Page 1

FIRElink-NANO Air Sampling System

INSTALLATION MANUAL

Page 2

Page 2 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

This manual details the installation of:

FIRElink-NANO Ai r Sampling Detector

If you have any queri es regarding this product or its functionality please cont ac t:

Hochiki Europe (UK ) Limited

Grosvenor Road

Gillingham Business Park

Gillingham

Kent ME8 0SA

Tel: +44 (0) 1634 260133

Fax: +44 (0) 1634 260132

Web: http:// www.hochik ieurope.com

Email: psupport@hoc hikieurope.com

©2010 Hochiki Europe (UK ) Ltd. All rights reserved. No part of this docum ent m ay be reproduced,

stored in a retri ev al system, or transmitted, i n any form or by any means, without the prior permission i n

writing of Hochiki Europe (UK) Ltd.

Hochiki Europe ( UK ) Limit ed r eserves the right to alter the specifications of its products from time to time

without notice. Although every effort has been made to ensure the accuracy of the information contained

in this document it is not warranted or represented by Hochik i E urope (UK) Limited to be a complete and

up-to-date description.

Document Detail s:

Title: FIRElink-NA NO Air Sampling Detector – Installation and User Manual

Issue 1.0

Issue Date July 2010

Part No. 9-5-0-425

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 3

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 3 of 21

Table of Contents

1 Introduction.................................................................................................................................. 4

2 Outside the Detector..................................................................................................................... 5

3 Inside the Detector....................................................................................................................... 7

4 Installation: Mechanical................................................................................................................ 8

5 Installation: Printable A4 Drilling Template................................................................................. 9

6 Installation: Electrical................................................................................................................. 10

7 Installation: Pipework................................................................................................................. 12

8 Configuration.............................................................................................................................. 13

8.1 Alarm Factor......................................................................................................................... 13

8.2 ClassiFire® Enabled.............................................................................................................. 13

8.3 Fixed Alarms Enabl ed .......................................................................................................... 14

8.4 Flow Limit Offset................................................................................................................... 14

8.5 Flow Delay........................................................................................................................... 14

8.6 Input Select.......................................................................................................................... 14

8.7 Auto Calibration.................................................................................................................... 14

9 Commissioning........................................................................................................................... 15

10 Maintenance................................................................................................................................ 16

11 Troubleshooting......................................................................................................................... 17

11.1 Nuisance Alarms.................................................................................................................. 17

11.2 Detector Will Not Pass Smoke Test...................................................................................... 17

11.3 Nuisance Flow Faults........................................................................................................... 17

11.4 Long Transport Times: ......................................................................................................... 18

12 Optional Communications Card................................................................................................. 19

13 Technical Data............................................................................................................................ 21

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 4

Page 4 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

1 Introduction

An aspirati ng smoke detector uses a fan to draw samples of air

from a network of pipes with sampling holes positi oned as if they

were point smoke det ec tors.

0832

Hochiki Europe (UK ) Limited

Grosvenor Road

Gillingham Business Park

Gillingham

Kent ME8 0SA, UK

09

0832-CPD-1467

EN54-20: 2006

Aspirati ng smoke detectors

for fire det ection and fire alarm

systems for buildings

CLASS A, B and C

Technical data: see INF48027 held

by the manufacturer

The detector i nc or por ates a patented artificial intelligence system

called ClassiFire

optimum sensitivity for any environment.

This smoke detect or is defined as Cl ass III in EN 60950. It is

designed to operate f r om S afet y Extra Low Voltages and does not

generate any hazardous voltages.

If this detector is to form part of an approved fire detection system,

its power must be supplied from a certified power supply ( typically

EN 54-4).

In order for the installation to conform to EN 54-20, pipes must

conform at least to EN 61386-1 Class 1131.

®

, which allows the unit to adjust itself to the

Please note that pri nted circuit boards are stati c sensit ive and must

not be handled without taking proper stati c precautions.

This symbol indicates that the detector i s a Class 1 laser pr oduc t

as defined in IEC 60825-1. This unit incorporat es a Class 3B

embedded laser which m ust not be removed from the detector, as

retinal damage m ay occur if t he beam enters t he ey e.

This symbol indicates that this product m ust NOT be disposed of

with other waste. It i s the user’s responsibility to dispose of this

product by sending it to an approved reprocessing company, or by

returning it to the manufacturer for reprocessing.

