terminal marked 0V. The

current switched by the contact will be a

maximum of 3 milliamps.

NOTE: Inputs on the I/O board are not supervised. These inputs are not

for primary initiating or detection of fire or life safety conditions.

These inputs are for programmable for secondary use only, and

not used for signaling Fire, Supervisory, or Trouble conditions. All

primary initiating or detection inputs must be connected to

applicable SLC devices listed for fire. See Section 5 of this manual

for SLC devices.

43

FireNET 4127 I & O Manual v1.90 UL

Page 44

4.3.2 Configuring Outputs

When configured as outputs, the I/O board channels supply a negative voltage (with

respect to the I/O board 24V power supply) via a transistor.

Because transistor elements can be damaged by excessive current drain, great care

should be taken when connecting to outputs. Particular care should be taken to ensure that

suppression diodes on relay coils are correctly polarized. Wrongly connected diodes will

damage the outputs. Diodes

should be connected with the

band to the positive 24V.

Individual channels can supply