NOTE: Every care has been tak en to ensure that the detector is as easy to install as possible by trained

fire Alarm engineers. In case of difficulty, please contact the Hochiki Product Support Department

(contact details are at the front of this manual) in the first instance to ensure trouble free

installation and operation.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 5

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 5 of 21

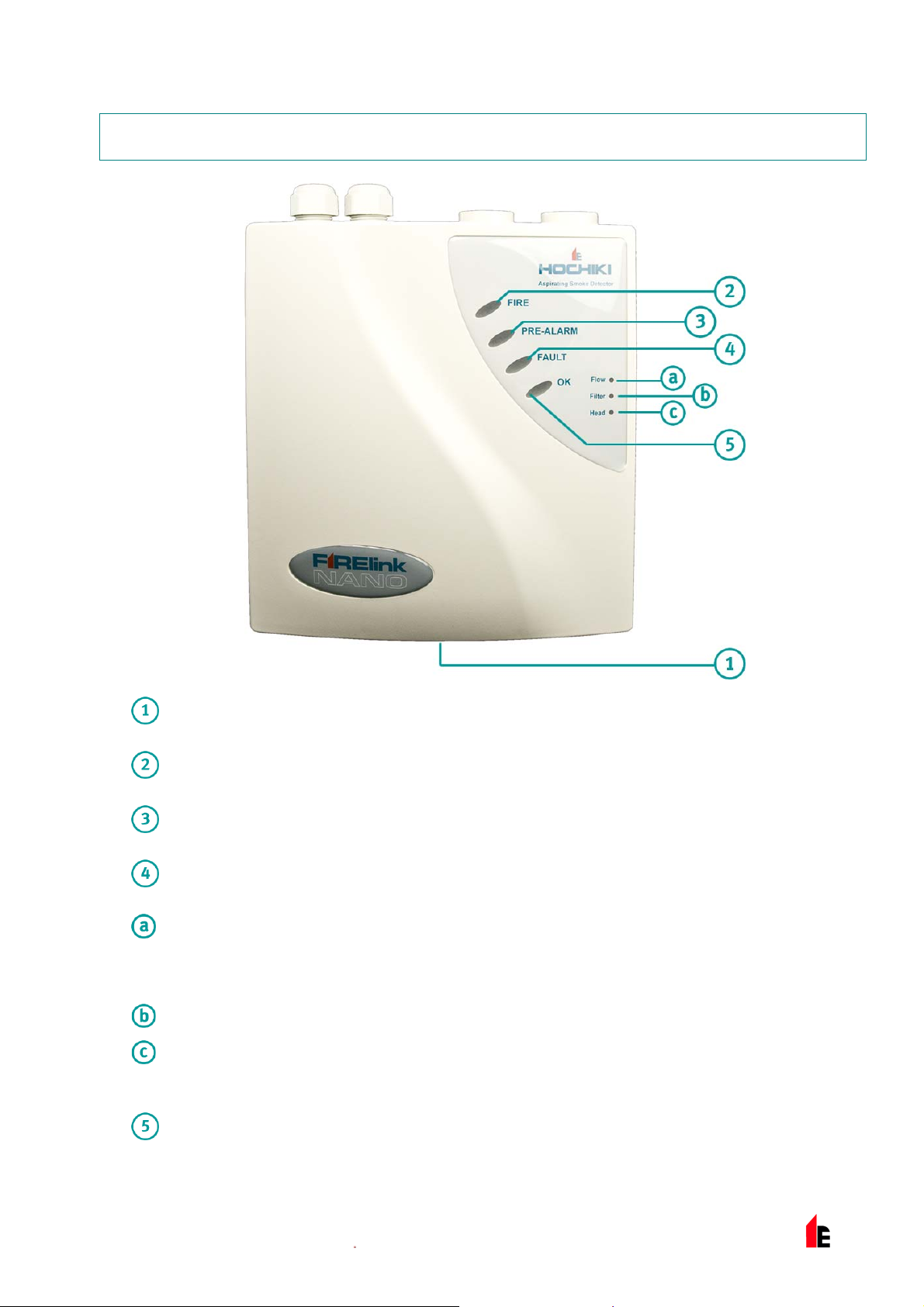

2 Outside the Detector

Front Cover Securing Screw: Leave sufficient cl ear ance bel ow the det ec tor to allow

screwdriver access to this screw.

Fire Alarm: Illuminates to indicate that the sm ok e lev el has passed the detector’s Fire 1

threshold, and t he normally open FIRE relay contacts have closed.

Pre Alarm: Illuminates to indicate that the sm ok e lev el has passed the detector’s Pre Alarm

threshold, and t he normally open PRE ALARM relay contacts have closed.

Fault: Illuminates to indicate a Fault conditi on and that the normally closed FAULT relay

contacts have opened. Three additional LEDs i ndic ate the type of fault:

Flow: Illuminates to indicate an airflow fault . This may be due to blocked or broken pipes,

although it can al so occur if, for example, factory warehouse doors are opened on a windy day,

or if industrial air conditioning tur ns on. Another possible cause is that the aspirating fan

connection c able is damaged or disconnected.

Filter: Illuminates to indi c ate t hat t he detector’s air filter needs to be changed.

Head: Illuminates to indicate a problem with the detector laser chamber, as might be caused if

the laser head connect ing cable is damaged or disconnect ed. It can also be caused by certai n

kinds of internal systems faults, which appear in the detector’s Event Log as “process err or s”.

OK: Illuminates to confirm normal oper ation.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 6

Page 6 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

NOTE: If the FAULT LED is ill umi nated but none of the additional LEDs are lit , it indicates a problem with

the power supply if its Fault output is connected t o the detect or ’s INP UT terminals and DIL switch

7 is set to OFF (its default position). Alternatively, this can happen if the INPUT terminals are left

open circuit and DIL switch 7 is OFF.

NOTE: During initial setup, the OK LED will flash for 15 mi nutes while the detector learns it s operat ing

environment . Thi s does not i ndic ate a problem with the detector.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 7

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 7 of 21

3 Inside the Detector

Aspirating Fan Connector Lead: If this lead is broken or not connected, the fan will not turn

and the detector will indicate a FLOW fault.

Main PCB: No user-serviceable parts. The PCB is fixed in plac e with 5 off M3 x 6 screws. The

detector must not be operated with any of the screws missing, as this may cause air leaks and

unreliable oper ation.

DIL switch: Used to configure user-selectable det ector func tions.

Detector Head Ribbon Connect or: If this lead is broken or not connec ted, the detector will

indicate a “Head” Fault .

Detector Head Co ver Plat e: This protects the laser head. The plat e should not be r em ov ed

from the detector.

Detector Head Assembly: No user-serviceable parts. Do not remove this from the detector

due to the risk of exposure t o the laser.

Replaceable Dust Filt er: This simply slides in and out of its mount ing. The filter and its

replacement hav e IN writt en in red on one side, and OUT on the other to indicate correct

orientati on. The part number for ordering spare dust fi lter s i s 30755.

NOTE: As viewed abov e, I N should be on the left and OUT should be on the right, as indi c ated by the

moulded-i n ar r ows next to the filter slot.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 8

Page 8 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

4 Installation: Mechanical

Cable Entries

2x 20mm Conduit Holes, for ex am pl e

for 20mm packing glands.

Drilling guides are provided for drilling

two additional 2x 20mm holes in the

top and 1x 20mm hole in the bott om if

needed.

Pipe Entries

¾” ABS Pipe.

Use a ¾” male to 25mm female

adaptor if 25mm pipe is used.

Note: Do not glue pipes into the detector, to

allow for future removal.

Fixing Holes (3 x M5 x 13 slots)

Refer to the pri ntable drilling template on nex t page f or accurate positioning.

NOTE: Ensure the det ector is fixed to a flat surface – otherwise the enclosure will twist and may be

damaged.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 9

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 9 of 21

5 Installation: Printable A4 Drilling

Template

Upper clearance

Remember to leave sufficient

clearance above the detector for the

cable glands and pi pe inlet stubs.

3 x wall fixing screw hol es

Use M4.5 pan-head screws suit able for

the wall to which the detector is to be

fixed.

NOTE: The positions of the cross-hairs on this

drawing act as an accurate dr ill

template only if the page is printed at

DIN A4 paper size wit h Print Scaling

disabled. Thi s is norm ally par t of the

main Print menu, and i s usually

enabled by defaul t.

Lower clearance

Remember to leave sufficient space

underneath the detec tor to allow

screwdriver access to the cover fixing

screw and any cable gl and fixed to the

bottom of the det ector .

The screw is M6 x 15 panhead

Pozidrive.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 10

Page 10 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

6 Installation: Electrical

Power Su pp ly Co nnectio ns

Connect “+24V” to PSU “+” termi nal

Connect “EART H” to PSU mains eart h terminal

Connect “0V” to PSU “-” terminal

Volt-free Relay Con t act s

NB: All relay contact positions are shown with t he detector in

the unpowered state.

The FIRE and PRE ALARM relay cont acts wil l change over

when the unit enters the appr opr iate Alarm state.

The FAULT relay will pull in when the detector is operating

normally. The relay c ontacts will drop out during a Fault

condition.

Remote control inpu t

DIL Switch 7 OFF: Connect to PSU Fault output contacts for

PSU monitoring; N/C OK, N/O PSU Fault*.

DIL Switch 7 ON: Classi F ire® Override will reduce detector

sensitivity by 50% while the input terminal s are short ed

together, e.g. by a key switch.

External communications terminals, optional

communications card fitted (RS-485 serial

communications mode):

Connect Command Module or detector RS-485

(SenseNET™) serial bus to A and B.

Use screened twisted pair c able. Connect screen to either of

the SCREEN terminal(s). Earth the screen at one end ONLY

(if one or more detect or s connected to a Command Module,

earth the cable screen at the Command Module only).

Optional APIC card fitted (addressable communications

mode):

Connect + and - IN and + and -OUT terminals to fire panel

using an APIC compatible with the panel’s communications

protocol.

When one or more detector s are connec ted to a Command

Module, it may be easier t o fit eac h detector with a

communications card and use a single APIC in the Comm and

Module, set t o cover the range of chosen detector addresses.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 11

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 11 of 21

In accordance wit h good wir ing practice, keep cabl es and i ndividual bared conduct or s as short as

possible whil e allowing stress-reliev ing cable forming. Power cables should be current-rated at 1A or

greater. RS- 485 c able shoul d be screened twisted pair, e.g. Belden 9841 24AWG.

*NOTE The factory default setting of DIL switch 7 is OFF, so that the detector can monitor a power

supply. If power supply m onitoring and ClassiFire Override are not required, l eave DIL switch 7

set to OFF and fit a wire link acr oss the two term inals to prevent a Faul t condition on power up.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 12

Page 12 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

7 Installation: Pipework

Sampling pipe

¾” pipe or 25mm pipe with a ¾” sleev e

adapter.

The maximum sampling pipe length is

50m.

Fit an end cap with an appropriately-sized

hole to optimize airflow through the pipe.

This end cap hole is al so a sampling hole.

Use the PipeCAD

software to pl an pipe installations. For E N

54-20 compliance, indicated hole

sensitivities must be better than, or equal

to: 0.80% obs/m (Cl ass A), 1.66% obs/m

(Class B) or 5.85% obs/m (Class C)

Do not glue the pipe into t he sampling

inlet.

®

pipe layout modelling

Exhaust pipe

¾” pipe or 25mm pipe with a ¾” sleev e

adapter.

If the protected area is at a lower

atmospheric pressure than the location in

which the detect or is i nstalled (e.g. a

closed air-c onditioned room), fit a retur n

pipe run from the detector exhaust to the

protected area, in order to equalise the

pressure. Thi s will im pr ov e detector

performance.

Even if the protected area and detector are

at the same atmospheri c pr essure, it is

good practic e to fit a pipe stub with a bend

to the exhaust, to prev ent debris falling into

the detector .

Do not glue the pipe into t he ex haust

outlet.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 13

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 13 of 21

8 Configuration

Configurati on is carried out via the DIL switch mount ed on the Main PCB.

Switch 1 Switch 2 Switch 3 Switch 4 Switch 5 Switch 6 Switch 7 Switch

Set Detector

Sensitivity

Alarm Factor 6

Alarm Factor 7 On Off

Alarm Factor 8 Off On

Alarm Factor 9 On On

ClassiFire® Enabled

Fixed Alarms

Enabled

Off Off

On

Off

8

Flow Limit Offset

±40 Off Off

±20 On Off

±5

±3 On On

Flow Delay

240sec

30sec On

Input Select

PSU Fault

ClassiFire Override On

Auto Calibration

Enable

Disable On

NOTE: Text in red denotes the EN 54-20 test configur ation (factory def ault) setting.

Off On

Off

Off

Off

8.1 Alarm Factor

The detector calculates sensitivit y relative to the ambient environmental conditi ons. Higher Alarm Factors

provide reduced sensit ivity (the Alarm t hr eshol d is maintained further away from the ambient level). Refer

to the Remote Software m anual for further details.

NOTE: Changing the Alarm Factor starts a new FastLearn cycle: during the initial 15 minute learning

period, the detec tor is incapable of reporting an alarm. The unit will take 24 hours to achieve

optimum performance, based on the ambient conditions.

8.2 ClassiFire® Enabled

Allows the artificial intelligenc e system to continuously adjust Alarm thresholds in order to avoid unwanted

Alarms from environm ental changes (recomm ended) .

NOTE: Enabli ng this feature means that nuisance alarms due to fluctuations i n the ambient environment

become less likely.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 14

Page 14 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

8.3 Fixed Alarms Enabled

Switches the artificial intelligence system off, locking sensitivity to that set at initial setup. This deactivates the dust f ilter monitoring system (not recommended).

NOTE: Enabli ng this feature means that nuisance alarms due to fluctuations i n am bient pollution levels

become more likely.

8.4 Flow Limit Offset

Sets the sensitiv ity of the airflow monitoring system. A small offset makes the system v ery sensit ive to air

flow changes. EN 54-20 system s must react to a ±20% change in airflow, which equates to a change in

flow sensor output of +

of airfl ow). Areas with fl uctuating air pressures may require a less sensitive setting.

NOTE: Changing the fl ow limi t offset starts a new flow calibration set up.

5 (this refers to a percentage of flow sensor full output and is not a direct measure

8.5 Flow Delay

Sets the period duri ng whic h abnor mally high or low air flow conditions must continue before the unit

indicates a “Flow” fault.

8.6 Input Select

When this switch is set to t he factory default OFF position, the detector input terminals may be connected

to a power supply fault out put relay so as to generate a detector “Fault” condition if the power supply

Fault relay contacts open. If power supply monit or ing is not required, eit her a wire link can be placed

across the input termi nals, or this switch can be set to ON to remove the fault.

®

Setting the switc h to ON enables the ClassiFire

50% as long as there is a short ci rcuit ac ross the input terminal s, e.g. contr olled by a key switch. This can

be used to prevent unwanted Alarms during planned intervals of smoke release, e. g., inc ense burning

during a church service.

NOTE: If a wire link is fitted across the INPUT terminals, it is important that this switch be set to OFF, or

the detector sensitivity will be dramatically reduced by the ClassiFire® Override function being

permanently enabled.

Override feature. This reduces detector sensit ivity by

8.7 Auto Calibration

Automatically starts a new FastLearn cycle when the detector is powered up. This may be disabled if the

previous setti ngs need to be r etained.

NOTE: if this functi on is enabl ed, the unit will also recalibrat e the flow sensors after power up.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 15

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 15 of 21

9 Commissioning

Local standards and speci fication requi r em ents must be adhered to. A typical commissioning procedure

might entail the following steps:

Check install ation against

design document ation

T

Set detector configuration DIL

switches as required

T

Disconnect detector from fire

panel if required

T

Power up detector and wait for

15 minute FastLearn cy cl e to

finish (steady “O K ” LED when

complete)

T

Check/test connec tions to main

Fire Detecti on and Al arm

System

T

Smoke test: check maximum

transport time is less than 120s,

verify sampling hole sensitiviti es

as required. Verify that smoke is

not prevented f r om reaching

sampling holes, e.g. by strong

air currents such as might be

caused by air-conditioning units

T

© 2010 Hochiki Europe (UK) Lt d

Reconnect detector to fire panel

required

if

T

Complete test records; record

settings and results for

referenc e by maint enanc e

engineers

9-5-0-425/ISS1/JUL10

Page 16

Page 16 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

10 Maintenance

Local standards and speci fication requi r em ents must be adhered to. A typical maintenanc e pr ocedure

could entail the following steps:

Check detector , wiring and

pipework for damage

T

Check original design is still

valid, e. g. changes due to

building upgrades

T

Check detector for

contamination and clean if

necessary

T

Check maintenance logs for

issues and rectify as appropriate

T

Isolate detec tor from the fire

panel if required

T

Smoke test to check detector

operation and Fi r e r elay

connection

T

Check transport times against

original r ec or ds: si gnificant

increases or decrease s i n

transport times may imply

damaged pipes or sam pling

holes that need clearing

T

Simulate a Fault to check the

Fault relay and connec tion

T

Complete and file maintenance

records

T

Reconnect detector to fire panel

if required

NOTE: It is prudent t o disconnect or isolate the detector from the fire panel during m aintenance to prevent

unintentional alarm activations.

NOTE: The detect or should be powered down dur ing internal cl eaning (use an air duster can or dry air

gun).

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 17

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 17 of 21

11 Troubleshooting

.1 Nuisance Alarms

This normall y i ndic ates that the detector is set at an Alarm F actor inappr opr iate for the installed

environment .

Increase the Alarm F actor t o reduce sensiti vity.

The sensor chamber m ay be cont ami nated.

Return the detecto r for f actor y cleaning and recalibration.

.2 Detector Will Not Pass Smoke Test

Detector may be in a FastLearn cycle.

Check if green OK LED is on and flashing.

The detector FastLear n c y cl e m ay have been carried out during, or immediately after, a smok e test.

Reinitiate FastLearn with the detector in a cl ean environment.

The Alarm Factor i s too high.

Change the Alarm Factor to a lower, more sensitive, setting.

.3 Nuisance Flow Faults

Flow monitoring is too sensitive for the environment.

Increase the flow li mit offset.

Airflow may be subjec t t o tempor ary changes (spikes).

Increase flow fault delay.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 18

Page 18 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

1.4 Long Transport Times:

The sampling pipe m ay be too long, may have too many sampling holes/capi llaries, or may have

incorrectly sized holes.

Check design with pip e modelli ng software.

Sampling pipes, sampling holes and/or the ex haust pipe may be partially blocked by dust or debris.

Clean pipewo rk with dry comp ressed ai r and/or clean the sampling holes.

Fan may be defective.

Send detector for repair.

Fan lead may be disconnected

Reconnect lead.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 19

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 19 of 21

12 Optional Communications Card

A communications card m ay be fit ted inside the detector.

Board Locating Post

Detector Address DIL Switch

The detector address i s set using a reverse binary code, i.e. switch 1 is the least signif icant bit

and switch 7 is the most signif ic ant bit. Switch 8 is not used.

Set the address fr om 001 to 127 in or der to identify the detector. Addresses in a detector

network do not have to be consecut ive but must be different.

2 off M3 x 6 Fixing Screws

Provided wit h boar d.

RS-232 Serial Port

Use 9-pin D-type null modem cable to connect to PC.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 20

Page 20 of 21 FIRElink-NA NO Air Sampling Detector – Installation and User Manual

Direct connect ion of a PC to the Communications Card is via a 9 pin RS-232 interface on the

Communicati ons Card, usi ng a null modem cable configurati on, as shown in the diagram below:

A connected PC may access the detec tor event memory to review previous or current events, such as

detector Alarms or Faults. The detector int er nal Char t Recorder may also be accessed to all ow analy si s

of detector behaviour (see separate Remot e S oft ware Manual for further information). The PC cannot be

used to configure the detector except to enter time and date settings for the detect or Event Log and Char t

Recorder to be viewed in t he Rem ote Software. The detector does not i nc or por ate a real time clock, so

the time and date need to be re- entered if the detector is powered down for any r eason.

Installation of the Communications Card also provides the detector with RS-485 network communic ation

via the A, B and SCREEN terminal s on the detector main board. This can be used f or simple remote

display i ndic ation or integration into a larger site wide management and displ ay system, separate from the

local Fire Detection and Alarm System.

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Page 21

FIRElink-NA NO Air Sampling Detector – Installation and User Manual Page 21 of 21

13 Technical Data

SELV Rating EN 60950 Class III

Supply Voltage. 21.6v – 26.4v DC

Current Consumpt ion 350mA

Electri c al Safety Complies with E N 610190-1

Size (mm) 190w x 230h x 110d

Weight 1.2kg

Operating Temperature Range.

Operating Humidity Range

IP Rating IP50

Sensitivity Range 0.4% to 25% obscuration/metre

Detection Principle Laser light forward scattering mass detection

0°C to 38°C (UL 268)

-10°C to 60°C (EN 54-20)

0 to 90% relative humidity, non-condensing

EN61010-1 Pollution Degree 1

EN61010-1 Installation Category II

Maximum Number of Sampling

Holes

Maximum Sampling Pipe

Length

Sampling Pipe I nlets 2 off 3/4” pipe inlets (sampling pipe and exhaust)

Alarm / Fault Relays Pre Alarm / Fire / Fault

Relay Contact Rati ng

(Changeover)

Programmi ng Internal DIL switc hes

PC Interrogation. Via optional Communications Card

APIC Compatible Yes

NOTE: Some devic es such as sounders and beacons have high inrush curr ents on activation, which can

damage relay contacts. It is good practice to consider fitting a suitabl e current limiting resistor in

series with the load to avoid this potential problem.

Cla ss A: 2

Cla ss B: 4

Class C: 10

50m

1A at 24V DC (resistiv e load)

© 2010 Hochiki Europe (UK) Lt d

9-5-0-425/ISS1/JUL10

Loading...

Loading...